Enterprises with the capacity to manage to respond to the new market demands and to transform them according to the changing environment have shown their sustainability in the market for long periods. But now-a-days the business environment is turbulent, and even such enterprises may find it difficult to survive. One of the proposals for any enterprise (the existing as well as new and emerging ones) in this turbulent environment is the Virtual Enterprise approach. In this context one of the critical issues is the transformation process of ‘Traditional’ Enterprises into Virtual Enterprises. The paper presents a simulation tool to support the model for the processes transformation and how this tool is to be used in some of the phases of the general transformation process. In the first part of this paper, differences between ‘Traditional’ Enterprises and the Virtual Enterprise approaches are presented. Then, in the second part, a partial model for transformation processes is presented, and in the third part a demonstrator simulation tool is presented as a contribution to support the transformation processes, of ‘Traditional’ Enterprises into Virtual Enterprise, along with a hypothetical example case.

Virtual Enterprise (VE) business environment is being one of the key areas for research in manufacturing worldwide. For example, Intelligent Manufacturing System (IMS) (Intelligent Manufacturing System, 2008) considers that one of five technical areas (Total Product Life Cycle Issues, Process Issues Strategy/Planning/Design Tools, Human/Organisational/Social Issues and Virtual/Extended Issues) is related with Virtual Enterprise. In the description of this area, IMS refers to a crucial aspect of the actual Virtual Enterprise paradigm, and the central point of the contribution of this paper for the transformation processes in enterprises, “However, the main challenge (of Virtual Enterprise) is organisational rather than technological” (Intelligent Manufacturing System, 2008). Also the European Technology Platform Manufuture refers that one of the enabling technologies for competitiveness and sustainability is the “new business models” (Manufuture, 2006).

So if all the stakeholders recognise the advantages of VE, why Enterprises don’t use them? Are there any missing links? There are some disablers like trust, transaction costs and intellectual property rights that constrain the development of the VE paradigm.

In this paper, Enterprises, “an organization created for business ventures” (WordWeb, 2006), are divided into two groups: ‘Traditional’ and Virtual. We consider the ‘Traditional’ Enterprises (TE) as a ‘stable’ structure that develops low level of partnerships (only with few customers and suppliers) and do not produce high level of dynamic reconfiguration and are with a long “life” if they are capable of. In opposition, Virtual Enterprises (VE) are characterised by their short “life” and show a high level of structural dynamics.

However, it is very critical to have a proper transformation process to convert the ‘Traditional’ Enterprise into the proposed organisational concept: Virtual Enterprises, successfully, in order to have the expected benefits and results (Putnik, Castro, & Shah, 2010).

The main objective of this paper is to present a simulation tool to support the transformation processes model and how this tool is to be used in some of the phases of the general transformation process. Within particular phases of the transformation process, the simulation tool has the following roles:

- (1)

To show the advantages of adapting to Virtual Enterprises and dynamic reconfiguration;

- (2)

To support learning processes as the requirement for effective adoption and implementation of the VE concept;

- (3)

To support the design of the VE to which the TE transforms (to define the VE parameters values that are possible to project);

- (4)

To support the evaluation of the benefits of the VE implementation under the given conditions (the conditions/parameters out of our influence).

The relevance of the paper is in conformance with the European Commission (EC) research policy, published in the document (EFFRA, 2010) as well as in the document (EC, 2010). For example, in the document (EFFRA, 2010) the relevance of the TE into VE transformation processes is addressed as the requirements for: “… transformation of enterprises due to the needs of customisation and sustainability, thus increasing the chances of success and global leadership…” (p. 10) “…c) short time-to-market (from the concept to new products on the market), enabled by ICT applications, which will increasingly be relevant in manufacturing industries;… e) adaptability/re-configurability through a modular approach in production systems, in order to maximise autonomy and interaction capability of machinery and continuous re-use of existing infrastructures…” (p. 13) “…- agile manufacturing and customisation involving process automation control, planning, simulation and optimisation technologies, robotics, and tools for sustainable manufacturing (smart factories); - value creation from global networked operations involving global supply chain management, product-service linkage and management of distributed manufacturing assets (virtual factories);…” (p. 17) “The Factories of the Future (FoF) initiative is part of the European Economic Recovery Plan launched in November 2008 to respond to the global economic crisis. …The ICT contribution to this initiative aims at improving the efficiency, adaptability and sustainability of manufacturing systems as well as their better integration within business processes in an increasingly globalised industrial context. Challenge 7 is fully dedicated to supporting the FoF PPP. The Challenge includes the areas: … ‘Virtual factories and enterprises’ addressing end-to-end integrated ICT allowing for innovation and higher management efficiency in networked operations and supporting the emergence of ‘smarter’ virtual factories and enterprises.” (p. 86) “This objective focuses on end-to-end integrated ICT solutions that enable innovation and higher management efficiency in networked enterprise operations. Target outcomes a) Distributed, adaptive, and interoperable virtual enterprise environments for business innovation, extensive monitoring, evaluation, forecasting, risk assessment and prevention, e.g. through collaborative business intelligence, productivity, knowledge management and/or mixed reality tools. R&D should aim at integrating novel management methods and ICT to help virtual factories and enterprises move beyond existing operational capability.” (p. 88)

The paper is organised as follows: in the first part, Sections 2 and 3, an introduction to VE and enterprise transformation strategies is presented. In the second part, Section 4, a model of ‘Traditional’ Enterprise to Virtual Enterprises transformation processes is presented. The relevance of this part of the paper is expressed on how the simulation tools are integrated in the TE to VE transformation process. The third part of the paper, Sections 5 and 6, presents the simulation tool as well as an example demonstrating how the VE, under certain VE parameters values, contributes to shortening Time-To-Market – the objective in accordance with the above recommendation in EFFRA (2010), EC (2010), and therefore, demonstrates the validity of transformation process to be undertaken. The paper closes with short conclusions and references.

2‘Traditional’ Enterprise vs. Virtual EnterpriseThe organisational paradigm proposed is the VE concept. This concept has been developed in the past decades to respond to the needs that companies and markets are now requiring, agility, market alignment, competitiveness, innovativeness and sustainability.

