Naturally available filaments have recently become attractive to researchers, engineers, and scientists because of suitability as an alternative reinforcement for fiber reinforced polymer composites. Low cost, fairly good mechanical properties, non-abrasive and bio-degradability attributes, abused as a swap for the regular fiber. The tractable properties of normal fiber reinforced composites are mainly influenced by the interfacial adhesion between the matrix and the fibers. In this article survey on biosoftening, adhesion, the effect of fiber length, the effect of chemical treatments of long areca fibers, Influence of mercerization on the tensile strength of long & short areca fibers, areca husk have been discussed.

The present world is confronting a difficult issue of growing new and propelled innovations and techniques to dispose or make use of solid wastes, especially non-actually reversible polymers. The procedures to break down those squanders are really not savvy and will in this manner create unsafe chemicals. Considering above parameters, strengthening polymers with natural fibers is the only way which will lead us to the solution. Regular strands are minimal effort, recyclable, low thickness, and eco-accommodating materials. Their tensile properties are great and can be utilized to supplant the customary strands, for example; glass, carbon in fortifying plastic materials. A noteworthy disadvantage of utilizing characteristic strands as fortification in plastics is the contrariness, bringing about poor attachment between normal filaments and lattice gums, hence prompt low pliable properties. To enhance fiber-network interfacial holding and improve malleable properties of the composites, some theories and surface modification techniques are developed. Also, it is evidently clear that the strength and stiffness of the natural fiber polymer composites are strongly dependent on fiber loading. The mechanical properties increases with increasing fiber weight ratio up to a certain amount. Mathematical models/finite element models can be used as a compelling instrument to anticipate the tensile properties of natural fiber strengthened composites.

Natural fiber consists of different constituents like cellulose, lignin, pectin and other materials. Because of the presence of these components, natural fiber have special characteristics and special properties and they will result in high moisture percentage & intern this affects the fiber-matrix bonding. To overcome from this difficulty some chemical treatment methods [1–5] are implemented and are studied in order to meet the properties as of other man-made fibers.

The areca/betel nut fiber reinforced composites finds greater advantages in the latest development of composite materials such as electrical insulation applications [6].

The tensile strength is more delicate to the grid properties, though the modulus is reliant on the fiber properties. To enhance the strength [4,6–8] a solid interface, low anxiety fixation, fiber introduction is required, while fiber concentration, fiber wetting in the matrix stage, and high fiber proportion decide elastic modulus.

In some of the tribological applications, treated betel nut fiber reinforced polymer composites were considered as superior than chopped strand mat glass fibre-reinforced polyester [9], betel nut polyester composite has similar mechanical properties to the glass-polyester composite. Hence betel nut fibers have a high potential to replace glass fibers [10] and for small load applications [11].

In the high tensile strength applications, chemically treated areca fiber reinforced natural rubber composite [12] and for high dimensional stability applications, low-density property of raw betel nut husk fiber has found the application in lightweight applications [13,14]. Natural fibers are cheap, biodegradable, reusable and eco-friendly materials. Eco-friendliness and bio-degradability nature of natural fibers may be the choice over the glass and carbon fibers [14]. Betel nut and sansevieria cylindrica in PP (polypropylene) composites have found applications where in strength and cost considerations are important [15]. Similarly, in packing industries, low-cost housing, and domestic purposes areca fiber and maize powder reinforced PF composites are used [16].

Areca sheath fiber found the applications in structural and non-structural application such as suitcases, post-boxes, grain storage, automobile interiors, partition boards and indoor applications [17].

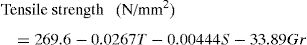

2Tensile strength2.1Effect of different chemical treatmentsFollowing classifications have been discussed on areca fiber/betel nut husk (BNH) fiber composites and hybrid composites with different parameters.

2.1.1NaOH treated Areca nut fibers/BNH fibersIn this literature, areca nut fiber reinforced composites are reported to explore the comparable tensile properties of untreated and treated with different chemicals. In general, the greater part of the common strands shows preferable rigidity over flexural quality. In the present review, the rigidity of areca strands was assessed and relative review has been made with the other surely understood characteristic filaments [1].

Areca nut fibers have been treated with P. chrysosporium and Phanerochaete sp. and observed tensile strengths of fibers were 125.2 Nm m−2 and 116.5 Nm m−2 respectively and untreated fiber had a tensile strength of 92.7 Nm m−2, this shows the versatility of biosoftened fiber procure after the treatment with both the living beings was practically identical [2]. The fiber treated with P. chrysosporium demonstrated 35.1% and Phanerochaete sp. indicated 25.7% expansion in quality when contrasted with the untreated fiber. Lignin is the part, which grants weakness to the fiber. Incomplete evacuation of lignin causes alternate parts of the filaments like cellulose to wind up noticeably more conservative and along these lines expands the quality and adaptability of the areca nut husk fiber.

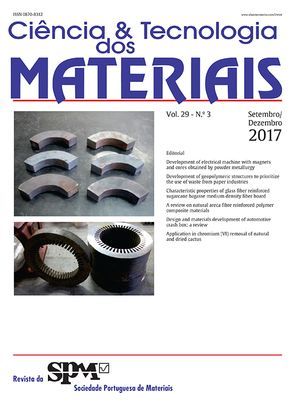

Betel nut fibers were alkalized in 1% NaOH solution for 1 h and are tested for mechanical properties. These alkalized fibers showed significantly high tensile strength of BFRPC with fiber loading from 10 to 30% but decrease with fiber loading 40% (Fig. 1) [3].

Effect of fiber content and length on tensile strength [3].

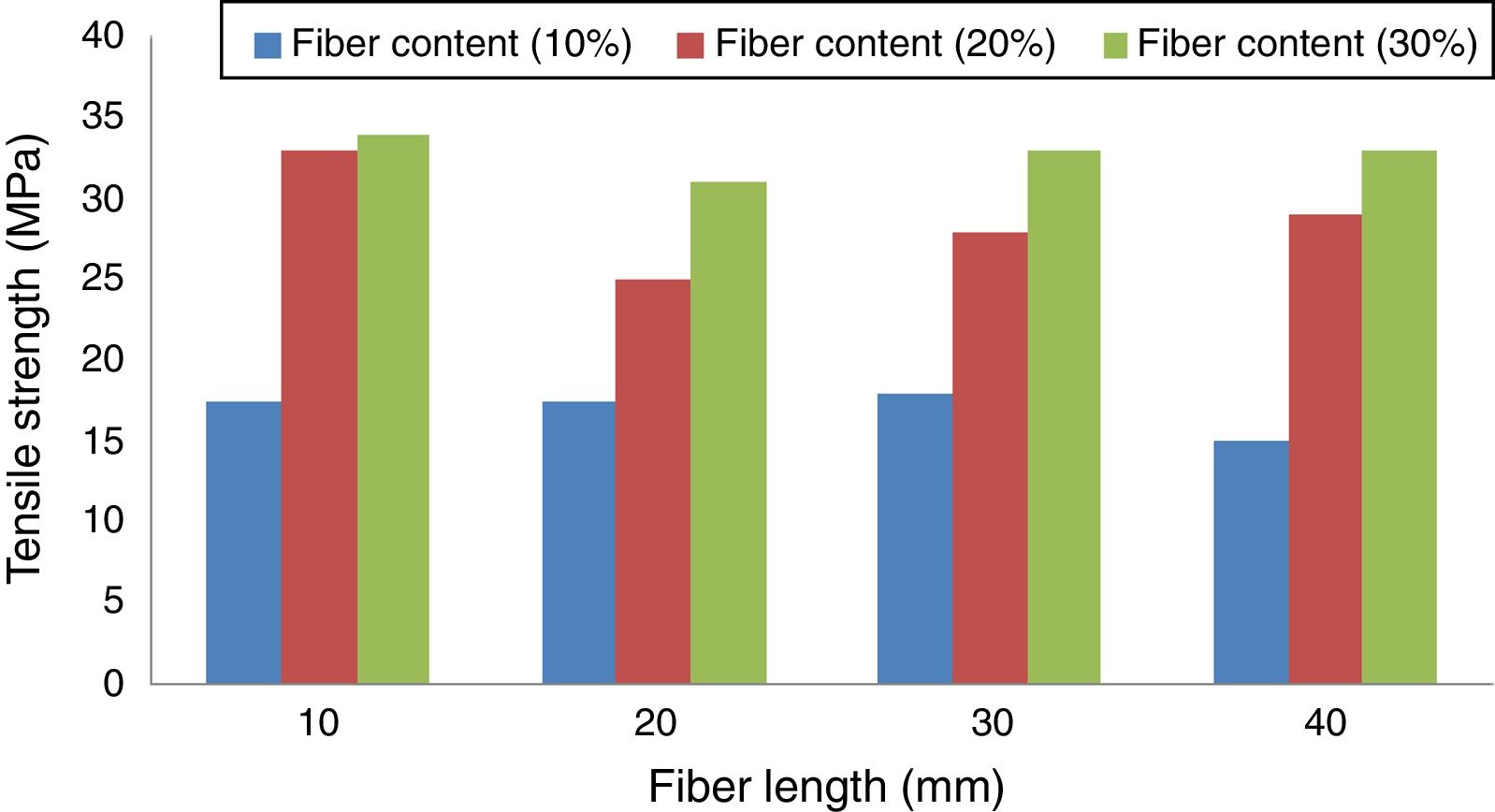

Some of the researchers had utilized KOH (Potassium Permanganate) treated filaments in the composites, these composites have shown more ductility (Fig. 2) than the untreated filament composites and also alkali treated strands have shown good elasticity properties [4].

Ultimate tensile strength of areca fibers reinforced epoxy composites [4].

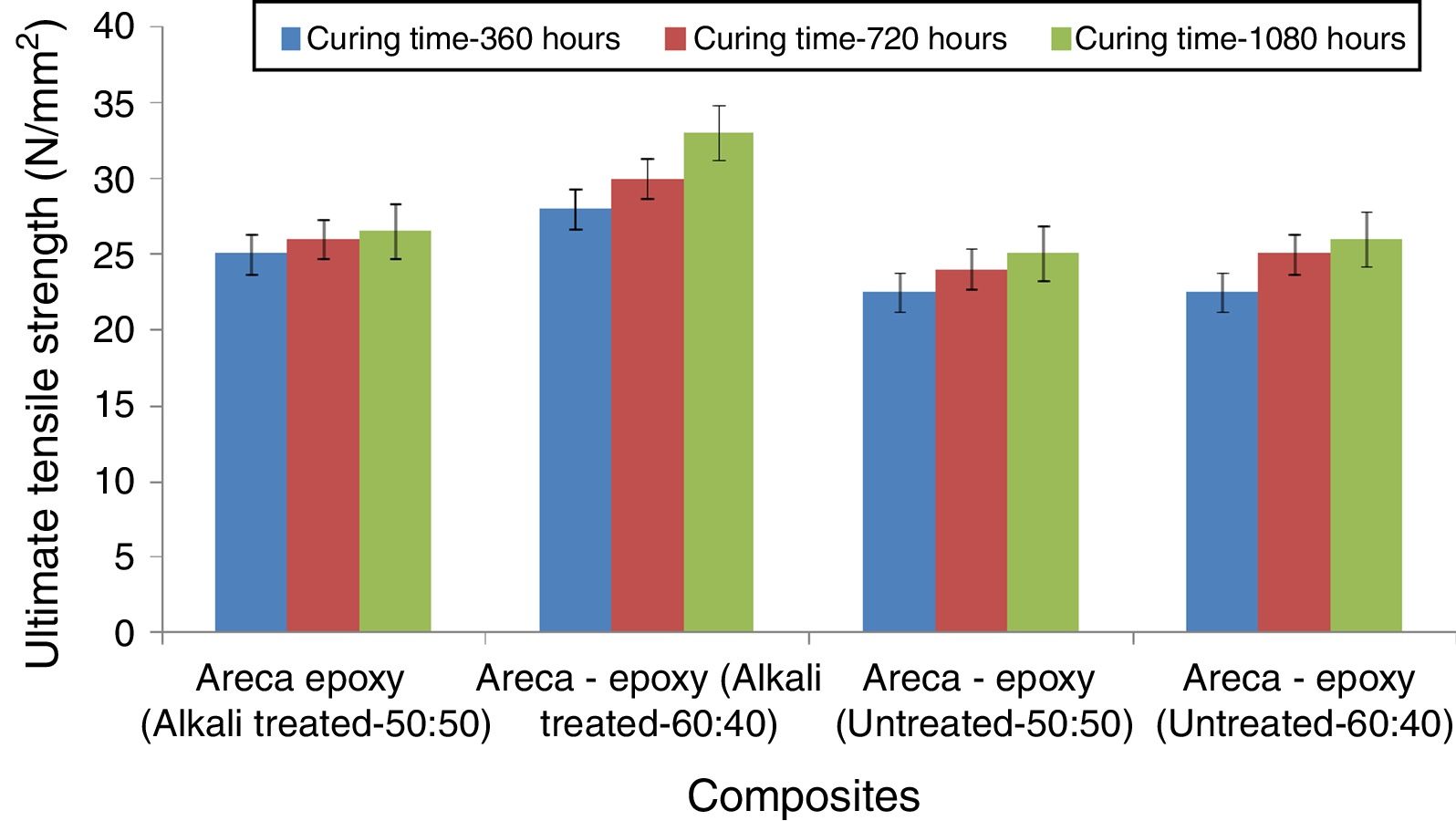

Impact of different treatment media on the breaking strength of long areca nut filaments has been studied. Study for sugar treatment process of areca leaf fiber with various concentrations of sugar solution are taken and to monitor the chemical changes during treatment process, the pH was measured as well as different solutions are used as a surface treatment medium like Jaggery, wheat flour solution. Tests were conducted for treated and untreated filaments to study the rigidity of areca fibers, as a result, fibers treated with sugar solution showed 34% more strength than the untreated fibers, and treatment with jaggery solution improved the strength by 31%. For fibers treated with wheat flour solution, the strength increased by 51%. Wheat flour treated fiber resulted in maximum strength compared to other treating media (Fig. 3) [5].

