Lithium silicate-based glass-ceramics are widely employed dental materials, showing superior aesthetics (determined by translucency) but poorer wear resistance under severe contact conditions than alternative, artificial crown materials. This work investigates possible correlations between the level of translucency and resistance to wear (in vitro) under sliding contact against hard zirconia antagonists in commercial lithium disilicate and zirconia-reinforced lithium silicate dental glass-ceramics. Wear rates are quantified, and mechanisms responsible for material removal are analyzed. Results are discussed in terms of the materials’ microstructure and mechanical properties within the framework of a fracture mechanics model. Finally, implications for materials selection in dentistry are briefly discussed.

Los vitrocerámicos a base de silicato de litio son ampliamente utilizados como materiales dentales, debido a que presentan una mejor estética (determinada por su traslucidez), aunque peor resistencia a desgaste bajo condiciones de contacto severo, que los materiales artificiales alternativos para coronas protésicas. Este trabajo investiga posibles correlaciones entre el grado de traslucidez y la resistencia a desgaste (in vitro) bajo contacto deslizante contra un antagonista duro de zirconia en vitrocerámicos dentales comerciales de disilicato de litio y silicato de litio reforzado con zirconia. Se cuantifican las tasas de desgaste y se analizan los mecanismos responsables de la eliminación de material. Los resultados se discuten con base en la microestructura y propiedades mecánicas de los materiales en el marco de un modelo de mecánica de la fractura. Finalmente, se discuten brevemente algunas implicaciones relativas a la selección de materiales en odontología.

Lithium silicate-based glass-ceramics such as lithium disilicate (LS2) and zirconia-reinforced lithium silicate (ZLS) are widely employed as dental materials. Their main attractive for use as prosthetic crowns is aesthetics. Indeed, unlike alternative dental ceramics such as zirconia-based materials, lithium silicate-based materials are highly translucent (around 40% visible light transmission [1]), thus permitting a closer match with the appearance/shades of natural dentition. Moreover, the level of translucency of lithium silicate-based dental glass-ceramics can be accurately controlled to suit specific needs, and commercial manufacturers offer materials in different varieties such as LT (low translucency), and HT (high translucency). Translucency of HT varieties is about 10% higher than that of LT varieties [2].

The main shortcoming of lithium silicate-based materials is that they possess poorer mechanical properties and durability compared to some of the other modern dental ceramics [2]. Indeed, while their fracture strength (∼300MPa [3,4]) is better than that of previous dental glass-ceramics (e.g., porcelains, feldspathic ceramic), it is still significantly lower than that of zirconia-based dental ceramics, which precludes their use in some applications at high loads (e.g., posterior restorations). Strength may be improved by adding zirconia in ZLS composites (>500MPa [4–6]), but at the expense of wear resistance [7]. Similarly, the fracture toughness of lithium silicate-based dental materials is better than that of previous glass-ceramics, but worse than that of zirconia-based materials [8,9]. A lower toughness results in decreased resistance to edge chipping from bite overloads [10,11].

From the mechanical point of view, one of the most serious concerns with lithium silicate-based materials is their susceptibility to long-term degradation in the form of wear. This is a result of their characteristic two-phase microstructure (micrometric crystals embedded in a glassy matrix), with weak interphases. Weak crystal-matrix interphases favour material removal processes at the microstructural scale, thereby resulting in a poor wear resistance—significantly lower than that of zirconia-based materials, and even the natural enamel, and comparable to that of softer dental materials such as polymer-ceramic composites [8,12].

The question arises as to whether commercial, lithium silicate-based dental glass-ceramics with different levels of optical translucency show different resistance to wear, as is the case with other relevant engineering ceramics. For example, polycrystalline alumina [13,14] and magnesium-aluminate spinel [15] show correlations between the level of translucency and sliding-wear resistance. Such correlations arise because in those materials both light transmittance/scattering and material removal processes are strongly dependent on grain size [14,16,17]. To investigate possible correlations in two-phase lithium silicate-based glass-ceramics, the present work compares the resistance to sliding-wear under conditions representative to heavy chewing of the LT and HT varieties of 3 commercial dental materials: LS2, and as-received and heat-treated ZLS. Results are discussed within the framework of established models of wear of ceramics, with a view to providing useful insights for the selection of currently available dental materials.

Materials and methodsThe materials investigated were obtained from commercially available CAD/CAM (computer-aided design/computer-aided manufacturing) blocks, heat treated in a dedicated dental furnace (Multimat Touch, Dentsply, PA, USA) in a dental/prosthetic facility (Clínica David Maestre, Valverde de Leganés, and LAB Dental, Badajoz, Spain), following the manufacturer's requirements.

Two LS2 materials, IPS emax.CAD LT and HT (Ivoclar Vivadent, NY, USA), were crystalized in a vacuum atmosphere by initial heating to 400°C (soaking 6min), followed by heating to 820°C at 90°C/min (soaking 10min), heating to 840°C at 30°C/min (soaking 7min); cooling was conducted gradually with the chamber closed until 550°C, and then opening the furnace doors.

Four ZLS materials were also prepared. Already crystallized Celtra Duo LT and HT (Dentsply Sirona, NC, USA) were employed both as-received (untreated) and heat-treated. The heat treatment recommended by the manufacturer, which does not significantly affect previous crystallization of the as-received material [18], consisted of initial heating to 500°C (soaking 3min), followed by heating to 820°C at 60°C/min (soaking 1min), and gradual cooling with the chamber closed until 500°C, and then opening the furnace doors.

Plane parallel test specimens were obtained from the materials by mechanical cutting. Subsequently, specimens were gently ground with fine sandpaper, lapped (30μm), and polished with diamond suspensions using routine ceramographic methods. The polishing routine consisted of the following steps: 15μm (10min), 9μm (10min), 6μm (10min), 3μm (15min), and 1μm (20min).

The microstructure of the materials was observed by scanning electron microscopy (FE-SEM; Quanta 3D FEG, FEI, The Netherlands) using backscattered electrons at intermediate accelerating voltages (10–15kV).

Mechanical property characterization was undertaken by indentation tests (MV-1, Matsuzawa, Japan) with a diamond Vickers tip on polished specimens at ambient conditions (humidity between 30% and 40%). The maximum load applied was 9.8N, with a dwell of 20s. A total of 10 indentations per material were performed. Hardness (H) and indentation fracture toughness (KC) were determined from the dimensions of the indentation scars (two scar diagonals for and four radial cracks emanating from the corners for each indentation), as measured by optical microscopy (Epiphot 300, Nikon, Tokyo, Japan) and image analysis software, using standard formulae [19,20].

