Current trends in the ceramic industry see an increasing interest on porcelain stoneware, by which is possible to produce large tiles and slabs. These products are manufactured by spray-dried powders, which have excellent technological properties but require high energy and water consumption. Dry-processed granulates allow to reduce such a consumption, but suffer from a different technological behavior. A solution to improve the environmental sustainability of ceramic tile-making is mixing powders prepared by the wet and the dry routes. The technological features of industrially manufactured mixed powders was investigated (rheological properties, compaction response and firing behavior) in order to point out advantages and possible pitfalls. Dry-processed and spray-dried granulates exhibit different distributions of size, shape and moisture that reflect on distinct rheological and compaction behaviors. Mixed powders show a more or less accentuated deviation from linearity between the end terms. This fact makes possible to add up to ∼50% dry granulates by keeping the technological properties close to current industrial bodies. Sparings of water, energy and CO2 emission for the milling and granulation stages are estimated for a mix 50% spray-dried and 50% dry-processed powders.

Las tendencias actuales en la industria cerámica ven un interés creciente en el gres porcelánico, mediante el cual es posible producir grandes baldosas y losas. Estos productos se fabrican mediante polvos atomizados, que tienen excelentes propiedades tecnológicas, pero requieren de un alto consumo de energía y agua. Los granulados procesados en seco permiten reducir dicho consumo, pero presentan un comportamiento tecnológico diferente. Una solución para mejorar la sostenibilidad medioambiental de la fabricación de baldosas cerámicas es mezclar polvos preparados por vía húmeda y seca. Se investigaron las características tecnológicas de los polvos mixtos fabricados industrialmente (propiedades reológicas, respuesta de compactación y comportamiento en cocción), con el fin de señalar las ventajas y posibles inconvenientes. Los granulados procesados en seco y atomizados exhiben diferentes distribuciones de tamaño, forma y humedad que se reflejan en distintos comportamientos reológicos y de compactación. Los polvos mixtos muestran una desviación más o menos acentuada de la linealidad entre los extremos. Este hecho permite añadir hasta ∼50% de granulado seco manteniendo las propiedades tecnológicas próximas a las piezas industriales actuales. Los ahorros de agua, energía y de emisiones de CO2 para las etapas de molienda y granulación se estiman para una mezcla de 50% de polvo atomizado y 50% de polvo granulado vía seca.

Spray drying is the quintessential technique used by the ceramic tile industry to get powders suitable for dry pressing [1]. In the latest years, it saw even increasing its diffusion worldwide, due to the growing production of porcelain stoneware tiles. This trend was recently strengthened by an overall market shift towards ever larger sizes, up to slabs of over 5 square meters, and thickness variable from 3 to 30mm [2,3]. Ceramic tile manufacturing requires powders with excellent flowability and compaction properties, especially in case of large slabs and thin or thick tiles, and ever stricter quality standards [4,5]. For this reason, spray-dried powders are typically preferred, because of generally better characteristics in comparison with other granulation techniques, like dry tumbling or intensive mixer, which are utilized in ceramic tile manufacturing as well [6–10]. However, spray drying entails a large energy consumption, mainly spent to evaporate water, and related CO2 release. It suffers also from a considerable water consumption, as slurries usually contain 30–35% water (by weight) while powders suitable for pressing need 5–7% moisture. Thus, spray drying is estimated to account on average for approximately 30% of the total energy and about 70% of the total water used in ceramic tile production [6,11–14].

Alternative granulation processes are used in the dry route, which ensures a substantial saving of both water and energy [7,8,14–16]. Notwithstanding such advantages, dry granulation still has a limited diffusion in the ceramic industry, being mostly addressed to small sized, porous tiles. This fact is essentially due to the worse characteristics of dry granulates with respect to spray-dried powders, particularly in terms of rheological properties, packing efficiency and compressibility [9,10,17]. Although recent technological innovation in the dry route made possible the obtainment of granulates with a consistently improved technological behavior [10,18], there is still some resistance from tile manufacturers to abandon the wet route entirely.

A simple technological solution, in a moment of transition towards a more sustainable production from the energetic and environmental points of view, can be a mixed dry-wet system. Spray drying would continue in use, but part of the production would be assured by another plant with dry milling and granulation technologies. Indeed, having the dry and wet routes in parallel allows a certain versatility in the preparation of powder mixes, which could be more easily adapted to the requirements of the ceramic production. However, little is known about the technological behavior, and possible pitfalls, of this kind of powder mixtures in ceramic tile-making.

At best of our knowledge, the only attempt to admix wet and dry granulates for ceramic tile production was a hybrid system, which consists of two-way split after conventional wet milling [12]. Part of the slip follows the usual spray-drying path, while the remaining slip undergoes filter-pressing, drying, and dry grinding, prior to be added directly in the spray drier to get a mix of spray-dried and dry-granulated powders [19]. Although its technical feasibility and advantages in terms of energy consumption were demonstrated, this hybrid system does not consider a primary dry milling. Furthermore, it is not as simple and versatile as our proposal, which guarantees that each milling and granulation route could be run independently to get the best technological properties of powders. Nevertheless, what must be considered is how powder properties – i.e., rheological, compaction and firing behaviors – vary with the ratio between spray-dried and dry-processed granules in the mixtures. Interestingly, the technological behavior of powders from the above-mentioned hybrid system is intermediate between that of the powders and compacts obtained by spray-drying and dry granulation processes. However, data are available only for one ratio: 1/3 spray-dried and 2/3 dry-processed powders [20,21].

Although technologically straightforward, powder mixing is not devoid of possible pitfalls, like granule segregation [22,23] and a non-linear behavior of the binary mixtures, especially in presence of cohesive powders [24]. In particular, it was observed that increasing the size ratio of the constituents led to a more severe segregation effect, as well as a higher density of powder mix [25]. Moreover, as the segregation effects can be related to product defects, the characteristics of the finished product also depend on the uniformity and correct handling of feeding powders, which are not so easy to keep under control [22,23]. Assessing to which extent these problems can count, in case of direct mixing of spray-dried and dry-granulated powders for ceramic tiles, is essential before planning any scale up to industrial trials.

Therefore, the goal of the present work is the evaluation of the technological behavior of powders mixes, in particular rheological and compaction properties relevant for ceramic tile-making. Different ratios of wet and dry powders, prepared at the industrial scale, were designed in order to disclose the best proportion of dry granulates that can be admixed with a spray-dried body.

