The use of by-products as additives in brick industry is gaining increased research attention due to their effective role in decreasing the total energy needs of industrial furnaces. In addition, these additives leave pores upon burning, causing a decrease in thermal conductivity and affect the mechanical properties of bricks as well. In the present study, various proportions of coal and wheat husk were used as additives in the initial ingredients of clay bricks. Microstructure, thermal conductivity, coefficient of thermal diffusivity, water absorption, shrinkage, compressive strength and bulk density of fired clay bricks with and without additives were investigated. Clay bricks containing 5–15wt.% additives were found to be within the permissible limits for most of the recommended standard specifications.

La investigación del uso de subproductos como aditivos en la industria del ladrillo está ganando atención debido a su papel eficaz en la disminución de las necesidades energéticas totales de los hornos industriales. Además, estos aditivos dejan poros después de la calcinación que causan una disminución en la conductividad térmica y afectan a las propiedades mecánicas de los ladrillos. En el presente estudio, varias proporciones de carbón y cáscara de trigo se han utilizado como aditivos en los ingredientes iniciales de ladrillos de arcilla. Se ha investigado la microestructura, conductividad térmica, coeficiente de difusividad térmica, absorción de agua, contracción, resistencia a la compresión y densidad aparente de los ladrillos de arcilla cocida con y sin aditivos. Los ladrillos de arcilla que contienen un 5-15% en peso de aditivos caen dentro de los límites permisibles para la mayoría de las especificaciones estándar recomendadas.

Pakistan is an agricultural country and 70% of its population is directly or indirectly dependent on agriculture [1]. Pakistan has rich coal deposits, estimated to above 185 billion tones [2]. Presently, coal is commonly used as fuel in bricks and roofing tiles kilns, as it is an ideal fuel for kilns, especially for heavy clay products. In Pakistan, about 50% of mined coal is used in the brick industry, making it a huge market for indigenous coal, in particular for private investors [3,4].

A number of materials are used in construction industry. The choice and suitability of a specific material depends mainly upon its availability, nature of the project, individual preference, durability, proximity and economic considerations. The use of renewable agricultural by-products and other wastes as performance increasing additives in brick industry is gaining more and more ground with time [5–7]. The additives mixed in the brick clay burn out during the firing process, generating extra energy within the brick, and decreasing the total energy needs of the industrial furnace. At the beginning, sawdust, wood chips and other wood-based materials were used, but more recently, polymers and renewable agricultural wastes, like rice-peel or seed-shell were also used as additives in the brick and tile industry. Environmentally friendly materials reprocessing and energy saving are significant research fields today. Furthermore, because of environmental regulations, the demand for clay bricks with higher insulation ability is increasing. Thermal conductivity is considered as a key factor for the heat-engineering concept of thermally insulating materials. One way to increase the insulation capacity of a brick is to increase its porosity. Combustible, organic pore-forming materials are the most frequently used additives for this purpose. Rimpel and Scmedders [8] determined the feasibility for the use of straw and reed residues produced during leached kraft pulp production, in clay brick manufacturing. Besides the composition of the waste, the feasibility was reported to depend on the porosity and structure of the clay body. To the first order, the clay body density determines the thermal conductivity [8,9].

A standard industry should be able to describe the thermal conductivity and other parameters primarily as a function of the concentration of the additive. Thermal conductivity is a measurable technological parameter and can be changed easily during the manufacturing process. Banhidi and Gomze [10] conducted a series of experiments to measure the influence of the type and concentration of the used waste materials on the thermal conductivity and mechanical properties of fired bricks. A number of mixtures were prepared using mined clay minerals with 0, 4 and 7wt.% additives (sawdust, rice-peel and seed-shell). The process used in the preparation of the sample products for these measurements was kept consistent with the industrial procedures, in order to assess the variation in properties due to the type of the material used as additive. Complete measurements were carried out at an average temperature of 61°C, and with a fixed 12°C temperature difference. This enabled comparison of results. The results of the heat conductivity measurements indicated that an increase in the quantity of organic by-products in the clay significantly decreased thermal conductivity of the product. With the addition of 7wt.% of by-products, the heat conductivity could be decreased by 16–37% from its original value. This indicated an improvement in the thermal properties compared to the industrially produced bricks [10].

The aim of the present study was to process low density clay bricks with high porosity without too much compromise on the mechanical strength. Coal and wheat husk were used as additives and their effect on the microstructure and properties of fired bricks were investigated.

Materials and methodsClay bricks were prepared by mixing 5, 10, 15, 20, 30, 40 and 50wt.% of coal and wheat husk individually with initial ingredients. The brick samples were made using a stainless steel mould by hand shaping, moulding, and hand pressing. The samples obtained with these shaping techniques were 20mm×15mm×10mm rectangular bars. The shaping technique was a simulation of the industrial processing performed at a laboratory scale. After having been formed, test pieces were subjected to drying and firing operations. To study the influence of heating rates, freshly shaped samples were placed in a drying oven at 110°C for over 4h to attain equilibrium residual moisture content in the clay bodies. Dried samples were placed directly in an electric furnace and sintered at a heating rate of 10°C/min to a maximum temperature of 1000°C and soaked for 1h. The fired bricks were allowed to cool down to room temperature naturally inside the furnace. In the present investigations, an attempt has been made to understand the effect of additives on the properties, such as thermal conductivity, microstructure, compressive strength and water absorption of sintered bricks.

Archimedes method was used to determine the water absorption and apparent porosity of different samples [9]. For this purpose, shaped samples were dried at 105°C to constant weight. The samples were weighed at dry state (W1), then boiled in water for 5h, cooled, and weighed in water (W2). The samples were weighed again at the saturated wet state in air (W3). The apparent porosity and water absorption of samples were calculated using Eqs. (1) and (2):

The microstructure of the samples was examined using a JSM-5910 (JEOL, Japan) scanning electron microscope (SEM), operating at 20kV. For SEM, sample were polished, thermally etched and then coated with gold to avoid charging under the electron beam. The chemical composition of samples was determined using a wavelength dispersive X-ray fluorescence (XRF) Spectrometer (Bruker AXS GmbH – S4 Pioneer, Germany), equipped with high power X-ray tube (X-ray tube (Rh anode, 75μm Be window)) of the maximum output of 4kW and eight diffracting crystals of various d-spacings, at PCSIR Laboratories Complex, Peshawar. The measuring conditions and settings were programmed using the computer programme. For low atomic number elements, low tube voltage was used and vice versa. The measurements were carried out in vacuum.

Mechanical strength of bricks was measured using a 100–500KN Universal Testing Machine (UTM, Testometric Co. Ltd., UK). The thermal conductivity (κ) and thermal diffusivity (α) of the samples were measured using a transient plane source (TPS) technique [11,12], by a calibrated Pt-100 thermometer, at Applied Thermal Physics Laboratory, COMSATS Institute of Information Technology, Islamabad. In this technique, a flat spiral heat source element is sandwiched between the sample halves as the heater and as the detector of temperature increase. The element was chosen according to the dimensions of the sample.

