This work studies the proportioning and the effects in fresh state rheology of the use of fine recycled aggregates (FRA) to produce self-compacting concrete (SCC). The recycled sand was incorporated in percentages of 0%, 20%, 50% and 100%. The mix proportioning was supported with tests on mortars, in which workability was measured from 10min to 90min. Once adjusted, full concrete was produced and fresh properties evaluated (empirical and rheometer tests). The most shocking result was that mixes with 50% and 100% recycled sand lost their SCC characteristics at 90min. Contrarily the mix with 20% replacement maintained suitable passing and filling ability.

Este artículo analiza la dosificación y los efectos sobre la reología en estado fresco del uso de áridos reciclados finos para producir hormigón autocompante. La arena reciclada se incorporó en porcentajes de 0%, 20%, 50% y 100%. El diseño de dosificaciones se basó en ensayos en morteros, en los cuales la trabajabilidad se midió de 10 a 90minutos. Una vez ajustada la mezcla se ensayó el hormigón completo y se evaluaron las propiedades reológicas (pruebas empíricas y con reómetro). El resultado más interesante consiste en el hecho de que las mezclas con arena reciclada al 50% y 100% perdieron sus características de hormigón autocompactante a los 90minutos. En cambio, la mezcla con el 20% de sustitución mantuvo una capacidad de paso y de relleno adecuada.

The use of fine recycled aggregates from recycled concrete is limited due to the high absorption of the material and the subsequent reduction in mechanical performance [1,2]. At the same time, self-compacting concrete (SCC) uses large amounts of fines to ensure its flowability. Therefore, this type of concrete could allow the use of fine recycled aggregates. Hence, the aim of this work is to study the proportioning and the effects in the microstructure and the fresh basic properties of the use of recycled sand to produce SCC.

In this research the natural sand is replaced by percentages of 0%, 20%, 50% and 100% of recycled sand and this type of sand presents a higher absorption. Thus, it is expected that the mortars and concrete with high substitution ratios of these aggregates will present lower workability. This could be dealt with by increasing the content of superplasticizer but in the extreme case of 100% of replacement this was not enough to provide acceptable workability. However, if the amount of superplasticizer varies, the different mixes would not be comparable. Therefore, the superplasticizer quantity was adjusted for the control concrete and kept constant for all substitution ratios.

1.1Use of fine recycled aggregate concreteThe possibility of the use of fine recycled aggregates (FRA) in self-compacting concrete (SCC) was demonstrated by Kou and Poon [3], who obtained SCC with acceptable workability and compressive strength using even 100% of both fine and coarse recycled aggregates. Other interesting reference of the use of FRA in SCC is the work of Corinaldesi and Moriconi [4] who achieved SCC concrete with coarse and fine recycled aggregates separately in percentages of 0% and 100%.

Research on the use of FRA in ordinary concrete is not extensive [5,6]. The main effect that is reported in the literature is the loss of compressive strength with the substitution ratio. Khatib [7] refers that concrete with 25% and 100% suffer reductions of 15% and 30% relative to the reference mix. Evangelista and de Brito [8] refer that with percentages of substitution up to 30% there were no significant reductions. The other important effect described is the loss of workability due to the high absorption of the FRA.

Another significant question is the variability of the quality of the FRA. For example, Pereira et al. [9] refer a FRA with 13.1% of absorption; on the other hand, Khatib [7] refers one with 6.3% of absorption and Zega and Di Maio [10] uses a FRA with an absorption of 8.5%.

1.2Fresh properties and rheology of SCCSCC is designed and produced with fresh-state properties in mind [11]. SCC exhibits enhanced capabilities substantially different than the ones of the ordinary concrete. The enhanced properties that are looked for in SCC are: flowability, viscosity (measure of the speed of flow), passing ability (flow without blocking) and segregation resistance [12,13].

The SCC fresh-state properties are used as reception criteria and one or two tests are performed when the concrete arrives at the construction site allowing acceptance or not of the concrete batch [14]. However, the evolution of the fresh properties over time is a key factor in the properties of concrete, i.e. the open time can be adjusted to the type of superplasticizer or retarders [12,14,15]. It has been observed that the rheological parameters worsen with time [16] and the open time varies in different mixes. This evolution can be observed in the equivalent mortar, where it is enhanced by the absence of coarse aggregate.

The empirical approach is useful but it is possible to study the phenomena in further detail. Fresh SCC can be modelled as a viscoelastic fluid with a model that relates the shear stress (τ) and shear rate (γ). There are various models for the equation that relates both properties, but the Bingham model is one of the simplest and most widely accepted [17].

There is a significant difference between the SCC when it is at rest for a long period of time or when it has been recently mixed, due to its thixotropy [18]. The resistance to deformation varies substantially, so that two parameters could be defined: static yield stress, that relates to undisturbed concrete, and dynamic yield stress that relates to disturbed concrete [19,20].

2Materials and methods2.1MaterialsA Portland cement, CEM I 42.5 R according to European Standard EN197-1, was used. In addition to this, the powder fraction was completed with limestone filler. The superplasticizer used to achieve suitable SCC mixes was a modified polycarboxylate type usual in SCC production. No retarder was used to control the hydration or the open time.

Three types of aggregates were used. The coarse fraction was a natural limestone gravel. Two fine aggregate were used: a natural limestone sand that was partially replaced by a recycled sand. The source of the natural aggregates was a crushed aggregate from a northern-western Spain stone quarry. The fine recycled aggregate came from crushed concrete from a local recycling plant (RECINOR).

The natural and recycled sands need to be well graded and have a size distribution as similar as possible. To achieve both objectives, it was necessary to adjust the grain size curve of one of the aggregates. In addition to the regular absorption test, a continuous measurement of water absorption of the aggregates was conducted. At the usual reference time of 10min the absorption of the recycled sand was 72% of the absorption at 24h, and in the case of natural gravel and sand it was 50% and 70% respectively.

A reference conventional SCC was designed with a water to cement (w/c) ratio of 0.46. Three SCCs were designed using 20%, 50% and 100% of fine recycled aggregate. Hence, four types of concretes were obtained to study their fresh-state and rheological properties. Moreover, their equivalent mortars were firstly prepared to adjust the design of concretes composition.

2.2Test methodsThe equivalent mortars were tested in fresh-state with the mini-slump flow test (mini-cone) and the mini-funnel test at 15, 30, 45, 60 and 90min.

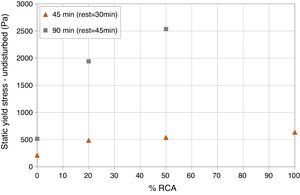

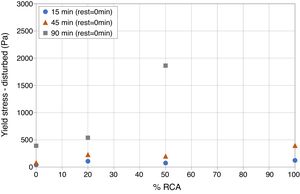

Regarding concrete mixes, two empirical tests were carried out to evaluate the fresh-state properties of concretes: the slump flow test (EN12350-8) and the V-funnel test (EN12350-9). Regarding the rheological tests, they were conducted with a rotational rheometer model in which a four-bladed vane rotates with axial symmetry at a variable speed. Two tests were carried out: a stress growth test and a flow curve test. The former was performed twice at each testing time (15, 45 and 90min), first under undisturbed conditions and then under disturbed conditions. In this work, a low and constant vane speed of 0.025rps was selected. Then, the yield stress was obtained under undisturbed (static) and under disturbed conditions.

After that, the flow curve test was started. In this test, after a period of 20s at a constant speed of 0.50rps, the torques at decreasing speeds (from 0.5 to 0.05rps in seven steps) were measured. Then, one a rheological model was applied, the plastic viscosity and the dynamic yield stress were determined. At the end, the vane was removed and concrete was remixed with a shovel and left to rest.

2.3Equivalent mortar designThere are many references about the design of SCC with different methodologies. The usual criterion is to set the strength level to be achieved and then the components’ content necessary to meet this objective. On the other hand, one can start from a given standard formulation that will be corrected to achieve the workability appropriate to the target application. In this work, the second option was used.