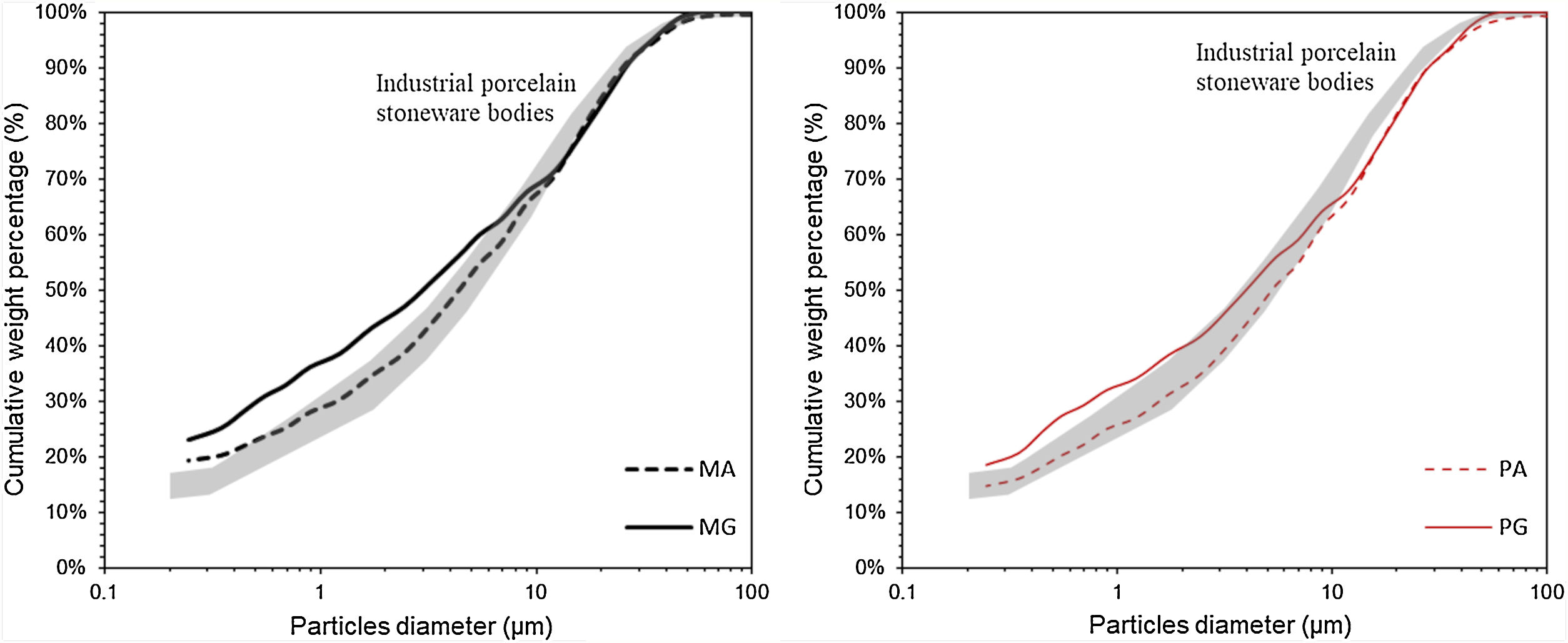

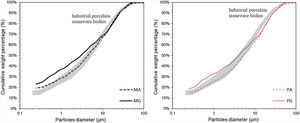

ExperimentalTwo industrially made batches (P and M) were considered, both currently utilized in the production of porcelain stoneware tiles and slabs. Their chemical composition (dry-basis) is: SiO2 71.69, 72.06; Al2O3 19.28, 18.25; Fe2O3 0.65, 1.07; TiO2 0.65, 0.69; CaO 0.81, 0.98; MgO 0.29, 0.51; K2O 2.16, 1.66; Na2O 4.48, 4.79 (M and P, respectively). Each batch was processed at the industrial scale by both the wet route (ball milling>spray drying) and the dry route (ball milling>sinusoidal granulator>fluid bed drying). In the case of batch P, preparation of dry granulates included the removal of the finest agglomerate fraction (<100μm) by dry sieving. This procedure is an option of the industrial manufacturing plant that can be activated on demand. By this way, two couples of samples were obtained and powders are named according to the batch and the preparation route: spray-dried (PA and MA) and dry-granulated (PG and MG) powders. Thus, each couple (PA-PG; MA-MG) has the same chemical and mineralogical composition and similar particle size distributions (Fig. 1).

The four powders were characterized by determining their particle size distribution by X-ray monitoring of gravity sedimentation (Micromeritics, SediGraph III 5125 plus) using the ASTM C958 method. The agglomerate size distribution was determined by dry sieving (meshes: 2, 1, 0.63, 0.5, 0.4, 0.315, 0.2, 0.1mm; ASTM C136), while the granule shape was observed under optical microscopy for each sieved fraction. In addition, the moisture distribution as a function of the agglomerate size was determined by weight difference of the wet and dry fractions for each sieve, after drying in oven (4h at 105°C).

Two series of mixtures were prepared by dosing spray-dried powders (PA or MA) with a growing percentage (25%, 50%, 75% by weight) of dry granulates (PG or MG). Samples are named according to the batch and the percentage of dry granulates (e.g., P25 stands for the mix PG:PA=25:75). Powders were carefully mixed in a sealed plastic bottle let to gently rotate on a roller conveyor for 1h. A total of ten samples (four end terms plus six binary mixes) were characterized for their rheological properties and compaction behavior.

Rheological behavior of powders was determined by measuring poured and tap density, Hausner ratio, Carr index, static and dynamic angles of repose, and mass flow rate through an orifice. The poured density was obtained by weighting a 100mL cylinder gently filled with the powder (ISO 23145). The tap density was determined in the same cylinder after 1000 taps (10min tapping time at 100 taps per minute). The Hausner ratio was calculated as ρt/ρp, while the Carr index as 100·(ρt–ρp)·ρt−1, where ρt is the tap density and ρp is the poured density. The static angle of repose was evaluated by leaving 300g of powder flowing through a 25mm orifice funnel moved gradually upward, having care to keep the orifice in touch with the powder under deposition. The angle was calculated by measuring height and base of the triangular section on a picture of the resulting cone. The dynamic angle of repose was measured by half-filling with powders a capped cylinder (60mm diameter and 50mm height). The cyclinder was put on a roller conveyor rotating at a speed of ∼2rpm. Powders cyclically roll up to a critical angle then fall to a minimal angle, which were measured on the freeze frames of a video. The angle of repose was calculated as the average of the critical and fall angles. The mass flow rate was evaluated by the time-of-flow of powders filling the volume of the Ford cup (type ASTM D1200). Results are expressed as mass (weighted after flow) passing through the area of the circular orifice (8mm in diameter) per unit time.

Compaction behavior was studied through uniaxial pressing of powders in a steel die (50mm in diameter) by applying increasing load (from 13 to 40MPa) with a laboratory hydraulic press (Nannetti, 40 tons). Powder compacts were weighted (balance accurate to 0.01g) and measured (diameter and volume with caliper accurate to 0.1mm) to calculate springback, bulk density, and compressibility, as well as to draw compaction response diagrams. Springback was determined as (Dp−Dd)/Dd, where Dd and Dp are the diameters of the die and the powder compact, respectively. Bulk density of powder compacts was calculated as the weight-to-volume ratio. Compressibility was expressed as (Vt−Vp)/Vt, where Vt and Vp are the volumes of the tapped powders and the compact pressed at 40MPa, respectively.

The firing behavior was determined as linear shrinkage (ASTM C326), water absorption, open porosity and bulk density (ASTM C373) measured on the samples fast fired in an electric kiln (Nannetti, model CV, 1200°C firing temperature, approximately 60min cold-to-cold).

