The humidity regulation in the interior spaces of buildings by means of passive solutions that do not require energy consumption is a topic of great interest due to the current needs for comfort and energy efficiency. This paper addresses the engineering of humidity regulating ceramic tiles that incorporate a functional coating formulated from gibbsite together with other common raw materials whose moisture regulating capacity has been demonstrated previously. A multi-layer coating tile system has been proposed, consisting of the following elements: an engobe layer, the functional coating with the regulating capacity, a decoration by inkjet technology and a protective topcoat glaze.

This system has been analysed with moisture adsorption–desorption tests. The moisture regulation capacity and the effect of the coating thickness on this property have been determined, allowing to optimise the functionality.

Finally, an analysis of the humidity regulation has been performed on the basis of demonstrators or small-sized cubicles that simulate the conditions of final use in rooms of buildings. The results show the different behaviour of the demonstrator with functional tiles in relation to conventional tiles, with an indoor ambient humidity that remains in the comfort zone for longer periods of time.

La regulación de humedad en espacios interiores mediante soluciones pasivas que no requieren consumo energético es un tema de gran interés debido a las necesidades actuales de confort y de eficiencia energética. Este trabajo aborda la ingeniería de baldosas cerámicas reguladoras de humedad que incorporan un recubrimiento funcional formulado a partir de gibbsita junto con otras materias primas comunes cuya capacidad reguladora de humedad ha sido demostrada previamente. Se ha propuesto un sistema de baldosa con recubrimiento multicapa compuesto por los siguientes elementos: una capa de engobe, el recubrimiento funcional con capacidad reguladora, una decoración por tecnología de inyección de tinta y un esmalte protector.

Este sistema ha sido analizado mediante ensayos de adsorción-desorción de humedad. Se ha determinado la capacidad de regulación de humedad y el efecto del espesor del recubrimiento sobre esta propiedad, lo que ha permitido optimizar la funcionalidad.

Finalmente, se ha realizado un análisis de la regulación de humedad mediante demostradores o pequeños cubículos que simulan las condiciones de uso final en estancias de edificios. Los resultados muestran el diferente comportamiento del demostrador con baldosas funcionales en relación con baldosas convencionales, con una humedad ambiental interior que se mantiene durante más tiempo en zona de confort.

Sustainability and energy efficiency are currently some of the main concerns in all sectors, causing a paradigm shift in which the use of clean and renewable energy sources and energy saving are taking on special importance. From a building point of view, the key factors to consider for healthy and energy-saving dwellings are insulation, airtightness and ventilation. The main focus is on increasing insulation and minimising air exchange with the outside, eliminating undesired air ingress and egress. Numerous studies have addressed the possibilities of thermal insulation in buildings, with results indicating an energy saving impact of more than 80% [1,2].

In addition, ventilation is other source to be considered in energy consumption. It can be generally accepted that the energy cost of ventilation for indoor spaces in buildings represents over 30% of the total air-conditioning consumption [3,4]. Thus, if ventilation rates in dwellings are reduced, energy will be saved, but at the same time indoor air quality will deteriorate, which can lead to unhealthy situations with detrimental effects on the occupants and an increase in the symptoms characteristic of sick building syndrome (SBS). These symptoms, commonly attributed to exposure to particular building environments, include irritation of the mucous membranes and skin, neurotoxic problems, hypersensitive reactions and odour and taste sensations among others [5].

According to the literature [6], the relative humidity range that corresponds to the comfort zone is between 40 and 70%. Excessively low humidity can cause dryness and irritation of eyes by increasing tear evaporation, scaly or itchy skin and nasal congestion due to dryness and irritation of the mucous membrane [7]. On the other hand, a high humidity environment favours the proliferation of dust mites and moulds, contributing to respiratory infections, allergies and asthma problems, as well as aggravating symptoms of rheumatism and other bone diseases [8]. Moreover, findings indicate an elevated proliferation of viruses in environments with extreme humidity [9,10].

A passive solution, without additional energy consumption, to satisfy comfort indoor humidity requirements is the use of self-regulating materials based on adsorption and desorption processes. There is extensive literature on humidity regulation by means of building materials with this behaviour [11–14]. These materials have porous structures including mesopores (pores between 2 and 50nm), which allow capillary condensation according to the Kelvin equation [15,16]. These materials also enhance air quality due to their ability to adsorb and reduce some of the most common pollutants in domestic environments, such as formaldehyde, ammonium gases, hydrogen sulphide, methanethiol or trimethylamine [17,18]. Osanyintola et al. [19] have already demonstrated the possibility of reducing heating energy consumption by 5% and cooling energy consumption by 30% when combining hygroscopic materials with properly controlled heating, ventilation and air conditioning systems.

