Research on sustainable manufacturing is currently gaining momentum and becoming a dynamically developing field that considers green innovations (GI). However, rapid dynamics cause the entire field to fragment into smaller topics with different research interests, impacts, and development dynamics over time. This study aims to create a comprehensive scientific map of GI in manufacturing by systematically processing 9376 documents retrieved from the Scopus database. The results show that this research domain gained significant momentum in 2019, with most studies published in the engineering and business subject area. Latent Dirichlet Allocation was used to identify 94 unique topics from all abstracts. We classified the topics into five territories regarding their level of systematization: uncharted (26 topics), discovering (23), expanding (15), well-recognized (19), and marginal (11). The least uncharted topics in the field of GI in manufacturing that have potential for systematization are Resource-based Performance Modeling, Sustainability-oriented Performance, and Supplier Decision Criteria and Fuzzy Logic. The most significant topics related to GI in manufacturing currently include Smart Technologies and Industry 4.0, Green Supply Chain, Carbon Emission Reduction, and Digital Transformation, with the last two having the most dynamic development. The results offer objective information for a wider scientific discussion regarding the direction of research in green manufacturing concept and point to uncharted areas that may represent future directions for the development of this concept.

In recent decades, the role of green innovations (GI) have evolved into a vital force supporting economic, social, and environmental goals, contributing to the overarching pursuit of sustainability (Eccles et al., 2013; Afeltra et al., 2023). The dynamic relationship between GI and sustainability has become a focal point, with thousands of scientific studies exploring various facets, depths, and levels of this impactful concept. As the breadth of research has expanded, the imperative to precisely define and systematize GI has become evident. Recognizing the growing importance of GI, researchers have focused on the systematic exploration of its diverse aspects. This includes probing into the drivers and motivations behind GI (Siyal et al., 2023; Ullah et al., 2022), classifying its different types (Degler et al., 2021), or assessing its impact on business performance (Wen et al., 2023). The dynamism and multidisciplinarity inherent in GI research have led to the concept becoming highly fragmented, a trend illustrated by a comprehensive review of significant studies focusing on GI.

GI encompasses the development of eco-friendly products or processes marked by advancements in technologies that facilitate energy and water conservation, pollution prevention, waste recycling, and corporate environmental management (Kraus et al., 2020). As proposed by some authors, another dimension of GI includes green systems or managerial innovations designed to mitigate or eliminate environmental harm (Abdullah et al., 2016; Siedschlag et al., 2022). Recognized as a strategic imperative for companies, GI presents a significant opportunity to meet customer demands while safeguarding the ecosystem (Albort-Morant et al., 2016). It serves as a means for organizations to mitigate the adverse effects of their operations on the natural environment (Shahzad et al., 2020).

In the face of escalating environmental concerns, GI has garnered increasing attention and is now viewed as a crucial avenue through which companies can achieve environmental sustainability (Borah et al., 2023; Shahzad et al., 2020). Positioned as a strategic requirement, GI not only meets customer expectations but also contributes to environmental sustainability, emerging as a potent competitive advantage for organizations (Borah et al., 2023).

Firms’ adoption of GI is influenced by various factors, including internal Research and Development (R&D) and technological capabilities, access to external knowledge, firm-specific characteristics, exposure to competition in international markets, spillovers from other green innovators, and public funding (Siedschlag et al., 2022). Notably, the development of green dynamic capabilities is a significant factor given its substantial impact on promoting green products and process innovation (Yuan & Cao, 2022). However, the presence or absence of these factors can act as enablers or barriers. Despite companies investing in GI, their inability to overcome existing barriers may hinder the successful introduction of new green processes or products to the market (Abdullah et al., 2016).

Appoloni et al. (2022) emphasized the role of industrialization in fostering solid, long-term development. Consequently, the manufacturing sector, which is recognized as a crucial economic driver, is one of the most environmentally impactful industries (Rehman et al., 2021; Aftab et al., 2022). Its substantial influence on the environment manifests through air, waste, and water pollution, natural resource depletion, contributions to climate change, and excessive consumption of natural resources (Kraus et al., 2020; Rehman et al., 2021). To mitigate these negative environmental effects and achieve sustainable development, manufacturing firms can proactively invest in GI capabilities (Borah et al., 2023; Kraus et al., 2020; Yin & Yu, 2023). The feasibility of industrialization is contingent on technology and innovation (Appoloni et al., 2022). Hence, promoting GI within manufacturing companies has emerged as a primary strategy for addressing environmental concerns (Yuan & Cao, 2022).

GI has evolved into a pivotal strategic tool for manufacturing companies to respond to escalating environmental pressures (Abdullah et al., 2016; Kraus et al., 2020). By incorporating sustainable development practices, manufacturing companies can strategically position their new products as environmentally friendly, aligning with growing consumer environmental consciousness (Borah et al., 2023; Chen & Chang, 2013). Successful GI performance not only enhances environmental efficiency, but also contributes to fostering a positive green image for companies (Albort-Morant et al., 2016).

It is widely acknowledged that GI represents a pathway to achieving sustainable development (Siedschlag et al., 2022) and enhancing environmental performance (Abdullah et al., 2016; Kraus et al., 2020). They have evolved into essential strategic tools for manufacturing companies (Albort-Morant et al., 2016; Kraus et al., 2020). However, despite their recognized benefits, barriers and challenges persist in implementing GI (Abdullah et al., 2016), necessitating a deeper understanding of the subject.

Given the significance and interest in this topic, a substantial body of literature on GI provides a valuable reference (Yin & Yu, 2023). The extensive nature of this literature requires a more sophisticated analysis approach that leverages Artificial Intelligence (AI) tools to comprehensively capture information on this theme. Consequently, this study aims to conduct a thorough analysis of the literature on GI in manufacturing, spanning from its inception to the present, with the objective of creating a comprehensive scientific map of GI in manufacturing. This study aims to achieve this objective by constructing an exhaustive scientific map detailing the research related to GI in manufacturing. Three key research questions guided our exploration of this ambitious goal.

- •

RQ1: What are the research trends and structures related to GI in manufacturing?

- •

RQ2: What are the latent topics related to GI in manufacturing, and which of them are uncovered and unsystematized?

- •

RQ3: What are the most significant topics and how do they evolve over time?

This paper is organized as follows. Section ``Introduction'' presents the introductory motivation, a brief literature review, and research gaps. Section ``Literature review'' contains a more in-depth literature review, and Section ``Methodology'' presents the research methodology and specifies the individual steps of the smart literature review in more detail. Section ``Results'' contains three segments, each of which contains the results relevant to one RQ. Sections ``Discussion and conclusion and Implications, limitations, and future directions'' present the discussion, conclusions, and implications of the study, along with its limitations and possible directions for future research.

Literature reviewResearch related to GI in manufacturing in recent yearsCurrent research is increasingly delving into the more fragmented aspects of GI, expanding the multidisciplinary nature of the concept. The manufacturing sector is a pivotal domain within GI research, which is marked by diverse practical and theoretical implications directly or indirectly linked to sustainability. This connection to sustainability serves as a significant driver of robust scientific interest in GI-related topics in manufacturing. However, even within the realm of manufacturing, there is a discernible trend toward gradual research fragmentation, as evidenced by some ongoing studies.

Product and process innovations manifest through enhancements in manufacturing processes and product design (Siedschlag et al., 2022). This encompasses exploitative GI, which concentrates on refining existing products, processes, and technologies to mitigate their negative environmental impact, and exploratory GI, which focuses on creating novel products, processes, and technologies capable of potentially reversing and mitigating environmental damage (Rehman et al., 2021).

The advantages of adopting GI include the reduction in environmental damage resulting from production processes and products (Guoyou et al., 2013; Yin & Yu, 2023; Alfalih & Hadj, 2024), along with the mitigation of pollution, resource utilization (including energy consumption), and other adverse environmental effects (Abdullah et al., 2016; Wang et al., 2023; Ghimire et al., 2023).

GI emphasizes environmental concerns, pollution prevention, and the implementation of long-term strategies (Rehman et al., 2021; Yi et al., 2021. The objectives of GI include the use of green raw materials and green product designs to minimize pollution, conserve energy resources (such as water and electricity), reduce waste, and diminish a firm's overall negative impact on the environment (Singh et al., 2021; El-Kassar & Singh, 2019). By fostering sustainable processes and optimizing resource and energy utilization, GI has become a crucial method for companies to enhance productivity and maintain competitiveness (Singh et al., 2021; Ahmed et al., 2023).

The primary motive behind adopting GI is achieving outcomes aligned with environmentally conscious consumer demands and strategically positioning new products as environmentally friendly to secure a market position (Shahzad et al., 2020; Appoloni et al., 2022). As a key component of organizations' sustainable development strategies, GI plays a pivotal role in meeting consumers' green consumption demands (Yuan & Cao, 2022).

Organizations face considerable pressure from various sources to adopt GI, with stakeholder influence emerging as a decisive factor in their decision-making (Guoyou et al., 2013; Weng et al., 2015; Siedschlag et al., 2022; Wang et al., 2023). Shareholders express concerns about corporate environmental strategies, adherence to regulatory and governmental rules and laws, investor influence on the adoption of environmental practices, societal and local community concerns regarding the negative environmental impacts of companies, and customer and market demand for green products, all contributing to the impetus for implementing green strategies (Guoyou et al., 2013; Weng et al., 2015; Siedschlag et al., 2022). According to Yuan and Cao (2022), five factors affect companies’ GI: market demand; stakeholder pressure (including suppliers, customers, competitors, employees, shareholders, media, community residents, and industry associations); green resource (knowledge and learning) sharing, transfer, and exchange through cooperation networks with external partners; organizational factors (such as organizational ability, strategy, scale, environmental management systems, governance structure, social capital, and knowledge); and robust environmental policies.

Dynamic capabilities are pivotal factors influencing the development of green products and process innovation within organizational contexts (Albort-Morant et al., 2016; Arshad et al., 2023). Specifically, green dynamic capability refers to a company's capacity to leverage its existing knowledge and resources to cultivate green organizational capabilities, enabling it to respond effectively to a dynamic market (Chen & Chang, 2013). These green dynamic capabilities empower a company to strategically orchestrate its resources, ultimately delivering value to GI initiatives (Arshad et al., 2023; Borah et al., 2023). The enhancement of green dynamic capabilities has become a catalyst for promoting corporate GI, providing management with insights into fostering innovation centered on environmentally responsible practices (Shahzad et al., 2022). This underscores the critical role of dynamic capabilities in steering organizations toward successful and sustainable GI.

The cultivation of dynamic capabilities is intricately linked to the development of green capabilities and human management practices, such as green human resource management and transformational leadership Chen & Chang, 2013; El-Kassar & Singh, 2019). Green human management practices, including green hiring, training, and performance-based rewards, play a crucial role in attracting, training, motivating, and retaining employees aligned with environmentally conscious values (Ahmed et al., 2023; Singh et al., 2020; Aftab et al., 2022). These practices are instrumental in acquiring, developing, and sustaining a workforce that embraces green values, thereby supporting a firm's strategic competitiveness through GI practices and enhancing its environmental performance (Aftab et al., 2022). Green human management practices serve as predictors and enablers of GI in processes, products, and services, contributing to sustained and superior environmental performance (Singh et al., 2020; Aftab et al., 2022). Moreover, green leadership is considered a preconditioning factor that serves as a strategic resource that companies must leverage to shape and implement green human resources management. This, in turn, influences GI, environmental performance, and the achievement of a company's environmental management goals (Singh et al., 2020).

In contemporary times, the development of green products and the promotion of GI necessitate the integration of Industry 4.0 technologies as the foundation for GI (Mubarak et al., 2021; Yiun & Yu, 2023). Digital GI involves the incorporation of digital technologies, including 5 G, AI, big data, the Internet of Things, and other emerging information and communication technologies into the ongoing evolution of GI (Yiun & Yu, 2023). The amalgamation of Industry 4.0 into GI plays a pivotal role in improving GI performance by enhancing process efficiency, facilitating resource integration, and bolstering environmental monitoring capacity (Mubarak et al., 2021; Yin & Yu, 2023). Digitalization has emerged as a significant facilitator in developing innovative, sustainable circular products with active customer involvement (Ghobakhloo et al., 2020; Agrawal et al., 2022). Consequently, the incorporation of these technologies serves as a distinguishing factor in the innovation of green products and processes.