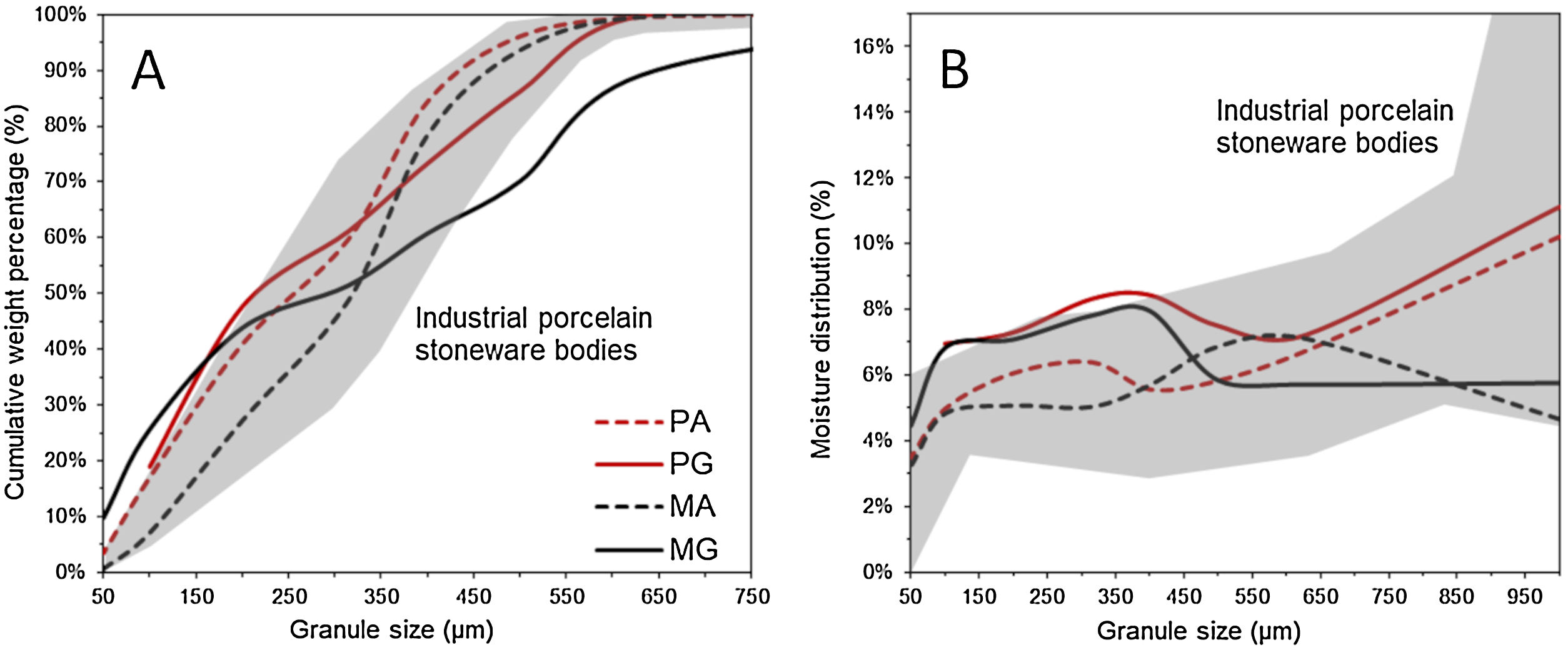

Results and discussionStarting powdersIt is well-known that spray-dried and dry-processed agglomerates have distinct grain size and shape, descending from their different granulation techniques [9,10,20,26]. The starting powders of the present study confirm that differences exist but, at the light of recent improvements in dry granulation, the distance with respect to spray drying is less than generally expected. Indeed, all the granule size distributions match the reference range of industrial bodies currently used in the production of porcelain stoneware tiles and slabs [4]. This occurs for both spray-dried powders, of course, and the dry granulate PG as well (Fig. 2A). The granulate MG falls to a large extent in the reference range, but for the coarsest fractions.

In detail, dry granulates exhibit a less steep curve, even though the median diameter of size distribution is similar to spray-dried agglomerates: 220 versus 260μm for PG and PA, 295 versus 325μm for MA and MG, respectively. This implies that the dry route brings about pronounced tails of the smaller and the coarser granules, together with less abundant intermediate sizes, once compared to spray-drying of porcelain stoneware batches (Fig. 2A). This distribution is different from other dry-processed powders for ceramic tiles, which exhibit a larger fraction of coarse granules but a similar amount of finer agglomerates with respect to spray-dried powders [9,17,20,26]. Although the total moisture content is practically the same (within the experimental error) in the M and P bodies (Table 1), its distribution as a function of the granule size is different, despite all curves fall within the reference field (Fig. 2B). In porcelain stoneware spray-dried powders, moisture is higher in coarser than in smaller granules [4] while the opposite occurs in dry granulates [10]. The peculiar curves of dry granulates exhibit a higher moisture below 400μm, which is likely to be a side-effect of the two-stage processing, consisting of a wetting and tumbling step followed by fluid bed drier to adjust moisture to the desired value.

Characteristics and rheological behavior of starting powders and reference field for spray-dried powders used in the production of porcelain stoneware tiles [4].

| Parameter | Unit | PA | PG | MA | MG | Spray-dried powders | e.u.a |

|---|---|---|---|---|---|---|---|

| Median agglomerate diameter | μm | 260 | 220 | 325 | 295 | 225–375 | 5 |

| Moisture content | % weight | 6.5 | 6.3 | 6.0 | 6.1 | 4.0–7.5 | 0.1 |

| Poured density | gcm−3 | 0.973 | 1.016 | 0.957 | 0.980 | 0.92–1.05 | 0.005 |

| Tap density | gcm−3 | 1.093 | 1.254 | 1.104 | 1.268 | 1.03–1.13 | 0.003 |

| Hausner ratio | 1 | 1.124 | 1.235 | 1.154 | 1.294 | 1.07–1.17 | 0.005 |

| Carr index | % | 11.0 | 19.0 | 13.3 | 22.7 | 8–15 | 0.3 |

| Static angle of repose | ° | 29.4 | 34.0 | 27.1 | 33.2 | 29–35 | 0.5 |

| Dynamic angle of repose | ° | 37.0 | 50.3 | 39.5 | 61.2 | 39–45 | 0.5 |

| Mass flow rate | gs−1cm−2 | 14.3 | 6.8 | 14.6 | 9.5 | 13–16 | 0.1 |

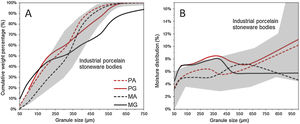

The shape of agglomerates is illustrated in Fig. 3, where clear differences stand out. Spray-dried granules have the expected subspherical shape with inner cavity, which is predominant below 500μm. Coarser fractions mainly consist of irregularly shaped aggregates made of two or more granules stuck together. In contrast, dry-processed powders have granules with a less regular shape, characterized by a bumpy surface. Such a shape is not related to the granule size, as it is constant in all size fractions. On average, dry granules exhibit a slightly higher aspect ratio with respect to spray-dried powders. These features are substantially comparable with other dry-processed powders for ceramic tiles [9,17,20,26].

All data concerning the rheological properties of agglomerates are summarized in Table 1, where the reference range for currently used spray-dried powders is also indicated. The poured density is always within the field of industrial spray-dried powders for all samples, even if it is higher in dry granulates (from 0.02 to 0.04gcm−3). In contrast, tap density varies a lot between spray-dried powders (1.09–1.10gcm−3) and dry granulates (1.25–1.27gcm−3). Consequently, spray-dried powders exhibit much lower values of both the Hausner ratio (1.12–1.15) and the Carr index (11–14%) with respect to dry granulates (1.24–1.29 and 19–23%, respectively). This was already noticed in case of dry-processed powders for ceramic tiles, even though differences in the Hausner ratio were in the 0.01–0.03 range [9,17,20,26].

The values of static angle of repose fall within the reference window for all samples, besides slightly higher for dry granulates (33–34°) than for spray-dried powders (27–30°). Much more sensitive is the dynamic angle of repose that remarkably discriminates powders from spray-drying (37–40°) versus dry granulation (51–60°). The latter angles are above the reference range for ceramic tiles.