As a novelty, this work aims to analyse the humidity control in interior spaces by means of ceramic tiles which incorporate a functional coating with regulating capacity. This has been performed from the engineering preparation of the tiles including the design and characterisation at laboratory level, the subsequent industrial development and the validation of the functionality by means of sensorised demonstrators.

The functional coating has been designed for suspension application on typical unfired tile bodies, in this case porcelain stoneware, and has been formulated from gibbsite-based compositions. For that purpose, the coating requires the preservation of a porous structure with mesopores after the firing cycle with maximum temperatures around 1180–1200°C, common values for this type of product [20]. The humidity regulation capacity of compositions with gibbsite has already been tested on a laboratory scale with satisfactory results that allowed obtaining optimised compositions with excellent regulating capacity by means of mesoporous structures with raised proportion of small pore size and high specific surface area [21]. The effect of the firing temperature was also analysed, so that the gibbsite-based compositions maintained an adequate microstructure and regulating capacity until the formation of alpha alumina (corundum) at high temperature [22].

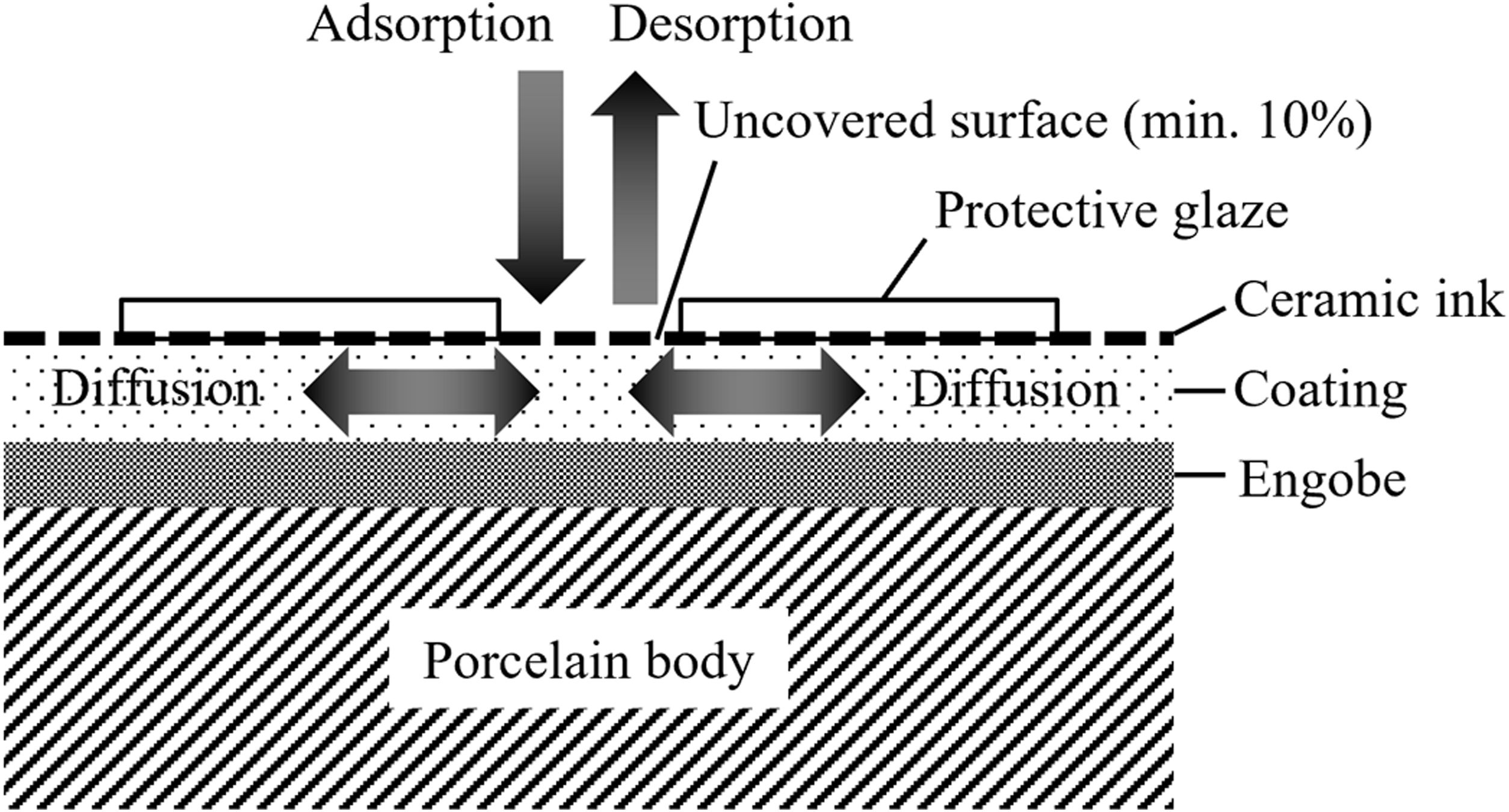

An important issue for ceramic tiles is nowadays the final superficial aesthetic appearance. Ceramic tiles are building materials that have undergone a strong evolution in terms of design in recent years [23]. The applied designs should not completely seal the coating and special configurations have to be implemented so that the surface is not completely covered to allow the exchange of water vapour between the coating and the environment. The function of the decorative layers is double, on the one hand to provide the tile with the desired aesthetic properties, on the other hand to increase the surface protection and cleanability of the coating.

The regulating behaviour of the tiles has been verified through the construction of demonstrators internally clad with coated tiles and conventional tiles, maintaining identical all other construction parameters, so that the conditions of final use in buildings and dwellings rooms are reliably simulated. The regulating capacity has been characterised by means of cycles in which the indoor relative humidity is varied using humidifiers and dehumidifiers, measuring and recording the evolution of the humidity using thermo-hygrometers.

Material and methodsLab-scale development of functional coatingThe moisture regulating tile is basically composed of a typical ceramic substrate and a coating with the self-regulating functionality that is subsequently decorated. A standard Spanish porcelain stoneware composition was selected as the substrate, which consists mainly of silica and alumina with small proportions of alkalis and alkaline earths to achieve adequate sintering at the usual firing temperature [24]. These compounds are provided by a composition mainly formulated from kaolinitic clay, feldspar and quartz [25,26]. The composition was used in the form of spray-dry powder, so that laboratory and industrial pieces were obtained by uniaxial pressing.