Pin-on-disk wear tests were performed using a dedicated tribometer (THT, Anton Paar, Graz, Austria) [21]. Because ZLS materials are intended as stronger variants of LS2 for possible used in high-load applications, conditions aimed at simulating severe wear were employed. To that end, a mirror-finished zirconia (3Y-TZP) sphere (pin) of radius 3mm (Goodfellow Cambridge Ltd., UK) was used to apply normal loads of 20N onto polished specimens (disks) of thickness ≈3mm. Zirconia is the hardest of all the dental materials, and thus can cause severe wear on the glass-ceramic disk specimens, with minimal pin wear. The radius of the zirconia sphere employed is within the anatomical range of radius of curvature values of molar cusps in primates [22]. The 20N load was the highest that could be applied without resulting in catastrophic wear damage on the disks [7]. The wear track radius was r=3mm, the sliding speed 10mm·s−1, and the total sliding distance L=150m. Artificial saliva (Lacer S.A., Barcelona, Spain), of viscosity 3.22cSt at 20°C, was used as the test environment. Tests were conducted three times per material. In each case, the wear volume of the disks was calculated from the wear track profile determined using optical profilometry (Profilm, Filmetrics, San Diego, CA) at the conclusion of the tests. Three separate profilometry measurements, spanning the entire scar width, were performed on each wear track, perpendicular to the sliding direction. The surface of the specimens after testing was inspected by SEM using secondary and backscattered electrons.

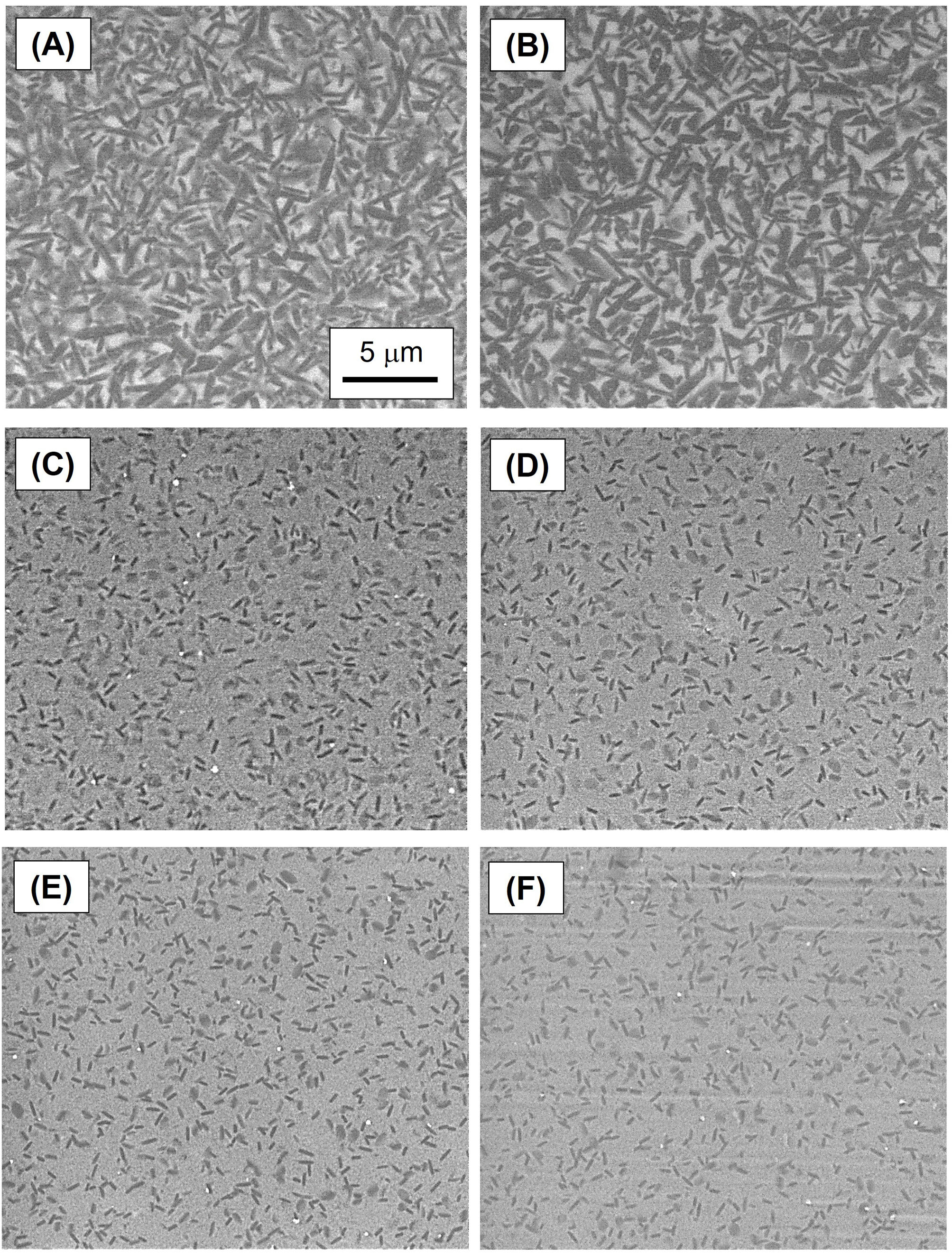

ResultsFig. 1 shows micrographs representative of the microstructure of the glass-ceramics investigated. All materials show a microstructure based on elongated, rod-shaped crystals of micrometric and sub-micrometric size embedded in a glassy matrix, with ZLS materials also containing smaller, nanometric crystals. Manufacturer specifications as well as previous studies [7,18,23–26], have measured a ≈70vol% content of crystals (lithium disilicate) in LS2, and a ≈50vol% content of crystals (lithium silicate, disilicate and phosphate) in ZLS; the matrix is a silicate glass in LS2 and a zirconia silicate glass in ZLS. There are no significant differences at the microstructural scale between the as-received and heat-treated ZLS materials (Fig. 1(C) vs.Fig. 1(E) and Fig. 1(D) vs.Fig. 1(F)), as the treatment recommended by the manufacturer does not significantly affect crystallization [18]; its effects are likely limited to flaw refinement aimed at improving the fracture strength. The versions of different translucency (LT and HT) of all three types of materials (LS2, as-received ZLS and heat-treated ZLS) also show the same microstructure (Fig. 1(A) vs.Fig. 1(B); Fig. 1(C) vs.Fig. 1(D); and Fig. 1(E) vs.Fig. 1(F)). Using image analysis software and the intercept method [27], the content/size/aspect ratio of rod-shaped crystals in each type of material are estimated to be ≈58vol%/2.2±0.3μm/4.3±0.7 (LS2) and ≈25vol%/0.7±0.1μm/3.5±0.6 (ZLS's) [7]. Note that equiaxed crystals were excluded from the image analysis, and that calculations using the intercept method are typically underestimations and are used only for comparative purposes.