The design method developed in this work is based on the Nepomuceno's method [21] using some recommendations from the CEM and rational methods. Schwartzentruber and Catherine [22,23] proposed the use of the concrete equivalent mortar (CEM) to study the rheology of fresh concrete with the assumption that the rheological properties of CEM should be correlated with those of the corresponding concrete. Related to this, the Nepomuceno et al. method [21,24] is a generalization of the one proposed by Ouchi et al. [25] and it centres its efforts on the characterization of the mortar and correlates the behaviour of mortar and the one of concrete. These equivalent mortar methods can give guidelines of how to adjust a mix to a set of properties like compressive strength and fresh-state parameters.

It would have been possible to strictly follow the CEM method [22,23] and include an extra content of recycled sand equivalent to the specific surface of the gravel. This would lead to an equal specific surface, but the absorption of this extra amount of sand would be much higher than the one of the gravel (their water absorption at 24h are 9.3% and 1.1% respectively). In this way, the equivalent mortar would only be equivalent in terms of specific surface but the influence of the absorption would be quite more relevant. So, finally, it was decided not to include this extra sand and assume that the mortar phase correlated accurately with the concrete. It should be noted that all mixes included 30% in volume of natural gravel, so the only variable of influence was the presence of FRA.

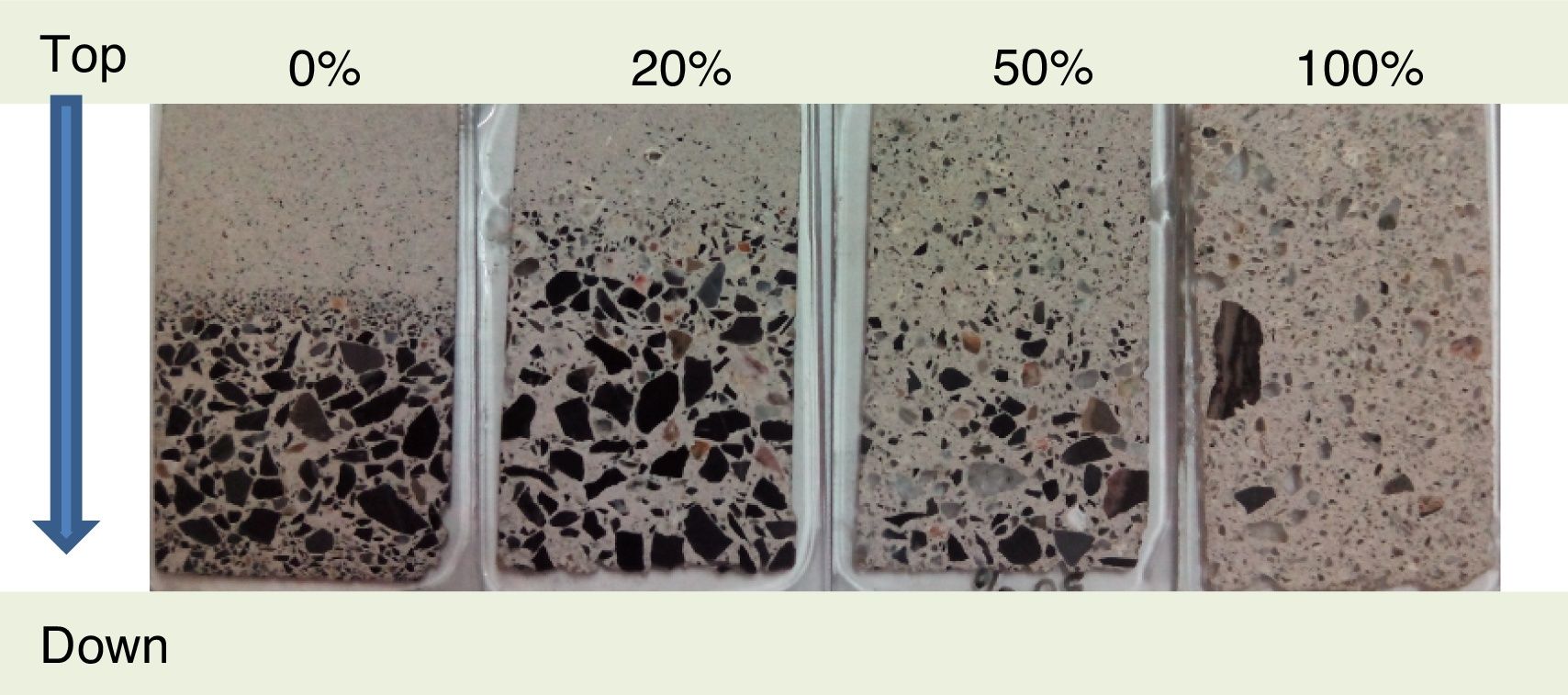

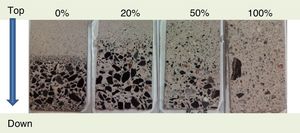

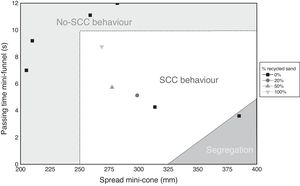

The Nepomuceno's limits were complied with [21,24] so the target spread values in mini-cone and flow time in mini-funnel were 251–263mm and 7.7–8.7s respectively. These limits were unreachable for all the mixes at the same time. If it were adjusted for 0% replacement, the mixes with 50% and above of FRA would not exhibit SCC behaviour. They were conventional mortars with fluid consistency and low values in spread in mini-cone; and also with high passing times in mini-funnel, when they did pass at all. On the other hand, if the mix were adjusted for 100% of FRA incorporation the result would be a severe increase in fluidity and reduction of viscosity. This would lead to severe segregation in the substitution percentages of 0% and 20%. This can be seen in the sections of Fig. 1 of a rejected mix with excessive fluidity and low viscosity that produced segregation for low substitution ratios.

It was detected that if the 100% FRA mix was adjusted and exhibited acceptable parameter in both mini-cone and mini-funnel tests (according to Nepomuceno's criterion), the mix with 0% replacement showed complete segregation of paste and aggregates (Fig. 1). When the 0% mix was the reference, the 100% mix lost the SCC behaviour. Therefore, it was clear that the complete fulfilment of the criterion was impossible, so new limits were set. In this way, it was possible to find out mixes where all batches showed SCC behaviour even though with some variability in viscosity and flowability. However, at least there were groups of SCC products under comparison, not conventional concrete compared to SCC.