The functional coating composition was prepared according to the formulation developed in other works with good humidity regulation properties and microstructures containing high presence of mesopores, which remained acceptably after firing cycles in laboratory furnaces [22,27]. This composition contains a high percentage of gibbsite, a key component for moisture regulation due to its particular microstructure that is largely preserved up to industrial firing temperatures (around 1200°C), together with percentages of other plastic (clays) and non-plastic materials (quartz and talc). The composition was prepared in the form of a concentrated aqueous suspension by wet grinding the raw materials in a ball mill to reduce the particle size, as prepared in the ceramic industry for application on the unfired (pressed) body. In addition, the suspension can be dried and dry milled to obtain a ceramic powder when necessary.

The firing behaviour of both materials was evaluated at laboratory level by determining the firing diagram from circular pieces with a diameter of 40mm and a thickness below 7mm. These pieces were obtained by pressing from powders. Pressures were 40MPa for the body composition and 30MPa for the coating composition. The firing was carried out in an electric laboratory furnace at maximum temperatures between 1160°C and 1220°C with a dwell time of 6min. The linear shrinkage was determined from the difference between the diameter of the specimen before and after firing, defining this parameter on a dry basis, and the water absorption was obtained by the vacuum method following the ISO 10545-3:20128 standard.

At laboratory level, the moisture regulating capacity of 10cm×10cm square pieces obtained from industrially prepared tiles with different coating thicknesses was also determined. Coating specific amounts tested were the following, 670, 1000, 1330 and 1670g/m2. The tests were performed in a climatic chamber (HC2020, Heraeus Vötsch) under isothermal conditions and variations in relative humidity following the procedure described in the previous research [21]. In the first place, the pieces were placed inside the chamber, the temperature was set at 23°C and the relative humidity at 50% for sufficient time to reach equilibrium with a minimum time of 16h. Then, the initial weight (m0) was determined, the pieces were reintroduced into the chamber, the relative humidity was increased to 90% and weighing was performed at increasing time periods (mt) for 24h. After that, moisture desorption was determined in an analogous way by changing the relative humidity from 90% to 50% and carrying out the corresponding weighing. The results were expressed as weight gain with respect to the initial weight (mt−m0) per unit surface area (S).

Industrial-scale developmentHexagonal substrates 16.5cm in size and 9mm in thickness were formed from the spray-dried porcelain stoneware powder, using an industrial press (PH-2590, Sacmi). Next, these substrates were coated with the functional composition by continuous bell application, a very common procedure for glazing in industrial practice. A layer of engobe was deposited on the bodies prior to the application of the coating in order to improve the adhesion between coating and body and reduce thermal expansion mismatch stresses, as is done in the industry.

