After the consolidation of the digital decoration technology in the ceramic tile industry, digital glazing is the next step toward a fully digital decoration line. To make this possible, a key requirement, regarding glaze suspensions characteristics, is the reduction of the actual particle size of the solids. In this context, the objective of this work is to evaluate the effect of the particle size distribution of frits used to produce a transparent glaze on the glaze layer characteristics and the ink behavior over the same. A frit was milled under different conditions. The milling process has mainly reduced the size of the larger particles, leading to narrower particle size distributions. As the distribution curves narrowed, the particles packing efficiency in the glaze layer decreased. For these more porous layers, faster ink absorption into the surface pores and a consequent more limited ink spreading were observed, which leaded to the production of smaller dots. Thus, changes in granulometry of the glaze raw materials affected not only the glaze layer porous structure, but also aspects of the image quality.

Después de la consolidación de la tecnología de decoración digital en la industria de las baldosas cerámicas, la esmaltación digital es el siguiente paso hacia una línea de decoración completamente digital. Para hacer esto posible, un requisito clave, con respecto a las características de las suspensiones de esmalte, es la reducción del tamaño de partícula actual de los sólidos. En este contexto, el objetivo de este trabajo es evaluar el efecto de la distribución del tamaño de partícula de las fritas utilizadas para producir un esmalte transparente en las características de la capa de esmalte y el comportamiento de la tinta sobre el mismo. La frita fue molida en diferentes condiciones. El proceso de molienda redujo principalmente el tamaño de las partículas más grandes, lo que lleva a distribuciones de tamaño de partícula más estrechas. A medida que las curvas de distribución se estrecharon, la eficiencia del empaquetamiento de las partículas en la capa de esmalte disminuyó. Para estas capas más porosas, se observó una absorción más rápida de la tinta en los poros de la superficie y una consiguiente propagación de la tinta más limitada, lo que condujo a la producción de puntos más pequeños. Por lo tanto, los cambios en la granulometría de las materias primas del esmalte afectaron no solo a la estructura porosa de la capa de esmalte, sino también aspectos de la calidad de la imagen.

Inkjet digital decoration is a consolidated reality in the ceramic tiles industry. The next step toward a full digital decoration line is digital glazing [1,2]. Although digital inks have been widely studied in recent researches [3,4], little is known about glazes adaptations required for digital printing. One of the key issues is the size of the particles in the glaze suspension. To avoid clogging of the printhead nozzles, particles must be considerably smaller than in suspensions for traditional glazing [5].

Changes in the particle size distribution of the glaze suspension raw materials affect its rheological behavior [6,7]. This, in turn, determines the glaze application success and, consequently, the characteristics of the glaze applied layer [8]. Since usually in the decoration processes the ink is applied over this glaze layer, its characteristics could affect the ink absorption. As reported in previous works, aspects of the decoration such as the resolution of image may be affected as a consequence [9–11]. The objective of this work was to study the effects of the particle size distribution of a frit, used to produce a transparent glaze, on the characteristics of the glaze layer and its interaction with inks applied by digital printing of ceramic tiles.