Comparison of results [5].

Tensile properties of hybrid betel nut (Areca Catechu) short fiber/Sansevieria cylindrica (Agavaceae) epoxy composites (strands treated with 5% NaOH course of action) have demonstrated the extension in filler content from 3% to 10%, the rigidity relentlessly extended, however the versatility of the composites is found to decrease with increasing filler loading by weight divide from 20% to 30% (w/w) [6].

Improved adhesive ability of the areca fiber with the matrix results in greater tensile strength of the composite material, particularly in the different densities of NaOH, 6% alkali treatment produced the highest tensile strength. Similarly, the effect of 5% NaOH treatment on tensile properties on betel nut fibers were studied, for untreated betel nut/unsaturated polyester composites decrement in tensile strength was observed due to poor fiber lattice expansion straightly with the expansion in fiber loading from 0% to 15% and further goes high in weight percentage [7].

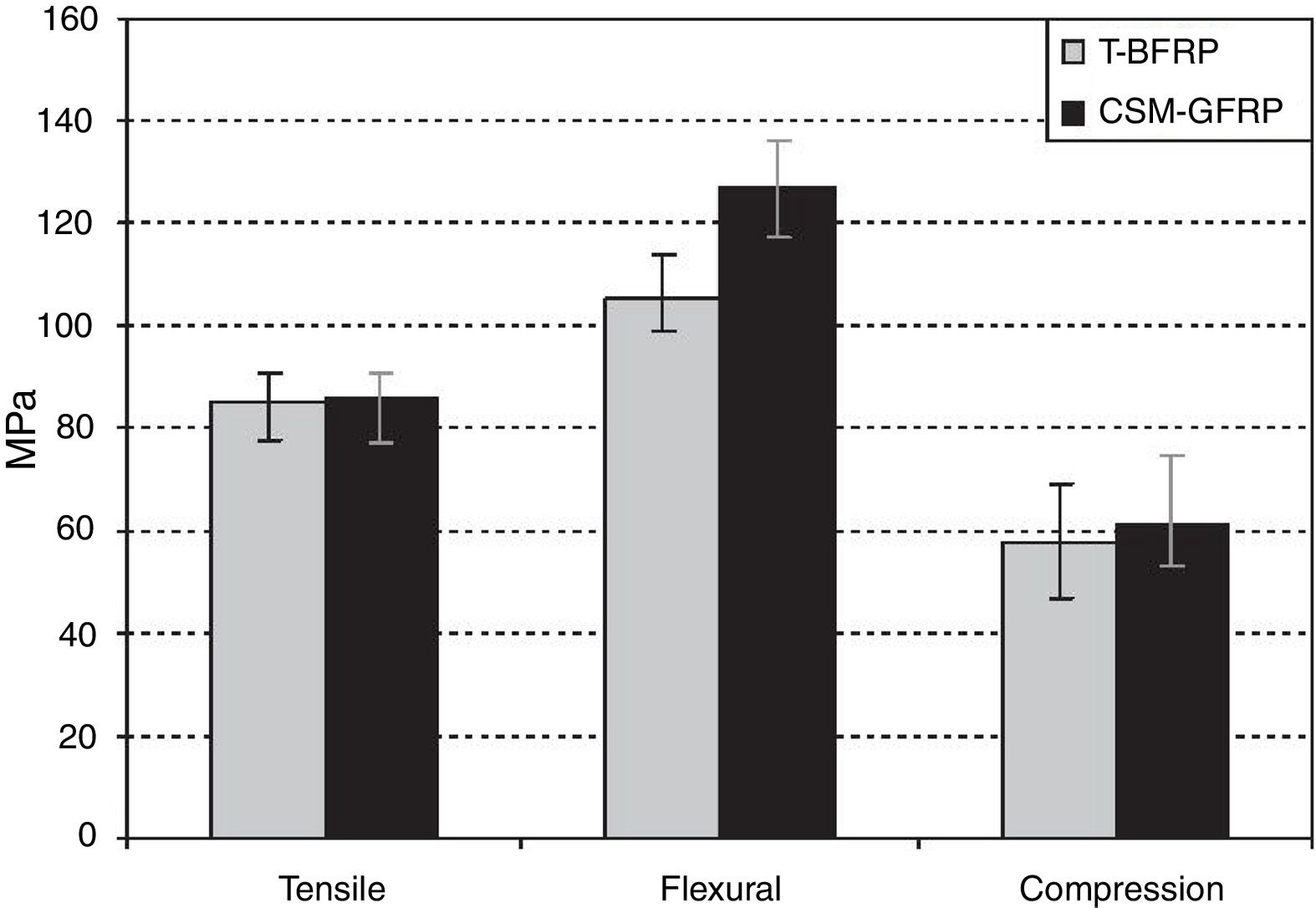

It was imputed that the surface roughness of the betel nut fiber will enhance the interlocking of fiber in the matrix and also mechanical properties of T-BFRP composite was found to have equivalent tensile and compression strengths of CSM-GFRP composites [8].

Highest value of the mechanical property is exhibited by the composites with 30% fiber loading. Similarly, a comparative study was made with treated betel nut fibre-reinforced polyester (T-BFRP) and chopped strand mat glass fiber-reinforced polyester (CSM-GFRP) composites (Fig. 4) [9].

Mechanical properties of T-BFRP and CSM-GFRP composites [9].

Replacement of glass fiber with the betel nut fiber for mechanical applications was considered for the reason of showing good tensile properties, this tensile property of betel nut fibers was because of the presence of trichomes on the outer edge of the betel nut fiber [10].

Improved adhesive ability of the areca fiber with the matrix in the fabricated composites was achieved with chemically treated areca fibers with different densities of NaOH solution (2, 4, 6, 8 and 10%) at room temperature for 1 h [18].

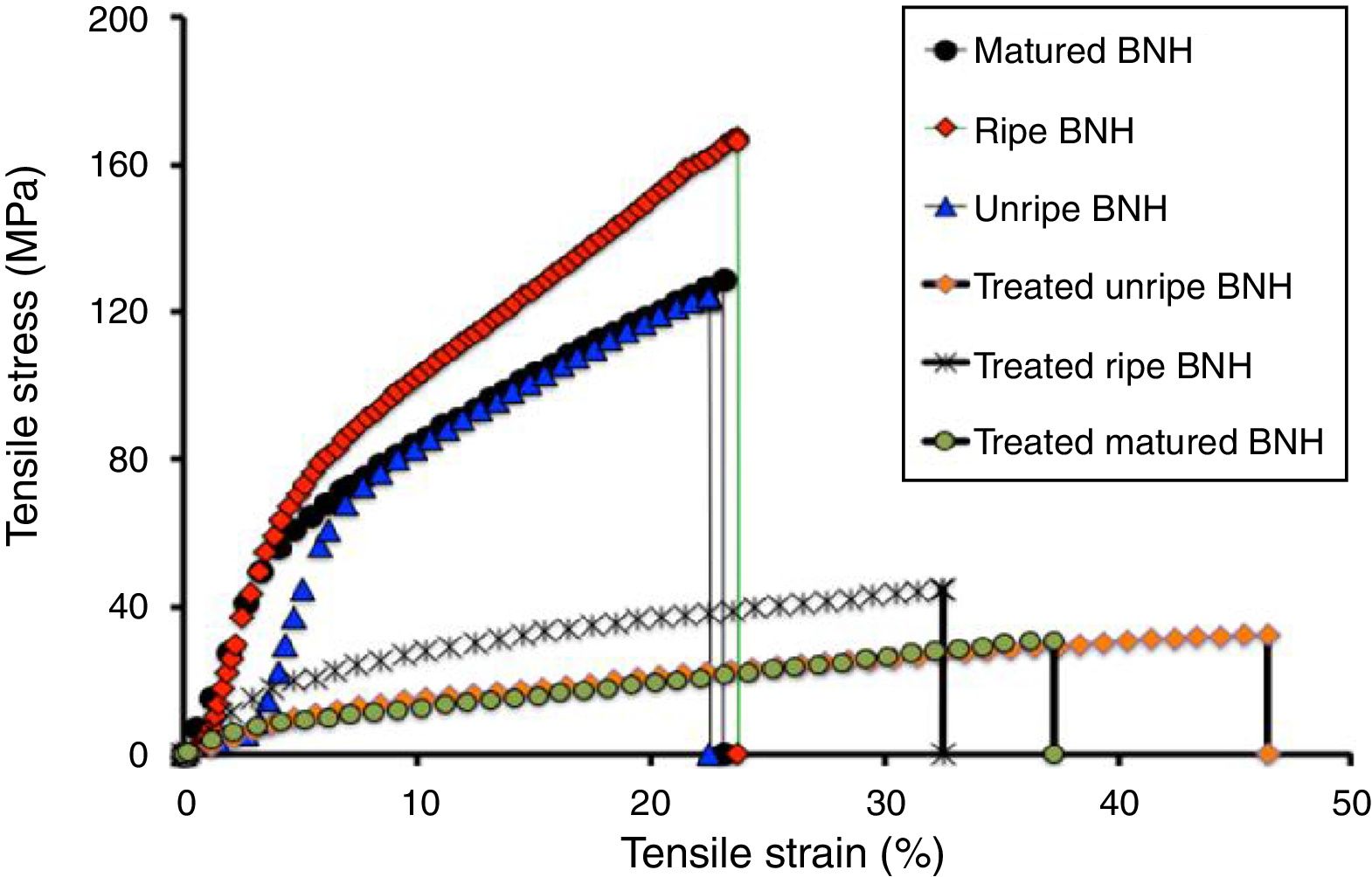

Untreated and alkali treated ripe BNH fibers have shown good results (Fig. 5) as compared to alkali treated as well as salt water and alkali treated unripe and mature fibers in terms of elasticity. Decay in elasticity was observed in the unripe and mature type of BNH fibers and also it was noticed that alkali treatment had shown good results with all type of BNH fibers [19].

Stress–strain curves of untreated and alkali treated unripe, ripe and matured BNH fibers [19].

In this section effect of different chemical treatments on tensile behavior of the areca nut/betel nut fibers have been discussed.

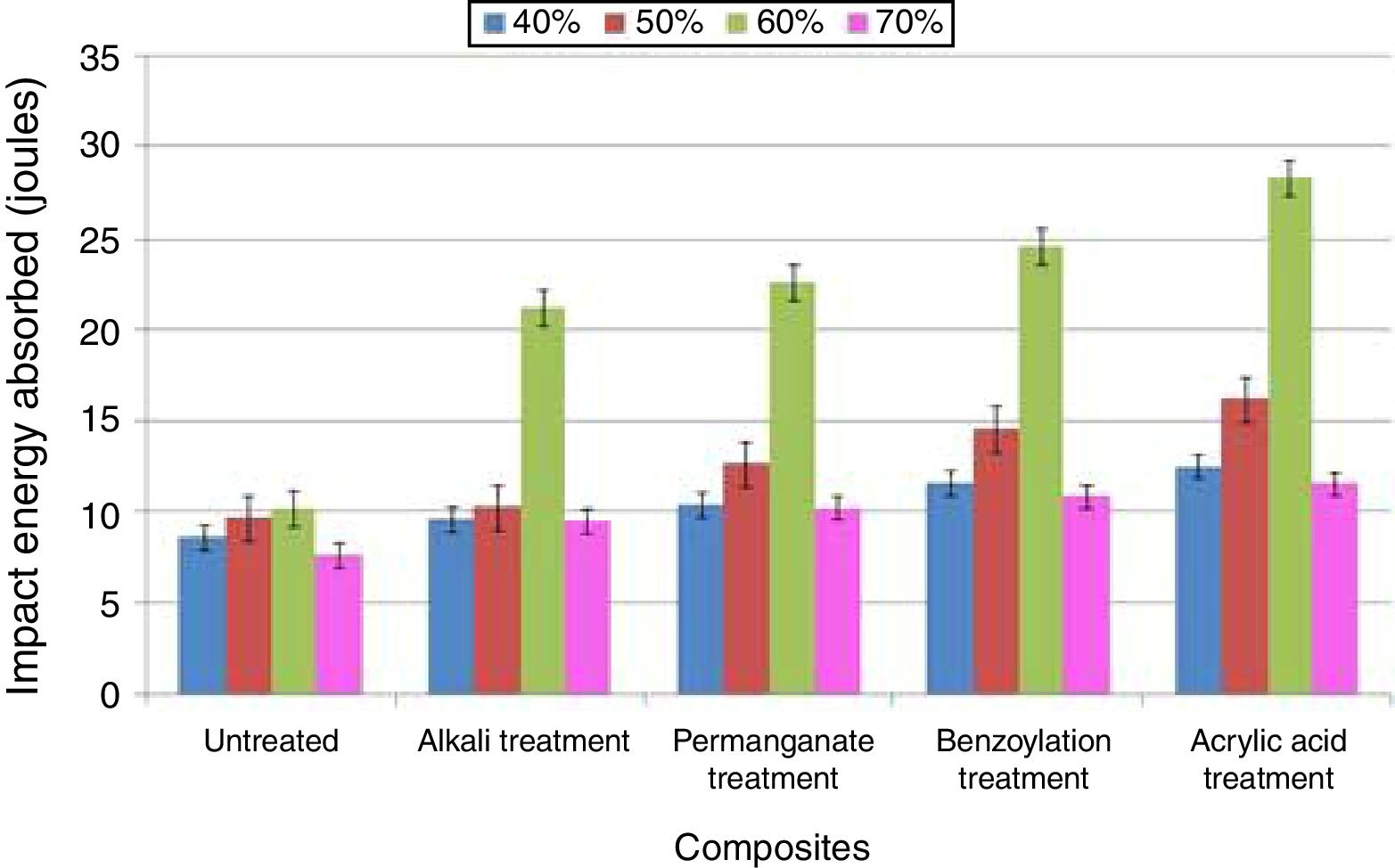

For the examination of the rigidity of untreated and all artificially treated areca fiber reinforced regular elastic composites, ASTM standard techniques have been embraced. It was observed that with increment in fiber loading up to 60%, the elasticity of untreated and all synthetically treated areca fiber fortified characteristic elastic composites were expanded and afterward, they demonstrated a decrease. Facilitate, among all treated and untreated areca fiber strengthened regular elastic composites, acrylic acid treated areca fiber strengthened common elastic composites with 60% fiber loading have demonstrated the higher rigidity [5].