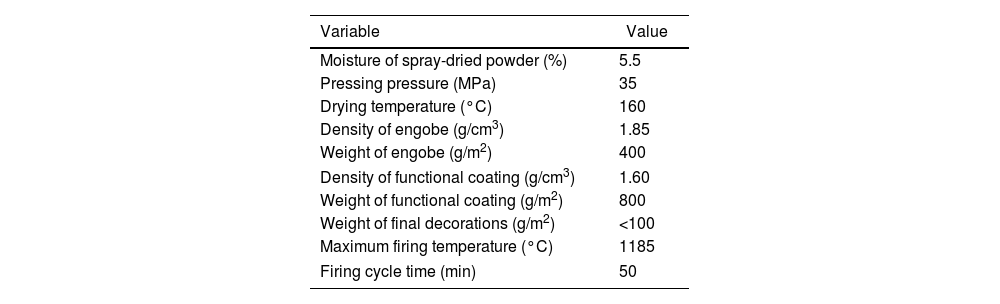

The functionally coated tiles were decorated using inkjet technology (S7, Kerajet) by applying inks and a top glaze. The decorations were carried out following a discontinuous pattern design, so that the coating surface was not completely sealed, and areas were left uncovered (approximately 15% of uncovered area). These decorations improve the aesthetic appearance, allow the exchange of water vapour with the environment and protect the porous coating surface against scratching and staining. Finally, the pieces were fired in an industrial double-channel roller kiln (FBS-2850/1134, Sacmi) following a standard fast thermal cycle. Table 1 shows the main industrial conditions for manufacturing the functional tiles.

Main industrial conditions for manufacturing the functional tiles.