Scanning electron microscopy (SEM) images representative of the microstructure of the dental glass-ceramics used in this study: (A) LS2 LT; (B) LS2 HT; (C) ZLS LT (as-received); (D) ZLS HT (as-received); (E) ZLS LT (heat-treated); (F) ZLS HT (heat-treated). All images are at the same scale.

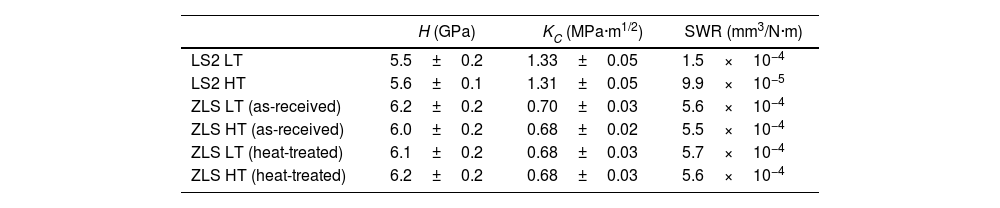

The mechanical properties of the materials measured by indentation tests are shown in Table 1. Hardness values between 5.5GPa and 6.2GPa, and indentation fracture toughness values between 0.68MPa·m1/2 and 1.33MPa·m1/2 are fairly similar to those of human dental enamel [28]. LS2 materials are somewhat softer and significantly tougher than the ZLS materials. The mechanical properties of ZLS materials are not affected by the heat treatment. And, within experimental errors, for all three types of materials, no significant differences in mechanical properties are observed between LT and HT versions.

Contact mechanical properties (hardness, H, and indentation fracture toughness, KC) and specific wear rate (SWR) of the dental glass-ceramics employed in this study.