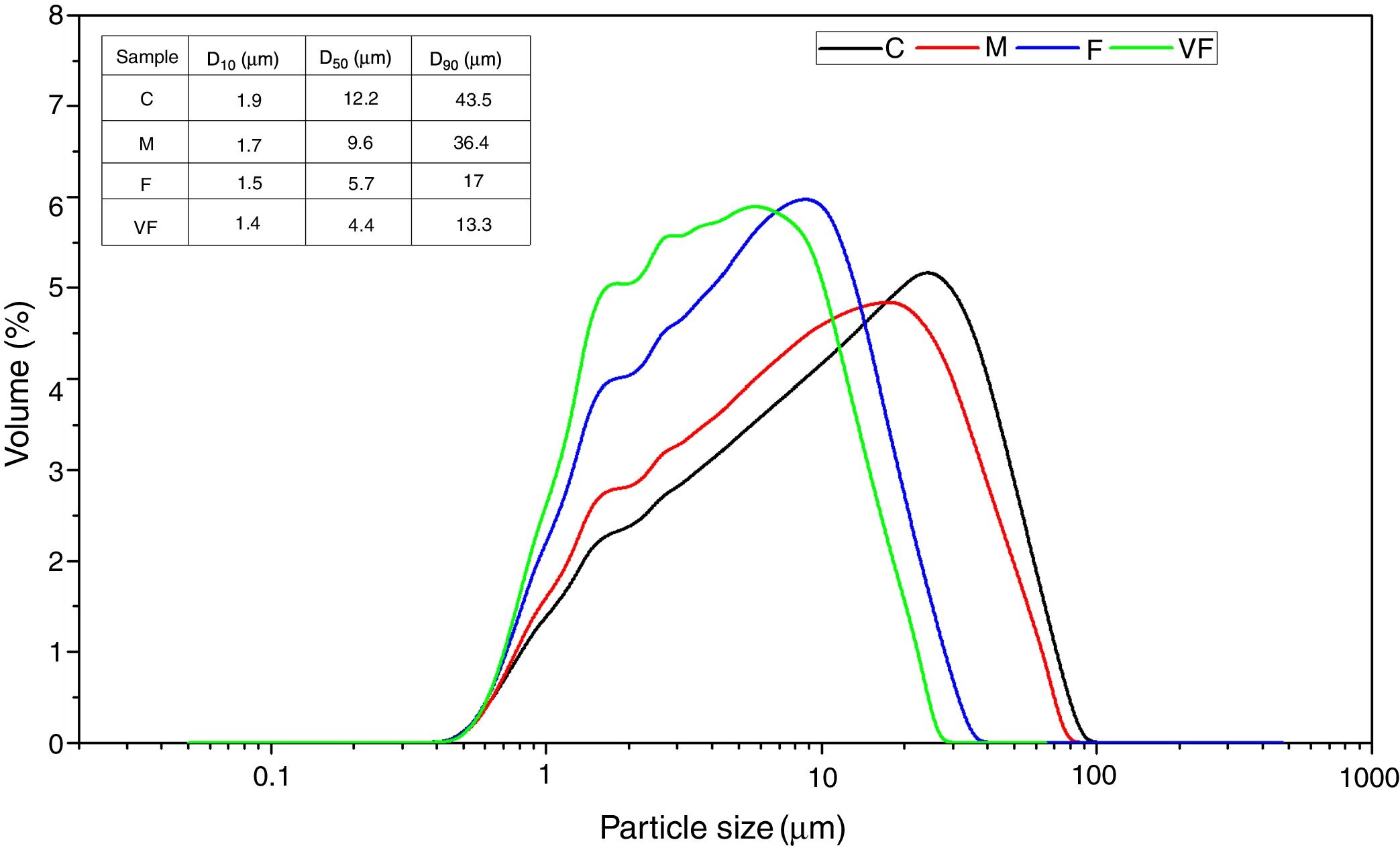

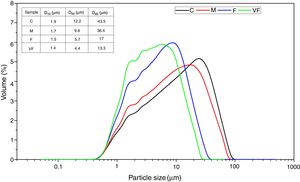

Experimental procedureAn industrial transparent frit was dry ground in a laboratory ball mill in four different conditions using alumina and zirconia media. The frits with different particle sizes were denominated as follows: C=coarse, M=medium, F=fine (micronized) and VF=very fine (micronized). The particle size distribution of the glazes was measured by laser diffraction (Mastersizer Microplus, Malvern, UK).

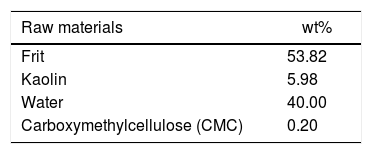

The formulation of the glaze suspensions is presented in Table 1. The amount of deflocculant (sodium tripolyphosphate) was adjusted in order to achieve the maximum deflocculation. The densities of the suspensions were kept constant.