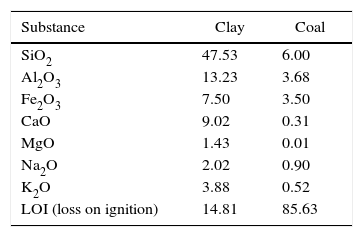

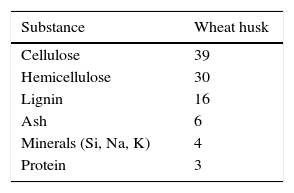

Results and discussionChemical composition of raw materialsThe main raw materials used in brick industry are clay and coal which in turn comprise silica, alumina, calcium oxide, and iron oxide. The composition of the raw materials used in the present study is given in Table 1. Oxides such as Fe2O3, CaO, K2O and Na2O acting as effective fluxes are known to lend good fired properties. A clay is considered as calcareous if it contains more than 6wt.% CaO [13]. If K2O, Fe2O3, CaO, MgO and TiO2 concentration amount to more than 9wt.%, the clay is referred to as low refractory and if the concentration of these oxides is lower than 9wt.%, the clay is referred to as highly refractory. In this perspective, the raw materials commonly used in brick industry can be considered as calcareous with low refractory properties. Wheat husk acts as a pore-forming additive or insulation material in brick manufacturing due to the constituent cellulose fibre. Chemical analysis results of wheat husk are given in Table 2.

