In this current research endeavor, a comprehensive exploration into the properties of ceramic coatings has been undertaken, utilizing bauxite, talc, and kaolin clay. The primary focus lies in the meticulous analysis of the mechanical strength of ceramic proppants. The proppant raw material employed is kaolin clay, treated through a dry coating technique and subsequently sintered at 1300°C. Evaluation of sample performance is based on the establishment of coating and substrate shrinkage. Shrinkage and density assessments are separately conducted for the coating mixtures and substrate. X-ray diffraction (XRD) is employed to discern the crystalline phases within the coatings, while structural characterization is facilitated through scanning electron microscopy (SEM) coupled with energy dispersive X-ray (EDX). Density and mechanical strength of proppants are meticulously investigated using picnometry and crush tests. The performances of the coated and uncoated samples were compared and investigated. Interestingly, the coated proppants demonstrate slightly higher density than their uncoated counterparts. Remarkably, the specimen featuring a coating composition of bauxite (72wt%)+clay (25wt%)+talc (3wt%) yields optimal results for mechanical strength. The sole crystalline phase detected in the coating is mullite, with a minimum coating thickness of 10μm.

Se ha llevado a cabo un estudio sobre las propiedades de los recubrimientos cerámicos empleando bauxita, talco y arcilla tipo caolín. El enfoque radica en el análisis de la resistencia mecánica de los apuntalantes. Se utilizó arcilla tipo caolín como materia prima para el apuntalante, sometiéndola a un proceso de recubrimiento en seco y posterior sinterización a 1.300°C. El rendimiento del material se basa en la determinación de la contracción tanto del recubrimiento como del sustrato, realizando evaluaciones separadas para cada uno. Las fases cristalinas en los recubrimientos se determinaron por DRX, mientras que la caracterización estructural se facilitó mediante MEB junto con espectroscopia de rayosX de energía dispersiva. La densidad y la resistencia mecánica de los apuntalantes se determinaron mediante picnometría y prueba de aplastamiento. Se compararon los rendimientos de las muestras recubiertas y no recubiertas, revelando que los apuntaladores recubiertos presentan una densidad ligeramente superior a sus contrapartes no recubiertas. La muestra que contiene una composición de recubrimiento de bauxita (72%p/p)+arcilla (25%p/p)+talco (3%p/p) mostró resultados óptimos en cuanto a resistencia mecánica. La única fase cristalina en el recubrimiento fue la mullita, con un espesor mínimo determinado de 10μm.

Ceramic proppants, pivotal in oil and gas applications, have remained a subject of persistent research and development owing to their indispensable role in stabilizing and enhancing production in oil wells. Commonly derived from raw materials such as bauxite and kaolin [1–11], ceramic proppants have demonstrated their efficacy in hydraulic fracturing and hydrocarbon production applications. These materials are obtained through the processes of granulation and heat treatment applied to the raw materials. To address the mechanical and chemical resistance challenges posed by future fracking operations in the industry, the development and application of ceramic coatings to conventional proppants is a possible way to solve these challenges. This work analyzes ceramic coatings with the goal of increasing mechanical strength while maintaining density. The coating experiment employs a straightforward modification of the established proppant manufacturing process, utilizing a known method for scalable production validation.

This manuscript explores an innovative coating strategy designed to increase the efficiency of proppants prepared from kaolin clay by enhancing their mechanical properties through the incorporation of alumina, while simultaneously enabling applications requiring chemical resistance. Enhancing mechanical properties is crucial for reducing fines generated from cracking in wells, thereby maintaining well conductivity.

The impact of the initial alumina content in the raw materials on the density of proppant agents has been extensively investigated [12,13]. Alumina content has emerged as a key determinant in enhancing mechanical properties [14]. Proppant agents with low alumina content typically exhibit densities below 2.6g/cm3, whereas those with high alumina content fall within the range of 3.1–3.3g/cm3. The densification of these agents is a crucial factor influencing their mechanical resistance, with an increase in density correlating to a heightened ability to withstand loads. Prior research has delved into the incorporation of additives aimed at reducing the sintering temperature of bauxite [15–19]. Proppant agents, existing in the forms of ‘fracture sands’ or ceramics [20], have witnessed the emergence of coating techniques as pivotal strategies aimed at enhancing their properties. The application of coatings to proppants serves not only to maintain their structural integrity under the extreme conditions within the exploited well but also to preserve well conductivity [21–23]. The diminished generation of fines and the plastic adhesion afforded by organic coatings contribute to heightened stability and prolonged efficacy of proppants in wells [24]. Despite the indisputable benefits, the adoption of organic coating technology poses inherent challenges, encompassing the associated costs of implementation and investment in specialized equipment [25]. This reality necessitates a careful evaluation when contemplating the widespread application of this technique in the industry.

In light of the potential constraints related to the scarcity and accessibility of high alumina resources, such as bauxite [1], there arises a compelling necessity to explore alternative avenues for the production of enhanced proppants. This research endeavors to introduce an innovative strategy centered around the utilization of kaolin-type clay as a base material, complemented by a coating rich in alumina. Using kaolin clay as the base material means it is the primary component of the coated material, which is significant because it is located in the same places where proppants are typically used. This approach leverages the abundance of readily available materials and the analogous mineralogy between kaolin and bauxite after sintering. The mineralogical similarity of these materials suggests effective adhesion at the interface between the coating and the base material [26–28]. Investigations into the expansion coefficients and mineralogy post-sintering have been conducted, with strategies explored to enhance the mechanical resistance of the coated material [29,30]. This enhancement involves assimilating the mineralogy and promoting contraction in both the coating and substrate materials [31].