After all, improvement in mechanical properties have been observed for areca fiber reinforced biodegradable composites with alkali treatment (1 N of Sodium carbonate solution [Na2CO3]), and it was observed that fibers surface modification can enhance the adhesion properties between areca fiber (maximum load of 38.96 N) [11].

Dhanalakshmi S. et al. [12], studied the effect of chemical treatments on tensile strength of areca fiber reinforced natural rubber composites, untreated, alkali treated, potassium permanganate treated, benzoyl chloride treated and acrylic acid treated areca fiber strengthened common elastic composites were manufactured by utilizing heat squeeze machine under 40%, 50%, 60% and 70% fiber loadings at an intensifying temperature of 130 °C and the influence of chemical modifications on the elasticity of areca fiber strengthened common elastic composites.

Positive impact on the performance of areca nut fiber reinforced PCL based unidirectional composites were observed for VTMS and gamma irradiation. Areca nut fiber treated with 4% silane and at 500 krad dose of gamma irradiation will alter the polymeric character of the fiber and results in highest mechanical properties [20].

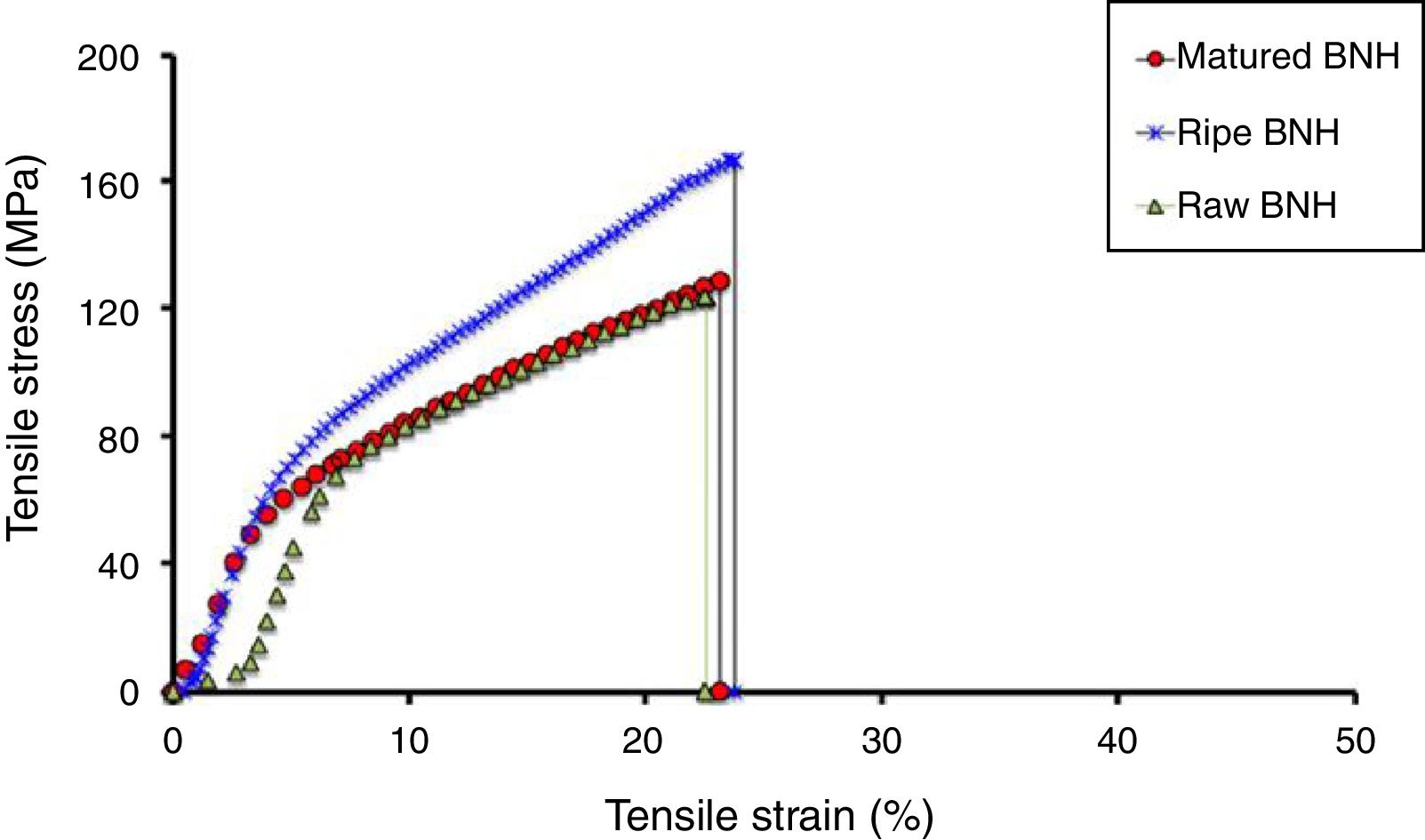

2.1.3Fiber maturityBetel nut husk (BNH) fibers of three different stages of maturity (raw, ripe, matured) were evaluated to study the influence of maturity level. Betel nut fruit showed good tensile strength for ripe BNH and this will make ripe BNH a good choice for reinforcement in polymer composites. Because of low moisture content dried BNH fibers exhibited the slightly low tensile strength as compared to ripe BNH fiber but dried BNH fibers have shown high dimensional stability [13]. Yet again to study the effect of fiber maturity on the mechanical properties of BNH fiber, among the available results [13,21] ripe stage BNH fiber shows the highest tensile strength (166.03 MPa), followed by matured (128.79 MPa) and raw (123.92 MPa) BNH fiber (Fig. 6). The tensile strength of BNH fiber was found to be close to the tensile strength of kenaf fiber (129–473 MPa).

Stress–strain curves of raw, ripe and matured BNH fibers [13,21].

The fuse of at least two filaments inside a solitary framework the subsequent material is a mixed composite, regularly truncated to simply ``Hybrid''. In this section incorporation of two fibers (treated/untreated areca and other) has been discussed.

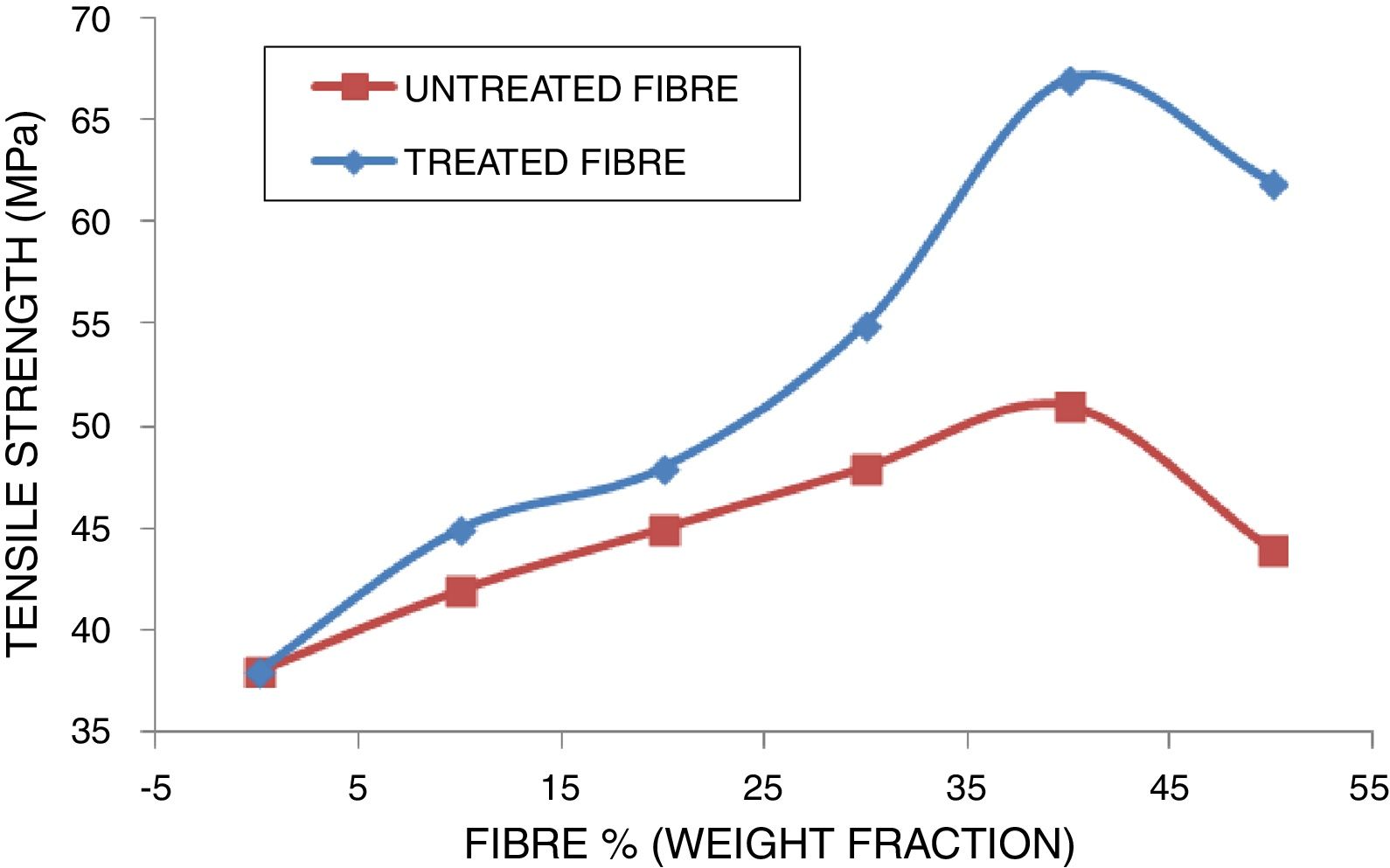

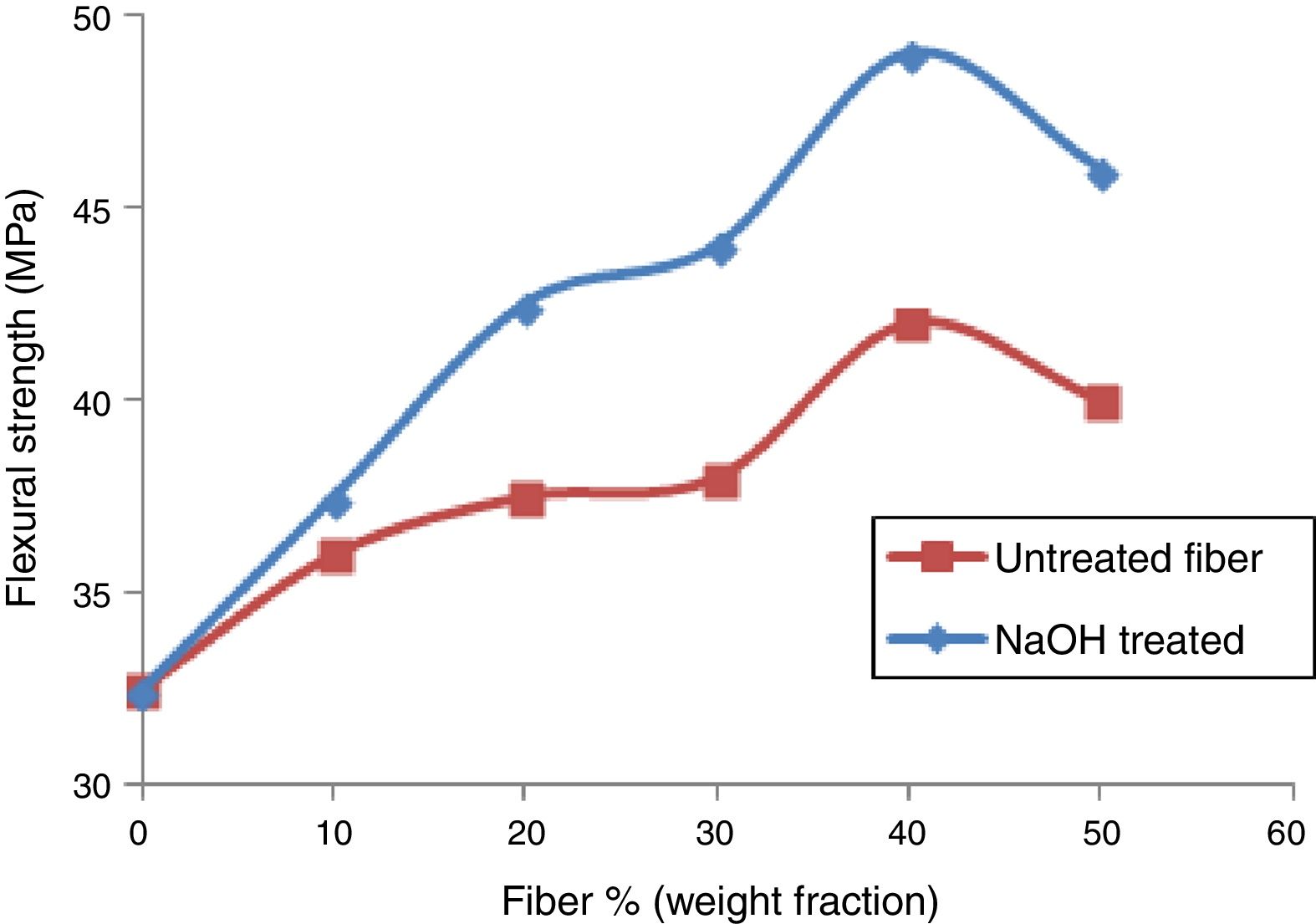

Alkali-treated areca and maize fiber hybrid composites and untreated fiber hybrid composites are considered to evaluate the tensile properties and it is observed that higher quality is achieved for treated fibers as compared to untreated one’s [1]. The gradual increment in the stress of 10% NaOH treated natural fiber-reinforced epoxy-hybrid (tamarind fruit fibers and the areca nut husk fibers) composites [8] was observed in Fig. 7.