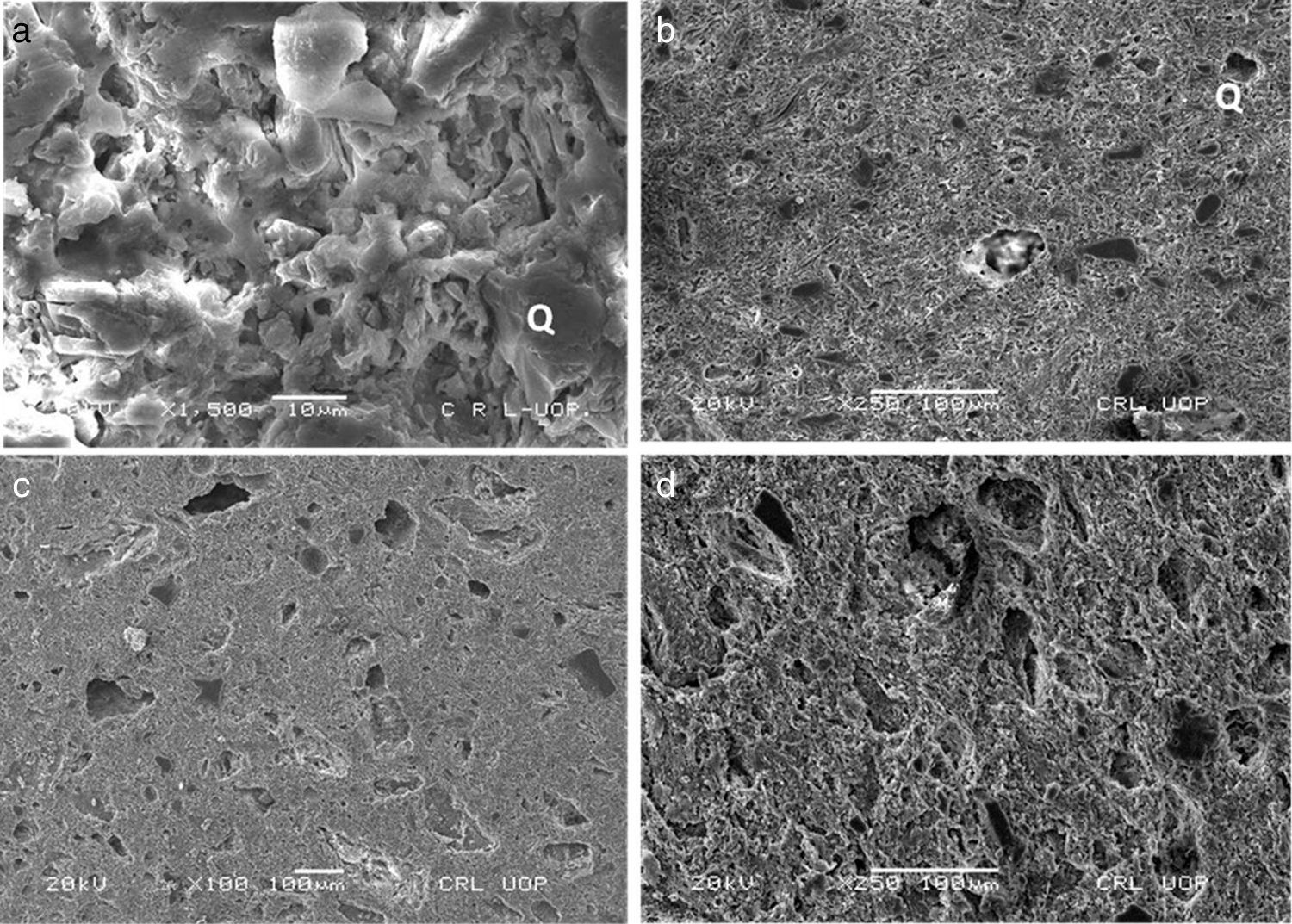

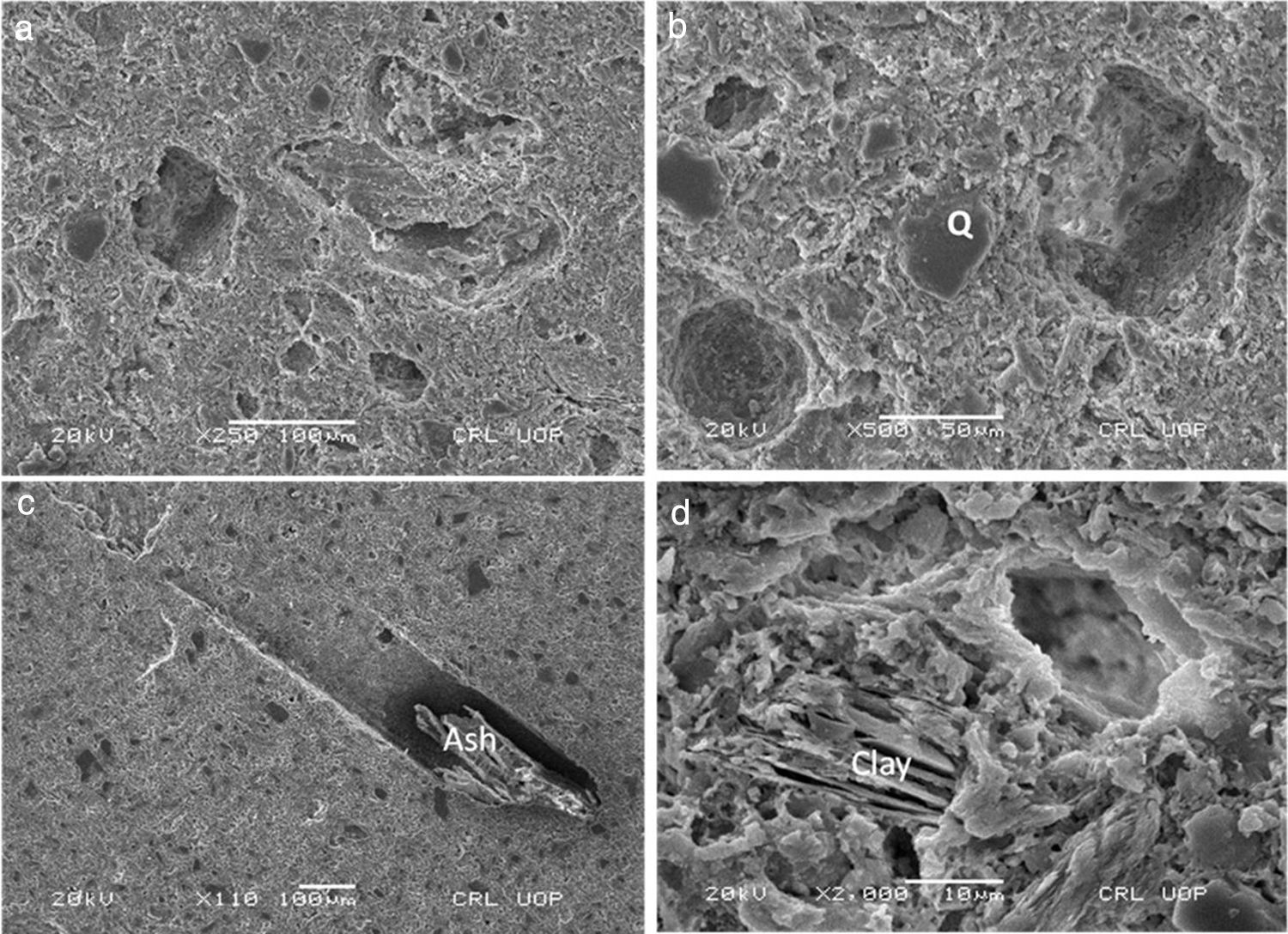

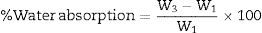

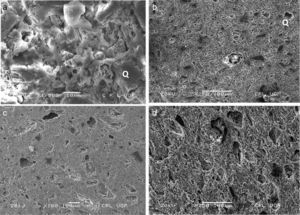

Fig. 1 shows the microstructure of fired bricks containing 0wt.%, 5wt.%, 10wt.%, and 15wt.% coal additive and Fig. 2 shows the microstructure of fired bricks containing 5wt.%, 10wt.%, 15wt.% and 20wt.% wheat husk. Both types of samples were fired at 1000°C. The microstructure of the coal as well as husk containing bricks comprised larger voids/pores than the bricks containing no additives. These voids appear due to complete burning of the additives. These images demonstrated that as coal content was increased, the concentration of voids increased, and hence water absorption. In such cases, water absorption can be decreased by increasing the firing temperature. The compressive strength was observed to decrease with an increase in coal content obviously due to increased porosity. Furthermore, a comparison of the microstructure of coal- and husk-added samples showed that wheat husk added bricks had larger pores/voids than the coal added bricks.

The assessment of samples shows that the porosity depends on the characteristics of the sample, and the size and nature of additive. As it can be seen in Fig. 2, the largest voids/pores (∼70–100μm), co-exist with the small micro-voids/pores (≤70μm). The voids are irregular in shape and pores are generally circular in shape. These images demonstrated that the concentration of pores increased with an increase in the amount of additives. The pores were probably formed by CaCO3 decomposition and burning of additives, as reported for the X-ray diffraction of the clay used in this study [14]. Wheat husk addition was more effective in terms of porosity, most probably due to its large grain size. From the economic point of view, production cost is controlled by producing bricks of relatively lower density. Moreover, a porous microstructure offers advantages for specific applications, such as insulation or even thermal shock-resistance which enables bricks to withstand rapid changes in temperature, due to the improved expansion tolerance and a certain decrease in the modulus of elasticity [15].