The coating application process has been carefully addressed, taking into account the inherent limitations of granulated clay, with a particular focus on the formation of agglomerates and the particle geometry. The implementation has been strategically designed to be compatible with the pelletizing machines employed in granulation, thereby ensuring efficient and reproducible integration into the production process.

The objectives of this study encompassed the development of an efficient procedure for the dry coating application using solid mixtures, the investigation of a series of solid mixtures containing bauxite to achieve effective coatings, and the microscopic identification of the coating. The primary goal was to attain a match in contraction coefficients and mineralogy between the substrate and the coating, thereby increasing the mechanical resistance of coated support agents through the dry coating technique. To fulfill these objectives, a diverse array of trials was conducted, involving the incorporation of various materials into the bauxite-based coating mixture with the aim of obtaining properties akin to those of the substrate. Additionally, independent measurements of density and shrinkage were performed for both coating and substrate mixtures. The phases present in the coating mixtures were identified, and the mechanical resistance and pycnometric density of the proppant agents were evaluated. Proppant agents exhibiting significant improvements in resistance underwent further analysis using scanning electron microscopy (SEM) and energy dispersive spectroscopy (EDX) techniques to identify and characterize the resulting outer layer. The production of resistant proppants represents a promising avenue of study with potential applications in the hydrocarbon and wellbore production industry, addressing key challenges and contributing to the ongoing advancement of technologies.

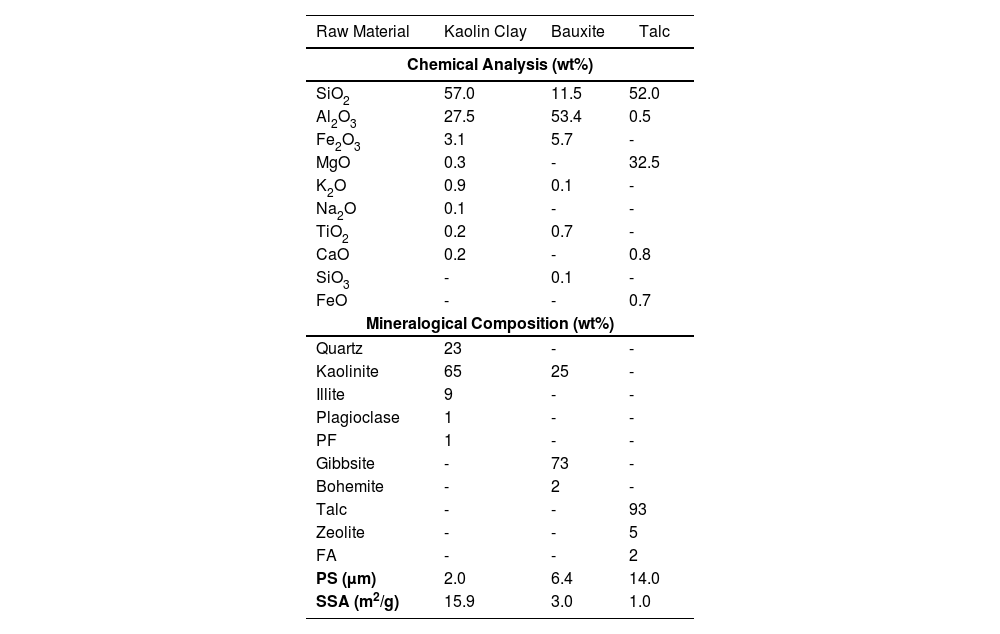

Materials and methodsRaw materialProppants were made from commercial kaolin clay, provided by Piedra Grande (Neuquen, Argentina). The coating material was made of mixtures of kaolin clay, same used for the proppant, bauxite, provided by Meranol, and talc, provided by Haicheng. The mean particle size, specific surface area, chemical and mineralogical composition of kaolin clay is presented in Table 1. The chemical composition was determined by X-ray fluorescence (XRF), using a Shimadzu Energy Dispersive Spectrometer (model EDX-800 HS) on dry samples at 110°C. The mineralogical phases were identified by X-ray diffraction (XRD), using a Philips diffractometer (PW3710) in the range from 5° to 70° with a step of 0.04° and a permanence of 2s/step. The mineralogical composition was determined by applying the Rietveld method and Fullprof structural refinement program to the XRD pattern. The measurement of the mean particle size and the specific surface area was carried out in the Malvern Mastersizer 2000 equipment with a hydro 2000G dispersion equipment, using a suspension diluted at 10wt%.