| H (GPa) | KC (MPa·m1/2) | SWR (mm3/N·m) | |

|---|---|---|---|

| LS2 LT | 5.5±0.2 | 1.33±0.05 | 1.5×10−4 |

| LS2 HT | 5.6±0.1 | 1.31±0.05 | 9.9×10−5 |

| ZLS LT (as-received) | 6.2±0.2 | 0.70±0.03 | 5.6×10−4 |

| ZLS HT (as-received) | 6.0±0.2 | 0.68±0.02 | 5.5×10−4 |

| ZLS LT (heat-treated) | 6.1±0.2 | 0.68±0.03 | 5.7×10−4 |

| ZLS HT (heat-treated) | 6.2±0.2 | 0.68±0.03 | 5.6×10−4 |

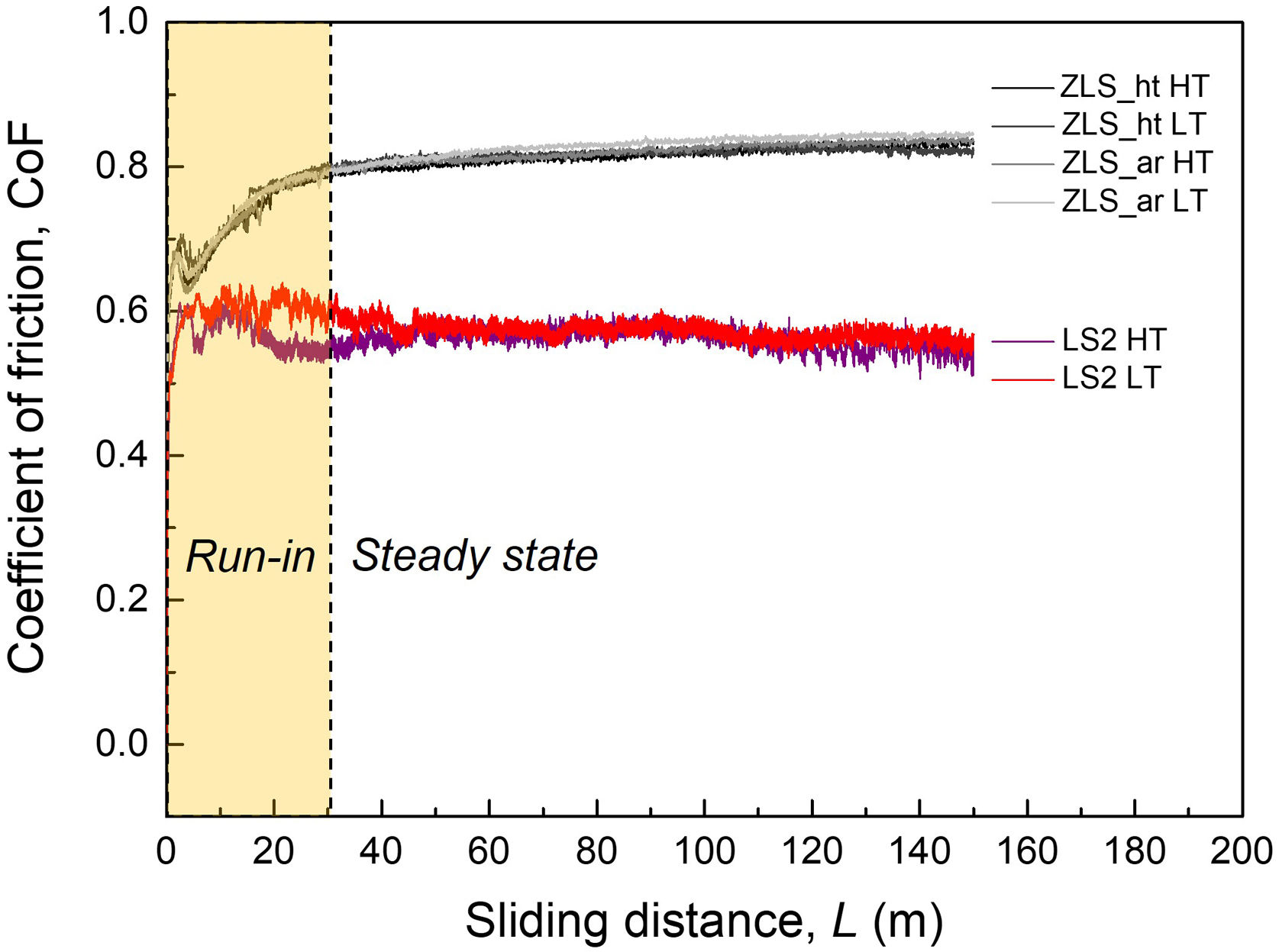

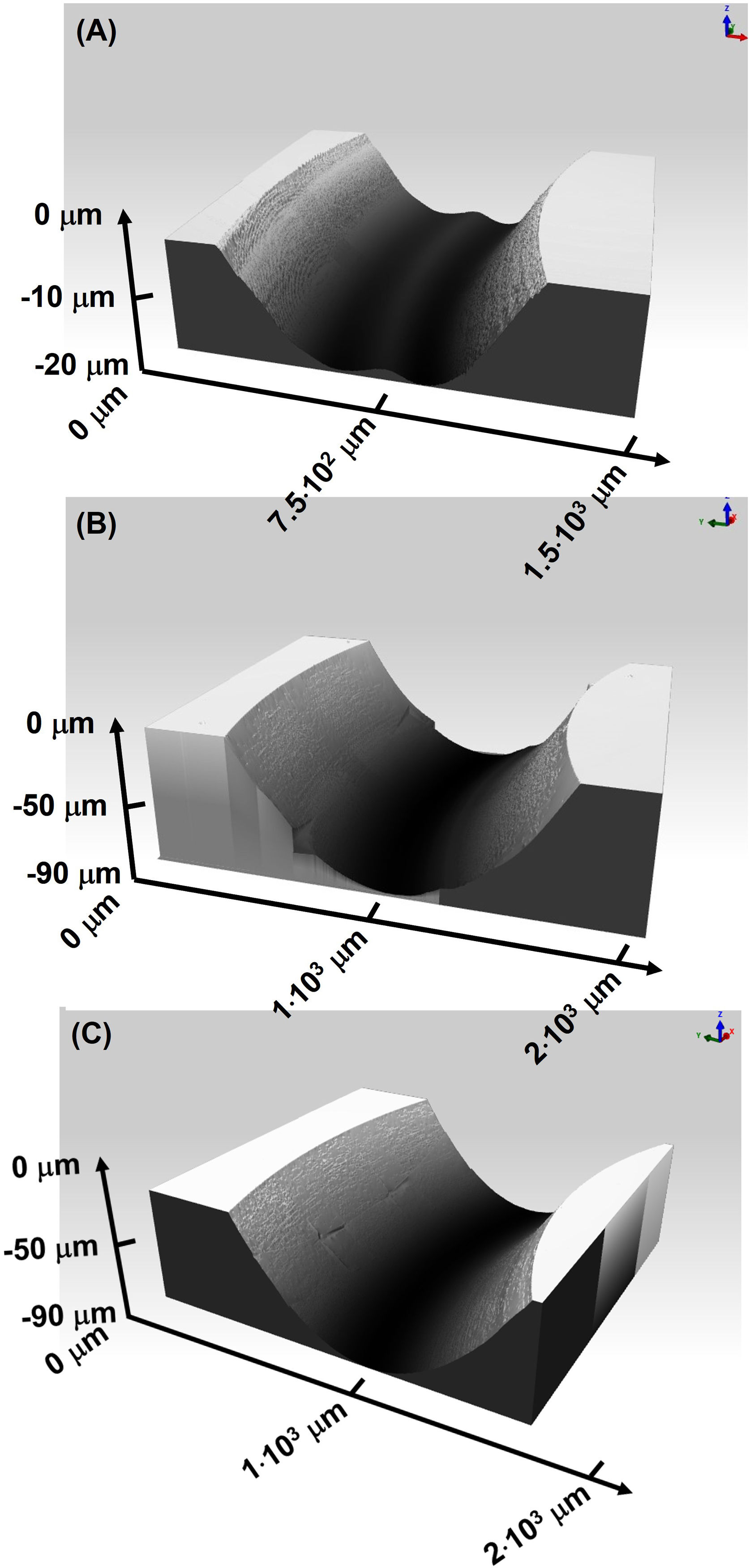

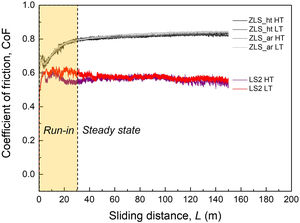

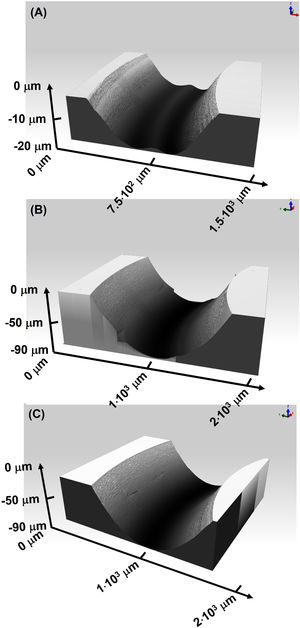

The contact conditions in the pin-on-disk wear tests resulted in relatively high values of coefficient of friction, CoF. Fig. 2 shows representative CoF vs.L curves for all materials. After approximately 30m of run-in phase, a stationary state (steady state wear) is reached, with average CoF values of ≈0.6 and ≈0.8 in LS2 and ZLS materials, respectively. The 3-D profiles of the wear scars on LS2 and ZLS disks at the end of the tests (Fig. 3) show that such scars are relatively large and conform to the zirconia counter sphere. Despite displaying some minor superficial scratches, the latter does not show significant volume loss compared to the disk specimens. No significant differences in the 3-D profiles of the wear scars are observed between the LT and HT versions of each of the materials.

