In this research, a novel ethylene propylene diene monomer rubber (EPDM) formulation for cable with high ceramization efficiency was prepared by the addition of functionalized sepiolite with boron fluxing compound nanoparticles (SEPTB) obtained by precipitation route. Non-functionalized sepiolite (SEP) has been incorporated to the system for reference. EPDM materials were characterized by standardized tests measuring their behavior against fire and important improvements were observed, especially in terms of smoke production (25% reduction of the smoke production compared with the formulation using SEP) presenting a remarkable behaviour against dripping and self-extinction when a flame is directly applied. The mechanism of ceramization under fire conditions was discussed. It was found that EPDM system with SEPTB additive transformed into a rigid ceramic after treating at 1000°C. In this particular case, the ceramization was more efficient due to the sepiolite transformation to enstatite at lower temperatures (∼750 vs ∼850°C) combined with the “in situ” formation of a glassy phase which notably enhances the reinforcement of the char layer by forming a reinforcing 3D enstatite fibers net structure that reduces smoke production and even totally avoids the dripping of melted polymer by the action of the heat in a fire event. This work provides new insights for the preparation of high-performance synergist additive based on sepiolite for the enhancement of fire retardance of EPDM system for cable applications.

En esta investigación, se ha preparado una nueva formulación de caucho etileno-propileno-dieno (EPDM) para cable con un efecto de ceramificación más eficiente mediante la adición de sepiolita funcionalizada con nanopartículas de un compuesto fundente de boro (SEPTB) obtenidas por vía de precipitación. La sepiolita no funcionalizada (SEP) se incorporó al sistema del cable como referencia. Los materiales de EPDM fueron caracterizados mediante ensayos estandarizados midiendo su comportamiento frente al fuego y se observaron importantes mejoras, especialmente en términos de producción de humos (reducción del 25% de la producción de humos respecto a la formulación utilizando SEP) presentando un notable comportamiento frente al goteo y autoextinción cuando se aplica directamente una llama. Se propone el mecanismo de ceramificación en condiciones de fuego. Se comprobó que el sistema EPDM con aditivo SEPTB se transformaba en una cerámica rígida tras tratarlo a 1.000°C. En este caso, la ceramificación fue más eficiente debido a la transformación de sepiolita en enstatita a temperaturas más bajas (∼750 vs ∼850°C) combinada con la formación in situ de una fase vítrea que mejora notablemente el refuerzo de la capa de carbonilla mediante la formación de una estructura de red 3D de fibras de enstatita que actuaba como refuerzo reduciendo la producción de humo e incluso evitando totalmente el goteo de polímero fundido por la acción del calor en un evento de incendio. Este trabajo aporta nuevos conocimientos para la preparación de aditivos sinérgicos de alto rendimiento basados en sepiolita para la mejora de la retardancia al fuego del EPDM.

Polymers are used in many applications worldwide due to their interesting properties. Their use has been growing for the last decades up to a global production of more than 400 million tons per year [1] and it is intended to continue growing. An important segment of the market are the wire and cable polymeric compounds. In 2021, the global market size for wire and cable compounds was USD 12.5 billion and it is projected to grow to USD 19.2 billion due to automotive, power and construction industries rise on demand [2]. Polymeric materials, as a counterpart, have poor resistance to fire and high temperatures and constitute an important fraction of the fire load in fires in homes, commercial buildings or means of transportation. For that reason, cables are considered as a possible source of ignition [3,4] and, apart from initiating a fire, they can contribute to its propagation [5]. The main polymers used for wire and cable are PVC (polyvinyl chloride), LDPE (low-density polyethylene) and ethylene copolymers such as EVA (ethylene-vinyl acetate) [6].

To improve the fire resistance of polymeric materials, it is needed to add flame retardant (FR) additives. Metal hydrates (aluminum hydroxide, ATH, and magnesium hydroxide, MDH) are the most used halogen-free FR systems for cable applications [7], replacing traditionally used halogenated FR due to their toxicity and environmental impact that make them not safe for health and nature [8–10]. In addition to this, European standards like construction product regulation (CPR) or fire protection on railway applications (EN45545) have been updated to increase the safety in these applications forcing the polymeric compounds to meet stricter performances in relation to their behavior against fire.

On the downside, formulations based on metal hydrates need high dosages to obtain a good performance of the formulation (more than 50%) [7]. The high quantity of inorganic additives affects drastically to the processing behavior of the compound and to the mechanical properties of the final material [11]. Frequently, even with high dosages of the FR, the requirements of the regulations are not achieved. For this reason, there is an intense activity in terms of research for new synergists that can comply with the regulations, improving the reaction to fire of the compounds and enhancing their mechanical properties reducing the dosage of the flame retardant [12].

One type of synergists studied are the clays. The most common clays used as synergists to improve flame retardant behavior of polymers are layered silicates and, among them, organically modified montmorillonite (MMT) has probably been the most used in research works and applications [13]. The mechanism by which organoclays improve the fire performance of polymeric materials is based on the reinforcement of the char created under fire conditions by dispersed clay particles. This reinforced char has improved barrier properties against heat and oxygen penetration, thus protecting the unburnt material, and slowing down the release to the combustion zone of flammable volatiles formed due to the degradation of polymer [14]. Many examples are available on the literature that confirm the synergistic effect of MMT in a wide range of polymeric matrices combined with different types of flame retardants [15–17].

Apart from MMT, another silicate that has demonstrated its synergistic effect in fire resistant formulations is sepiolite. Sepiolite is a relatively rare mineral in nature due to the unique conditions required for its formation and stability. Moreover, the properties are origin dependent because there are close relationships between origin, crystal structure and chemical composition. Spain is the largest producer of sepiolite and accounted for about 95% of the world's annual production [18]. The sepiolite deposits of the Madrid Basin are the most important in the world due to their high purity and excellent physicochemical properties. Sepiolite is a needle-like natural magnesium phyllosilicate which structure has channels and tunnels along the needles [19]. The surface of the sepiolite is covered with silanol groups, that make the surface able to be organically modified and functionalized with different compounds by covalent interaction [20]. It can be also, by means of activation processes, used as a pattern to grow inorganic species as metal oxides, metallic phosphates, etc. [21,22] obtaining a controlled size and homogeneous distribution all along the fiber. These modification and functionalization possibilities make sepiolite an interesting candidate as synergistic additive for flame retardant polymeric systems among other applications. The incorporation of organically modified sepiolite to polymeric matrices, is translated into an enhancement of the carbonaceous char following a mechanism similar to other silicates, improving the flame retardancy, reducing the heat release and the smoke production [23–25]. In addition, the dispersion into the polymer of sepiolite's fibers, creates a reinforcing 3D net that reduces and even totally avoids the dripping of melted polymer by the action of the heat in a fire event [26]. Studies as the one carried out by Bilotti et al. [27] suggest that the reinforcing efficiency of sepiolite, because of its highest aspect ratio, is higher than for layered montmorillonite.

Another interesting trend in research is the concept of polymer-based ceramifiable composites (PCCs). Ceramization or ceramification process is described by the formation of ceramic from polymer composite highly filled with inorganic particles during heat treatment. The created structure can block the propagation of flames and decrease the rate of flammable volatile compounds production, created during thermo oxidative degradation of polymer matrix, by preventing the burning material from deeper penetration of oxygen [28]. PCCs can be considered as a solution for the wire and cable industry focused on safety cables design, which must be able to create a self-supporting insulation layer in case of fire accident, preventing the fire propagation and protecting the conductor from melting, guaranteeing the integrity of the circuit for longer times than conventional insulation materials [29]. By using this approach, other polymers different to traditionally used silicone rubber, due to its capacity to create amorphous silica during thermal degradation acting as a binder between mineral fillers [30], can be used and, as a result, formulation cost would be reduced and processability of the material enhanced [28,31]. Boron compounds are used in many FR formulations as they have different modes of action (char stabilization, fuel dilution, flame inhibition) [32]. As fluxing agents, they present relatively low melting or decomposition temperatures generating glassy phases that, together with the other compounds on the formulation, as the silicates and the flame retardants, can form a vitreous-ceramic-like structure [29,33]. To obtain good performance of the material, the selection of the fluxing agent and its combination with the other formulation components is the key. The use of sepiolite as a substrate for particle growth brings the advantage, in comparison with simple particle mixing, of the improvement on the ceramification efficiency completely avoiding any agglomeration.