In 1984 the authors (Miles & Snow, 1984) referred to what is characterised as VE “…companies must be able to form network of reliable subcontractors … held in temporary alignment by a variety of market mechanisms”. Then the labels were born: network organisation (Miles & Snow, 1986), value-adding partnership (Johnson & Lawrence, 1988), organic network (Morgan, 1989), intelligent enterprise (Quinn, 1990), and Virtual Enterprise models, such as virtual value chains (Benjamin & Wigand, 1995), Virtual Enterprise (Drucker, 1990), virtual corporation (Davidow & Malone, 1992), extended enterprise (Browne, Sacket, & Wortmann, 1995), electronic markets and electronic hierarchies (Malone, Yates, & Benjamin, 1987), Electronic commerce or Electronic markets (Bakos, 1991). There is a broadened terminology to range VE concept, some sharing similarities and sometimes exclusive.

However, unfortunately or not, until today, there is not a universally accepted definition, or model, of the VE. But Putnik, Cunha, Sousa, and Ávila (2005) refers that there are three fundamental features of the VE concept that make the fundamental difference between the VE and the TE, and that generate a number of consequences, making that paradigm “shift”. These are:

- 1.

Dynamics of network reconfiguration,

- 2.

Virtuality, and

- 3.

External entities {Meta- (Virtual) Enterprise structures} as environments for enabling, or supporting the VE integration itself, as well as its reconfiguration dynamics.

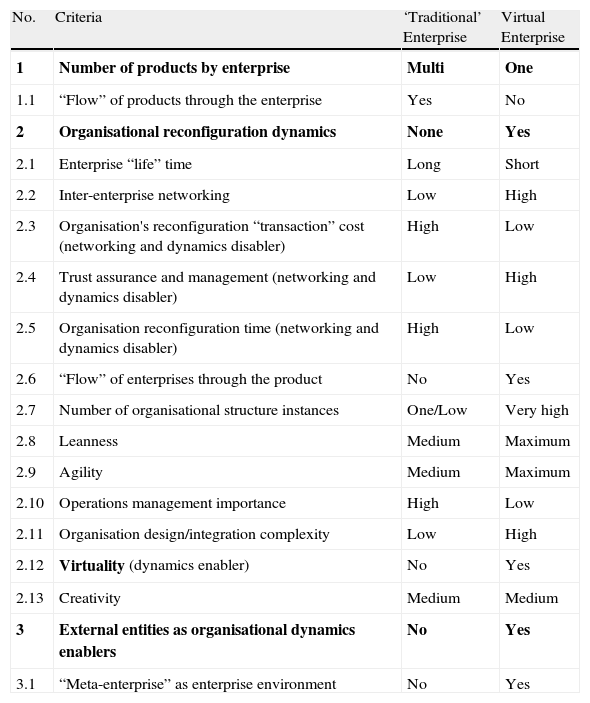

In Table 1, a comparison between ‘Traditional’ Enterprises and Virtual Enterprises potentials, concerning the three above-mentioned features, and a number of their consequences, are presented.

“Traditional” Enterprise (TE) vs. Virtual Enterprise (VE) potentials (Putnik et al., 2005).

| No. | Criteria | ‘Traditional’ Enterprise | Virtual Enterprise |

| 1 | Number of products by enterprise | Multi | One |

| 1.1 | “Flow” of products through the enterprise | Yes | No |

| 2 | Organisational reconfiguration dynamics | None | Yes |

| 2.1 | Enterprise “life” time | Long | Short |

| 2.2 | Inter-enterprise networking | Low | High |

| 2.3 | Organisation's reconfiguration “transaction” cost (networking and dynamics disabler) | High | Low |

| 2.4 | Trust assurance and management (networking and dynamics disabler) | Low | High |

| 2.5 | Organisation reconfiguration time (networking and dynamics disabler) | High | Low |

| 2.6 | “Flow” of enterprises through the product | No | Yes |

| 2.7 | Number of organisational structure instances | One/Low | Very high |

| 2.8 | Leanness | Medium | Maximum |

| 2.9 | Agility | Medium | Maximum |

| 2.10 | Operations management importance | High | Low |

| 2.11 | Organisation design/integration complexity | Low | High |

| 2.12 | Virtuality (dynamics enabler) | No | Yes |

| 2.13 | Creativity | Medium | Medium |

| 3 | External entities as organisational dynamics enablers | No | Yes |

| 3.1 | “Meta-enterprise” as enterprise environment | No | Yes |

After analysing this table, we could affirm that TE and VE are almost antagonist approaches. Due to the characteristics of these two approaches (TE and VE), the term “transformation” is almost reaching the notion of revolution.

3About the transformation strategiesThis type of transformation requires a shift in the enterprises. In literature, some of the transformation strategies are Total Quality Management (TQM), Business Process Reengineering (BPR) and more recently Chaordic System Thinking (CST), which impulse enterprises to change (ASQ, 2008; Eijnatten, 2004a, 2004b; Hammer, 1990; Hammer & Champy, 1993).

According to the American Society for Quality, “…Total Quality Management (TQM) is a management approach to long-term success through customer satisfaction” (ASQ, 2008) and further “…all members of an organization participate in improving processes, products, services and the culture in which they work”. This strategy begins in the Japanese manufacturing industry and focuses essentially in the incremental improvements of the enterprise members, pointing to customer satisfaction. TQM is considered to involve all organisation and aiming quality as a strategic objective.

The Business Process Reengineering was introduced by Hammer (1990) and the term ‘reengineering’ was used, for the first time, in the Harvard Business Review article: Reengineering Work: Don’t Automate Obliterate. And then in his book, co-authored with James Champy, Reengineering the Corporation (Hammer & Champy, 1993), they expressed the need for transformation. The definition the authors set for reengineering was: “the fundamental rethinking and radical redesign of business processes to achieve dramatic improvements in critical, contemporary measures of performance…”. These authors refer that this definition contains four keywords, but we emphasise three explicit keywords and one implicit in this definition: fundamental, radical, processes and, the implicit, people.

The general objectives of BPR stay up-to-date because environment is still unstable and highly dynamic. The non-deterministic dynamism is called, also, as turbulence. For these reasons it is fundamental to generate mechanisms to support business sustainability. As presented in the previous table, TE does not have intrinsic characteristics to be competitive and sustainable in turbulent markets, as, for example, the organisation reconfiguration time and agility. The shift is essential and requires a radical change in ‘traditional’ organisations. These changes will affect how enterprises develop their business model and processes will be different. And for the involvement and commitment of these challenges it is necessary that people participate actively.