| Variable | Value |

|---|---|

| Moisture of spray-dried powder (%) | 5.5 |

| Pressing pressure (MPa) | 35 |

| Drying temperature (°C) | 160 |

| Density of engobe (g/cm3) | 1.85 |

| Weight of engobe (g/m2) | 400 |

| Density of functional coating (g/cm3) | 1.60 |

| Weight of functional coating (g/m2) | 800 |

| Weight of final decorations (g/m2) | <100 |

| Maximum firing temperature (°C) | 1185 |

| Firing cycle time (min) | 50 |

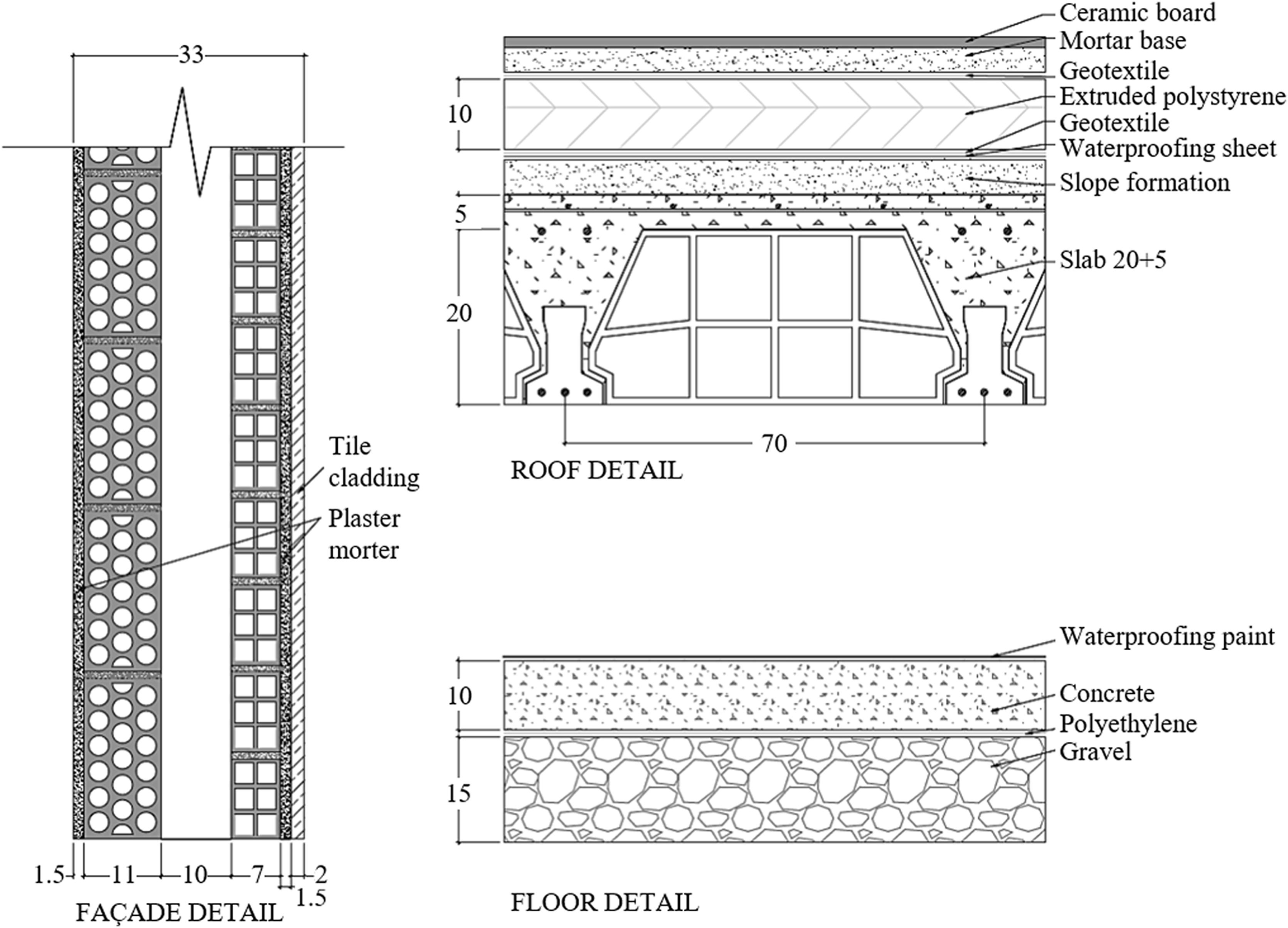

Small-sized demonstrators inside the Universitat Jaume I (UJI) campus in Castellón (Mediterranean area) were built to evaluate the humidity regulation behaviour. Two demonstrators were built, one with the walls covered with functional coating tiles and the other with conventional tiles which were named FT and CT respectively. The screed was coated with waterproofing paint to prevent water infiltration and moisture leakage, the façade was built with an air chamber and the interior walls were tiled with the different ceramic products (functional or conventional tiles). Meanwhile, the roof construction was insulated to reduce heat exchange with the outside. Details of floor, façade and roof are shown in Fig. 1. In addition, pictures of the demonstrators are shown in Fig. 2. The demonstrators were equipped with lighting systems and sockets to connect humidity conditioning equipment.

Humidity measurements were made using thermo-hygrometers (EasyLog EL-USB-2, Lascar) with the ability to record and store temperature (resolution 0.5°C) and relative humidity (resolution 0.5%) data at different times with an accuracy in the analysed range under 3%. These sensors were verified in a climatic chamber using salt-water saturated solutions, confirming an uncertainty with coverage factor 2 below 3% for both humidity and temperature. Two sensors per demonstrator were used at different heights to measure indoor humidity while an additional sensor was installed outside protected from the sun and adverse weather conditions by a small metal visor, giving a total of six sensors. Fig. 2c shows an image with a schematic of the sensors installed inside the rooms as well as their references. The reference for the outer sensors was OUT1 and OUT2 for FT and CT demonstrators respectively. The humidity conditions inside the demonstrators were regulated using ultrasonic humidifiers (7692, EDM) to increase the relative humidity and condensation dehumidifiers (DH-10, FM) to reduce it. The equipment was connected to the mains by means of programmable plugs to control the on and off times.

Results and discussionFiring behaviour of dried specimensFig. 3 shows the variation of linear shrinkage and water absorption (firing diagram) of all the dried specimens of both porcelain tile composition (body) and functional composition (coating). The firing diagram is a very useful tool to evaluate the behaviour of a given ceramic composition in industrial firing, as described elsewhere [28,29]. Linear shrinkage and water absorption represent two parameters of vital importance in the firing of porcelain stoneware tiles, since the objective for this type of product is to obtain zero water absorption (these are completely impermeable tiles) with the minimum possible shrinkage, as described in the literature [30]. As observed in Fig. 3, the variation followed by the porcelain tile composition corresponds to the densification experienced through a sintering process with the presence of liquid phase coming from fluxing oxides present in the starting composition (mainly sodium and potassium oxides). Zero water absorption value is reached at 1200°C with an approximate linear shrinkage of 8.5%, which correspond to values of the industrial practice. On the other hand, the sintering of the functional composition has hardly evolved at the typical temperatures of porcelain stoneware tile firing, as would be expected. It should be noted that this is a composition based on gibbsite together with the presence of silica and magnesia, which would lead to sintering processes at much higher temperatures [31]. Thus, it is observed at a temperature of 1200°C that the water absorption of the functional composition is maintained at values of 30%, which will facilitate water exchange and internal diffusion in the process of humidity regulation.