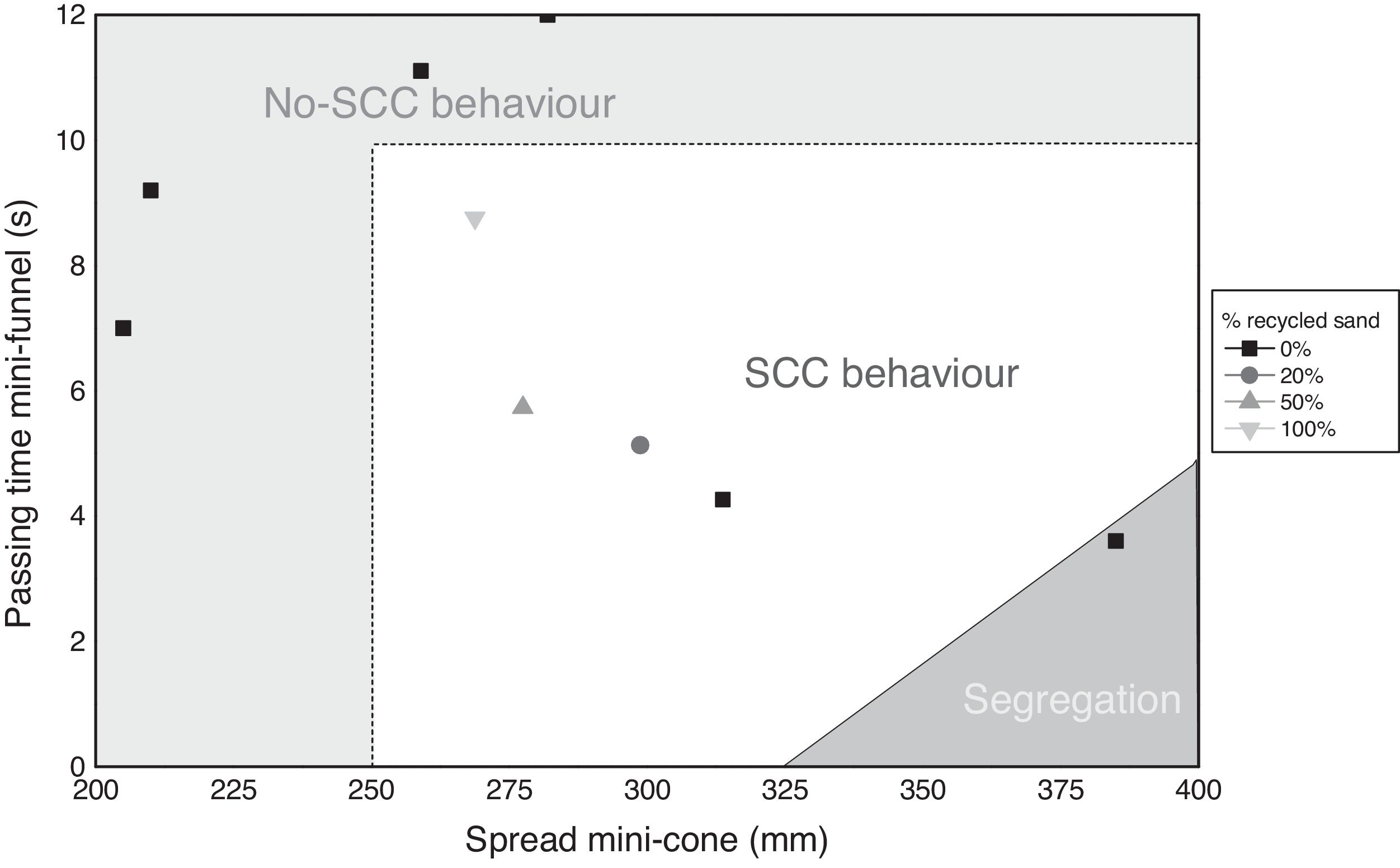

This new criteria is represented in Fig. 2, where it can be seen that the narrow range that Nepomuceno's method indicates is widely expanded (mini-cone: 251–263mm and mini-funnel: 7.7–8.7s). However, when the values of mini-cone spread grew substantially, segregation problems started to appear. Therefore these mixes are also not valid.

Another question that should be addressed properly is the time at which the mix is adjusted. In this phase, the fresh-state parameters were measured just after the finishing the mixing process (at 15min).

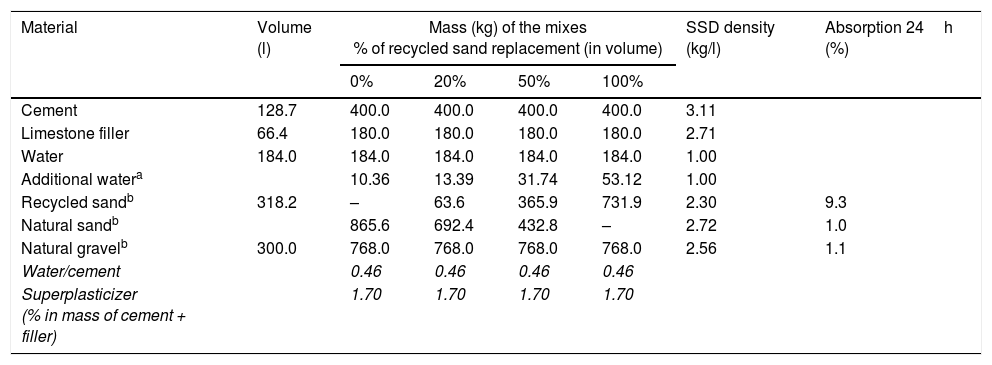

2.4Concrete mixesUsing the equivalent mortar method concrete mixes were developed. This mix design in two stages, first mortar and later full concrete, was helpful to achieve in a rapid way suitable compositions of SCC with FRA. Additionally, it should be emphasized that the only variable that affected the flowability and viscosity of the mix was the presence of FRA. Based on this, the other mixes were designed by replacing a given volume of natural sand with recycled sand. The replacement ratios were 0%, 20%, 50% and 100% (Table 1).

Concrete composition of the mixes.

| Material | Volume (l) | Mass (kg) of the mixes % of recycled sand replacement (in volume) | SSD density (kg/l) | Absorption 24h (%) | |||

|---|---|---|---|---|---|---|---|

| 0% | 20% | 50% | 100% | ||||

| Cement | 128.7 | 400.0 | 400.0 | 400.0 | 400.0 | 3.11 | |

| Limestone filler | 66.4 | 180.0 | 180.0 | 180.0 | 180.0 | 2.71 | |

| Water | 184.0 | 184.0 | 184.0 | 184.0 | 184.0 | 1.00 | |

| Additional watera | 10.36 | 13.39 | 31.74 | 53.12 | 1.00 | ||

| Recycled sandb | 318.2 | – | 63.6 | 365.9 | 731.9 | 2.30 | 9.3 |

| Natural sandb | 865.6 | 692.4 | 432.8 | – | 2.72 | 1.0 | |

| Natural gravelb | 300.0 | 768.0 | 768.0 | 768.0 | 768.0 | 2.56 | 1.1 |

| Water/cement | 0.46 | 0.46 | 0.46 | 0.46 | |||

| Superplasticizer (% in mass of cement + filler) | 1.70 | 1.70 | 1.70 | 1.70 | |||

Regarding the high water absorption of the recycled aggregates, it was necessary to adjust the mixing water, which was done by adding extra water. However, not all the 24h water absorption was compensated, rather the absorption at 10min. This criterion was also used before by other authors [2,9]. To ensure comparability, all materials were oven dried before their use.

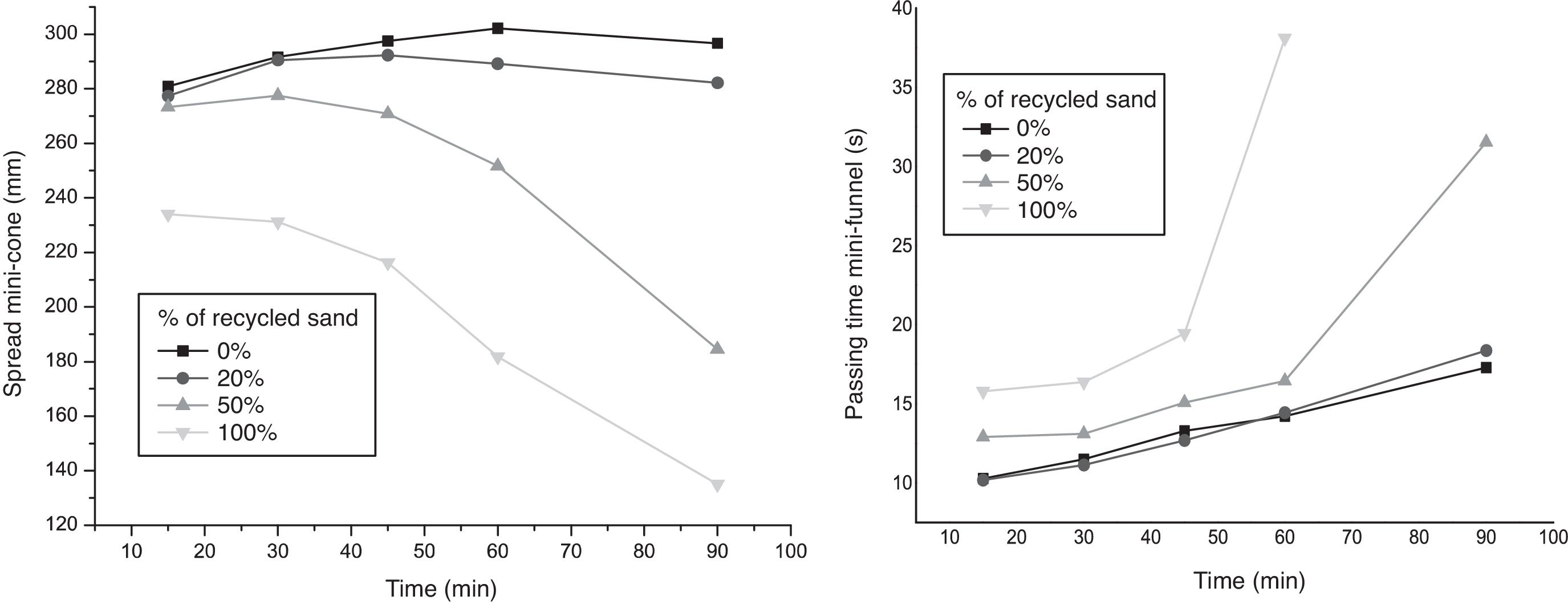

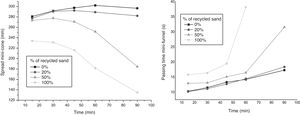

3Mortar results3.1Fresh state propertiesThe mortars were tested over time by means of the mini-cone and mini-funnel tests (Fig. 3). In the mix that includes 100% of recycled sand, at 90min the mini-funnel test was unfeasible due to the rigidity of the mix.