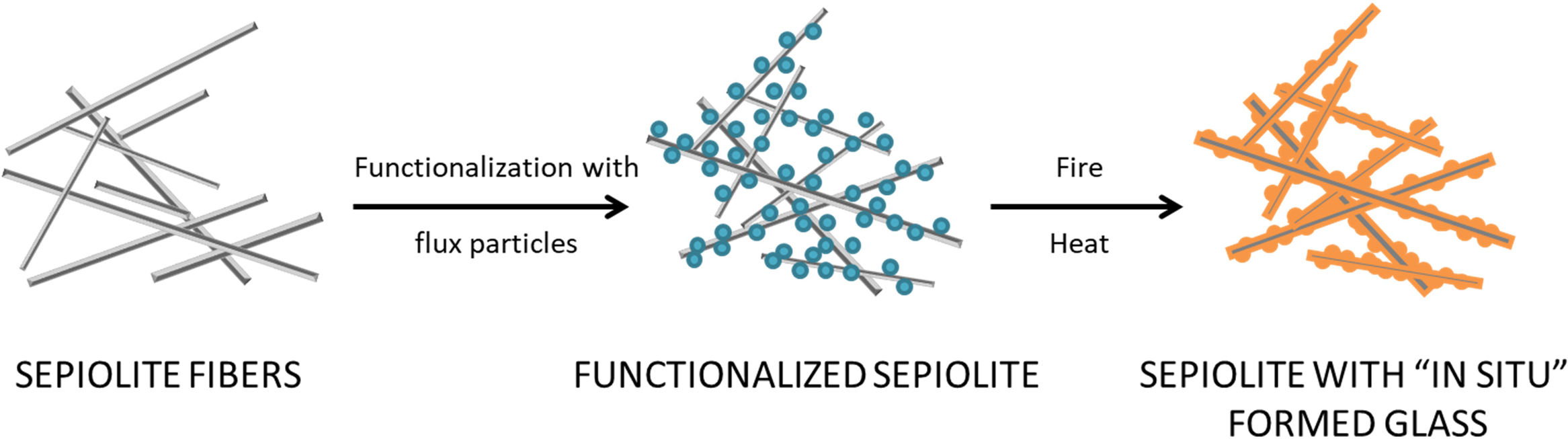

In this work, in order to improve the synergistic effect of sepiolite when introduced in FR polymeric formulations and applying the concept of PCCs, a new additive based on sepiolite with boron-based flux particles homogeneously attached to its surface was prepared. The union of the fibrillar structure with the flux particles could form a kind of ceramic network under the action of high temperatures reached during a fire. This ceramic network will be able to reinforce the carbonaceous char formed, enhancing its mechanical and barrier properties and, therefore, reducing the heat release and the smoke production when the polymeric material burns.

Methodology and materialsMaterialsPurified and micronized sepiolite (SEP) (content of sepiolite >95%), with a specific surface of 320m2/g, from Vicálvaro (Madrid) was prepared by Tolsa, S.A., Spain. Sodium tetraborate decahydrate (Na2B4O7·10H2O, chemically pure) was purchased from Quimipur, Spain.

To prepare the cable formulation, the materials were collected as follows: EPDM (Nordel IP 4725P, Dow) was purchased from Resinex Spain. Aluminum hydroxide (ATH, Martinal OL 107) was supplied by Huber Engineered Materials. Peroxide (Perkadox 14-40 MB) was supplied by Nouryon. Triallyl cyanurate (TAC) 97% pure (coagent for peroxide crosslinking), was purchased from Sigma Aldrich. Stearic acid (40% stearic, 60% palmitic), paraffinic oil and zinc oxide (>95% pure) were all purchased at Quimipur, Spain.

Functionalization of sepiolite with boron-based nanoparticlesTo improve the performance of flame-resistant polymeric formulations using sepiolite-based additives, by achieving an advanced reinforcement of the char layer, a strategy based on the functionalization of the surface of the silicate with fluxing agent nanoparticles was followed. The choice of this combination is inspired by the concept of ceramifiable polymers, introduced previously in the text, which aims to generate, under fire conditions, a cohesive char residue with high mechanical properties by the combination in the formulation of flame retardant additives, a silicate and a fluxing agent. For this purpose, a boron-based fluxing compound belonging to Na2O–B2O3 equilibrium system [34] was selected based on the low melting point of its composition (<950°C) as well as the positive action in the flame retardant mechanism of boron compounds as char stabilizers and flame retardants.

To prepare the additive (SEPTB), as the fluxing agent selected is soluble in water, a precipitation route for the synthesis of nanoparticles attached to the surface of the sepiolite was followed. Firstly, the sodium tetraborate, in a quantity to represent 15wt% of the additive composition, was dissolved in water at 70°C and then incorporated slowly to sepiolite at room temperature under stirring. The decrease of the temperature for the sodium tetraborate solution caused the precipitation of particles on the surface of the sepiolite which acted as nucleating agent. After this step, the resulting material was dried at 80°C in a stove until reaching a moisture lower than 4% and then milled to obtain a particle size below 45μm. Fig. 1 graphically describes the approach to be achieved by the design of the additive.

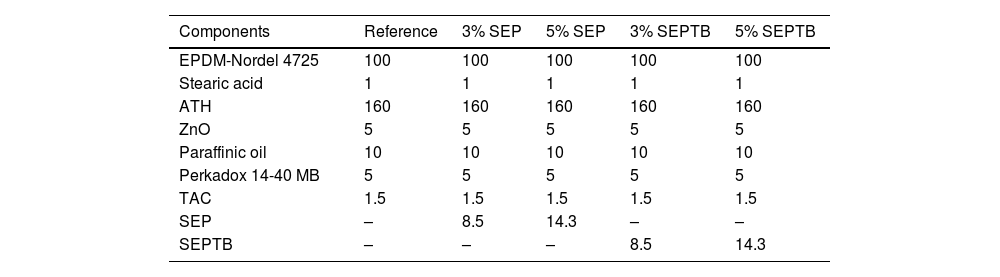

Preparation of EPDM fire retardant compoundsTo evaluate the performance under fire conditions of the additive designed, an EPDM basic formulation for cable was selected and the materials detailed in Table 1 were prepared. Reference sepiolite for comparison and functionalized sepiolite with flux particles were organically modified to improve compatibility of the additives with EPDM matrix. The sepiolite organic modification was carried out following the same procedure described by García et al. [20]. Both additives were added on top of the formulation at a dosage of 3wt% (8.5 parts per hundred rubber (phr)) and 5wt% (14.3phr). These dosages selected are based on previous own studies and are in line with the typical dosages for clay-based flame retardant synergists used in cable compounds [24,35,36].

Formulation of EPDM system for cable. The composition is shown in phr (parts per hundred rubber).

| Components | Reference | 3% SEP | 5% SEP | 3% SEPTB | 5% SEPTB |

|---|---|---|---|---|---|

| EPDM-Nordel 4725 | 100 | 100 | 100 | 100 | 100 |

| Stearic acid | 1 | 1 | 1 | 1 | 1 |

| ATH | 160 | 160 | 160 | 160 | 160 |

| ZnO | 5 | 5 | 5 | 5 | 5 |

| Paraffinic oil | 10 | 10 | 10 | 10 | 10 |

| Perkadox 14-40 MB | 5 | 5 | 5 | 5 | 5 |

| TAC | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 |

| SEP | – | 8.5 | 14.3 | – | – |

| SEPTB | – | – | – | 8.5 | 14.3 |

Components were blended in a Banbury mixer at a speed of 60rpm and a temperature of 160°C following a homogenization step using an open twin-roll mill. Vulcanization agent was incorporated at this stage. Vulcanization was made at 180°C using a hot plate press. Duration of the vulcanization step (t95, time required to achieve 95% of the maximum torque) was determined previously by a moving die rheometer (Monsanto MDR 2000E).