Mineralogical and chemical composition, mean particle size (PS) and specific surface area (SSA) of kaolin clay, bauxite and talc.

| Raw Material | Kaolin Clay | Bauxite | Talc |

|---|---|---|---|

| Chemical Analysis (wt%) | |||

| SiO2 | 57.0 | 11.5 | 52.0 |

| Al2O3 | 27.5 | 53.4 | 0.5 |

| Fe2O3 | 3.1 | 5.7 | - |

| MgO | 0.3 | - | 32.5 |

| K2O | 0.9 | 0.1 | - |

| Na2O | 0.1 | - | - |

| TiO2 | 0.2 | 0.7 | - |

| CaO | 0.2 | - | 0.8 |

| SiO3 | - | 0.1 | - |

| FeO | - | - | 0.7 |

| Mineralogical Composition (wt%) | |||

| Quartz | 23 | - | - |

| Kaolinite | 65 | 25 | - |

| Illite | 9 | - | - |

| Plagioclase | 1 | - | - |

| PF | 1 | - | - |

| Gibbsite | - | 73 | - |

| Bohemite | - | 2 | - |

| Talc | - | - | 93 |

| Zeolite | - | - | 5 |

| FA | - | - | 2 |

| PS (μm) | 2.0 | 6.4 | 14.0 |

| SSA (m2/g) | 15.9 | 3.0 | 1.0 |

PF: Potassium Feldspar; FA: Ferro-actinolite; PS: particle size; SSA: Specific surface area.

Table 1 presents the chemical and mineralogical composition, mean particle size, specific surface area of bauxite and talc.

Propping agent formationThe granules were produced using a mechanical granulator designed for laboratory scale production of proppants. This granulator consists of a rotating cylindrical drum with a capacity of 20l. The central axis of the drum is inclined at an angle to the horizontal, and it is equipped with rotating blades positioned eccentrically to the axis of rotation. The blade rotations ranged from 0 to 4800rpm. The cylindrical drum itself rotated at a constant speed of 70rpm. Additionally, the pellet mill was equipped with a deflector blade designed to prevent the accumulation of material on the drum walls.

To initiate the granulation process, 1000g of clay were loaded into the pelletizer, which was then started at a speed of 4800rpm. During the operation, 17wt% water was introduced, and the process continued for a duration of 5min.

Composition and preparation of the coating solid mixtureTwo coating composition mixtures were formulated. The initial mixture, referred to as “BT-90/10” was comprised of 90wt% bauxite and 10wt% talc. Experimental observations unequivocally established that any deviation from this 10wt% talc composition within the solid mixture had adverse effects on the coating. Specifically, an escalation in talc concentration exceeding 10wt% resulted in the detachment of the coating subsequent to sintering the coated material at the designated experimental temperature. Consequently, no further variations in talc content were considered in this experimental context.

To address these observed limitations, a novel coating composition mixture was meticulously prepared, incorporating kaolin clay to enhance the sintering behavior of bauxite. This mixture aimed to include 25wt% of kaolin clay in conjunction with a reduction in the proportions of talc and bauxite. The revised composition consisted of 72wt% bauxite, 25wt% kaolin clay, and 3wt% talc, designated as “BCT-72/25/3”.

The two coating mixtures were prepared separately and using the same procedure. Initially, the raw materials were introduced in their respective proportions into a ball mill. Specifically, 200g of the corresponding proportions of the compounds and 200g of distilled water were charged into the mill. The mill was then operated for 2h, employing alumina balls with approximate diameters of 20mm. Subsequently, the resulting mixture was dried in a container placed in an oven set at 110°C. Upon achieving complete dryness, the mixture was broken up in a mortar and subsequently sieved using a 149μm (100 mesh) sieve. The passing fraction from the sieve was used in the subsequent experiments.

Coating solid mixture depositionThe addition of the coating powder must be meticulously timed to coincide with the final stage of shaping the proppants. This timing is crucial due to the presence of humidity emanating from the forming water. As time elapses, this moisture content gradually diminishes.

The proppants were initially shaped and subsequently sieved, with proppants passing through a 400μm (40 mesh) sieve being discarded. A 500g sample of the sieved proppants was carefully selected and reintroduced into the pelletizer for the coating process, while the remaining proppants were set aside for subsequent analysis. A precisely measured quantity of 110g of the coating mixture powder was introduced into the pelletizer. The blade rotation speed was set at 1200rpm, and the machine was allowed to operate at this speed for a duration of 5min. The continuous rotation of both materials within the pelletizer effectively facilitated the dispersion and homogenization of the coating material across the entire external surface of the proppants. Following this coating step, both the coated and uncoated proppants were subjected to drying in an oven maintained at a temperature of 110°C.

Several tests were conducted with experimental observations made to establish a reliable application process. Subsequently, three repetitions of coating deposition were performed for each solid mixture (BT-90/10 and BCT-72/25/3), resulting in three samples of coated proppants and three samples of uncoated proppants for each experimental process.

Sintering conditionsThe sintering of the specimens was carried out in an MHI electric furnace at 1300°C in an air atmosphere, with a ramp of 5°C/min and a dwell of 2h. Afterwards, cooling was carried out at room temperature in the same furnace.

Characterization of the materials used for the coatings and for the proppantsCharacterization of the materials used for the coatings and the proppants involved the identification of phases in the sintered samples of propping agents, and the coating solid mixtures BT-90/10 and BCT-72/25/3. This identification process was conducted using the same method as detailed for determining the mineralogical composition of the kaolin clay.