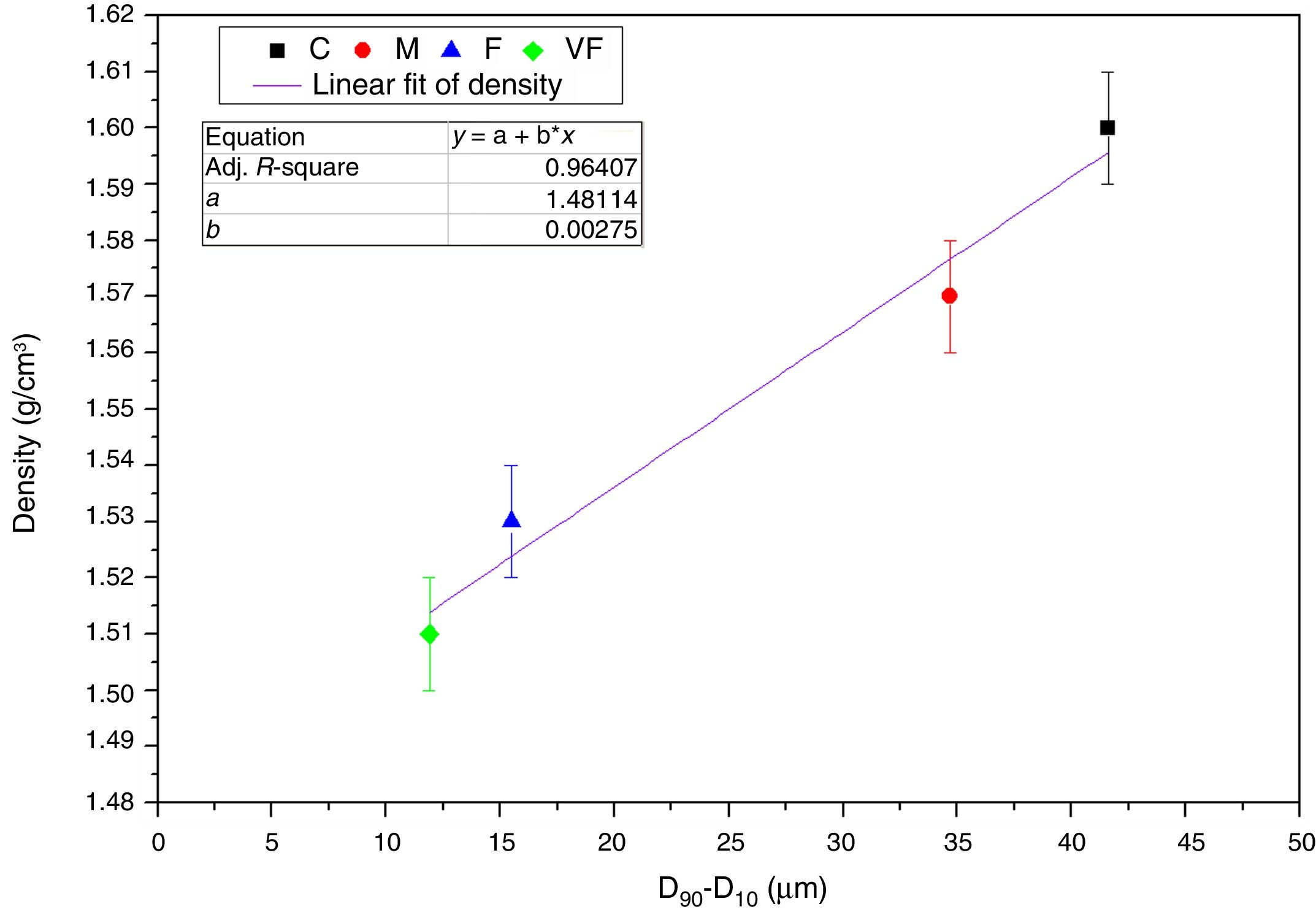

Given the practical difficulty in measuring the actual apparent density of the applied glaze layers and characterize its evolution during firing, an alternative method was adopted. The glazes were dried and granulated. Cylindrical green bodies with dimensions of 6×2cm were prepared by pressing the granulated powder at 400kgf/cm2 in a uniaxial automatic press. The apparent density of the compacts was determined by mercury immersion. It is well known that the arrangement of the particles in the compacts does not equal the arrangement of the particles in the digital printed layer. However, it was presumed that the changes in the frits granulometry would affect the density of the green bodies similar to what would be observed for the density of the applied layer.