Most recently, Eijnatten presented the Chaordic System Thinking (CST) “…a recent, qualitative framework in the domain of Complexity that both combines and generalizes exiting ideas from various disciplines, rather than inventing new concepts.” (Eijnatten, 2004a). CST is based on the Chaos and complexity management theory and provides a new approach to “…uncontrollability, uncertainty and complexity…” (Eijnatten, 2004b) in enterprises.

Eijnatten refers to five core properties of a Chaordic System: “consciousness”, “connectivity”, “indeterminacy”, “dissipation” and “emergence”, and puts man at the centre of the CST strategy.

In the strategies mentioned before, the intentions to transform enterprises are clear; in some cases the transformation processes are considered to be conservative (TQM) and in other cases are almost revolutionary (BPR and CST).

However, none of the mentioned strategies refers to the problem of TE for VE transformation. For this reason the next chapter presents a model that addresses this issue.

4A model of ‘Traditional’ Enterprise to Virtual Enterprises transformation processes4.1A global model of transformation processesThe purpose of this section is to present how the simulation tool is involved in the TE to VE transformation processes.

To proceed towards a strategic transformation and to achieve a full understanding of the advantages for enterprises to transform, a set of processes and tools is required. The simulation tool presented in the following chapter is one of the tools required for the proposed model of ‘TE to VE’ transformation processes.

The proposed model of ‘Traditional’ Enterprise to Virtual Enterprises transformation processes focus on the following two objectives:

- •

Preparedness of all the Enterprise staff, from blue-shirt to white-collar, to the VE approach.

- •

Transformation of ‘Traditional’ Enterprises, and not only to manage enterprise changes.

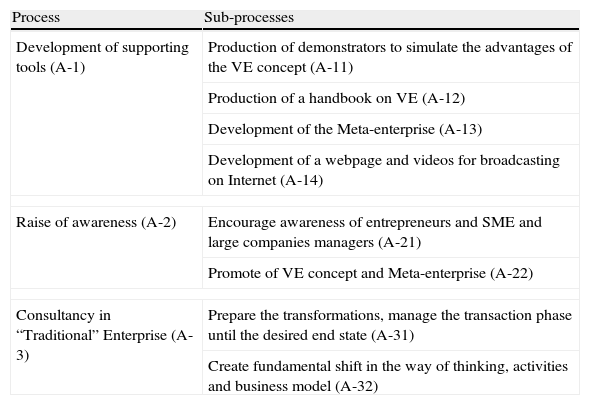

Some other processes should be included but in this paper we contribute with 3 (three) transformation processes (Table 2):

- •

Development of supporting tools;

- •

Raise of awareness;

- •

Consultancy in ‘Traditional’ Enterprise.

Transformation processes and sub-processes.

| Process | Sub-processes |

| Development of supporting tools (A-1) | Production of demonstrators to simulate the advantages of the VE concept (A-11) |

| Production of a handbook on VE (A-12) | |

| Development of the Meta-enterprise (A-13) | |

| Development of a webpage and videos for broadcasting on Internet (A-14) | |

| Raise of awareness (A-2) | Encourage awareness of entrepreneurs and SME and large companies managers (A-21) |

| Promote of VE concept and Meta-enterprise (A-22) | |

| Consultancy in “Traditional” Enterprise (A-3) | Prepare the transformations, manage the transaction phase until the desired end state (A-31) |

| Create fundamental shift in the way of thinking, activities and business model (A-32) | |