CharacterizationX-ray diffraction (XRD) to determine the crystalline structure was performed using a Bruker AXS D8 advanced spectrometer using Cu Kα radiation (λ=0.15042nm) generated at 40kV and 35mA. To analyze the microstructure of the materials field emission scanning electron microscopy (FSEM Nova NanoSEM 230, FEI, Hillsboro, OR) and transmission electron microscopy (TEM JEOL FXII) were used. TEM images were obtained at 120kV. Differential thermal analysis (DTA) and thermogravimetric analysis (TG) were carried out on the samples in a Stanton model STA 781 equipment. The measurements were carried out in platinum crucibles in air atmospheres with a dynamic gas flow of 50ml/min and a heating rate from 10°C/min up to 1000°C. The material used as reference was α-Al2O3. Hot-stage microscopy was performed using a Hesse Instruments HR18 furnace with rhodium heating elements coupled with Leica-Microsystems optics and EMI Image Analysis, at a heating speed of 10°C/min.

Squared specimens of the EPDM compounds were tested against fire to check the performance by the cone calorimeter test (FTT, UK) and the smoke chamber test, determining the density by means of the transmission measured between a photo-emitter and a photo-detector placed inside a close chamber where the specimen is exposed to controlled heat conditions. In both tests, the conditions used were a heat exposure of 50kW/m2 and a distance between specimen surface and radiation source of 25mm, following respectively the standards ISO 5660-1 and ISO 5659-2. Tests had a duration of 1200s and were run in triplicate. Vertical burning behavior of the EPDM materials was tested according to the standard UL-94, with a thickness of the specimens of 3.2mm and performing 5 repetitions for each different formulation. International rubber hardness degree (IRHD) was measured in a Wallace Rubber Hardness Tester (Dorking, UK). Each flat sample was tested in five different places.

