Ceramic findings from “Grotta deiCocci” and dating back to the Early Neolithic were studied. The ceramic samples have been characterized by a combined use of Optical Microscopy (OM), X-ray Powder Diffraction (XRPD) and Scanning Electron Microscopy (SEM-EDAX) to define the mineralogical assemblage, to estimate firing conditions and to provide information on raw materials used for the production. The results show that the main mineral inclusions are quartz, flint and carbonate rocks and minor amount of biotite, calcite, feldspar and pyroxene; in addiction, fragments of magmatic rocks have been identified.

The optical active matrix and the presence of mineral inclusions of primary calcite allow the estimation of the maximum firing temperature in the range 750–850°C under uncontrolled atmosphere conditions. Finally, a local origin of raw materials is supported by the presence of sedimentary and magmatic rocks that outcrop close to the archaeological site.

Prehistory is defined as the period of human history before the birth of writing in the 4th millennium BC. The absence of writing documents and sources made the study of the archaeological materials produced during this period the most diffuse way to reconstruct the life, habits and traditions of the ancient civilizations [1–5]. Preserved and closed archaeological contexts can be particularly useful delivering to the present a picture of a specific past moment.

The “Grotta dei Cocci” (Terni, Italy), literally “The cave of sherds”, is an important example in which ancient materials became fundamental to reconstruct the past occupation of Neolithic communities. Indeed, the entrance opens about 70m above the current river level, and the possibility to reach it only with ropes, helped in the conservation and preservation of this exceptional archaeological context.

However, the re-use of the same site by populations during the Bronze Age has partially altered the features referable to more ancient attendances causing in some cave areas a mix of Neolithic materials with those of the Bronze Age [6]. The main problem is represented by numerous lootings, having taken place starting from the discovery in the 1950s which have only partially affected the stratigraphy and preserving most of the Neolithic structures. Despite all these interferences, the “Grotta dei Cocci” can still be considered a closed context allowing therefore, archaeological speculations about related positions of artefacts discovered and ritual behaviours or habits.

The Bronze Age layers brought to light elements, displaced in the ground without apparent organization; on the contrary, the structures referable to the Neolithic layers show a very different complexity. Arranged on different levels, ceramic materials are associated with faunistic and floristic remains, with disarticulated human bones, lithic and bone industries. Most of the objects were aggregated and the analysis of the location of each object seems to suggest a specific choice in the deposition of each single element [7,8]. The presence of disarticulated human bones could be attributed to the cult or rituals of the dead; however, the identification and definition of the ritual or cult carried out in the “Grotta dei Cocci” is still under study. The considerable importance of this place underlined the need of archaeometric characterizations of ceramic materials, useful for the archaeologists to reconstruct the story of this cave.

At the moment the archaeometric investigations are one of the tools at disposition to reconstruct an overall picture about ancient societies. Indeed, the series of conscious choices made by the potter (chaîne opératoire) reflect the material and technological knowledge of specific traditions. Consequently, the aim of this work is to characterize from the mineralogical, petrographic and chemical point of view the ceramic sherds discovered in the “Grotta deiCocci” with the aim to achieve information about the technological knowledge and the sources of the raw material supplied. The multi-analytical approach by means of Optical Microscopy (OM), X-ray Powder Diffraction (XRPD) and Scanning Electron Microscopy with X-ray microanalysis (SEM-EDS) was chosen to obtain combining information useful for our aims [9–14]. All the aspects of ceramic production that could be related to intentional choices made by the potter (i.e., firing conditions, selection of raw materials, modelling, tempering and provenance) were considered and discussed in detail.