Subsequently, separate dilatometric tests were conducted on the kaolin clay and the coating solid mixtures. Sample preparation involved a series of sequential steps. Initially, kaolin clay was introduced into a ball mill, with the mill operating under identical conditions as described for the preparation of the coating solid mixture. Subsequently, the resulting mixture was poured into a plaster cast and allowed to dry, yielding a cylindrical geometry that was later rectified. This process was repeated for the materials BT-90/10 and BCT-72/25/3.

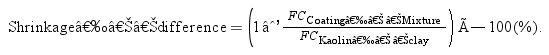

For the dilatometric testing, a Linseis L70 integrated with a Thorlabs Z825B high-performance digital camera dilatometer was employed. A temperature ramp of 10°C/min was applied, reaching up to a temperature of 1300°C, with a 1-h dwell time. The final temperature in the dilatometric test aligned with the final sintering temperature of the specimens. The final contraction (FC) of each sample was determined as the last recorded contraction during the sintering program. The FC measurement allowed for the determination of the shrinkage difference between the coating solid mixtures and the kaolin clay. The percentage shrinkage difference was calculated using the following equation, with the final contraction of the kaolin clay serving as the reference:

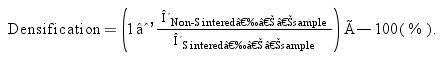

The densities of the kaolin clay and the coating solid mixtures were measured separately; the sample preparation was similar to that described in the dilatometric test. The Archimedes method in kerosene and water was used for non-sintered and sintered samples, respectively. Five samples were prepared for each material: kaolin clay, BT-90/10, and BCT-72/25/3, resulting in a total of fifteen samples. Each sample underwent a density test, first in the non-sintered state and then in the sintered state. This process provided five individual density values for each non-sintered material and five individual density values for each sintered material. From the collected data, the average density and standard deviation were calculated for each material group. These average density measurements, denoted δSintered and δNon-Sintered, served as crucial metrics for assessing the density behavior of the materials employed in the production of the coated proppant. The percentage densification was calculated with the following equation, taking as reference the average density of the designed sintered sample.

Characterization of the propping agentAfter the sintering process, the proppants were sieved through 841μm and 400μm sieves (passing through the 841μm sieve and retained by the 400μm sieve). Subsequently, the apparent density and breakage ratio at 34.4MPa of the proppants were measured.

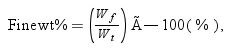

The breakage ratio, serving as an indicator of the mechanical strength of the proppants, was determined in strict accordance with the API 19C standards [32]. To measure the breakage ratio, a sample of the proppant was loaded into the testing cell. Compressive pressure was applied and maintained at 34.4MPa for a duration of 2min. Following the compression test, the sample was carefully removed and sieved using 841μm and 400μm (20/40 mesh) sieves to separate any fines generated during the crushing process. To quantify the fines produced during crushing, the material that passed through the 841μm and 400μm sieves was weighed. The weight fraction of fine generation, denoted as Finewt%, was calculated using the following equation:

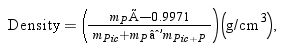

here Wf represents the weight of fine particles generated after the crush test, and Wt represents the initial weight of the proppants before testing. It is worth noting that the API 19C standard mandates a maximum Finewt% value of 10% (or 10wt%) for proppants to be suitable for hydraulic fracture applications.The apparent density was determined using picnometry, evaluating the mass of the material per unit volume of the proppants, accounting for their internal porosity. The weight of the pycnometer, filled with water at a temperature of 21°C, was established and recorded as mPic. Next, the pycnometer was partially emptied until it weighed mPic/2, and a dry sample of proppants was carefully introduced. Subsequently, the pycnometer, now containing the proppants, was subjected to a vacuum until the open pores were saturated with the immersion liquid. The mass of the pycnometer and the proppants, filled with water, was determined and recorded as mPic/2+P. To complete the measurement, water at a temperature of 21°C was added to the upper rim of the pycnometer, and its total weight was recorded as mPic+P. The apparent density was calculated using Eq. (4):

where mP is the mass of the proppants (g) calculated as mPic/2+P−mPic/2; 0.9971g/cm3 is the density of water at a temperature of 21°C.The conducted experiment on proppants resulted in 12 sintered samples: three samples for the proppant coated with BT-90/10, three for its uncoated counterpart, three samples for the proppant coated with BCT-72/25/3, and three for its uncoated counterpart. Apparent density and resistance measurements were individually conducted on these samples. This methodology produced three distinct results for both the coated and uncoated materials in each experimental process. Subsequently, the average and standard deviation of these results were calculated for each experimental process.

Preparation of the specimens for analysis and coating characterizationThe coated proppants were carefully placed and embedded in resin, then ground and polished with SiC abrasive paper up to 1000 mesh. The polished cross-section were observed with scanning electron microscopy (SEM) (JEOL JCM-6000 Neo Scope) and characterized with energy dispersive spectroscopy (EDX) (EDX-JEOL). The coating thickness was established using the EDX with SEM scale bar.