Mass flow rates of dry granulates are in the 7–10gs−1cm−2 range, clearly below the rates of spray-dried powders (14–15gs−1cm−2) that correspond to the common performance in the tile industry. Therefore, all the rheological data denote a gap in the flow properties of dry granulates that can be a challenge to the application of mixed powders.

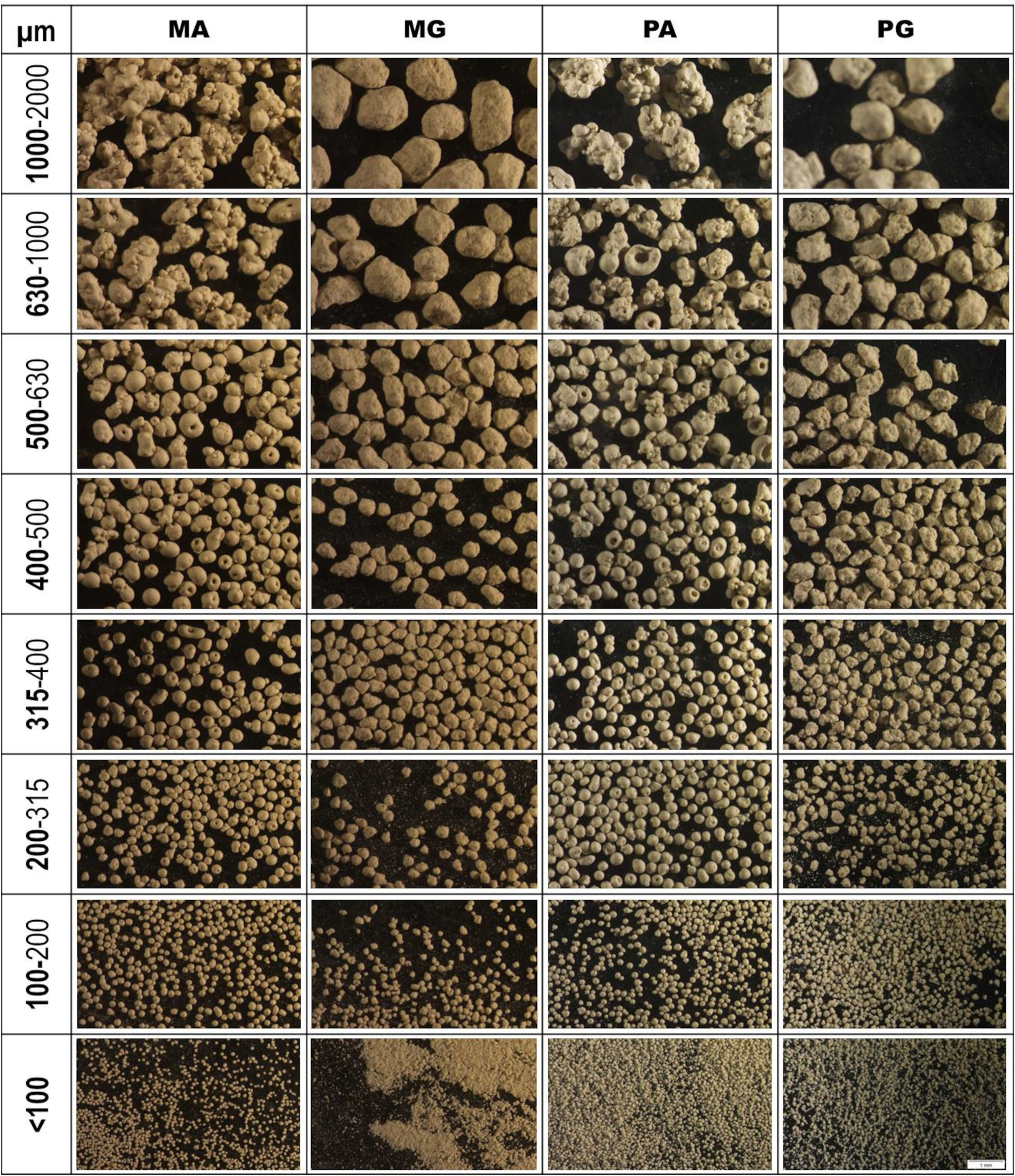

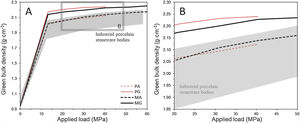

About the powder behavior during pressing, the compaction response diagram is shown in Fig. 4. As expected, compaction curves show a green bulk density higher for dry granulates than for spray-dried samples, as already remarked for ceramic tile powders [9,17,20,26].

As a matter of fact, dry granulates have a much more efficient densification under pressing, leading to green bulk density values (2.23–2.24gcm−3) impossible to obtain by using spray-dried powders. Although close to the maximum achievable with porcelain stoneware bodies, MA and PA reach a bulk density of 2.12–2.14gcm−3 at most (Fig. 4B). Such a bulk density increase allowed by dry granulates is comparable to what achieved with other dry processes [9,17,20,26]. Hence, compaction data point out a key advantage of dry granulates with respect to spray dried bodies. However, it is fundamental to understand to which extent this advantage is transferred to mixed powders.

Technological properties of mixed powdersNo apparent granule segregation occurred during mixing and handling of mixed powders. However, no specific test was carried out for assessing powder segregation. This does not mean that no segregation of the powders may arise, as a consequence of the different granule density of spray-dried and dry granulates, in particular in the discharge of silos.