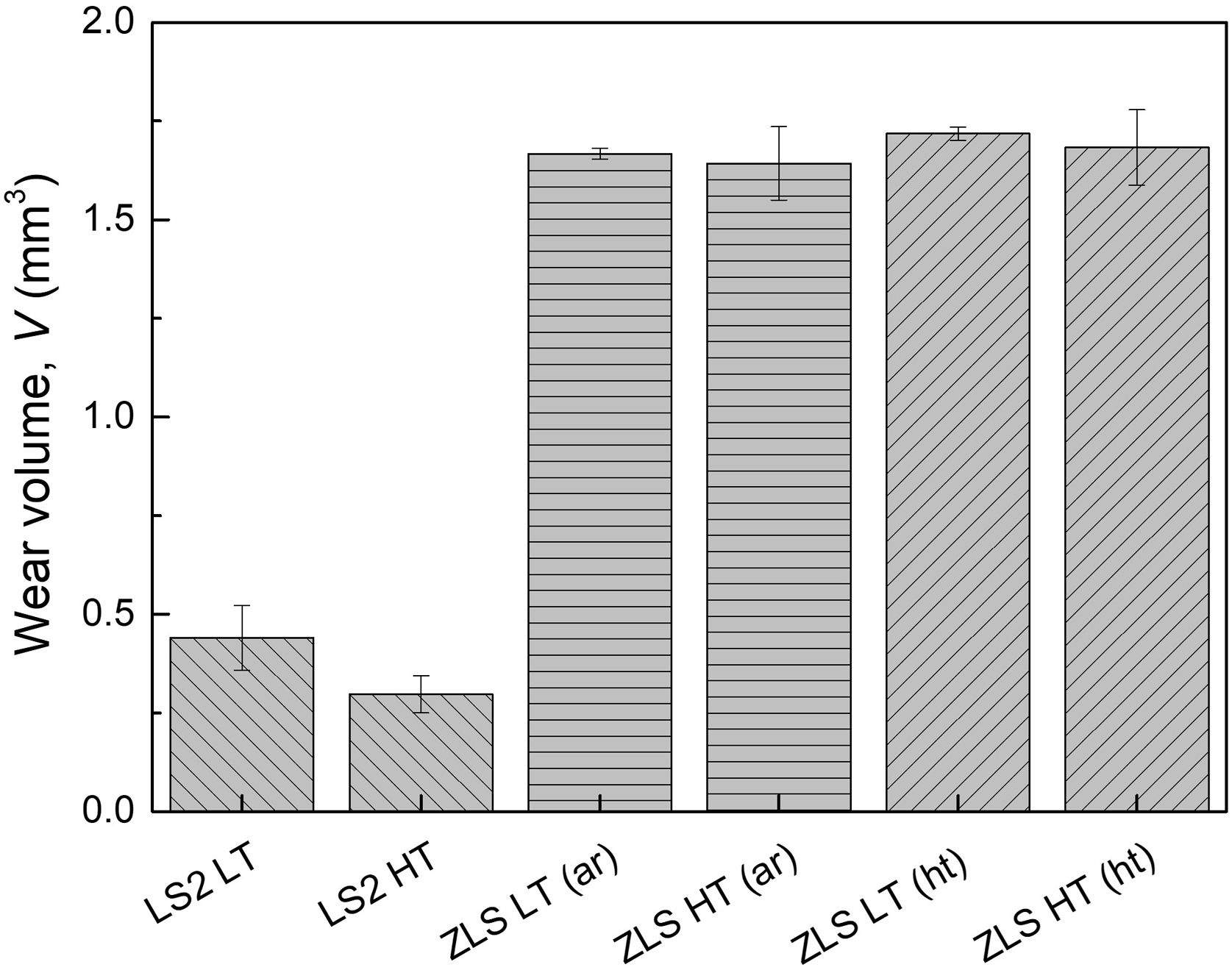

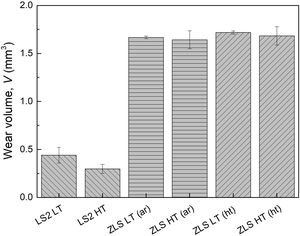

The wear volumes calculated from the profilometry images are shown in Fig. 4. Despite the limited number of specimens tested per material (N=3), the experimental results show relatively low dispersion, as one would expect given that, unlike in natural dental materials (i.e., enamel, dentine), the microstructures of artificial materials are very homogeneous (Fig. 1). The LS2 materials undergo considerably lower wear than the ZLS materials, and the differences are statistically significant, e.g. comparison between LS2 HT and heat-treated ZLS HT gives a p-value in Student-T test of 2 10−5; p-values lower than 0.05 are also obtained in the rest of cross-comparisons between LS2 and ZLS materials. On the other hand, differences between as-received and heat-treated ZLS materials are not statistically significant, with a p-value in Student T-test of 0.53 [7]. Finally, for all three types of materials, no significant differences in wear volume are observed between variants of different translucency, as inferred from p-values 0.06 (LS2 HT vs. LS2 LT), 0.68 (as-received ZLS HT vs. as-received ZLS LT), and 0.71 (heat-treated ZLS HT vs. heat-treated ZLS LT). Given the limited duration of the wear tests, it is not expected that chemical degradation under artificial saliva affected the results significantly [29].

Wear volume of the dental glass-ceramics investigated in this study at the conclusion of the pin-on-disk tests. As-received and heat-treated materials are labelled ‘ar’ and ‘ht’, respectively. The bar chart plots mean and standard deviation of the measured wear volume values for the three groups/types of materials (3 separate measurements in N=3 specimens, totaling 9 measurements in each group).

Table 1 shows the specific wear rates (SWR, defined as wear volume divided by sliding distance and normal load) which, in all cases, indicate severe wear (SWR>10−6mm3/N·m) [30]. Wear rates greater than 10−6mm3/N·m are in accordance with results obtained in other experiments, also under severe conditions but using a different contact configuration [8]. Comparatively, SWR values are almost one order of magnitude greater in ZLS materials than in LS2.