The literature highlights several benefits of implementing GI. Both process and product innovations notably enhance a company's market and financial performance (Singh et al., 2021). Green processes and product innovation not only mitigate the negative environmental impact of business operations, but also enhance organizational, social, and financial performance by minimizing costs and waste (Wang et al., 2023). GI play a vital role in achieving sustainable environmental performance by reducing air emissions, energy usage, material usage, and the consumption of harmful materials (Weng et al., 2015; Ghimire et al., 2023; Kraus et al., 2020). The capability of GI aids manufacturing firms in continuously improving their operational processes to minimize waste during production (Borah et al., 2023; Shahzad et al., 2022).

Attempts of systemization of GI concept in manufacturingThe fragmented research on GI in manufacturing has led to various efforts to systematize this field. Experts worldwide have conducted literature reviews to gain a comprehensive understanding of the multiple aspects of GI. The following provides an overview of key works based on recent systematic and bibliometric literature reviews.

Karimi Takalo et al. (2021) conducted a comprehensive study based on a thorough systematic literature review of GI. They selected and examined articles discussing the real-world advantages of GI and categorized them by study area. The manufacturing sector accounted for the largest share, with a significant focus on Industry 4.0 (I4.0) and sustainability. Rosa et al. (2019) explored the knowledge relationship between I4.0 and the Circular Economy (CE) through a detailed review, developing an innovative framework to map an integrated perspective. Dantas et al. (2021) identified a link between CE and I4.0 by combining practices and technology. Kipper et al. (2021) analyzed the competencies necessary for I4.0, revealing the current topics and authors in the field. Hernandes Korner et al. (2020) analyzed business model innovation and sustainability in additive manufacturing (Hernandez Korner et al., 2020), while Felsberger et al. (2020) examined scientific progress related to sustainability in I4.0. Jia et al. (2020) identified motivations, barriers, practices, and indicators of sustainable performance in applying a CE to the textile and clothing industry. Shirvanimoghaddam et al. (2020) discussed approaches for recycling textile waste and disruptive innovations in the textile industry. Kravchenko et al. (2019) provided an overview of the key performance indicators related to sustainability in CE strategies.

Chaurasia et al. (2020) proposed a model for high-to-moderate levels of shared-value co-creation. Secinaro et al. (2020) conducted a bibliometric analysis of business models for electric cars, revealing the need for more research in this area. Budler et al. (2021) and Lu et al. (2020) examined the impact of critical research topics on publications in the business subdisciplines of strategy, entrepreneurship, and innovation. Taddeo et al. (2019) provided a qualitative and quantitative review of Lean and Clean (L&C) research, indicating an expected increase in related literature. Cioffi et al. (2020) analyzed the scientific literature on the application of artificial intelligence and machine learning in the industry, particularly after the introduction of I4.0. Agrawal et al. (2021) explored future research directions for the CE and Sustainable Business Performance (SBP) in the context of digitization. Rosário and Dias (2022) conducted a systematic bibliometric literature review of the contribution of digital transitions to environmental, economic, and social sustainability, considering them as fundamental pillars of current human needs.

Research gapExploration of GI within the realm of manufacturing has been the subject of extensive research, resulting in a rich tapestry of scientific publications. Given the evolving and multidisciplinary nature of GI, delving into the prior literature is crucial to establish a robust framework for comprehending current breakthroughs and potential future research paths. In this landscape, researchers have grappled with the dilemma of choosing between two predominant types of literature reviews: Systematic Literature Review (SLR) studies, known for their in-depth analysis, albeit with a limited number of articles; and Bibliometric Literature Review (BLR) studies, characterized by their broad scope but often lacking depth. SLRs allow researchers to delve deeply into a narrowly defined range of papers, whereas BLRs involves broader exploration at the cost of depth.

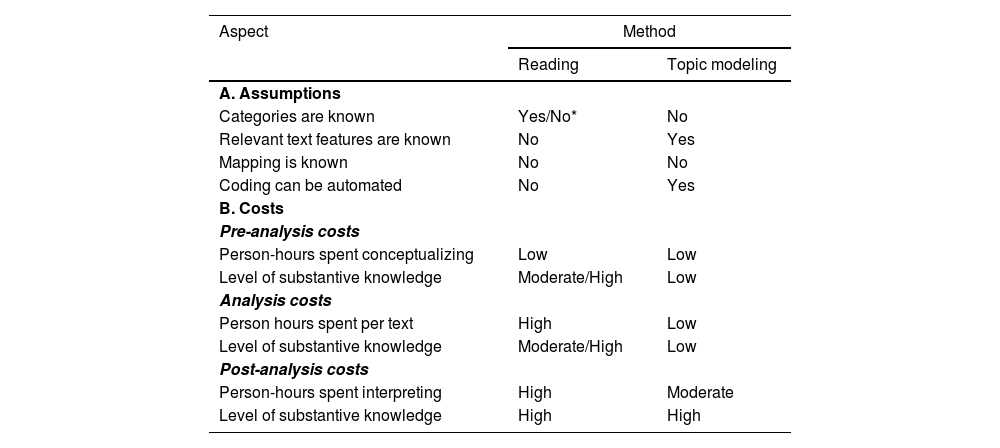

The advent of AI algorithms has revolutionized this landscape, offering a hybrid approach that combines the strengths of SLRs and BLRs. A noteworthy advancement was made by Asmussen and Møller in 2019 when they introduced the concept of a 'smart literature review.' They argued that manual exploratory literature reviews should be relegated to the past, given the maturity of technology and the development of machine learning methods. Their approach relies on a meticulous analysis of the relationships between terms in research papers, facilitating the classification of papers into thematic topics. Table 1 provides a compelling comparison between traditional and topic modeling approaches.

Comparison between alternative methods to literature review.

| Aspect | Method | |

|---|---|---|

| Reading | Topic modeling | |

| A. Assumptions | ||

| Categories are known | Yes/No* | No |

| Relevant text features are known | No | Yes |

| Mapping is known | No | No |

| Coding can be automated | No | Yes |

| B. Costs | ||

| Pre-analysis costs | ||

| Person-hours spent conceptualizing | Low | Low |

| Level of substantive knowledge | Moderate/High | Low |

| Analysis costs | ||

| Person hours spent per text | High | Low |

| Level of substantive knowledge | Moderate/High | Low |

| Post-analysis costs | ||

| Person-hours spent interpreting | High | Moderate |

| Level of substantive knowledge | High | High |

Yes when the analysis is based on a pre-defined framework; No when a new theoretical framework needs to be developed; Source: Adapted from Asmussen and Møller (2019).

Since its inception, this innovative approach to literature reviews has found widespread applications, ranging from the analysis of a few thousand papers (Aziz et al., 2021; Barravecchia et al., 2021) to an extensive examination of over 100 thousand papers (Madzík et al., 2023). The topic modeling approach has emerged as a relevant and reliable tool for conducting in-depth research across a vast array of research papers. The field of GI in manufacturing is particularly attractive due to its dynamic nature and robust academic interest. However, research in this area is dispersed across multiple disciplines, hindering a comprehensive understanding of GI topics and their evolution over time (Afeltra et al., 2023). This study aims to conduct a thorough analysis of literature on GI in manufacturing, spanning from its inception to the present, with the objective of creating a comprehensive scientific map of GI in manufacturing.

MethodologyData acquisitionThe Scopus database, one of the most relevant and significant sources of scientific data, was used to map the current scientific knowledge in the field of GI in manufacturing. We predefined a search query as follows: ("innovati*" OR "eco-innovat*") AND ("sustainab*" OR "green" OR "circular economy") AND ("manufact*" OR "industry 4.0″ OR "industry 5.0″). This query was applied to the title, abstract, and keyword fields, resulting in 9398 documents retrieved as of October 6, 2023. We chose to use only one database (Scopus) to ensure uniformity of results. Since several later analyzes considered variables whose values differed across other databases, only one database was selected. If we were to combining data from several databases, such as Scopus and Web of Science, would yield a larger dataset, however, it could introduce incosistencies in variables such as citation counts and subject areas, making replication of results more challenging and leading to less reliable analyses. Therefore, only one database was chosen.

Data preprocessingThe recorded attributes included authors, title, year, source title, number of citations (cited by), abstract, author keywords, and index keywords. After excluding documents lacking abstracts or containing "[No abstract available]," the dataset comprised 9376 documents for subsequent bibliometric analyses. To address RQ1 on topic representation across scientific areas, we further expanded the dataset to incorporate the documents’ affiliation with individual subject areas. This affiliation was determined based on the source title's association with one of the 26 defined subject areas.1 The time series and numbers of citations in individual years were analyzed, and data were visualized through the subject areas. These variables were selected for analysis to capture the trends and structure of research related to GI in manufacturing. Based on the defined affiliations of the source documents, we assigned information regarding the subject areas to individual records. It is important to note that one document could belong to several subject areas, just as one source title can belong to several subject areas.

We performed a smart literature review based on topic modeling of abstracts from the obtained and modified datasets pertaining to GI in manufacturing. Before the actual topic modeling phase, we created a text corpus from the abstracts, which we preprocessed for more efficient and faster topic modeling analysis. The preprocessing phase included standard and customized preprocessing. Standard text pre-processing involved replacing certain special characters with spaces, eliminating punctuation, numbers, and English stopwords defined in the tm package.

Customized preprocessing was performed during the text corpus preprocessing phase. In this phase, we identified additional words that were subsequently removed from the corpus. These words were not defined in the stopword vector in the tm package but were considered relevant for our analysis they were words with a general meaning. These words lacked relevance in the GI manufacturing. Including these terms in the topics allocation process posed a risk of distorting and inaccurately representing the results. After removing these words, we removed the extra spaces and performed stemming, which included trimming the words in the document to a word basis. After corpus preprocessing, we continued the topic modeling phase using Latent Dirichlet Allocation (LDA).

Latent dirichlet allocationLatent Dirichlet Allocation is a text analysis method used in natural language processing. It operates on the basis of probabilistic clustering principles. It is a hierarchical model: documents are a mixture of multiple topics, and the probability of a topic belonging to a document lies between 〈0; 1〉. LDA assumes that topics are uncorrelated (Blei & Lafferty, 2009; Blei et al., 2003; Grün & Hornik, 2011). At the same time, each topic is a mixture of several words that are defined in the given topic with a certain probability.

In the LDA model, the order of individual words is irrelevant (Blei and Lafferty, 2009). The name of this method originates from Dirichlet distribution. The probability distribution of examined documents across topics and the probability distribution of words within individual documents rely on the Dirichlet probability distribution (Ponweiser, 2012). This distribution is characterized by the following density function:

where Γ is a Gamma function and α→ is a positive K-vector, where K is a specified number of topics.Formally, the generative probabilistic LDA model is defined as follows (Blei et al., 2003; Blei & Lafferty, 2009; Ponweiser, 2012):

- 1.

For every topic k, k=1…K,

- a.

Determine the distribution of probable words for a specific topic k. In other words, definine a probability distribution of words per topic ϕk. Let the variable ϕkhave a Dirichlet distribution Dir(β), where β is a positive V-vector, where V is the size of the dictionary in the examined corpus and beta is a hyperparameter of the model

- a.

- 2.

For every document d from document corpus D:

- a.

Determine the distribution of probable topics in document d. In other words, defining a probability distribution of topics in a document d denoted as θd. Let the variable θd have a K-dimensional Dirichlet distribution Dir(α) where K is the number of words in vocabulary and alpha is a hyperparameter of the model.

- b.

For each word wi in a document d

- i.

Assign an appropriate topic zd,i∼Multinomial(θd). Note that zd,i∈{1…K}. Note that in LDA, each word in document di can be assigned to only one topic.

- ii.

Based on a selected topic, choose a word wd,ifrom a multinomial probability distribution conditioned on the topic ϕk, kde k=zd,i

- i.

- a.

