It generally takes 2.5 to 3 years for an enterprise to implement total productive maintenance (TPM) in a full swing; however, the actual duration depends on each company's corporate status. Generally speaking, for a company with big staff, it even takes 3 to 5 years, but the major consideration should depend on whether the actual benefit is remarkable or not. This research aims to find out whether TPM was carried out by enterprises, to inspect the enterprises’ current performance, and to make comparison with those enterprises that have successfully carried out TPM. Through the findings, we hope to provide reference for enterprise owners when they carry out TPM, so as to reduce the cost for fumble.

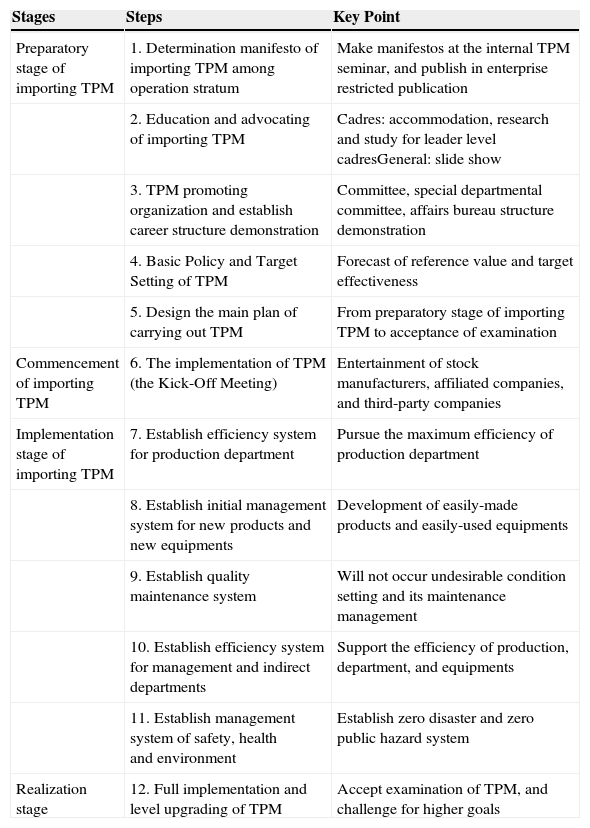

Silver and Fiechter (1995) emphasized that it was not possible to immediately carry out the eight supporting activities of total productive maintenance (TPM) when an enterprise decided to import TPM. He pointed out that it's better to comply with the twelve steps of TPM implementation and push forward steadily, and this was called mastering the key to success. The twelve steps of TPM can be divided into four stages (Table 1).

The twelve steps of TPM implementation.

| Stages | Steps | Key Point |

|---|---|---|

| Preparatory stage of importing TPM | 1. Determination manifesto of importing TPM among operation stratum | Make manifestos at the internal TPM seminar, and publish in enterprise restricted publication |

| 2. Education and advocating of importing TPM | Cadres: accommodation, research and study for leader level cadresGeneral: slide show | |

| 3. TPM promoting organization and establish career structure demonstration | Committee, special departmental committee, affairs bureau structure demonstration | |

| 4. Basic Policy and Target Setting of TPM | Forecast of reference value and target effectiveness | |

| 5. Design the main plan of carrying out TPM | From preparatory stage of importing TPM to acceptance of examination | |

| Commencement of importing TPM | 6. The implementation of TPM (the Kick-Off Meeting) | Entertainment of stock manufacturers, affiliated companies, and third-party companies |

| Implementation stage of importing TPM | 7. Establish efficiency system for production department | Pursue the maximum efficiency of production department |

| 8. Establish initial management system for new products and new equipments | Development of easily-made products and easily-used equipments | |

| 9. Establish quality maintenance system | Will not occur undesirable condition setting and its maintenance management | |

| 10. Establish efficiency system for management and indirect departments | Support the efficiency of production, department, and equipments | |

| 11. Establish management system of safety, health and environment | Establish zero disaster and zero public hazard system | |

| Realization stage | 12. Full implementation and level upgrading of TPM | Accept examination of TPM, and challenge for higher goals |

TPM is composed by the first English letters of T (Total) PM (Productive Maintenance). Its definition was as follows:

- 1.