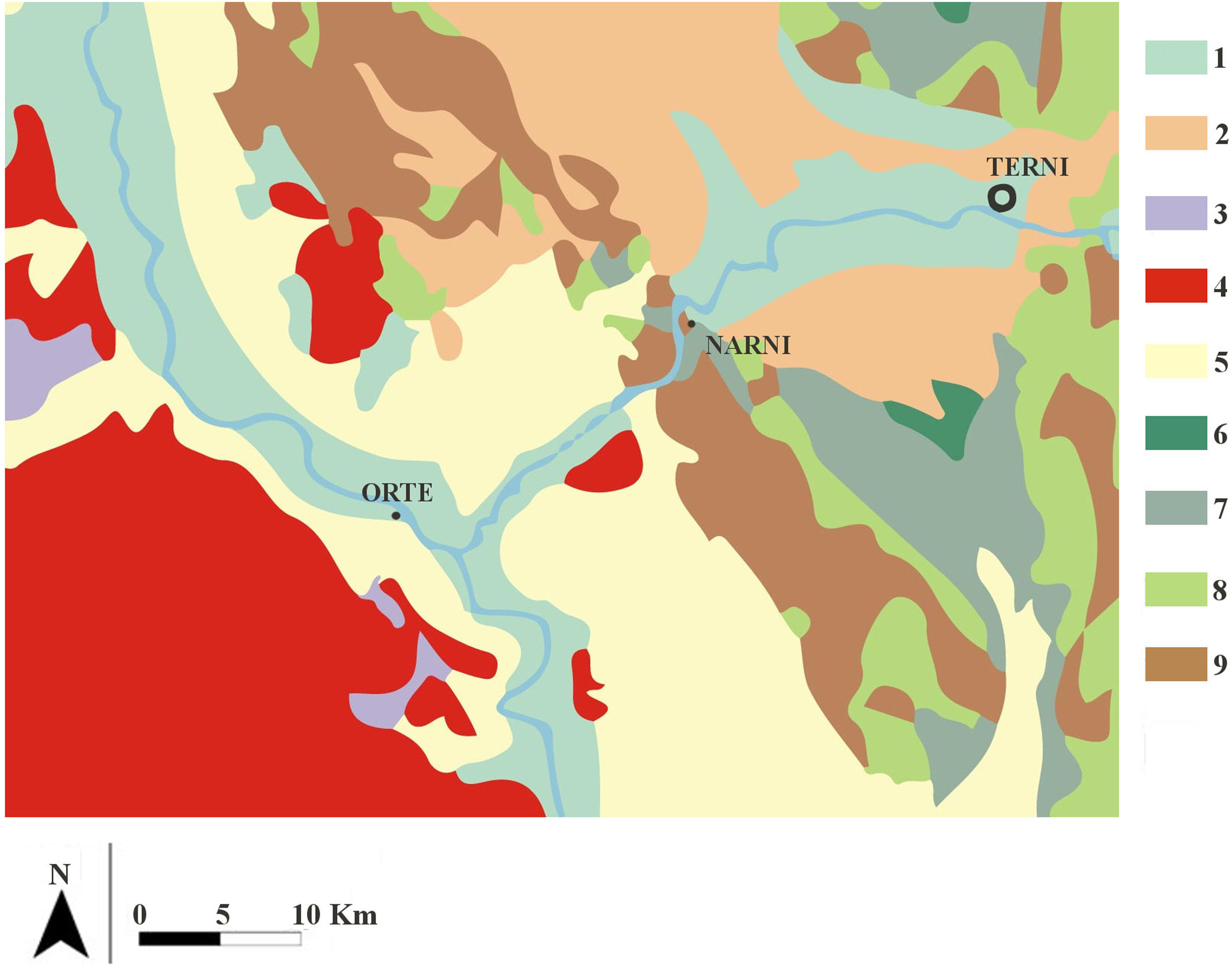

Geological settingThe “Grotta dei Cocci” site is located in the Umbria region (central part of Italy) on the right bank of the Nera River, in front of the ancient city of Narni. The geological setting of this area is complex (Fig. 1); however, it is possible to summarize it as follows. The close area is mainly characterized by the Pleistocene volcanic products (such as ignimbrites) from the Cimino Volcanic District, and the Vicano Volcanic District. However, the outcrops at the proximity of the archaeological site are mainly represented by Triassic deposits of massive limestone, terrestrial marine deposits of the Pliocene and Pleistocene, and Quaternary alluvial deposits. In addition, close to the Nera banks, Pleistocene volcanic unit, limestone deposits (Calcari Diaspini) from the Middle Liassic to the Early Cretaceous and marl deposits from the Early Cretaceous and to the Early Miocene are also present [15]. Near Orte the succession at 66m depth shows gravely alluvial deposits (35m thick) of the second order terrace of the Tiber River, followed by 15m of late Pliocene – early Pleistocene claystones directly on the limestones of the Early Liassic Calcare massiccio Formation of the Umbria-Marche Succession. Near Narni, the Umbria-Marche Succession consists of Pleistocene sandy – gravely marine deposits (45m thick) on the Late Triassic Rhaetavicula contorta Formation [15].

Geological map of the surroundings of the archaeological site. Geological map of the study area in central Italy. (1 alluvial deposits (Quaternary); 2 alluvial and lacustrine sediments (Quaternary); 3 travertines (Holocene); 4 volcanic units of the Vulsini Mountains, Cimini Mountains and Vicano districts (Pleistocene); 5 terrigenous marine deposits (Pliocene – Pleistocene); 6 Schlier (Middle Miocene); 7 Bisciaro, Scaglia and Marne a Fucoidi (Early Cretaceous – Early Miocene); 8 Maiolica, Calcari diasprini and Rosso Ammonitico (Middle Liassic – Early Cretaceous); 9 Calcare Massiccio, Rhaetavicula contorta Formation and Anidriti di Burano Formation (Late Triassic – Early Liassic) (modified from [15]).

In the 1950s Carlo Castellani from Narni for the first time reported the presence of the “Grotta dei Cocci”, but only since 1989 archaeological excavations have taken place under the direction of the Soprintendenza Archeologica dell’Umbria[6,16]. Stratigraphic records allow the reconstruction of two important phases of human occupation: the older during the half of the 6th millennium and the more recent referred to the Ancient and Middle Bronze Age [6]. In the phase of Neolithic age ceramic materials, faunal and floristic remains were recovered, whereas the layers dated in the Bronze Age brought to light only ceramic remains [17].

The archaeological site is mainly composed of small rooms in a cave. After a short and low burrow, an almost triangular large room (Fig. 2a) is opened where collapsing boulders hide another long and low burrow. On the left side of the main hall, some smaller areas are opened. The central room was the area in which the archaeological excavations took place (Fig. 2b).

“Grotta dei Cocci”: (a) map of the Cave; (b) map of the excavated area (modified from [16]).

