The purpose of this paper is to identify success factors in human resource management during the transition process to Lean Production. Using case study research in the aeronautics industry, the results show a series of explanatory factors that are then grouped into main factors depending on the phase of the transition process. Thus, in the pre-adoption phase, the setting up of joint management-trade unions committees is the main factor. Five main factors are found in the other three phases of the adoption and implementation process: training, communication, rewards, job design, and work organization. Moreover, a variety of explanatory elements are identified in each of the main factors found in each phase of the transition process to Lean Production. Finally, a model is developed to understand the sequence that leads to the cultural change associated with Lean Production.

Lean Production (LP) has been adopted by companies in various service and industrial sectors in recent decades and these companies have subsequently moved forward in its implementation. In many cases this has enabled them to improve their results and competitiveness (Moyano-Fuentes and Sacristán-Díaz, 2012). However, empirical evidence shows that the transition to LP is a complex task that generally has to contend with a large number of obstacles (Scherrer-Rathje et al., 2009).

LP adoption entails significant organizational change which requires companies to properly manage the key factors that might influence on the success of the adoption process. Although the literature highlights the crucial role of people (e.g., Sawhney and Chason, 2005; de Treville and Antonakis, 2006), there is a lack of studies that examine the changes that take place in Human Resource (HR) management during the adoption process (Needy et al., 2002).

As far as the implementation of LP is concerned, a number of recent studies state that not enough research has been conducted into the human aspects associated with this phase (Angelis et al., 2011; Bonavía and Marín-García, 2011). Despite LP involving significant changes in HR practices and policies (Biazzo and Panizzolo, 2000), there is no consensus in the literature on the way that LP might affect people (Conti et al., 2006; de Treville and Antonakis, 2006), or the role of HR policies and practices during the LP implementation process (Liker and Hoseus, 2010; Bonavía and Marín-García, 2011).

Consequently, it is important to address in depth the role that people play during the different phases of the transition process to LP, including both LP adoption and implementation. Therefore, our main research question is: How do companies manage their human resources in such a way that they ease the transition process towards LP and move it forwards? We intend to achieve the following operating aims:

- •

To identify the HR explanatory success factors during the different phases of the transition process to LP.

- •

To group the explanatory success factors associated with HR management into main factors linked to human resource management during each of the transition process phases to LP.

- •

To propose a model that includes these main factors and the relationships among them during the various phases of the transition process to LP in order to gain a better understanding of the cultural change associated with the transition to LP.

LP is a management system focused on eliminating the types of waste identified by Ohno (1988) and other wastes related with internal variability and external variability produced by relationships in the supply chain (de Treville and Antonakis, 2006; Shah and Ward, 2007). As such, LP can be defined as “an integrated socio-technical system whose main objective is to eliminate waste by concurrently reducing or minimizing supplier, customer, and internal variability” (Shah and Ward, 2007, p. 791). The main objective of this management system is, therefore, to achieve maximum efficiency, carrying out operations at a minimum cost and with zero waste.

LP is a management philosophy based on continuous improvement, which requires the involvement and commitment of everyone in the organization and provides an opportunity to improve the results in terms of quality, costs and lead times (Womack and Jones, 1996; Moyano-Fuentes et al., 2012). Since it was first disseminated, LP adoption has therefore spread to companies in a range of industrial and service sectors and has, in many cases, enabled these firms to improve their results (Moyano-Fuentes and Sacristán-Díaz, 2012). However, although numerous companies have implemented LP successfully, others have not achieved the results that they anticipated, and failed implementations are common (Staats et al., 2011), as is the inability to maintain results over the medium and long term (Lucey et al., 2005). This is a consequence of the LP implementation process’ inherent complexity (Scherrer-Rathje et al., 2009).

This has driven research interest in the factors that facilitate and inhibit the LP adoption and implementation processes. Prior research has identified a series of factors that facilitate theses processes and there is a broad consensus that HR and cultural change are critical factors for the success of Lean initiatives (Emiliani, 2006) and their sustainability over time (Bateman, 2005).

There is also a broad consensus that the success of a Lean transformation not only depends on the application of tools and techniques (hard side), but that for the sustainable benefits of these to be achieved, it is necessary to pay attention to the human factor and the establishment of a culture that sustains the Lean transformation (soft side). In other words, as LP is an integrated socio-technical system, success comes from these two facets being applied simultaneously and systematically (Dibia and Onuh, 2010; Liker and Hoseus, 2010; Badurdeen et al., 2011).

2.2Lean Production and Human Resource ManagementThere are various lines of research in the literature that links LP and HR management that focus on describing the HR policies and practices associated with LP (e.g., Forza, 1996; Niepce and Molleman, 1996; Pil and MacDuffie, 1996; Biazzo and Panizzolo, 2000; Olivella et al., 2008), the impact that LP implementation has on people (e.g., Forrester, 1995; Niepce and Molleman, 1996; Conti et al., 2006; de Treville and Antonakis, 2006) and the influence that LP-associated HR practices have on performance (e.g., Shah and Ward, 2003; Bonavía and Marín-García, 2011).

However, despite the importance of managing HR for LP, a greater emphasis has been detected in the literature on technical aspects than on the roles of people and cultural change in the transition process to LP. Thus, while a range of studies have analyzed the general success factors in LP adoption and implementation (e.g., Worley and Doolen, 2006; Turesky and Connell, 2010; Pedersen and Huniche, 2011), there are few that analyze the success factors of HR management in detail.

There is no consensus on what the main success factors are in these studies, although certain factors are suggested by different authors. Olivella et al. (2008), for example, identify LP-oriented work organization strategies, including standardization, ongoing training, teamwork, participation and empowerment, versatility, commitment to company values, and contingent rewards. Meanwhile, Bonavía and Marín-García (2011) point to LP-oriented companies promoting flexibility and versatility, investing in training and committing to variable compensation. The literature on advanced human resource practices (Huselid, 1995; MacDuffie, 1995; Pil and MacDuffie, 1996) identifies HR factors that have a good fit with LP, including teamwork, job rotation, ongoing training, contingent rewards, job security, versatility and participation.

LP adoption entails significant organizational change, which means that companies should manage people at the beginning of a Lean transformation (Sawhney and Chason, 2005; de Treville and Antonakis, 2006). LP can be especially complex in this respect due to the high degree of worker participation required to organize the work (Pil and MacDuffie, 1996). In addition, cultural change and the commitment and support of company management are some of the greatest challenges to Lean being accepted by people (Sawhney and Chason, 2005; Beauvallet and Houy, 2010), and might slow the adoption process down (Emiliani, 2006). Addressing in depth the changes that take place in HR management during the LP adoption process is therefore a major issue.

Similarly, there is no consensus with regard to the way that LP could affect personnel (Conti et al., 2006; de Treville and Antonakis, 2006), or to the role that HR practices and policies play during the LP implementation process (Liker and Hoseus, 2010; Bonavía and Marín-García, 2011).

In other respects, current researches consider the transition to LP as a single process and throughout which people are assumed to play a uniform role. This paper therefore focuses on identifying the success factors in HR management during the LP transition process distinguishing between the adoption and implementation phases, with the goal of establishing a road-map that facilitates this process and enables improvements to be made to it.

3Research methodology3.1Research designLP adoption and implementation in the aeronautics industry is an emerging research area, which means that the case study is a suitable research method. Specifically, this method is especially suitable for exploratory studies such as this (Benbasat et al., 1987; Voss et al., 2002; Yin, 2003). Benbasat et al. (1987, p. 370) state that “the case method lends itself to early, exploratory investigations where the variables are still unknown and the phenomenon not at all understood”. These are the conditions found in this research as the key factors have still not been identified that enable the role of human resource management to be understood in the transition process to LP.

Case studies are also especially applicable for the analysis of longitudinal change processes (Eisenhardt, 1989), for gaining a holistic perspective of a phenomenon (Gummesson, 2000), when the phenomenon being studied cannot be understood separately from its context, and for explaining relationships that are too complex to be studied using quantitative research methods (McCutcheon and Meredith, 1993; Yin, 2003). The case study is also more appropriate for responding to “why?” and “how?” type questions than other research strategies (Yin, 2003).

For all these reasons we consider that the case study provides the depth required for exploring why and how companies have successfully managed human resources during the LP adoption and implementation processes. We use a multicase study to explore these questions and build theory, as this method is suitable for observing and describing a complex research phenomenon and improving its understanding (Meredith, 1998; Eisenhardt and Graebner, 2007). This method also helps to reinforce internal validity and enables the findings to be replicated, thus increasing the external validity of the research (Eisenhardt, 1989). At the same time it helps to avoid observer bias (Handfield and Melnyk, 1998), aids triangulation and improves the generality of findings (Voss et al., 2002; Yin, 2003), making the research more robust overall (Herriot and Firestone, 1983).