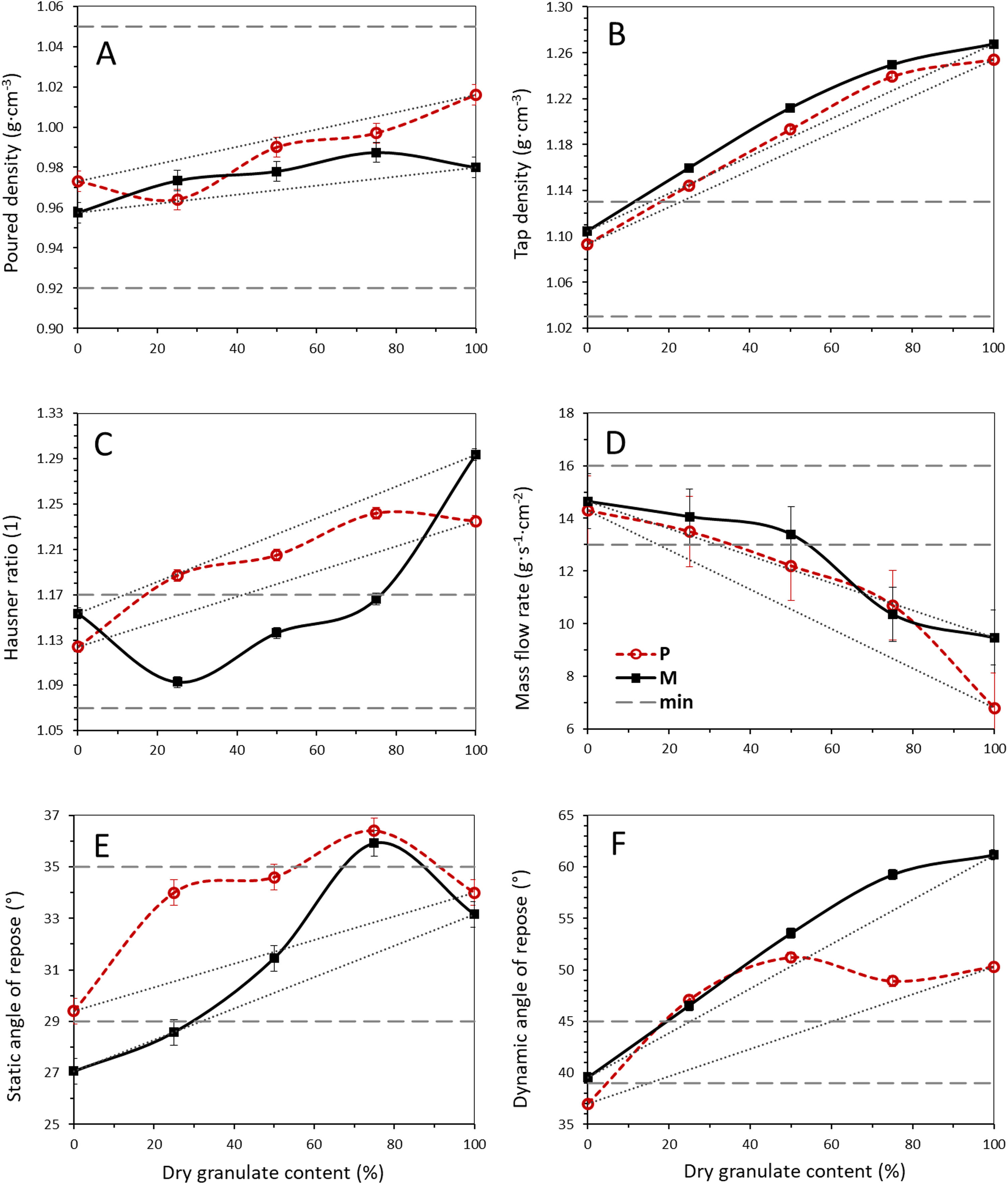

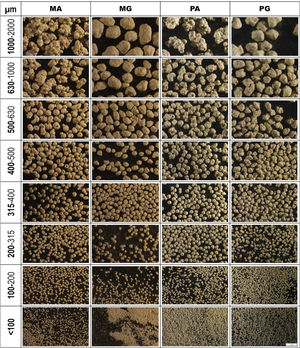

Data concerning the rheological behavior of mixtures are summarized in Table 2 and plotted as a function of the dry granulates percentage in Fig. 5.

Rheological properties and compaction behavior of mixed powders.

| Parameter | Unit | PA | P25 | P50 | P75 | PG | MA | M25 | M50 | M75 | MG | e.u.a |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Poured density | gcm−3 | 0.973 | 0.964 | 0.990 | 0.997 | 1.016 | 0.957 | 0.973 | 0.978 | 0.987 | 0.980 | 0.005 |

| Tap density | gcm−3 | 1.093 | 1.144 | 1.193 | 1.239 | 1.254 | 1.104 | 1.159 | 1.212 | 1.249 | 1.268 | 0.003 |

| Hausner ratio | 1 | 1.124 | 1.187 | 1.205 | 1.242 | 1.235 | 1.154 | 1.093 | 1.136 | 1.166 | 1.294 | 0.005 |

| Carr index | % | 11.0 | 15.7 | 17.0 | 19.5 | 19.0 | 13.3 | 16.0 | 19.3 | 21.0 | 22.7 | 0.3 |

| Mass flow rate | gs−1cm−2 | 14.3 | 13.5 | 12.2 | 10.7 | 6.8 | 14.6 | 14.1 | 13.4 | 10.4 | 9.5 | 0.1 |

| Static angle of repose | ° | 29.4 | 34.0 | 34.6 | 36.4 | 34.0 | 27.1 | 28.6 | 31.5 | 35.9 | 33.2 | 0.5 |

| Dynamic angle of repose | ° | 37.0 | 47.1 | 51.2 | 48.9 | 50.3 | 39.5 | 46.5 | 53.5 | 59.2 | 61.2 | 0.5 |

| Bulk density | gcm−3 | 2.115 | 2.138 | 2.162 | 2.199 | 2.242 | 2.138 | 2.127 | 2.146 | 2.170 | 2.227 | 0.002 |

| Springback | cmm−1 | 0.53 | 0.50 | 0.45 | 0.41 | 0.37 | 0.58 | 0.58 | 0.55 | 0.52 | 0.43 | 0.02 |

| Powder compressibility | % | 48.3 | 46.5 | 44.8 | 43.6 | 44.1 | 48.3 | 45.5 | 43.5 | 42.4 | 43.1 | 0.3 |

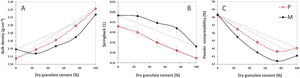

Rheological behavior of powder mixes as a function of dry granulate percentage. (A) Poured density, (B) tap density, (C) Hausner ratio, (D) mass flow rate, (E) static angle of repose, (F) dynamic angle of repose. Dotted lines are the linear trend between end members. Reference ranges for spray-dried powders currently used in the ceramic tile industry refer to Table 1.