Based on Blei et al. (2003), the joint distribution, which is the composition of topic mixture θ, set of assigned topics z, terms distributions in topic ϕ, and set of words denoted as w, is formally defined according to Ponweiser (2012) as:

Let us define ϕk,v, which represents the probability that term v is drawn when the topic is chosen to be k. Then, let us define the probability distributions for all topics and all wordsϕ, as described by Ponweiser (2012) as:

Let us define the probability distribution of topics over a documentθ, which is defined according to Blei et al. (2003) and Ponweiser (2012) as:

Let us define the topic to words assignmentzd,i, which specifies the affiliation of the ith word in the document d with a specific topic. This affiliation depends on the distribution θ, i. e., on the topics distribution for a document d. In addition, let us define nd,k as the number of times a topic k is assigned to words in document d. Then, the probability of z for all topics and all documents is defined according to Ponweiser (2012), as follows:

Finally, the probability of a corpus w is defined as (Ponweiser, 2012):

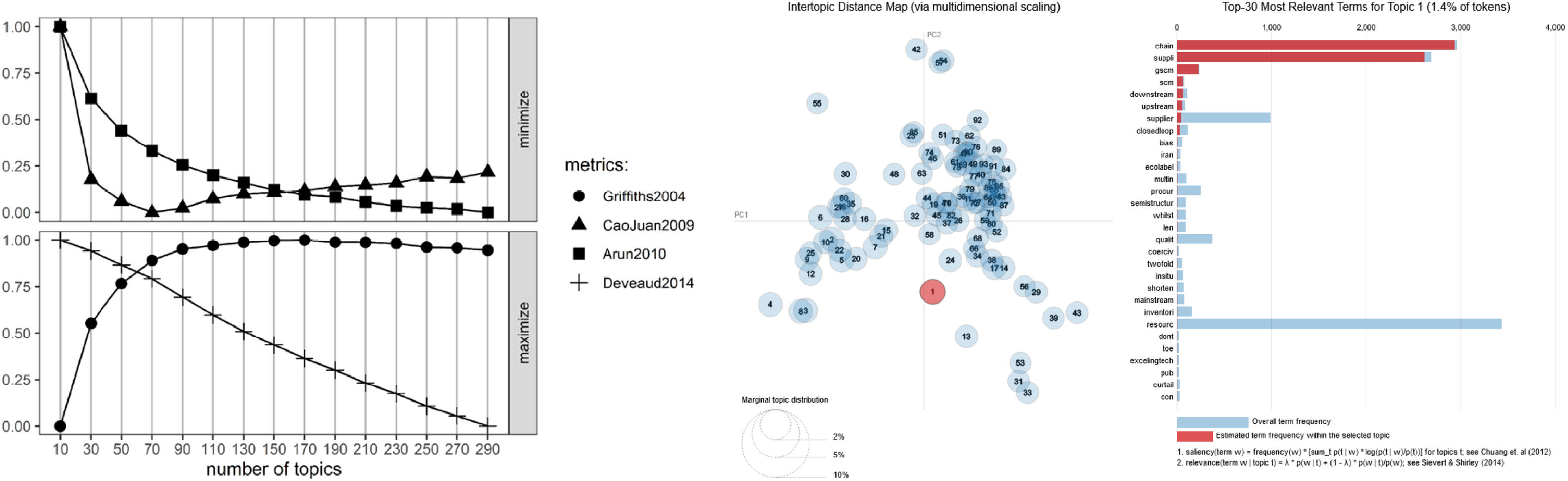

Topic modellingAs previously mentioned, we employed a topic modeling approach utilizing the LDA method to uncover themes within the corpus of abstracts. After preprocessing the text corpus, we proceeded with topic modeling. However, the LDA method assumes that the number of topics k is known before the actual allocation of topics from the corpus. Therefore, we first determined the optimal number of topics for each abstract corpus. We used a statistical approach that considered four statistical metrics: Arun2010 (2010), CaoJuan2009 (2009), Griffiths2004 (2004) and Deveaud2014 (2014). We inverted the CaoJuan2009 and Arun2010 metrics and determined the optimal number of topics as the maximum mean value of these metrics.

The LDA method parameters were quantified using the Gibbs sampling method, with 2000 iterations set for each algorithm run. To enhance the reliability of the results, we selectively included every 200th iteration of the aforementioned runs in the final results. For each tested number of topics (k), we conducted five runs and retained only the best results for each k. To ensure the replicability of our solution, we defined the seed list as {453, 965,132, 35, 761, 19}. Our analysis encompassed a set number of topics (k) ranging from 10 to 300 in multiples of 10. Subsequently, at intervals of 90 to 100, we analyzed each topic number k. The results of this procedure regarding the number of topics and the final intertopic distance map are illustrated in Fig. 1.

The text corpus preprocessing and topic modeling through Latent Dirichlet Allocation were conducted using the programming language R and several R packages. Specifically, we used the “tm” package for corpus preprocessing and “SnowballC” package for stemming. To determine the optimal number of topics, we used the “ldatuning” package and the “topicmodels” package for the topics extraction process using LDA with the selected number of topics.

ResultsThe analysis of research trends related to GI in manufacturing is presented in the following sections. The first part (4.1) of this analysis addresses RQ1 and provides insights into the number of papers and their citations regarding this theme over time. The subsequent section (4.2) explains the latent topics emerging from this analysis, addressing RQ2. The final section (4.3) provides insights into the most significant topics emerging in this field, providing guidance for future researchers and highlighting hot research topics. This addresses RQ3.

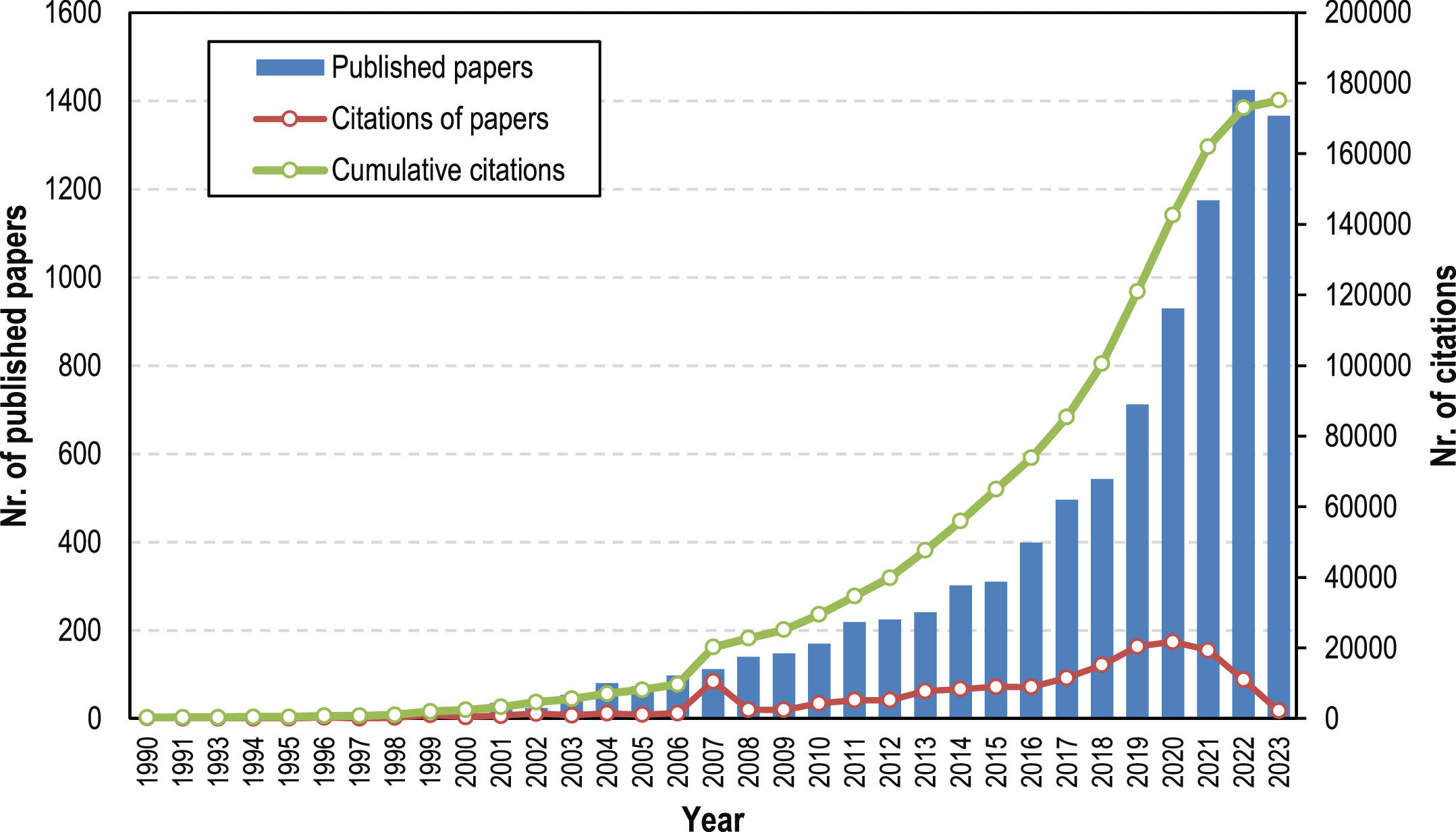

Trends and structure of research related to GI in manufacturingThe manufacturing sector has long been engaged in discussions surrounding green themes, however, the constantly rising focus on climate change has accelerated this trend in recent years. A significant catalyst in this process occurred after the Paris Climate Change Conference in November 2015 (Cuerdo-Mir & Ibar-Alonso, 2023). A review of published papers (representing research interests) related to GI in the manufacturing sector confirms this trend (Fig. 2). Post-2015, there was a visible and remarkable increase in the number of papers published on GI in manufacturing. While there appears to be a slight decline in the number of papers published in 2023 (just under 1400) compared to those published in 2022 (over 1400 papers), the actual numbers will be known once the 2023 period ends. The number of citations, representing the research impact of these published papers, has also been consistently increasing, except for some outlier values, such as in 2007. The trend of citations shows a decline post-2020, which can be attributed to the fact that recently published articles take time to accrue citations. Therefore, we may observe a reversal of this declining trend as more years pass.

The results show that research interest in GI in manufacturing is growing exponentially. According to some studies, similar growth has been recorded in the broader field of sustainability (D'Amato et al., 2017), which, according to the Scopus database, has been the subject of more than one million scientific studies (more than 100,000 in 2023). GI in manufacturing is an aspect of sustainability. Given the growing interest in addressing climate change, the surge in research interest and impact shown in Fig. 2 is understandable.

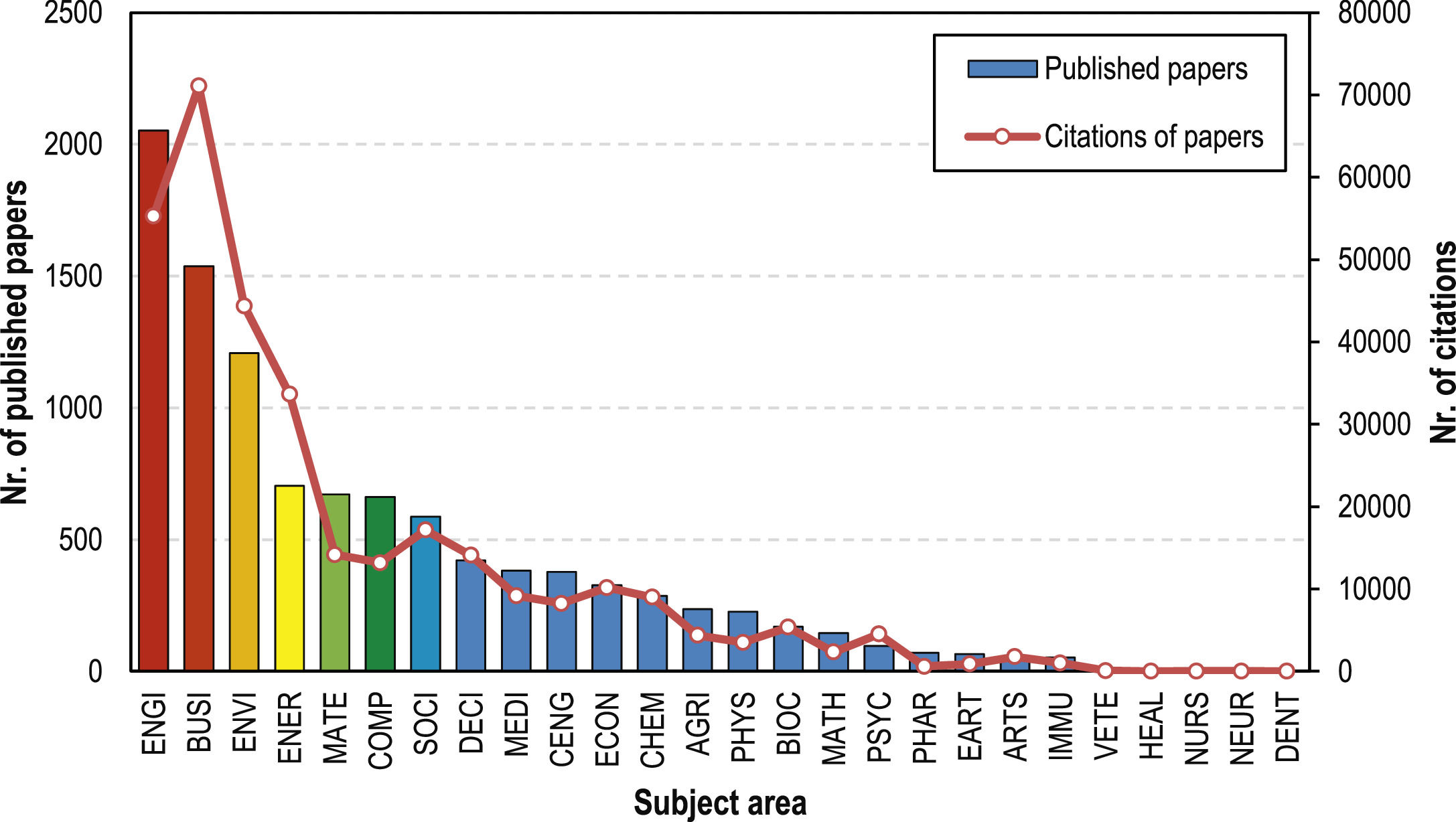

In addition to the overall trend, the papers were analyzed according to their subject areas. The Scopus database contains 28 subject areas, and most sources (journals, conference proceedings, books, etc.) are assigned to one or more subject areas. Thus, the dataset of papers related to GI in manufacturing could be analyzed from this perspective. Fig. 3 shows that the maximum research interest in published papers was in ENGI, BUSI, and ENVI, with over 100 papers published in these subject areas. Interestingly, these segments also boast the highest number of citations, exceeding 40,000, indicating an overwhelming research interest in these domains.