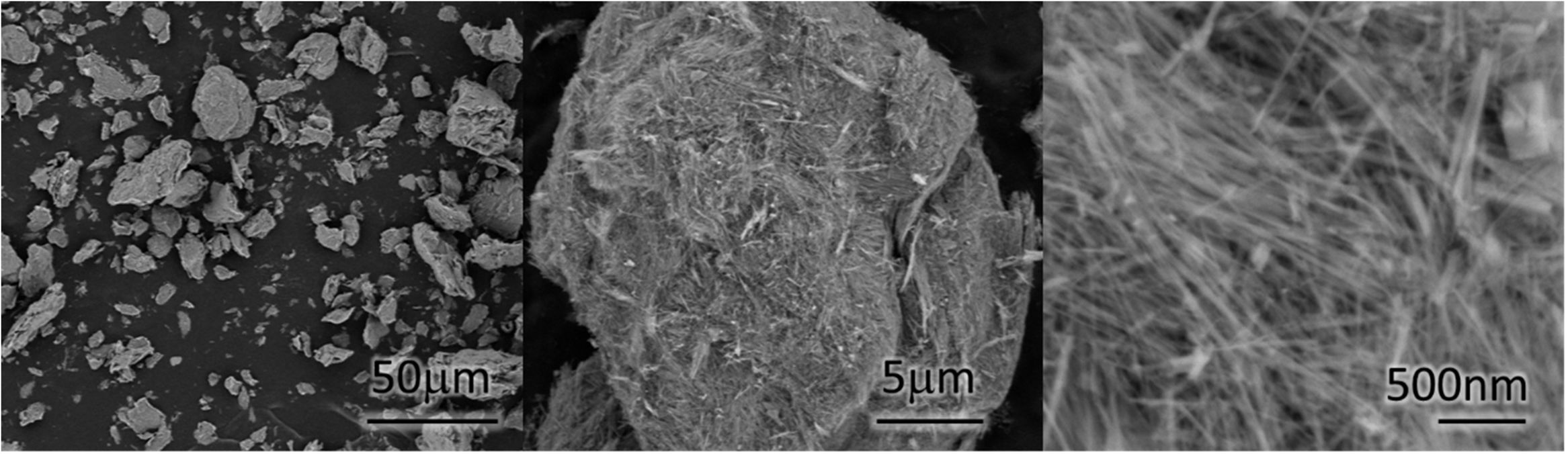

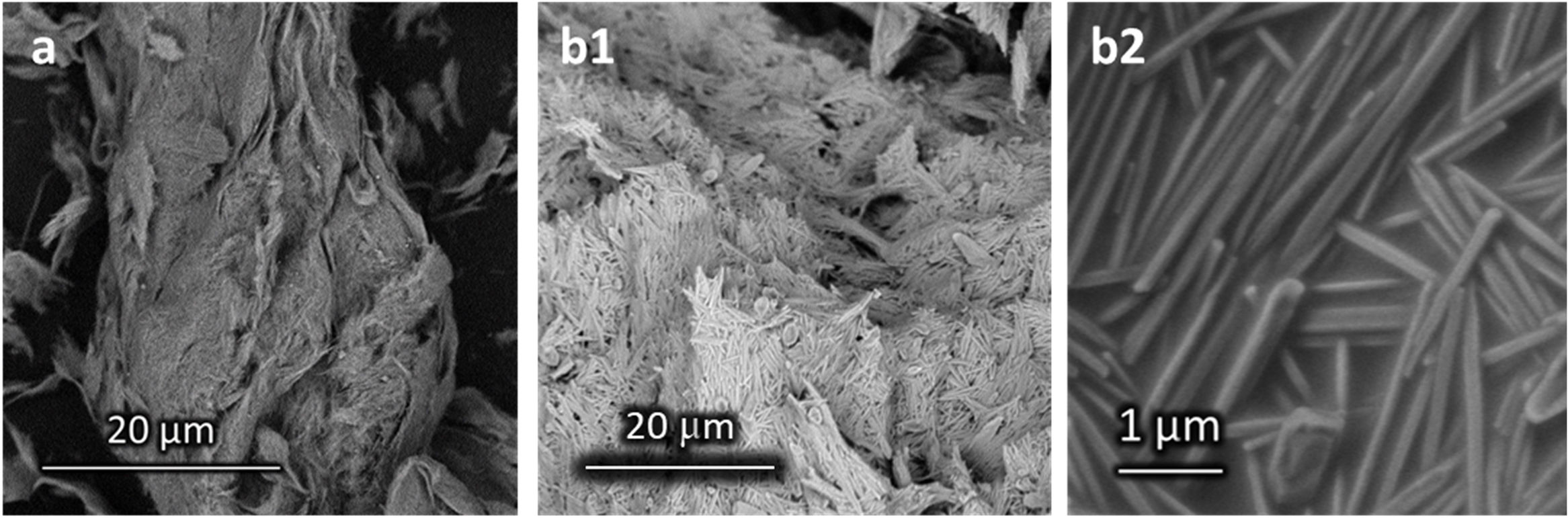

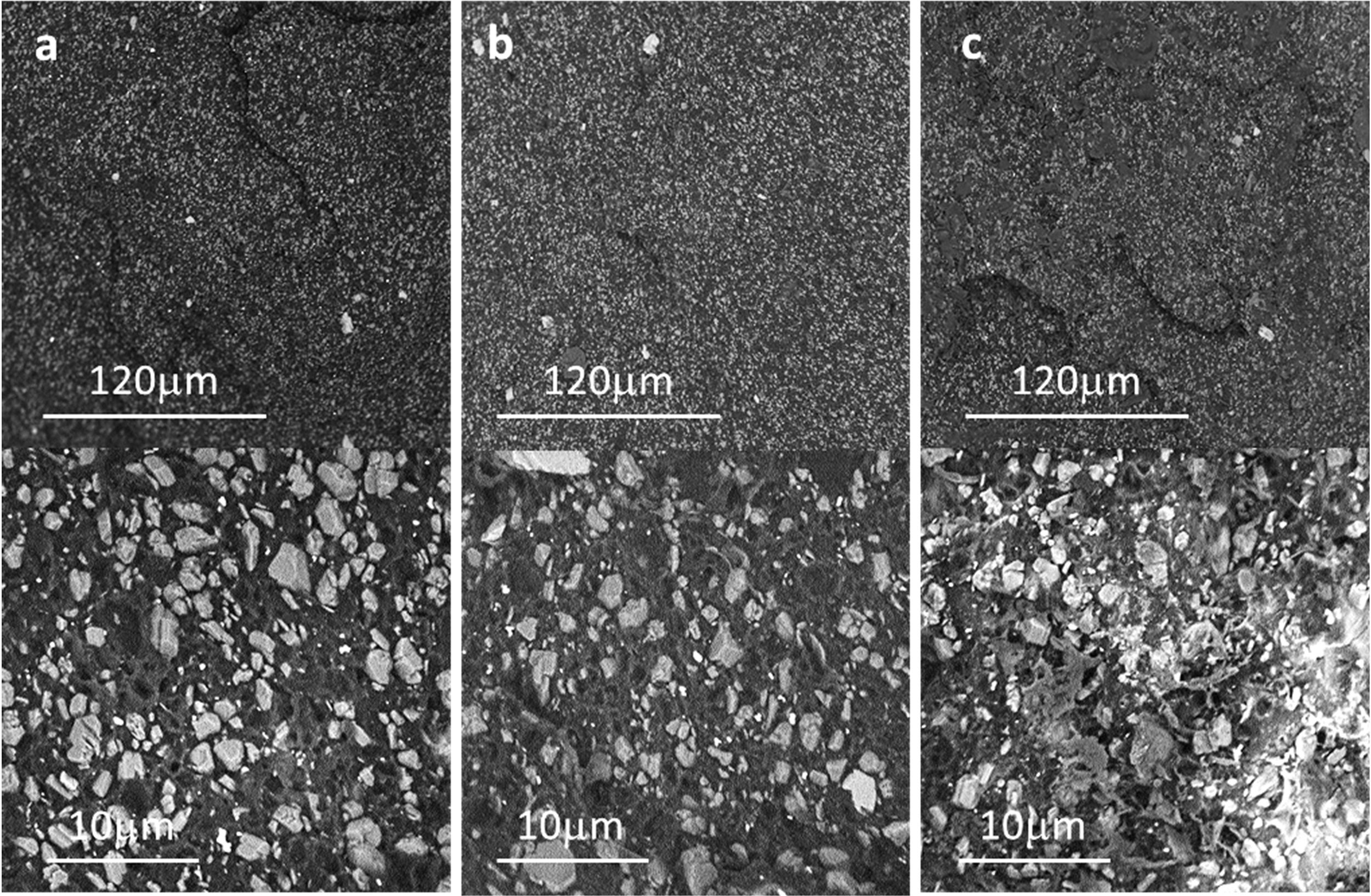

Results and discussionCharacterization of sepiolite-based additive (SEPTB)Sepiolite functionalized with fluxing agent particles (SEPTB) was characterized by SEM. Images obtained (Fig. 2) shows agglomerates of homogeneous appearance and it can be assumed that the fluxing agent has precipitated on the sepiolite surface as no independent particles or agglomerates of these compounds are observed. In the micrographs at higher magnifications, it is not possible to observe the particles of the flux on the sepiolite fiber.

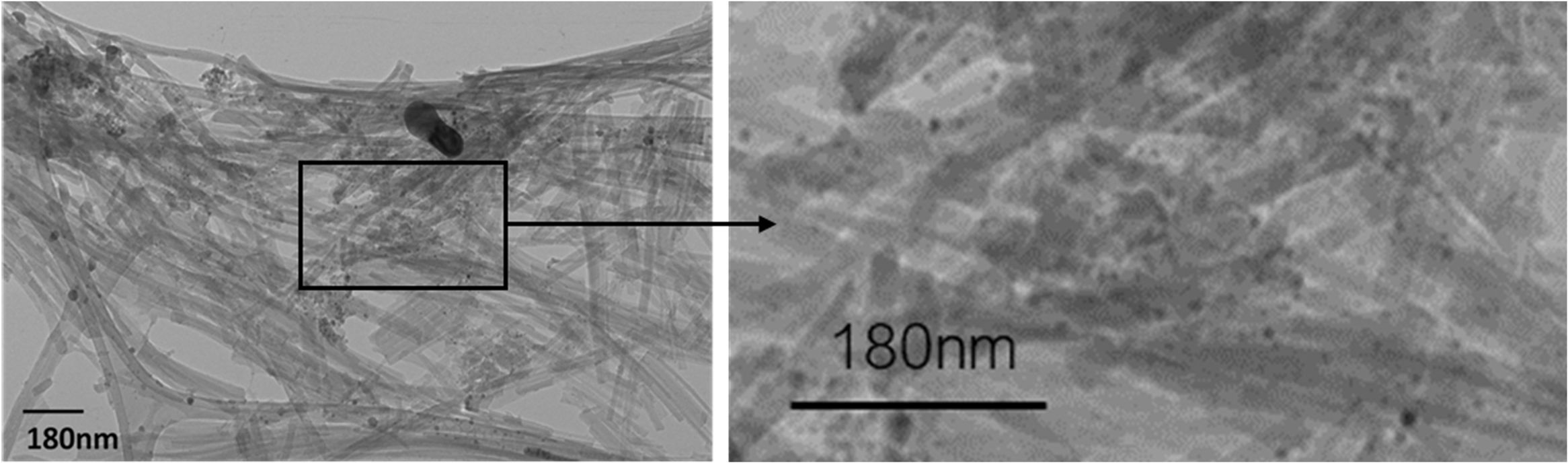

The characterization of the additive by means of transmission electron microscopy (TEM) does show the presence of nanoparticles on the surface of the sepiolite, with sizes between 10 and 20nm, as well as some agglomerates of these (Fig. 3).