3.2Case selectionThe first decision that had to be taken to guarantee the validity of the findings involved selecting the case studies and unit of analysis (Stuart et al., 2002). A theoretical sampling model was used for this (Eisenhardt, 1989; Yin, 2003) with the aim of obtaining companies that provided an optimum ‘chance to learn’ (Stake, 1995) and, consequently, that the resulting case studies could provide relevant and significant findings. Our strategy was based on enabling literal replication, using information-rich cases distributed in such a way as to achieve maximum variation (Miles and Huberman, 1994; Stuart et al., 2002).

The unit of analysis chosen was Lean adoption and implementation in plants belonging to prime contractors in the aeronautics industry. There were a number of reasons for the choice of this unit of analysis. On the one hand, it is a unit of analysis that is especially suitable for case studies and even more so when the aim is to explain the cultural change that is inherent in the transition process to LP. On the other hand, it also enables LP adoption and implementation to be investigated as a sequential process in plants where both have taken place in recent times.

The case studies investigated were LP adoption and implementation at five production plants. Two of these were aircraft final assembly lines (FALs) and the other three were prime contractors devoted to manufacturing and assembling parts, subassemblies and large aerostructures, primarily for the FALs.

3.3Data collectionBefore beginning the field work, a case study protocol was designed that contained the data collection instruments and the procedures and general rules for carrying out the multi-case study. This protocol was updated and enhanced with each visit that took place (de Weerd-Nederhof, 2001), affording the research greater reliability (Yin, 2003).

A tentative script was designed for the in-depth semi-structured interview based on a review of the literature on LP in general and on LP in the aeronautics industry in particular. A preliminary version of the interview script was pretested with two prestigious researchers in Operations Management and two widely acknowledged experts in the aeronautics industry. Finally, a pilot study was conducted in a manufacturing plant in said industry. New questions were included as a result of this process and some changes were made to the wording of the questions to prevent any misunderstandings in the interviews (the final interview script is provided in Appendix 3).

Both primary and secondary information sources were used in order to triangulate the data. This helped to ensure construct validity (Easterby-Smith et al., 2002). In-depth semi-structured interviews, surveys, plant visits/factory tours and, in some cases, managers’ statements and conversations with blue-collar workers were used as the primary sources of information. The secondary sources used were company documentation, reports and annual reports, websites, published interviews and similar sources.

The same pretest process was used in the survey, which was designed to triangulate information, as that described for the preliminary version of the interview script. This guaranteed that the definitions of the questionnaire items made sense and were not misunderstood (the survey is available from the authors on request).

To ensure validity, a number of senior managers were interviewed in all cases (between two and three key informants). A total of twelve senior managers were interviewed. When visiting some facilities we also had the opportunity to talk to plant employees about a number of aspects of LP. This contributed to our understanding of the changes that occurred in the role of people during the LP adoption and implementation process.

Two researchers were always present at the interviews. This enabled us to take independent explanatory field notes, clarify any ambiguous issues and identify any questions of interest during the data collection process. It also helped to limit observer bias (Eisenhardt, 1989).

The data collection process took place from October 2010 to March 2011. Each interview lasted between 75 and 105mins and each tour of the facilities took an average of 60mins. All the interviews were recorded and transcribed immediately afterwards. A database was created with the transcriptions of the interviews, questionnaires, documents and explanatory field notes. This also helped to make the research more reliable as it provided easy audible traceability of the events.

3.4Data analysisA number of measures were adopted to ensure the validity of the analysis and interpretation process. The analysis was done on a case-by-case basis and a cross-case analysis was subsequently done of the various case studies. The within-case analysis helped us to begin to progressively make sense of the large quantity of data collected and interpret them (Eisenhardt, 1989). The emerging topics for exploration and explanation were identified from the analysis of the interviews and data, and the relationships found among the variables were explored and defined in the subsequent interviews (Miles and Huberman, 1994).

Within-case (e.g., by comparing primary and secondary data) and cross-case (e.g., by comparing the data collected at the different production plants) triangulation was thus done. Confirming the findings in each of the cases in subsequent cases controlled both internal and external research validity.

The data analysis followed a number of steps based on the Grounded Theory coding paradigm proposed by Strauss and Corbin (1998). This comprises open, axial and selective coding stages to ensure conceptual development and density (these stages are illustrated graphically in Appendix 1). The core idea of using this paradigm is to use a structured method to establish a connection between unformatted text and the research objectives (Binder and Edwards, 2010).

In the open coding phase the data were coded, analyzed and conceptualized. As a basis for this we used the transcriptions of the interviews and statements made by senior management (56,925 words). The first step was to work on each interview individually, using the phrase-by-phrase coding tactic to forge a strong link with the data collected.

We were mindful of the two phases of the transition to LP (adoption and implementation, that had initially been defined in the interview script – theoretical sampling–) during the coding, and the coding was different for each of the phases. However, as the field study and analysis moved on, four different phases were identified within the adoption and implementation processes.

Codes with the same meaning were grouped together in more abstract concepts. Similarly, the concepts and their corresponding properties and dimensions were identified and defined as the process moved forward. A number of memos were also generated depending on how the coding was interpreted and the data from the field notes. The concepts were compared to other terms to check similarities and differences (Figs. 2.1 and 2.2 in Appendix 2 show some examples of the open coding process and a memo, respectively).

During the axial coding phase we continued to compare within- and cross-case codes, and the relationships among them became clearer, leading us to group codes with a similar meaning in more abstract initial (tentative) conceptual subcategories and categories. The subcategories were then related to their categories, for which an analytical tool for integrating structure with process, called “paradigm” (Strauss and Corbin, 1998, p. 127) was used. In our specific case, the general process considered is human resource management during the transition to LP, where the sequence of actions/interactions (subprocesses) are the human resource practices/tools deployed depending on the structure (or conditions), which is represented by the phases that make up the transition process as a whole.

In this way, the subcategories and categories were simultaneously interconnected with each of the four phases identified. This process therefore enabled us to see how the subcategories were related to the categories in each phase of the LP transition process.

The category that represents the core research theme was identified in the selective coding phase for integrating and refining theory: the human resource management process during the transition to LP. Subsequently, the four phases that are part of the core category were linked. Choosing the “process” as the core category of a theory and broken down this into “subprocesses” is supported by Strauss and Corbin (1998, p. 179).

The categories and subcategories that emerged from the open and axial coding were refined and interconnected with the goal of creating a theoretical framework that would help to explain the core phenomenon under study. Subsequently, a more advanced theoretical framework was constructed by making a comparison with the prior literature and the researchers’ experience in the area of study. The process ended when a point of theoretical saturation was reached.

The results of the open, axial and selective coding were constantly compared as they are mutually independent and iterative phases.

It should be highlighted that conceptual maps were used to link the codes, subcategories and categories conceptually (Novak, 1998). The use of this “visual representation” tool is very useful for progressively developing both the concepts and their interrelationships (Miles and Huberman, 1994; Maxwell, 2005). By way of example, Fig. 2.3 in Appendix 2 shows a coding tree for a specific factor.

To ensure the consistency of the findings, the authors analyzed the data independently and later met on a number of separate occasions to compare their results. Some details also required confirmation by the interviewees after the interviews (e.g., in telephone conversations held with them or by email to clarify some issues). This helped to control the research construct validity. It should be stated that a qualitative research software package (Atlas.ti) was used to code the data. The use of this software facilitated coding by linking text segments to codes, creating memos, and providing a visual representation of the data and findings.

4ResultsThe findings enabled us to distinguish four phases closely linked to the role of HR in the transition process to LP: (1) Management of the labor relations framework prior to LP adoption; (2) LP adoption in pilot areas; (3) LP adoption deployed throughout the whole plant; and (4) LP implementation. We found various explanatory success factors in each phase that, in the case of the adoption and implementation phases (phases 2, 3 and 4), were grouped into five main factors: training, communication, rewards, job design and work organization.

Table 1 shows the main factors (categories), the explanatory success factors (subcategories) and the key concepts that were identified. All the explanatory factors are also illustrated with one or more quotations from the interviews to comply with the principles of consistency and transparency by providing examples of coded text that enable other researchers to understand how the analysis was done.