Identified latent topics related to GI in manufacturingThe abstracts of the analyzed documents formed the basis for the application of topic modeling. During the pre-processing phase, stopwords (lists) were defined, which comprised words with generic or irrelevant meanings that could negatively affect the interpretability of the topics. Using metrics to evaluate the clustering process, the optimal number of topics was determined to be 94. Each research paper was assigned to one of these topics, and information regarding its membership was entered into the data matrix. Subsequently, it was possible to conduct a complex analysis of topics related to GI in manufacturing.

A multilevel circular chart is shown in Fig. 4. This chart has several levels, and information about individual topics should be read from the middle to the higher levels. Level A contains the designation of topics T-01 to T-94. Level B contains a blue line chart representing the number of papers in each topic. The number of papers, indicating research interest, ranges from 23 (T-70) to 235 (T-01). Level C shows the average number of citations per paper, representing research impact, for each topic, ranging from 5.04 (T-69) to 129.06 (T-47). Level D contains a list of top-five terms related to a particular topic. This list of five terms provides basic information for evaluating the focus of a topic and has a strong influence on its later naming. Level E contains stacked bar charts representing the number of papers in individual subject areas. For better readability, only the 10 most numerous subject areas are displayed. The inner part of the circle chart shows the relationships between individual topics based on bivariate correlation analysis measured using Pearson's linear correlation coefficient r Only the 20 most intense relationships are shown. Only negligible correlations were identified between the topics, indicating that the topics were sufficiently unique and distinguishable. The strongest ties are shown by blue ribbons (r > 0.200), and the weaker ones are shown by red ribbons (r < 0.200). This figure contains comprehensive information for each of the 94 topics.

To enhance our understanding of the landscape of topics related to GI in manufacturing, we delve into the key insights derived from our analysis. These topics vary not only in content but also in research interest (measured by article count) and impact (measured by citations). We dissected the entire dataset into 94 topics ranging from substantial T-01, T-24, T-11, and T-07 (each containing more than 200 papers) to more compact T-57, T-60, T-55, T-58, and T-70 (with fewer than 40 papers). Surprisingly, the Pareto rule did not fully apply, as the top 20 % of topics encompassed only 35.2 % of all papers. Even smaller topics with significantly lower research interest could not be dismissed as entirely marginal. This trend extended to research impact, where 20 % of the most cited articles accounted for 45.5 % of all citations. A moderate correlation (Pearson's coefficient of r = 0.673) revealed that as research interest grows, so does the research impact. This suggests that topics that attract researchers' attention tend to attract more citations.

When analyzing the composition of individual topics, it was found that despite the fact that the most numerous subject area was ENGI, some large topics consisted of papers falling into another subject area. Looking at the composition of the first 10 most numerous topics, only three are dominated by the ENGI subject area. These included topics T-34 (containing the terms “supplier,” “decis,” “criteria,” “decisionmak,” "fuzzi"), T-15 (containing the terms "vehicle,” "automot,” "electr,” "car,” "automobil"), and T-10 (containing the terms "cement,” "ash,” "replac,” "geopolym,” "durabl"). Other topics were more connected with other subject areas than with ENGI. For example, T-01, covering the area of green supply chain management (containing the terms "chain,” "suppli,” "gscm,” "scm,” "downstream") is most related to BUSI. Two large topics related to performance, T-31 (containing the terms "relationship,” "equat,” "perform,” "model,” "resourcebas") and T-13 (containing the terms "perform,” “equat,” “sustainabilityori,” “variance,” “relationship”), were also related to BUSI. Other large topics such as T-09 (containing the terms "polym,” "fiber,” "fibr,” "biodegrad,” "cellulos") and T-32 (containing the terms "textile,” "fashion,” "cloth,” “apparel,” “dye”) were most related to MATE. Topic T-17 was most closely related to subject area ENVI (containing the terms "polici,” "govern,” "subsidy,” "tax,” "incent"), while T-05 was most closely related to subject area CENG (containing the terms “chemist,” “chemists,” “reaction,” “catalyst,” “solvent”). As evident from the above composition, the concept of GI is relatively fragmented even within the field of manufacturing, highlighting its complexity and partially explaining its dynamic development.