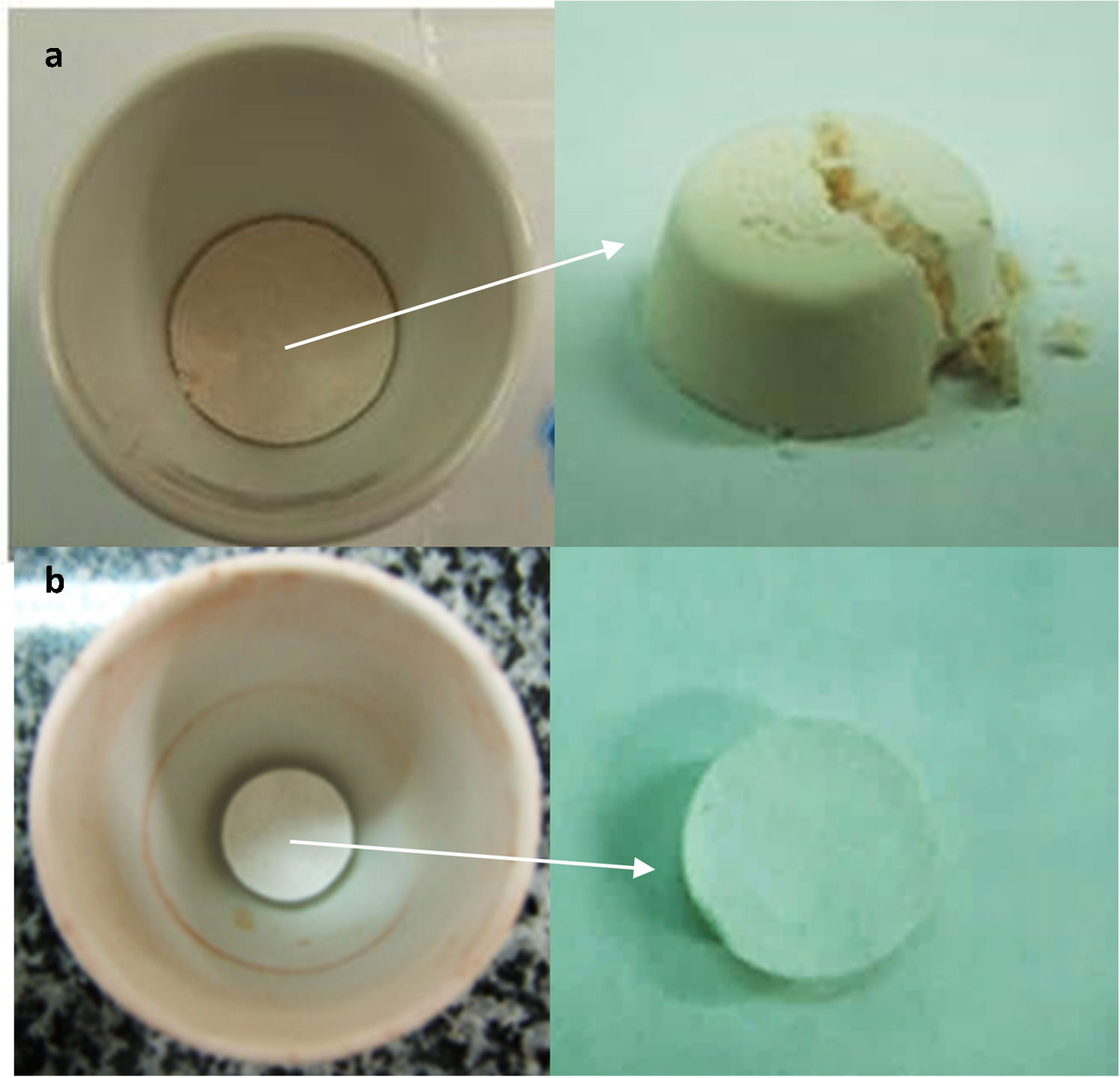

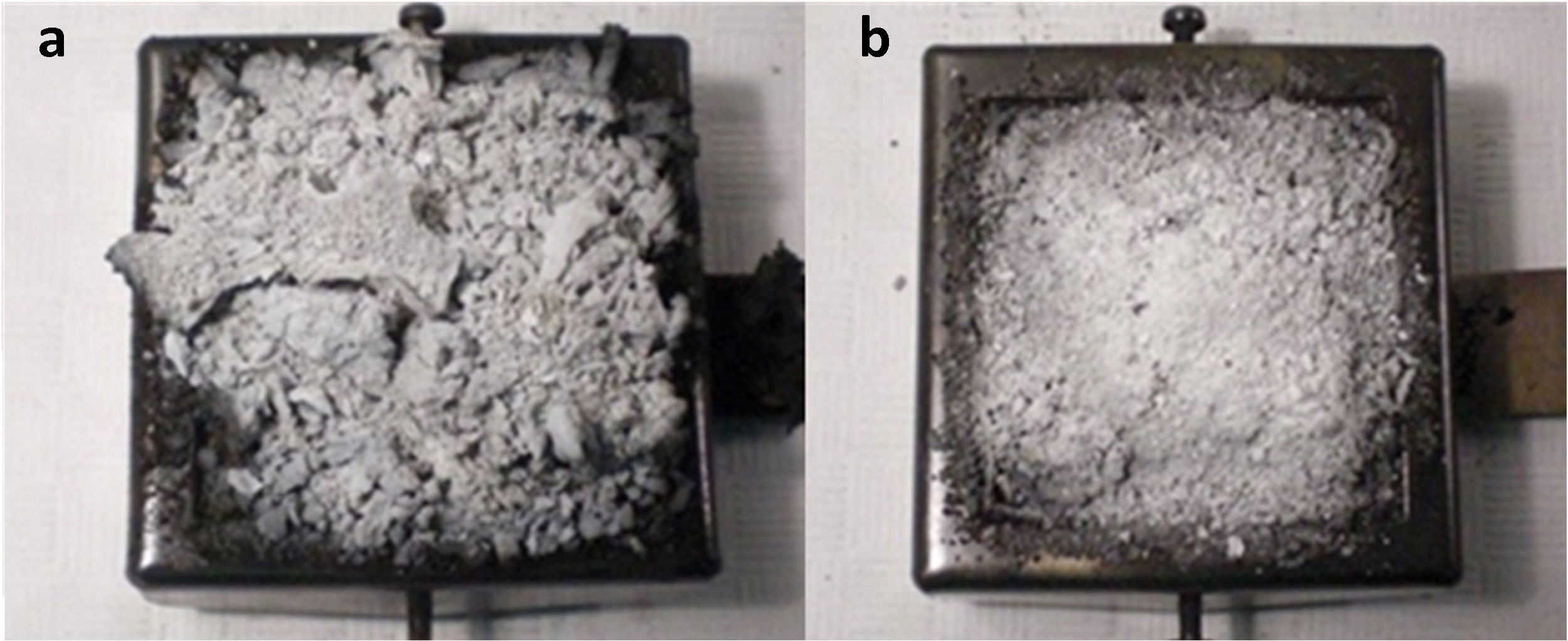

To verify the capacity of the additive to form structures with high mechanical resistance due to the presence of the flux particles, the additive prepared, in powder form and without any compaction has been heat treated in a muffle at 1000°C for 1h. To compare, the same thermal treatment has been applied to reference sepiolite (SEP). In Fig. 4 a slight compaction of the residue obtained can be seen, but without presenting mechanical resistance while, for SEPTB, a residue in form of a compact pellet with increased mechanical resistance was obtained.

Residues obtained, shown in Fig. 4, were characterized by SEM (Fig. 5) and XRD (Fig. 6). The micrographs of SEPTB show the presence of enstatite (Fig. 5b1), due to the phase change that sepiolite undergoes at high temperatures [37], and embedded in the liquid phase generated by the presence of the flux in the additive (Fig. 5b2).