Main and explanatory success factors of human resource management in LP adoption and implementation.

| Main factors/explanatory success factors | Key concepts | Quotes |

| Phase 1. Management of labor relations framework prior to LP adoption | ||

| Role of Trade Unions | ||

| Forming of joint management-social representation committees | Preparing the ground, joint negotiation with unions prior to LP adoption.Need to control the role of the unions before initiating LP adoption, to modify past social aspects to the benefit of adoption and to achieve agreements on Lean adoption and implementation. | “When we decided to adopt Lean, one of the really essential things was to pave the way for it, to do the groundwork, and that was all linked to the social agents modifying certain aspects that were in place here in an organized way but which didn’t go with the new philosophy (…) One of the key things at the very beginning was the agreements with the unions which were set out in the labor agreement on those things we had to organize from the bottom up.” (Lean MD, P4). |

| Phase 2. LP adoption in pilot areas | ||

| Objectives: to ensure adoption is successful in the area, to focus resources, motivate people in the area, and in the organization after success achieved, to learn from the experience in the initiative, standardize it, improve it, to serve as an example and to achieve a knock-on effect in other areas and spread it to the rest of the plant. | ||

| Initial factor: workers’ initial attitude of skepticism and resistance towards LP | Initial belief that Lean is just another passing fad, that it cannot be applied to the aeronautics industry, linking it to previous failed initiatives and distrust due to past role of management. | “At the beginning there was resistance, it's normal, it's logical, it's human to come across resistance to change, skepticism… and at the beginning they think it's just another fad.” (Plant MD, P3). |

| Training | ||

| More philosophical, aimed at changing the mindsets of a critical mass of people | Training programs, initially in pilot areas and subsequently in deployment areas. Training focused on changing the mindset of a critical mass in the organization to facilitate change. | “As for Lean training, the first training was done in the pilot areas …, and, what was really important, it was designed to focus on changing people's mindsets, it focused on the benefits of Lean, not so much on the tools, but on changing people's perceptions of Lean.” (Corporate Lean Leader). |

| Aimed at practice, focused on simplest and easily applied tools | More practical training, methodology applied to LP (on-the-job training), focused on simple and easily applied tools. | “There's been more practical training in the sense that it was aimed at pointing the workers straight in the direction of the concept, with no unnecessary frills and theory, quite hands-on and easily understandable stuff, and we got really good results with that type of training.” (Lean Expert, P5). |

| Communication | ||

| Changes in the roles of top and middle management (greater accountability, transparency and contact) | Change in management behavior: communication, transparency and contact with the shop floor, less information flow stagnation and continuous management support along with greater accountability to workers. | “There's been a complete change in the way the management behaves … communication, transparency and contact, I think those are the three things that sum up the change there's been.” (Plant MD, P2). |

| Top-down persuasion | Management presentation of Lean objectives, top-down mindset change. | “The first move to get involved has to come from the management. Then the management sets out the objectives to the pilot teams and then the work team worked hard to achieve those objectives.” (Plant MD, P3). “Bit by bit we changed our mentality from the top to the bottom.” (Plant MD, P5). |

| Content focused on need for change and benefits of Lean | Meetings focusing on need for Lean adoption and its benefits, not only for the company but stressing direct worker benefits. | “The workers didn’t trust Lean, but we got over that by having meetings where we explained to them that Lean means making savings, increasing efficiency and not only for the company, but it makes their job better.” (Plant MD, P1). |

| Visibility of improvements to rest of plant | Communication to other plant sections of advantages gained in pilot area, motivation of people in pilot area, serving as an example to other areas of the organization, achieving a knock-on effect in other areas of the plant. | “The reason why the first Lean tools were put in place (5S, VSM and visual management) in a pilot area was to make the improvements much easier for the rest of the plant to see, so it was an example, getting to learn by experience and creating a knock-on effect for the other areas and motivating the rest of the plant personnel.” (Corporate Lean Leader). |

| Reward | ||

| Non monetary (consideration/study and implementation of workers’ proposals by management) | Taking workers’ opinions and proposals into account, valuing their proposals to motivate them, implementing proposals or, should they not be applicable, explaining why. | “When we first adopted Lean we asked all the workers to work with us to see what could be improved and we listened to what they said. But it wasn’t easy because before that we (the management) didn’t use to pay them any attention, and they didn’t trust us… but now we’ve changed and we think about what they say because their opinions count.” (Plant MD, P1). |

| Job design | ||

| Physical changes caused by applying accessible and easily understood Lean tools that are useful and provide the worker with immediate positive results (VSM, 5S, Visual Management) | Initially, tools that workers can easily access and understand, such as 5S, VSM and visual management to improve the work environment and ergonomics, resulting in direct benefits to the worker. Objective: people see that there are direct and positive benefits for them (daily work made easier, improved ergonomics) and to their work environment. Spreads to other sections of the plant (contagion). | “We started off with 5S and visual management in the pilot teams… we used 5S with the workers to improve the work environment, the ergonomics, to make it better and pleasanter, and that ends up benefiting the worker (…) The seating, for instance, was designed to help people and cut out unnecessary movements.” (Plant MD, P1). |

| Work standardization | Importance of standardizing the work station as a keystone of Lean, through step-by-step standardization of work procedures, with the target of reducing variability. Standardization by workers themselves: structured method and increased sense of ownership. | “Right from the beginning we tried to standardize work, that's one of the keystones of Lean.” (Plant MD, P1). |

| Work organization | ||

| Work teams formed with multifunctional support | Importance for creating first seeds of work team. First step: forming work teams with help of support department (production, engineering, quality, maintenance, supply chain, etc.) to achieve objectives jointly. Do work by team and get workers used to working in this way. | “We’ve always taken different factors into account, right from the time the adoption started. One key factor is the work team, that is, the objectives we want to achieve, it's the team on the production line that achieves them (…) And that way when the first analyses were done of the value stream in a specific area, the work team with multifunctional support worked hard to achieve the targets that had been set.” (Plant MD, P3). |

| Phase 3. Deployment of LP adoption to the whole plant | ||

| Initial factor: initial attitude of workers’ skepticism and resistance towards LP | Initial way of thinking is that Lean is just another passing fashion that cannot be applied to the aeronautics industry and is linked to earlier initiatives that failed, lack of trust in management due to their track record. | “We came up against some skepticism among some of the workers in the deployment phase because people like to have their shelves full to feel easy and when they see they’re empty, they feel a bit uneasy and start to worry that they might be going to lose their jobs, I mean, comments that are quite…, when we walk past, because of that.” (Lean MD, P4). |

| Training | ||

| Training provided by expert internal personnel | First training provided by external consultants. Subsequently, internal training after contracting experts in Lean implementation from other sectors (automobile) for it to be carried out in a deeper, strategic way and to achieve the greater engagement of people and cultural change. | “During the phase when the training was rolled out to the whole of the plant we decided not to bring in someone from outside like we did at the beginning but to do some internal training.” (Corporate Lean Leader). “The Lean training was transmitted to the whole of the personnel through a Lean Academy set up on the group level.” (Plant MD, P2). |

| Specific by-level Lean training (Lean leaders, Team Leader, Workers) | Training adjusted to different levels. Focused on the role that each member of the organization plays in the Lean environment. Training given to Lean Leaders collective on how to engage personnel, recognizing the importance of workers’ knowledge, intelligence and experience. Workers do not take on the job of Team Leader until they have received the proper training. | “During the second training phase, the training is total, what I mean is, when the Lean training was rolled out to the personnel in all the plant, the training that was done, it wasn’t just about Lean, but about what part, what roles all the workers would play in the Lean environment, and that was crucial.” (Corporate Lean Leader). |

| More philosophical, aimed at changing the mindsets of a critical mass of people | Training programs in deployment areas. Training focused on changing the mindsets of a critical mass in the organization to facilitate change. | “When LP was being adopted there were special Lean training courses for all the plant to explain that there are improvement methodologies, like Lean, that have better results than other improvement initiatives… and we invested in training courses to change people's mindsets.” (Plant MD, P1). |

| Practice oriented, focused on simplest and easily applied tools | Training programs in deployment areas. More practical training, methodology applied to LP (on-the-job training), visual training (Model Factory), focused on simple tools that can be applied easily. | “A Model Factory was set up during the training, here on the shop floor, using a hands-on game and everyone came through here so they could see what Lean was all about and see what the benefits were… It's an extremely visual game, you see, and we did it in the Lean discourse which is a bit like where you are surprised by how you can do something about the haphazardness of a process by applying Lean.” (Plant MD, P4). |

| Communication | ||

| Changes in the roles of top and middle management (greater accountability, transparency and contact) | Change in management behavior: communication, transparency and contact with shop floor, fewer delays in information flow and continuous management support along with greater accountability to workers. Importance of command chain as key factor for success in worker engagement and involvement. | “We saw that the role of the chain of command is vital, the way they interact and communicate with the other plant levels, one of the success factors in getting the rest of the plant to respond, getting them involved and engaged depends a lot on the quality, on the communication… on the role of the chain of command.” (Plant MD, P3). |

| Top-down persuasion | Lean objectives presented by management, top-down mindset change, involvement of all management levels. | “Another idea that was clear for us was that Lean is not a bottom up process, but top down. We worked hard on being the drivers of the need, I mean, transmitting to the rest of the organization that we were serious about it and that we were going forward with it, that it brings results and that the rest of the organization has to get involved in Lean.” (Plant MD, P3). |