Variation of tensile strength with fiber loading (weight fraction) [NaOH treated and untreated fibers] [8].

Mechanical performance (tensile, bending and impact) of Polypropylene (PP) composites filled with betel nut (Areca catechu) short fibre (Bn) at different compositions (3, 5, 10, 20 and 30 wt.%), have shown decreased tensile properties with the increased % of the filler, and composites with 10% betel nut fiber exhibited the better mechanical properties. This will enhance the performance of the hybrid fiber reinforced composites through hybridization of betel nut and Sansevieria cylindrica with PP matrix at optimized ratio (Bn10: Sc10: PP: 80) of the fiber matrix formulation, these composites can be used in various applications as structural materials where strength and cost considerations are important [15].

Blends of areca fiber, maize powder, and phenol formaldehyde resins were used in the preparation of composites with different configurations and were tested [16] and it is noticed that the tensile strength obtained is 135 MPa in 300B (700 g Areca fiber + 300 gm maize powder + 300 ml phenol formaldehyde) composite, which is maximum value among all the components prepared. An attempt was made to evaluate the tensile properties of untreated natural areca sheath fiber reinforced polymer matrix (UNASFRPM) bio-composite. Experimental and finite element analysis (FEA) was made on chopped UNASFRPM and obtained results (16.16 N/mm2 and 19.6473 N/mm2, experimental and FEA results respectively) are near to matched close values [17].

Meanwhile, studies on adhesive tensile characteristics of areca and maize fibers reinforced urea formaldehyde composites have shown good adhesive tensile behavior. Adhesive strength (tensile) of the composites with weight division proportion 7:3 of areca filaments to maize powder was demonstrated higher than the remaining [22]. Similarly, short areca fiber and wood powder reinforced phenol formaldehyde composites were prepared for different combinations (200, 300, 400 and 500) and in these combinations also it was observed that combination with 300B code has shown the greatest heap of 0.95 kN with a diversion of 5.48 mm. The Young's modulus for a composite plate of 300B is 91.59 MPa [23].

Enhancement in the rigidity of the areca nut fiber composites by adding casuarina fiber to it, an expansion in the elasticity was observed and also decrease in thickness by the expansion of areca nut and casuarina fiber to flawless epoxy [24]. Hybridization of natural fibers with synthetic that is layered areca and waste nylon fiber strengthened hybrid polypropylene (PP) composites have shown the expansion in the elasticity [25], as the number of fiber layer increases (as 2, 3 or 4) and also it was observed that the strands turn out to be consistently scattered into the framework and percentage prolongation at break expanded with the improvement of number of fiber layers.

Locally available areca husk fibers at the place Balinese (Indonesia) are compared with the other region areca fibers in this study. Local Balinese AHF has exhibited the good physical and chemical compositions as compared to another region AHF. Also, this Balinese AHF has shown slightly good tensile properties, which will enhance the use of AHF as a replacement for synthetic fibers [26].

3Flexural strengthBefore the study of the bending strength of chemically treated areca fiber reinforced composites, characterization of areca fiber reinforced composites with some additives was studied. Some of the studies have shown that the bending load for the composites will increase with an increase in phenol–formaldehyde [1].

In the previous section, it was observed that chemical treatment or surface modification of natural fibers will increase some properties. In this section also effect of chemical treatment on flexural properties of areca/betel nut fibers has been discussed. Flexural strength also increases significantly with fiber content from 10 to 30% because of increase in betel nut fiber content in different lengths [3].

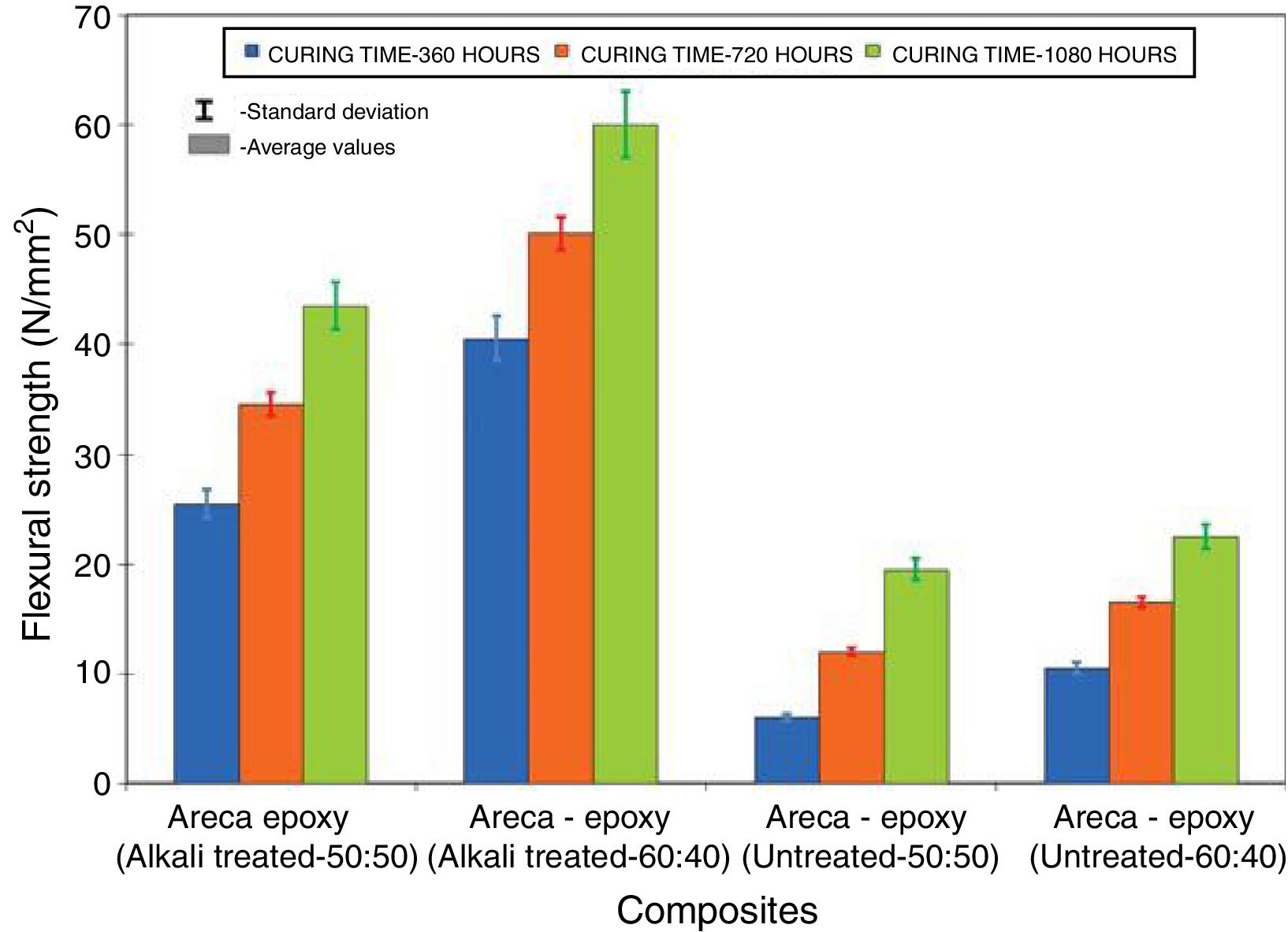

Untreated and alkali (KOH) treated areca fiber reinforced epoxy composites were tested for flexural characteristics, tests have shown that alkali treated areca fibers reinforced epoxy composites under flexure shows good results (Fig. 8) as compared to untreated fiber composites [4], will also increase the flexural properties of the composites.

Flexural strength of areca fibers reinforced epoxy composites [4].

Strength gradually increased as fibers loading grows from 10% to 40%, but downfall in a further increase of reinforcement (50%) [8]. 18% growth in the flexural strength was found when compared with untreated fiber reinforced composites and 48% growth in comparison with pure epoxy was found. Flexural strength of the hybrid composites before and after NaOH treatment is shown in Fig. 9 as a function of fiber loading (weight percentage)

Variation of flexural strength with fiber loading (weight fraction) [NaOH treated and untreated fibers] [8].

Flexural strength was calculated from the following equation (1)[8],

Hybrid composites with areca fiber and maize powder reinforced phenol formaldehyde have shown increment in bending load as the areca fiber percentage decreases and percentage of maize powder increases [16].

In the composite containing 10% of alkali treated areca fiber with epoxy resin, and composite containing 5% of alkali treated areca fiber and 5% of alkali treated casuarina fiber with epoxy resin, abbreviations used are E for Epoxy composites, EA for epoxy with 10% alkali treated areca fiber and EAC for epoxy with 10% alkali treated areca and 5% alkali treated casuarina fibers. Out of thee composites, E has the higher bending load (75.119 N) than that of EA (46.728 N) and EAC (38.061 N). Both EA and EAC examples withstand bring down flexural load because of the fragile conduct of areca nut fiber [24].

Flexural strength found to be increasing in hybrid composites of polypropylene matrix reinforced with areca and waste nylon fibers due to the increase in number of fiber layers, this might be because of the lower measure of grouping of strands which comes about due to the non-uniform scattering of filaments with expanding/diminishing fiber layers [25].

Higher flexural strength was noticed with the alkali treated fibers as compared to those without alkali treatment. And also, the flexural strength of all fiber reinforced composites increases with the volume fraction of the fibers was found by Srinivasa C. V. et al., [27]. The most extreme static flexural heap of the areca-strengthened UF composite plate was 380 N. The comparing flexural quality amid break for this example was 27.36 MPa, and the base static flexural heap of 210 N was recorded for UF50 untreated composite, and the flexural quality amid break for this example was 15.12 MPa. Addition of melamine to urea formaldehyde has a vital role in better adhesion strength with areca fiber, which indicates that maximum flexural load for treated MUF50 (Melamine-Urea Formaldehyde 50) (i.e. 520 N).

Flexural strength value of areca fiber reinforced epoxy composites was found to be increasing after chemical modification and higher value of flexural strength was achieved for 60% fiber loading for all untreated and artificially treated areca/epoxy composites [28]. Amongst all the treatments carried out, acrylic acid treated areca/epoxy composites of 60% fiber loading showed maximum flexural strength value, followed by benzoyl chloride treatment, permanganate treatment and alkali treatment at same 60% fiber loading.

Betel nut husk fibers with different maturities (Ripe, matured and unripe) were used in forming the composites with vinyl ester and flexural properties of these composites have been found with considerable variations with respect to maturity. That is the highest improvement in the flexural modulus was observed in the ripe BNH fiber-reinforced composites with 10 wt.%. But further increment in BNH fiber content resulted in a decrease in flexural modulus. Fiber maturity was found to have a very minimal effect on the flexural properties of the BNH-reinforced composites [29].