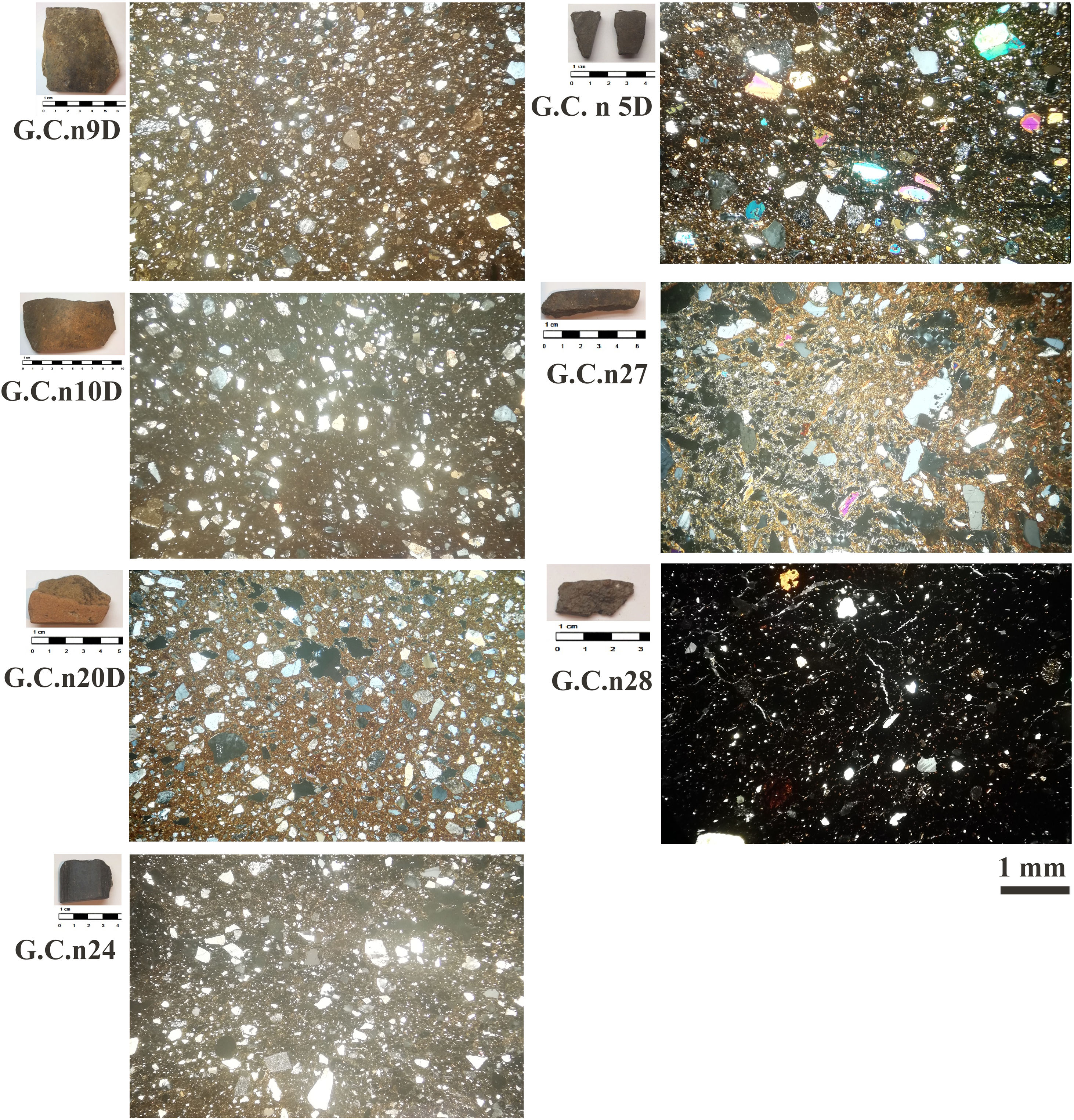

Ceramic samples recovered in the “Grotta dei Cocci”, dating back to the ancient Neolithic, were analysed. The samples are selected by the archaeologists considering functional classifications, contextual stratigraphic origin and macroscopic features to be representative of the materials found in that exceptional archaeological context (Fig. 3). The samples are analysed by OM, XRPD and SEM-EDS to define the minero-petrographic and chemical composition of sherds.

Thin sections were prepared, cutting the piece parallel to the lip, at the “Thin section Laboratory” of Department of Earth Science of Sapienza University of Rome and then analysed by a Zeiss D-7082 Oberkochen polarized optical microscope. Petrographic analysis was performed according to Whitbread's criteria [18] paying particular attention to the nature of matrix, shape and nature of inclusions and the occurrence of particular microscopic features useful to define the technological processes behind the ceramic production.

Part of the material recovered during the cutting for the thin section preparation has been finely grounded in an agate mortar and then analysed by a Siemens D500 diffractometer (Department of Earth Sciences, Sapienza University, Rome, Italy). It used a CuKα radiation at operating conditions of 40kV and 30mA, in the range of 3–60° 2θ, at a speed of 1°/min and 2s/step, 1° diverging slide, slide receiver of 0.1mm and sled antiscatter of 2°. The data were processed using XPowder 12 and by comparison with standards of the American Mineralogist Crystal Structure Database.

Finally, the thin sections were analysed by SEM-EDS after metallization by graphite. A FEI Quanta 400 (Department of Earth Sciences, Sapienza University, Rome, Italy) instrument equipped with the unit of X-ray microanalysis Genesis was used to define in detail the microstructure and the chemical composition of both ceramic body and inclusions.

ResultsPetrographic analysisPetrographic analysis highlights common features among the analysed samples (Table 1, Fig. 3): the matrix is not calcareous with a high amount of plastic clay pallets, showing a brown-reddish heterogeneous colour, and optically active. The percentage of inclusions is variable with both equant and elongated shape, from angular to rounded following a unimodal grain size distribution, from poorly to moderately sorted, without any alignment. The low porosity is mainly represented by vesicles and vughs not aligned to the margin of the vessel.

Microscopic features of ceramic samples from the “Grotta dei Cocci”.

| Sample | Matrix | Voids | Inclusions |

|---|---|---|---|

| G.C. n 9D | 65%Brown-reddishHeterogeneous non calcareousOptically active | 10%Vesicles and vughs from macro to microNot aligned | 25%Equant/elongatedAngular/sub-roundedSingle spacedUnimodalModerately sortedDominant: quartz (equant/elongated, sub-rounded/angular, 0.02–0.8mm)Common: flint (equant, sub-angular, 0.3–0.7mm);calcite (equant, sub-angular, 0.1–0.8mm);fragments of calcareous rocks (equant/elongated, sub-rounded/sub-angular, 0.3–1.1mm);plagioclase (equant, sub.angular/sub-rounded, 0.02–0.7mm);Few: mica (elongated, angular, 0.03mm);Clay pallets (equant, rounded/sub-rounded, 0.5–1.2mm)Nodules of iron oxides (equant, elongated, sub-angular/sub-rounded, 0.1–0.5mm);Fossils (equant, rounded, 0.1–0.2mm) |

| G.C. n 10D | 60%Brown-reddishHeterogeneous non calcareousOptically active | 5–10%Vesicles and vughs from micro to macroNot aligned | 25%Equant/elongatedAngular/roundedClosed-Single spacedUnimodalModerately sortedDominant: quartz (equant/elongated, sub-rounded/angular, 0.02–0.6mm)Frequent: flint (equant, sub-rounded/sub-angular, 0.1–0.7mm);Common: plagioclase (equant, sub-angular/sub-rounded,<0.6mm);Few: K-feldspar (equant, sub-rounded, 0.2mm);Rare: fragments of calcareous rocks (equant, rounded, 0.4–1.1mm);fragments of volcanic rocks (elongated, sub-angular,<0.8mm);nodules of iron oxides (equant, sub-rounded/rounded, 0.3mm)Very rare: ortopyroxene (equant, rounded/sub-rounded, 0.2–1.1mm)Calcite (equant, sub-rounded/angular, <0.4mm) |

| G.C. n 20D | 75%Brown-reddishHeterogeneous non calcareousOptically active | 10%Micro-vesicles and macro-vughsNot aligned | 15%Equant/elongatedSub-angular/sub-roundedClosed-double spacedUnimodalModerately sortedFrequent: quartz (equant, sub-angular/sub-rounded, 0.1–0.7mm)Common: flint (equant, sub-rounded, 0.1–0.7mm);plagioclase (equant, sub-angular/sub-rounded, <0.4mm);nodules of iron oxides (equant, sub-rounded/rounded, 0.3–0.5mm);fragments of calcareous rocks (equant, sub-rounded/rounded, 0.8–1.5mm);K-feldspar (equant, sub-angular, 0.1–0.8mm);Few: fragments of volcanic rocks (equant, sub-angular/sub-rounded, 0.2–0.6mm) |

| G.C. n 24 | 65%Brown-reddish (black core)Heterogeneous non calcareousOptically active | 20%Vesicles, vughs, channels from macro to microNot aligned | 15%Equant/elongatedSub-angular/sub-roundedClosed-single spacedUnimodalModerately sortedFrequent: quartz (equant, sub-angular, 0.4–1.1mm); plagioclase (equant/elongated, sub-angular/sub-rounded, 0.4mm);Common: clay pallet (equant, sub-rounded, 0.5mm);Fragments of volcanic rocks (eqaunt, sub-angular, 0.7mm);Very rare: K-feldspars (equant, sub-angular, 0.3mm);Biotite (elongated, sub-angular, 0.1mm) |