For the evaluation of the ink behavior over the glaze layer, the suspensions were applied on the surface of 15×15cm previously fired tiles pieces. A Binil manual applicator was used to apply 0.4mm thick layers. The samples were dried and subsequently drops of black inks were applied over the surface by a method successfully used in a previous work [12]. Ink drops were released from a fixed volume micropipette (30μL) positioned 13mm above the surface. The dried samples – support/glaze layer/ink drops – were fired at 1070, 1100 and 1130°C in fast fire cycles in a laboratory electric kiln.

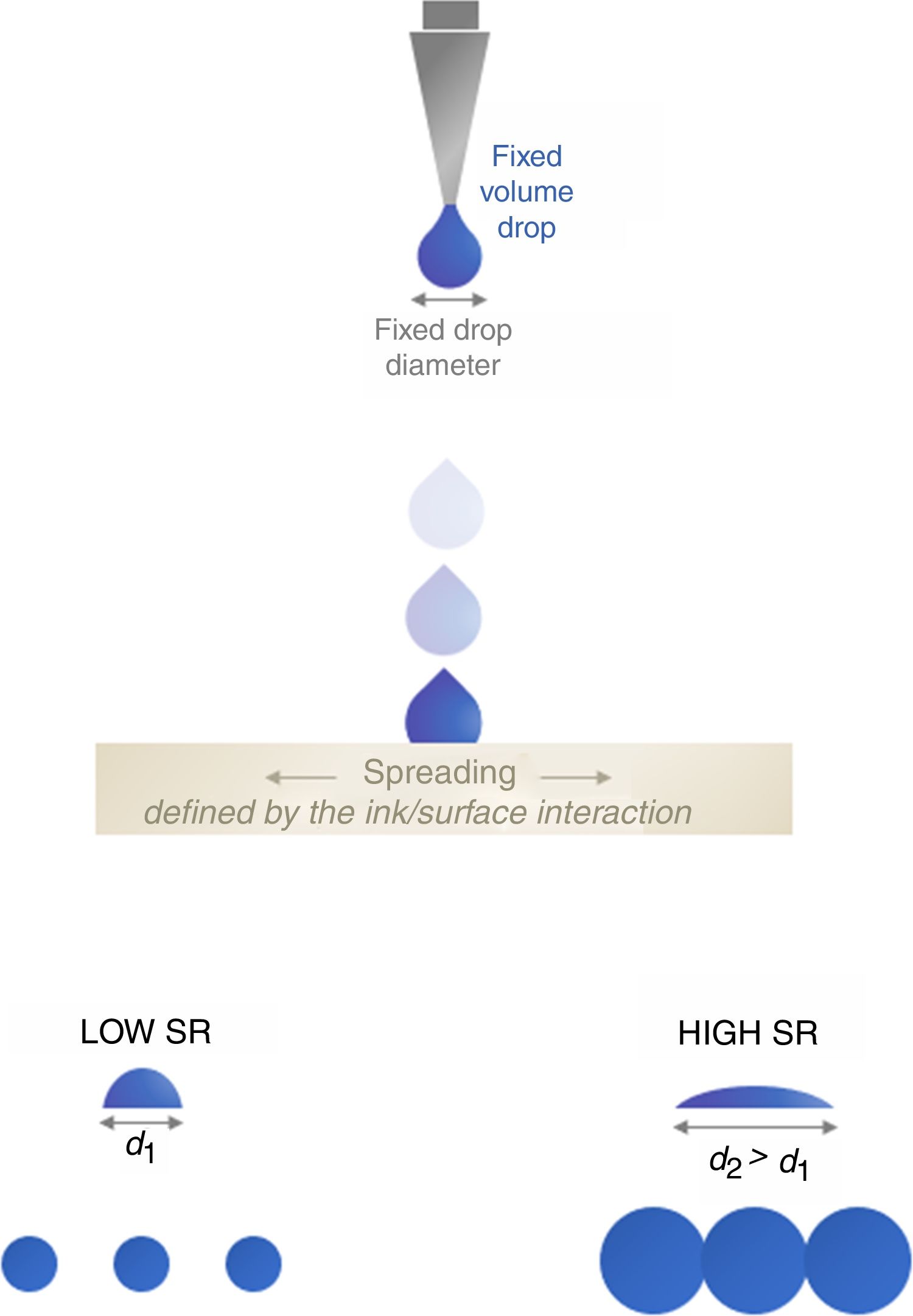

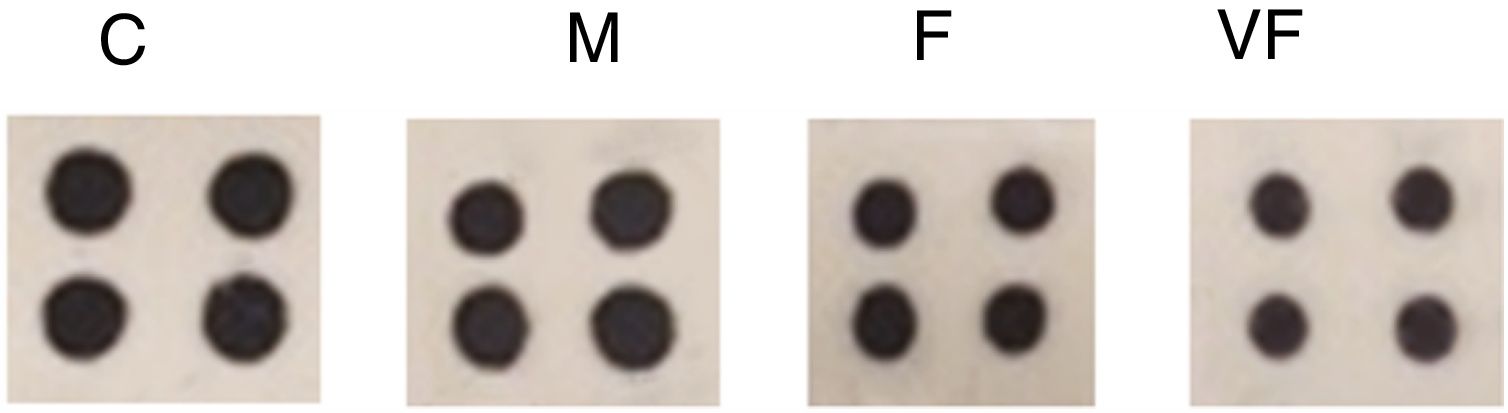

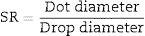

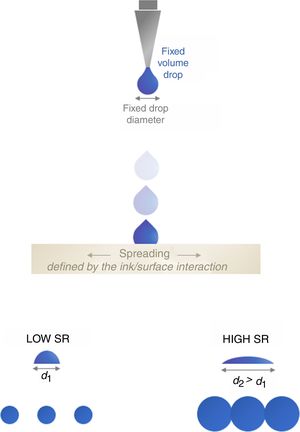

The ink drops spreading behaviors were investigated through the determination of the spreading ratio (SR). The SR is calculated as the ratio between the diameter of the ink dot formed over the surface (determined with image analysis software) and the diameter of the initial drop (assumed as the same as the pipette outlet port), according to the following relation [13].

Fig. 1 illustrates dots of different sizes formed from fixed initial diameter drops and guaranteeing a constant volume was applied. A higher SR is related to larger dots, produced when the ink spreads in a higher extent over a given substrate. In these cases, a higher ink yield may be expected since, with a given number of drops emitted by the printer, a larger surface area of the ceramic piece is covered. On the other hand, lower SR indicates that smaller dots can be printed and, as a consequence, higher image resolution may be achieved in printing.

Results and discussionFig. 2 illustrates the particle size distribution of the frits submitted to different milling conditions. The statistical parameters D10, D50 and D90 represent the particle diameter when the mass percentage is equal to 10, 50 and 90% of the total, respectively. The results have shown that D10 is very similar for all the glazes, while D50 and D90 decrease considerably from C to VF frits. It indicates that the milling process has produced a size reduction mainly for the larger particles, leading to narrower particle size distributions. As a result of these changes, the particles packing in the applied glaze layer over the ceramic surface should be affected.