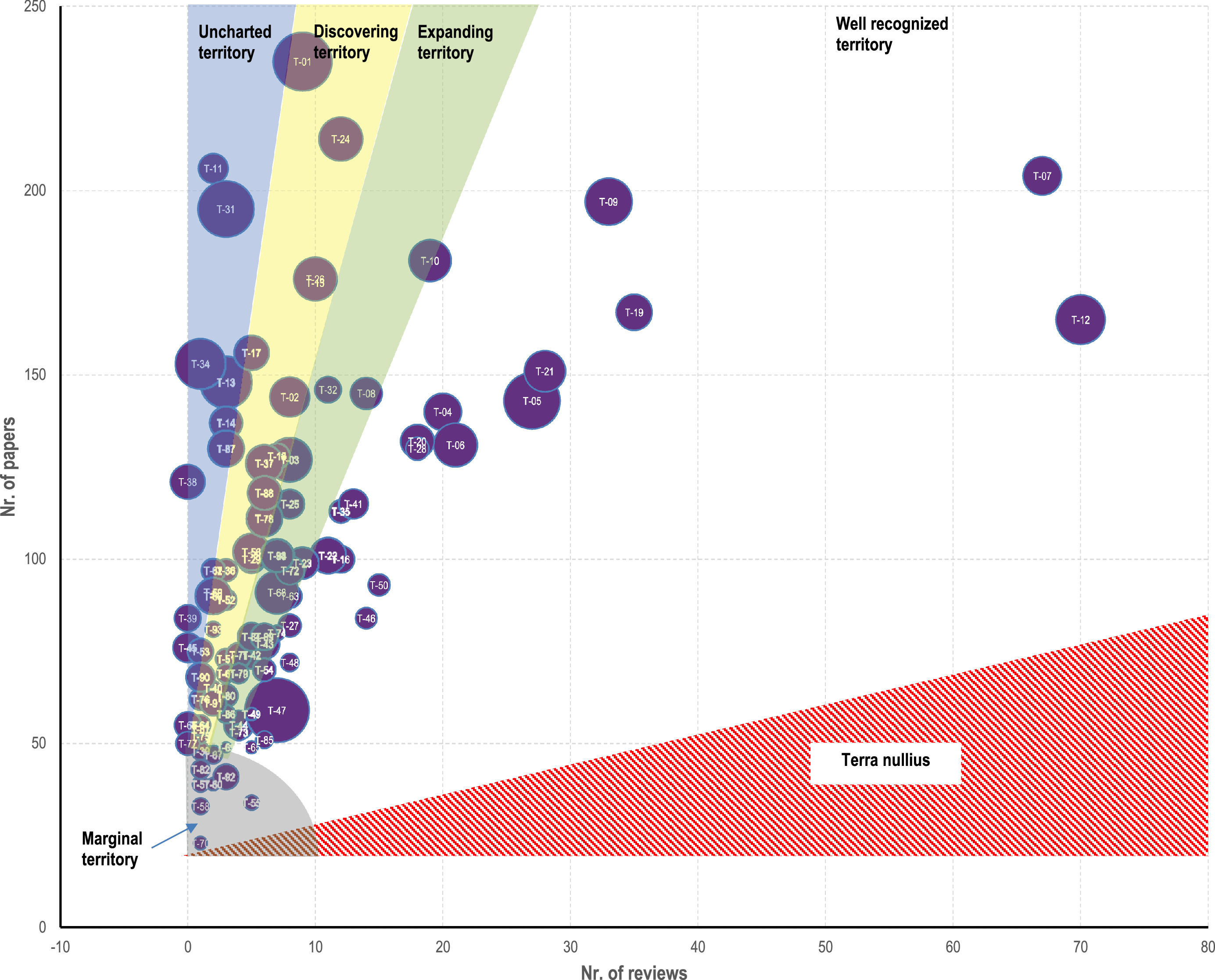

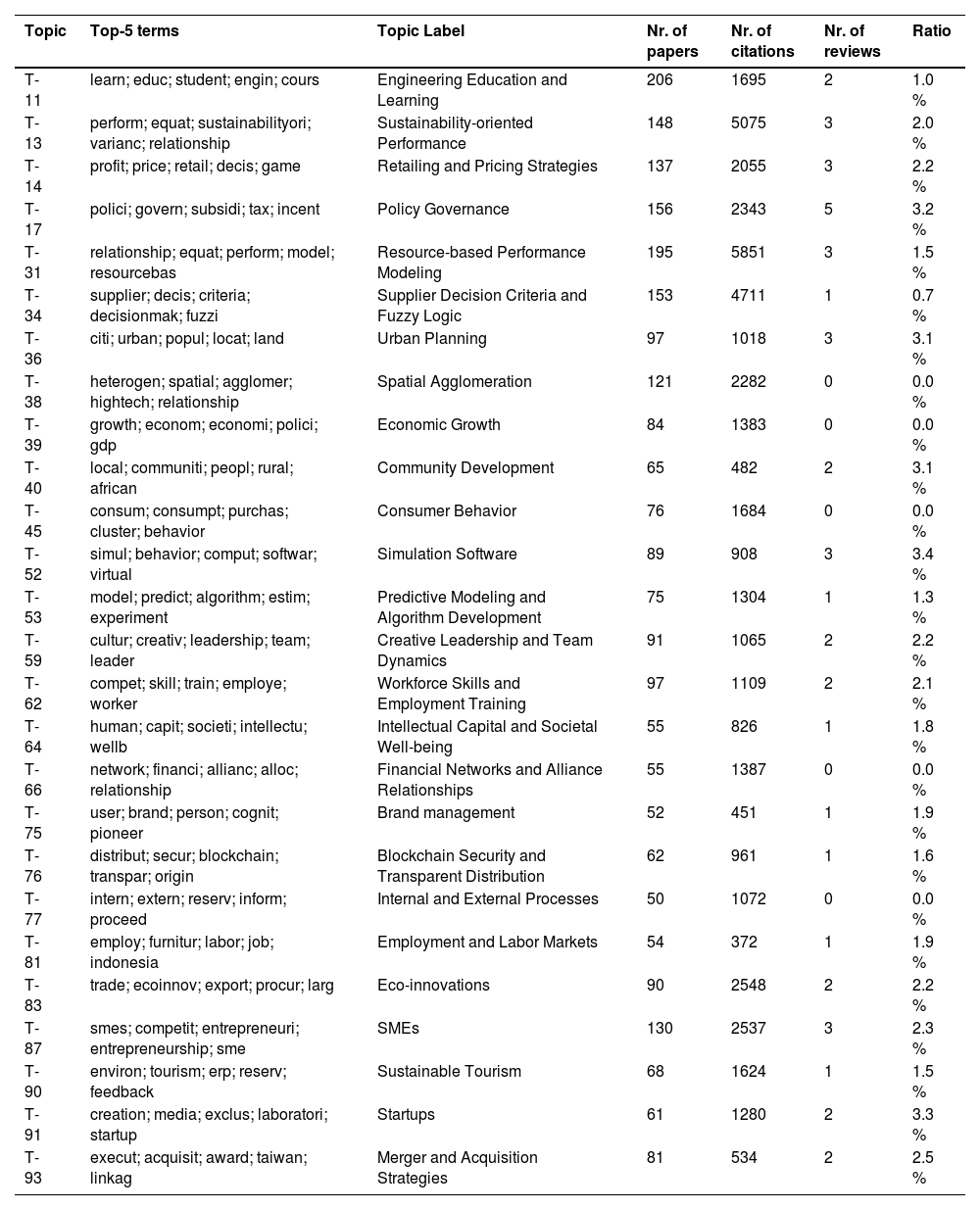

By examining the number and focus of topics, we observed a fragmented landscape of GI in manufacturing. Although some topics enjoy recognition by the scientific community, others identified through LDA may be latent and not yet fully systematized. To verify this, we analyzed the composition of paper types on individual topics, distinguishing between well-established and latent topics. The resulting visualization (Fig. 5) categorizes topics (represented by bubbles of different sizes and based on the number of citations) into different territories. The 'land of nobody' is a red dashed area where no topic can surpass the total number of papers in terms of review papers. The gray marginal territory features topics of limited research interest and a small number of reviews. The uncharted territory in blue contains topics for which review studies constitute less than 3.5 %, revealing the hidden aspects of the GI concept. In the discovering territory (yellow), topics have 3.5 % to 7 % of review papers, indicating partial recognition or gradual acknowledgment. The expanding territory in green includes topics with 7 % to 10.5 % of review papers, signifying known topics receiving adequate attention. Finally, the well-recognized territory comprises topics for which the ratio of review papers to the total exceeds 10.5 %. This analysis underscores the intricate and evolving nature of the GI concept in manufacturing, with undiscovered areas and partially recognized topics that contribute to its dynamism.

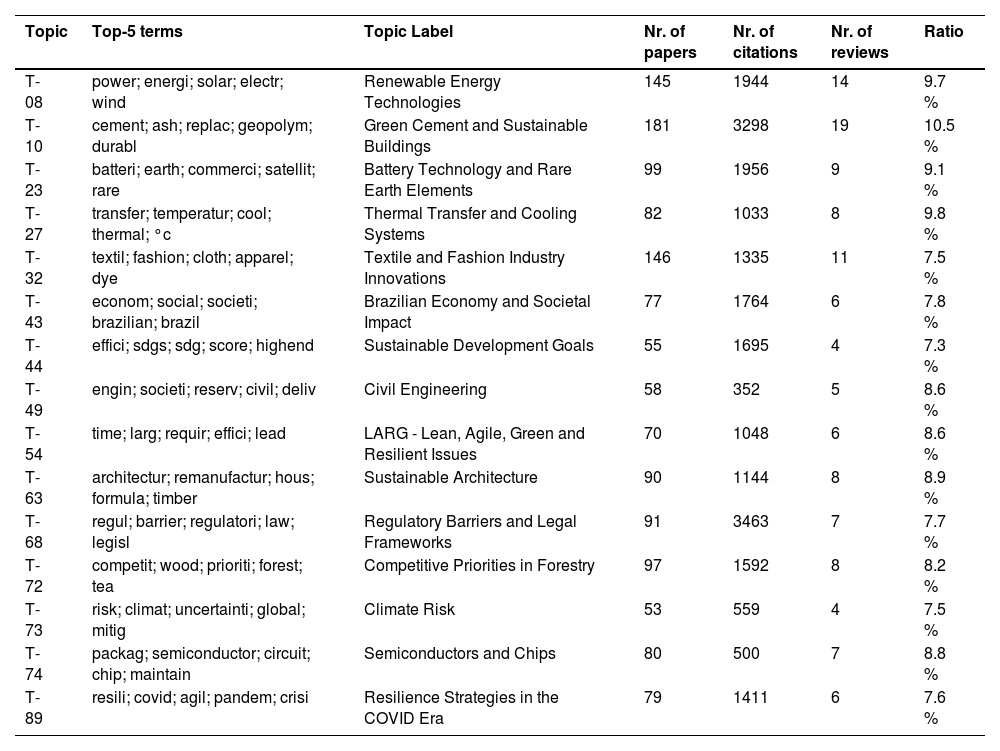

This figure shows that the all papers/review papers ratio is different. There are topics in which review papers make up a significant part of all papers (e.g., T-12 and T-07), but also topics with zero review papers (specifically, T-38, T-39, T-46, T-66, and T-77). There were 770 review papers in the entire dataset, corresponding to a 7.3 % share of all (9376) papers. Therefore, the boundaries between more and less recognized topics were set at 3.5 %, which resulted in the first two territories having below-average all papers/review papers ratio (specifically, uncharted territory and discovering territory) and the other two having an above-average ratio (expanding territory and well-recognized territory). Topics with fewer than 50 papers were classified as marginal. Overall, according to these criteria, uncharted territory included 26 topics, while discovering included 23, expanding included 15, well-recognized included 19, and 11 topics were classified as marginal. Tables 2 to 6 show all the territories and related topics. Each topic was named and contained information on the number of papers, number of citations, number of review papers, and all papers/review papers ratio.

Uncharted territory of GI in manufacturing - topics overview.

| Topic | Top-5 terms | Topic Label | Nr. of papers | Nr. of citations | Nr. of reviews | Ratio |

|---|---|---|---|---|---|---|

| T-11 | learn; educ; student; engin; cours | Engineering Education and Learning | 206 | 1695 | 2 | 1.0 % |

| T-13 | perform; equat; sustainabilityori; varianc; relationship | Sustainability-oriented Performance | 148 | 5075 | 3 | 2.0 % |

| T-14 | profit; price; retail; decis; game | Retailing and Pricing Strategies | 137 | 2055 | 3 | 2.2 % |

| T-17 | polici; govern; subsidi; tax; incent | Policy Governance | 156 | 2343 | 5 | 3.2 % |

| T-31 | relationship; equat; perform; model; resourcebas | Resource-based Performance Modeling | 195 | 5851 | 3 | 1.5 % |

| T-34 | supplier; decis; criteria; decisionmak; fuzzi | Supplier Decision Criteria and Fuzzy Logic | 153 | 4711 | 1 | 0.7 % |

| T-36 | citi; urban; popul; locat; land | Urban Planning | 97 | 1018 | 3 | 3.1 % |

| T-38 | heterogen; spatial; agglomer; hightech; relationship | Spatial Agglomeration | 121 | 2282 | 0 | 0.0 % |

| T-39 | growth; econom; economi; polici; gdp | Economic Growth | 84 | 1383 | 0 | 0.0 % |

| T-40 | local; communiti; peopl; rural; african | Community Development | 65 | 482 | 2 | 3.1 % |

| T-45 | consum; consumpt; purchas; cluster; behavior | Consumer Behavior | 76 | 1684 | 0 | 0.0 % |

| T-52 | simul; behavior; comput; softwar; virtual | Simulation Software | 89 | 908 | 3 | 3.4 % |

| T-53 | model; predict; algorithm; estim; experiment | Predictive Modeling and Algorithm Development | 75 | 1304 | 1 | 1.3 % |

| T-59 | cultur; creativ; leadership; team; leader | Creative Leadership and Team Dynamics | 91 | 1065 | 2 | 2.2 % |

| T-62 | compet; skill; train; employe; worker | Workforce Skills and Employment Training | 97 | 1109 | 2 | 2.1 % |

| T-64 | human; capit; societi; intellectu; wellb | Intellectual Capital and Societal Well-being | 55 | 826 | 1 | 1.8 % |

| T-66 | network; financi; allianc; alloc; relationship | Financial Networks and Alliance Relationships | 55 | 1387 | 0 | 0.0 % |

| T-75 | user; brand; person; cognit; pioneer | Brand management | 52 | 451 | 1 | 1.9 % |

| T-76 | distribut; secur; blockchain; transpar; origin | Blockchain Security and Transparent Distribution | 62 | 961 | 1 | 1.6 % |

| T-77 | intern; extern; reserv; inform; proceed | Internal and External Processes | 50 | 1072 | 0 | 0.0 % |

| T-81 | employ; furnitur; labor; job; indonesia | Employment and Labor Markets | 54 | 372 | 1 | 1.9 % |

| T-83 | trade; ecoinnov; export; procur; larg | Eco-innovations | 90 | 2548 | 2 | 2.2 % |

| T-87 | smes; competit; entrepreneuri; entrepreneurship; sme | SMEs | 130 | 2537 | 3 | 2.3 % |

| T-90 | environ; tourism; erp; reserv; feedback | Sustainable Tourism | 68 | 1624 | 1 | 1.5 % |

| T-91 | creation; media; exclus; laboratori; startup | Startups | 61 | 1280 | 2 | 3.3 % |

| T-93 | execut; acquisit; award; taiwan; linkag | Merger and Acquisition Strategies | 81 | 534 | 2 | 2.5 % |

Table 2 presents several findings. Among the topics with the highest research impact (measured by the number of citations) was Resource-based Performance Modeling (T-31), although there were only three review studies on this topic. Two of them were published in last years. Jia et al.’s (2020) study offers an overview of the CE in the textile and apparel industry, where the authors found four thematic drivers, barriers, practices, and indicators of sustainable performance when applying a CE in the textile and apparel industry. The second study was prepared by a team of authors led by De Guimarães and focused on creating a framework for analysis of the manufacturing industry based on antecedents, mediators, and consequences of sustainable operations (De Guimarães et al., 2020). Apart from these two review studies, which summarize the knowledge of Resource-based Performance Modeling, no other studies have examined this topic more deeply with regard to GI in manufacturing, which represents a significant research gap. A similar research gap can also be identified with the topic of Sustainability-oriented Performance (T-13), which, in addition to its high research impact (5075 citations), also has high research interest (148 published papers). There are also only three review studies on this topic that did not have a high research impact: Daraban et al. (2019) focused on metal additive manufacturing recycling and used tools for sustainability performance; Zhou et al. (2016) investigated multi-dimensional tech-innovation behavior on tech-innovation performance; and Ogiemwonyi et al. (2023) focused on GI behavior, the impact of I4.0, and open innovation. These studies, with the exception of the last one, attempted to systematize GI in a certain aspect of manufacturing, which offers a fragmented but good overview of the topic of sustainability-oriented performance. Of the total number of papers on this topic, however, this is only a fraction, which opens space for a wider systematization of this topic. The third topic that shows wide potential for deeper systematization is Supplier Decision Criteria and Fuzzy Logic (T-34), whose research impact is very high (4711 citations). Some studies have focused on supplier decision criteria (Azadnia, Saman, & Wong, 2015)(Schramm et al., 2020). However, this remains an unexplored area in the field of GI. In addition to these three topics, all the others listed in Table 1 have greater or lesser potential for research that would systematize their position within GI in manufacturing. Topics with a higher rate of mapping within GI in manufacturing also have further research potential. Regarding the all papers/review papers ratio, they can be classified as discovering territory (Table 3).