Distinct behaviour during firing as well as different properties (porosity) has been evidenced between the porcelain stoneware tile composition and the functional composition. Therefore, industrial scaling of the functional composition should be as a coating of the porcelain stoneware substrate. Furthermore, it will require the application of an intermediate layer with characteristics in-between the body and the functional layer named engobe what is a common practice in the manufacture of glazed tiles.

Effect of the amount (thickness) of functional coating on humidity regulation capability of tilesAs mentioned above, the moisture regulating capacity of the functional composition studied has been demonstrated in previous works, including the investigation of the effect of firing temperature. Thus, it has been observed that the functionality is preserved up to temperatures typical of porcelain stoneware tile firing (1180–1200°C) [22]. However, this verification has been carried out based on bulk samples. Since the functional composition is going to be applied as a coating on the unfired ceramic body, it is considered necessary to determine the relationship between the moisture regulating capacity and the amount of the deposited coating. This will allow the determination of the optimum amount, according to regulation needs.

Fig. 4a shows the adsorption and desorption curves in 24h cycles for the pieces with the four functional coating specific amounts tested: 670, 1000, 1330 and 1670g/m2, resulting in layer thickness on the fired pieces between 250 and 800μm approximately. This range is slightly higher than the usual glaze thickness used in the ceramic tile industry (75–500μm) [32]. As can be seen and in line with previous works [21,22], the desorption process occurs at a faster rate than adsorption. Thus, water vapour release is completed in less than 2h, whereas water vapour adsorption requires longer periods of time than 24h in the case of very thick applied layers. Furthermore, the amount of adsorbed water increases as the amount of functional coating grows. Fig. 4b confirms this expected proportionality between maximum adsorbed moisture in 24h cycles and amount of coating. The value of the slope is 0.058, which means that the amount of adsorbed water in 24h increases by 5.8g per 100g of coating applied. Slope value depends exclusively on the specific surface area obtained by nitrogen gas adsorption and the existence of mesopores in the sintered ceramic composition, which are determined by the starting composition and the sintering temperature. According to the results of previous researches [22,27], there is a parallelism between nitrogen gas and water vapour adsorptions.

Industry scale-up of the development of the functional coatingThe tiles with functional coating must finally be decorated to achieve the aesthetic and decorative surface appearance characteristic of this type of product. The decoration on the functional coating was carried out using ceramic inks and a protective topcoat glaze with inkjet technology. On the one hand, inkjet decoration provides the desired aesthetic characteristics of the final tile. On the other hand, the glaze acts as a covering topcoat to modify the surface brightness and protect the inkjet decoration and the functional coating.

The whole decorative coating above the functional layer should provide a surface which is not completely sealed. According to adsorption and desorption cycles on low sintered porous substrates with discontinuous glaze layer in the literature [33], it is sufficient to keep 10% of the surface uncovered, but it is desirable to glaze up to a maximum between 80 and 85%, for the water exchange to take place accordingly. Fig. 5 shows the tile design model that guarantees the production of ceramic tiles with the technical and aesthetic characteristics together with the functionality of humidity regulation.

Following the proposed model, hexagonal pieces of 16.5cm side were manufactured on an industrial production line as shown in Table 1. The amount of functional coating applied was 800g/m2, although this amount could be increased for extreme regulation needs. Fig. 6 shows a photograph of a set of fired tiles together with a cross-section cut showing the engobe and functional coating and its interface with the ceramic substrate.

Adsorption and desorption tests were carried out on a sample of a specimen of 10cm×10cm to confirm that the moisture regulating capacity of the decorated piece manufactured on an industrial scale was maintained. Results confirm that the engineered tile system keeps its functionality at the same level as that observed for an undecorated functional tile (moisture adsorption above 40g/cm2).

Monitoring of humidity regulating functionalityBased on the demonstrators built, the sensors installed and the humidity conditioning equipment, an experimental plan was defined to validate the proposed passive solution. Preliminary tests were carried out with humidification and dehumidification cycles to evaluate the relative humidity response and potential condensations inside the demonstrators. The time periods for each of the tests had to be established according to the time by the equipment to modify the relative humidity and the response rate of the room itself, which is related to the dimensions of the room, the type of product used (conventional or functional tiles) and the air exchange with the outside, among others.