The spread is higher with low sand substitution percentages. However, for the reference mortar, and also for the one with 20% of sand substitution there is a slight increase in the spread values from 15 to 60min. Regarding the passing time (V-funnel), it could be said that there is a clear trend towards reduced values with time and with replacement percentage. This contrasts with the results reported by Jin [16], who found out a continuous decrease of spread and increase of the passing time over time.

However, as seen in Fig. 3, these parameters change with time and, in the case of the 100% substitution, a mix that presented complete SCC behaviour lost all fluidity and passing ability after 90min.

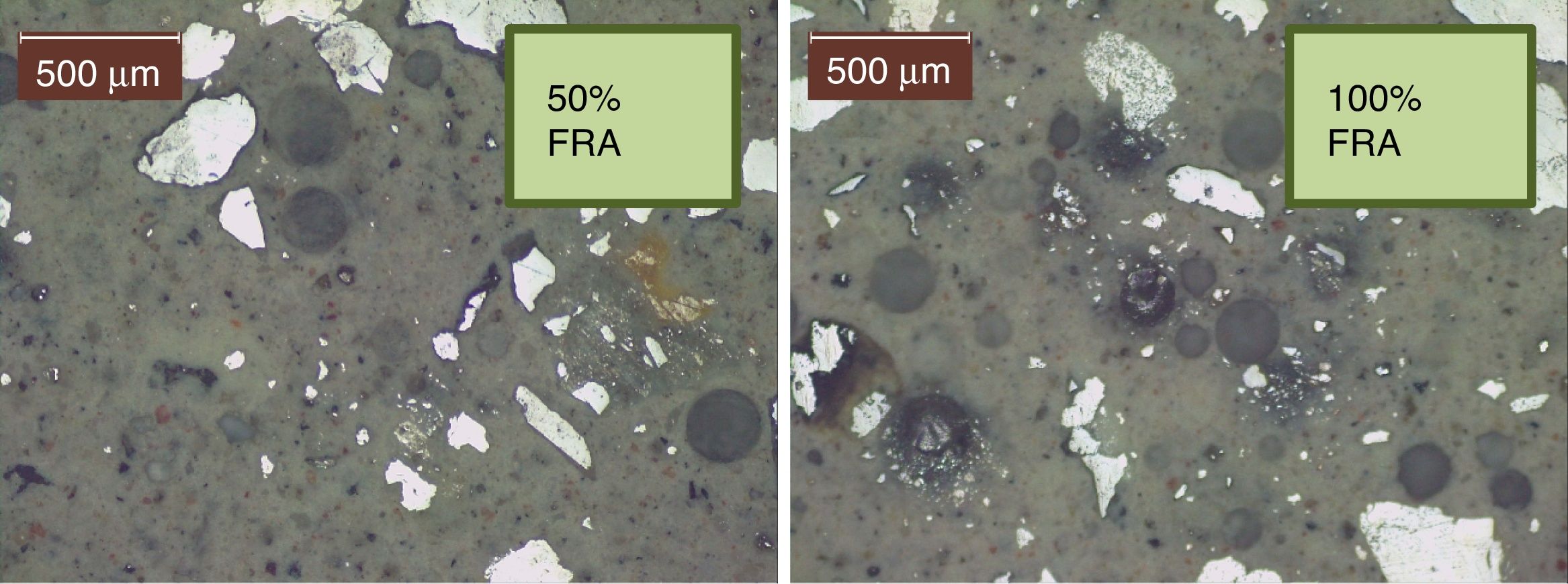

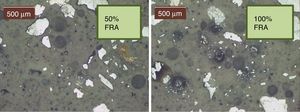

3.2MicrostructureThe selected mixes were studied under optic microscopy at the age of 14 days in a preparation of petrographic thin sections. The pictures (Fig. 4) show a significant increase in porosity with the percentage of FRA. These pores are clean with no precipitate in them and with size varying from 50 to 250μm.

It was not possible to visualize the different interfacial transition zone (ITZ) of the aggregates, because this is easier in coarse aggregates and rather difficult with recycled sand. This ITZ has been referred to be the weak part of the microstructure [26].

However, in the 100% replacement mix there was a fraction of natural aggregate – from the original concrete – that seemed to be separated from the original paste. This could be attributed to the processing of the aggregates.

4Concrete fresh-state properties and rheology4.1Empirical resultsOnce the mix proportion was tested in the mortar phase, the next step was to produce equivalent concrete mixes. At this stage the empirical tests used were the usual slump-flow test and V-funnel. In addition, tests with rheometer were performed: stress growth test and flow curve test. In the two first all substitution ratios were performed but in the case of the concrete with a 100% of replacement the results at 90min showed a complete loss of the SCC behaviour. After these results, it was decided to go on only with 0% and 50% replacement. This allows studying the effect of the incorporation of the recycled sand.

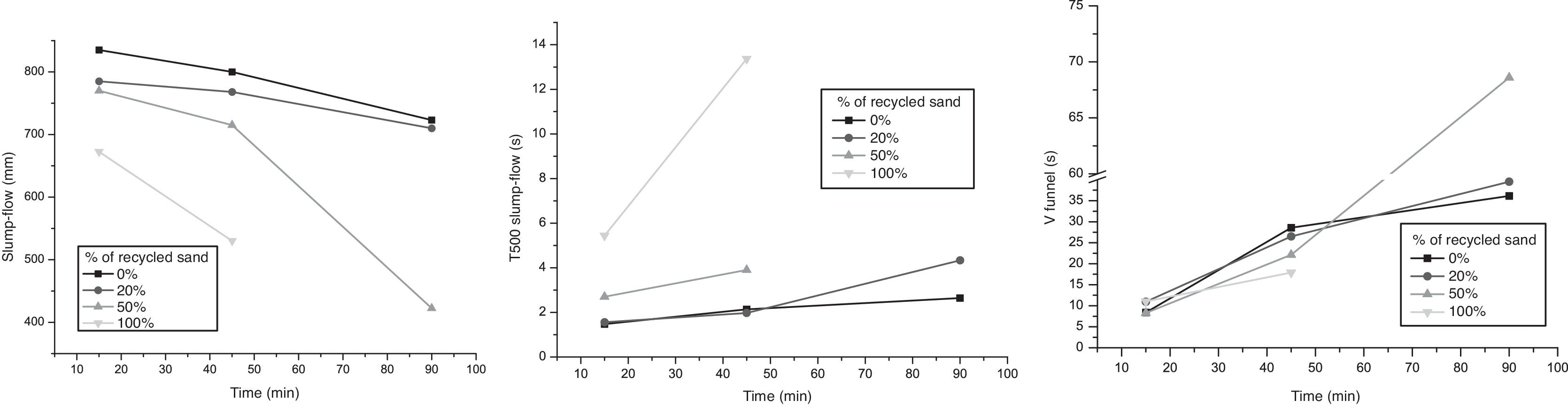

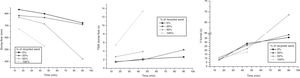

In Fig. 5 the results of slump-flow test are presented. A reduction over time of the spread and an increase in the T500, higher with the substitution ratios, can be seen. A similar trend was detected in the case of the V-funnel results (Fig. 5), but there where substantial differences between the 0% and 20% and the 50% and 100% group. In this last group, the effect of time is stronger; it seems that the concrete loses flowing ability with the incorporation of recycled sand.