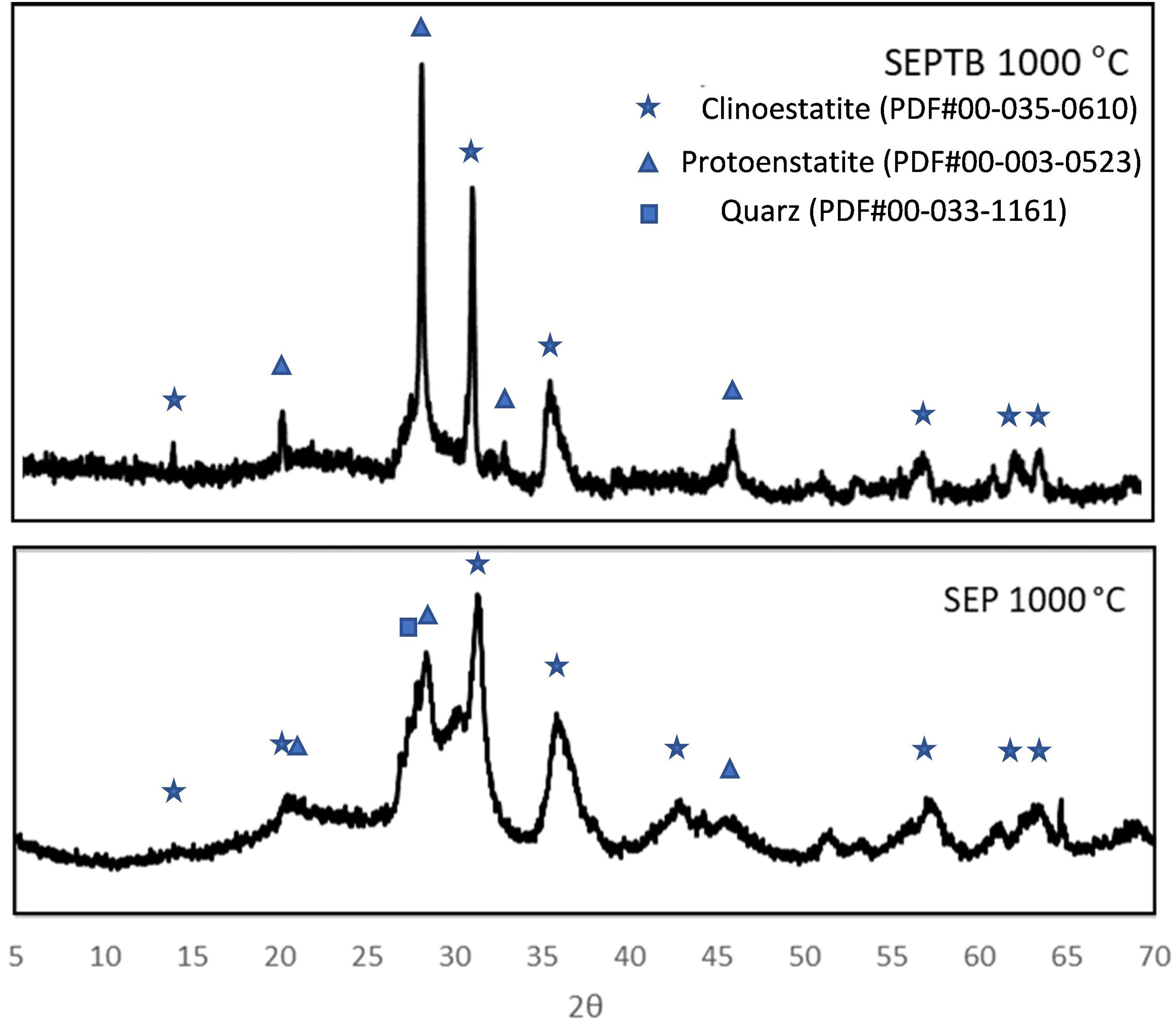

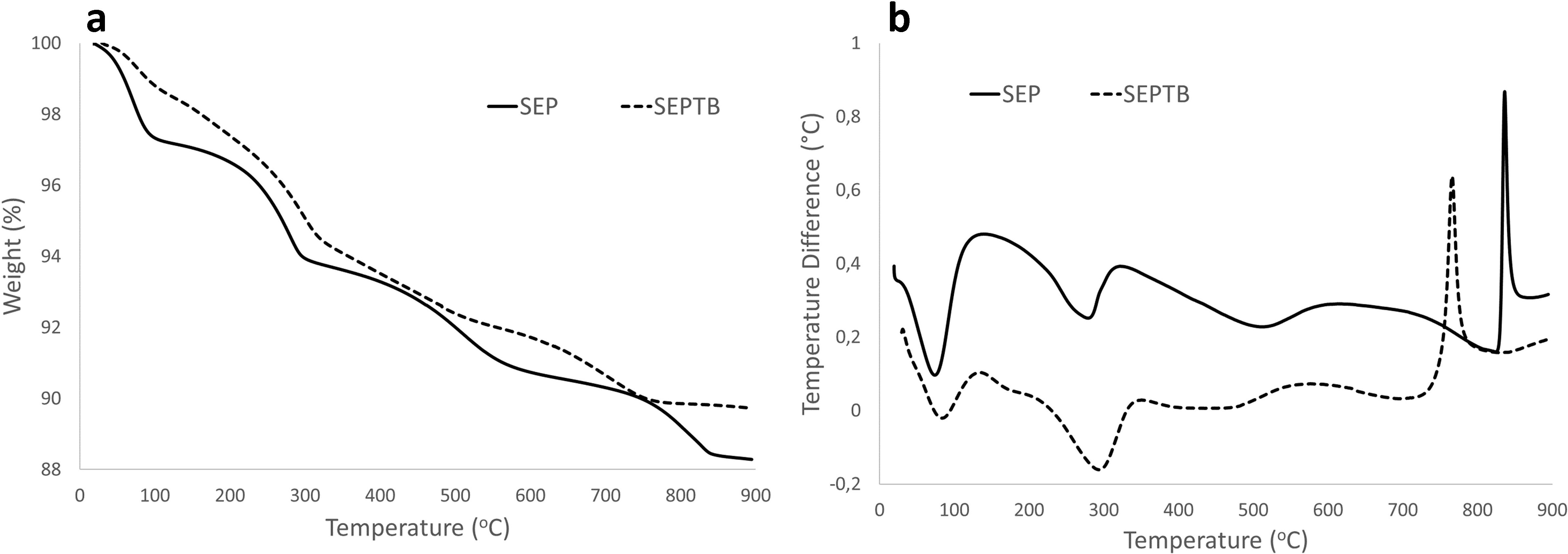

In the diffractograms obtained (Fig. 6), the reflections corresponding to enstatite-type structures resulting from the heat treatment to sepiolite are identified. Regarding the presence of the boron-based flux compound, no crystalline phases that can be attributed to its presence are observed, but an elevation of the lower part of the diffractogram around 2θ=15–25 can be noted, which could be associated with the presence of an amorphous phase, product of the interaction of the flux with sepiolite when the temperature increases. The influence by the presence of the flux in the additive is also observed comparing the clinoestatite and protoestatite crystalline reflections obtained for the reference versus the additive. This effect is also observed in the ATD-TG analysis of the additive, with the decrease of the temperature of nucleation of enstatite from 836°C to 766°C (Fig. 7).