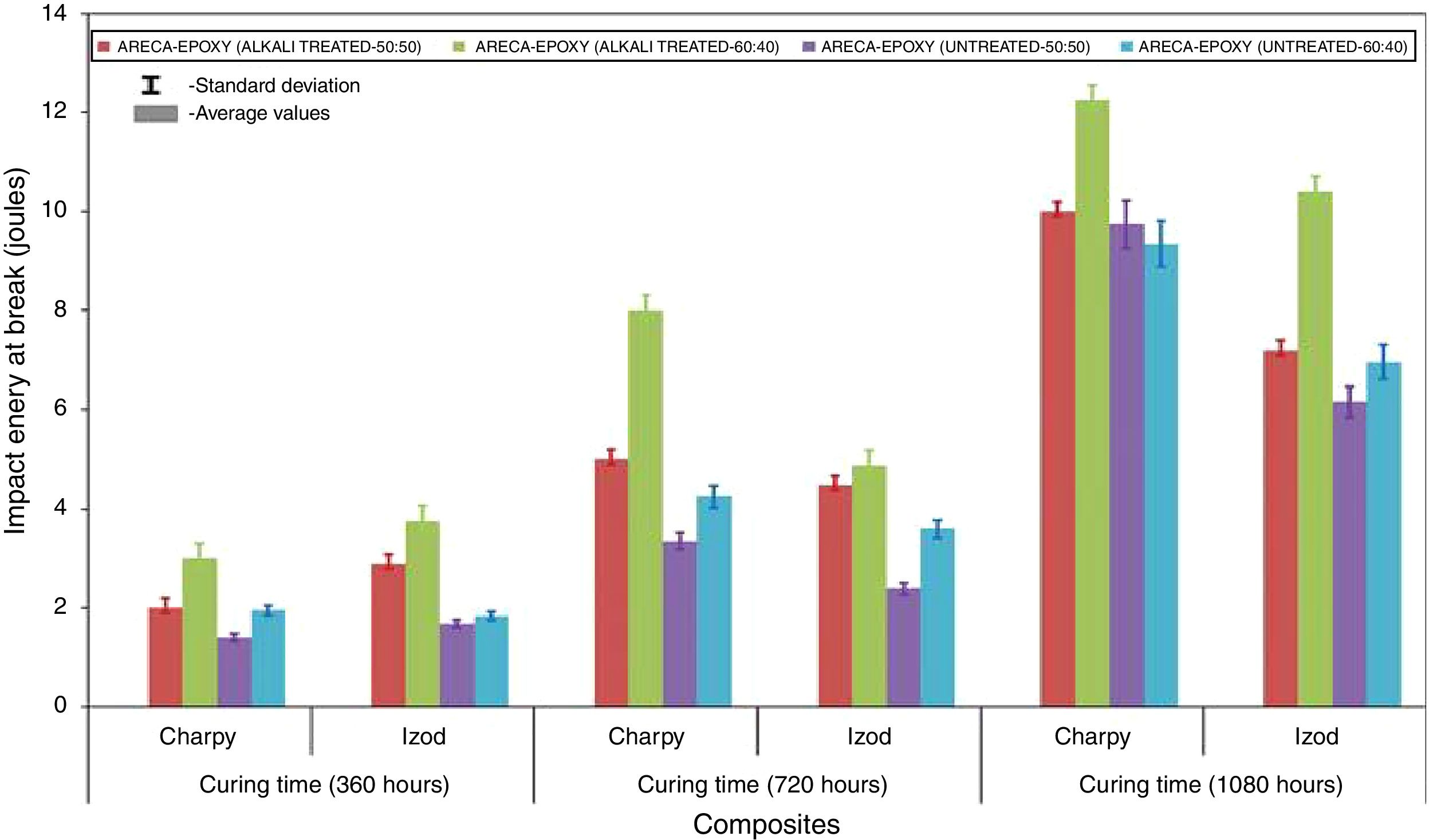

4Impact strengthImpact quality is characterized by the capacity of a material to oppose break under anxiety connected at rapid. The effect properties of composite materials are straightforwardly identified with its general durability. As a result of reinforcement of betel nut fibers impact strength increases with the increase in fiber loading [3], also it was observed that the impact strength of composites increases with curing time (Fig. 10) at a more prominent rate than that of the weight proportion of fiber to lattice in the composite [4].

Impact strength of areca fibers reinforced epoxy composites [4].

Most extreme effect vitality retained was for treated fiber and for a fiber loading (weight division) of 50%, there is an expansion of 30% in the energy absorbed when contrasted and untreated filaments strengthened crossover composites [8].

5% NaOH treated betel nut (Bn) and Sansevieria cylindrical (Sc) have been evaluated for the impact properties, composites made of these fibers had set increasing trend with increasing Bn content from 3% to 10%, followed by a decreasing trend. It was anticipated that as the size of the filler becomes a slightly greater interaction between the filler and matrix could result in better and more efficient stress transfer which intern could increase the impact strength of the composite, this results in a composite of 10% Bn content exhibits better mechanical behavior [15].

Sodium hydroxide, potassium permanganate, benzoyl chloride and acrylic acid treated areca/epoxy composites with 60% fiber loading appeared 107.23%, 121.09%, 139.84% and 176.17% increment in effect quality separately when contrasted with untreated areca/epoxy composite with same 60% fiber loading. Among all compound medications did, acrylic acid treated areca fiber reinforced epoxy composites of 60% fiber loading demonstrated greatest effect vitality assimilated.

S. Dhanalakshmi et al. [30] observed that areca/epoxy composites with 60% fiber loading indicated maximum impact energy absorbed compared to areca/epoxy composites with other fiber loadings. These outcomes plainly prove that, these chemical substances are exceptionally viable in the surface adjustment of the areca fiber and in enhancing the mechanical properties of synthetically treated areca/epoxy composites (Fig. 11) [30].

Impact energy absorbed by areca fiber reinforced epoxy composites with different loadings [30].

Composites containing 50 and 60% of alkali treated or untreated areca fibers, contained urea formaldehyde resin (UFR), melamine urea formaldehyde resin (MUFR) and epoxy resin have exhibited the good impact results. Since epoxy has a higher sub-atomic weight than the urea formaldehyde or melamine urea formaldehyde, the areca filaments composites indicate predominant vitality retention limit (over 40%) then the areca strands strengthened melamine urea formaldehyde or urea formaldehyde. In this work, it was observed that the epoxy has more noteworthy effect quality when contrasted with urea formaldehyde and melamine urea formaldehyde [31].

The impact strength of composites increments with curing time to a more prominent degree when contrasted with fiber volume in the composite. The imperative perspective with respect to affecting the quality of the areca composite is that, as the composite curing time builds the antacid treated composites turn out to be more fragile than the untreated strands [32].

Some studies have shown that the vitality retention enhances in spite of the fact that the augmentation is minor if there should be an occurrence of composites with untreated filaments. Furthermore; an alteration of the fiber surface by alkali treatment prompts an expansion of grip amongst fiber and network. This thusly builds the energy absorption limit of the composites independent of grid materials [33].

5Moisture absorptionIt has found that the amount of moisture in the composite go high with time and later it becomes constant. Composites absorb moisture about 6–7.2% of its weight [1] with varying fiber lengths will absorb 5–10% of water [3]. Amount of water absorption increases as the fiber volume fraction increases.

And it is understood that the lowest uptake of water by the composites indicates that more OH groups of cellulose content in the fibers of the composites are being blocked by their interaction with the EP matrix [6].

By immersing the betel nut epoxy (BnEP) composites in distilled water at 28 °C, moisture absorption study was made and it was found that initial rate of water absorption and equilibrium absorption of water increases with increasing fiber content. Therefore, the water absorption is found to increase with fiber loading, owing to the increased cellulose content.

Moisture absorption tests were conducted on areca fibers reinforced epoxy composites under different types of water (lake water, river water, and seawater) for alkali-treated and untreated fiber composites. Results have shown that areca fiber-reinforced epoxy composites have a greater affinity for water absorption when the lake water is used and have less water absorption compared with wood-based particleboard, whose absorption is known to be more than 40% [4]. The effect of this absorbed moisture will degrade the material properties such as elastic strength [23]. The increase in resin percentage resulted in a decrease in the moisture absorption of composite plates by 5.6–7.3% for D-500D (700 g of Areca fiber and 300 g of wood powder nearby 300 ml of phenol–formaldehyde resin are consistently blended and utilized for readiness D-500D of sheets) specimens as compared to other specimens [23].

The percentage moisture content is expressed as,

where FW = Final Weight; IW = Initial Weight [24].EA (epoxy + areca nut) and EAC (epoxy + areca nut + casuarina) composite show better water absorption property compared to wooden based particle [24], Both EA and EAC ingests around 5–6% of its weight, whereas dampness retention for business wood-based molecule board is more than 30–40%. Most natural filaments absorb excessive water content as compared to manmade fibers. Water is predominantly absorbed in the fiber–matrix interface [24].

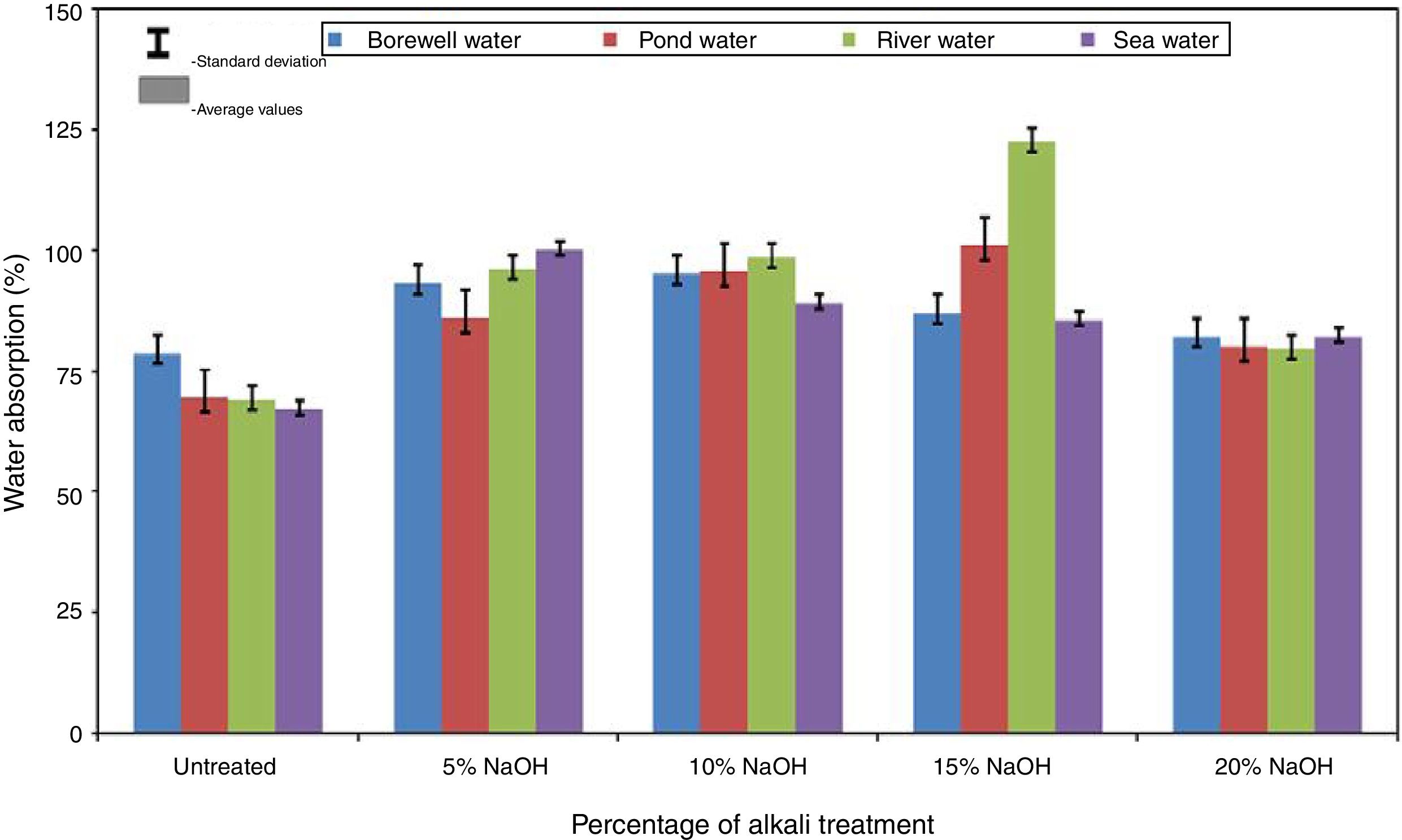

S. Dhanalakshmi et al. [35] investigated the impact of alkali treatment on water assimilation of areca strands is displayed in Fig. 12. It demonstrates that alkali treatment had enhanced the capacity of areca filaments to ingest water. This change is likely due to the expulsion of the sticky and waxy substances from the crude filaments. As observed for an alkalisation 5%, 10%, 15%, 20% NaOH arrangements driving the expulsion of all other hydrophobic mixes from the filaments, the fiber treated with 15% NaOH demonstrated most extreme water absorption in lake water and river water; fiber treated with 10% NaOH indicated most extreme water assimilation in borewell water; and fiber treated with 5% NaOH demonstrated greatest water ingestion in ocean water. Water absorption property of areca fiber was found to be inversely proportional to the degree of acetylation which is because of reduction of hydrophilicity of the fiber [34].

Effect of alkali-treatment on water absorption of areca fiber [35].

Areca fiber reinforced with urea-formaldehyde resin are tended to ingest ocean water (39.02%), the filaments strengthened with melamine urea formaldehyde had a greater fondness towards waterway water (39.06%), and the areca-epoxy composites had a greater proclivity towards lake water (28.03%) [27,36]. Also, it is observed that the higher fiber volume content composites with 60 wt.% have less water absorption than composites using 50% volume content. This may be due to the higher compatibility between the hydrophilic fiber and matrix for composites (60%).