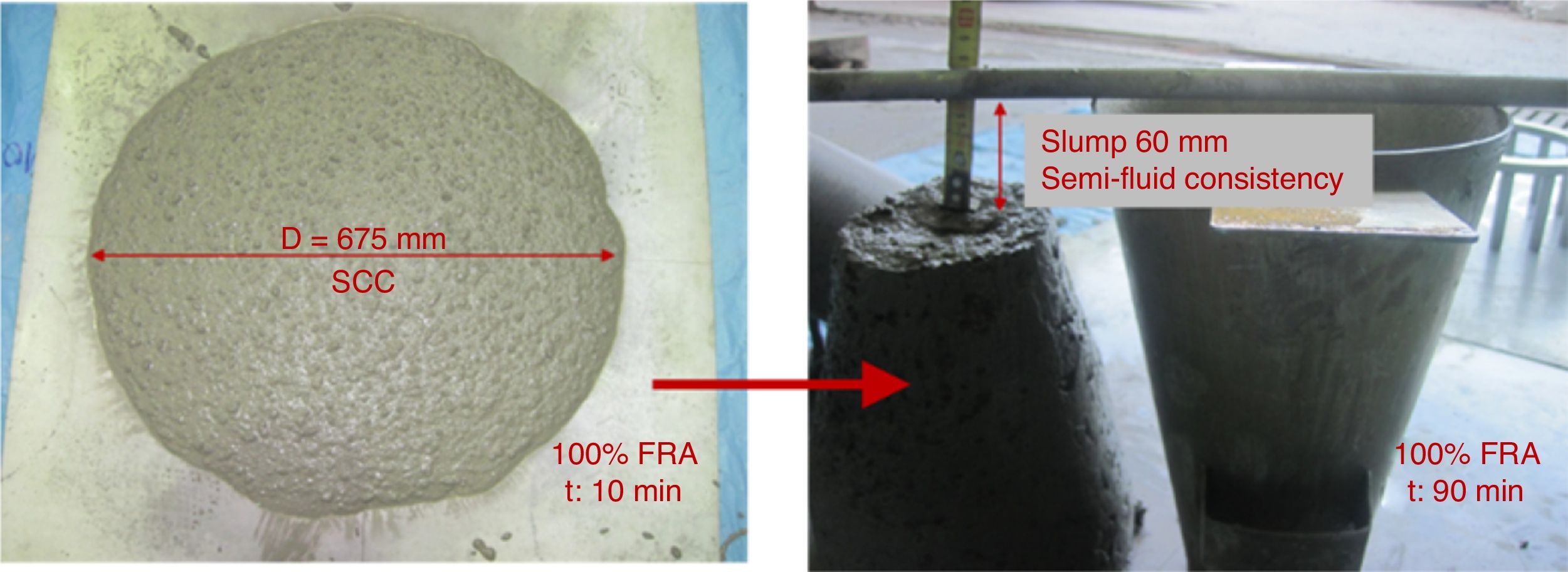

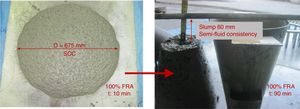

The flowability of the 50% and 100% mixes suffered a severe reduction, losing their SCC behaviour. In the case of the 100% mix, it was even impossible to achieve a flowable concrete (Fig. 6).

4.2Rheological resultsPortland cement concrete rheology has been thoroughly studied and found to fit the Bingham model (Eq. (1)). However, the Bingham model cannot be always applied to describe the rheological properties of SCC, due to the generation of negative yield stresses [27]:

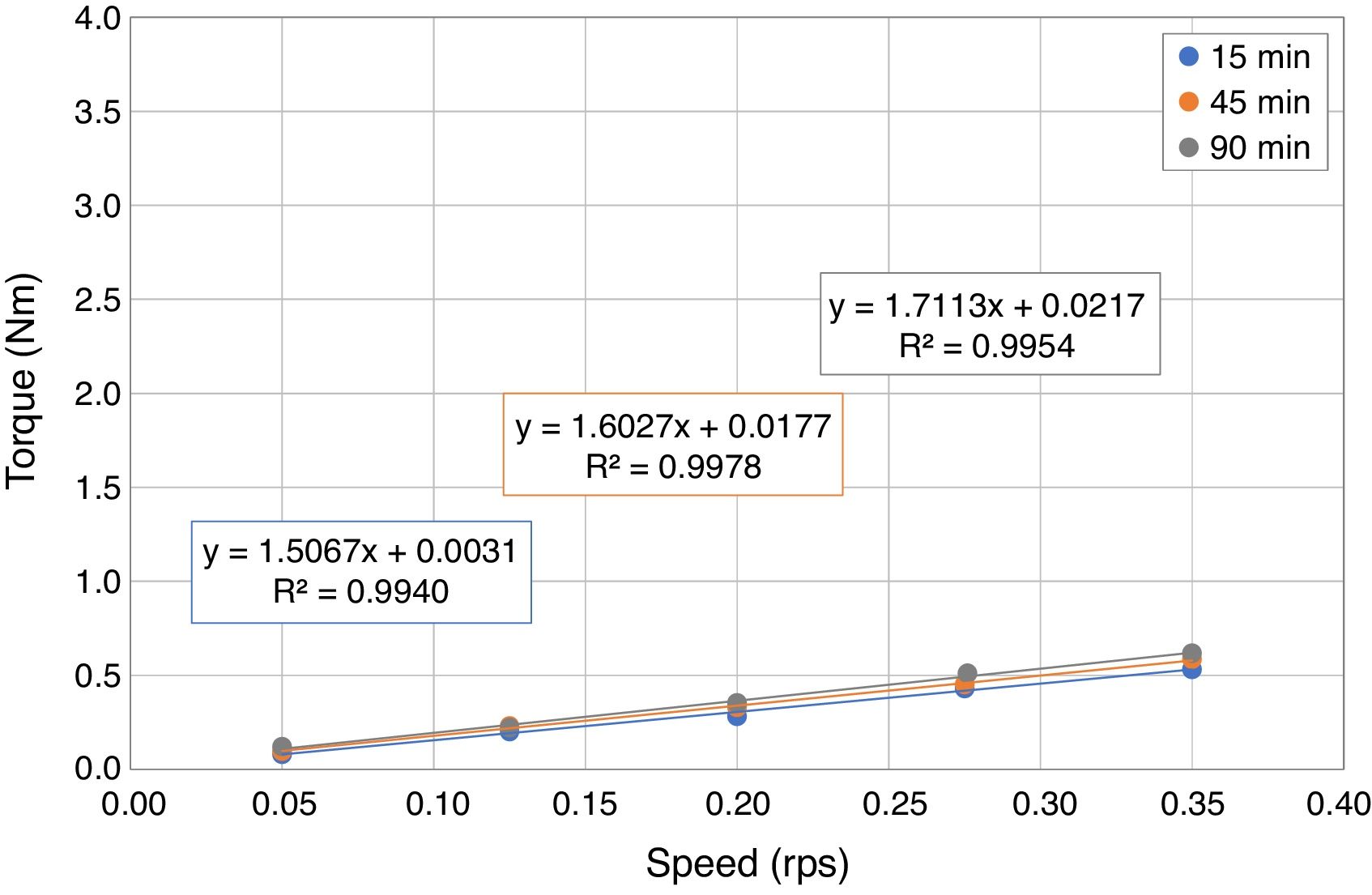

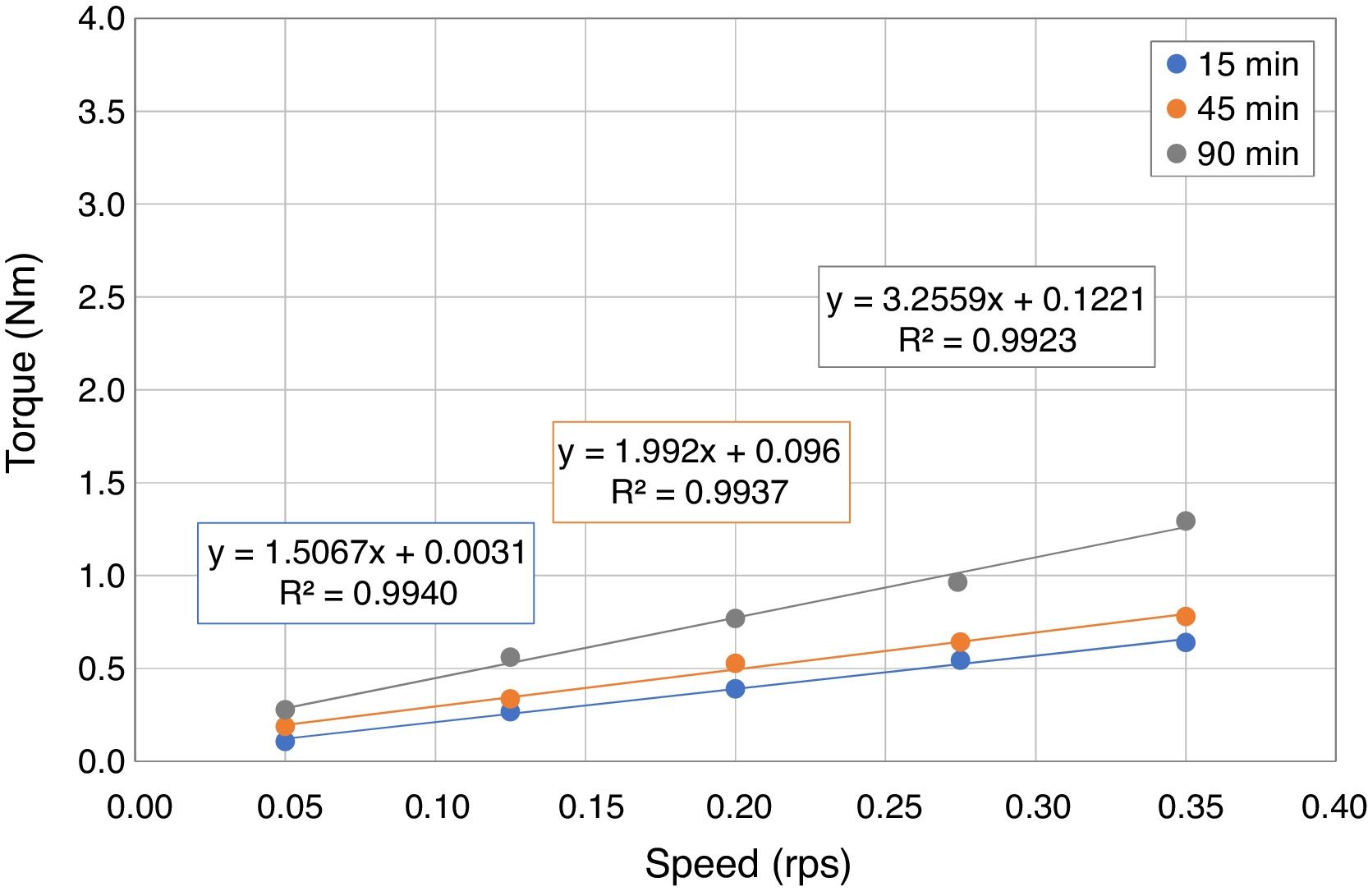

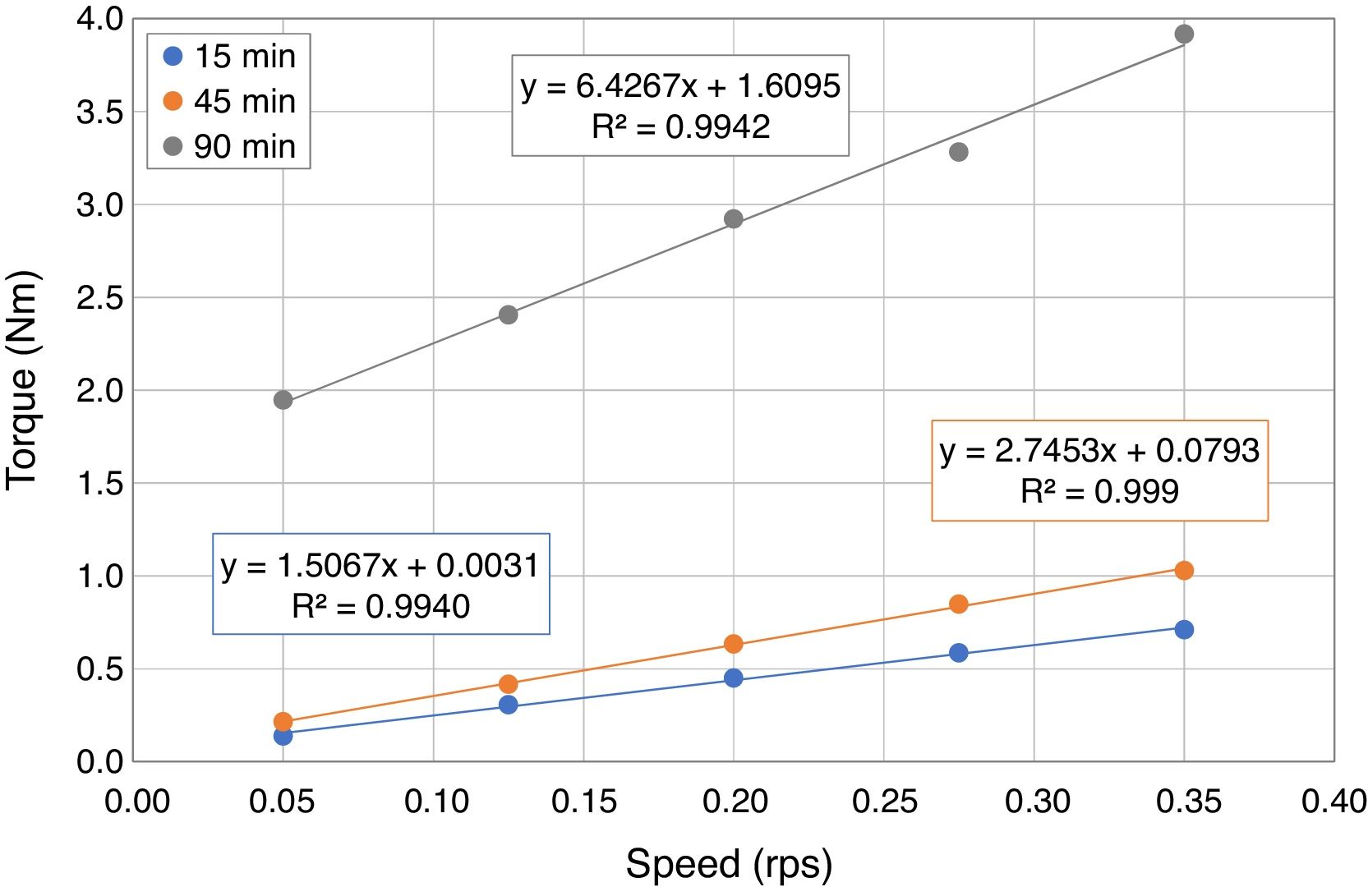

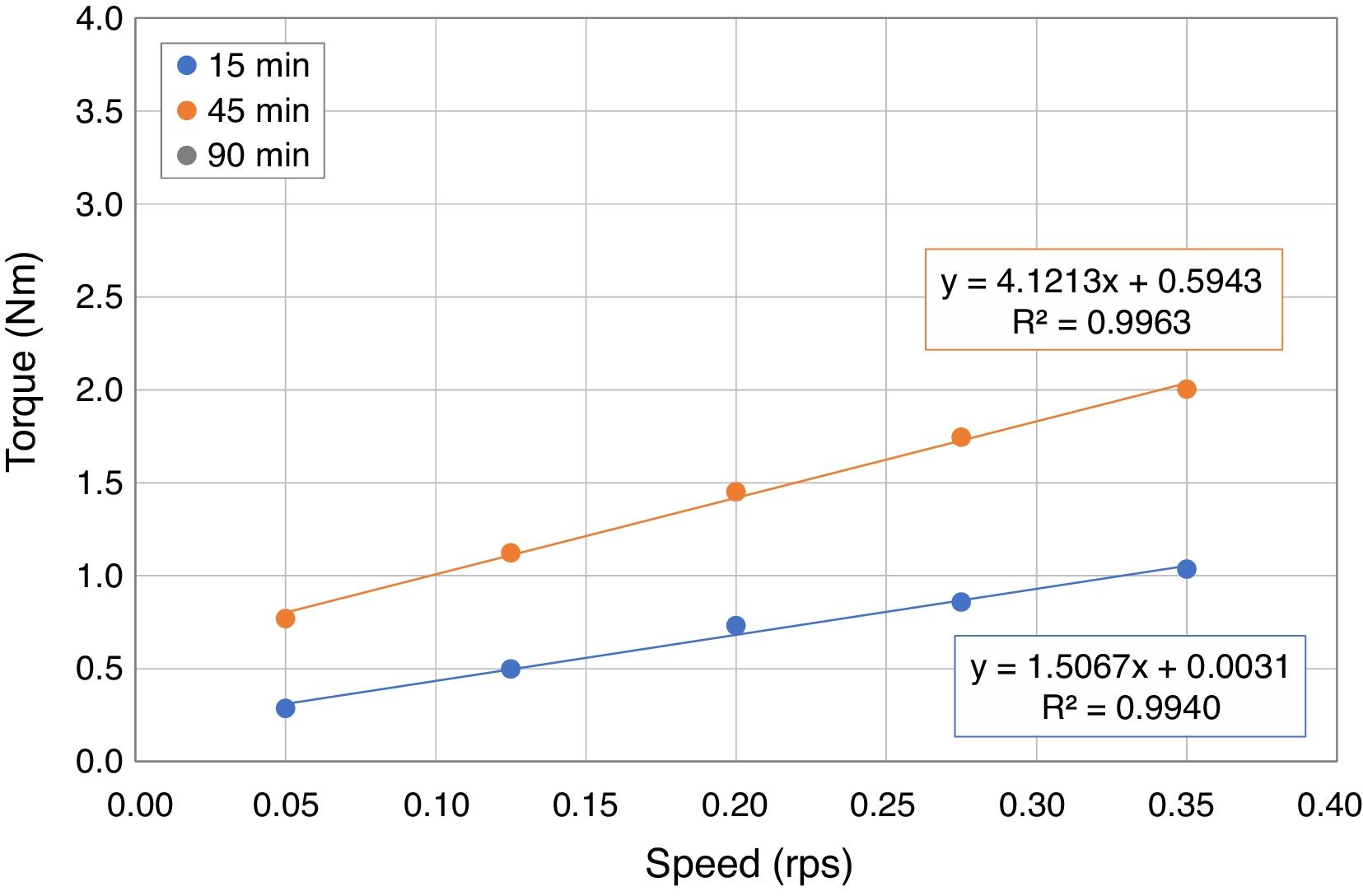

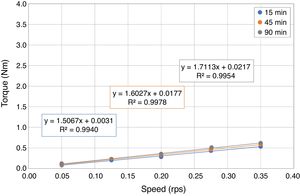

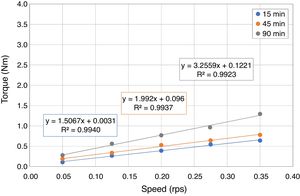

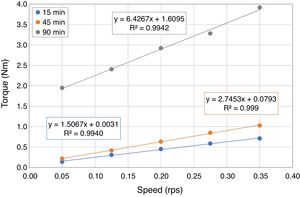

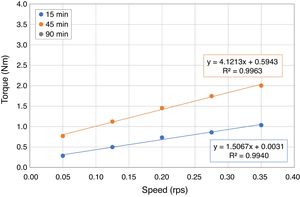

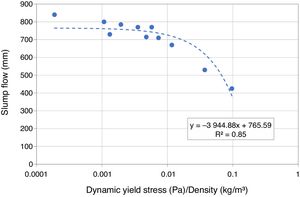

where τ is the shear stress (Pa), τ0 is the yield stress (Pa), μp is the plastic viscosity of Bingham model (Pas) and γ˙ is the shear rate (1/s).Moreover, due to thixotropy and segregation, some measurements can result in apparent non-linear behaviour and then they should be eliminated [28]. Thus, the stepwise decrease of rotational speed was analyzed in the flow curve tests carried out. Each step equilibrium was verified by plotting torque versus time and assuring that, on average, the torque was constant for the duration of testing. The two points related to the first two steps (the two highest rotational speeds) were not considered and both were eliminated from the data set. Then, the Bingham 5-lowest model was selected to define the flow curves (Figs. 7–10).

Once the rheological model was defined, the Reiner–Riwlin equations [27] for the Bingham model were applied to the experimental data to convert the torque-rotational velocity relationship into a shear stress-shear rate relationship, expressed in fundamental units (Pa and Pas) (Eqs. (2) and (3)). This procedure transforms a relationship between torque and rotational velocity into a relationship between shear stress and shear rate, expressed in fundamental units (Pa and Pas):