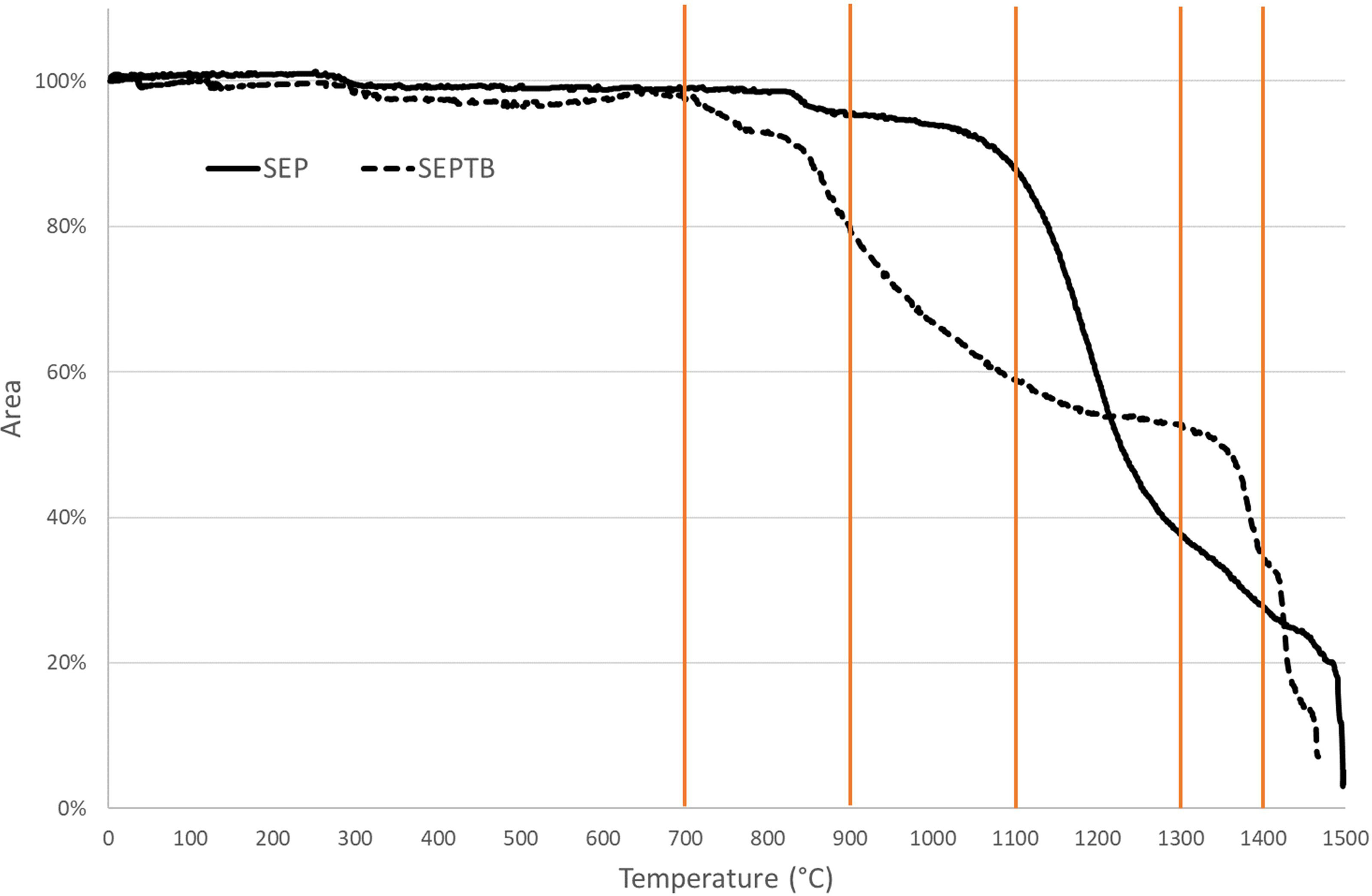

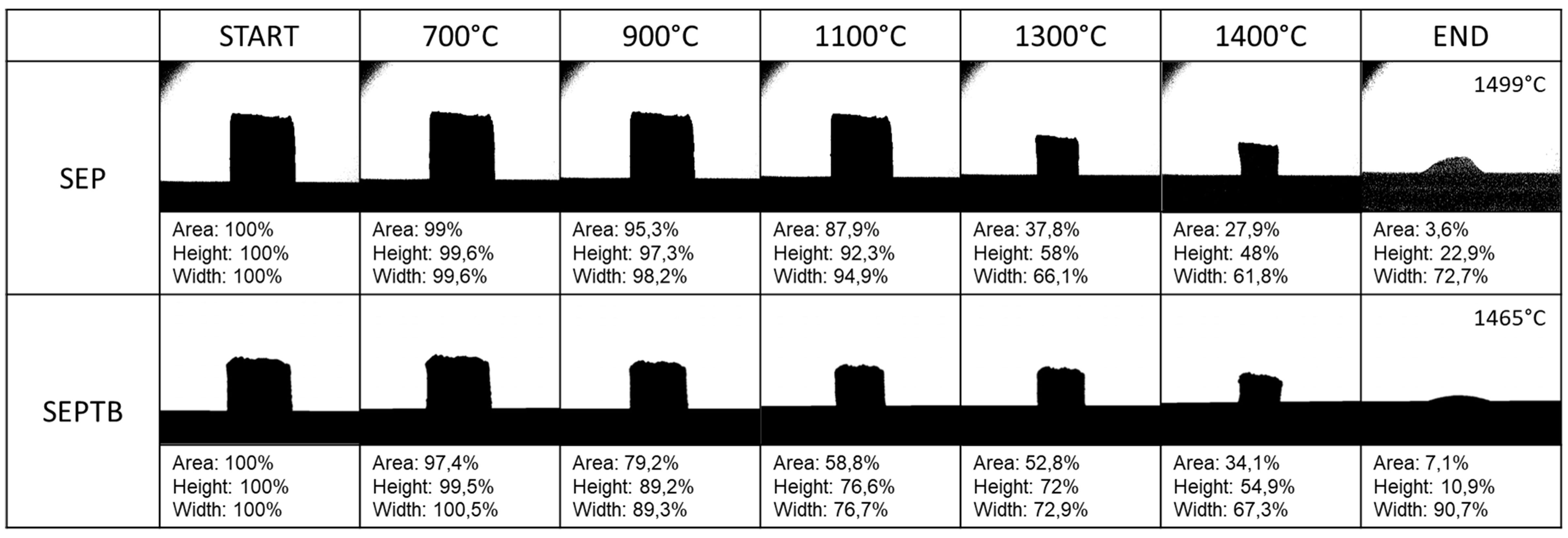

The characterization using hot-stage microscopy of the additive, in comparison with sepiolite, is consistent with the observations made in the previous analyses. Fig. 8 shows that the variation in the nucleation temperature of the enstatite is also reflected in the variation in the dimensions of the specimen (contraction associated in the range of 700–800°C). For SEPTB, shrinkage due to the formation of the liquid phase begins at temperatures significantly lower than for SEP. To illustrate the formation of the compact residue and the differences between the additive SEPTB and the sepiolite, Fig. 9 shows the specimen dimensions (area, height and width) at the temperatures indicated by the orange vertical lines in Fig. 8 during the hot-stage microscopy tests. At 900°C it is observed that for SEPTB a contraction of 20% has been reached.

Characterization of EPDM compoundsMicrostructure of the compoundsSEM characterization of the compounds was carried out to verify the correct dispersion of components into the polymeric matrix. Fig. 10 shows micrographs of the reference without any sepiolite-based additive (EPDMREF), reference with SEP at a concentration of 5wt% (EPDM_5SEP) and formulation with 5wt% of additive SEPTB (EPDM_5SEPTB) which are representative of the dispersion level for all the different formulations prepared. In the micrographs, a homogeneous dispersion of the different additives in the formula is observed. Adequate dispersion of sepiolite-based additives is verified by the lack of big agglomerates of them, as identifying the individual fibrils would be very difficult in these kind of formulation with high level of filler content. In all the formulations, big agglomerates were not found so it could be assumed that the additives SEP and SEPTB are correctly dispersed.

Another indication of the adequate dispersion is by checking properties related to the reinforcement obtained with the additives. Introducing clay particles in a polymeric formulation usually increase the hardness of the material due to the reinforcement of the microstructure of the material. For the formulations prepared in this work, the reference (EPDMREF) obtained a value of hardness of 81±0.5 IRHD. With the incorporation of 3wt% of the additives, formulations EPDM_3SEP and EPDM_3SEPTB reached respectively values of 84±1 and 83±1 IRHD. The incorporation of 5wt% of the additives made formulations EPDM_5SEP and EPDM_5SEPTB to reach values of 87±1 and 86±1 IRHD respectively. Analyzing the results obtained, it could be said that the hardness value is directly affected by the dosage of sepiolite dispersed into the polymeric matrix.

Vertical burning test based on UL-94The application of flame twice during ten seconds as the UL-94 standard describes, indicated that all the formulations present a very good fire resistance behavior obtaining the best classification (V-0), probably due to its high inorganic content that allowed the control of the dripping and the self-extinction of the flame. To strengthen the conditions of the tests, to see differences between the materials behavior, a third flame application of 10s was consecutively applied. Formulation EPDMREF, after the third flame application remained burning until dripping with flame and burning the cotton. Dripping was avoided in formulations EPDM_3SEP and EPDM_5SEP, but these materials were not able to extinguish the flame and remained burning for a long time, higher than 60s, probably due to the impact of the sepiolite-based additive in the viscosity of the melt polymer reducing the capacity of water release by ATH. Conversely, formulations EPDM_3SEPTB and EPDM_5SEPTB, presented self-extinguishing behavior, remaining burning only few seconds after the end of the third flame application, demonstrating the positive effect of the presence of flux particles homogeneously in the additive.