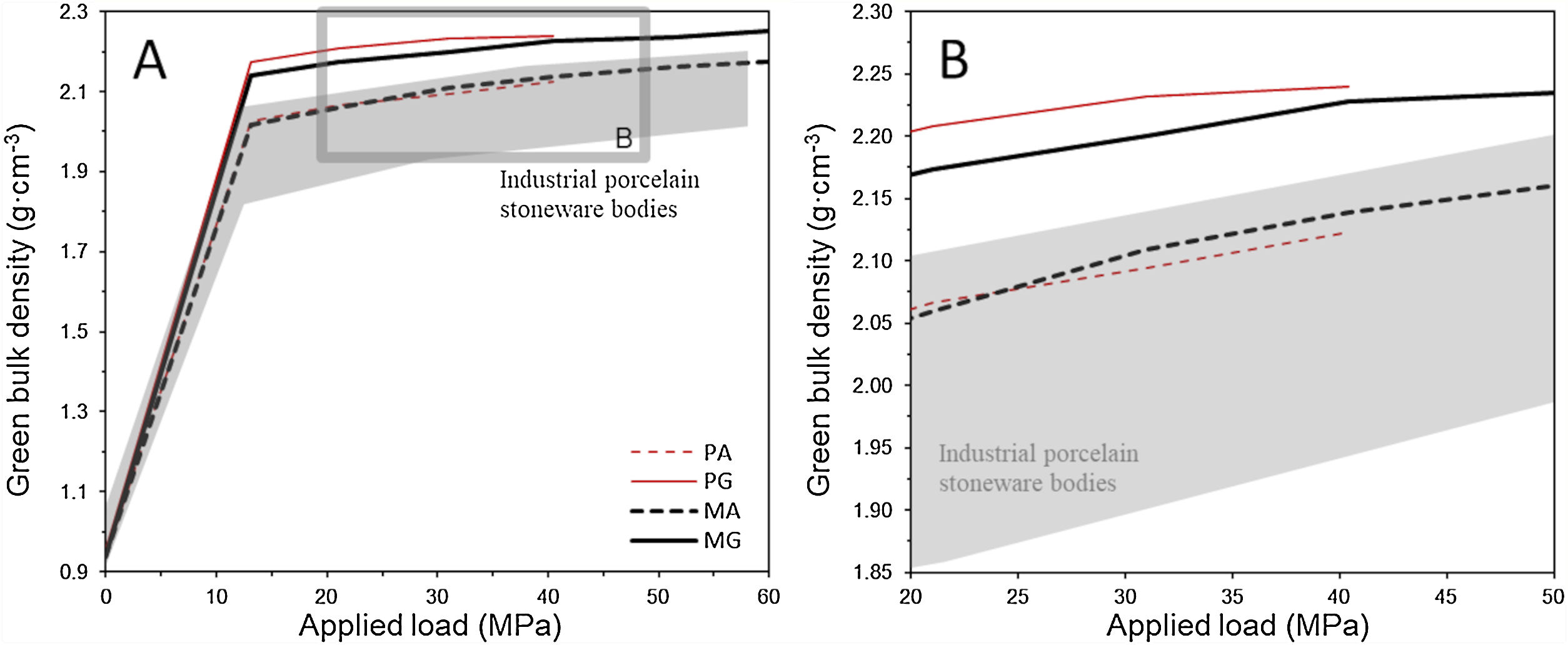

At the first glance, data vary according to the ratio between spray-dried and dry-granulated powders. In particular, poured density, tap density, Hausner ratio and angles of repose increased with the fraction of dry granulates, while the mass flow rate decreased in both series. However, more or less accentuated deviations from the linear trend between end members occurred (Fig. 5) and, except for short traits, data never evolve linearly. Although expected for binary mixtures [24,27], this experimental observation prevents using the lever rule to predict the rheological behavior of mixed powders for ceramic tiles.

Interestingly, these deviations from linearity can be sometimes modest (e.g., tap density) or in other cases conspicuous (mass flow rate, angles of repose). Surprisingly, the two series exhibit an opposite trend of poured density (and consequently Hausner ratio). Such deviations are of great importance to define which is the best proportion of dry granulates that can be added to a spray-dried body. Following the join from spray-dried powders to dry granulates, two scenarios can be drawn: trending upward (as for tap density, Hausner ratio, angles of repose) or downward (i.e., mass flow rate). In the former case, a concave trend is preferable, because it implies that mixtures keep values closer to those of spray-dried powders than what predictable by the lever rule. At reverse, for the downward trend is better to have a convex deviation, which means that mixes behave like spray-dried powders more than what foreseen by the linear relationship.

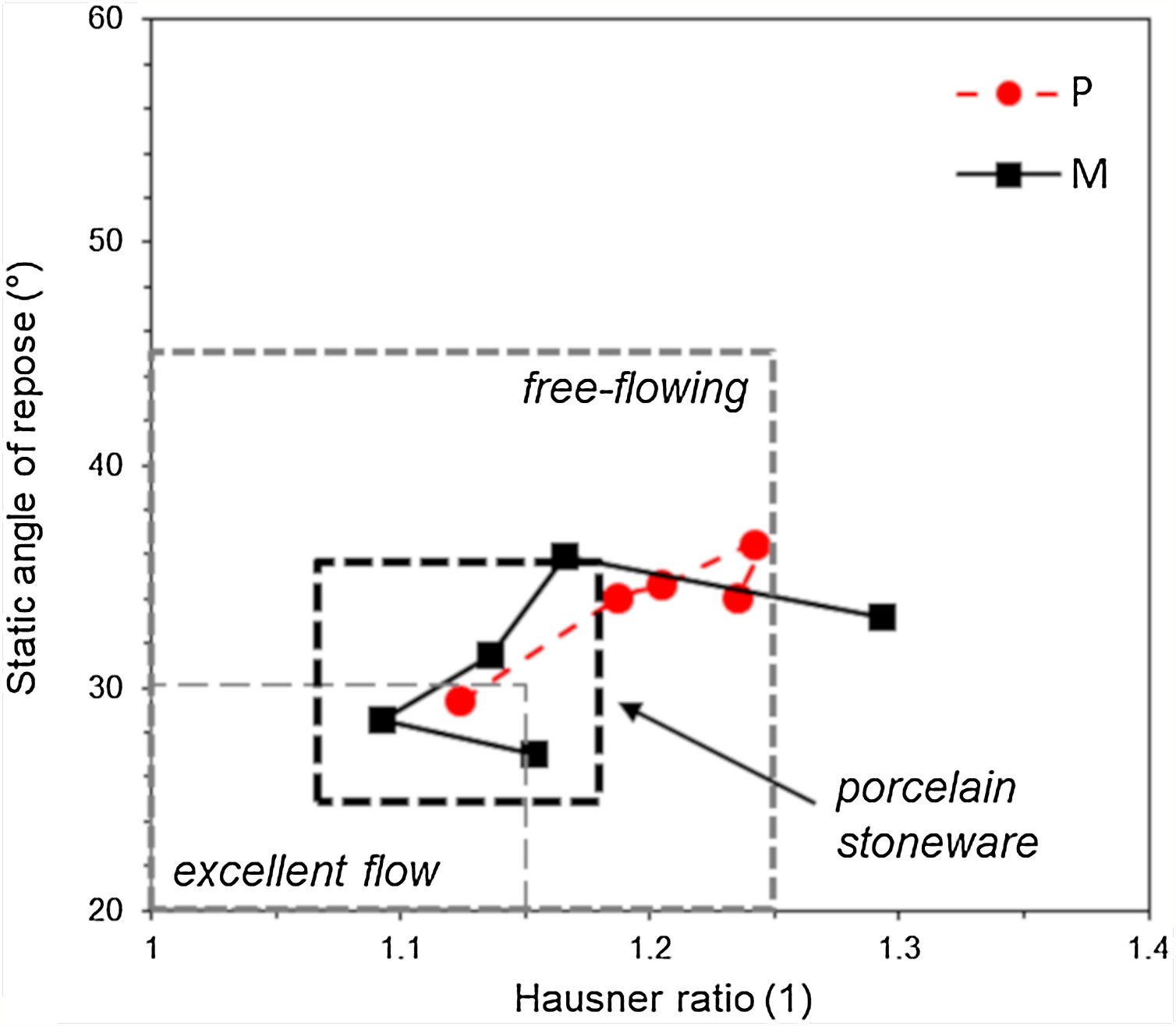

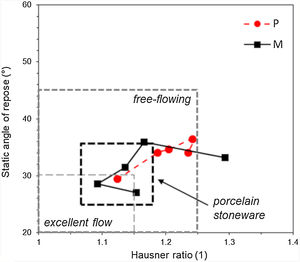

The overall flowability of powders can be predicted combining values of Hausner ratio and static angle of repose (Fig. 6). By this way, powders can be distinguished in free-flowing or not, according to the literature [28]. The series P keeps always within the field of free-flowing powders, while the series M plots within the field of spray-dried powders for porcelain stoneware up to 75% dry granulates. Such a classification is confirmed by the Carr index, as both series exhibit a fair flowability (<20%) and even a good performance for percentages of dry granulates below 25%.

Basically, the mixing effect changes according to the variables considered and the target constituted by the reference ranges in Table 1. The mass flow rate exhibits the desired convex trend (as the Hausner ratio draws a concave one for the series M). On the contrary, tap density and both angles of repose define undesired convex trends. However, repercussions are different: the mixtures fall within the reference window up to approximately 50% dry granulates for the mass flow rate and even beyond for the static angle of repose, and the Hausner ratio (series M). The same occurs in mixes up to approximately 20% dry granulates for the tap density, the dynamic angle of repose, and the Hausner ratio (series P). The poured density is always within the reference range.