Target to achieve the maximum equipment efficiency (over all efficiency).

- 2.

Establish TPM system which targets at equipment life of maintenance prevention, preventive maintenance and corrective maintenance.

- 3.

All related persons should participate jointly, e.g. equipment planner (Planning Department), equipment user (Manufacturing Department), and maintenance person (Maintenance Department), etc.

- 4.

Promote TPM by independent small group activities.

In order to carry out in full swing throughout the company, Okogbaa, Huang, & Shell (1992) put forward a new definition, i.e. TPM throughout company. The definition is as follows (Pintelonm & Wassenhove, 1990):

- 1.

Pursue the maximum efficiency of manufacturing system (overall efficiency), aiming at improving enterprises’ quality.

- 2.

Under the framework at scene and with material, and targeted at the entire life circle, pursue zero disaster, zero defectiveness, zero breakdown and prevent all losses in advance.

- 3.

Except manufacturing department, all departments (developing department, sales department, management department) are also involved.

- 4.

Overall employee involvement, up from the operational strata, and under to the front-line.

- 5.

Achieve the goal of zero losses through repeated small group activities.

In addition, some other scholars gave definition to TPM as follows: a collaborative approach for continuous improvement on product quality, operational effectiveness, grasp of productivity and safety between organization functions, especially between productivity and maintenance, also emphasize that the “Total” in “TPM” means overall employee involvement in enterprises, i.e. continuous improvement on overall efficiency and active employee involvement. Roup (1999) considered that there were three components of TPM:

- 1.

Emphasize on continuous improvement of equipment.

- 2.

Jointly share the responsibility of equipment maintenance.

- 3.

Emphasize on autonomous work teams on equipment.

While MacAdam and Duffner (1996) considered that TPM was not only a problem on technology and machinery, or 5S, OEE, TPM is exactly a change in management method. This research plans to adopt Yamashina's definition to TPM which is relatively complete; moreover, other scholars’ definitions are all covered in his definition (Yamashina, 2000).