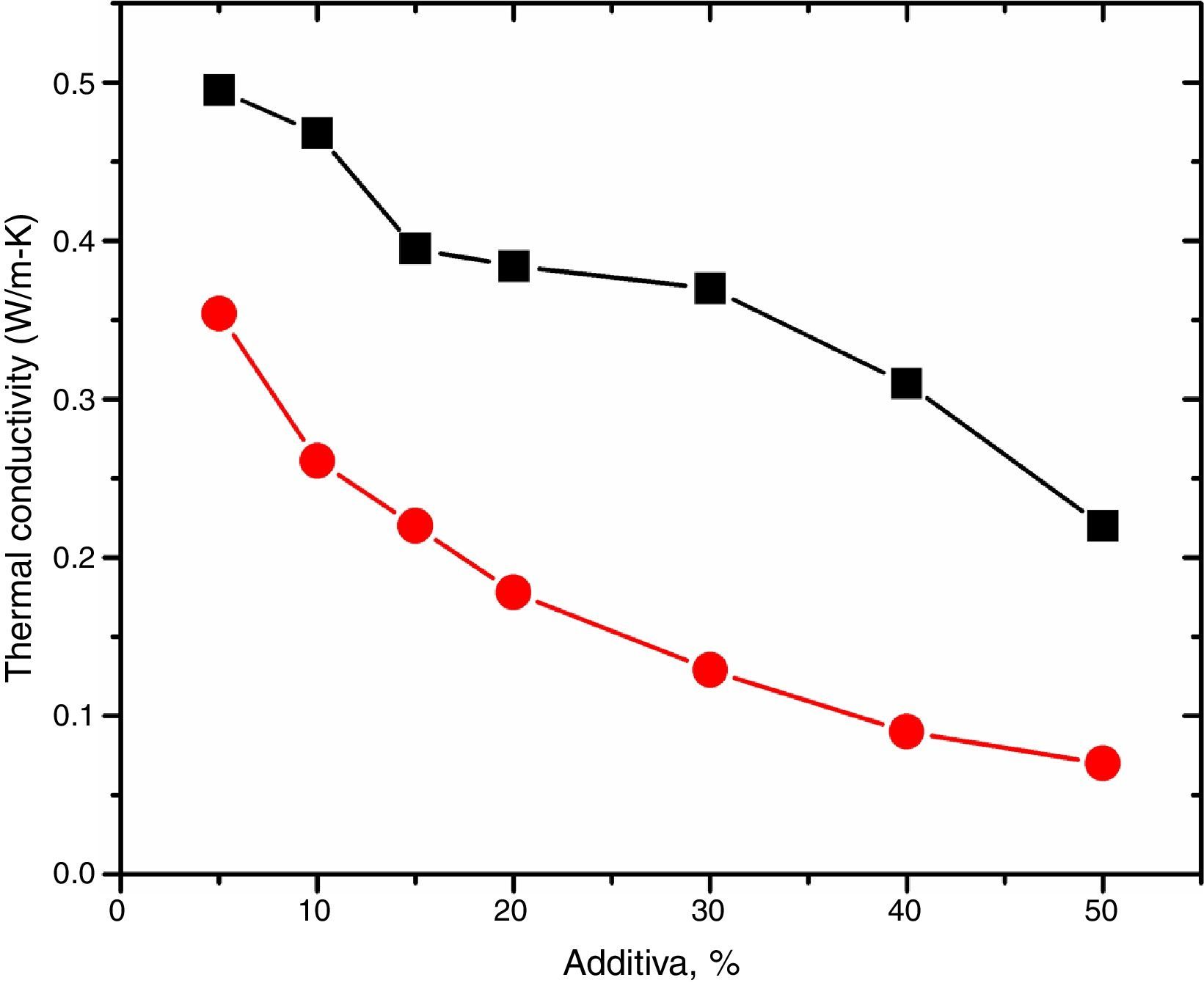

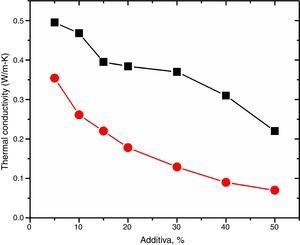

Thermal conductivityThermal conductivity depends not only on the properties of brick clay but also on the size, shape, and amount of the additives [16]. Fig. 3 shows the thermal conductivity results of the samples investigated in the present study. The current results demonstrated that the thermal conductivity considerably decreased with an increase in the amount of additives. Thermal conductivity of brick samples without any additive was λ=0.68W/mK, which decreased by 27% and even 68%, with the addition of 5 and 50wt.% coal, respectively. These measurements also showed that wheat husk was a relatively more effective additive in improving the insulating behaviour of the clay brick, leading to a decrease in thermal conductivity by 48%–92% with an increase in wheat husk content from 5 to 50wt.%. The observed decrease in thermal conductivity was even more than the common hollow bricks, because during wall building the mortar can enter the holes of the brick which is undesirable due to the consequent increase in the density of the wall and hence thermal conductivity [17]. The additives leave voids and pores in structure upon burning during firing. This seems to be the most probable reason for the observed decrease in thermal conductivity and improved thermal insulating properties. The presence of pores decreases the concentration of thermal conduction pathways; therefore, the higher the proportion of air inside a brick body the higher will be the thermal insulation character of the material since air is a good insulator in comparison to the solids. The microstructure, particle size distribution, and the amount of air space or voids created during the firing of a body govern the thermal conductivity of these materials [16]. The relationship between insulation power and texture or porosity cannot be expressed in simple terms. This needs to consider the influence of porosity because thermal conductivity depends upon the solid to air ratio which the heat has to traverse in passing through the material [18].

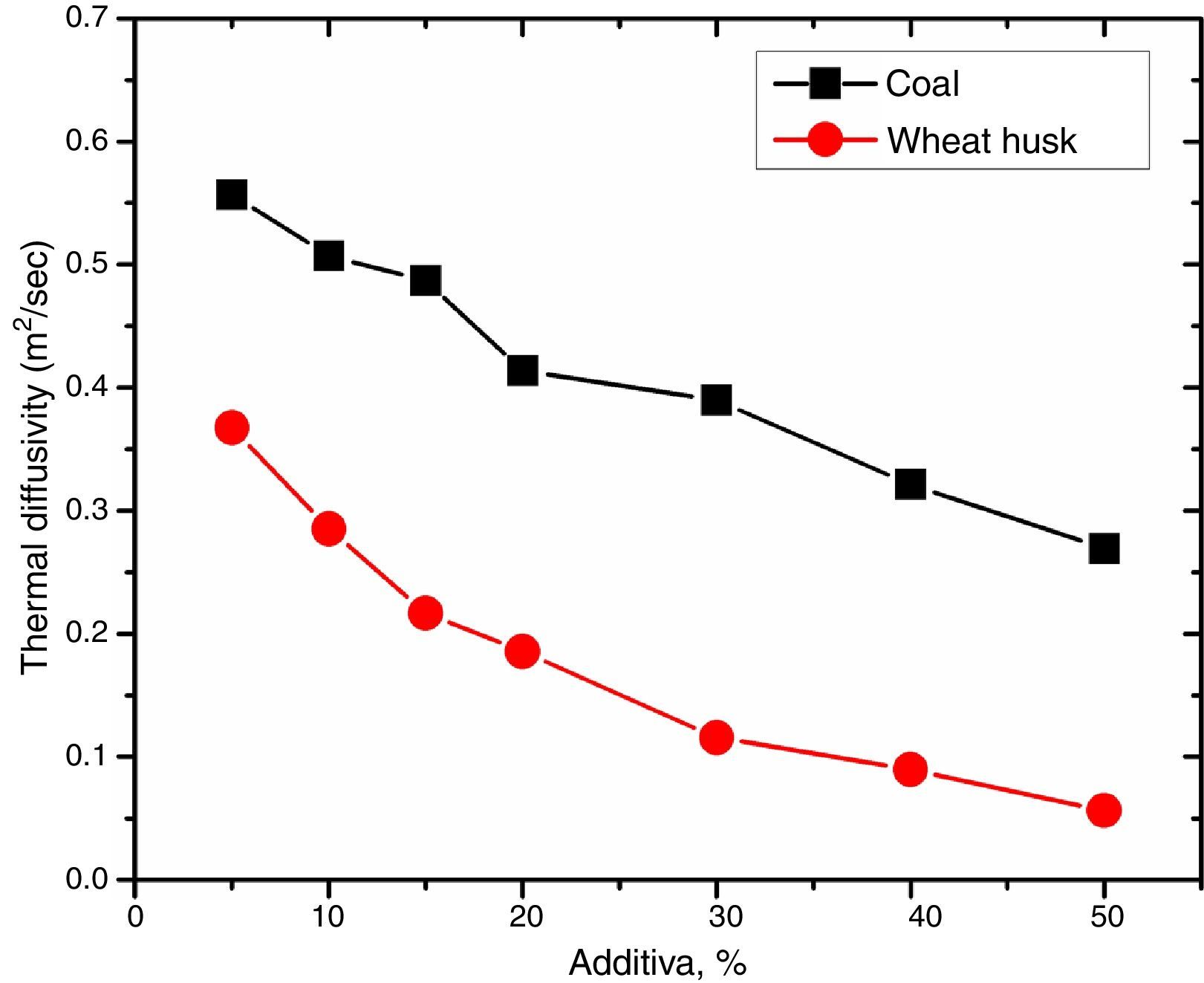

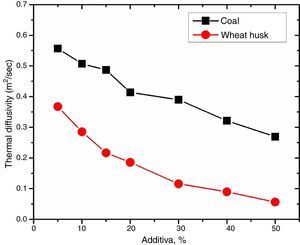

Thermal diffusivityThermal diffusivity (α) is a thermo-physical parameter unique for every material which is a measure of the heat flux rate through a medium, and depends on the composition and structure of the material. Physically, thermal diffusivity expresses how fast heat propagates across a material, being an important variable in transient heat transfer conditions [19]. The time rate of change of temperature depends on the numerical value of thermal diffusivity. The physical significance of thermal diffusivity is associated with the diffusion of heat into the medium during changes of temperature with time. Clay bricks with high thermal mass will take longer for heat to travel from the hotter face of a brick to the colder face [17]. Fig. 4 shows a decrease in the coefficient of thermal diffusivity with an increase in the amount of additives. The thermal diffusivity of brick samples without any additive was α=0.65m2/s, which decreased by 15–60% for 5–50wt.% coal additives. The present measurements also showed that the addition of wheat husk substantially influenced the thermal diffusivity of the clay brick and decreased the thermal diffusivity by 44–92% with an increase in wheat husk content from 5 to 50wt.%. The low thermal diffusivity values are required for minimizing heat conduction. The physical significance of low thermal diffusivity is associated with the low rate of change of temperature through the material during the heating process. The observed low values of the coefficient of thermal diffusivity in the present study demonstrated that the investigated samples are suitable for use as thermal insulators [19].