Nonetheless, the mass flow rate takes on a greater importance because it mimics better than other rheological parameters the powder behavior during hopper unload and die filling. From this standpoint, the mixing of powders can be considered feasible, in terms of rheological behavior, up to approximately a 50:50 ratio between spray-dried and dry-granulated powders.

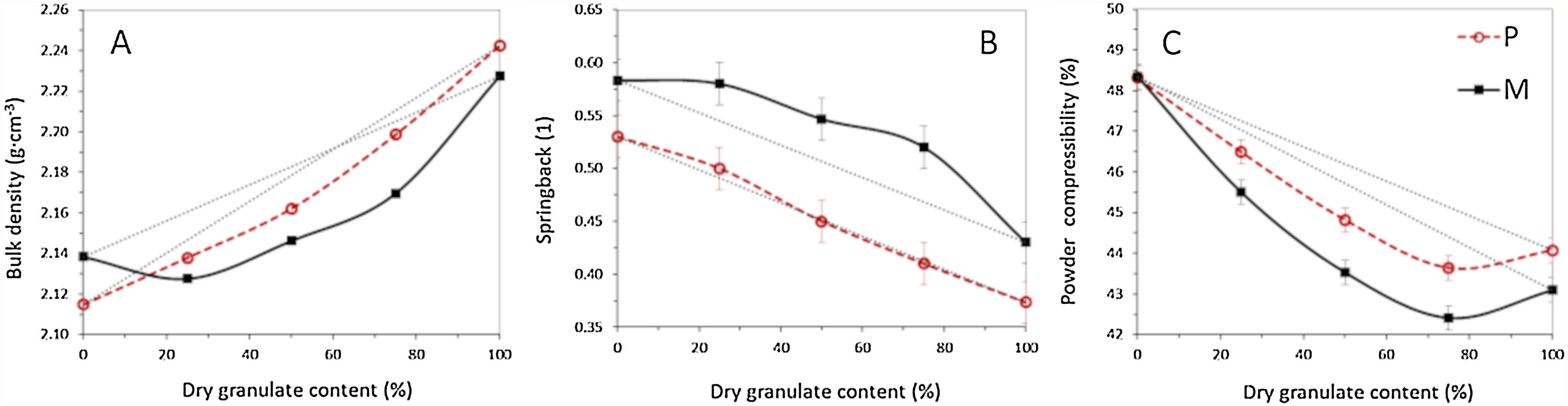

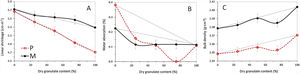

Compaction behavior of mixed powdersThe results of mixtures do not follow, in most cases, the linear trend between dry-granulated and spray-dried powders, as appreciable in Table 2 and Fig. 7. This happens for bulk density and especially for compressibility, since some values fall out of the range defined by the end terms. At variance, springback seems to be less affected, and the series P even follows nearly the linear trend.

In principle, increasing the bulk density of green compacts is beneficial, as reducing compressibility and springback is desirable while pressing ceramic powders [29,30]. Thus, the addition of dry granulates is in any case able to improve the compaction response of spray-dried powders, or at least it should not bring about any detrimental effect. However, the question is not to improve substantially the performance under compaction but, instead, maintaining it not too different from that of current industrial bodies.

Therefore, to keep the mixture behavior as close as possible to that of spray-dried powders, deviations from the reference line should be concave (in case of upward trend with dry granulates percent) or convex (if the trend is downward). This is actually observed for bulk density (Fig. 7A) and springback (Fig. 7B), while compressibility (Fig. 7C) tends to go rapidly towards the values of dry granulates (and beyond). In detail, it is evident that the P series has a behavior closer to an ideal mix, particularly about springback and to a lesser extent bulk density or compressibility. Moreover, samples P25, P50 and P75 reach a higher density, if compared to the corresponding mixtures of the M series. This behavior is opposite to what expected looking at the spray-dried powders, since PA is less dense than MA. No literature data about ceramic tile bodies are available to compare with our results. There is just the case of 1/3 wet and 2/3 dry, which is not a mechanical mixture but the outcome of a hybrid granulation system [20]. Interestingly, its bulk density is lower than expected by the lever rule, as it occurs with our mixes.

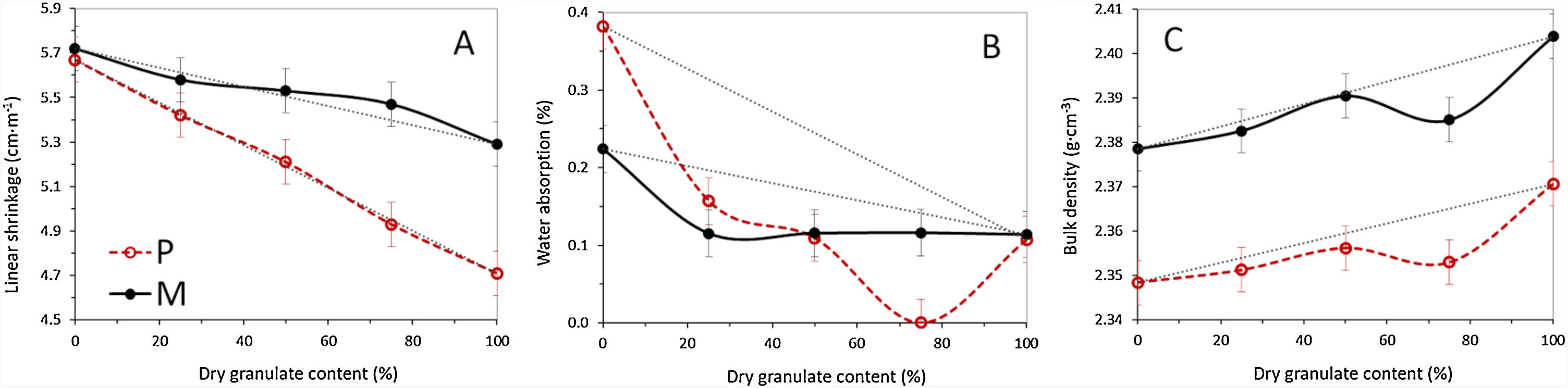

Firing behavior of mixed powdersThe firing behavior of mixtures follows the linear trend between dry-granulated and spray-dried powders for linear shrinkage and bulk density (Table 3 and Fig. 8). There is only a deviation from linearity for the 3:1 ratio (dry-to-wet) especially for bulk density. Significantly, this goal was achieved with other dry-processed powders only for firing shrinkage, which is always lower than in case of spray-dried powders [9,17,20,26]. Bulk density was either slightly higher [9,26]. or clearly lower [17] than the reference products manufactured by the wet route.

Firing behavior of mixed powder compacts fast fired at 1200°C.

| Parameter | Unit | PA | P25 | P50 | P75 | PG | MA | M25 | M50 | M75 | MG | e.u.a |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Bulk density | gcm−3 | 2.385 | 2.403 | 2.410 | 2.416 | 2.417 | 2.409 | 2.420 | 2.426 | 2.432 | 2.450 | 0.002 |

| Linear shrinkage | cmm−1 | 5.67 | 5.42 | 5.21 | 4.93 | 4.71 | 5.72 | 5.58 | 5.53 | 5.47 | 5.29 | 0.05 |

| Water absorption | % wt. | 0.38 | 0.16 | 0.11 | 0.00 | 0.11 | 0.22 | 0.12 | 0.12 | 0.12 | 0.11 | 0.01 |

| Open porosity | % vol. | 0.91 | 0.38 | 0.26 | 0.00 | 0.26 | 0.54 | 0.28 | 0.28 | 0.28 | 0.28 | 0.01 |

The reduction of the linear shrinkage is favorable, since it implies a smaller stress during sintering, which is a relevant factor for large tiles and slabs. Even more valid is the increase in bulk density, thanks to which the final performances are improved without changing the process conditions.