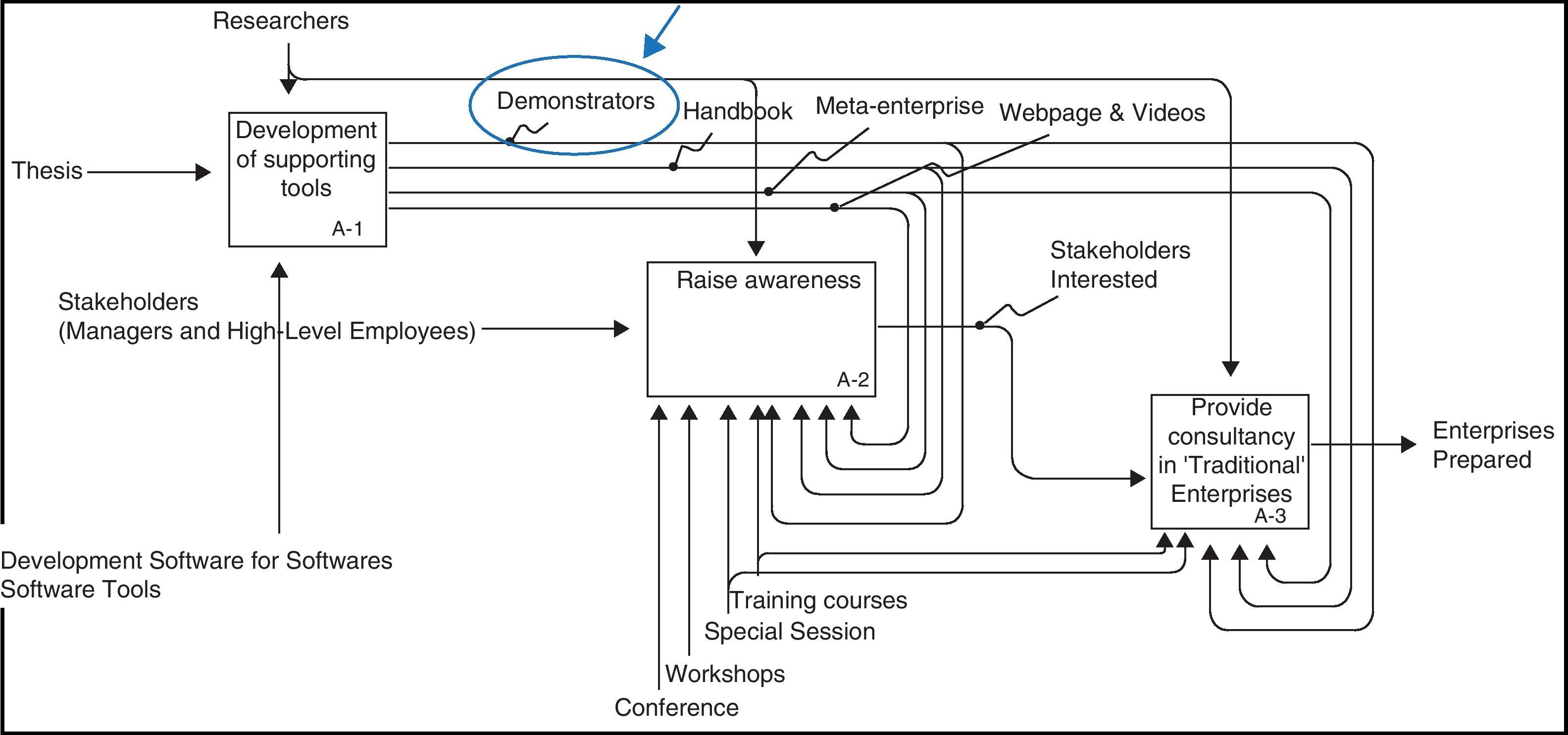

The modelling methodology IDEF0 (ICAM Definition Method – IDEF), based on graphically modelling language, was chosen for the specification of the transformation processes. The IDEF method was selected due to being a method designed to model processes and sub-processes.

The following IDEF0 diagram (Fig. 1) represents the overall operation of the Transformation Strategy that consists on the Development of supporting tools (Process A-1), then Raise of awareness (Process A-2) of enterprise owners, managers and others high-level employees (stakeholders) for the VE approach, and provide Consultancy in ‘Traditional’ Enterprise (Process A-3) of interested stakeholders to prepare enterprises for VE. The preparation and implementation of this Transformation will involve a group of researchers.

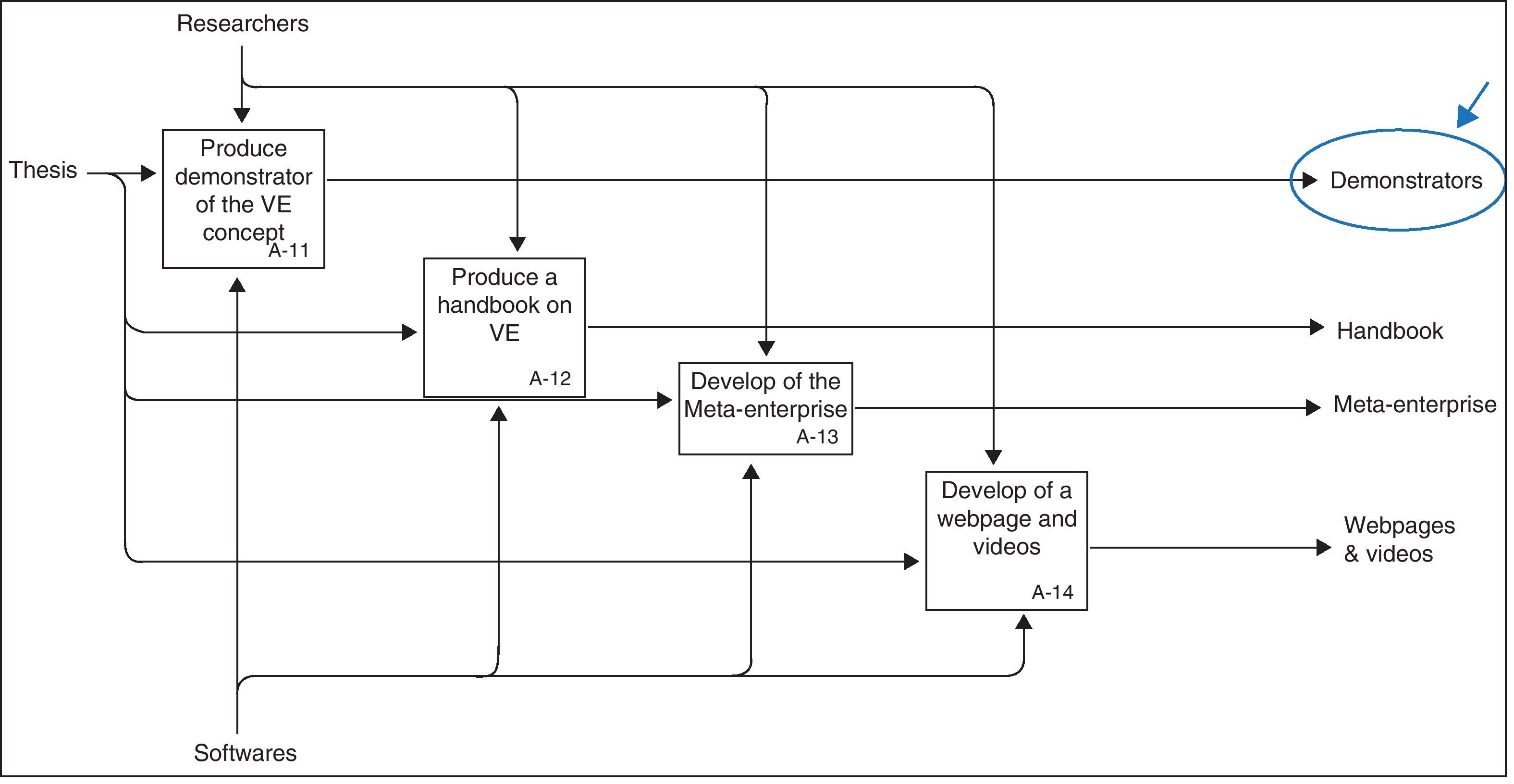

4.2Process A-1: development of supporting toolsThis process corresponds to the development of supporting tools to disseminate and corroborate the validity of the concept. Tools, like the proposed simulation tool, are critical to affirm and support the new paradigms.

So, it will be important to: (1) produce simulators to demonstrate the advantage of VE; (2) produce a handbook on VE; (3) development of a Meta-enterprise; and (4) development of a webpage and videos for broadcasting in Internet.

Indeed, this process consists of creating and spreading of instruments to create general consciousness about VE paradigm. And the proposed simulation tool, introduced in this paper, emerges from this particular process.