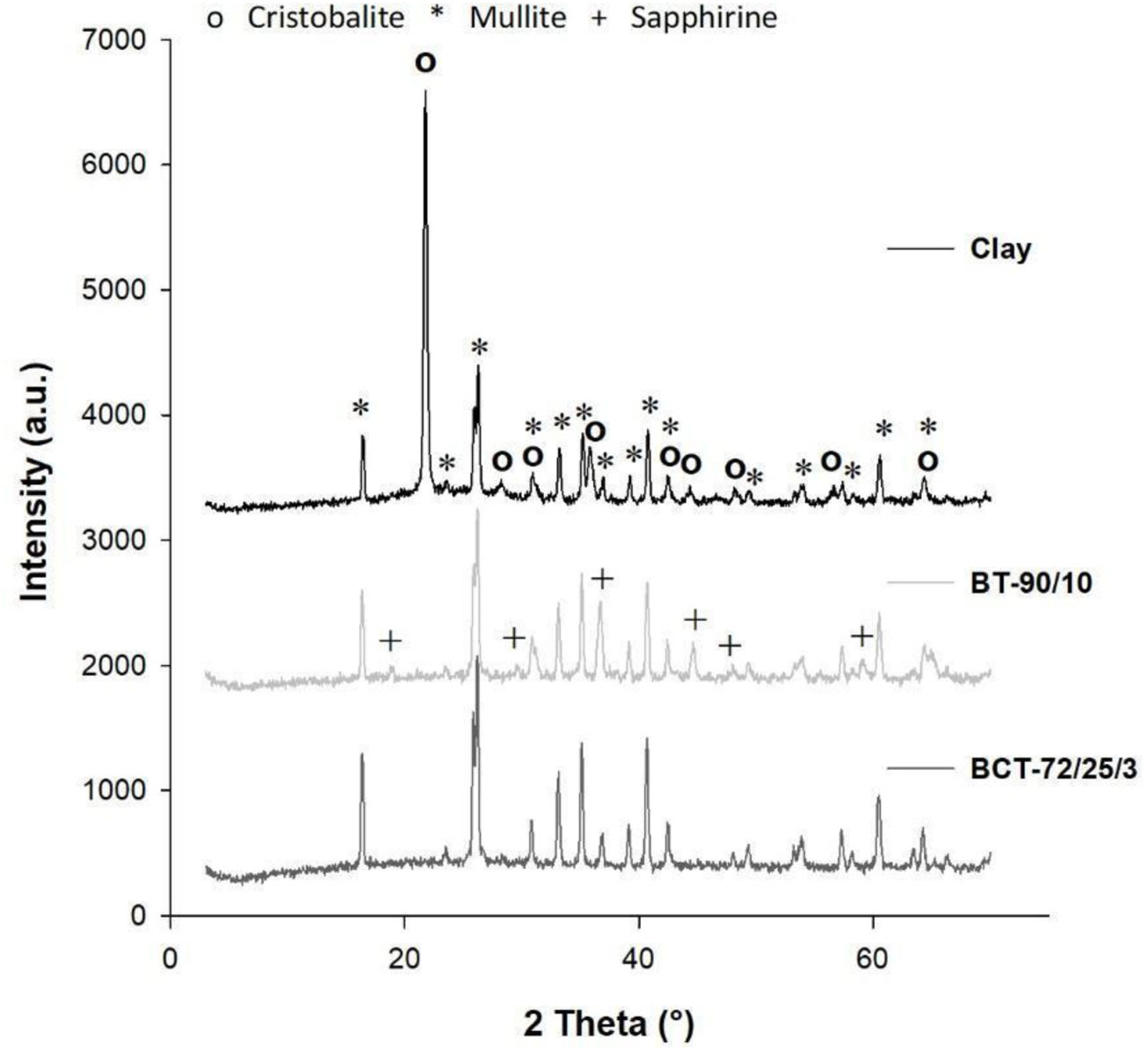

Results and discussionXRD of clay, BT-90/10 and BCT-72/25/3 samplesFig. 1 presents the diffractograms of kaolin clay and the solid mixtures BT-90/10 and BCT-72/25/3, all subjected to sintering at 1300°C. For the kaolin clay, the identified crystalline phases include mullite (3Al2O3·2SiO2) and cristobalite (SiO2), along with the presence of a non-crystalline phase. Qualitatively, it is evident that the clay exhibits a substantial formation of cristobalite, suggesting a high degree of crystallinity in the clay raw material, as observed previously [33], or due to its low alkali and alkaline earth content [34]. Additionally, the diffractogram of the clay reveals a discernible band between 20° and 30° 2θ, attributed to the glassy phase resulting from SiO2 vitrification. The heightened presence of glass is attributed to the elevated percentage of the SiO2 component and alkalis in the raw material.

In contrast, for the sintered BT-90/10 mixture, the crystalline phases identified include mullite (3Al2O3·2SiO2) and sapphirine (7MgO·9Al2O3·3SiO2). In the case of the sintered BCT-72/25/3 mixture, mullite (3Al2O3·2SiO2) is the sole crystalline phase identified. This suggests that kaolin clay acts as a promoter for the crystallization of mullite, while the low quantity of incorporated MgO remains undetected. The liquid-phase sintering mechanism of kaolin-type clays plays a crucial role in promoting mullite formation during thermal treatment [35]. The primary advantages of mullite are its high mechanical and chemical resistance, as well as its dimensional stability under varying temperature conditions, which is why it is of interest for coating applications [36,37].