| G.C. n 5D | 80%Brown-reddishHeterogeneous non calcareousOptically active | 5%Vesicles and vughs from meso to microNot aligned | 15%Equant/elongatedAngular/sub-roundedSingle-double spacedUnimodalPoorly sortedFrequent: clinopyroxene, equant, sub-rounded/angular, 0.04–0.7mm);Common: quartz (equant, sub-rounded/angular, 0.2–1.3mm);Few: fragments of volcanic rocks (equant, sub-angular/sub-rounded, <0.8mm);clay pallets: (equant, sub-rounded, 0.2–0.7mm);Very few: biotite (elongate, angular, 0.2–0.7mm);K-feldspar (equant, sub-angular, <0.5mm);Flint (equant, sub-rounded, 0.2–0.9mm);Nodules of iron oxides (equant, rounded, 0.1–0.4mm). |

| G.C. n 27 | 70%Brown-reddish to yellowHeterogeneous non calcareousOptically active | 5%Vesicles and vughs from micro to macroNot aligned | 25%Equant/elongatedSub-angular/sub-roundedClosed-single spacedUnimodalModerately sortedFrequent: K-feldspars (equant/elongated, sub-angular/sub-rounded, 0.1–1.2mm);biotite (elongated, sub-angular/angular, 0.3–1.2mm)Common: plagioclase (equant, sub-angular/sub-rounded, 0.1–0.7mm)Few: clinopyroxene (equant, sub-rounded/rounded, 0.2–0.9mm)Very few: nodules of iron oxides (equant, sub-rounded/rounded, 0.1–0.3mm) |

| G.C. n 28 | 75%Brown-reddish to yellow (black core)Heterogeneous non calcareousOptically active | 20%Vesicles, vughs and channels from micro to macro | 10%Equant/elongatedSub-angular/sub-roundedopen-single spacedUnimodalModerately sortedDominant: K-feldspars (equant, sub-angular/sub-rounded, 0.4–1.2mm);Flint (equant, sub-angular/sub-rounded, 0.3–1.4mm)Common: clinopyroxene (equant, rounded/sub-rounded, 0.2–0.4mm);Quartz (equant, sub-angular, sub-rounded, 0.5–0.8mm);Fragments of volcanic rocks (equant, angular/sub-angular, 0.5–1.4mm)Few: nodules of iron oxides (equant, rounded, <0.3mm) |

The mineralogical composition of samples G.C. n 9D, G.C. n 10D, G.C. n 20D and G.C. n 24 are mainly characterized by the presence of quartz with a uniform grain size, common feldspars and minor diffuse flint, fragments of volcanic and calcareous rock, pyroxene and biotite. On the other hand, sample G.C. n 5D shows clinopyroxene as dominant inclusion, common quartz, few fragments of volcanic rocks biotite and feldspars. The abundant presence of micas and feldspars with different grain size are the typical features of samples G.C. n 27, whereas sample G.C. n 28 shows a very low percentage of inclusions, diffuse feldspars and carbonate rock fragments.

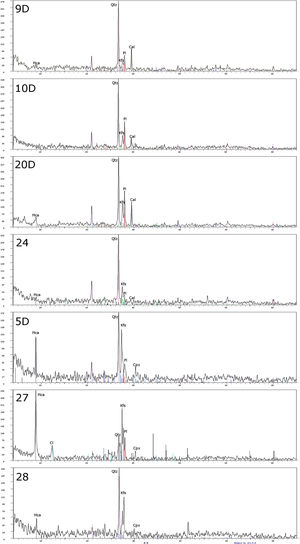

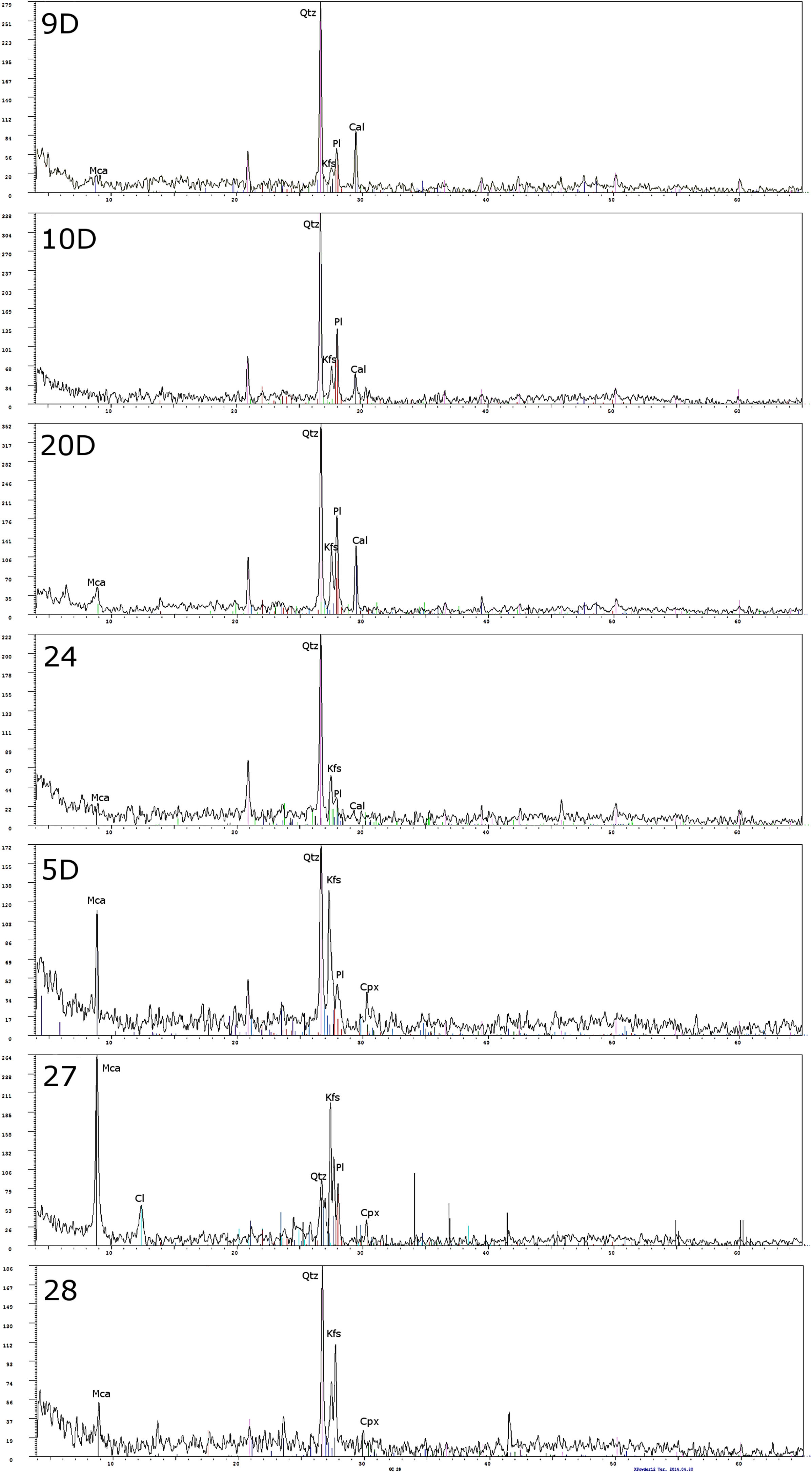

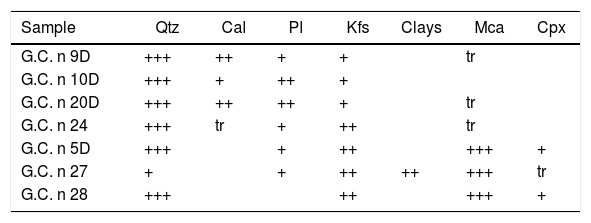

XRPD analysisThe mineralogical assemblages obtained by XRPD analysis are summarized in Table 2 and shown in Fig. 4.