4.3Process A-2: raise of awarenessThis process consists on Encouraging awareness of entrepreneurs, Small and Medium Enterprises, and Large Enterprises; and to promote the Virtual Enterprise concept and Meta-enterprise. The encouragement of the awareness of entrepreneurs and all types of enterprises will require the organisation and development of conferences and workshops (Fig. 2). To achieve a higher level of understanding of the VE concept and mechanisms such as Meta-enterprises, Training Courses, Special Session and Software Tools will be prepared to Promote VE concept and Meta-enterprise (Fig. 3).

In this process, the simulation tool presented in this paper will be used to promote VE concept and Meta-enterprises.

4.4Process A-3: consultancy in ‘Traditional’ EnterpriseThis process represents detailed tailored made work in each TE interested in transformation towards a VE. First of all, it is necessary to support/help enterprises to prepare the transformations, manage the transaction phase until being prepared to develop VE, the desired end state. Then, create a fundamental mind-set of all staff, a shift in the way of thinking, activities and business model. In this consultancy process, the simulation tool will be applied to prepare companies in transformation (Fig. 4).

5Simulation toolAs mentioned before in this paper, Putnik et al. (2005) refers that there are three fundamental features of the VE (1. Dynamic of network reconfiguration; 2. Virtuality; 3. External entities {Meta- (Virtual) Enterprise structures} as environments for enabling, or supporting, the VE integration itself, as well as of reconfiguration dynamics). Considering two of these three fundamental features (1 and 3), the following software was developed with the objectives to develop a better understanding about the meaning of VE dynamic reconfiguration and the impact that it will produce on Product Time-To-Market.

5.1Dynamic reconfigurationIn general, dynamic reconfiguration keeps the partnership aligned with business requirements, i.e., business and market dynamics. The degree of the VE reconfigurability is the ability of fast change face to the unpredictable changes in the environment (market).

Putnik, Cunha, Cortes, and Avila (2007) affirm that reconfiguration means substitution, adding or removing of the VE partners, which are the resources providers, generating a new instantiation of the VE. Reconfiguration can happen mainly from four reasons:

- 1.

Reconfiguration during the network or VE life cycle, as a consequence of the product redesign in the product life cycle, to keep the network, or VE, aligned with the market requirements, i.e., to deliver the right product (either modified or a new product).

- 2.

Reconfiguration as a consequence of the nature of the particular product life cycle phase (the evolutionary phases of the product).

- 3.

Reconfiguration can happen also as a consequence of the evaluation of the partners, i.e. resources providers’ performance during one instantiation of the network, or a consequence of voluntary contract rescission by participating partners (or resources providers), willing to disentail from the network.

- 4.

Reconfiguration can also be a consequence of fluctuation in the demand side, or even a consequence of the so-called bull-whip effect phenomenon in the supply chain, where a little fluctuation in end customer demand can be dramatically amplified at the upstream company, requiring a fast adaptation for a short period of time. Supply chain dynamics is a strong cause of possible and unexpected reconfiguration needs in the network, or VE, originating a new instantiation of the network, or VE, substituting or reinforcing the provision of any partners (or resources providers), which is independent from the integrated resources performance, or from the product or business lifecycle.

The authors add that this requirement (for dynamic reconfiguration) implies the ability of:

- 1.

Flexible and almost instantaneous access to the optimal resources (partners, resources providers) to integrate in the enterprise;

- 2.

Design, negotiation, business management and manufacturing management functions independently from the physical barrier of space;

- 3.

Minimisation of the reconfiguration or integration time; and

- 4.

Minimisation of the transaction costs (transaction cost is also a function of the reconfiguration or integration time).

A consequence of the above-mentioned abilities is the reduction of Product Time-To-Market.

Reduction of Time-To-Market is a competitive factor. However, there is question on the reconfiguration model and its concrete parameterisation in terms of the required and possible real values for the model variables, that is, the variables of the VE dynamic reconfiguration transaction cost model.

The VE dynamic reconfiguration transaction cost model follows the model presented in Cunha and Putnik (2006a, 2006b).

The presented software tool “Simulator of the Impact of Virtual Enterprise Dynamic Reconfiguration on Product Time-To-Market” simulates, i.e., calculates, the effects of VE dynamic reconfiguration on reduction of the Product Time-To-Market conditioned by given values of the cost and time variables of the model (Putnik, Castro, Shah, & Cunha, 2009). In fact, the simulation tool assists to the VE and meta-organisational environment design by simulation.

The “Simulator of the Impact of Virtual Enterprise Dynamic Reconfiguration on Product Time-To-Market” simulates the effects of a Virtual Enterprise dynamic reconfiguration for two different models (supporting mechanisms). The first model refers to the use of traditionally available Internet tools (search engines, portals, e-catalogues, and e-marketplaces) for searching partners, negotiating, etc. This model is referred to as “e-Traditional”. And the second model refers to the use of a meta-organisation, in particular, the model “Market of Resources” as an organisation that assures a set of functionalities favourable to VE dynamic reconfiguration. This meta-organisation's main activity is to provide an electronically based environment for supporting intermediation integration services and processes among VE partners and brokers (VE managers).

Concerning the implementation of the simulator, it is an Internet-based software, developed in HTML language and traditional client-server architecture.