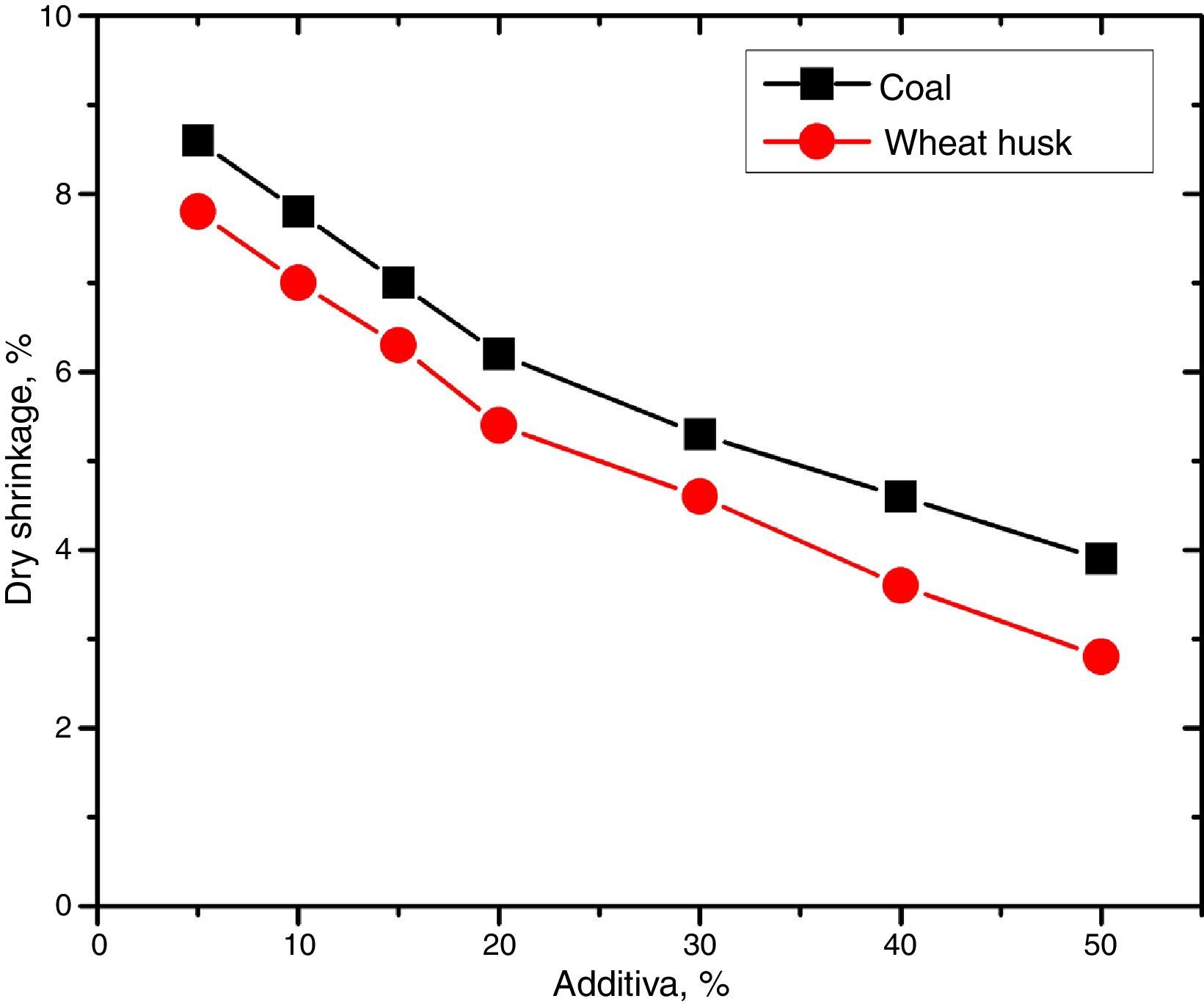

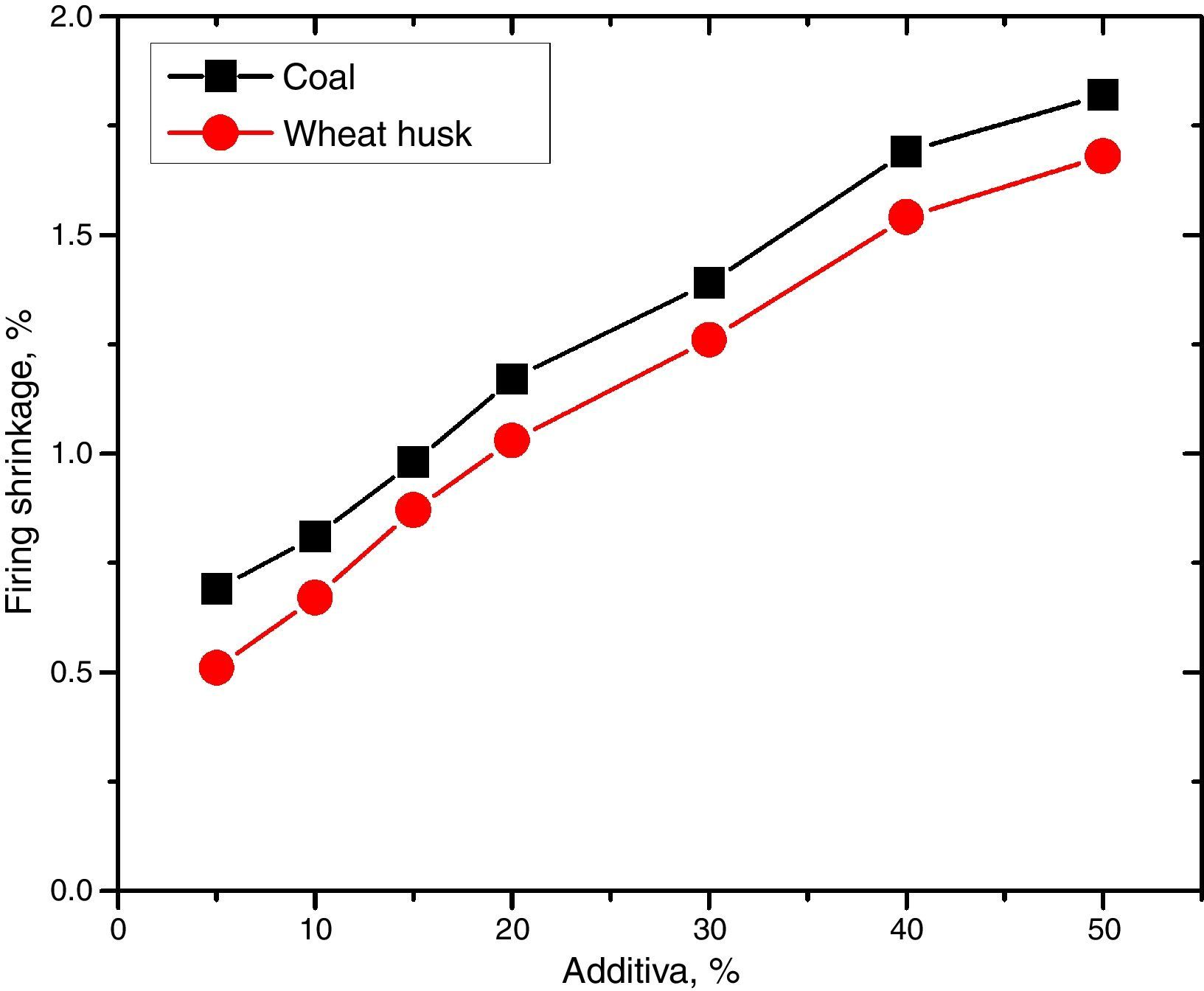

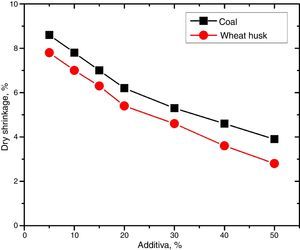

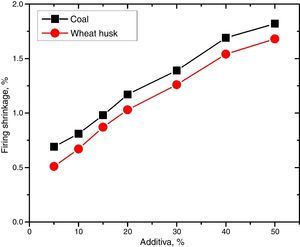

ShrinkageFigs. 5 and 6 show the observed shrinkage during the drying and firing cycles of clay bricks containing different concentrations of additives. The shrinkage during drying depends on the amount of water content present in the material under test. Usually, the quality of a brick is considered good if its drying shrinkage is lower than 8% (standard range) [20]. Therefore, at additives concentration ≥5%, the calculated values fall within the standard range. It is evident from Fig. 6 that the percentage of firing shrinkage increased with an increase in the amount of coal as well as wheat husk. The observed relatively lower values of firing shrinkage may be due to the removal of residual and chemically combined water as well as conversion of additives into ashes which evidently decrease the volume, but the higher values may be due to the migration of gases as a result of decomposition of carbonates, chlorine and sulphates (SO3) [21]. These chemical reactions during firing along with the rearrangement of grains/particles and orientational ordering in the crystal lattice form a more compact solid texture in comparison to the initial state which cause “shrinkage” [22,23].