| Content focused on need for change and benefits of Lean | Meetings focusing on the need for Lean adoption and its benefits not only for the company but putting special stress on direct benefits for the worker. | “The people, they think that Lean is just like everything else, that it's just another training course we’re giving them, and that's it… So, if the people don’t think that Lean is useful, then there's no reason for them… we upped the communication a lot, and we explained how Lean was useful and that Lean has some effects on them, too.” (Plant MD, P2). |

| Reward | ||

| Non monetary (consideration/study and implementation of workers’ proposals by management) | Workers’ opinions and proposals taken into account, valuing of proposals to motivate workers, implementation of proposals and, if they are not applicable, explanation of the reasons why. | “Now the management takes the workers’ suggestions into account and implements them… there's been a complete change in the way we behave… and that's the way you get people hooked, we’re going to listen to their suggestions and implement them. That's good for getting new ideas, and that's the second phase of getting people on board.” (Plant MD, P1). |

| Job design | ||

| Physical changes caused by applying accessible and easily understood Lean tools that are useful and provide the worker with immediate positive results (VSM, 5S, Visual Management) | Initial use of tools that are accessible to workers and easily understood, such as 5S, VSM and visual management to improve the work environment, and ergonomics, which have direct benefits for the worker. Target: people see that they have positive direct results that affect them (easier day-to-day work, better ergonomics) and their work environment. | “Lean won’t succeed if people don’t really see that it really does give results. Workers have got to see that right from the start. The people saw how the first tools (VSM, 5S and Visual Management) were helping them, making their day-to-day work easier… That's how you really get people hooked, when they really see it working. We got people on board because of facts, because of results.” (Plant MD, P3). |

| Work standardization | Importance of standardizing the work station as one of the mainstays of Lean, through standardizing work procedures step-by-step in order to reduce variability. Standardization by the workers themselves: structured method and increased feeling of ownership. | “One of the really important tools at the beginning was standardizing work, as it's what allows you to get the work process in order and get rid of more wastage.” (Lean MD, P2). |

| Work organization | ||

| Specific department created to take charge of Lean (with a Lean Manager) | Creating a Lean department means resources tied up with the lean initiative full time, working as a success factor.Creation of a Lean department on the corporate level and at each of the plants, provision of specific resources for the Lean initiative aimed at structuring implementation and monitoring advances in implementation.Setting the Lean targets with the work teams and the other levels of the organization. Help and direct support given to Team Leaders. | “You can’t make Lean work without the right resources. In the past, some of us managers in the plant had been making changes of this type more or less part-time… and we spent some of our time on it, too; but it's obvious, an initiative like Lean is only possible if you’ve got resources absolutely fully dedicated to it.”“Creating a Lean department was one of Lean's success stories, it's a really powerful thing to have people exclusively devoted to it, working and organizing the whole change to Lean.” (Plant MD, P5). |

| Setting up of work teams (with a Team Leader) | Emergence of the figure of Team Leader to lead the work teams. Importance of work teams with multifunctional support in the pilot areas for creating the beginnings of the work team. Team Leader chosen democratically by all the members of the work team. Is the driver of Lean methodology, high knowledge of what can be done within the work team. Specific prior training for working as Team Leader. | “When the work teams with multifunctional support had been formed in the pilot areas, then the figure of the Team Leader was officially defined in the Labor Agreement. That's the person who sets out and drives forward all the Lean methodology in a natural work group.” (Lean MD, P4). |

| Setting up of multifunctional teams | Creation of multifunctional teams with personnel from different company departments to achieve specific targets. | “In the Deployment Phase we created multifunctional teams that worked towards some specific objectives. We got the teams from different departments to systematically try to encourage the sharing of ideas and opinions in these teams.” (Plant MD, P5). |

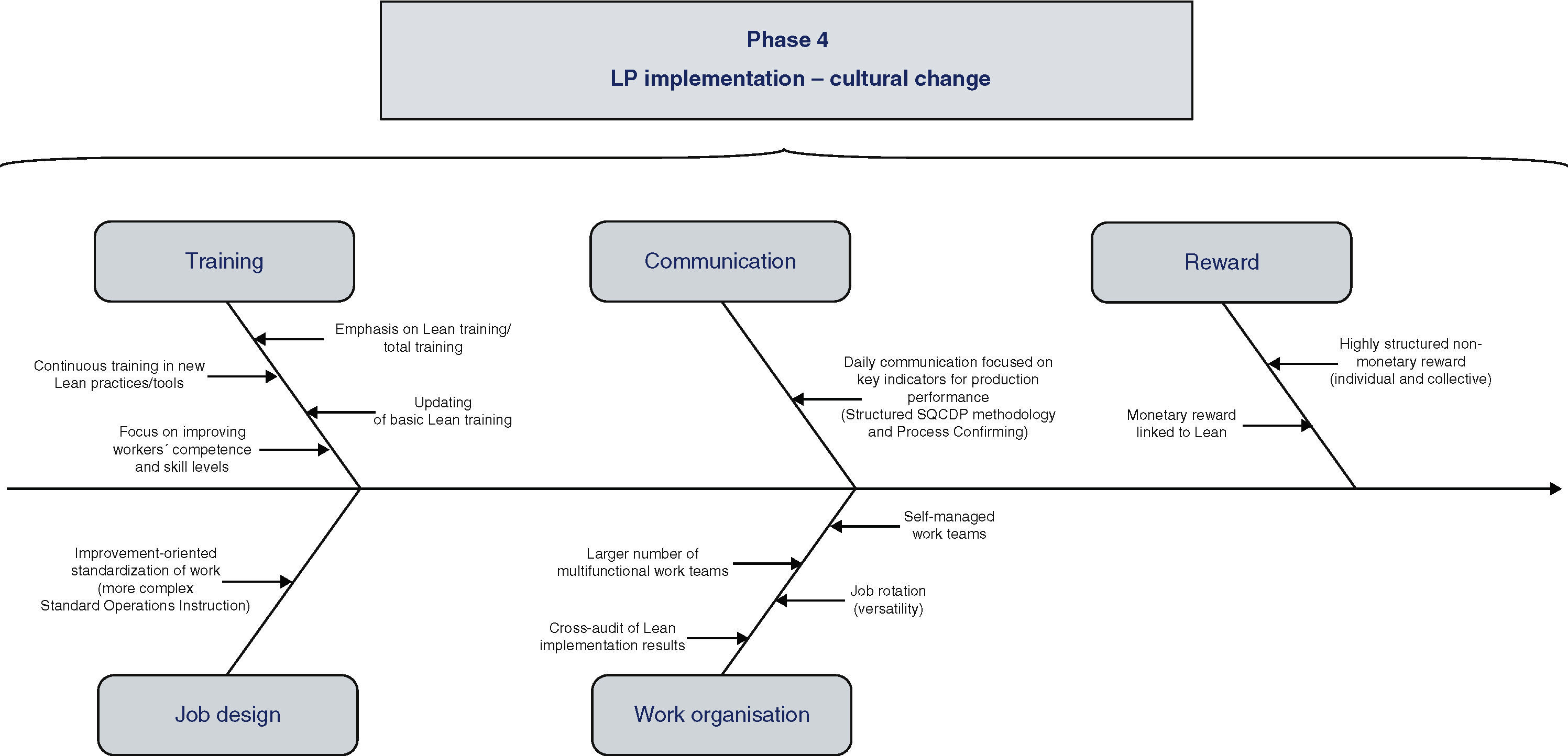

| Phase 4. LP implementation, cultural change | ||

| Training | ||

| Emphasis on Lean training/total training | Continuous effort put into the importance of Lean training to keep moving towards cultural change (high percentage of all training given, strategic character of Lean). | “Currently 70% of personnel training is on Lean, that is, 44hours of training per year out of the total.” (Plant MD, P1).“We’ve made a huge effort in training… altogether, out of all the training a person receives, some 70–80% is aimed at Lean.” (Plant MD, P2). |

| Continuous training in new Lean practices/tools | Continuous training in more complex practices and tools. Emphasis on training focusing on applied methodology (on-the-job training). | “We’ve got training fully deployed and coordinated with the Lean Academy on the group level, and we’ve got full training programs deployed and they’re updated annually … we give training on new tools and there's a package for this program.” (Plant MD, P4). |

| Updating of basic Lean training | Visual training refresher (Model Factory). | “We’ve currently got plans for all the operators to go back -and it's easy to say all the operators-, to go back through the Model Factory again to have a refresher course on the whole practical side of Lean Training.” (Lean MD, P4). |