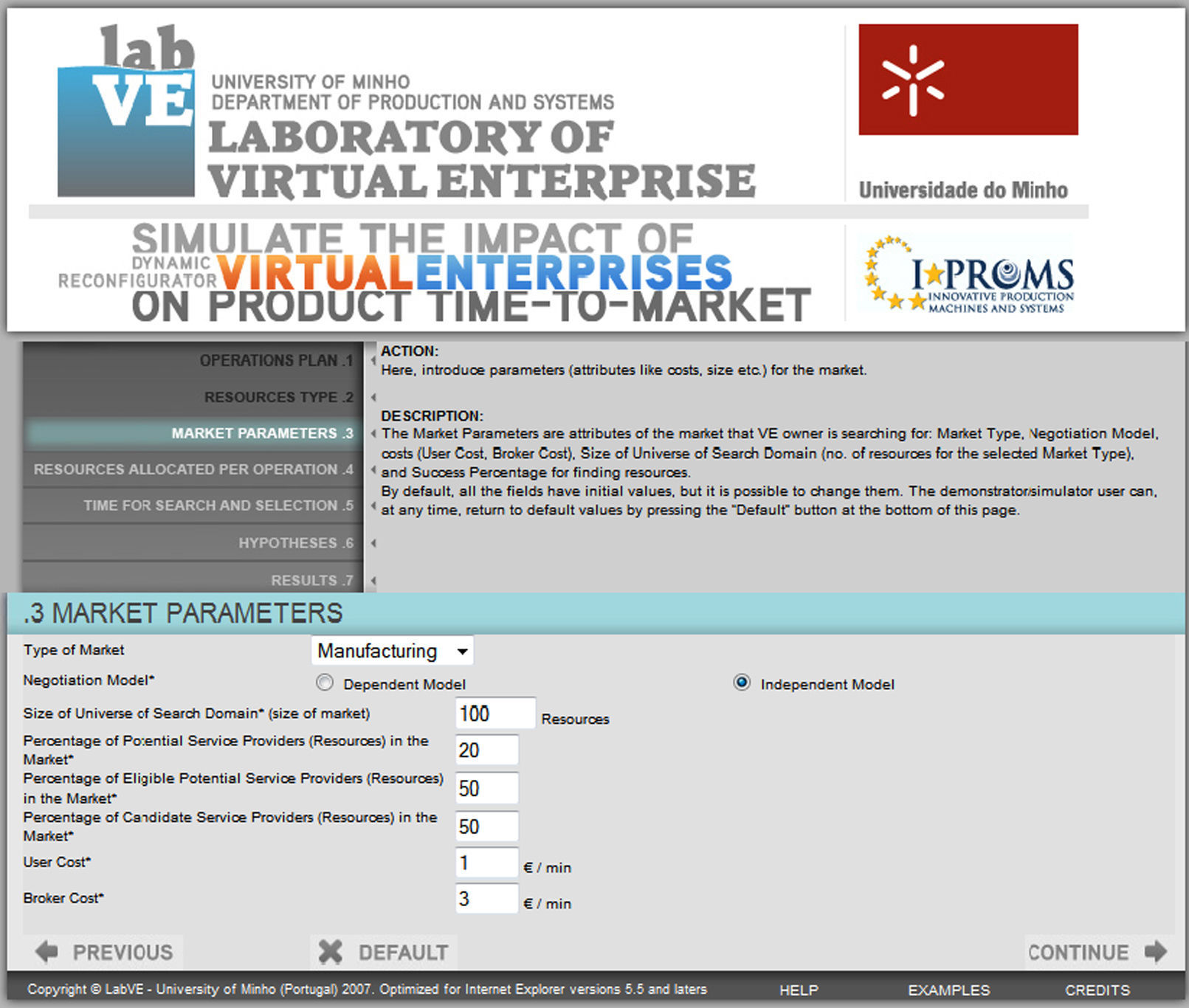

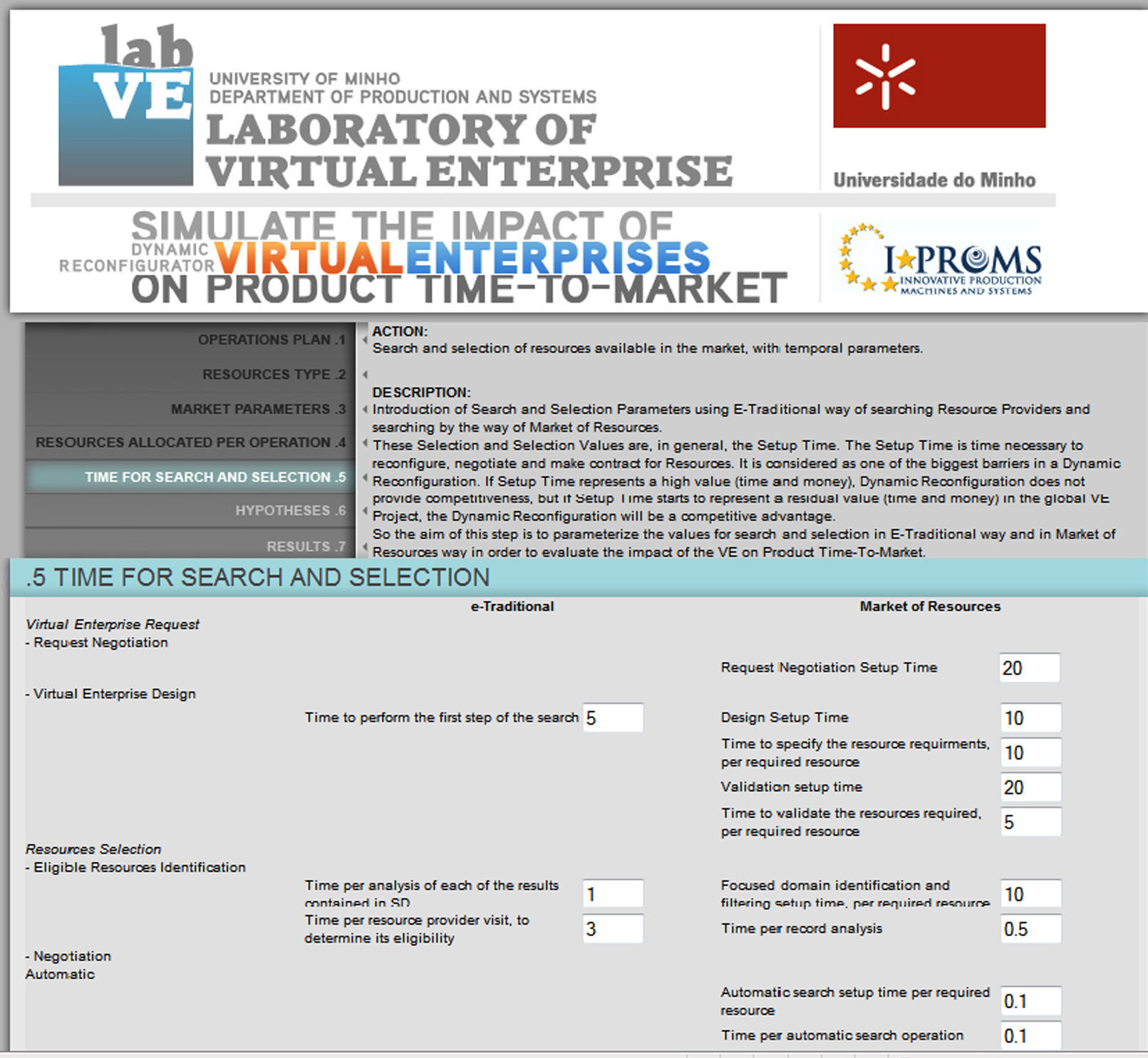

The simulator's start-up page is given in Fig. 5.