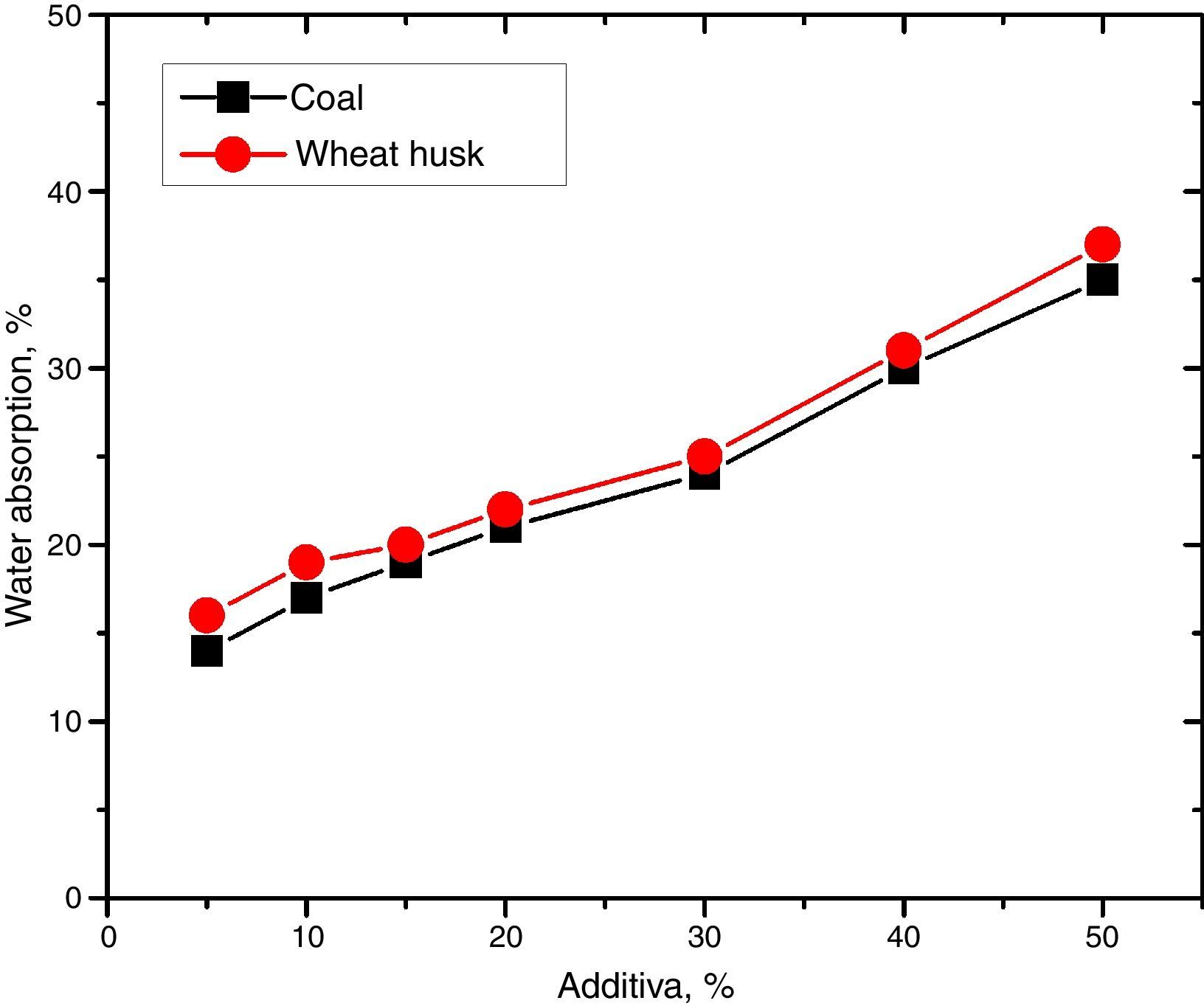

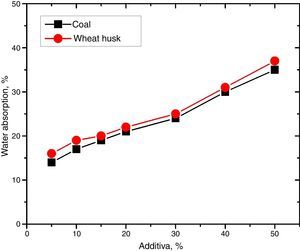

Water absorptionWater absorption of clay bricks without additives varies roughly from 8 to 21% and this variation is mainly due to slight differences in raw materials and the manufacturing process [24]. However, the water absorption of a good quality brick should not exceed 20% of its dry weight when kept immersed in water for 24h [25]. As shown in Fig. 7, the water absorption of the clay bricks with additives and fired at 1000°C in the present study was in the range of 14–35% for coal addition and 16–37% for wheat husk addition. It has been noted that the additives of more than 15% cross the acceptable limit (20%) of water absorption. Water absorption was closely related to the apparent porosity. The internal structure of bricks must be dense enough to stop the intrusion of water. To increase density and decrease water absorption of bricks, the firing temperature must be raised. Thus, porosity in fired specimens occurred as a consequence of burning of additives during firing.