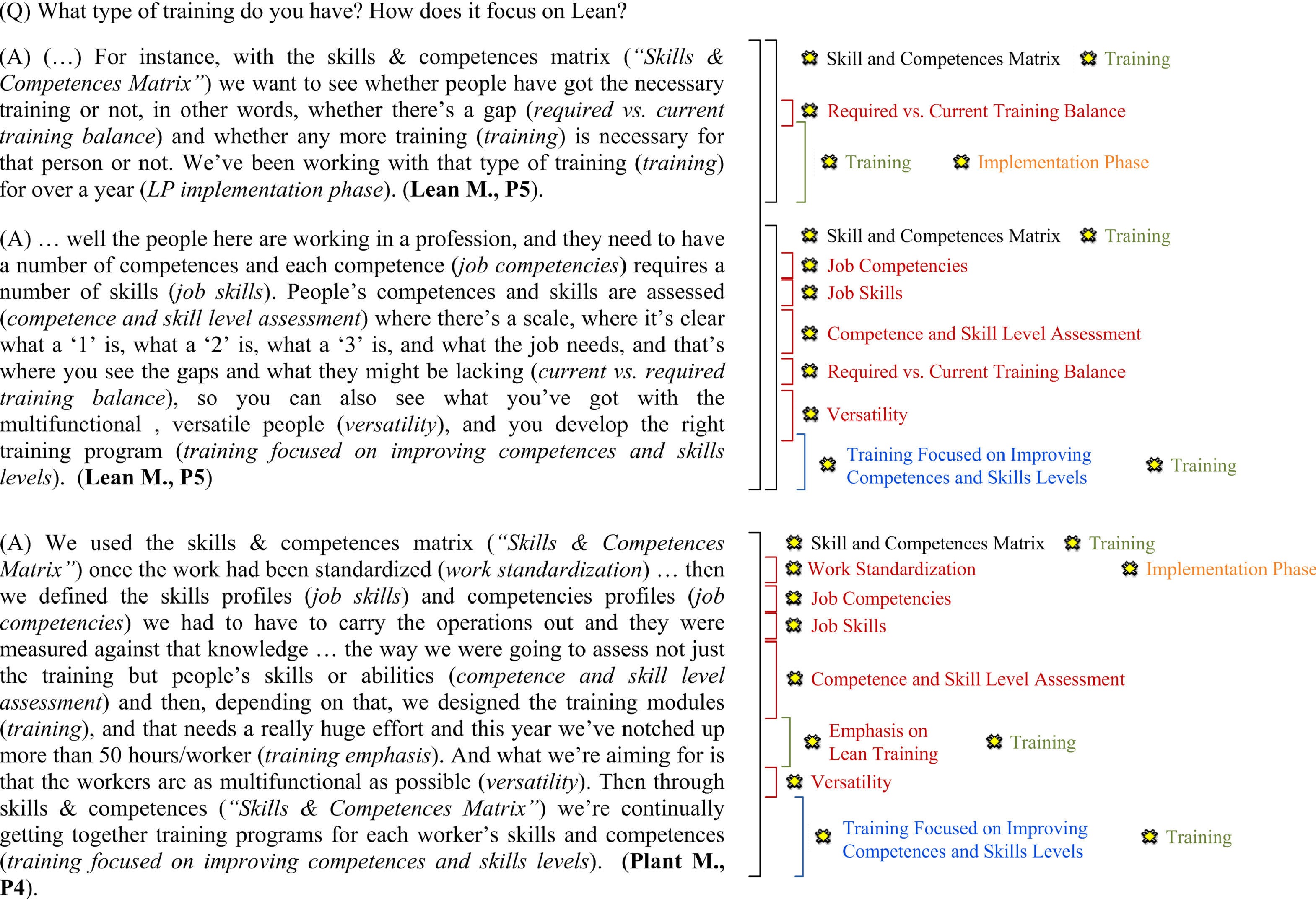

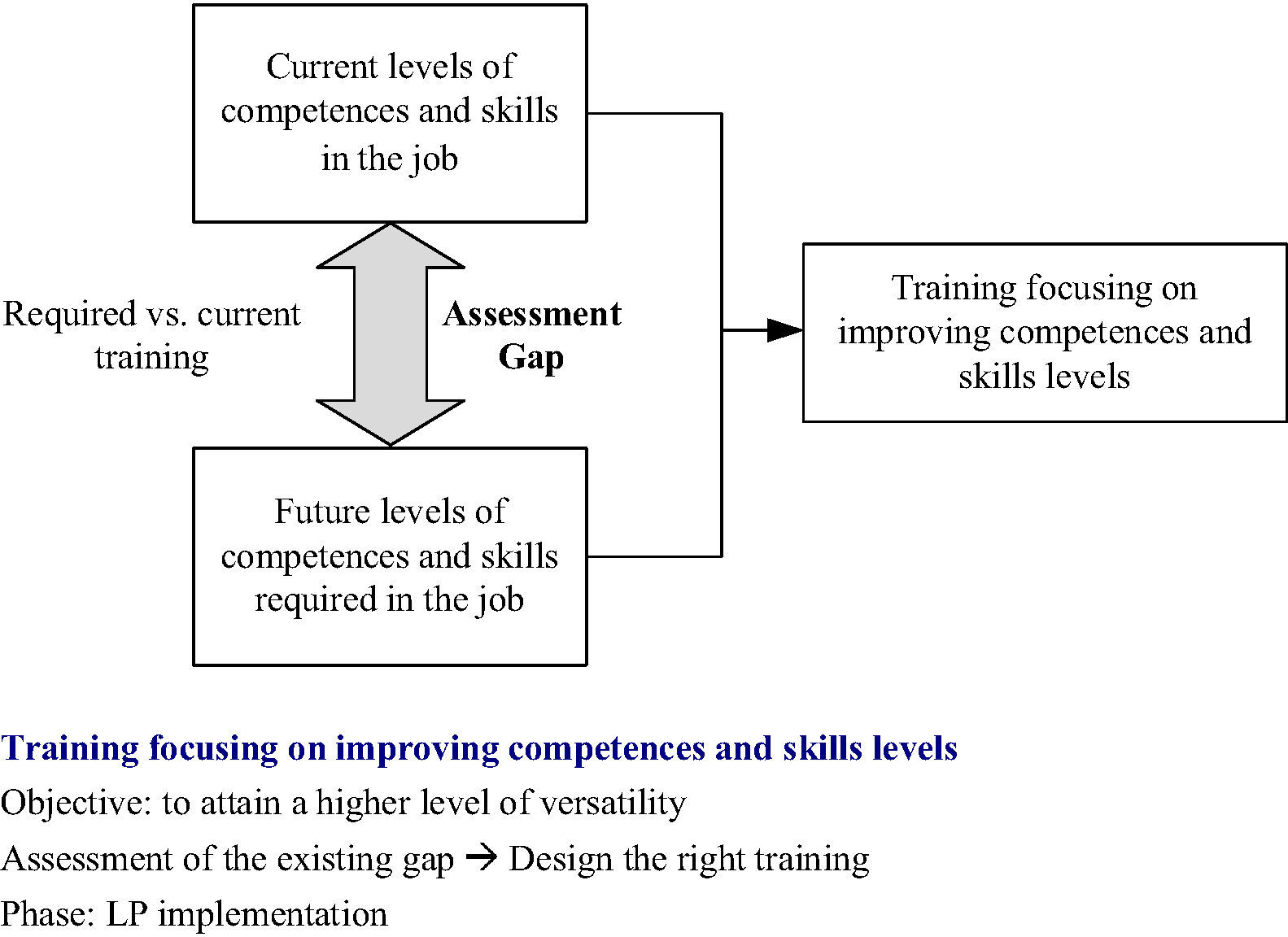

| Focused on improving competence and skill levels | Emphasis on training to improve level of skills and competences in order to achieve a greater level of worker versatility. On-the-job-training. Target: to achieve a greater level of internal and inter-plant flexibility. | “We’ve developed a major training program, it really took a huge effort, and with the Skill and Competences tool we’re continually regularizing all the operators’ skills and competences. There's a whole training package to get them up to scratch every year and what we’re aiming for is to make the operators as versatile as possible…, this year it's been over 50hours/operator.” (Plant MD, P4). |

| Communication | ||

| Daily communication focused on key indicators for production performance (Structured SQCDP Methodology and Process Confirming) | Daily communication with the target of achieving daily feedback on workshop indicators (Safety, Quality, Cost, Delivery, People; SQCDP).Target: to achieve fluid communication, higher coordination levels and internal integration, visual management of the plant, communication structured by level, direct worker participation at SQCDP meetings and Process Confirming, improvement suggestion system integrated in SQCDP methodology. | “The fact that we’re getting people together in an organized way every day, and following a series of structured indicators with them, all the people who work together on a specific plant level I mean, everyone on their own particular level and everyone at their own particular time, means everything's been really, really well coordinated. It's incredible how much it helps cultural change, how to do things in a different way.” (Lean MD, P3). |