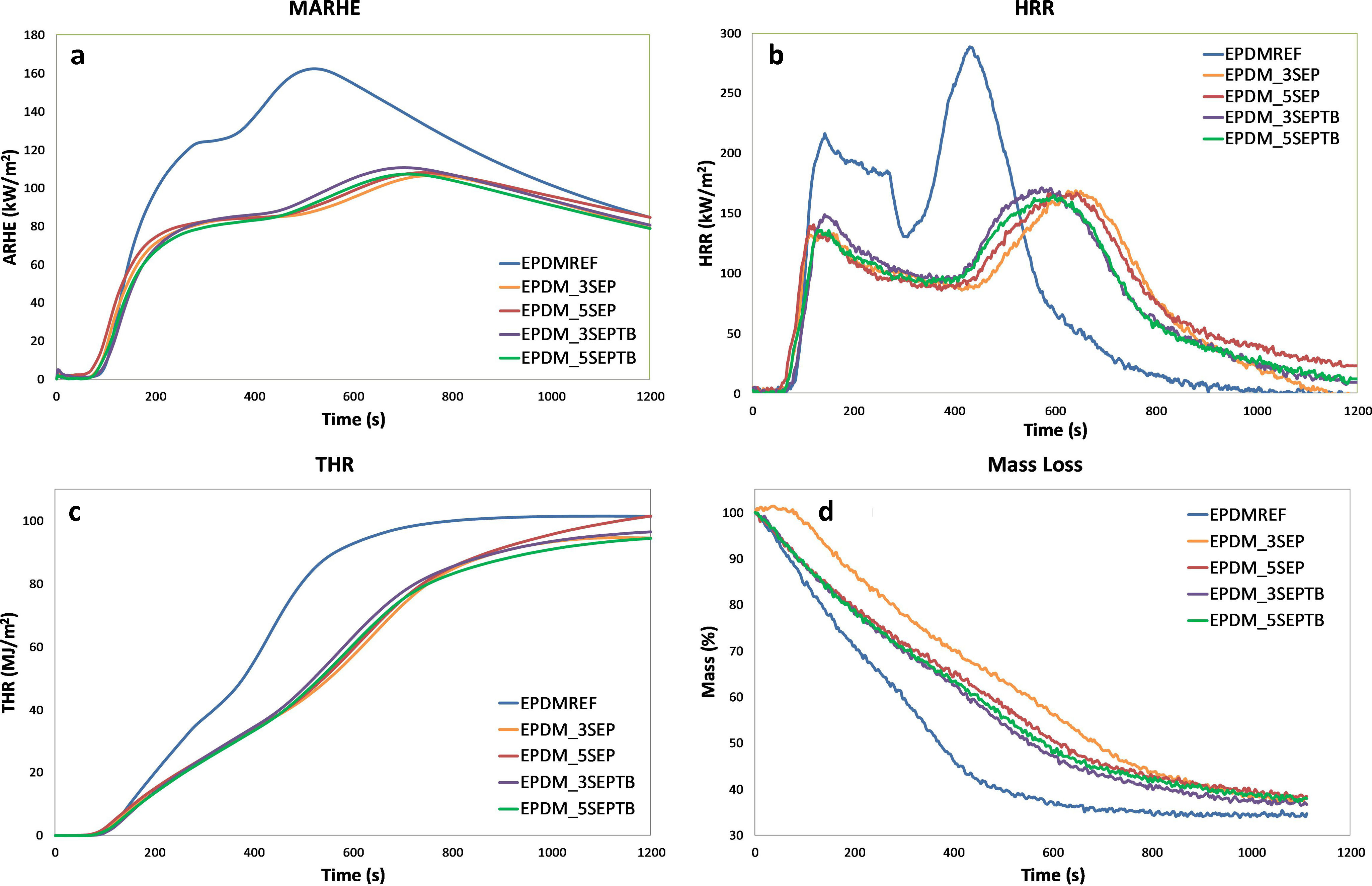

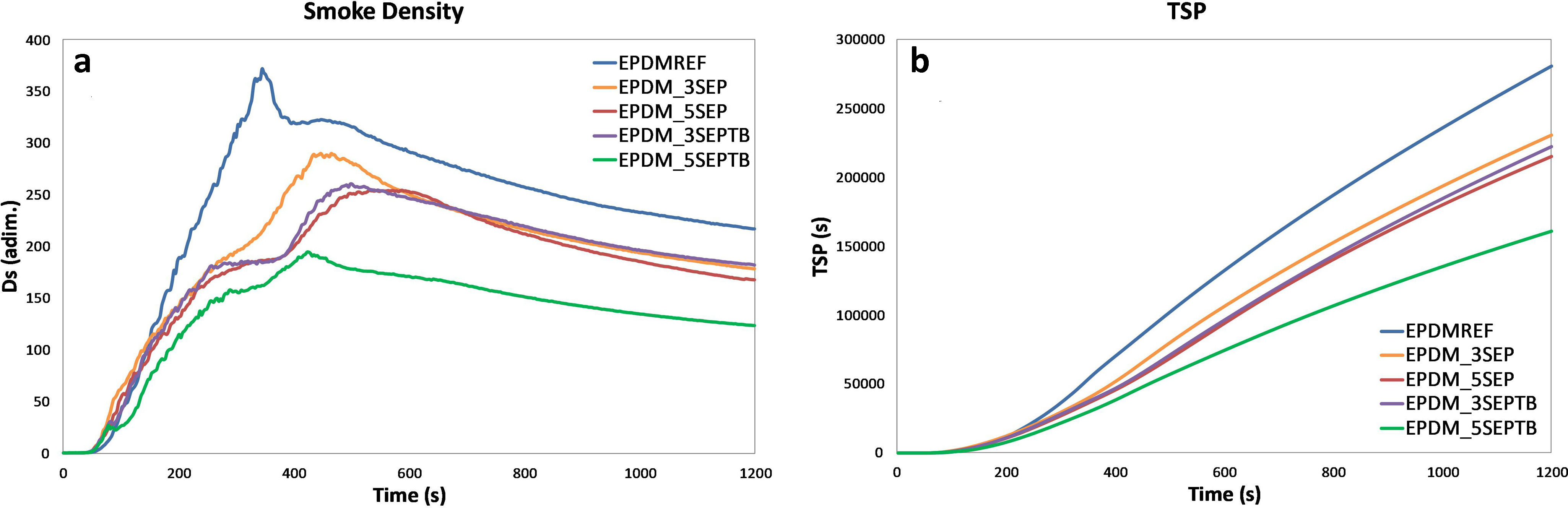

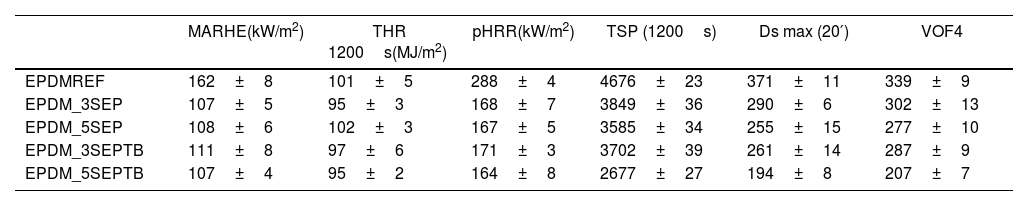

Cone calorimeter and smoke chamber testsTo complete the characterization against fire of the formulations, they have been evaluated by cone calorimetry and by the smoke chamber test. The results obtained are shown in Table 2, Fig. 11 and Fig. 12. Regarding the behavior obtained in the calorimetric cone, all the additives based on sepiolite present important improvements with respect to the reference formulation (reductions of the MARHE (higher than 30%) and the pHRR (higher than 40%). If the formulations including the sepiolite-based additives are compared, no significant differences are observed that could be associated with the design of the additive or the dosage in the formulation. All present a good behavior thanks to the reinforcement by ceramization of the developed carbon layer which can be confirmed in the results by the reduction and displacement of the second peak of the heat release rate (HRR) to longer times, indicator of the improvement of the properties of the carbon layer.

Cone calorimeter and smoke chamber results.

| MARHE(kW/m2) | THR 1200s(MJ/m2) | pHRR(kW/m2) | TSP (1200s) | Ds max (20′) | VOF4 | |

|---|---|---|---|---|---|---|

| EPDMREF | 162±8 | 101±5 | 288±4 | 4676±23 | 371±11 | 339±9 |

| EPDM_3SEP | 107±5 | 95±3 | 168±7 | 3849±36 | 290±6 | 302±13 |

| EPDM_5SEP | 108±6 | 102±3 | 167±5 | 3585±34 | 255±15 | 277±10 |

| EPDM_3SEPTB | 111±8 | 97±6 | 171±3 | 3702±39 | 261±14 | 287±9 |

| EPDM_5SEPTB | 107±4 | 95±2 | 164±8 | 2677±27 | 194±8 | 207±7 |

MARHE (kW/m2): maximum average rate of heat emission; THR 1200s (MJ/m2): total heat release; pHRR (kW/m2): peak of heat release rate; TSP 1200s: total smoke production after 1200s; Ds max (20′): maximum specific optical density obtained within the 20min test period; VOF4: parameter of the rate of smoke production during the first 4min of the test.

In the results obtained in the smoke chamber test, all the formulations including additives based on sepiolite show improvements, significantly reducing the density and production of smoke. Among the results obtained, the performance carried out by the formulation with 5% of the SEPTB additive stands out. The reduction achieved in smoke density and production is the best among all the samples tested, reaching a decrease of 47% in the value of the maximum optical density reached during the test (Ds max (20′)) and a reduction of 42% of the total smoke production (TSP), both values with respect to the reference without additives based on sepiolite. If compared to the formulation with the SEP additive at 5% dosage, EPDM_5SEPTB present remarkable reductions of 25% in total smoke production and 23% in maximum optimum smoke density. Also, a 38% reduction of the VOF4 parameter is achieved, important to meet the requirements of the regulations for the transport sector, which is also a possible application of this type of polymeric formulations.

Since the SEPTB additive is focused on the generation of a high-performance ceramified reinforcement in the polymer to improve the properties of the carbon layer obtained during a fire event, the residues obtained after the smoke chamber test have been analyzed. With this analysis it has been possible to conclude that, on the one hand, the residues of the compounds prepared with the sepiolite-based additives have better mechanical resistance and, on the other, that the formulation with 5% of the SEPTB additive, which has obtained the best results in terms of density and smoke production, has generated the carbon layer with the best properties. Fig. 13 shows photographs of the materials after the test where differences between the reference sample (EPDMREF) and the formulation with 5% of the SEPTB additive (EPDM_5SEPTB) which presents the residue much better preserved and more compact.

ConclusionsAn additive based on sepiolite functionalized with a boron flux compound was successfully prepared. The functionalization was achieved by the precipitation of flux particles of reduced size homogeneously on the sepiolite surface, which acted as a nucleating agent. The additive, when incorporated in a polymeric matrix, is able to generate an “in situ” glass phase together with the formation of enstatite fibers which allow to improve efficiently the char layer reinforcement in an event of a fire, showing an even better behavior than traditional organically modified sepiolite-based additives, especially in terms of smoke production (reduction of 25% of the smoke production) and in terms of burning behavior, as shown in the vertical burning test regarding the self-extinction of the flame. This coupling between enstatite fibers and glass results in a high ceramization efficiency with the development of a novel three-dimensional rigid support structure, which is generated during the thermal treatment.

Declaration of competing interestThe authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

This work was supported by Spanish Ministry of Economy and Competitiveness (MINECO) under SEPIFIRE project (RTC-2014-2033-4).