Mineralogical composition by XRPD analysis of the sherds from “Grotta dei Cocci”.

| Sample | Qtz | Cal | Pl | Kfs | Clays | Mca | Cpx |

|---|---|---|---|---|---|---|---|

| G.C. n 9D | +++ | ++ | + | + | tr | ||

| G.C. n 10D | +++ | + | ++ | + | |||

| G.C. n 20D | +++ | ++ | ++ | + | tr | ||

| G.C. n 24 | +++ | tr | + | ++ | tr | ||

| G.C. n 5D | +++ | + | ++ | +++ | + | ||

| G.C. n 27 | + | + | ++ | ++ | +++ | tr | |

| G.C. n 28 | +++ | ++ | +++ | + |

Qtz: quartz; Cal: calcite; Pl: plagioclase; Kfs: K-feldspars, clays: kaolinite; Mca: mica; Cpx: clinopyroxene. +++=dominant, ++=present, +=scarce, tr=traces.

The results confirm the OM results, allowing the identification of the association quartz±calcite±plagioclase±K-feldspar±rare mica for samples G.C. n 9D, G.C. n 10D, G.C. n 20D and G.C. n 24. Sample G.C. n 5D instead is characterized by predominant quartz and micas with minor amounts of K-feldspar, plagioclase and clinopyroxene. High amounts of micas is also identified in samples G.C. n 27 and sample G.C. n 28; in addition, the first shows diffuse clay minerals and K-feldspars, with scarce quartz and plagioclase, whereas the second one is mainly composed of quartz, K-feldspars, and scarce clinopyroxene.

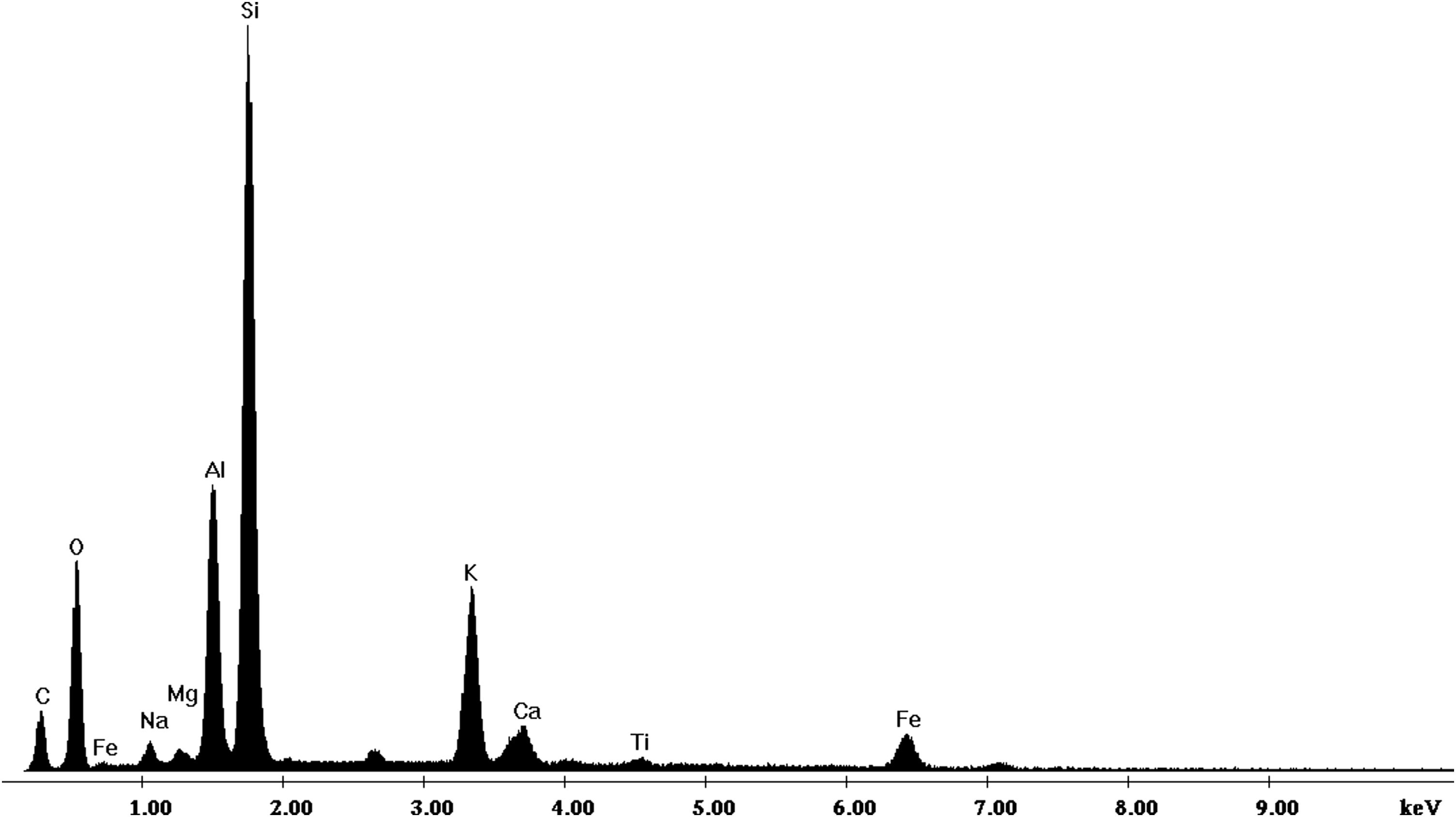

SEM-EDS analysisThe chemical composition of inclusions and matrix is analysed in detail by SEM-EDS to identify helpful mineralogical phases to reconstruct the provenance of the starting raw materials.

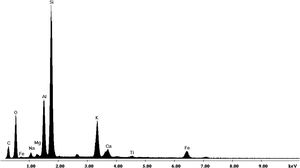

The non-calcareous nature of the matrix observed by OM is confirmed by EDS spectra collected at different points in the matrix. Fig. 5 shows a representative EDS spectrum and semi-quantitative analysis of the matrix with high amounts of Si, Al and K, minor of Na, Ti and Fe and traces of Mg and Ca. In addition, point to point analyses from rim to core are performed to evaluate possible differences in the chemical compositions of matrix. The spectra and the semi-quantitative analysis show a variation in composition from the core to the margin in Fe (3.95–6.23wt%), Ca (2.11–3.29wt%) and K (8.52–3.55wt%), however the variation cannot be considered significant. In addition, the micromorphological analysis performed by means of backscattered electron images (BSE) highlights the absence of any vitreous phases.