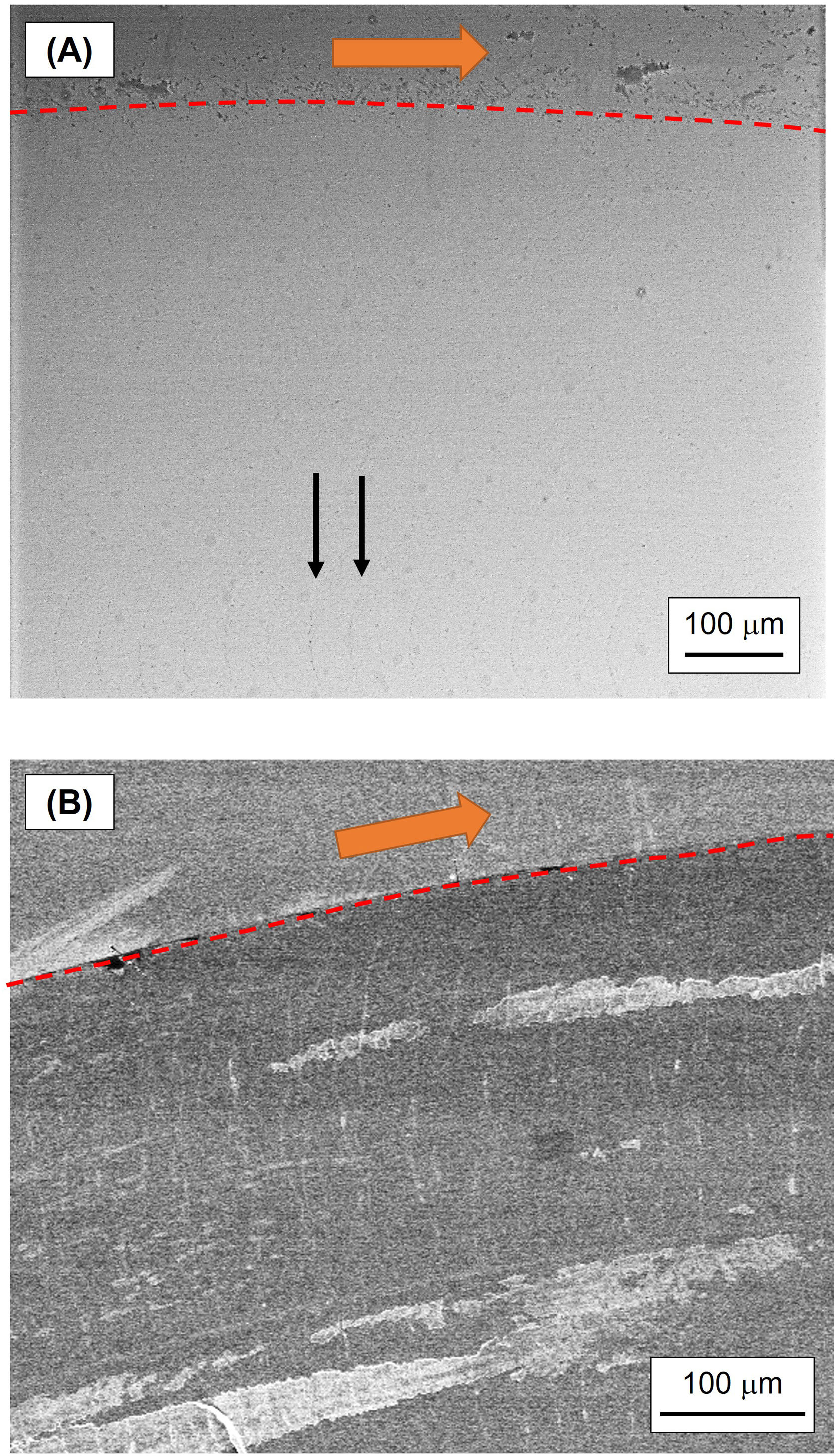

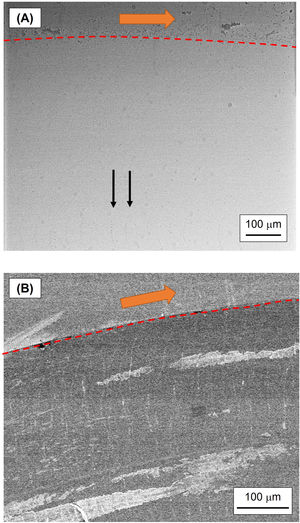

Fig. 5 shows SEM images representative of the wear damage. Fundamental differences can be observed between LS2 and ZLS materials, but not between as-received and heat-treated materials and between versions of different translucency (LT vs. HT). Images taken in uncoated specimens (i.e., non-metallized prior to SEM observation) show a smooth wear surface in LS2 materials, which contains disperse, very faint cracks perpendicular to the sliding direction, highlighted by black arrows (Fig. 5(A)). By contrast, the wear surface of ZLS materials appears to be significantly rougher (Fig. 5(B)). It shows extensive partial cone cracking perpendicular to the sliding direction, as well as relatively large chipped off areas where material was removed from deeper within. The larger extent of microscopic damage in ZLS materials is qualitatively consistent with their greater wear volume compared to LS2 (Fig. 4).

Low-magnification SEM images representative of the wear damage in LS2 and ZLS glass-ceramics: (A) LS2 HT; (B) ZLS HT (as-received). Broken red lines mark the edge of the wear track and orange arrows indicate the sliding direction. Black arrows in (A) highlight partial cone-cracks. The surface of the specimens was not metallized prior to SEM observation.