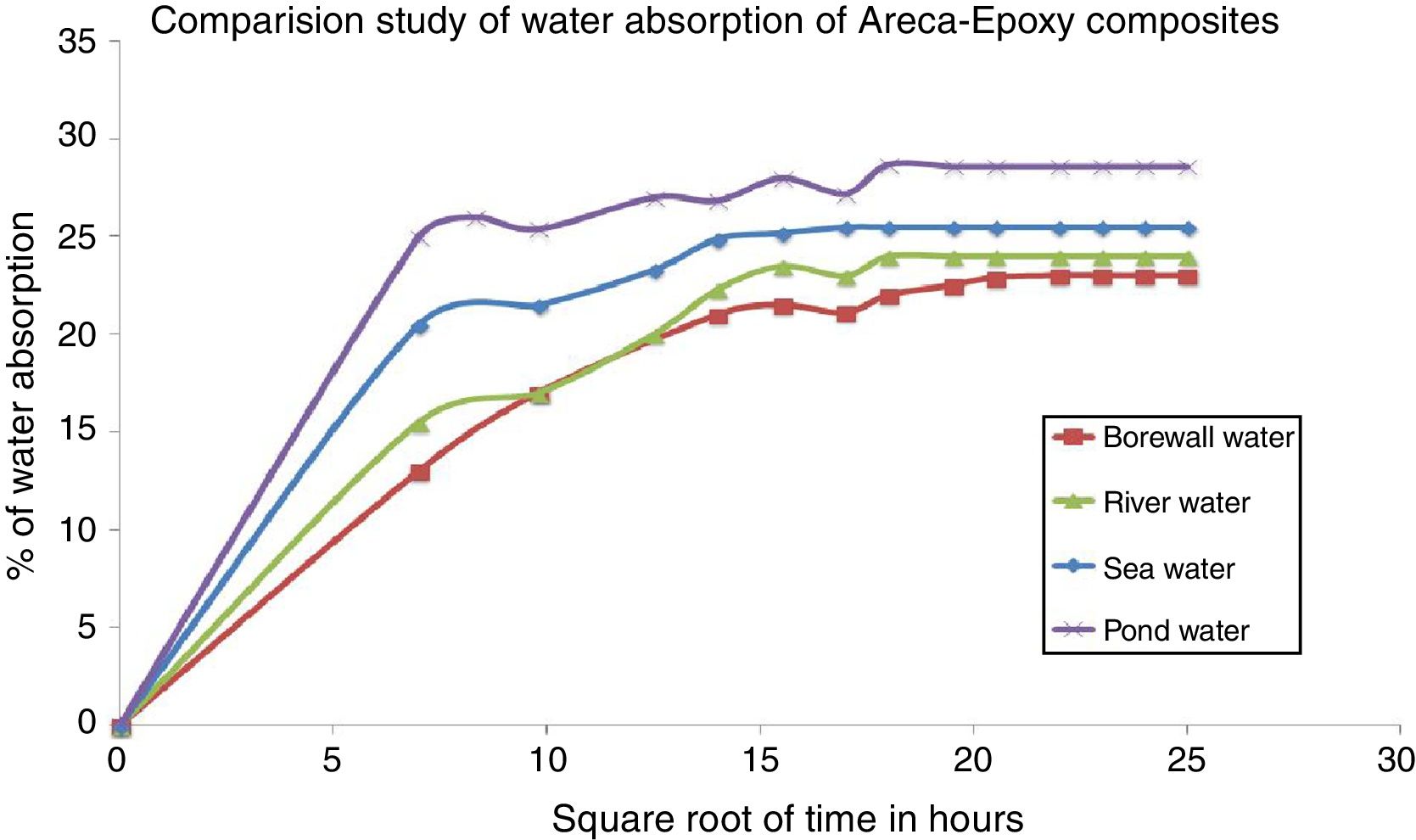

It is found that specimens absorbed water by 32.41%, 25.10%, 20.52%, and 18.90% of its weight in pond water, river water, seawater and ground water respectively. Fig. 13 shows the comparative study of water absorption of areca-epoxy composites.

Water absorption of composites for various types of water [36].

Hardness is the quality or condition of being hard or it is a measure of how resistant solid matter is to various kinds of permanent shape change when a compressive force is applied. Some materials (e.g. metals) are harder than others (e.g. plastics). Macroscopic hardness is generally characterized by strong intermolecular bonds, but the behavior of solid materials under force is complex.

The hardness test is the most valuable and most widely used mechanical test for evaluating the properties of metals as well as certain other materials. The hardness of a material usually is considered resistance to permanent indentation. In this section composites made of areca fiber/betel nut fiber with different matrix materials or hybrid composites were discussed for hardness properties. Hardness was found to be increasing for the alkali treated areca-epoxy composites (60:40) as compared to other composites and also it was noticed that curing time had improved the hardness property of the composites [4]. It depends on the uniform distribution of the filler into the matrix.

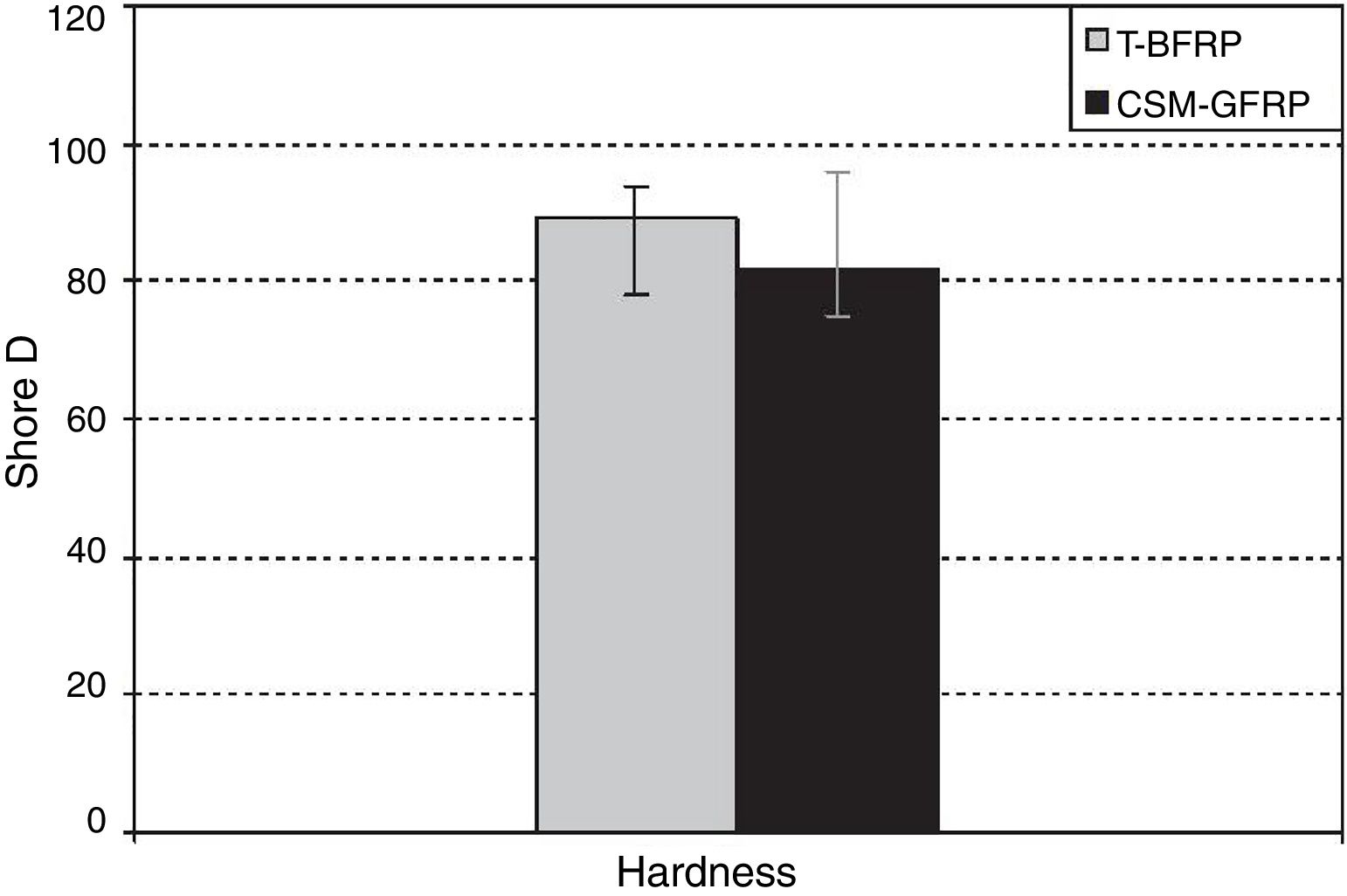

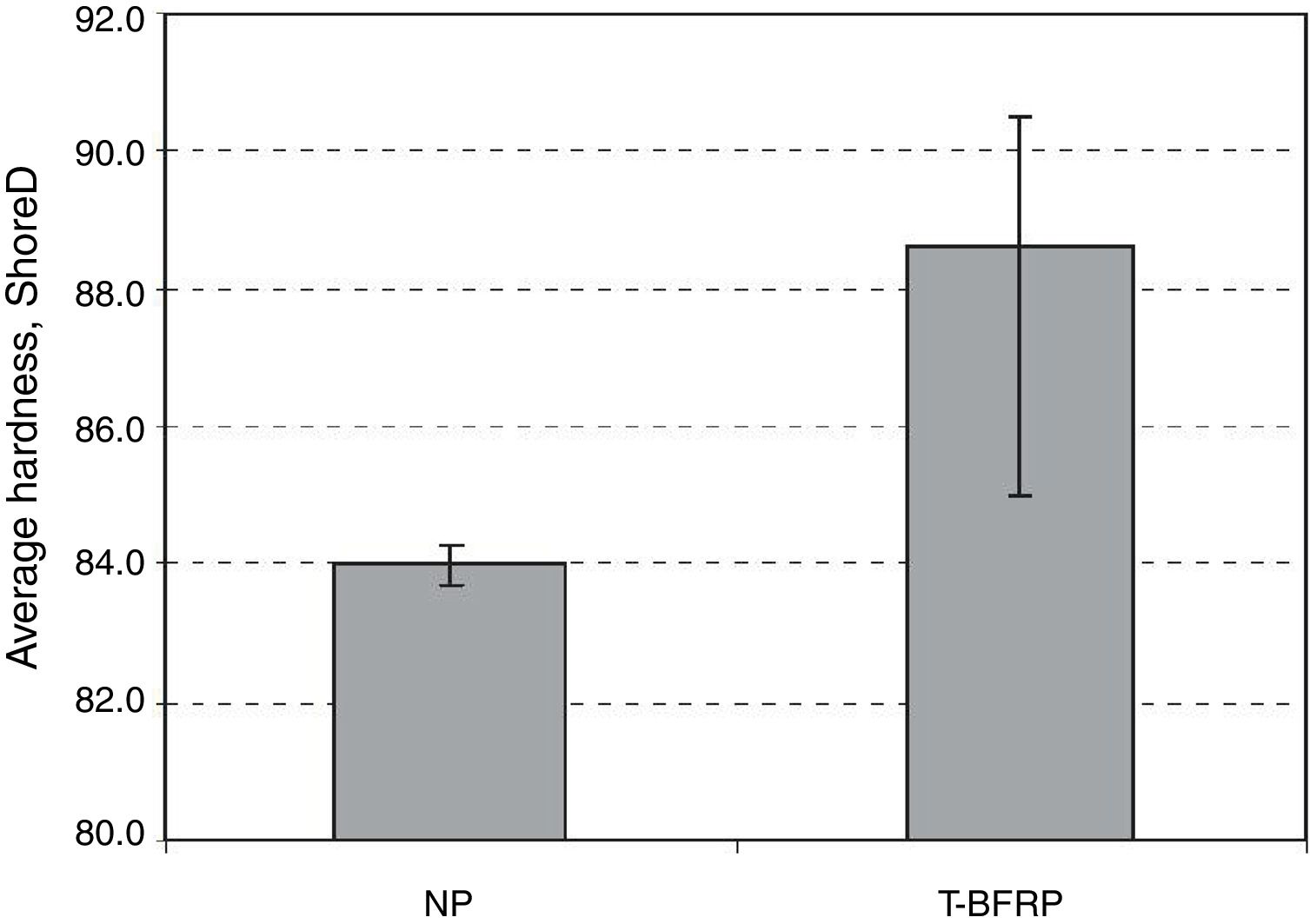

With a fiber to resin ratio of about 48%, by volume, used during composite fabrication for both betel nut and CSM glass fibers, the T-BFRP composite has a hardness of about 8.54% higher, compared to CSMGFRP (Fig. 14) [9]. 6% Enhancement in the hardness property of treated betel nut fiber reinforced polyester composites was observed with the neat polyester composites Fig. 15[10].

Hardness properties of T-BFRP and CSM-GFRP composites [9].

Hardness properties of NP and the T-BFRP composite [10].