At variance, water absorption is clearly affected by a mix effect, as values of mixtures went even below the dry granulate end term, although the absolute variations are modest (Fig. 8B). Such a downward trend, with a marked concave deviation from linearity, is positive because water absorption decreased by increasing the fraction of dry granulates. Data are always below the standard threshold for porcelain stoneware (BIa Group≤0.5%, ISO 13006). They are particularly significant as the problem of a higher water absorption in fired tiles produced with dry granulates, raised in the literature, is not shown in our series. In previous works comparing wet and dry granulation, water absorption of tiles produced with spray-dried powders was always around 0.1% or lower, while the corresponding bodies processed by the dry route exhibited values between 0.4 and 0.8% [9,17,21,26]. This limitation can be attenuated by changing the dry granulation conditions [17,18,26], as demonstrated by the dry-processed powders used in this work, and particularly following the hybrid route [10].

Advantages of using mixed powdersPowder processing by the wet and the dry routes requires a different consumption of water, deflocculant, electrical and thermal energy, and consequently brings about distinct emissions of carbon dioxide [13]. In the literature, recent audits are available to compare wet milling and spray-drying versus dry milling and granulation [14,16] or versus a hybrid solution, i.e. 1/3 wet and 2/3 dry [19]. Data are summarized in Table 4 and compared with energy and water consumption estimated for the wet and dry processes described in the present work.

Comparison of water, energy and deflocculant consumption and carbon dioxide emissions of the wet and dry processes for milling and granulation of ceramic tile powders (average data). Energy, water, deflocculant and CO2 sparings for a mixed powders solution (50% spray-dried and 50% dry-granulated, by weight) with respect to the full wet process for ceramic tiles of the BIa and BIb groups (ISO 13006).

| Process | Parameter | Unit | Mezquita et al. (2010) | Shu et al. (2011) | Bonucchi (2013) | Mixed powders (this work) |

|---|---|---|---|---|---|---|

| Wet | Water consumption | m3Mg−1 | 0.52 | 0.45 | 0.43 | 0.36 |

| Electric energy consumption | kWhMg−1 | 52 | 64 | 36 | 66 | |

| Thermal energy consumption | kWhMg−1 | 452 | 408 | 459 | 358 | |

| CO2 emission | kgMg−1 | 81 | 74 | 81 | 70 | |

| Deflocculant consumption | kgMg−1 | n.a. | n.a. | 5.3 | 6.0 | |

| Dry (Hybrid) | Water consumption | m3Mg−1 | 0.14 | 0.29 | 0.15 | 0.10 |

| Electric energy consumption | kWhMg−1 | 33 | 77 | 23 | 74 | |

| Thermal energy consumption | kWhMg−1 | 98 | 243 | 204 | 139 | |

| CO2 emission | kgMg−1 | 18 | 44 | 36 | 27 | |

| Deflocculant | kgMg−1 | n.a. | n.a. | 0.0 | 0.0 | |

| Sparing 50%Wet50%Dry (Hybrid) | Water consumption | % | −36% | −36% | −33% | −36% |

| Electric energy consumption | % | −18% | +20% | −18% | +6% | |

| Thermal energy consumption | % | −39% | −40% | −28% | −31% | |

| CO2 emission | % | −39% | −40% | −28% | −31% | |

| Deflocculant | % | n.a. | n.a. | −50% | −50% | |

| Typology of ceramic tiles | Group | BIb | BIa | BIb | BIa | |

Looking at the sparings in Table 4, those permitted by mixing 50% dry granulates and 50% spray-dried powders amount to approximately 36% of water and 31% of thermal energy and CO2 emission for the same production cycle of porcelain stoneware tiles. It must be noticed that this comparison did not consider cogeneration in the wet route (although a frequent option in the industrial practice). Further sparings regard additives (-50% deflocculant added to the slurry) while electricity consumption shows a slight increase. Significantly, our values are fully comparable with calculations based on data by Mezquita et al. [14] and Bonucchi [16], despite both are referred to a lesser intensive process, i.e. production of stoneware (Group BIb, water absorption between 0.5% and 3%). About the CO2 emission, a recent assessment about porcelain stoneware manufacturing [31] has demonstrated that differences between the routes may be less than expectable from data in Table 4 (CO2 emission approximately −18% in the dry route with respect to the wet). Such a LCA approach, however, denoted a limited difference in terms of impact on the various environmental categories [31]. Finally, direct mixing of dry and wet processed powders allows some advantages, mainly in terms of electric energy consumption, with respect to a hybrid route for porcelain stoneware [19].

ConclusionsAs spray drying can roughly reach 30% of the energy consumption and 70% of the water use of the entire ceramic tile production, admixing together dry-processed with spray-dried powders ensures a significant cutback of both water and energy demand. Mechanical mixing appears undoubtedly simpler and versatile if compared to other solutions. However, ceramic powders processed by the dry or the wet route exhibit different features, as density and the distributions of shape and moisture as a function of the granule dimension. This circumstance brings about distinct rheological and compaction behaviors, which ultimately entail slight improvements in the properties of fired tiles. The performance of mechanically mixed powders, manufactured at industrial level, was for the first time investigated for porcelain stoneware bodies used to produce ceramic tiles.

No granule segregation occurred during powder mixing and handling. The behavior of mixed powders does not follow, except for few variables, the linear trend between the end terms, and conspicuous deviations were often observed. Although expected, these deviations are evident for some parameters, while appear negligible for others, making them unpredictable by the lever rule. In particular, poured density, Hausner ratio, static and dynamic angles of repose show a large deviation from ideal mixing, while tap density and mass flow rate remain fairly close to linearity, ensuring an acceptable behavior during powder handling. Similarly, significant deviations in bulk density and powder compressibility are balanced by a nearly linear variation of springback, ensuring a proper response to compaction.

Nevertheless, such deviations from linearity make possible to add a large amount of dry granulates to spray-dried powders and keep the technological properties close to current bodies utilized by the ceramic tile industry. Thus, mixing of powders can be considered feasible, up to approximately a 50% spray-dried and 50% dry-processed granulates, even though with pros and cons: the compaction response and firing behavior are somehow improved, but rheological properties are slightly worsened. This conclusion requires caution when extended to other bodies and the appropriate dry-to-wet ratio must be assessed on a case-by-case basis.

It must be emphasized that finished products based on mixed powders always comply the standard requirements for porcelain stoneware tiles (BIa Group) and particularly water absorption below 0.5%, which was a drawback raised in the literature about the dry route.

Most important, however, is the substantial enhancement in the environmental and economic sustainability of ceramic tile production by adopting a wet-dry route. The main advantages in the milling and granulation stage of porcelain stoneware – for a mix 50% spray-dried and 50% dry-processed powders – consist in the possible reduction of water consumption (−36%) and energy consumption (−33% thermal energy and −13% electric energy) along with the potential drop of 33% in the CO2 emission and 50% in the use of additives (deflocculant added to the slurry). The actual drop in the CO2 emission will be lower, however, if cogeneration is entailed in the wet route. A life cycle assessment is necessary to understand what the real benefits are in terms of environmental impact.