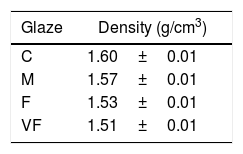

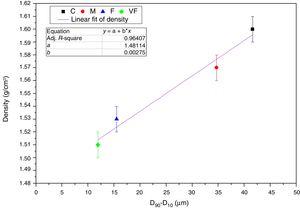

Apparent density results for the granulated glazes compacts are presented in Table 2. From frit C to VF the density of the compacts decreases. Both the increase in the finer fraction of particles and the consequent narrowing in the particle size distribution may have contributed to this result. According to the literature, a decrease in particle size increases the superficial forces with respect to the gravitational/hydrodynamics ones [14]. It favors floc formation and leads to less efficient particles packing in suspensions and green bodies [15]. In addition, for wider particle sizes distributions, the accommodation of smaller particles in spaces between larger ones contributes to increase packing efficiency. On the other hand, when the particles have similar sizes (narrower particle sizes distribution), lower packing densities are achieved.

In Fig. 3, a linear decrease in the glaze green bodies apparent density with the difference between D90 and D10 is shown. It confirms that particle packing efficiency is strongly correlated to the particle size distribution of the frits, altered by milling conditions. Although these results refer to cylindrical compacts, with the narrowing in particle size distribution of the frits, a similar density reduction is expected for the glaze layers obtained from a suspension.