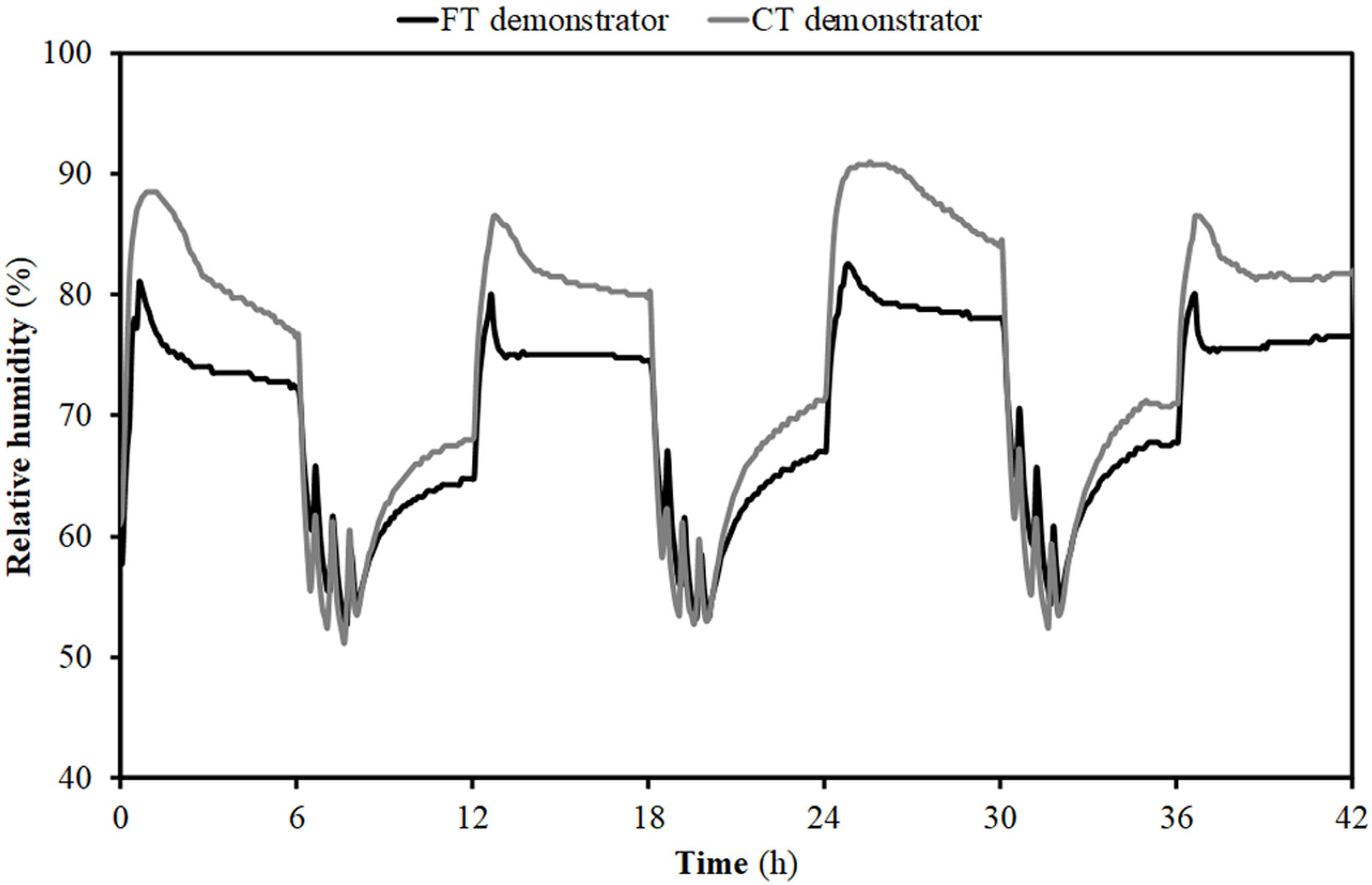

As a result, humidification and dehumidification cycles of 12h total duration were established. On the one hand, 30min of humidifier operation at maximum power and 5.5h of standby with the equipment off were selected for the humidification cycle (6h). On the other hand, 2h of dehumidifier operation at maximum power with 4h of standby were considered for the dehumidification cycle (6h). Relative humidity and temperature data were recorded with the sensors every 5min.