In all examined mixtures (BT-90/10 and BCT-72/25/3), the absence of the amorphous phase band between 20° and 30° 2θ was observed, in contrast to what was observed in the kaolin clay. Specifically, for the BCT-72/25/3 mixture, this phenomenon can be attributed to the relatively low percentage of kaolin clay within the solid mixture. The reduced clay content implies that the amorphous band does not appreciably manifest after the heat treatment, indicative of distinct material behavior.

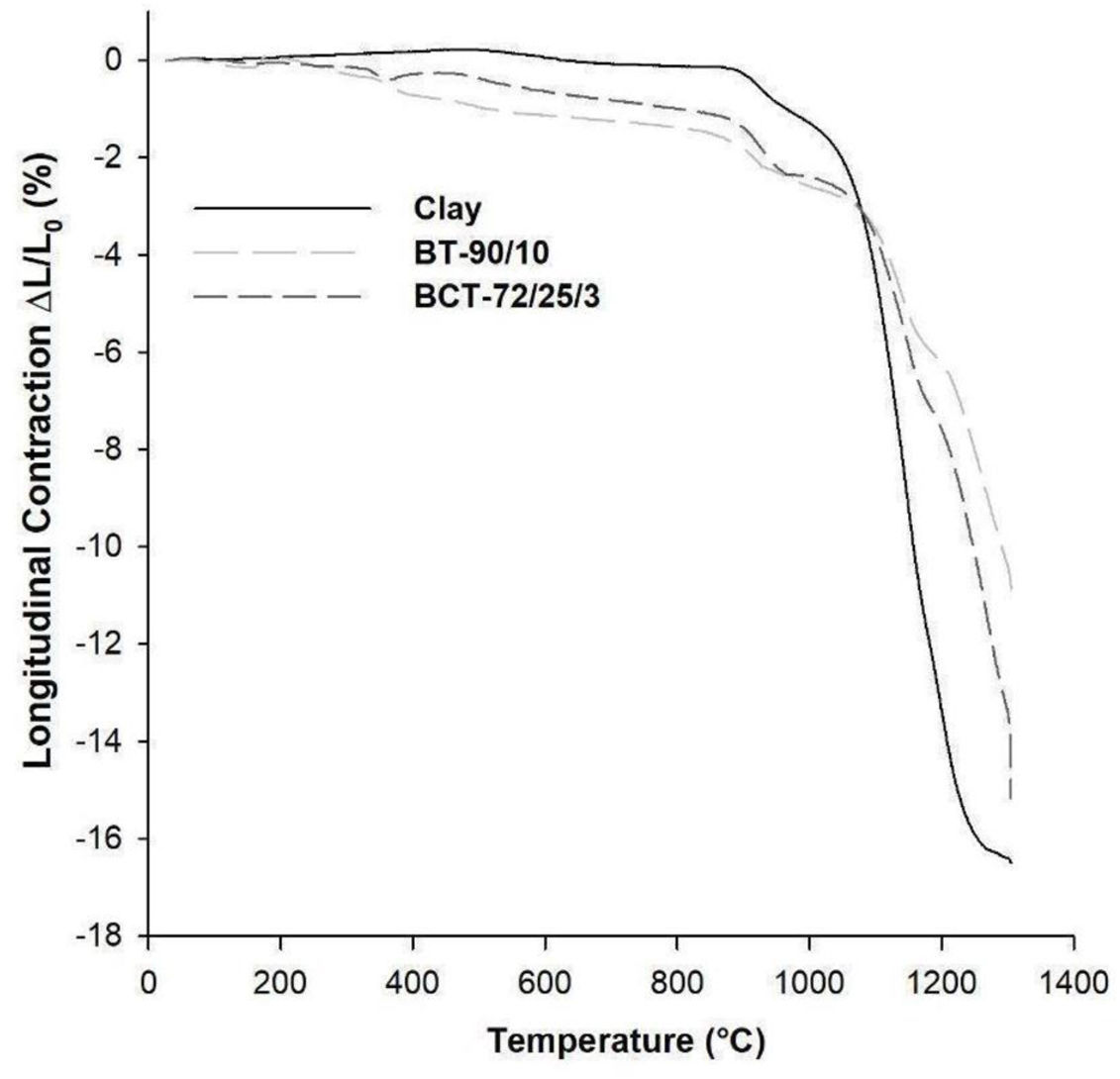

Dilatometric test of clay, BT-90/10 and BCT-72/25/3 samplesThe results of the dilatometry analysis conducted on clay kaolin and the solid mixtures BT-90/10 and BCT-72/25/3 are depicted in Fig. 2. In the case of clay, a contraction of 16.50%, in absolute value, is observed at the end of the test. The dilatometric curve maintains a flat profile up to the temperature range of 950–1000°C. Subsequently, the rate of contraction begins to escalate within the temperature range of 1050–1250°C, attributed to densification by the glass phase. Notably, the rate of shrinkage diminishes in the temperature range of 1250–1300°C as the mullite phase initiates formation. Within this temperature range, the material gives rise to secondary mullite crystals [33], leading to a reduction in the shrinkage rate.