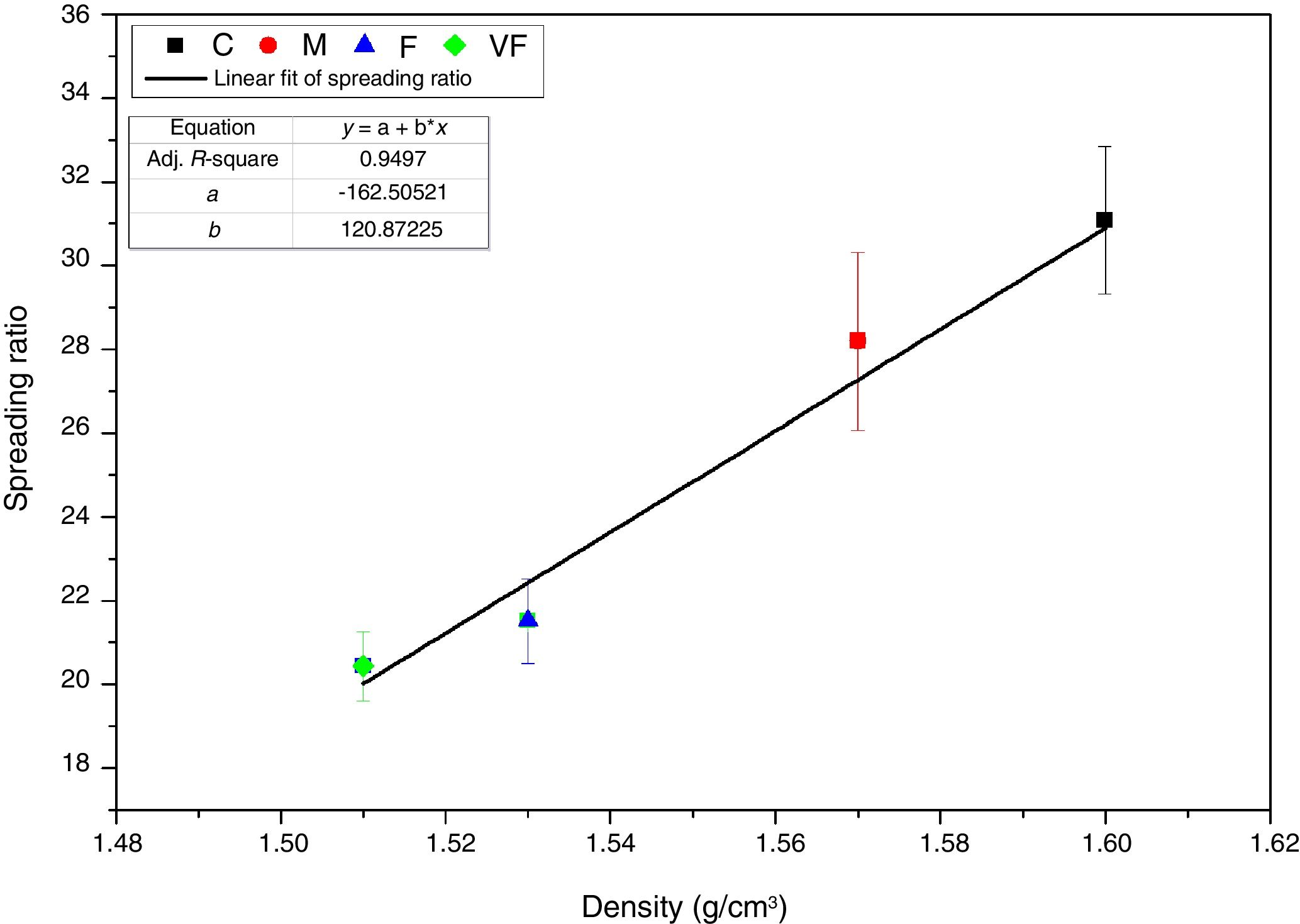

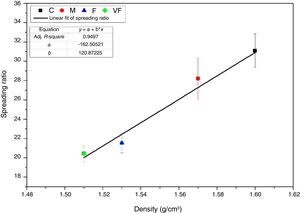

Packing of particles in the glaze layer determines its porosity, which should affect the penetration of the inks applied in digital decoration into the surface. Fig. 4 presents the spreading behavior of digital inks over the surface of the four different fired glaze layers studied. These results are correlated to the apparent density obtained for the cylindrical compacts previously evaluated, taken as an indicative of the density of the glaze layers on which the inks drops were applied.

One can note that the SR decreases linearly with respect to the packing density of the glaze compacts, reduced from frit C to VF. It was confirmed, therefore, that the changes in apparent density of the glaze due to changes in the granulometry of the frits influenced the ink spreading over the surface.

A decrease in the SR with the reduction of the apparent density of the glaze compacts can be explained by its higher porosity. When an ink drop impacts a surface, its behavior is controlled by different physical processes and driven by inertial, capillary and gravitational forces [16]. For surfaces with greater porosity, the ink penetrates more quickly. Consequently, the drop dries before it spreads to its maximum extent, which leads to the formation of a smaller dot. On the other hand, more efficiently packed layers are less permeable. Then, the ink drop spreads further over the surface, forming a larger dot.

Therefore, it can be stated that changes in the frits granulometry affect the glaze layer porous structure and, consequently, the inks absorption and spreading in the decoration stage. This, in turn, determines the diameter of the produced dots, which interferes with the ink yield and also the resolution of the printed images.

Fig. 5 shows an image of applied drops in the glaze surface, after firing. It is observed the drops have a similar circular shape.

ConclusionsThe different milling conditions changed considerably the particle size distribution of the frits, which affected the particle packing and the porous structure of the glaze layers. From frit C to VF the fraction of course particles was reduced and the granulometric distribution curve narrowed. As indicated by the apparent density results for the cylinders pressed with the granulated suspension, the glaze layers produced from frits with narrower particle size distribution are less efficiently packed. The higher porosity of these layers lead to a faster ink absorption and more limited ink spreading over the surface. Consequently, smaller dots were formed, which could contribute to higher resolution of the printed images, despite a reduction in the ink yield.

This study was financed in part by the Coordenação de Aperfeiçoamento de Pessoal de Nível Superior – Brasil (CAPES) – Finance Code 001. The authors would like to thank Conselho Nacional de Desenvolvimento Científico e Tecnológico (CNPq) (Brazilian Federal Agency for Support of Research, Development and Innovation) for granting scholarships to Leidy J. Jaramillo Nieves and Ana V. Lot.