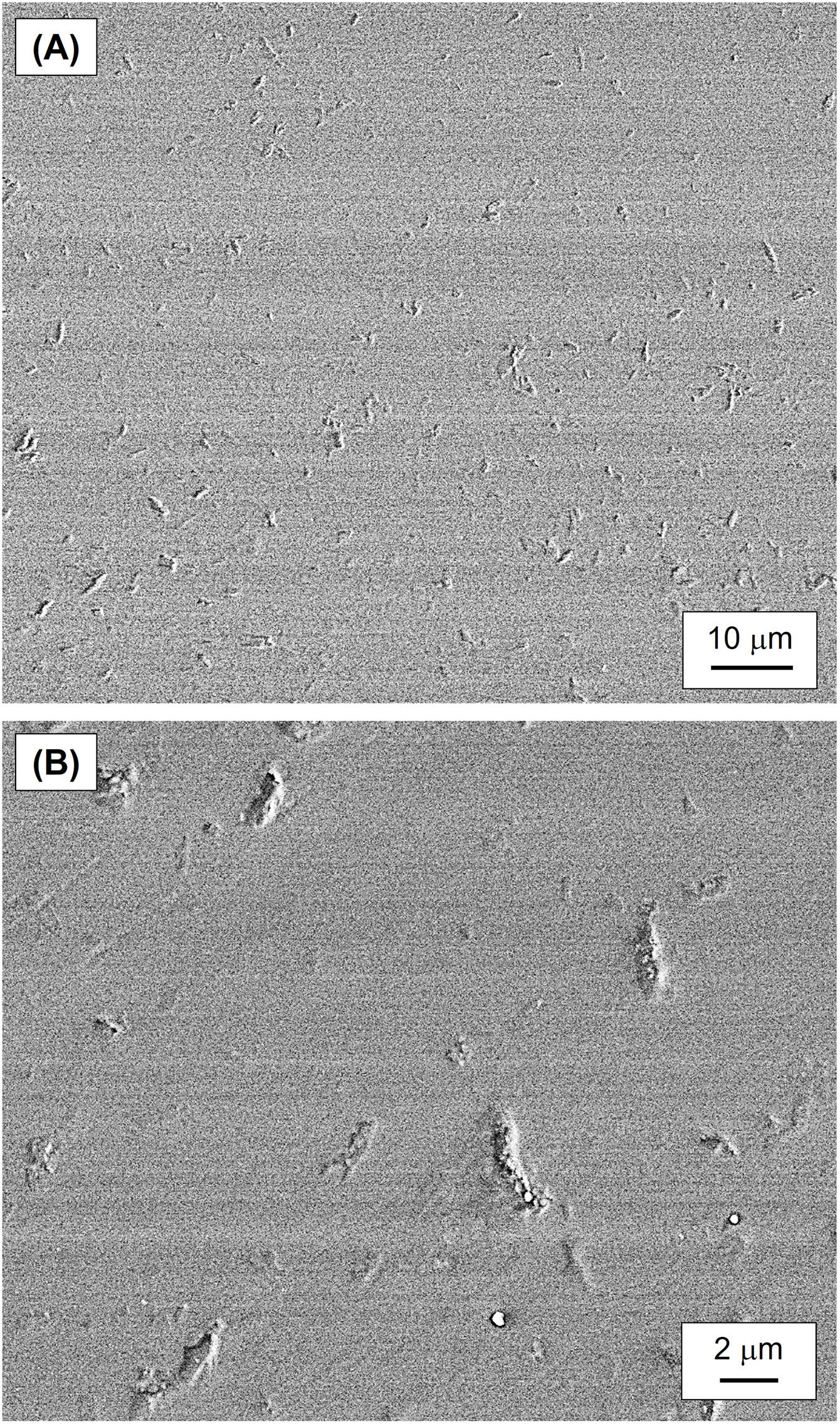

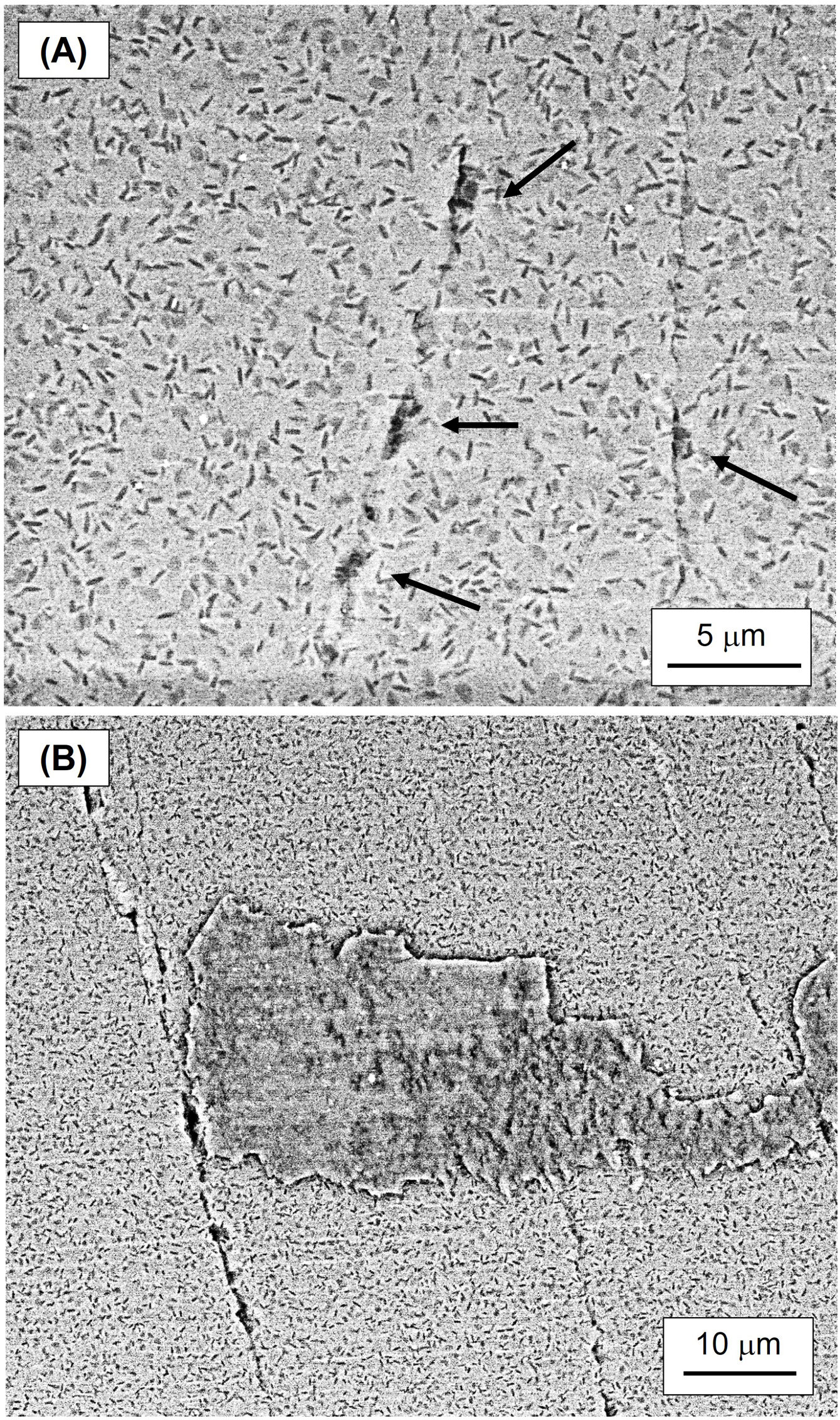

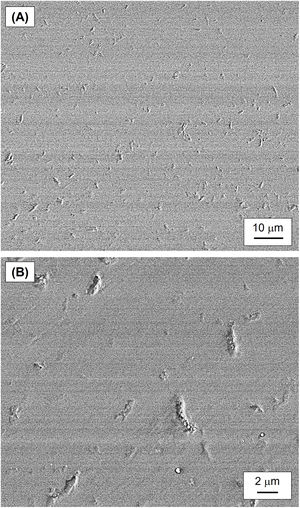

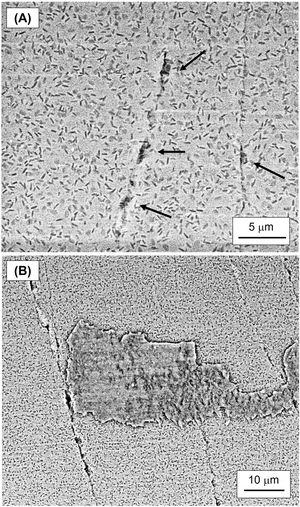

Higher magnification micrographs of the wear damage in LS2 glass-ceramics are shown in Fig. 6. Images taken on gold-coated specimens reveal additional details of the material removal mechanisms in the form of crystal pull-out. It can be observed that some of the rod-shaped crystals are removed wholesale, resulting in micrometre-sized pits scattered across the wear scar. In addition, microscopic scratches parallel to the sliding direction can be seen. Fig. 7 shows high magnification details of the damage around partial cone cracks in ZLS (uncoated specimens). It is noted that partial cone cracks widen in given locations, highlighted by arrows in Fig. 7(A), which appear to act as precursors of the larger chips (Fig. 7(B)).