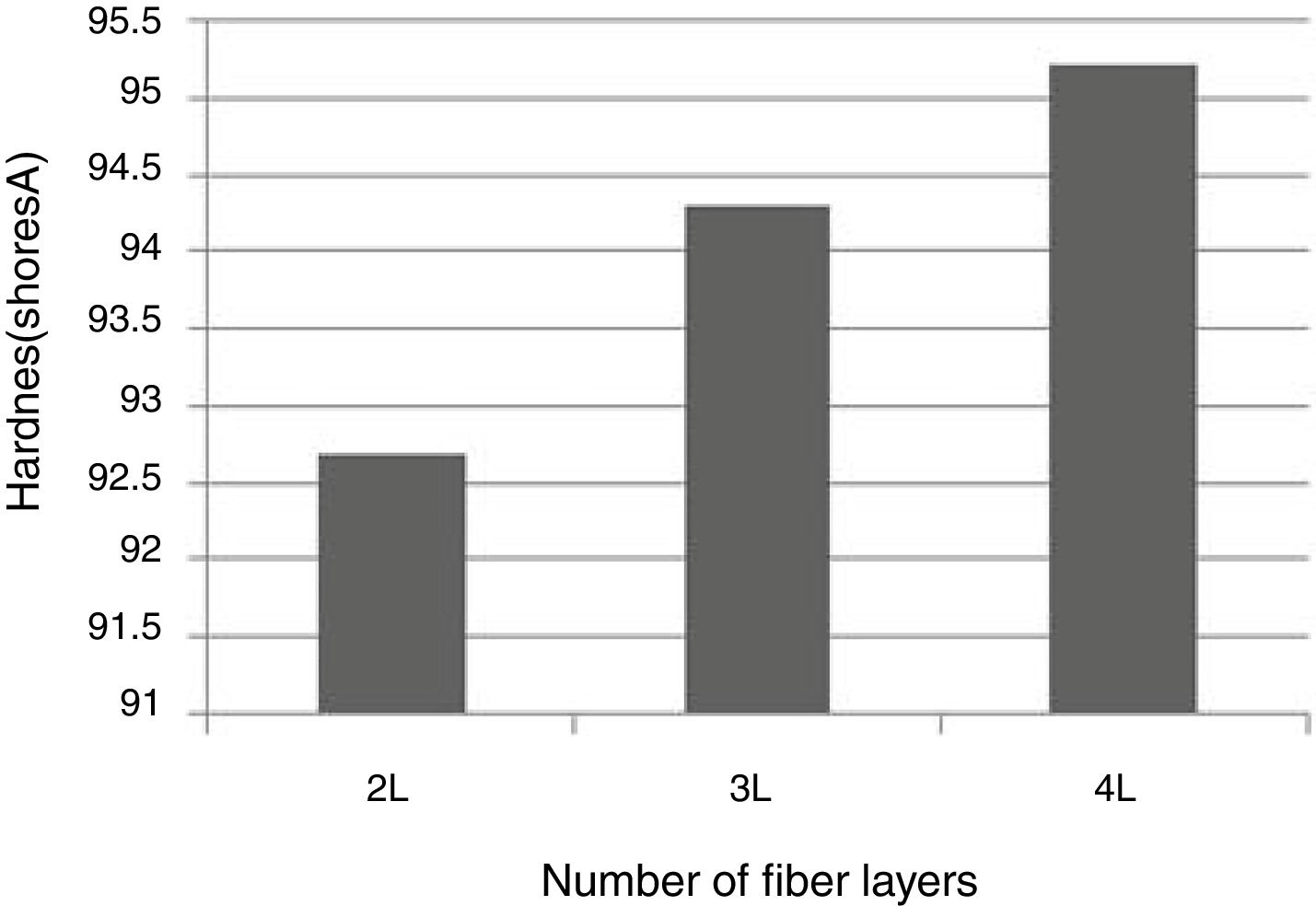

Hardness is enhanced when the flexibility of matrix is reduced. The presence of a rigid fiber material into the PP matrix results into more rigid composites. Due to the decrease of the flexibility of respective composite the hardness of areca waste nylon fiber reinforced hybrid PP composites showed a slightly increasing trend with an increase in the number of fiber layers [25], Fig. 16 shows the different hardness numbers for a different number of layers, and it is observed that hardness value is an increasing trend with the increase in the number of layers.

Variation of shore hardness with number of fiber layers [25].

In some of the studies adherness of the fibers with the matrix was observed with single betel nut/areca nut fibers. Fibers were examined with the fiber pull-out tests, and few results available in the literature are discussed below.

Interfacial shear strength (IFSS) of untreated and alkali treated unripe, ripe and matured BNH fibers were evaluated, and in the case of Untreated (UT) fiber, matured betel nut husk (BNH) fiber showed superior (1.57 ± 0.02) IFSS relative to unripe and ripe BNH fibers [19]. And also, single fiber tests were performed to determine the tensile properties of alkali treated BNH fibers. These tensile properties of alkali treated BNH fibers were compared with the untreated BNH fibers. It was observed that UT BNH fiber, matured BNH fiber shows higher Young’s modulus (2569.03 ± 637.3) than those of unripe and ripe BNH fiber. Ripe BNH fiber shows high tensile strength (166.03 ± 55.1) and a slightly lower Young’s modulus value than matured BNH fiber [19].

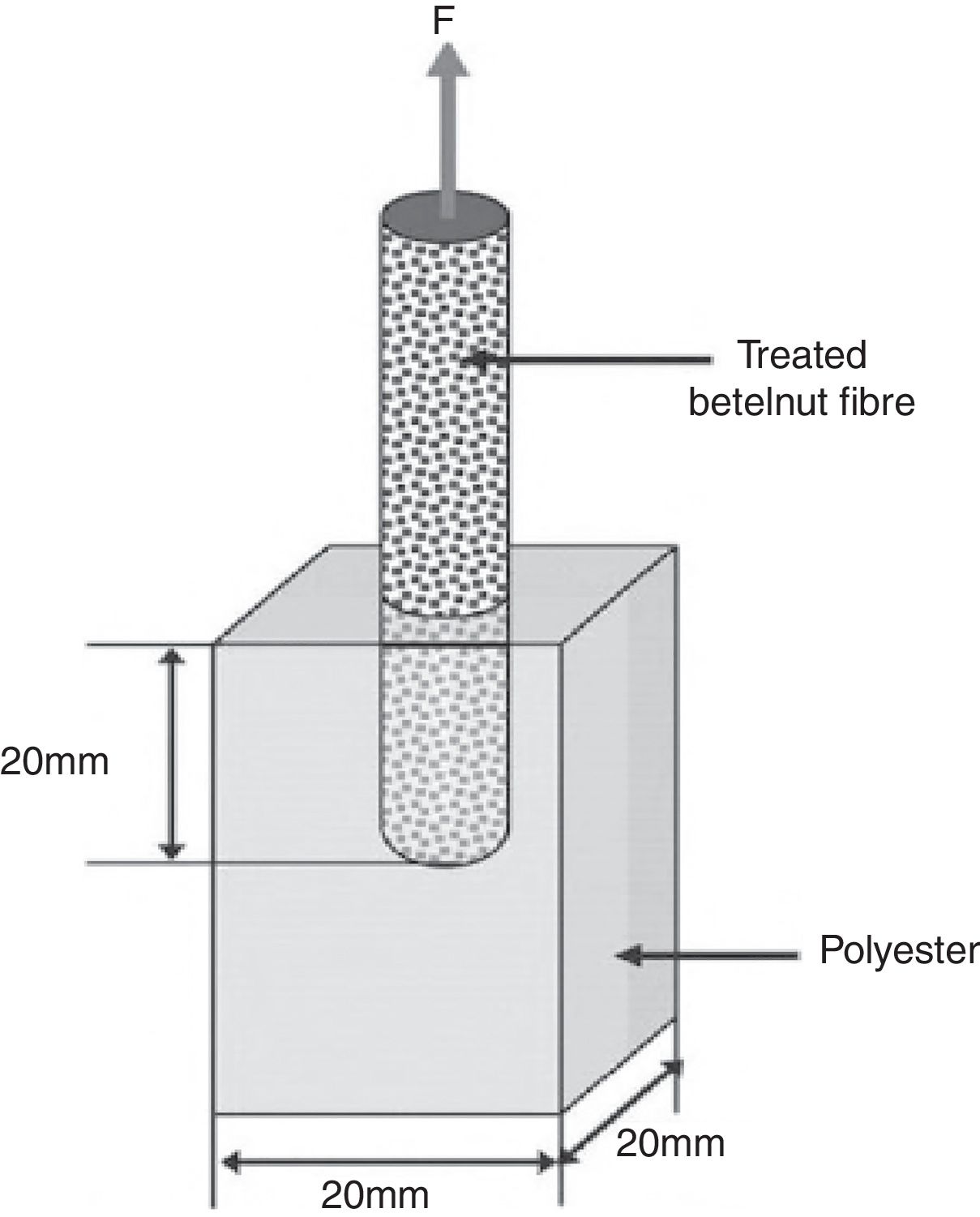

The betel nut fiber specimens were partially embedded into different thermosetting polymer matrix (polyester and epoxy) as reinforcement blocks. Single fiber pull-out tests were carried out for both the untreated (UT) and treated betel nut fibres with different resins and tested under dry conditions for betel nut fibres treated with 4% and 6% of HCl and NaOH respectively. The studies revealed the differences of interfacial adhesion strengths for the various test specimens of betel nut fibres treated with the polyester and epoxy matrix and also it was proven that fibres treated with 6% of NaOH exhibits excellent interfacial adhesion properties. The interfacial adhesion shear strength of these fibres using polyester and epoxy has improved by 141% and 115% correspondingly compared to untreated fiber under the same treatment [37].

Betel nut fiber were treated in water containing 6% NaOH solution and tested for single fiber pull-out test (SFPT) [38,39], fibers have shown ductile like behavior during the test where the maximum pull-out force was about 16 N at a fiber elongation of approximately 4 mm.

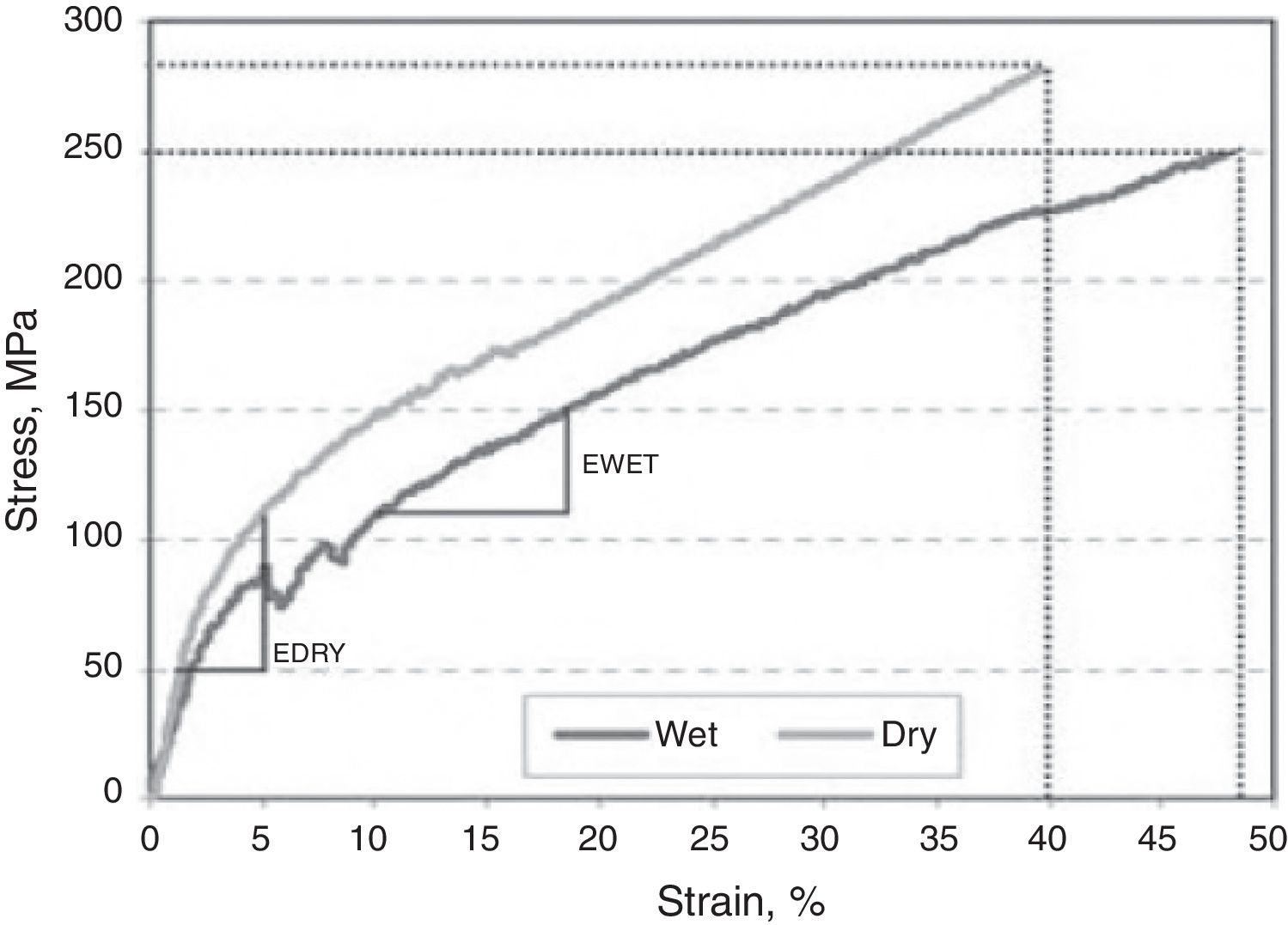

Artificial adhesion characteristics of treated betel nut fiber with polyester matrix was studied for single dry and wet fiber pull-out as shown in test Fig. 17[40], and the results obtained were nearly similar for both dry and wet fibers that is 280 MPa and 250 MPa respectively as shown in Fig. 18. It was concluded that there was no pull-out of fiber took place during the test [40].

Single betel nut fiber pull-out test [39].

Stress/strain curve for single betel nut fiber test [39].

Based on the above discussions, applications of naturally available, eco-friendly, renewable and reproducible, nontoxic, low cost, and easily available reinforcing material (areca/betel nut fibers) composites are summarizes that areca fiber as a good substitute for wood in indoor applications and following points have been listed which are available in literature.

- •

Increase in dielectric strength of betel nut (Bn) composites was noticed with increase in volume fraction of fiber in the composite. This is a very rare phenomenon which is not observed in many of the natural fiber composites. Hence, based on the availability, cheaper and good dielectric strength of Bn fiber composite can certainly be considered for electrical insulation applications [6]. And also, hybrid composites using Bn and Sansevieria cylindrica in EP, which may find diverse applications as structural mater [6].

- •

Based on the availability, cheaper and good strength of areca fiber composites, these are used in the fabrication of lightweight materials which find the applications in automobile body building, office furniture packaging industry, partition panels, and others compared to wood-based plywood or particle boards [8,27,31,32].