| Reward | ||

| Highly structured non monetary (individual and collective) | Acts of recognition, on both the collective and individual levels. Efforts aimed at achieving a structured model to give it greater significance and boost recognition.Fundamental role in achieving motivation, engagement and the participation of people in the Lean initiative. Primacy over economic incentive. | “We discovered that recognition motivates people, there's no doubt about it, it's an essential tool … you can’t implement lean unless you’ve got all your human resources aligned….” (Plant MD, P3). |

| Monetary, linked to Lean | Economic incentives agreed with social representation structured by labor agreement, linked to the achievement of lean targets. | “We’ve got the whole economic incentive thing organized, it's in the Labor Agreement, no less. It's all agreed with the social representatives. Basically we’ve got the incentive system linked to achieving some specific targets, where the role Lean is playing is the engine behind these targets being achieved, they’re linked to Lean.” (Plant MD, P3). |

| Job design | ||

| Improvement-oriented standardization of work | More complex SOI (Standard Operations Instruction) with the goal of achieving a higher level of maturity in job standardization. First IT developments. | “In the implementation phase we’re working hard on SOI (Standard Operations Instruction)…, shall we say we’re trying to reach a very high maturity level where the operation is perfectly defined: tools, times, the method, with a graphic process, etc.” (Plant MD, P4). |

| Work organization | ||

| Self-managed work teams | Mature, self-managing work teams. Average 90% of workforce doing self-managed work. | “These days, the work teams have got past the initial stages and now they’re mature, independent and they work as they should (…) During the first phases, us department heads, the ones involved, would go, and I would go to meetings with the work teams, we were there, and we really got down to the nitty-gritty, but not these days any more…” (Plant MD, P3). |

| Larger number of multifunctional work teams | Greater number of multifunctional teams and greater ability to solve problems. On average, 26.5% of workers are included in multifunctional teams. | “As for the multifunctional teams, many of them are really brutally strong now. For example, the multifunctional group that deals with the maintenance of a machine that was really giving us a headache, they’re running that machine now, they own it, they’re engineering it, in charge of the process, quality, maintenance, and the operators…, and that's an example of Lean culture and how through Lean methodology the team manages the whole process environment.” (Plant MD, P4). |

| Job rotation | Greater worker versatility due to training effort focused on improving levels of competences and skills. Greater level of task rotation both on the plant and inter-plant levels. On average, 23.33% of employees rotate between tasks. | “The operators are now a lot more versatile…, but even inside the group's plants, depending on the plants’ workloads, we’re working on flexibility.” (Lean MD, P4). |

| Cross-audit of Lean implementation results | Audits by Lean Managers and Lean Experts on the plant level of other plants in the group. External Lean Assessment. Target: to obtain a less subjective external vision and more suggestions for improvement. | “We now get people coming here from other plants, and we go there so there are new opinions, new ideas… more than just the “per se” internal valuations, there are recommendations that can provide opportunities for improvement.” (Lean Expert, P5). |

It was possible to deduce a model from the analysis that includes both the main factors and the explanatory factors that were identified and the relationships among them depending on the phase under analysis.

5DiscussionThe factors that were identified in each of the phases and in all the cases analyzed are discussed below and quotations are given to support the findings.

5.1Phase 1: Management of the labor relations framework prior to LP adoptionA prior requisite to LP adoption was the setting up of joint committees between management and social representation. This was done to modify some past social aspects that might later become obstacles to the adoption and implementation process. If negotiations on the Lean transformation are held with unions at the beginning, this might smooth the way and remove some of the obstacles to the organizational cultural change required by this management system and, ultimately, enable LP to be implemented successfully. “There's a really important factor, and that's social representation. We’ve been doing it hand in hand right from the start (…) Then we set up some committees for the whole Lean adoption process. These are joint committees between social representation and the management, so it's done all smooth and easy, with everything agreed. The fact is, when we first presented Lean to the workforce, the first part was done by the head of the works council and I was the one who wound it up, the same meeting, the two of us together, and that gives it some real bite.” (Plant MD, P3).

This finding sheds some light on prior research into the role that the unions play in LP that has not provided conclusive evidence (Kochan et al., 1997; Shah and Ward, 2003). We found that managing the role of the unions is crucial for guaranteeing that LP adoption and implementation are undertaken successfully and at the same time could result in less worker resistance to change. Our results are in line with the findings of Kim and Bae (2005), who state that a crucial factor in LP adoption is knowing whether the organization is unionized or not, as the innovative practices of Lean in the workplace strongly depend on the strength of the trade union and the strategy should consequently be focused differently depending on the state of unionization.

5.2Phase 2: LP adoption in pilot areasTargeting a pilot area as an LP adoption strategy is a success factor in itself. Targeting resources to a pilot area principally helps build motivation among the people involved in the project, and serves as an example to other areas, triggering the roll out of the LP initiative to the rest of the plant. This finding is in line with the gradual implementation of events approach (Wilson, 2009).

However, we identified an initial attitude of skepticism and resistance to LP among blue-collar workers which, despite being tempered by the joint negotiations with the unions, had to be managed using a number of mechanisms, specifically the following five main factors.

5.2.1TrainingTraining focused on changing the mindsets of the people in the area, both the line workers’ and the managers’. This first explanatory factor has been the object of little attention in the literature, although a number of authors state that a change in mentality is crucial for achieving success in Lean (Niepce and Molleman, 1996; Sawhney et al., 2010). “When we started the training in the pilot areas, first and foremost it was designed to change people's mindsets…, the first thing you have to do is change the mindsets of a critical mass of people in the organization. I think it's essential that the first bit of training you give is not designed to provide tools, but to change mindsets. That was absolutely essential.” (Plant MD, P5).

A second explanatory success factor was practical training in the use of basic and easily applied tools through what is known as on-the-job-training or learning-by-doing. This finding supports what is stated in the prior literature about how important applied training is for people to better assimilate and learn the first Lean tools (Barton and Delbridge, 2001; Stewart et al., 2010).

5.2.2CommunicationCommunication has been widely recognized in the literature as a vital component of LP (Womack et al., 1990; Spear and Bowen, 1999). The first explanatory success factor was the change in the role of senior and middle-management, with these being the first to encourage greater contact with shop floor personnel and more transparent feedback. “The management started having a lot more contact with the shop-floor workers, meetings right there on the shop floor itself, something we hadn’t usually done before, so we started having a closer relationship with the shop floor… before that, in the past, the management used to be set apart a lot more, unapproachable.” (Lean MD, P2).

This reinforces the importance that the literature places on the change in managers’ roles and functions within the context of the adoption of Lean tools (e.g., Power and Sohal, 2000). This was the very beginning of participatory management and the delegation of responsibilities to workers, as well as greater support being given to them (Beauvallet and Houy, 2010; Turesky and Connell, 2010).

A second explanatory success factor was communication aimed at winning people over from the top down and focusing on the need for change and the benefits of Lean so as to overcome people's initial skepticism and resistance to LP. Thus, a number of authors found that failing to create and communicate a sense of urgency in Lean transformations and a lack of information about the initiative and need for change might cause the Lean initiative to fail (Womack and Jones, 1996; Lucey et al., 2005; Worley and Doolen, 2006; Scherrer-Rathje et al., 2009). In this same respect, Gagnon et al. (2008) find that if workers are well-informed about the Lean strategy, this could be a prior step to them committing to it.

Finally, we found that the visibility of the improvements achieved by the workers in the pilot area was the key to recognizing the efforts made by the team and to acting as an example to the other areas of the company. Scherrer-Rathje et al. (2009) state that communicating the success of Lean to the rest of the organization from the very beginning is critical for giving workers a better understanding of the Lean benefits and creating a positive perception of LP among the rest of the members of the organization.

5.2.3RewardsDuring the adoption phase rewards were linked exclusively with management considering and implementing workers’ proposals. “Us managers, we’ve changed now, we take their proposals into consideration because their opinions count. That's the way to get people on board, we’re willing to take a look at their proposals and implement them (…) The basic difference is that now we’re listening to what they have to say and if we don’t use their proposals, then we tell them why we don’t.” (Plant MD, P1).

This issue was a key feature in getting workers to trust managers, to overcome the inertia of the past and align workers with the Lean initiative, and to boost motivation (MacDuffie, 1995; Worley and Doolen, 2006). In support of this idea, Boudreau et al. (2003) state that rewarding people's “good work” in a non-monetary way may contribute to improving results in production plants that are already making headway in a Lean initiative.