For the solid mixture BT-90/10, the observed shrinkage at the end of the test is 10.9%, in absolute value. The curve illustrates a contraction in the coating material from 200°C to the temperature range of 1000–1100°C. This contraction results from moisture losses in the bauxite, initially due to the conversion of gibbsite to boehmite and subsequently, in the second stage, due to the conversion of boehmite to alumina (Al2O3) [38]. The rate of shrinkage increases within the temperature range of 1150–1250°C, signifying the initiation of reactions between silica, alumina, and magnesium oxide. The rate of contraction stabilizes within the temperature range of 1250–1300°C, remaining approximately constant.

In the case of the solid mixture BCT-72/25/3, the observed shrinkage at the end of the test is 15.2%, in absolute value. Similar to the BT-90/10 mixture, the curve reveals a contraction from 200°C to the temperature range of 1000–1100°C. This contraction is attributed to phenomena similar to those presented by the BT-90/10 mixture. The rate of shrinkage increases within the temperature range of 1150–1200°C, indicating the onset of reactions between silica and alumina. The rate of contraction stabilizes within the temperature range of 1200–1300°C, remaining approximately constant. At 1300°C, during the heat treatment plateau, contraction persists, attributed to a liquid phase sintering mechanism originating from the clay.

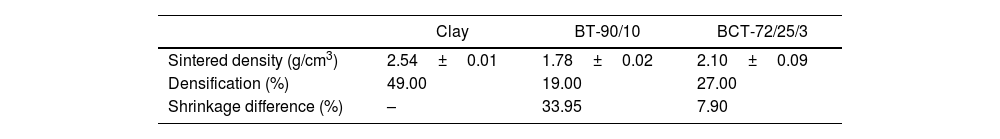

Sintered properties of clay, BT-90/10 and BCT-72/25/3 samplesTable 2 presents values for the average sintered density along with its deviation. These values are calculated from five samples, encompassing the shrinkage difference determined by Eq. (1) and the densification calculated using Eq. (2). The investigation extends to kaolin clay and the mixtures BT-90/10 and BCT-72/25/3.

The base material exhibits a higher average density and greater densification compared to the BT-90/10 and BCT-72/25/3 mixtures. This is attributed to the inadequacy of the maximum heat treatment temperature to achieve optimal sintering in solid mixtures. The densification percentage for BT-90/10 is observed to be 60% lower compared to kaolin clay, while BCT-72/25/3 exhibits a densification percentage 45% lower than that of clay.

Examining the shrinkage difference concerning clay as the reference, approximately 34% and 7.9% are observed for BT-90/10 and BCT-72/25/3, respectively. This distinction is attributed to the greater contraction caused by the liquid-phase sintering mechanism in clay.

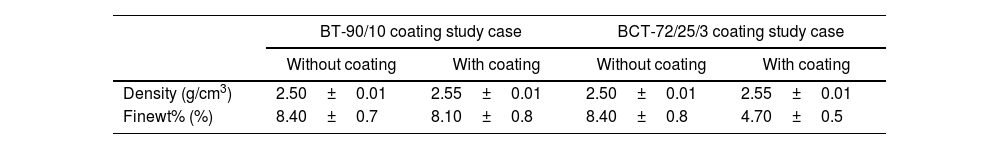

Measurement of density and crush resistanceTable 3 presents the average values along with their respective deviations for the percentage of fines obtained from the crush test, as calculated using Eq. (3). Additionally, the apparent density, determined through Eq. (4), is provided for both uncoated and coated proppants. A notable observation is that the apparent density values for the coated proppants, whether treated with the solid mixture BT-90/10 or the mixture BCT-72/25/3, exhibited a slight elevation compared to the apparent density of their respective uncovered counterparts. This marginal increase in density can be attributed to the presence of alumina in the coating. The introduction of alumina into this substrate-coating system induces densification reactions at the interface, resulting in a slightly higher density of the proppant.

Average values, along with their respective deviations, for the apparent density and mechanical resistance of the proppants.

| BT-90/10 coating study case | BCT-72/25/3 coating study case | |||

|---|---|---|---|---|

| Without coating | With coating | Without coating | With coating | |

| Density (g/cm3) | 2.50±0.01 | 2.55±0.01 | 2.50±0.01 | 2.55±0.01 |

| Finewt% (%) | 8.40±0.7 | 8.10±0.8 | 8.40±0.8 | 4.70±0.5 |

In the BT-90/10 coating case study, it is noteworthy that the percentage of fines for the coated proppant closely approximates the corresponding percentage for the uncoated proppant. Conversely, in the case study involving the BCT-72/25/3 coating, the average percentage of fines for the coated proppant is observed to be 44% lower than the percentage associated with the uncoated proppant. This disparity suggests a significant reduction in fine generation, highlighting the efficacy of the BCT-72/25/3 coating in enhancing the crush resistance of the proppant.

Ceramics, renowned for their inherent brittleness, are characterized by a significant array of cracks and defects that are introduced during the processing stages. The stress state experienced by the ceramic surface during heat treatment surpasses that of any other region within its structure. Inhomogeneities situated on the surface tend to initiate cracks, subsequently propagating into the ceramic matrix. Moreover, the shrinkage disparities between the substrate and the coating contribute to the formation of surface cracks. The greater this difference, the more significant the surface stresses generated, which can induce cracks.