5.3Simulator general data flowThe simulator general structure is composed of two interfaces for data input and output, calculation and database (VE reconfiguration domain DB), presented in Fig. 6.

5.4Data input procedures and interfacesInput data are introduced through six steps.

1st step – in this step the production process plan, named “Operations Plan”, i.e. the number of Operations, Operations’ names, Quantities of each Operation, Acceptable Price per Operation per Resource, and Type of Negotiation, is introduced by the user.The input screen is presented in Fig. 7.

2nd step – in this step, named “Resources Type”, the values of the attributes like location, dimension of enterprise and quality certifications are introduced.

The input screen is presented in Fig. 8.

3rd step – in this step, “Market Parameters”, the values of the market attributes such as Market Type, Negotiation Model, Costs (User Cost, Broker Cost), Size of the Universe of Search Domain (no. of resources for the selected Market Type), and Success Percentage are introduced for finding resources.

By default, all fields have initial values, but it is possible to change these values. At any time the user could return to default values by pressing in the “Default” button.

The input screen is presented in Fig. 9.

4th step – in the step “Resources Allocated per Operation” it is possible to change the values, to input new values, of the attribute values of the operations and resources (candidate VE partner enterprises) selected by the calculation module after the 3rd step. There can be change in the values of the attributes: maximum production capacity per day, price per unit, shift hours per day and resource efficiency per resource and per operation.

One of the particularities of this step is that each Resource has its own Efficiency. Resource Efficiency means the percentage of work that a Resource already has allocated in its production capacity. For example, an enterprise has a maximum production capacity of 2000 units per day. If, on one day, the resource has 70% of efficiency, it means that on this day the resource allocated 70% of its production capacity and produced 1400 units (=2000units*70%) and the remaining 30% (600units) could be produced next day or by other partner if required.

The input screen is presented in Fig. 10.

5th step – in the step “Time for Search and Selection” search and selection parameters values for “e-Traditional” model and “Market of Resources” model are introduced. These “search” and “selection” values are, in general, the reconfiguration/setup time. The reconfiguration/setup time is necessary to reconfigure, i.e., to search, select, negotiate and contract resources. It is one of the major barriers for achieving a higher degree of reconfiguration dynamics. If reconfiguration/setup time is very long, high reconfiguration does not contribute to competitiveness, contrarily. However, if reconfiguration/setup time is very short then the high degree of reconfiguration will represent a competitive advantage (through reduction of Time-To-Market).

The input screen is presented in Fig. 11.

6th step – in this step, “Hypothesis”, it is possible to input data for creation of a maximum of 5 possible scenarios to simulate hypotheses of reconfiguration.

Each hypothesis is characterised by the number of days between two reconfigurations. In other words, during the life time of the VE, reconfigurations will be made periodically according to the number of days between reconfiguration defined for each scenario.

For example, if life time of the VE is 20 days and it is defined for in one scenario that the number of days between two reconfigurations is 7 days, it means that VE will be reconfigure two times, in day 7 and day 14.

The input screen is presented in Fig. 12.

5.5VE reconfiguration domain databaseThis database contains two tables: one table with resources efficiency and another with predefined attribute values of resources.

5.6Calculation moduleThe calculation module operates after the 3rd step of data input and after the 6th step.

The calculation algorithm follows the model achieved in Cunha and Putnik (2006b) and extended for the purpose of Time-To-Market and cost calculation.

5.7Data outputThere are two interfaces for data output, the first one is the interface of the intermediate results after the 3rd step of data input (see above) which is presented in Fig. 10.

The second interface for data output presents the final simulation results.