- •

Because of superiority results in wear of treated betel nut fiber reinforced polymer composites (T-BFRP) (98%) as compared to chopped strand mat glass fibre-reinforced polyester (CSM-GFRP). Under dry and wet conditions T-BFRP composite to be a potential candidate in some of the tribological applications [9].

- •

The betel nut polyester composite has similar mechanical properties to the glass-polyester composite hence betel nut fibers have a high potential to replace glass fibers for mechanical application. In addition, betel nut fibers have better support to the polyester matrix when compared with other types of natural fibers [10].

- •

For small load carrying applications studies have been made on alkali treated areca fibers composites and improved the mechanical properties to some extent in the areca fibers was observed [11].

- •

For the high tensile strength applications, chemically treated areca fiber reinforced natural rubber composites [12].

- •

High dimensional stability applications, low moisture, and water uptake properties of dried BNH fibers became merits for different uses and low-density property of raw BNH fiber has found the application in lightweight applications [13].

- •

Some of the studies have proven that areca fruit husk fibers as a potential reinforcement in polymer composites because of its moderate tensile strength properties, better strength and bonding properties with rough surface morphology in lightweight applications [14].

- •

Hybrid composites using betel nut and Sansevieria cylindrica in PP (polypropylene), which may find diverse applications as structural materials where strength and cost considerations are important [15].

- •

Areca fiber and maize powder reinforced PF composite materials can be used in packing industries, low-cost housing, and domestic purposes and can be used as a commutative material for plywood [16].

- •

A structural and non-structural application such as suitcases, post-boxes, grain storage, automobile interiors, partition boards and indoor applications untreated chopped natural areca sheath fiber reinforced polymer matrix bio-composites are best suited [17].

- •

For high flexural strength applications, chemically treated areca fiber reinforced epoxy composites [28] chemically treated areca fiber reinforced epoxy composites for applications where high impact strength is required [30] for all the three cases fiber loading considered was 60% fiber loading.

At present, the modern world is in search of new and advanced methods to develop new reinforcements for the regular usage. Cost effective synthetic fibers have got more attention of all researchers but the production of harmful chemicals after usage has led us to find few more naturally reversible polymers which will be extracted from agriculture wastes or from plants. Considering above words, reinforcement of natural fiber is the way to get modern materials for the replacement of artificial fiber composites. These fibers are renewable resources that can be grown and made within a short period of time and which are abundantly available with free of the cost compared with the synthetic fibers (like Glass, Carbon, Graphite Kevlar, Aramid fibers).

- •

Some of the studies have shown that use of areca nut fibers will give more efficient strength results with increasing fiber weight ratio up to a certain amount, which is bounded with the resin matrix and good adhesive strength. Further increment in fiber weight ratio has resulted in decreased tensile strength.

- •

At long last, it can be found that the primary shortcoming to anticipate the malleable properties of plant-based fiber composites by demonstrating was giving excessively idealistic esteems. Study on chemically treated and untreated areca fiber composites have been listed to know the behavior of fibers with different matrix materials and comparison of these test have shown that use of areca fiber is a good replacement compared to all other fibers to improve the tensile property of composites. The modeling has to be improved to allow improvements in the prediction of tensile properties of composites reinforced with both plant-based fibers.

- •

Flexural properties have been observed for different combinations with areca fiber composites, they have shown much improvement in bending load capacity with an increase in a number of fiber layer, chemical treatment, the addition of melamine and fiber content.

- •

Few of the studies have shown that affect the quality of all untreated and artificially treated areca fiber strengthened epoxy composites expanded with increment in fiber loading up to 60% and later it demonstrated a decrease. Among all the chemical treatments completed (with acrylic acid, benzoyl chloride, permanganate and alkali treatment), acrylic acid treated areca/epoxy composites of 60% fiber loading indicated greatest effect of energy absorbed by benzoyl chloride treatment, permanganate treatment and salt treatment with impact energy absorbed. And the areca fiber composites are also showing good impact strength properties with curing time. As the curing time increases (alkali-treated and acetylene treated) the impact strength will also increases.

- •

And the surface modification also results in the reduced moisture absorption as compared to the untreated areca fiber composites. The acetylene treated areca fiber composites are showing good results with moisture absorption compared with alkali treated fiber composite. When Acetylene treated fibers immersed in river water are showing maximum absorption of water when compared with the sea, bore well and pond water. Whereas alkali treated areca fiber composites are considered as the most moisture absorbing composites with bore well water. And the curing time also studied by some of the researchers and they have got a linear increase in moisture absorption and this will gradually increase with time of curing. It is observed that the amount of water in the areca fiber composite increases with time and later becomes saturated.

- •

Hardness was found to be increasing with the areca fiber diameter, percentage of fiber in different matrix materials, alkali treatment of areca fiber, and a number of layers of areca fiber composites.

- •

Single fiber pullout tests have shown that, there was proper bonding between the fiber and the matrix material, in the case of chemically treated fibers. And some of the studies showed that maturity and chemical treatment will also affect the interfacial bonding between the matrix materials.

The particular properties of the areca fiber composites were now and again superior to those of glass and other regular fiber composites. This proposes areca fiber composites can possibly replace man-made fibers and other natural fibers in many applications.

The first author would like to thank the Management and Principal of PES Institute of Technology and Management, Shivamogga, Karnataka, India for the kind encouragement and support provided. The second author would like to thank the Management and Principal Dr. P. Prakash of GM Institute of Technology, Davanagere, Karnataka, India for the kind encouragement and support provided. The third author would like to thank the Management and Principal of Alva’s Institute of Engineering and Technology, Moodabidri, Karnataka, India for the kind encouragement and support provided.

The authors are thankful to the Vision Group on Science & Technology, Department of IT, BT and Science & Technology, Government of Karnataka for financial support in the form of sanctioning a Research Project for the Proposal Titled: “Establishment of Green Engineering Research Center and Research on Bio-Based Sandwich Composite Structures”, to carry out the present investigation (Grant Ref. No: KSTePS/VGST/05/K-FIST/2015-16, Dt.:20.06.2016, GRD-No.: 486).

![Effect of fiber content and length on tensile strength [3]. Effect of fiber content and length on tensile strength [3].](https://static.elsevier.es/multimedia/26036363/0000003000000002/v3_201811290636/S2603636318300319/v3_201811290636/en/main.assets/thumbnail/gr1.jpeg?xkr=ue/ImdikoIMrsJoerZ+w96p5LBcBpyJTqfwgorxm+Ow=)

![Ultimate tensile strength of areca fibers reinforced epoxy composites [4]. Ultimate tensile strength of areca fibers reinforced epoxy composites [4].](https://static.elsevier.es/multimedia/26036363/0000003000000002/v3_201811290636/S2603636318300319/v3_201811290636/en/main.assets/thumbnail/gr2.jpeg?xkr=ue/ImdikoIMrsJoerZ+w96p5LBcBpyJTqfwgorxm+Ow=)

![Comparison of results [5]. Comparison of results [5].](https://static.elsevier.es/multimedia/26036363/0000003000000002/v3_201811290636/S2603636318300319/v3_201811290636/en/main.assets/thumbnail/gr3.jpeg?xkr=ue/ImdikoIMrsJoerZ+w96p5LBcBpyJTqfwgorxm+Ow=)

![Mechanical properties of T-BFRP and CSM-GFRP composites [9]. Mechanical properties of T-BFRP and CSM-GFRP composites [9].](https://static.elsevier.es/multimedia/26036363/0000003000000002/v3_201811290636/S2603636318300319/v3_201811290636/en/main.assets/thumbnail/gr4.jpeg?xkr=ue/ImdikoIMrsJoerZ+w96p5LBcBpyJTqfwgorxm+Ow=)

![Stress–strain curves of untreated and alkali treated unripe, ripe and matured BNH fibers [19]. Stress–strain curves of untreated and alkali treated unripe, ripe and matured BNH fibers [19].](https://static.elsevier.es/multimedia/26036363/0000003000000002/v3_201811290636/S2603636318300319/v3_201811290636/en/main.assets/thumbnail/gr5.jpeg?xkr=ue/ImdikoIMrsJoerZ+w96p5LBcBpyJTqfwgorxm+Ow=)

![Stress–strain curves of raw, ripe and matured BNH fibers [13,21]. Stress–strain curves of raw, ripe and matured BNH fibers [13,21].](https://static.elsevier.es/multimedia/26036363/0000003000000002/v3_201811290636/S2603636318300319/v3_201811290636/en/main.assets/thumbnail/gr6.jpeg?xkr=ue/ImdikoIMrsJoerZ+w96p5LBcBpyJTqfwgorxm+Ow=)

![Variation of tensile strength with fiber loading (weight fraction) [NaOH treated and untreated fibers] [8]. Variation of tensile strength with fiber loading (weight fraction) [NaOH treated and untreated fibers] [8].](https://static.elsevier.es/multimedia/26036363/0000003000000002/v3_201811290636/S2603636318300319/v3_201811290636/en/main.assets/thumbnail/gr7.jpeg?xkr=ue/ImdikoIMrsJoerZ+w96p5LBcBpyJTqfwgorxm+Ow=)

![Flexural strength of areca fibers reinforced epoxy composites [4]. Flexural strength of areca fibers reinforced epoxy composites [4].](https://static.elsevier.es/multimedia/26036363/0000003000000002/v3_201811290636/S2603636318300319/v3_201811290636/en/main.assets/thumbnail/gr8.jpeg?xkr=ue/ImdikoIMrsJoerZ+w96p5LBcBpyJTqfwgorxm+Ow=)

![Variation of flexural strength with fiber loading (weight fraction) [NaOH treated and untreated fibers] [8]. Variation of flexural strength with fiber loading (weight fraction) [NaOH treated and untreated fibers] [8].](https://static.elsevier.es/multimedia/26036363/0000003000000002/v3_201811290636/S2603636318300319/v3_201811290636/en/main.assets/thumbnail/gr9.jpeg?xkr=ue/ImdikoIMrsJoerZ+w96p5LBcBpyJTqfwgorxm+Ow=)

![Impact strength of areca fibers reinforced epoxy composites [4]. Impact strength of areca fibers reinforced epoxy composites [4].](https://static.elsevier.es/multimedia/26036363/0000003000000002/v3_201811290636/S2603636318300319/v3_201811290636/en/main.assets/thumbnail/gr10.jpeg?xkr=ue/ImdikoIMrsJoerZ+w96p5LBcBpyJTqfwgorxm+Ow=)

![Impact energy absorbed by areca fiber reinforced epoxy composites with different loadings [30]. Impact energy absorbed by areca fiber reinforced epoxy composites with different loadings [30].](https://static.elsevier.es/multimedia/26036363/0000003000000002/v3_201811290636/S2603636318300319/v3_201811290636/en/main.assets/thumbnail/gr11.jpeg?xkr=ue/ImdikoIMrsJoerZ+w96p5LBcBpyJTqfwgorxm+Ow=)

![Effect of alkali-treatment on water absorption of areca fiber [35]. Effect of alkali-treatment on water absorption of areca fiber [35].](https://static.elsevier.es/multimedia/26036363/0000003000000002/v3_201811290636/S2603636318300319/v3_201811290636/en/main.assets/thumbnail/gr12.jpeg?xkr=ue/ImdikoIMrsJoerZ+w96p5LBcBpyJTqfwgorxm+Ow=)

![Water absorption of composites for various types of water [36]. Water absorption of composites for various types of water [36].](https://static.elsevier.es/multimedia/26036363/0000003000000002/v3_201811290636/S2603636318300319/v3_201811290636/en/main.assets/thumbnail/gr13.jpeg?xkr=ue/ImdikoIMrsJoerZ+w96p5LBcBpyJTqfwgorxm+Ow=)

![Hardness properties of T-BFRP and CSM-GFRP composites [9]. Hardness properties of T-BFRP and CSM-GFRP composites [9].](https://static.elsevier.es/multimedia/26036363/0000003000000002/v3_201811290636/S2603636318300319/v3_201811290636/en/main.assets/thumbnail/gr14.jpeg?xkr=ue/ImdikoIMrsJoerZ+w96p5LBcBpyJTqfwgorxm+Ow=)

![Hardness properties of NP and the T-BFRP composite [10]. Hardness properties of NP and the T-BFRP composite [10].](https://static.elsevier.es/multimedia/26036363/0000003000000002/v3_201811290636/S2603636318300319/v3_201811290636/en/main.assets/thumbnail/gr15.jpeg?xkr=ue/ImdikoIMrsJoerZ+w96p5LBcBpyJTqfwgorxm+Ow=)

![Variation of shore hardness with number of fiber layers [25]. Variation of shore hardness with number of fiber layers [25].](https://static.elsevier.es/multimedia/26036363/0000003000000002/v3_201811290636/S2603636318300319/v3_201811290636/en/main.assets/thumbnail/gr16.jpeg?xkr=ue/ImdikoIMrsJoerZ+w96p5LBcBpyJTqfwgorxm+Ow=)

![Single betel nut fiber pull-out test [39]. Single betel nut fiber pull-out test [39].](https://static.elsevier.es/multimedia/26036363/0000003000000002/v3_201811290636/S2603636318300319/v3_201811290636/en/main.assets/thumbnail/gr17.jpeg?xkr=ue/ImdikoIMrsJoerZ+w96p5LBcBpyJTqfwgorxm+Ow=)

![Stress/strain curve for single betel nut fiber test [39]. Stress/strain curve for single betel nut fiber test [39].](https://static.elsevier.es/multimedia/26036363/0000003000000002/v3_201811290636/S2603636318300319/v3_201811290636/en/main.assets/thumbnail/gr18.jpeg?xkr=ue/ImdikoIMrsJoerZ+w96p5LBcBpyJTqfwgorxm+Ow=)