The utilization of a compressive layer to impede incipient cracks has been investigated [39]. It is well-established that maintaining a state of compression throughout all stages of ceramic heat treatment enhances toughness and reduces susceptibility to crack propagation [40]. The differential shrinkage attained with the BCT-72/25/3 coating and the clay facilitates the imposition of a state of compressive stress on the surface. This transformative effect converts tensile stress into compressive stress on the outermost surface of the material during high-temperature conditions. This phenomenon, occurring during heat treatment, contributes to the enhancement of the mechanical properties of the proppant.

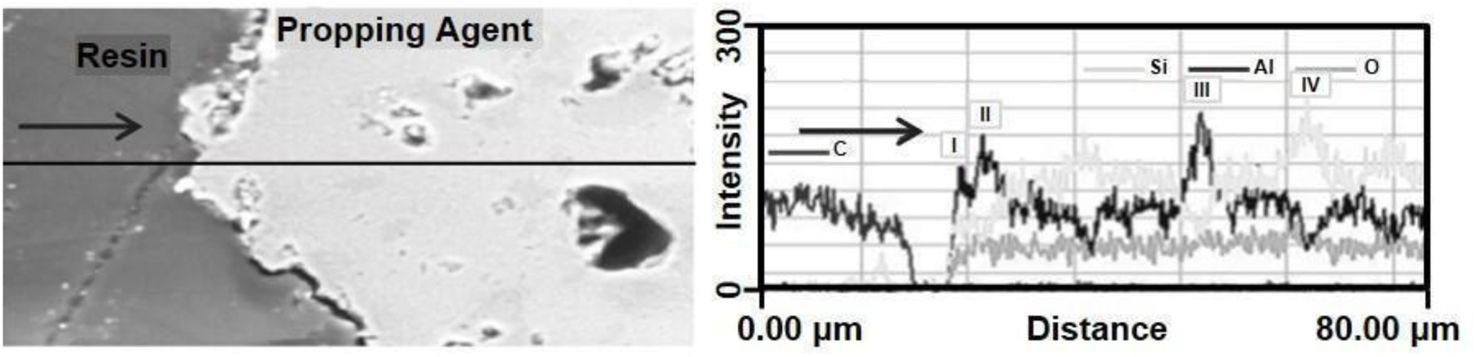

Characterization of coating in proppantFig. 3 illustrates the EDX test conducted along a straight line spanning from the external to the internal regions of the proppant, encompassing a portion of the resin used for sample inclusion. The analysis reveals a gradual increase in silica concentration from the external to the internal zone of the proppant, attributed to the migration of silica during sintering from the base material to the coating [37]. This migration enhances the degree of sintering through the liquid phase sintering mechanism and improves adhesion at the interface.

On the EDX line, four peaks were identified; peaks I, II, and III were assigned to the alumina compound, while peak IV was designated for the silica compound. Peaks I and II are observed within distances of 20–30μm, peak III between distances 50 and 60μm, and peak IV between distances 60 and 70μm. The presence of alumina and silica peaks in the innermost part of the proppant is attributed to the non-homogeneity of the material.

The two peaks on the outermost surface (I, II) result from the high concentration of alumina in that line segment, indicative of the applied coating causing an elevation in alumina concentration on the surface. Between peaks I and II, a gradual increase in silica content is observed, marking the transition from the coated region to the underlying base material. Within the line segment spanning distances of 30–35μm, the silica content exceeds that of alumina, indicating the termination of the coating layer. This assessment enabled us to estimate a minimum coating thickness of 10μm.

Beyond peak II and until peak III, silica continues to exceed alumina, suggesting a material composition involving clay. Peak III, located in the interior of the proppant, indicates a sharp decrease in silica concentration and a sharp increase in alumina concentration. A specific EDX analysis reveals a high mass percentage of alumina and titanium compounds, hinting at the possible presence of an alumina and titanium oxide phase undetectable by XRD due to its low concentration.

Post-peak III, the percentage of silica surpasses that of alumina. Peak IV of silica in the internal zone of the proppant is attributed to the presence of cristobalite in that specific segment of the line.

ConclusionThe mechanical strength of proppants was enhanced through the deposition of a ceramic coating using the solid composition BCT-72/25/3. The proppant coated with this composition exhibited an average fines percentage of 4.7%, representing a 44% reduction in fines during the crush test compared to the uncoated counterpart. This reduction in fines is attributed to the improved mechanical strength.

The final shrinkage value of kaolin clay was determined to be 16.50%. The BT-90/10 material exhibited a shrinkage difference of approximately 34%, with a densification of 19%. The BCT-72/25/3 mixture showed a shrinkage difference of around 8%, with a densification of 27%, and the identified crystalline phase was mullite. While the mechanical resistance of the proppant coated with BT-90/10 did not show a significant increase, the coating solid mixture BCT-72/25/3 resulted in improved mechanical strength. Enhanced densification of the coating solid mixture has been a key factor in the improvement of the mechanical properties of proppants. The mixture BCT-72/25/3 proved to be compatible with the base material at the given sintering temperature, enabling better properties of the proppant.

EDX analysis revealed a delineation between the coating and substrate within the range of 30–35μm, demonstrating a progressive decrease in alumina concentration from the external to the internal zone of the coated material. The sintering of the coating solid mixture and the base material was satisfactory for this material, further contributing to the improvement of the mechanical properties of proppants.