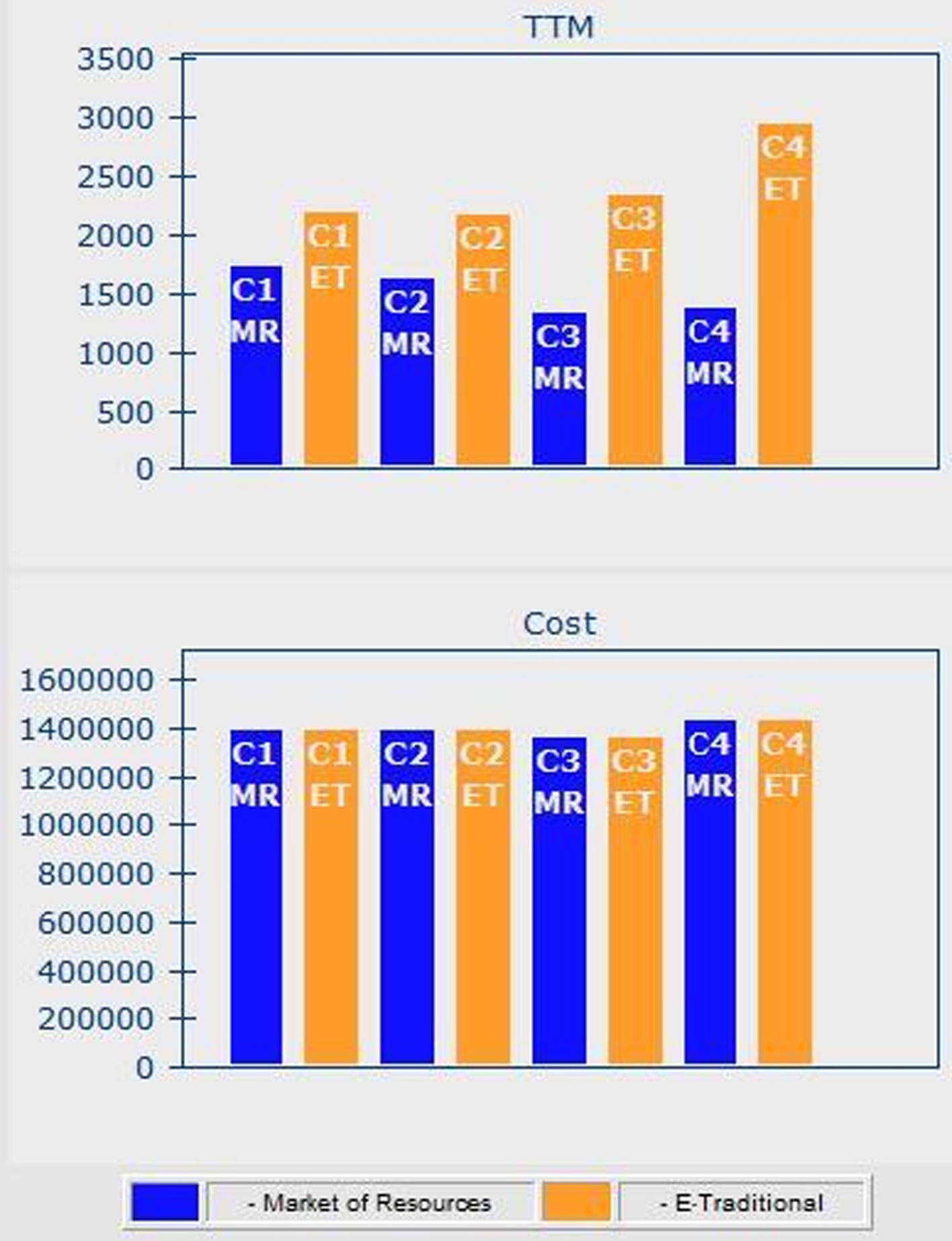

The calculated Time-To-Market and VE overall costs for each hypothesis of reconfiguration dynamics are presented in tabular and chart format for each scenario and for “e-Traditional” model and “Market of Resources” model.

A major part of the output screen is presented in Fig. 13. A part of the output screen is charts output, and in Fig. 14 a chart output is presented in detail.

6An example caseTo have a better understanding of the simulation tool, an example case is presented. This ‘academic’ example case simulates and calculates the effect of VE adoption and its dynamic reconfiguration on Time-To-Market reduction.

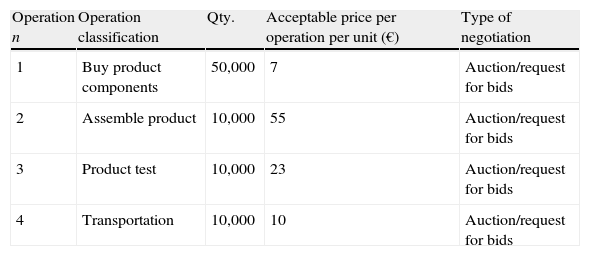

6.1Input dataThe example case is an example of a Virtual Enterprise creation to assemble products and this VE is divided on the operations presented in Table 3.

Operations list.

| Operation n | Operation classification | Qty. | Acceptable price per operation per unit (€) | Type of negotiation |

| 1 | Buy product components | 50,000 | 7 | Auction/request for bids |

| 2 | Assemble product | 10,000 | 55 | Auction/request for bids |

| 3 | Product test | 10,000 | 23 | Auction/request for bids |

| 4 | Transportation | 10,000 | 10 | Auction/request for bids |

This example case has the following input data:

- •

Type of market=manufacturing

- •

Negotiation model=independent model

- •

Universe of search domain=1000 resource

- •

Percentage of potential service provider in the search domain=10%

- •

Percentage of eligible potential service providers (resources) in the market=50%

- •

Percentage of candidate service providers (resources) in the market=10%

- •

User cost=1€/min

- •

Broker cost=3€/min

- •

Save resources

Finally, for the example case, the hypotheses on the reconfiguration dynamics tested were:

- •

Case 1 time between configuration=60 days

- •

Case 2 time between configuration=40 days

- •

Case 3 time between configuration=20 days

- •

Case 4 time between configuration=10 days

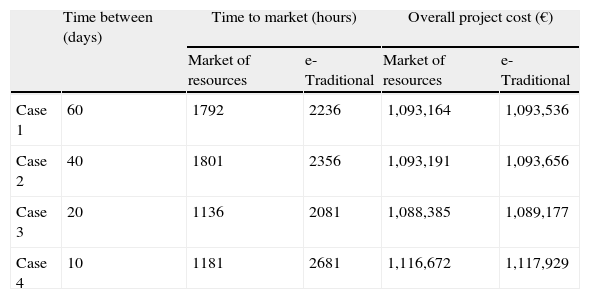

As seen in the output screen in Fig. 15 and in Table 4, the example refers to the 4 hypotheses analysed in this paper. The output shows the Product Time-to-Market and Overall Cost in the two models – Market of Resources and the e-Traditional way. Comparing the results, it is clearly seen that the Market of Resources, under the defined variable values, perform better than the e-Traditional way.

Table results of the example.

| Time between (days) | Time to market (hours) | Overall project cost (€) | |||

| Market of resources | e-Traditional | Market of resources | e-Traditional | ||

| Case 1 | 60 | 1792 | 2236 | 1,093,164 | 1,093,536 |

| Case 2 | 40 | 1801 | 2356 | 1,093,191 | 1,093,656 |

| Case 3 | 20 | 1136 | 2081 | 1,088,385 | 1,089,177 |

| Case 4 | 10 | 1181 | 2681 | 1,116,672 | 1,117,929 |

The purpose of this paper was also to present how the simulation tool could be used to evaluate impact of VE dynamic reconfiguration in Product Time-To-Market. As seen from the analysis of the results of the example case, applying the VE dynamic reconfiguration, it is clear to see significant reduction in the number of hours (duration) for product to reach to the market using the “Market of Resources approach” as compared to the e-Traditional approach. The impact introduced in the Product Time-To-Market is interpreted by the authors as direct influence on the enterprise capacity to adapt to rapidly changing markets and its sustainability in the market for long periods. However, it should not be lost from the view that the VE advantages are only under certain values of the variables, which demonstrate the importance of the design and development of tools and instruments which enable the VE parameters values that provide the expected advantages.

Finally, the authors conclude that this simulation tool is just one from the set of diverse tools and instruments which support transformation processes of ‘Traditional’ Enterprises into Virtual Enterprise.

The authors wish to acknowledge the support of: (1) The Foundation for Science and Technology – FCT, Project PTDC/EME-GIN/102143/2008, ‘Ubiquitous oriented embedded systems for globally distributed factories of manufacturing enterprises’ and (2) EUREKA, Project E!4177- Pro-Factory UES.