Fig. 7 shows the results of the six thermo-hygrometers over different humidification and dehumidification cycles, corresponding to inside and outside of the two demonstrators. The temperature inside the demonstrators was maintained at values around 14°C with variations of approximately 2°C during the tests as shown in Fig. 7b. It is observed in Fig. 7a that the relative humidity reaches maximum values close to 90% after 30min of humidifier operation and there is a very clear difference between the behaviour of the demonstrator with humidity regulating tiles (FT) and that with conventional tiles (CT). The relative humidity decreases more rapidly in the FT demonstrator compared to CT once the equipment is switched off, so that values close to the comfort zone are reached in a shorter time (relative humidity below 70%). In addition, differences are observed for the sensors at different heights, with higher humidity values for the sensors installed close to the ground (FT1 and CT1).

Regarding the cycles with the dehumidifier, it is observed that the humidity reached hardly falls below 50%, with a sawtooth behaviour. This is due to some internal mechanism of the dehumidifier which switches it off at intervals of approximately 30min. Under these conditions, it is difficult to discern the behaviour at low humidity, although it is observed that the lowest values correspond to the demonstrator with conventional tiles (CT). Moreover, the lines for FT and CT cross once the equipment is stopped, so that the humidity is higher at the end of the cycle, after 6h, for CT.

The outdoor humidity records are similar for the 2 thermo-hygrometers used (OUT1 and OUT2). The outdoor humidity varies between approximately 40% and 80%, although there is a strong dependence on temperature, with values around 20°C in the central hours of the day when the humidity is lower and below 10°C in the periods of time with higher humidity. Variations in outdoor humidity are therefore more influenced by temperature than by changes in water vapour concentration itself. Although in the selected cycles there is hardly any influence of external conditions on the results inside the demonstrators, a strong influence of windy conditions or high external humidity (rainy periods) on the indoor relative humidity records was evident.

The graph in Fig. 8 can be constructed from the individual values of the indoor thermo-hygrometers to show the average relative humidity inside the demonstrators over the different humidification and dehumidification cycles. From the differences in behaviour between FT and CT in the figure, the effect of the humidity regulating tiles is more clearly distinguishable. The relative humidity changes are more attenuated in the case of FT demonstrator, with values remaining more constant, especially when analysing high humidity conditions.

For the analysis of possible condensation, a visual assessment of the interior appearance of the demonstrators was carried out after 2h of operation of the ultrasonic humidifiers and a waiting time of 1h with the equipment off to allow the tiles to adsorb the excess moisture. Fig. 9 shows the images taken for both demonstrators. In the image on the left (Fig. 9a), corresponding to the FT demonstrator, only a small patch of moisture can be seen on the floor. In the image on the right (Fig. 9b), corresponding to the CT demonstrator, there is abundant water in the soil. The evaluation shows that it is indeed possible to eliminate or at least minimise condensation problems in poorly ventilated rooms with high humidity using the regulating tiles developed.

ConclusionsAn industrially scalable ceramic tile has been designed that incorporates a coating whose moisture regulating capacity had already been successfully demonstrated before. The coating must be incorporated in sufficient thickness to satisfy the required moisture regulation needs per unit area, with a linear relationship between the amount of coating applied and the quantity of moisture adsorbed.

The designed ceramic tile combines the aesthetic requirements of these materials with the functionality of humidity regulation. For this purpose, a multi-layer covering has been proposed, consisting of the following elements: an engobe layer, the functional covering, a decoration by inkjet technology and a protective topcoat. The layers above the functional coating should allow a minimum uncovered area of 10% to facilitate moisture exchange with the outside of the functional coating.

The construction of demonstrators has made it possible to validate the passive technology consisting of humidity regulation in interior spaces using the developed functional tiles:

Tests carried out using humidification and dehumidification cycles with air conditioning equipment show the difference in behaviour between the demonstrator with functional tiles and the demonstrator with conventional tiles. The demonstrator with functional tiles buffers humidity variations and reaches the comfort zone (relative humidity between 40% and 70%) more quickly.

Annoying condensation problems are prevented in the functional tile demonstrator. The ability of the tiles to regulate humidity through water vapour adsorption and capillary condensation promotes healthier environments by keeping humidity at more comfortable levels for humans.

Although the tiles have the capacity to ameliorate environments with low relative humidity, the greatest interest in the conditions tested (Mediterranean climate in the Castellón area during the winter season) lies in their capacity to reduce humidity when it reaches high values, above 80%.

Acknowledging Ministerio de Ciencia e Innovación of Spanish Government and European Regional Development Fund (ERDF) of European Union for the funding received in the framework of RTC-2017-5904-5 CONFORTMA project.