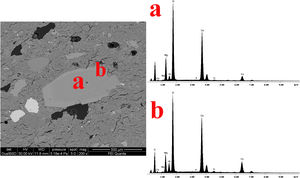

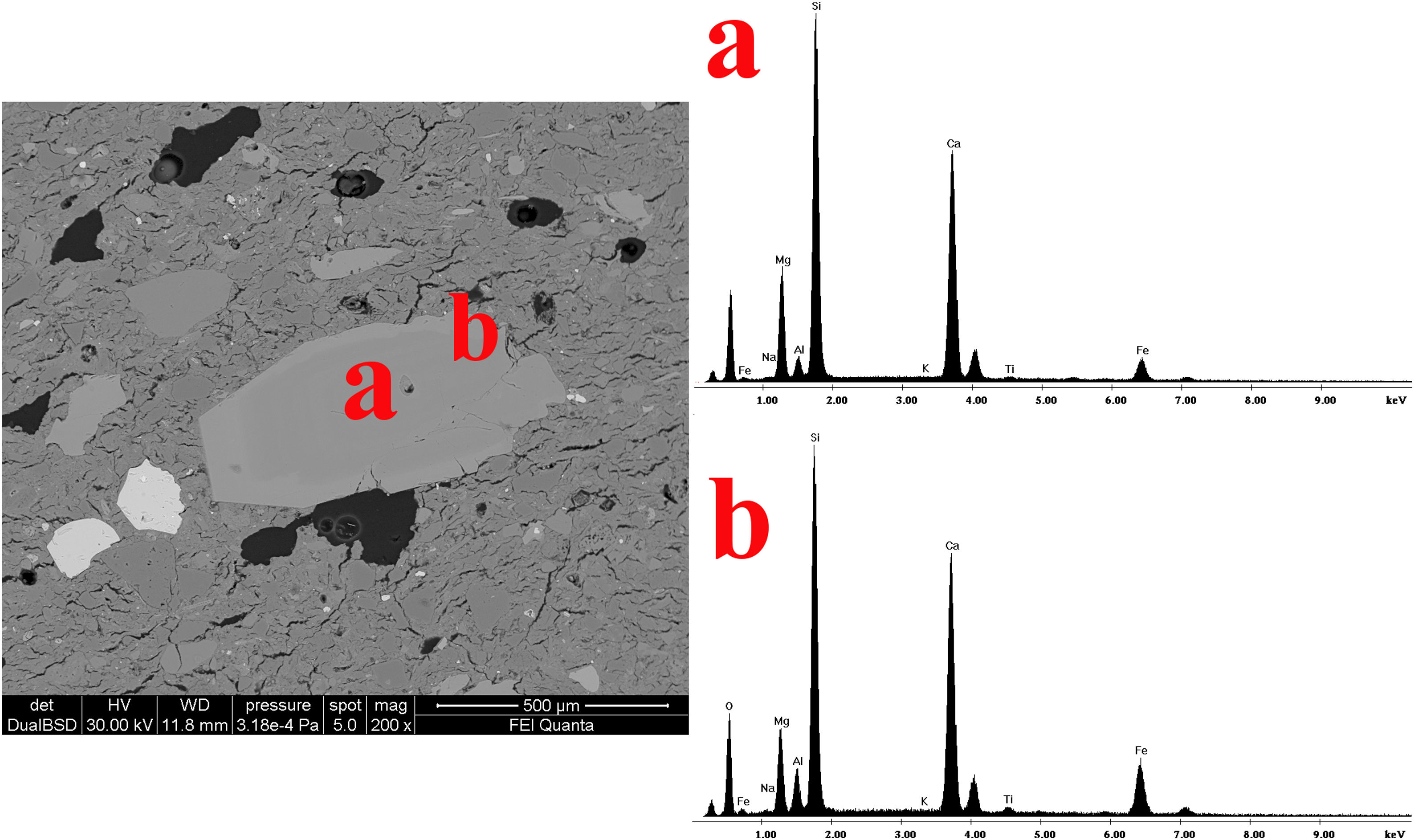

Concerning the inclusions, pyroxenes could be considered a marker inclusion for the reconstruction of the provenance, therefore a detailed chemical characterization has been performed. The BSE image in Fig. 6 shows a zoned diopside whose composition varies from the core to the rim. Particularly, semi-quantitative analysis highlights a variation of Mg from 16.57 to 12.30wt%, of Fe from 4.35 to 9.54wt% and of Al from 3.03 to 5.83wt%.