Discovering territory of GI in manufacturing - topics overview.

| Topic | Top-5 terms | Topic Label | Nr. of papers | Nr. of citations | Nr. of reviews | Ratio |

|---|---|---|---|---|---|---|

| T-01 | chain; suppli; gscm; scm; downstream | Green Supply Chain | 235 | 6380 | 9 | 3.8 % |

| T-02 | carbon; emiss; reduct; lowcarbon; reduc | Carbon Emission Reduction | 144 | 2997 | 8 | 5.6 % |

| T-03 | energi; consumpt; renew; effici; conserv | Energy Consuption | 127 | 3733 | 8 | 6.3 % |

| T-15 | vehicl; automot; electr; car; automobil | Electric Vehicles and Automotive Technology | 175 | 2231 | 10 | 5.7 % |

| T-18 | steel; lightweight; experiment; resist; fatigu | Lightweight Steel and Structural Experimentation | 128 | 1232 | 7 | 5.5 % |

| T-24 | digit; transform; twin; digitalis; revolut | Digital Transformation | 214 | 3617 | 12 | 5.6 % |

| T-25 | brick; thermal; absorpt; insul; agent | Thermal Insulation | 115 | 1675 | 8 | 7.0 % |

| T-26 | smart; internet; revolut; iot; fourth | Smart Technologies and Industry 4.0 | 176 | 3557 | 10 | 5.7 % |

| T-29 | economi; econom; russian; russia; socioeconom | Socioeconomic Analysis | 100 | 1540 | 5 | 5.0 % |

| T-33 | model; converg; multidimension; uncertain; decisionmak | Multidimensional Models in Decision Making | 101 | 2187 | 7 | 6.9 % |

| T-37 | assess; cycl; lca; iso; lifecycl | Life Cycle Assessment | 126 | 2660 | 6 | 4.8 % |

| T-42 | requir; assembl; prototyp; hybrid; larg | Assembly | 74 | 1479 | 5 | 6.8 % |

| T-51 | equip; origin; mainten; reliabl; requir | Equipment Reliability and Maintenance | 73 | 864 | 3 | 4.1 % |

| T-56 | social; corpor; ethic; esg; reput | Corporate Social Responsibility | 102 | 2604 | 5 | 4.9 % |

| T-61 | transport; infrastructur; diffus; nich; regim | Transportation Infrastructure | 69 | 719 | 3 | 4.3 % |

| T-71 | invest; asset; portfolio; expenditur; longterm | Asset Portfolio Management | 74 | 1244 | 4 | 5.4 % |

| T-78 | servic; pss; servit; productservic; lifecycl | Product/Service Lifecycle Management | 111 | 2469 | 6 | 5.4 % |

| T-79 | qualiti; maintain; defin; satisfact; tqm | Total Quality Management | 69 | 802 | 4 | 5.8 % |

| T-80 | collabor; ecosystem; disrupt; cocreat; foster | Ecosystem Collaboration | 63 | 1097 | 3 | 4.8 % |

| T-84 | strateg; matur; radic; strategi; asia | Strategic Innovation and Asia's Growth Patterns | 79 | 1526 | 5 | 6.3 % |

| T-86 | plan; patent; longterm; reserv; famili | Long-term Planning | 58 | 687 | 3 | 5.2 % |

| T-88 | lean; analyt; big; perform; sigma | Lean Six Sigma and Big Data Analytics | 118 | 2181 | 6 | 5.1 % |

| T-94 | stakehold; logist; csr; revers; proactiv | Stakeholder Engagement and Proactive CSR | 101 | 2034 | 7 | 6.9 % |

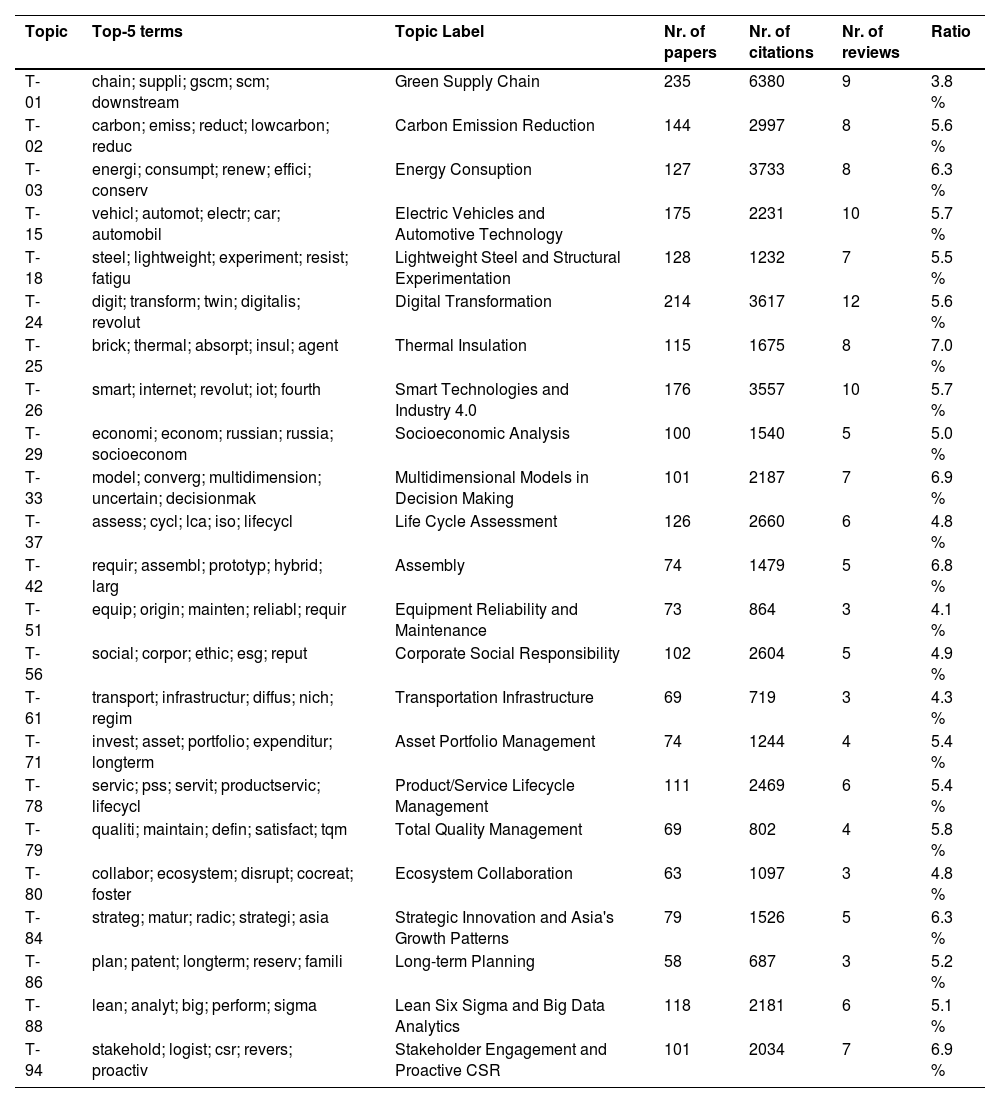

Discovering territory related to GI in manufacturing included 23 topics. Among these, the Green Supply Chain (T-01) stood out. This topic is among the largest in the entire dataset, while its research interest is the largest in the entire dataset (235 papers), and its research impact is the second largest (6380 citations). According to the current data in the Scopus database, more than 9000 studies have been published on the topic of green supply chains, while 438 (4.8 %) are review studies. However, if we look at the green supply chain from the perspective of GI in manufacturing, there are slightly fewer studies (235 papers), while reviews make up 3.8 % (nine papers). However, research in the field of green supply chains related to GI in manufacturing has only gained momentum over the last two or three years. Of the nine papers reviewed, seven have been published since 2021. It can be concluded from this that the areas of green supply chains, GI, and manufacturing will attract the attention of more researchers, and efforts to link these areas will grow. Based on the data in Table 1, the strongest dynamic increase in research can also be assumed for the topics of Digital Transformation (T-24), Smart Technologies and Industry 4.0 (T-26), and Electric Vehicles and Automotive Technology (T-15). Topics with a higher all papers/review papers ratio, which can be included in the expanding territory (Table 4), show a higher degree of systematization than the aforementioned topics.

Expanding territory of GI in manufacturing - topics overview.

| Topic | Top-5 terms | Topic Label | Nr. of papers | Nr. of citations | Nr. of reviews | Ratio |

|---|---|---|---|---|---|---|

| T-08 | power; energi; solar; electr; wind | Renewable Energy Technologies | 145 | 1944 | 14 | 9.7 % |

| T-10 | cement; ash; replac; geopolym; durabl | Green Cement and Sustainable Buildings | 181 | 3298 | 19 | 10.5 % |

| T-23 | batteri; earth; commerci; satellit; rare | Battery Technology and Rare Earth Elements | 99 | 1956 | 9 | 9.1 % |

| T-27 | transfer; temperatur; cool; thermal; °c | Thermal Transfer and Cooling Systems | 82 | 1033 | 8 | 9.8 % |

| T-32 | textil; fashion; cloth; apparel; dye | Textile and Fashion Industry Innovations | 146 | 1335 | 11 | 7.5 % |

| T-43 | econom; social; societi; brazilian; brazil | Brazilian Economy and Societal Impact | 77 | 1764 | 6 | 7.8 % |

| T-44 | effici; sdgs; sdg; score; highend | Sustainable Development Goals | 55 | 1695 | 4 | 7.3 % |

| T-49 | engin; societi; reserv; civil; deliv | Civil Engineering | 58 | 352 | 5 | 8.6 % |

| T-54 | time; larg; requir; effici; lead | LARG - Lean, Agile, Green and Resilient Issues | 70 | 1048 | 6 | 8.6 % |

| T-63 | architectur; remanufactur; hous; formula; timber | Sustainable Architecture | 90 | 1144 | 8 | 8.9 % |

| T-68 | regul; barrier; regulatori; law; legisl | Regulatory Barriers and Legal Frameworks | 91 | 3463 | 7 | 7.7 % |

| T-72 | competit; wood; prioriti; forest; tea | Competitive Priorities in Forestry | 97 | 1592 | 8 | 8.2 % |

| T-73 | risk; climat; uncertainti; global; mitig | Climate Risk | 53 | 559 | 4 | 7.5 % |

| T-74 | packag; semiconductor; circuit; chip; maintain | Semiconductors and Chips | 80 | 500 | 7 | 8.8 % |

| T-89 | resili; covid; agil; pandem; crisi | Resilience Strategies in the COVID Era | 79 | 1411 | 6 | 7.6 % |

In the area of GI in manufacturing, there are topics with a relatively good level of recognition; however, as Table 3 shows, these are primarily medium-sized. The rate of systematization was higher than that of uncharted and discovering territories, as the ratio between all papers and review papers was higher. The topics are a mix of conceptual and technical perspectives on GI in the manufacturing industry. Other conceptual topics include Renewable Energy Technologies (T-08), Sustainable Development Goals (T-44), Civil Engineering (T-49), and Climate Risk (T-73). Technical topics focused on specific technologies, areas, or technical aspects of GI included Green Cement and Sustainable Buildings (T-10), Battery Technology and Rare Earth Elements (T-23), Thermal Transfer and Cooling Systems (T-27), and Sustainable Architecture (T-63). Among these topics, Renewable Energy Technologies and Green Cement and Sustainable Buildings show the most dynamic growth. With these two topics, it can be assumed that they will gradually become well-recognized.

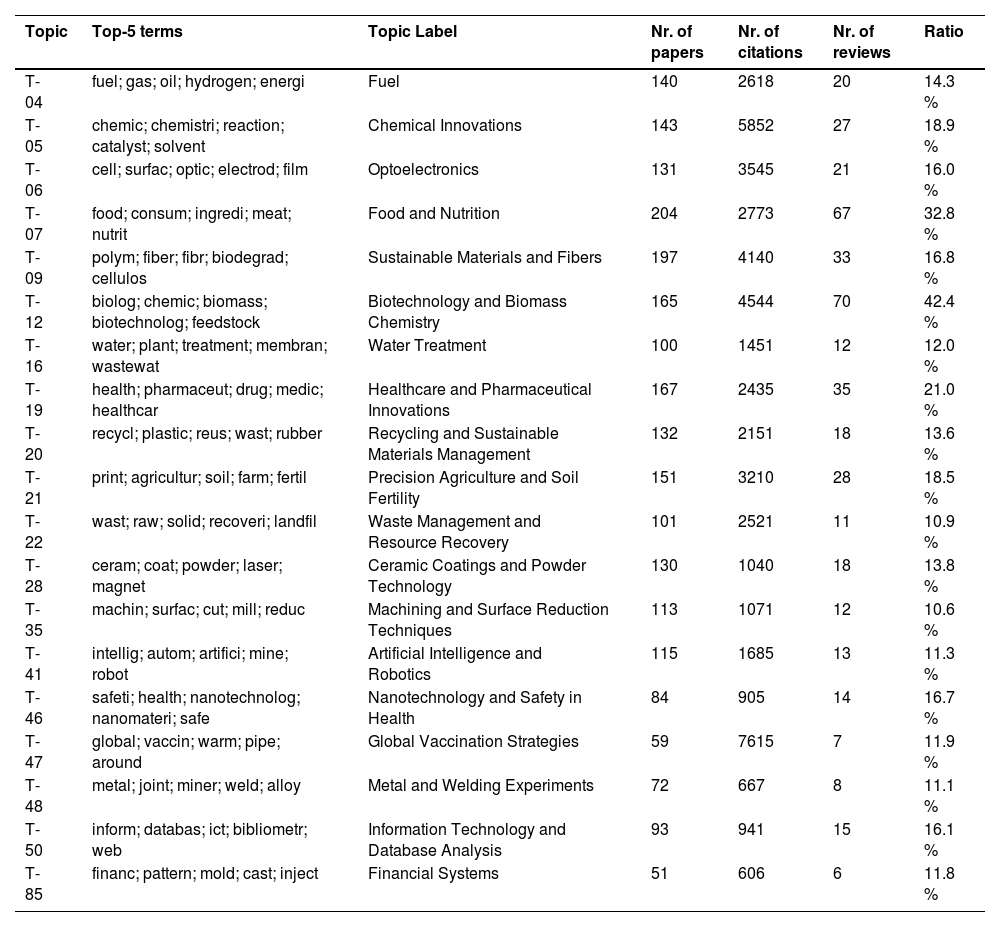

The field of GI in manufacturing includes several topics that belong to established research streams. In our analysis, we identified 19 such topics, the characteristics of which are presented in Table 5. The ratio between the number of papers and number of reviews on these topics was very high. Table 5 shows that these are relatively important topics with regard to their research interest (number of papers), and impact (number of citations). The highest research interest was recorded for Global Vaccination Strategies (T-47). This result can be explained by the dramatic social, economic, and technological impacts and changes caused by the pandemic, which are directly related to the topic. Well-recognized topics directly related to GI and manufacturing include dominant topics such as Food and Nutrition (T-07), Sustainable Materials and Fibers (T-09), Healthcare and Pharmaceutical Innovation (T −19), and Biotechnology and Biomass Chemistry (T-12).