The microscopy examinations of the damage after the pin-on-disk tests (Fig. 5) indicate that the wear mode of lithium silicate-based glass-ceramics under sliding contact is two-body abrasion, caused by the sliding, harder zirconia counter-sphere. The specific wear mechanisms are a combination of deformation and fracture. Deformation is caused by the shear component of the stress field, which has a maximum just under the surface, ahead of the normal loading axis. Fracture is caused by the tensile component of the stress field, which has a maximum on the surface, at the trailing edge of the moving contact, and radial orientation, thus opening partial cone cracks [31,32].

While all the lithium silicate-based glass-ceramics show evidence of both deformation and fracture, the dominance of one mechanism over the other ultimately depends on materials’ microstructure [7]. In particular, a greater proportion of larger and more elongated crystals in LS2 materials result in enhanced quasi-plasticity [33] (i.e., permanent deformation by interfacial microcracking and subsequent relative sliding under resolved shear stress [34]) and, together with their relatively softer glass matrix, in a lower hardness than ZLS materials. The main element of quasi-plasticity is interfacial weakness, which is evidenced in Fig. 6: failure (micro-cracking) of weak crystal-matrix interfaces in LS2 leads to the wholesale pull-out of some of the crystals. In addition, elongated crystals improve the efficiency of crack bridging mechanisms [20,35], which make LS2 tougher than ZLS. Indeed, Fig. 7 shows that crystals in ZLS are significantly smaller than the characteristic dimensions of the cracks, and do not form an interlocked network, thus being less effective at toughening. As a result, wear by deformation/quasi-plasticity is dominant in the LS2 materials, and wear by fracture (i.e., by chipping processes initiated in the more brittle glass matrix [36]) in the ZLS materials. Because the latter is typically more severe than the former [33,37], ZLS glass-ceramics show greater SWR values than LS2 glass-ceramics (Table 1).

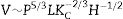

The experimental results indicate that in lithium silicate-based dental glass-ceramics, a correlation between translucency and wear resistance does not exist within a given material type. That is, for the two types of materials investigated (i.e., LS2 and ZLS), the LT and HT versions show essentially the same wear resistance—the minor differences in the average wear volume values are not statistically significant, with p-values greater than 0.05 in all Student T-tests. This result can be explained using established analytical models of severe wear of ceramic materials [37–39]. In particular, according to [37], since material removal processes are a combination of deformation and fracture, the wear volume (V) is inversely proportional to the hardness (H), taken as a measure of resistance to deformation, and the indentation fracture toughness (KC), taken as a measure of resistance to fracture. A mechanics analysis yields the following expression:

where P is the applied load and L the sliding distance (both the same in all materials investigated in this study). It follows from the structure-property relation that because the LT and HT versions of any given lithium silicate-based glass-ceramic have the same microstructure (Fig. 1), they also have the same hardness and indentation fracture toughness values (Table 1). In accordance with Eq. (1), LT and HT materials thus show the same resistance to wear. Eq. (1) is also qualitatively consistent with LS2 materials being more wear resistant than ZLS, ultimately a result of greater toughness conferred by the interlocked network of elongated crystals in the former [40,41], and with heat treatment not affecting the wear resistance of already crystallized ZLS materials [7].It is important to note that the absence of a correlation between translucency and wear resistance within a given type of lithium silicate-based dental glass-ceramic material contrasts with what occurs in other relevant engineering ceramics such as polycrystalline alumina, or magnesium-aluminate spinels [13–15]. The results obtained suggest that unlike in those engineering ceramics, in lithium silicate-based materials the mechanisms that control the contact-mechanical properties and light transmittance operate at different length-scales. Indeed, while material removal processes are controlled at the microstructural scale, optical properties are probably affected to a larger extent by the structure at the atomic scale, for example by the presence of impurities in the glass phase. Note that different types of lithium silicate-glass materials, with different compositions and microstructures, may have different translucency values, but that does not necessarily indicate a causal relationship between microstructure and translucency.

This work has some useful implications for the selection of currently available dental materials. Lithium silicate-based glass-ceramics are widely used as prosthetic crowns due to their superior aesthetics. However, as usual with materials selection, property tradeoffs need to be considered. From the mechanical point of view, the main limitations of lithium silicate-based materials for use in dentistry are insufficient strength—improved somewhat by zirconia additions in ZLS—and low wear resistance, which could result in prostheses of durability lower than desired in applications under severe contact conditions (e.g. posterior restorations) [7,42]. Our results suggest that the specific material aesthetics, achieved by means of a low (LT) or a high (HT) translucency, do not affect the contact mechanical properties and resistance to wear of any given type of lithium silicate-based dental ceramic, and thus should not impact the durability of the prostheses.

ConclusionsWe have compared the sliding-wear resistance of commercial lithium silicate-based dental glass-ceramics of different levels of translucency (LT and HT). Based on the results and analyses, the following conclusions can be drawn:

- 1.

In all types of lithium silicate-based dental materials (LS2, and as-received and heat treated ZLS), the level of translucency does not affect the microstructure and mechanical properties. LS2 materials show enhanced quasi-plasticity, and are softer but tougher/less brittle, than ZLS.

- 2.

The wear mode of lithium silicate-based dental materials under sliding contact against a hard antagonist is two body abrasion, and the wear mechanisms are (quasi) plastic deformation (dominant in LS2) and fracture (dominant in ZLS).

- 3.

The level of optical translucency is not correlated with wear resistance in lithium silicate-based dental glass-ceramics.

This study was supported by the Ministry of Science and Innovation, Spain (grant n°. PID2019-105377RB-I00), and the Junta de Extremadura, Spain and FEDER/ERDF funds (grant n°. GR18149).