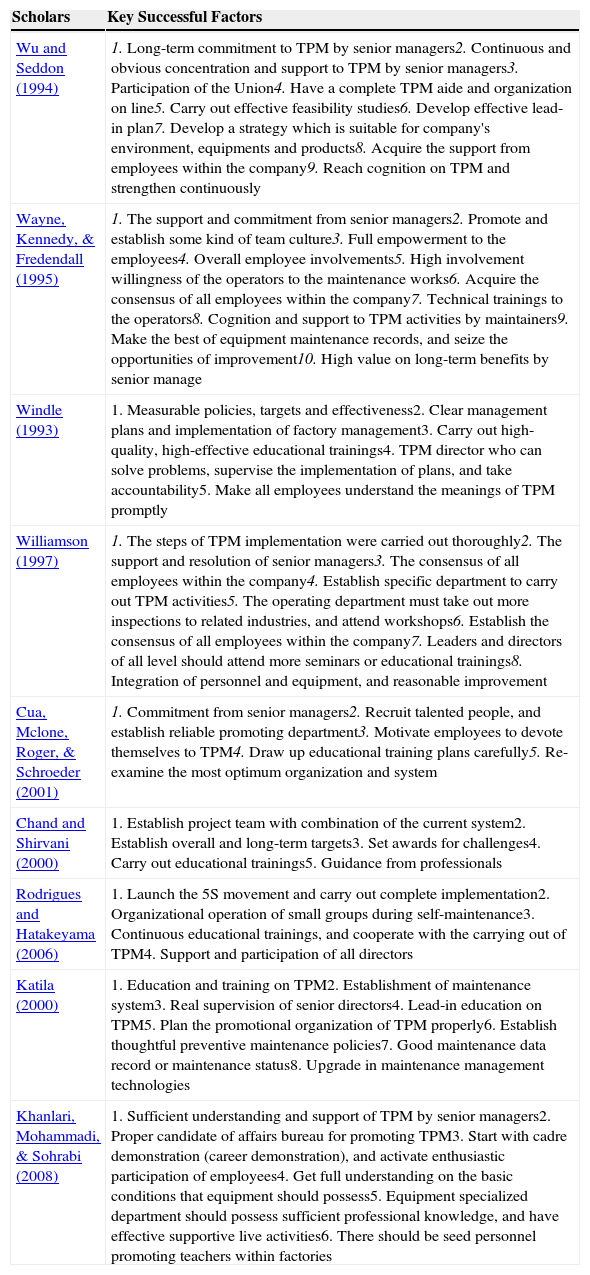

3. Discussion on Key Successful Factors of TPMLixin, Shicheng, Yunqi, & Guiwen (2011) pointed out that in aspects of domestic cases developed TPM gradually and steadily in three stages. Through comparison between literature discussion, and the researches and perspectives of key successful factors of TPM by many scholars and experts, we get the summary listed in the attached Table 2. The core factors proposed by foreign scholars and experts are exactly consistent when being compared. Most of these factors emphasized on the commitment and involvement of management, the promotional organization and overall involvement.

Summary of key successful factors.

| Scholars | Key Successful Factors |

|---|---|

| Wu and Seddon (1994) | 1. Long-term commitment to TPM by senior managers2. Continuous and obvious concentration and support to TPM by senior managers3. Participation of the Union4. Have a complete TPM aide and organization on line5. Carry out effective feasibility studies6. Develop effective lead-in plan7. Develop a strategy which is suitable for company's environment, equipments and products8. Acquire the support from employees within the company9. Reach cognition on TPM and strengthen continuously |

| Wayne, Kennedy, & Fredendall (1995) | 1. The support and commitment from senior managers2. Promote and establish some kind of team culture3. Full empowerment to the employees4. Overall employee involvements5. High involvement willingness of the operators to the maintenance works6. Acquire the consensus of all employees within the company7. Technical trainings to the operators8. Cognition and support to TPM activities by maintainers9. Make the best of equipment maintenance records, and seize the opportunities of improvement10. High value on long-term benefits by senior manage |

| Windle (1993) | 1. Measurable policies, targets and effectiveness2. Clear management plans and implementation of factory management3. Carry out high-quality, high-effective educational trainings4. TPM director who can solve problems, supervise the implementation of plans, and take accountability5. Make all employees understand the meanings of TPM promptly |

| Williamson (1997) | 1. The steps of TPM implementation were carried out thoroughly2. The support and resolution of senior managers3. The consensus of all employees within the company4. Establish specific department to carry out TPM activities5. The operating department must take out more inspections to related industries, and attend workshops6. Establish the consensus of all employees within the company7. Leaders and directors of all level should attend more seminars or educational trainings8. Integration of personnel and equipment, and reasonable improvement |

| Cua, Mclone, Roger, & Schroeder (2001) | 1. Commitment from senior managers2. Recruit talented people, and establish reliable promoting department3. Motivate employees to devote themselves to TPM4. Draw up educational training plans carefully5. Re-examine the most optimum organization and system |

| Chand and Shirvani (2000) | 1. Establish project team with combination of the current system2. Establish overall and long-term targets3. Set awards for challenges4. Carry out educational trainings5. Guidance from professionals |

| Rodrigues and Hatakeyama (2006) | 1. Launch the 5S movement and carry out complete implementation2. Organizational operation of small groups during self-maintenance3. Continuous educational trainings, and cooperate with the carrying out of TPM4. Support and participation of all directors |

| Katila (2000) | 1. Education and training on TPM2. Establishment of maintenance system3. Real supervision of senior directors4. Lead-in education on TPM5. Plan the promotional organization of TPM properly6. Establish thoughtful preventive maintenance policies7. Good maintenance data record or maintenance status8. Upgrade in maintenance management technologies |

| Khanlari, Mohammadi, & Sohrabi (2008) | 1. Sufficient understanding and support of TPM by senior managers2. Proper candidate of affairs bureau for promoting TPM3. Start with cadre demonstration (career demonstration), and activate enthusiastic participation of employees4. Get full understanding on the basic conditions that equipment should possess5. Equipment specialized department should possess sufficient professional knowledge, and have effective supportive live activities6. There should be seed personnel promoting teachers within factories |

Through comparison between literatures and actual cases, this research aims to understand the successful factors of implementation of TPM. And through comparison with those enterprises that have successfully carried out TPM, this research helps to understand the steps of carrying out TPM.