Well-recognized territory of GI in manufacturing - topics overview.

| Topic | Top-5 terms | Topic Label | Nr. of papers | Nr. of citations | Nr. of reviews | Ratio |

|---|---|---|---|---|---|---|

| T-04 | fuel; gas; oil; hydrogen; energi | Fuel | 140 | 2618 | 20 | 14.3 % |

| T-05 | chemic; chemistri; reaction; catalyst; solvent | Chemical Innovations | 143 | 5852 | 27 | 18.9 % |

| T-06 | cell; surfac; optic; electrod; film | Optoelectronics | 131 | 3545 | 21 | 16.0 % |

| T-07 | food; consum; ingredi; meat; nutrit | Food and Nutrition | 204 | 2773 | 67 | 32.8 % |

| T-09 | polym; fiber; fibr; biodegrad; cellulos | Sustainable Materials and Fibers | 197 | 4140 | 33 | 16.8 % |

| T-12 | biolog; chemic; biomass; biotechnolog; feedstock | Biotechnology and Biomass Chemistry | 165 | 4544 | 70 | 42.4 % |

| T-16 | water; plant; treatment; membran; wastewat | Water Treatment | 100 | 1451 | 12 | 12.0 % |

| T-19 | health; pharmaceut; drug; medic; healthcar | Healthcare and Pharmaceutical Innovations | 167 | 2435 | 35 | 21.0 % |

| T-20 | recycl; plastic; reus; wast; rubber | Recycling and Sustainable Materials Management | 132 | 2151 | 18 | 13.6 % |

| T-21 | print; agricultur; soil; farm; fertil | Precision Agriculture and Soil Fertility | 151 | 3210 | 28 | 18.5 % |

| T-22 | wast; raw; solid; recoveri; landfil | Waste Management and Resource Recovery | 101 | 2521 | 11 | 10.9 % |

| T-28 | ceram; coat; powder; laser; magnet | Ceramic Coatings and Powder Technology | 130 | 1040 | 18 | 13.8 % |

| T-35 | machin; surfac; cut; mill; reduc | Machining and Surface Reduction Techniques | 113 | 1071 | 12 | 10.6 % |

| T-41 | intellig; autom; artifici; mine; robot | Artificial Intelligence and Robotics | 115 | 1685 | 13 | 11.3 % |

| T-46 | safeti; health; nanotechnolog; nanomateri; safe | Nanotechnology and Safety in Health | 84 | 905 | 14 | 16.7 % |

| T-47 | global; vaccin; warm; pipe; around | Global Vaccination Strategies | 59 | 7615 | 7 | 11.9 % |

| T-48 | metal; joint; miner; weld; alloy | Metal and Welding Experiments | 72 | 667 | 8 | 11.1 % |

| T-50 | inform; databas; ict; bibliometr; web | Information Technology and Database Analysis | 93 | 941 | 15 | 16.1 % |

| T-85 | financ; pattern; mold; cast; inject | Financial Systems | 51 | 606 | 6 | 11.8 % |

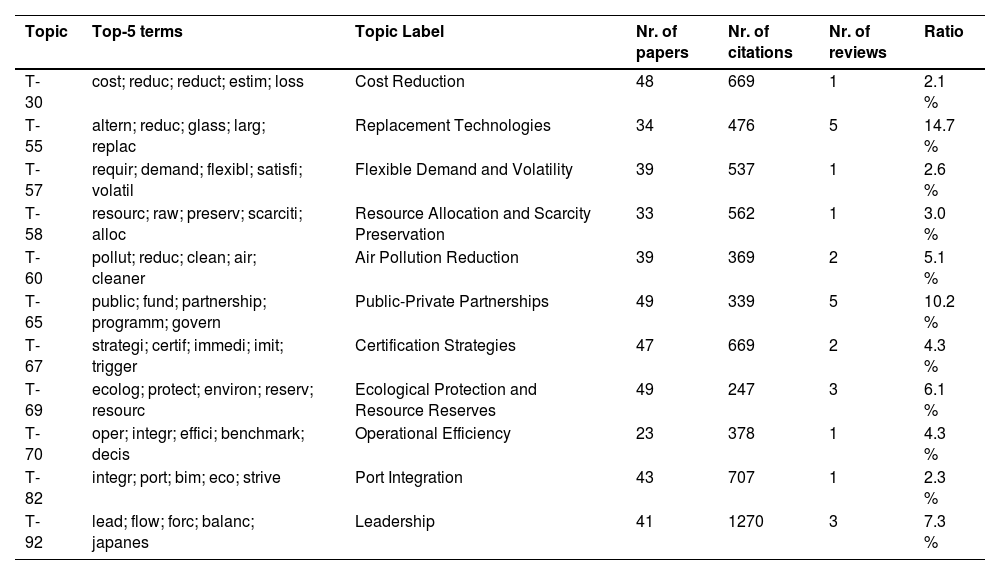

The last group of topics includes those areas that are marginal from the perspective of research interest. Table 6 provides an overview of these topics, although we noticed some relatively marginal topics with relatively low research interest. The analysis of trends shows that approximately three studies per year increase for each topic; therefore, we do not expect any of the mentioned topics to gain any significant momentum in the near future.

Marginal territory of GI in manufacturing - topics overview.

| Topic | Top-5 terms | Topic Label | Nr. of papers | Nr. of citations | Nr. of reviews | Ratio |

|---|---|---|---|---|---|---|

| T-30 | cost; reduc; reduct; estim; loss | Cost Reduction | 48 | 669 | 1 | 2.1 % |

| T-55 | altern; reduc; glass; larg; replac | Replacement Technologies | 34 | 476 | 5 | 14.7 % |

| T-57 | requir; demand; flexibl; satisfi; volatil | Flexible Demand and Volatility | 39 | 537 | 1 | 2.6 % |

| T-58 | resourc; raw; preserv; scarciti; alloc | Resource Allocation and Scarcity Preservation | 33 | 562 | 1 | 3.0 % |

| T-60 | pollut; reduc; clean; air; cleaner | Air Pollution Reduction | 39 | 369 | 2 | 5.1 % |

| T-65 | public; fund; partnership; programm; govern | Public-Private Partnerships | 49 | 339 | 5 | 10.2 % |

| T-67 | strategi; certif; immedi; imit; trigger | Certification Strategies | 47 | 669 | 2 | 4.3 % |

| T-69 | ecolog; protect; environ; reserv; resourc | Ecological Protection and Resource Reserves | 49 | 247 | 3 | 6.1 % |

| T-70 | oper; integr; effici; benchmark; decis | Operational Efficiency | 23 | 378 | 1 | 4.3 % |

| T-82 | integr; port; bim; eco; strive | Port Integration | 43 | 707 | 1 | 2.3 % |

| T-92 | lead; flow; forc; balanc; japanes | Leadership | 41 | 1270 | 3 | 7.3 % |

The analysis of the five territories in this section aimed to map the position, level of systematization, and dynamics of topics related to GI and manufacturing. However, we can abstract this detailed information to identify the most significant topics related to GI in manufacturing. These topics are identified in Section ``The most significant topics and their evolution over time''.

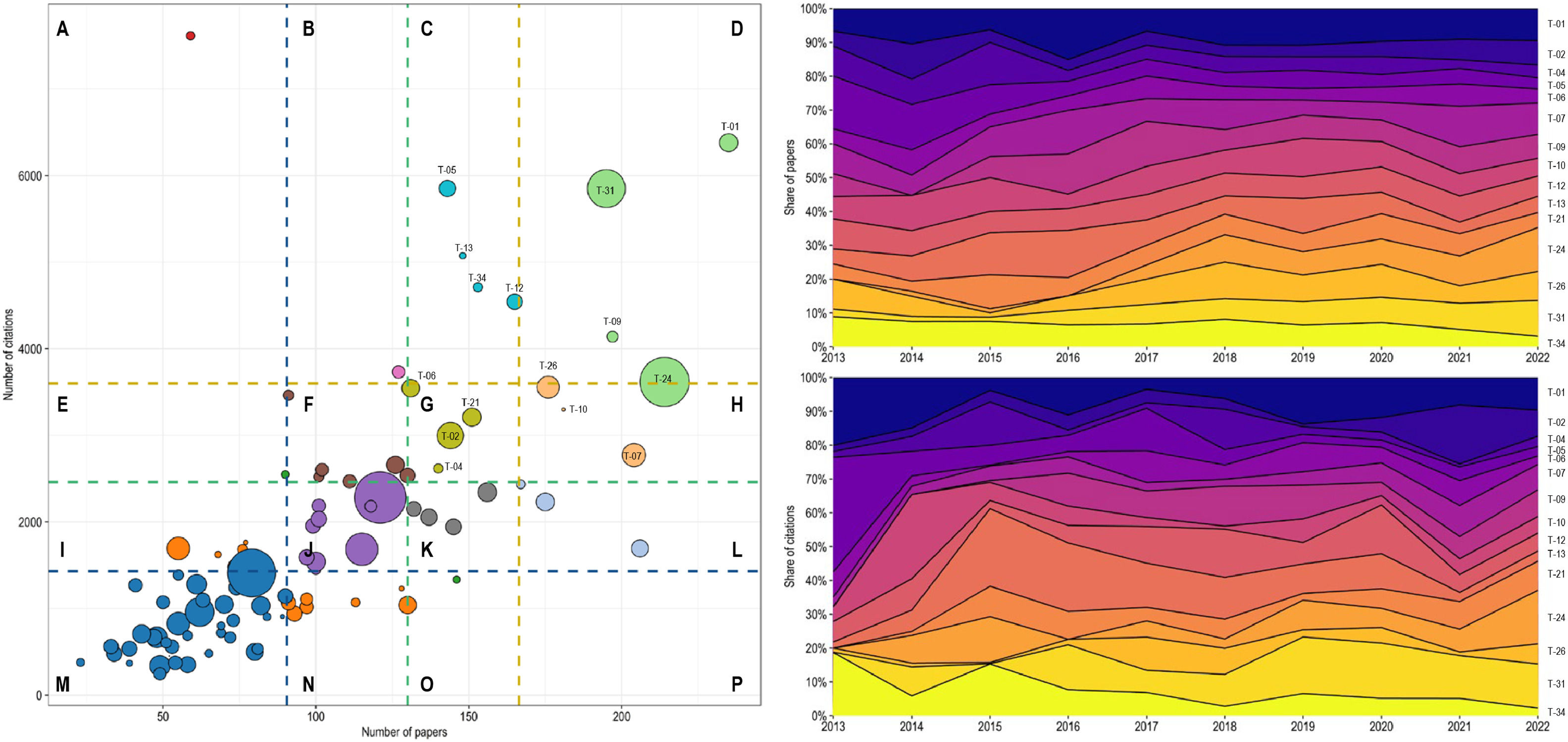

The most significant topics and their evolution over timeAfter identifying both well-known and less-known topics related to GI in manufacturing, it is appropriate to identify the topics that are most significant in the long-term. Three characteristics were considered for this purpose: the number of papers; number of citations, and growth in the number of papers (in the last four years). The results of the comparison of these three characteristics are shown in Fig. 6, with each bubble representing one topic and its size indicating the increase in publications over the last four years. The left side of the figure is divided into sections according to the median (blue dashed line), third quartile (green dashed line), and ninth decile (yellow dashed line). The most significant topics, located in sections C, D, G, and H, will be discussed in the following paragraphs.