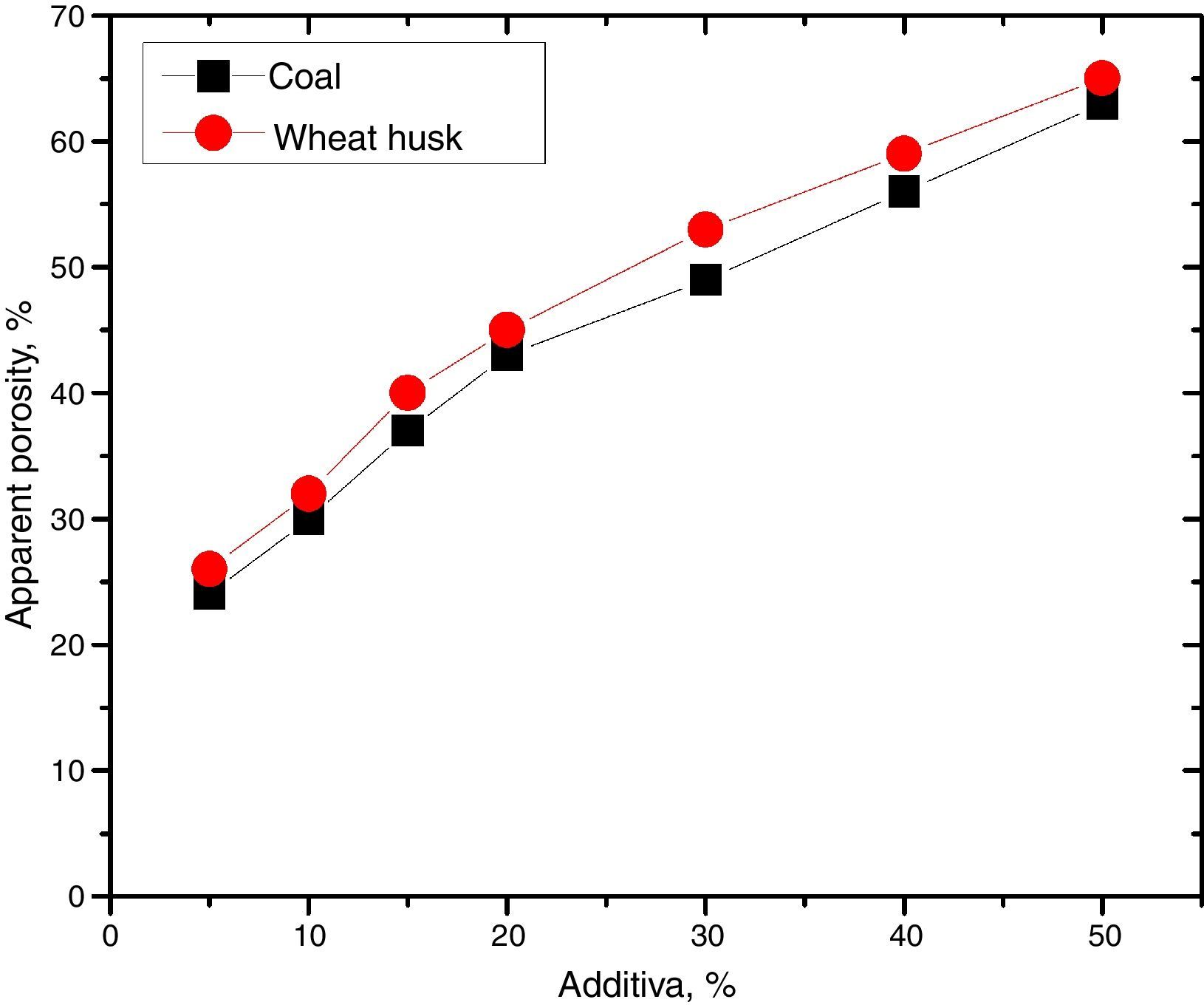

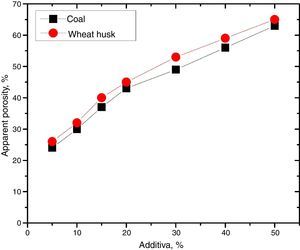

Apparent porosityPorosity refers to the proportion of voids (or pores) per unit volume of a porous solid. Usually porosity is related to mineralogy, internal brick structure and geometry. During firing of clay based products, liquid phase formation begins at temperatures above 900°C that helps in the elimination of voids and pores via filling the intra- and inter-granular areas. The present results demonstrated that fired bricks exhibited different apparent porosity values depending on the amount of additives. Thus, porosity or empty spaces in the fired test samples strongly depended on the amount of a specific additive which burnt during the firing process and resulted in the observed porosity. These empty spaces or voids (though may contain air) insulate thermal flow, causing a decrease in thermal conductivity of the samples as the amount of coal or wheat husk was increased. Fig. 8 showed that the highest porosity was 65% with 50% wheat husk addition, and the lowest porosity ∼24% with 5% coal addition. The high values of porosity and water absorption caused high thermal resistance [26].