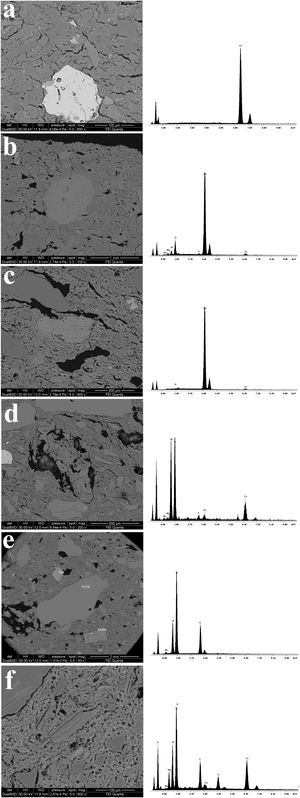

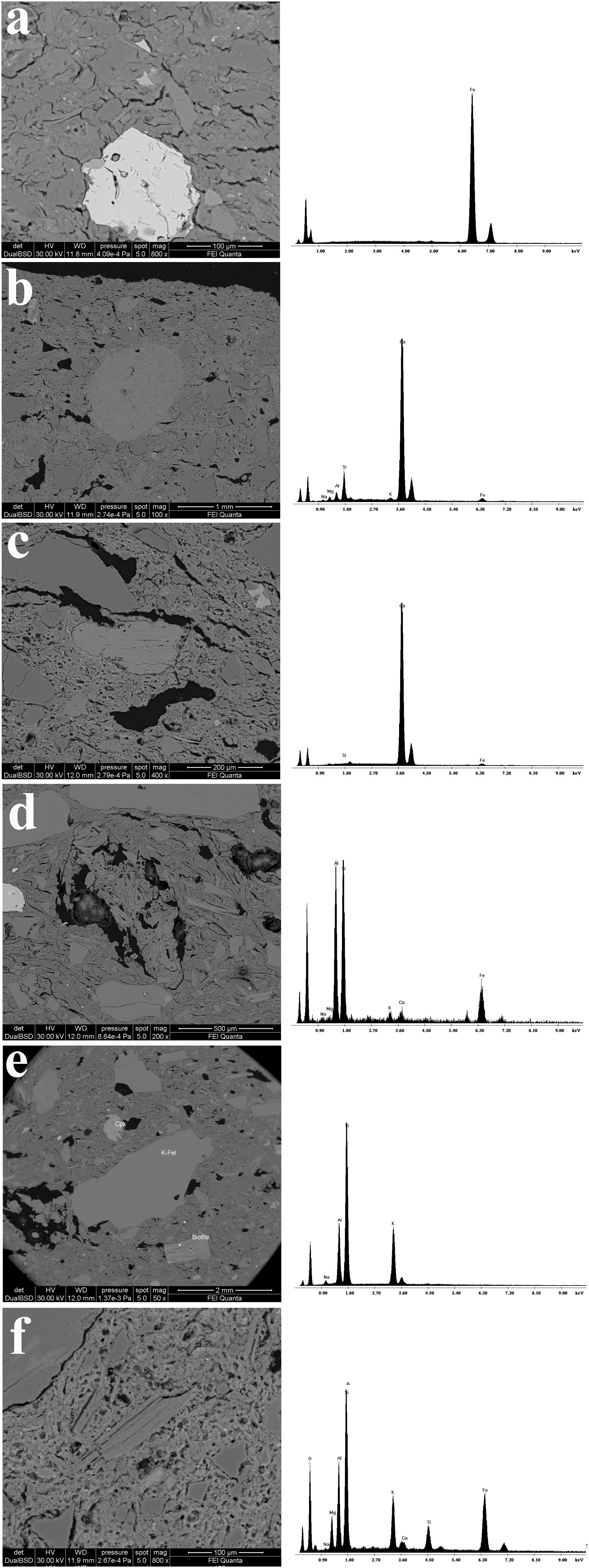

In addition, other inclusions are analysed, further supporting the OM results: nodules of iron oxides (Fig. 7a), fragments of calcareous rock (Fig. 7b), crystal of calcite (Fig. 7c), clay pallet (Fig. 7d), sanidine (Fig. 7e) and biotite (Fig. 7f).

DiscussionsProduction processThe combined application of OM, XRPD and SEM-EDS gives important details about the technological and material knowledge that produced the ceramics discovered in the “Grotta dei Cocci”, which combined with the results of previous analysis [19] can help archaeologists in the reconstruction of the ceramic role in this cave.

Concerning samples G.C. n 9D, G.C. n 10D, G.C. n 20D and G.C. n 24, the combined results suggest that the starting raw material consisted in a kaolinitic clay with quartz and feldspars, fragments of flint, and fragments of sedimentary rock. The material underwent a selection process before the production with the aim to remove the coarser fraction as suggested by the absence of coarse inclusions. An intentional selection of the material is usually referred to high quality ceramic, connected to a particular end use and that would suggest the importance of the context [20,21]. After this selection the paste was not properly mixed with water, probably for a short time or with a low amount of water, as suggested by the diffusion of clay pallets which represent incomplete hydrated particles that were not reached by the water [11].

The mixing was followed by the phase of shaping. The analysis of the type of shaping is based on thin section analysis, however, due to the parallel direction of the cut in the preparation of thin sections [22], we cannot be sure about the handle technique employed (coiling, slab, moulding, pinching, paddle and anvil or the recently identified spiralled patchwork [23]).

Once dried, the vessels were fired at low temperatures and the firing process was not completely controlled. Commonly, archaeologists discriminate between “open firing to “kiln firing” [24–26]. The term “open firing” generally indicates bonfire, characterized by open firing with vases surrounded by fire, and pit where ceramics are put into a hole with fuel that surrounds the vases [27]. On the contrary, “kiln firing” includes structures with a chamber and it is assumed a high maximum firing temperature, slow heating rates, long permanence times and variable redox conditions which are usually oxidizing. A preliminary indication of firing atmosphere is provided by the colour of the ceramic body. The total amount of iron in the raw material and the redox conditions are the main factors that drive the colour of ceramic. The red colour is associated to the occurrence of hematite formed in oxidizing conditions [11,28,29], whereas in reducing atmosphere iron oxides and hydroxides react with CO resulting in the formation of magnetite α-Fe3O4 or maghemite γ-Fe2O3[11,30]. The analysed samples show a heterogeneous colour of the matrix, ranging from red to black also in the same section. The extreme variability of the colour in the same sample suggests uncontrolled firing conditions, which were frequent in open firing structures, where the control of temperature and the diffusion of oxygen were difficult to monitor and keep constant [13,31,32].

Considering the optical activity of the matrix, temperatures are hypothesized lower than 850°C [10]. In addition, the identification of primary calcite crystals in high amount strongly supports the hypothesis of a temperature lower than that at which usually the decarbonation process should take place. In particular, calcite decomposition starts at about 650°C, producing CaO and CO2, and ends at about 950°C (710–950°C [33]; 850° C [34]; 650–800°C [35]). The thermal decomposition of calcium carbonate is strongly influenced by different variables from both the firing procedure (heating rate, steam, oxygen presence, etc.) and the nature of carbonates (particle size, quantity, crystalline structure, etc.) [36], therefore, a wide range of temperatures have to be considered.

At the upper limit temperature of the decarbonation process, at about 850–900°C the formation of calcium silicate or calcium aluminum silicates, the so-called neo-formed minerals, takes place [37]. The absence of any neo-formed minerals, such as gehlenite, wollastonite or pyroxenes [38] and the lack of vitreous phases in the SEM images [39] strongly support the hypothesis of low firing temperatures. However, the absence of clay minerals, highlighted by XRPD results, allows indicating 750°C as lower firing limit, the temperature at which clay minerals (in particular kaolinite) should be completely degraded [40].

The other samples (G.C. n 5D, G.C. n 27 and G.C. n 28) were probably produced with a different raw material as suggested by the absence of calcite and calcareous rock fragments. The analytical results allow hypothesizing that they were produced with a kaolinitic clay with quartz and feldspars, fragments of flint, clinopyroxene, biotite, fragments of magmatic rock, in variable amount.

The identification of coarse inclusions in the ceramic fragments and their unimodal grain size distribution suggest the use of not purified clay, without the addition of tempers, probably used as it was supplied [11]. However, the sub-angular and angular shapes of some coarse inclusions could suggest a voluntarily addition by the potter to modify the plastic features of the paste [19]. At the moment, the identification of tempers added is a difficult task, even more if the starting clay was not purified [11]. In addition, considering the coarse inclusions, the slight variability observed in the mineralogical composition among samples G.C. n 5D, G.C. n 27 and G.C. n 28 should not indicate different sources for these three samples, but it could be connected to the natural variability occurring in the same deposit.