The development dynamics differ among individual research topics related to GI in manufacturing. Some topics have seen a dramatic increase in interest in the last four years, while the growth of some has been stable for a long time, and interest in some topics is decreasing. Therefore, these three categories are gradually introduced in more detail.

Descending topics. These topics have received relatively little attention over the last four years (measured by the number of published papers). For example, Sustainable Materials and Fibers (T-09) was previously a strong area in GI and manufacturing, but its position is currently weakening. Similarly, Fuel (T-04) shows a decreasing trend in research interest and impact. However, both topics are relatively well-systematized within GI and manufacturing, as they belong to the category of well-recognized topics. Declining topics include Supplier Decision Criteria and Fuzzy Logic (T-34), and Sustainability-oriented Performance (T-13). These topics belong to an uncharted territory; however, their long-term trends are decreasing. Although they significant in terms of research impact and interest, this negative trend may indicate that their potential for systematization in GI in manufacturing will remain unexplored. Another topic with a negative long-term trend is Green Cement and Sustainable Buildings (T-10). Long-term attention has been paid to this topic since 2008, and it has also been well systematized in terms of GI and manufacturing (belonging to the discovering territory).

Steadily growing topics. Interest in the topics in this category is standard. The topics belonging to this category are relatively well systematized and mapped as far as GI in manufacturing is concerned. The largest part of the steadily growing topics belongs to a well-recognized territory. These include Food and Nutrition (T-07), Precision Agriculture and Soil Fertility (T-21), Optoelectronics (T-06), Chemical Innovations (T-05), and Biotechnology and Biomass Chemistry (T-12). The other two belong to the discovering territory: Smart Technologies and Industry 4.0 (T-26) and Green Supply Chain (T-01). The growth trends in these topics indicate that they will receive adequate attention in the future and will continue to form dominant research areas in the coming years.

Dynamically growing topics. These are rapidly growing topics with a high number of research papers, particularly in the last four years. Digital Transformation (T-24) is the most dynamically growing research topic. The number of research papers has increased four-fold in the last four years, and the most research papers (70) were published on this topic in 2023. This topic belongs to the discovering territory; otherwise, its mapping and systematization in the GI and manufacturing domain is relatively good. We assume that this topic gained momentum primarily under the influence of the pandemic, which acted as a catalyst for the growing interest in topics related to digitization. Another topic of dynamic growth is Resource-based Performance Modeling (T-31), which has seen an approximately 2.5-fold increase in the number of papers published over the last four years. The research impact on this topic is among the highest among all topics. At the same time, this topic is uncharted because there are only three review studies out of 195 research papers. Resource-based Performance Modeling, together with GI and manufacturing, thus represents the highest potential for systematization among all topics (e.g., through the processing of a systematic literature review). The third topic with dynamic growth is Carbon Emission Reduction (T-02). Although the growth dynamics for this topic are not as intense as those for the previous two (a 1.2-fold increase in the number of papers over the last four years), they are still relatively high. This topic belongs to the discovering territory; therefore, its potential for systematization within GI in manufacturing may not yet be fully utilized.

Discussion and conclusionThe results presented in the previous section identified topics that belong to so-far uncharted and discovering territories. These are topics with relatively low systematization because only a fraction of them are review studies compared to the total number of papers. The results show that the uncharted category has 26 topics and discovering has another 23. Topic systematization is possible through the application of an SLR to specific topics, as such a review could better place them in the context of GI and manufacturing. Resource-based Performance Modeling has the greatest potential for systematization, with only two current review studies (Jia et al., 2020; De Guimarães et al., 2020). A related topic with a high potential for systematization is Sustainability-oriented Performance, which has only one current review study (Ogiemwonyi et al., 2023) and thus can be well mapped through an SLR. Another topic with good potential for systematization is Supplier Decision Criteria and Fuzzy Logic, which has only one review study focused on environmental footprint, social impacts, and transparency (Gonçalves & Silva, 2021).

Research on dynamic topics, including GI in manufacturing, is currently so intensive that attempts to systematize the topic manually have become unfeasible. The reason is the very high number of research papers, making manual analysis ineffective (Asmussen & Møller, 2019). Researchers striving for systematization often focus on smaller subtopics where they see growing potential. Although this results in a deeper understanding of smaller topics, it contributes to the increasing fragmentation of the main topic. Our approach comprehensively analyzed GI in manufacturing using LDA, which falls under the field of unsupervised machine learning. The potential for a broad and deep exploration of topics is demonstrated in the results section of this paper. LDA was used for the first time to extract latent topics in the field of GI in manufacturing. Among the more than 9000 documents analyzed, only three studies used LDA. Bongini et al. (2022) focused on topic modeling analysis of white papers in security token offerings, identifying nine topics using LDA. Mendes et al. (2022) analyzed the dimensions of digital transformation in modern agricultural (MA), identifying eight topics (dimensions) using LDA. Sun and Ju used LDA to analyze the promotion of energy vehicles from consumer and manufacturer perspectives, revealing seven latent topics (Sun & Ju, 2022). Each study focused on a certain domain related to GI and manufacturing; thus, it is an analysis of subtopics. Our study is complex and presents the analytical potential of LDA in smart literature reviews. This approach is becoming popular, as demonstrated by some of the current review studies focusing on various topics such as the supply chain (Madzík et al., 2023), machine learning in business (Pramanik and Jana, 2022) , sustainable development goals (Reyes-Menendez et al., 2023), and human resource management in the age of I4.0 (Ammirato et al., 2023), among others.

Eliminating the negative impacts of society on the environment is gaining increasing importance for addressing climate challenges. Research into sustainability and GI has gained momentum in the manufacturing industry. However, since it is a multidisciplinary domain, it is becoming increasingly fragmented, and its systematization is essential for its future direction.

This study reveals several top-trending topics that have intensively gained importance over the last four years. The fastest-growing topic is Digital Transformation, which was catalyzed by the pandemic, and topics related to digitization are among the most widespread in the field of GI and manufacturing. In the future, we can expect the emergence of new subtopics related to digitalization or stronger research on a wide range of topics. These include digital GI (Yin et al., 2022), Society 5.0 (Carayannis & Morawska-Jancelewicz, 2022), the roles of sustainable business development practices and information management (Huang et al., 2022), digital finance (Chang et al., 2023), and developing CE business models (Neligan et al., 2023), among others. This study provides a comprehensive scientific map of GI in manufacturing. Through LDA, 94 unique topics were identified, some of which had not yet been placed in the context of GI in manufacturing. The results presented in this study aim to offer a platform for a wider scientific discussion on past, present, and future manufacturing trends toward sustainability challenges.

Implications, limitations, and future directionsTheoretical and practical implicationsThe results presented in the previous section contribute to theory development in three main areas: i) demonstrating the use of AI tools for mapping a certain domain (in our case, GI in manufacturing); ii) identifying uncharted and discovering territories that have a high potential for systematization; and iii) identifying research trends. New findings in comparison with previous research were provided in the previous section. Additionally, some existing theories on GI in manufacturing are relevant. For instance, according to the ecological modernization theory, environmental innovations lay the foundation for development in any economy or business sector (Chen & Jin, 2023). Modernization theory also suggests that industrialization is integral to modernization and development (Yadav et al., 2024). Therefore, by accelerating GI in different manufacturing domains, developing countries can propel their development agendas, while developed countries can maintain their competitive edge. Similarly, resource-based theory asserts that introducing green practices in the supply chain fosters sustainability, enhances the performance of supply chain entities, and increases chain efficiency (Zaholi et al., 2023). Our research echoes this assertion, as Resource-based Performance Modeling (T-31) emerged as a dynamically growing topic. Similarly, Green Supply Chain Management (T-01) is also a steadily growing topic. However, the risks associated with GI cannot be ignored. Although this study shows that this research area is progressing exponentially, it must consider related risks, as noted by Sun et al. (2020) in GI research based on grounded theory. They identified several risks related to GI, including valuable resources remaining unutilized, innovation instability, low return on investment, limited staff involvement in GI, feelings of exclusion, and lack of recognition of innovations.

This study has several practical implications for researchers, policymakers, practicing managers, and standardization agencies, as outlined below.

- (i)

For academics / researchers / scientists:

As evident from the territories analysis (Section ``Identified latent topics related to GI in manufacturing''), some areas in the “uncharted territories” include Engineering Education and Learning, as well as Workforce Skills and Employment Training. This demonstrates the potential for researchers and academics to plan courses and training in GI. On the other hand, researchers can find significant support for their forthcoming research from prior literature, as well as its review in fields related to Fuel, Food and Nutrition, Sustainable Materials and Fibers, Water Treatment, Artificial Intelligence and Robotics, and Recycling and Sustainable Materials Management, among others, as these fields are in the “well-recognized” territory. Themes such as Cost Reduction and Replacement Technologies can always attract the attention of industries and are in the “marginal category,” showing significant scope for further research based on available literature. Some interdisciplinary research can be conducted by linking GI in manufacturing with other areas of management, such as Total Quality Management, Green Supply Chain, and Product/Service Lifecycle Management, as these themes are in the discovering territory.

- (ii)

For policy makers:

The implications of this study will help policymakers decide which sectors lead and lag behind climate change and GI initiatives. Research related to fuels, chemical innovations, food sector, water treatment, biotechnology, recycling, waste management, agriculture, cement, and ceramics is already leading GI in manufacturing. Governments can recognize, award, and benchmark these sectors and incentivize other sectors to develop new GI.

Policy formation in specific areas can be identified through this study's findings. For instance, Table 6 shows that the Public-Private Partnership for GI is in a marginal territory; this shows the need for further research in this area to bring it to a well-recognized or expanding territory. Product manufacturing and manufacturing processes are system-level activities that result in greater carbon generation, pollution, and environmental damage (Panagiotopoulou et al., 2022). Panagiotopoulou et al. (2021) stressed that transportation and energy use are the most significant contributors to pollution (Panagiotopoulou et al., 2022). Table 6 shows Port Integration as a GI topic in a marginal territory. If policies are aimed in this direction, substantial carbon footprints can be reduced.

Similarly, policies can be framed based on Ecological Protection and Resource Reserves. This topic also falls within the marginal research territory. Urban Planning is an uncharted territory. Although many governments are currently working on smart city concepts, they must be linked to manufacturing activities, such as end-of-life product management, to align manufacturing with smart cities. While making policies, it is crucial to ensure that we are not robbing Peter to pay Paul; that is, reducing carbon footprints and pollution from one sector at the expense of another. By introducing measures such as drone supplies, port integration, flying taxis, and electric vehicles, we might reduce emissions from one sector, such as food and retail, but we may increase the liability of other sectors, such as technology equipment and battery manufacturing. Policy Governance is in the uncharted territory of GI-related research and can prove extremely beneficial if due attention is paid to this aspect.

- (iii)

For managers/industries:

The role of SMEs in GI remains largely unresearched, as this theme appears in the uncharted territory. Brand management in manufacturing industries based on GI innovations also presents an opportunity for practicing managers of such units, as highlighted in the uncharted territory research categorization of this aspect. How mergers and acquisitions can benefit from or influence GI is also a potential decision-making opportunity for managers of manufacturing enterprises. This also appeared in the uncharted category. This study suggests that integrating GI into the supply chain can be a rewarding initiative, and managers should consider this direction.

The world's top polluting organization categories are fuel industries, agriculture (including food production and processing), the fashion industry, food retail, transport, construction, and technology (Garner, 2023). Managers of organizations in these sectors will, therefore, be under pressure to develop more eco-innovations. Eco-innovations from sectors such as Chemicals, Food and Nutrition, Ceramics, Biotechnology, Healthcare and Pharmaceuticals, and Metals and Welding are in the well-recognized research category (Table 5). Similarly, sectors such as Green Cement and Sustainable Buildings, Battery Technology and Sustainable Buildings, Textile and Fashion Industry, and Semiconductors and Chips are in the expanding category (Table 4). However, Electric Vehicles and Automotive Technology, and Lightweight Steel and Structural Experimentation are in the uncharted territory (Table 3). Therefore, managers of organizations from these uncharted territory sectors must catch up with eco-innovations.

- (iv)

For ecosystem developers, e.g., management system certification agencies and international standard development bodies such as ISO (International Organization for Standardization):