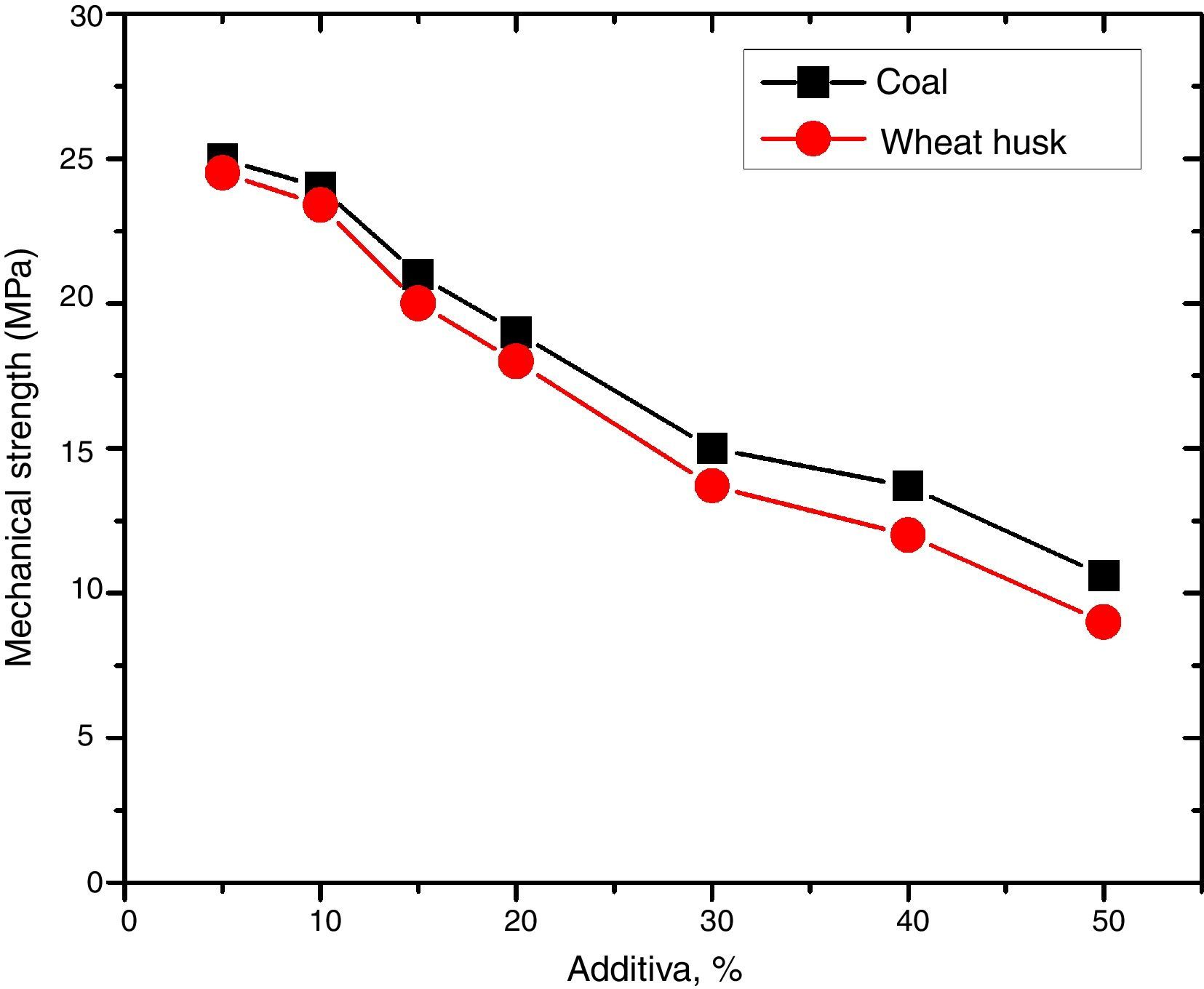

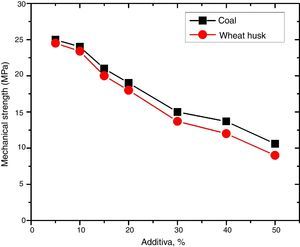

Mechanical strengthFig. 9 shows the observed variation in mechanical strength of coal and wheat husk added clay bricks. The present results indicated that the strength of test specimens depended on the quantity of additives. The observed compressive strength indicated that the compressive strength of test specimens fired at 1000°C decreased with an increase in the amount of coal as well as wheat husk. Compressive strength was observed to decrease from 15 to 4MPa and 14 to 3MPa, when coal and wheat husk contents were increased from 5 to 50wt.%, respectively. Generally, in clay based ceramic systems, strength decreases with an increase in porosity.

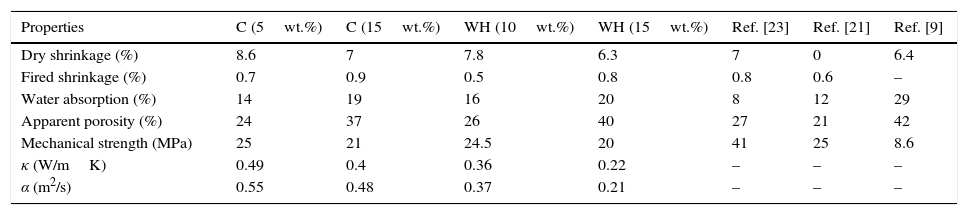

The aim of the present study was to process highly porous, low density clay bricks without too much compromise on the mechanical strength. The addition of large amounts of additives to brick clay is undesirable due to its adverse effects on the physical properties of the sintered bricks, due to the poor contact among various body ingredients hindering their mutual reaction. Moreover, an increase in additives concentration at the expense of the clay also affected the strength adversely due to the deficiency of the main clay content. This in turn led to a decrease in the amount of the vitreous or liquid phase which decreased the mechanical strength. Also, the migration of gases through the matrix produced due to burning of additives created a highly porous clay body which reflected negatively on the mechanical strength. Therefore, the amount of additives must be controlled to avoid adverse effects. Generally, the average compressive strength of locally made clay bricks without additive was ∼25MPa. The densification characteristics of some samples were in good agreement with the British Standard Institution [27] for good quality bricks, i.e., 15MPa. The compressive strength of any individual brick should not fall below the minimum average compressive strength specified for the corresponding class of brick by more than 20%. The technological properties of 5 and 15wt.% coal and wheat husk added samples are compared with literature (Table 3). Hence, the mechanical strength of the clay bricks containing 5–15wt.% additives lie within the permissible limits for most of the recommended standard specifications [9,27].

Comparison of the technological properties of 5 and 15wt.% coal (C) and wheat husk (WH) additives with the literature.

| Properties | C (5wt.%) | C (15wt.%) | WH (10wt.%) | WH (15wt.%) | Ref. [23] | Ref. [21] | Ref. [9] |

|---|---|---|---|---|---|---|---|

| Dry shrinkage (%) | 8.6 | 7 | 7.8 | 6.3 | 7 | 0 | 6.4 |

| Fired shrinkage (%) | 0.7 | 0.9 | 0.5 | 0.8 | 0.8 | 0.6 | – |

| Water absorption (%) | 14 | 19 | 16 | 20 | 8 | 12 | 29 |

| Apparent porosity (%) | 24 | 37 | 26 | 40 | 27 | 21 | 42 |

| Mechanical strength (MPa) | 25 | 21 | 24.5 | 20 | 41 | 25 | 8.6 |

| κ (W/mK) | 0.49 | 0.4 | 0.36 | 0.22 | – | – | – |

| α (m2/s) | 0.55 | 0.48 | 0.37 | 0.21 | – | – | – |

Clay brick samples containing coal and wheat husk as additives were prepared and characterized. Microstructural analysis of the samples revealed larger voids/pores in coal and wheat husk added samples than the normal bricks when fired at 1000°C. Thermal conductivity considerably decreased by 27% and even by 68%, with the addition of 5 and 50wt.% coal additives, respectively. A low coefficient of thermal diffusivity was observed with increasing additives which demonstrated that the investigated samples were suitable for use as thermal insulators. The water absorption of the clay bricks was in the range of 14–35% for coal added samples and 16–37% for wheat husk added samples. The highest porosity was 65% with 50% of wheat husk addition. Compressive strength was observed to decrease from 15 to 4MPa and 14 to 3MPa, when coal and wheat husk addition was increased from 5 to 50wt.% respectively. The densification characteristics of some samples were in good agreement with the international standard for good quality bricks ∼20MPa or the compressive strength of any individual brick should not fall below the minimum average compressive strength specified for the corresponding class of brick by more than 20 percent. Hence clay brick containing 5–15wt.% additives showed good results in comparison to the previously reported data.

The authors thank to the Khyber Pakhtunkhwa Government for the financial support through the Directorate of S&T, Peshawar for the upgradation of Materials Research Laboratory, University of Peshawar.