5.2.4Job designOne first explanatory success factor was the physical changes that came from implementing basic, easy-to-understand Lean tools. The objective of starting with tools like VSM, 5S and Visual Management was to improve the work station and its ergonomics, which was of direct benefit to the workers. This resulted in the personnel becoming more engaged with the initiative and helped it to spread to other sections of the plant. These findings are similar to those of Abdulmalek et al. (2006), who state that there are tools that can be easily applied in any industry and which can be an excellent starting-point for identifying sources of waste, and also to those of Antony (2011), for whom these tools help to organize the work place, motivating employees to forge ahead with adoption and the early involvement of the rest of the plant. A second explanatory success factor was work standardization, and, specifically, that this was done by the workers themselves with the help of the support departments in order to enhance the feeling of ownership, tracking and continuous improvement. The literature highlights the role of standardization as a key tool for coordinating work in a Lean environment (e.g., Parker, 2003; Olivella et al., 2008) as it facilitates the implementation of different techniques and task rotation (Niepce and Molleman, 1996; Olivella et al., 2008). “At the kaizen events to standardize jobs, it was the workers who did it, and if they do it, they don’t just take responsibility for maintenance …, what I mean is, when they do it at the beginning, they can do it better or worse, but it's them who's done it, right? And they’re the ones who do it day after day and the ones who know what all the problems are and all the ins-and-outs of what they do on their bit of the shop floor … and they say to you, I did it and what's more, it's up to me to keep it right, and on top of that, I’m happy because I know I’ve just put an end to all the problems I used to have.” (Lean MD, P3).

The explanatory success factor that we found here was the setting up of work teams with multifunctional support. The setting up of work teams with support on the production line was crucial for creating the beginnings of the work teams of the next phase, for getting the workers used to the way that people have to work in a Lean environment and for implementing the principles of participatory management and delegation of responsibilities. Little analyzed in the prior literature, our finding nonetheless corroborates the findings of Åhlström (1998), who states that the first work teams in LP adoption must receive support if they are to be successful. “One major concept was giving the production line our support, getting the production line to be supported to the hilt by the support departments… Then we got a team of people together, on both the shop floor level, with shop floor workers I mean, and with people from the other departments involved.” (Plant MD, P3).

The initial skepticism and resistance of people towards Lean was also detected during this stage. However, our analysis shows that the joint negotiation with trade unions and displaying the improvements in the pilot area to the rest of the plant made it possible to moderate this attitude. Various factors also contributed to success.

5.3.1TrainingTraining did not only focus on changing the mindsets of the people in the organization and was not only oriented towards practice, as in the previous phase, but was provided by internal experts. This was an explanatory success factor as it enabled training to be implemented more strategically and engaged people more in the objective of making advances towards the cultural change. Well-trained workers are likely to adapt to changes because they use their knowledge and experience to facilitate the process of new technology adoption (Lee et al., 2011). The use of internal expert personnel for training helped to speed up the Lean adaptation process. A second factor was the provision of specific Lean training by level: “The training plans were rolled out depending on the level. You know, there's Lean training specifically for the Lean Leader, Team Leaders and for the shop floor workers…” (Plant MD, P4).

In this respect, deploying different training depending on the level (Lean Leaders, Team Leaders or workers) was the key to each member of the organization getting to know what role s/he had to play in the Lean environment (Turesky and Connell, 2010). Thus, the appearance of Team Leaders in the work teams meant that these received the specific training that they required to carry out their functions. Similarly, the Lean Leaders received training in Lean leadership in order to get the plant personnel engaged and aligned with the initiative.

5.3.2CommunicationThe key difference that we found compared to the preceding phase was the leadership of the whole chain of command as a crucial aspect for achieving worker participation and the roll out of LP to the rest of the plant. Here we found that the response of line workers to Lean and their engagement were closely connected with the command chain's leadership, findings in line with Groebner and Merz (1994) and Forza (1996). “The whole way of thinking, we changed it bit by bit, from top to bottom, but we couldn’t go onto the next stage of Lean until we’d properly got through all the preceding stages, from the top level in the plant to the following one and so on… and we saw that the role of the people in charge, it's quite clearly a major point… At the beginning the response we got from the people working in the plant was pretty mixed… it depended a lot on the way they were being led from above, how it was put to them down the chain of command, that was what was at the heart of it.” (Plant MD, P5).

The same explanatory success factors were found as in the preceding phase.

5.3.4Work organizationWe found three explanatory success factors linked to this factor. The first of these was the creation of a Lean Department, which facilitated the success of the adoption by providing the initiative with full-time personnel devoted to the initiative (Lean Manager, Lean Leaders, Lean Experts and Change Agents) thus enabling the adoption to be structured and any advances made to be tracked. A second factor was the setting up of work teams with Team Leaders. The Team Leader emerges as the main driver of Lean methodology in the work team. Team Leaders are democratically elected by their workmates in their teams and are in charge of standardization and improving processes (Forrester, 1995; Delbridge et al., 2000). The third explanatory factor that we found was the setting up of multifunctional teams with specific goals for improvement, which supports prior empirical evidence (Forza, 1996; Åhlström, 1998). “The Lean Leaders at all the plants, they’ve played a really important role in Lean…, for me it's one of the factors that's most driven the change.” (Plant MD, P2). “One of the keys to success was the Team Leader. They’re chosen by their workmates in their teams, voted in once a year, and they really know all the ins-and-outs of what's done in their areas, they’re the ones who’re involved in the VSMs…” (Lean MD, P4).

We found the five main factors in this fourth phase, albeit with different explanatory success factors.

5.4.1TrainingFirst we found the major importance given to Lean training as part of the total amount of training. “Currently 70% of personnel training is related to Lean, that's 44hours of training a year out of all the training they get.” (Plant MD, P1).

Secondly, continuous training in new Lean tools and practices. Our findings demonstrate the strategic importance of ongoing training in the use of new Lean tools and practices for moving forward in the culture change and upgrading employees’ skills and knowledge (Birdi et al., 2008). A third explanatory success factor was training focused on updating basic Lean tools and techniques in order to keep workers engaged with LP as a key aspect for keeping up worker commitment to the Lean initiative, an aspect which has been less analyzed in the prior literature.

Lastly, training focusing on improving workers’ competence and skill levels in order to increase their versatility and, in the final instance, to achieve a greater level of flexibility and adaptability in the organization (Ritzman and Safizadeh, 1999). This was initially possible due to a high level of standardization being achieved at the work stations throughout the whole of the plant. Once this level of work station standardization had been achieved throughout the plant, workers were trained to carry out different types of tasks in the production process, mainly through theory classes and at the work stations themselves (on-the-job training) through task rotation. “(…) For example, with the skill & competences matrix tool we can see if people are properly trained or not, what I mean is, if there's a skills and competences gap and if a person needs more training.” (Lean MD, P4).

The explanatory success factor was the development of structured communication methodology based around daily meetings and key indicators of the results of LP implementation. Implementing SQCDP (Safety, Quality, Cost, Delivery, People) visual display panels and a structured methodology with daily meetings and Process Confirming among the different levels in the organization enabled communication to flow more easily throughout the plant and helped raise internal coordination and integration levels. These findings corroborate those of various authors who underscore the importance of transparency of information about Lean objectives and continuous feedback on and continuous evaluation of results (Worley and Doolen, 2006; Turesky and Connell, 2010). Thus, a structured communication procedure can improve worker involvement, provide the workers with greater accountability and give them a greater feeling of ownership of Lean achievements (Lucey et al., 2005). Continuous information feedback can also give a rapid response to any departure from the objectives set (Mehta and Shah, 2005) and the bases for continuous improvement (Spear and Bowen, 1999). “With this structured SQCDP (Safety, Quality, Cost, Delivery and People) methodology and Process Confirming workers can feel that they’re the ones who’re driving all the improvements first thing in the morning and report all the problems they’ve got, and the MD hears all about it within an hour and a half, and that's really good for them, really important. Any problems they’ve got get sorted out right away…” (Corporate Lean Leader).

In this phase we found that rewards in connection with the Lean objectives came in the form of both monetary incentives and non-monetary recognition. However, non-monetary individual and collective rewards predominate over monetary incentives. This finding sheds light on prior research into the role of rewards and economic incentives as facilitating and inhibiting factors in the transition process to LP. Our findings complement the findings of Karlsson and Åhlström (1996) who maintain that there is a trend for a monetary incentive system to act more as an inhibitor in the adoption phase, but that with time it tends to facilitate the implementation process. Our findings show that whereas in the initial phases of LP adoption there is no monetary incentive, only management recognition of the improvements achieved, both monetary incentive and non-monetary recognition systems are put in place subsequently, in the implementation phase. Lean-related rewards can acknowledge versatility and teamwork, and increase worker participation and commitment (Olivella et al., 2008). We’re working on acts of acknowledgement at the moment, both collective and individual. And we’ve been working to make them have greater effect, beefing them up, giving them some sort of structure, that's the way forward. Making them stand out more, more conspicuous and, of course, tying it all in with executing and implementing Lean (…) We’ve realized that in today's world, in today's society, acknowledgement is a priority over economic issues.” (Plant MD, P3).