The clay as it was supplied was carelessly mixed with water, as testified by the abundant presence of clay pallets [11] and handled shaped.

After drying, a firing process took place. The heterogeneous colour of the matrix indicates uncontrolled firing conditions, which were frequent in open firing structures [13,31,32].

Concerning firing temperature, the optical activity of the matrix indicates firing temperatures lower than 850°C, in agreement with previous analysis [19]. The absence of clay minerals in samples G.C. n 5D and G.C. n 27 suggests for these samples a firing temperature in the range 750–850°C; on the contrary, the high amount of clay minerals in samples G.C. n 27 suggests a temperature lower than 750°C, the maximum temperature at which kaolinite persists [40].

The comparison with previous results on ceramic materials from “Grotta dei Cocci” [19] suggests similar minero-petrographic composition with samples G.C. n 5D, G.C. n 27 and G.C. n 28. On the contrary, the identification of bioclastic packstone in one sample by Comodi et al. [19] do not find any correspondence with samples under analysis.

Provenance of the materialsThe mineralogical and petrographic characterization of the inclusions in the ceramics allow to infer some hypothesis about the supplied areas of the raw materials.

Even though the results suggest two different areas of supply for the production, (the first one consisting in a clay with quartz and feldspars, fragments of flint, and fragments of sedimentary rock – samples G.C. n 9D, G.C. n 10D, G.C. n 20D and G.C. n 24 - and the other one without calcareous inclusions with clinopyroxene, biotite, and fragments of magmatic rock, in variable amount – samples G.C. n 5D, G.C. n 27 and G.C. n 28), the nature of the inclusions identified is consistent with the geological setting of the area, thus suggesting a local supply of the materials.

The mineralogical and petrographic composition of ceramic sherds, in particular the non-calcareous nature, the abundance of quartz, clinopyroxene, biotite and fragments of volcanic rock support the hypothesis of a local supply of the materials. Indeed, the Cave is located in a geological area characterized by terrigenous marine deposits of the Pliocene and Pleistocene, by alluvial Quaternary sediments as well as, volcanic units related to the Vulsini Mountains, the Cimini Mountains and Vicano districts of the Pleistocene outcrop along the left bank of the Nera river, as identified also by Comodi et al. [19]. Therefore, a supply from these alluvial and terrigenous deposits (Fig. 1) are suggested for samples G.C. n 9D, G.C. n 10D, G.C. n 20D and G.C. n 24 whereas, the left bank of the Nera river (Fig. 1) could be the source of the material supplied for the production of samples G.C. n 5D, G.C. n 27 and G.C. n 28.

ConclusionsThe study of ceramic fragments from the archeological site of “Grotta deiCocci” by a multi-analytical approach (i.e., OM, XRPD and SEM-EDS) provided information about the nature of the raw materials, their selection, technological process of production, firing conditions and the supply area of the materials.

For the following group of samples (samples G.C. n 9D, G.C. n 10D, G.C. n 20D and G.C. n 24) the minero-petrographic analysis defined the use of a purified clay composed of Qtz±Cal±Pl±Kfs. The supply area is related to terrigenous, alluvial deposits close to the site. The optical activity of the matrix, the occurrence of calcite and the absence of clay minerals suggested firing temperatures in the range 750–850°C under uncontrolled atmosphere conditions.

The other samples (G.C. n 5D, G.C. n 27 and G.C. n 28) are characterized by a production starting from a clay containing inclusions of Qtz±Pl±Kfs±Biot±Cpx, naturally present in the starting local clay. The supplying outcrop is probably located on the left bank of the Nera river where the terrigenous, alluvial deposits are associated to those volcanic. The firing process underwent under uncontrolled atmosphere conditions at temperatures similar to the other samples, except for one sample whose temperature is estimated lower than 750°C.

The identification of two groups of samples characterized by different starting raw materials and different technology production could be interesting to evaluate differences among ceramic shapes, archaeological contexts and final use. Indeed, the presence of different cultural elements could be useful to investigate the particular function of this cave.

This research was funded by Sapienza University of Rome, Italy. The authors thank the Dr. M.C. De Angelis for the archaeological setting and Dr. Vanessa Forte for the archaeological revision. Laura Medeghini: Conceptualization, Formal analysis, Writing – original draft.

Silvano Mignardi: Writing – review & editing, Supervision. Caterina De Vito: acquisition of data, Writing – review & editing, Funding acquisition supervision.

![Geological map of the surroundings of the archaeological site. Geological map of the study area in central Italy. (1 alluvial deposits (Quaternary); 2 alluvial and lacustrine sediments (Quaternary); 3 travertines (Holocene); 4 volcanic units of the Vulsini Mountains, Cimini Mountains and Vicano districts (Pleistocene); 5 terrigenous marine deposits (Pliocene – Pleistocene); 6 Schlier (Middle Miocene); 7 Bisciaro, Scaglia and Marne a Fucoidi (Early Cretaceous – Early Miocene); 8 Maiolica, Calcari diasprini and Rosso Ammonitico (Middle Liassic – Early Cretaceous); 9 Calcare Massiccio, Rhaetavicula contorta Formation and Anidriti di Burano Formation (Late Triassic – Early Liassic) (modified from [15]). Geological map of the surroundings of the archaeological site. Geological map of the study area in central Italy. (1 alluvial deposits (Quaternary); 2 alluvial and lacustrine sediments (Quaternary); 3 travertines (Holocene); 4 volcanic units of the Vulsini Mountains, Cimini Mountains and Vicano districts (Pleistocene); 5 terrigenous marine deposits (Pliocene – Pleistocene); 6 Schlier (Middle Miocene); 7 Bisciaro, Scaglia and Marne a Fucoidi (Early Cretaceous – Early Miocene); 8 Maiolica, Calcari diasprini and Rosso Ammonitico (Middle Liassic – Early Cretaceous); 9 Calcare Massiccio, Rhaetavicula contorta Formation and Anidriti di Burano Formation (Late Triassic – Early Liassic) (modified from [15]).](https://static.elsevier.es/multimedia/03663175/0000006100000002/v2_202206010315/S0366317520300893/v2_202206010315/en/main.assets/thumbnail/gr1.jpeg?xkr=ue/ImdikoIMrsJoerZ+w96p5LBcBpyJTqfwgorxm+Ow=)

![“Grotta dei Cocci”: (a) map of the Cave; (b) map of the excavated area (modified from [16]). “Grotta dei Cocci”: (a) map of the Cave; (b) map of the excavated area (modified from [16]).](https://static.elsevier.es/multimedia/03663175/0000006100000002/v2_202206010315/S0366317520300893/v2_202206010315/en/main.assets/thumbnail/gr2.jpeg?xkr=ue/ImdikoIMrsJoerZ+w96p5LBcBpyJTqfwgorxm+Ow=)