We found that continuous improvement-oriented work standardization was an explanatory success factor. A key factor, therefore, is improving the Standard Operations Instructions (SOI) so that these are fully developed and help to reduce internal variability, a key LP goal. “We’re working so you can have an SOI (Standard Operation Instruction) for example. These are standardized instructions with pictures to illustrate the operations, very visual, they ensure that the processes that are carried out are always done in the same way and being continuously improved, and can be seen as you’re doing the work, you finalize the operations as you do them.” (Lean MD, P5).

We found several explanatory success factors. With regard to work teams, these matured and became more self-managing. It should be noted that approximately 90% of the plant personnel was organized into work teams. Greater consolidation of the multifunctional teams was also detected. These had grown in number and now involved an average of about 27% of the personnel in all the plants. These results corroborate the findings of Forza (1996) and Martínez-Sánchez and Pérez-Pérez (2001), who found that the work teams and multifunctional teams become more and more consolidated as LP implementation progresses further. We also found increased task rotation between work stations as a direct result of the training to improve workers’ competences and skills and work stations now being standardized to a high degree. This not only meant that a high level of internal flexibility had now been achieved, but that the workers were now becoming much more versatile and that there was greater inter-plant flexibility, all of which are aspects stated in the literature (e.g., MacDuffie, 1995; Forza, 1996; Pil and MacDuffie, 1996; Power and Sohal, 1997, 2000; Angelis et al., 2011). “Now there's a certain flexibility about our personnel thanks to the versatility we’ve achieved, and this lets us play with our capacity …, we’ve got the flexibility we need to adapt to any variations we might get.” (Plant MD, P3).

Finally, we found one important factor that has not been analyzed in the literature to any great extent is the setting up of teams to carry out inter-plant lean audits to assess the results of Lean implementation. With this “Lean Assessment” an external and less subjective view of a plant's work structure and suggestions for improvements can be obtained with the aim of implementing suggestions for improvement that enable advances to be made in LP implementation.

6ConclusionsOur study contributes to connecting the Operations Management and Human Resources areas which have traditionally been analyzed individually but which, as Boudreau et al. (2003) state, have significant links. This connection is especially important for explaining the transition process to LP as, despite the major role that people play in this management system, prior research has not looked in depth at the role of human resource management and the cultural change required for the process to be executed successfully. With respect to people, research has focused on the characteristics of work organization in Lean environments (Forza, 1996; Biazzo and Panizzolo, 2000), on analyzing LP-associated advanced human resource management practices (Huselid, 1995; Bonavía and Marín-García, 2011) and on examining how LP affects workers (Niepce and Molleman, 1996; de Treville and Antonakis, 2006). However, this paper addresses a prior step relating to the role that people play before and during the LP adoption process and tries to discover which aspects favor workers’ adaptation to this management system. It also gives the success factors in human resource management once the adoption process has concluded and while advances are being made in LP implementation. This study therefore considers that it is necessary to investigate the underlying success factors, during both the adoption process and the implementation process, for the cultural change that LP requires to be understood.

In this way, this paper contributes to understand the complexity associated with the transition to LP (Scherrer-Rathje et al., 2009) by focusing on the key role that people play in this process (Sawhney and Chason, 2005; de Treville and Antonakis, 2006), but shifting the focus by trying to understand the aspects of human resource management that contribute to overcoming workers’ negative attitudes and initial resistance to LP and to successfully adapting to this management system.

By digging deeper in the results, our analysis has enabled us to differentiate among four phases closely linked to the role of human resources in the LP transition process. These phases complement other authors who propose the sequential implementation of LP through the foundation, planning, implementation and continuous improvement phases (Turesky and Connell, 2010; Pedersen and Huniche, 2011).

As for the implications of these findings for management, it should be stated that they can be used as guidelines for companies proposing to adopt LP and for managers responsible for the LP implementation process, and act as an aid for defining aligned and sequenced action plans for attaining and maintaining the results that LP affords.

It is necessary to stress that the factors identified should not be considered in an isolated way in each of these phases, but from a holistic focus, where each of the factors interacts with the others in each of the phases. This is the only way to understand the sequence that leads to the cultural change associated with LP.

To conclude, it should be stated that although the main factors and the explanatory factors were found in all the cases that were analyzed, there is some variation in the frequency with which some tools/human resource management techniques appear (explanatory factors). The information obtained from the interviews does not allow us to explain this variation. This paper is also a qualitative and exploratory study undertaken in a specific industry, which means that the generalization of our findings is limited. It would be useful to do further research to overcome these limitations by testing the proposed model in other contexts. Meanwhile, although the paper recognizes the relationships between the explanatory factors and their main factors it does not allow their intensity or strength to be measured. Bearing these limitations in mind we suggest some lines of future research. It is suggested that the models that have been developed are validated in other industrial and geographical contexts, in keeping with logical replication. It would also be interesting to examine whether the proposed models could be applicable to or should be adapted to other levels of the aeronautics industry supply chain. We also propose further research be done to try to measure the intensity of the relationships that have been identified. Finally, it is proposed that qualitative and quantitative methodologies are combined in order to overcome the previously mentioned generalization issues and thus allow further conceptual development.

This study was funded by Andalusian Regional Government and Spanish Ministry of Economy and Competitiveness research projects P08-SEJ3607 and ECO2010-22105-C03-02. Pilar Jerez acknowledges the financial support from Spanish Ministry of Economy and Competitiveness research project ECO2011-24921.

See Fig. 1.1.

Stages in open, axial and selective coding.

This script is a guide only as the interviews will be semi-structured and in-depth. There is a number of questions directly related to the research goals. However, the interviewee will be allowed to answer the issues as fully as s/he wishes and stress will be put on any interesting aspects that arise at any given moment in order to find out about both the aspects targeted by the questions and any other determining factors connected with Lean Production. Instructions and/or tips for interviewers are given in italics in the script, while the questions to be put to the interviewee/s are numbered and in bold.

Interviewers introduce themselves and present research project; give thanks for interviewee's cooperation. Brief explanation of what will happen in interview, and ask for permission to record same. Then series of questions asked relating to research objectives.

- 1.

Why did you decide to adopt Lean Production at your production plant? In other words, what were the reasons behind the decision? When was the decision taken?

Changes in the environment. What internal aspects? What new competitive priorities do you hope to achieve? Cultural change.

- 2.

What was the first area or section of the plant where you began to adopt Lean Production? Why did you decide on this/these area/s? In other words, what criteria led to this decision? Why this/these area/s and not some other? What role did people play in this decision?

Visibility and importance of the area. Variability. How qualified were the workers? Prior multifunctional teams.

- 3.

What practices and/or tools did adoption begin with? Why these? What role did people play?

Worker training, 5S, visual management.

What areas did you work on next to roll out Lean Production implementation at your plant? What were the reasons behind this?

Other production flow lines, new product development, logistics, purchases, administrative processes.

What areas are working most according to the principles of Lean Production at the current time? And in the future, what areas do you intend to roll out the principles of Lean Production to? How long do you think it is going to take to fully implement Lean throughout your company?

- 4.

What role have the senior managers played in the adoption of Lean Production? And in the implementation process? What role are the senior managers playing at the current time?

Leadership of senior management. Frequently communicate with all the workers about Lean objectives, investments made to ease the way for adoption and implementation, acknowledgement of role of workers in continuous improvement, adapting organizational structure to aid adoption and implementation, reward system.

- 5.

What role did the workers play in adopting Lean Production? What role did workers play in Lean Production implementation and what role are they playing now?

Worker engagement/resistance, suggestions, involvement in improvement programs, triggered improvement to work organization.

- 6.

Did you allocate resources for implementing Lean Production? What? With regard to human resources, is there a person exclusively in charge of Lean? Has any specific department associated with Lean been created? Has the company organigram been changed as a result of Lean being implemented? Has everyone received training in Lean, for example? Please tell us about this training in a little more detail.

Other types of resources.

- 7.

What factors do you think have favored the adoption and implementation of Lean Production at your plant? Please tell us how these factors favored implementation?

Internal and external factors. Role of people.

- 8.

What obstacles or difficulties did you encounter during both the adoption and implementation of Lean Production at you plant? How did you solve them? Did you find any resistance from people at the beginning? And what about now?

- 9.

What changes have there been in the workers’ behavior (in the way that they work)? Would you mind giving us a few examples? Are there more suggestions now, or are people more motivated? What reward system do you run?

Increased responsibility for one's own work (self-responsibility), greater concern for work being well done. Motivation, communication, problem solving, commitment to quality and continuous improvement, flexibility, rotation, variety of work, worker stress.