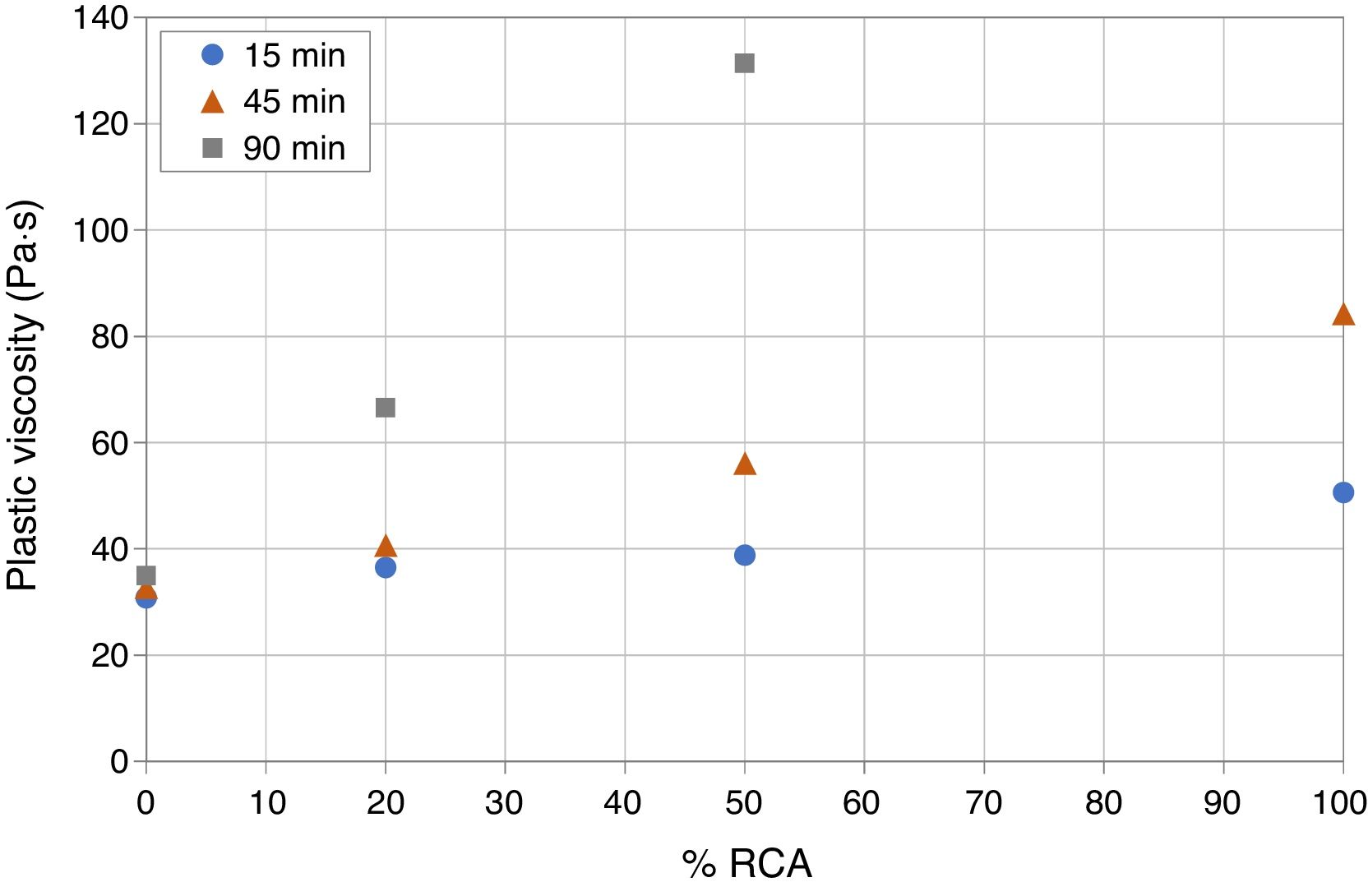

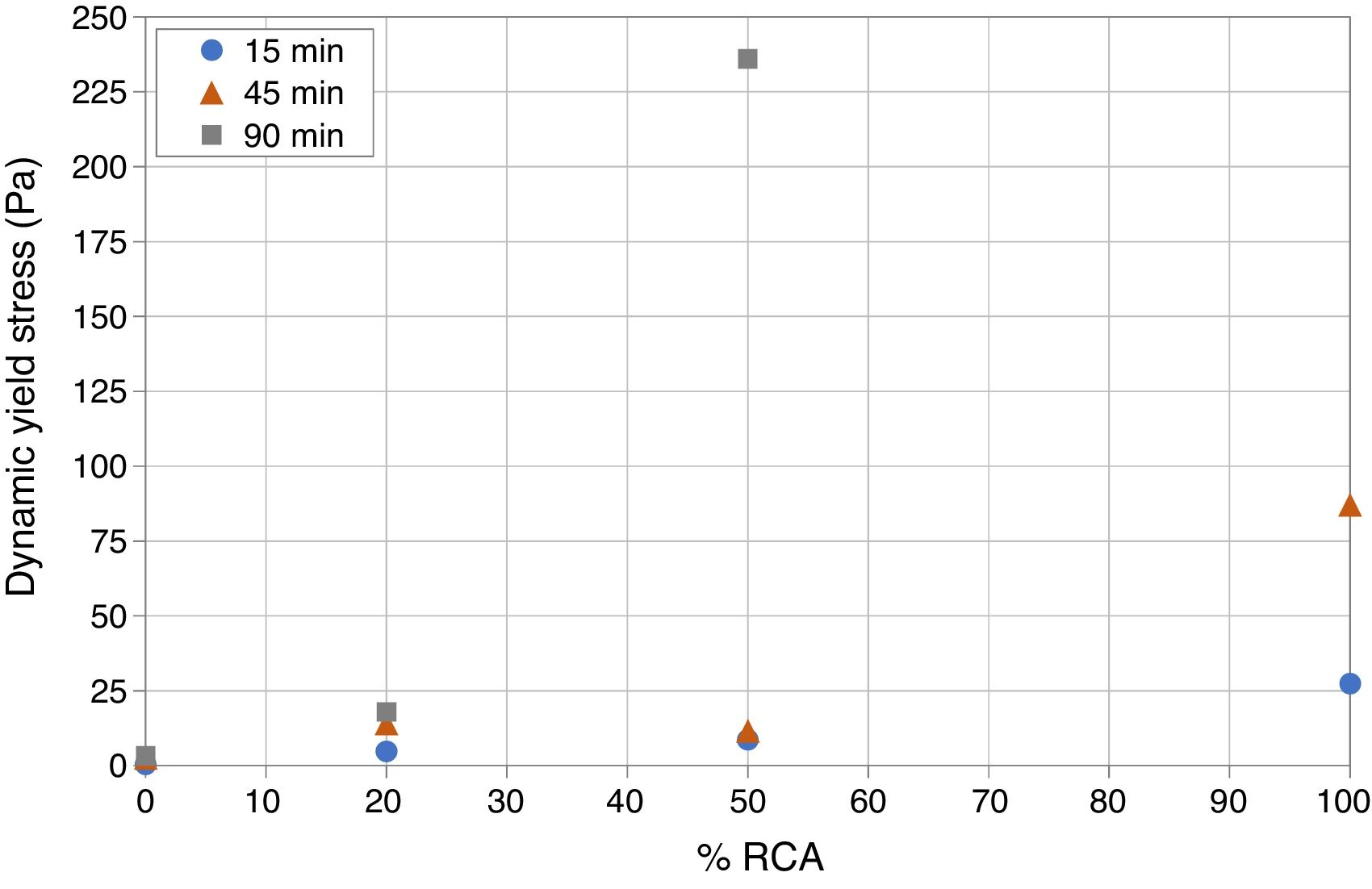

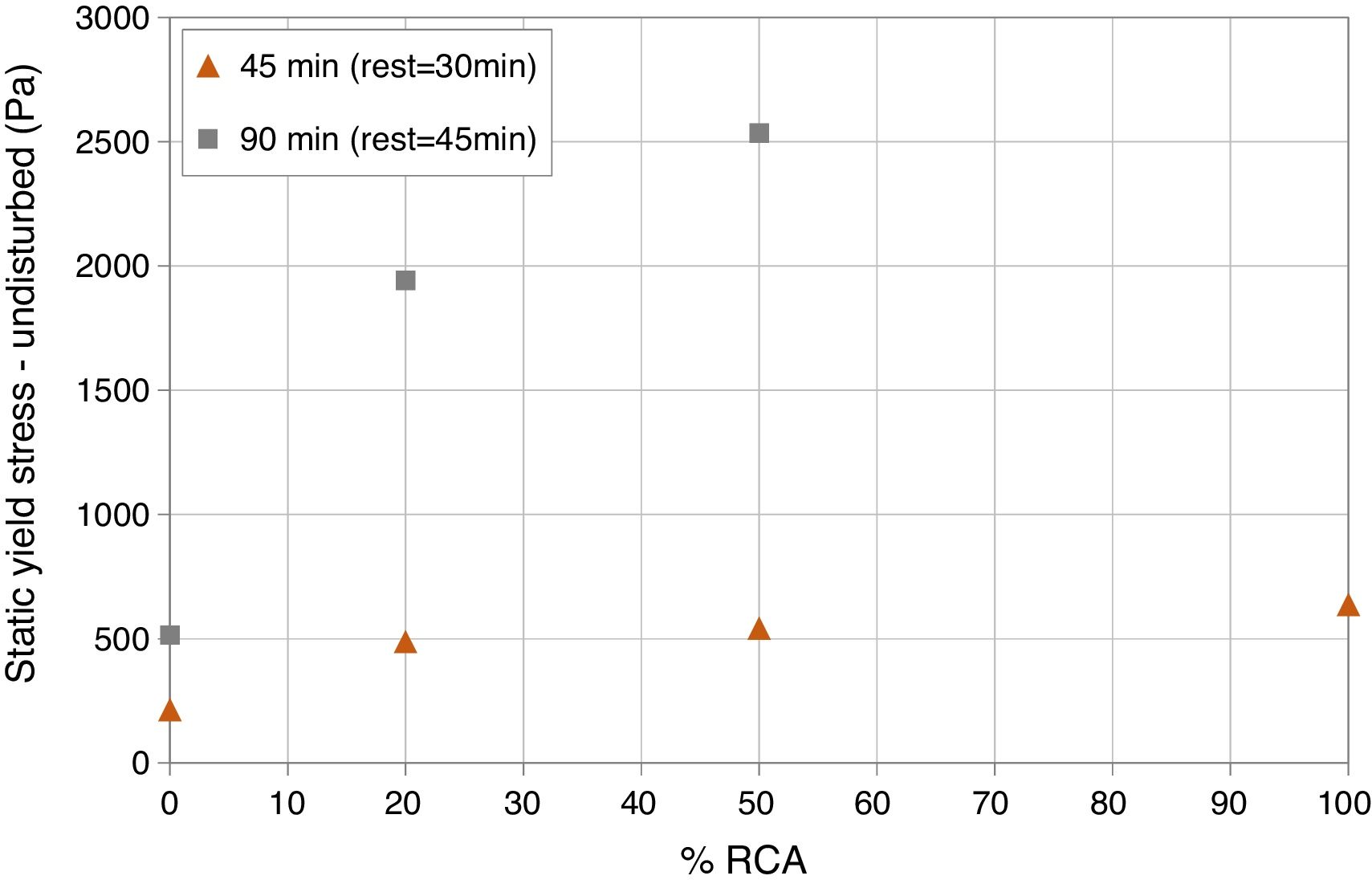

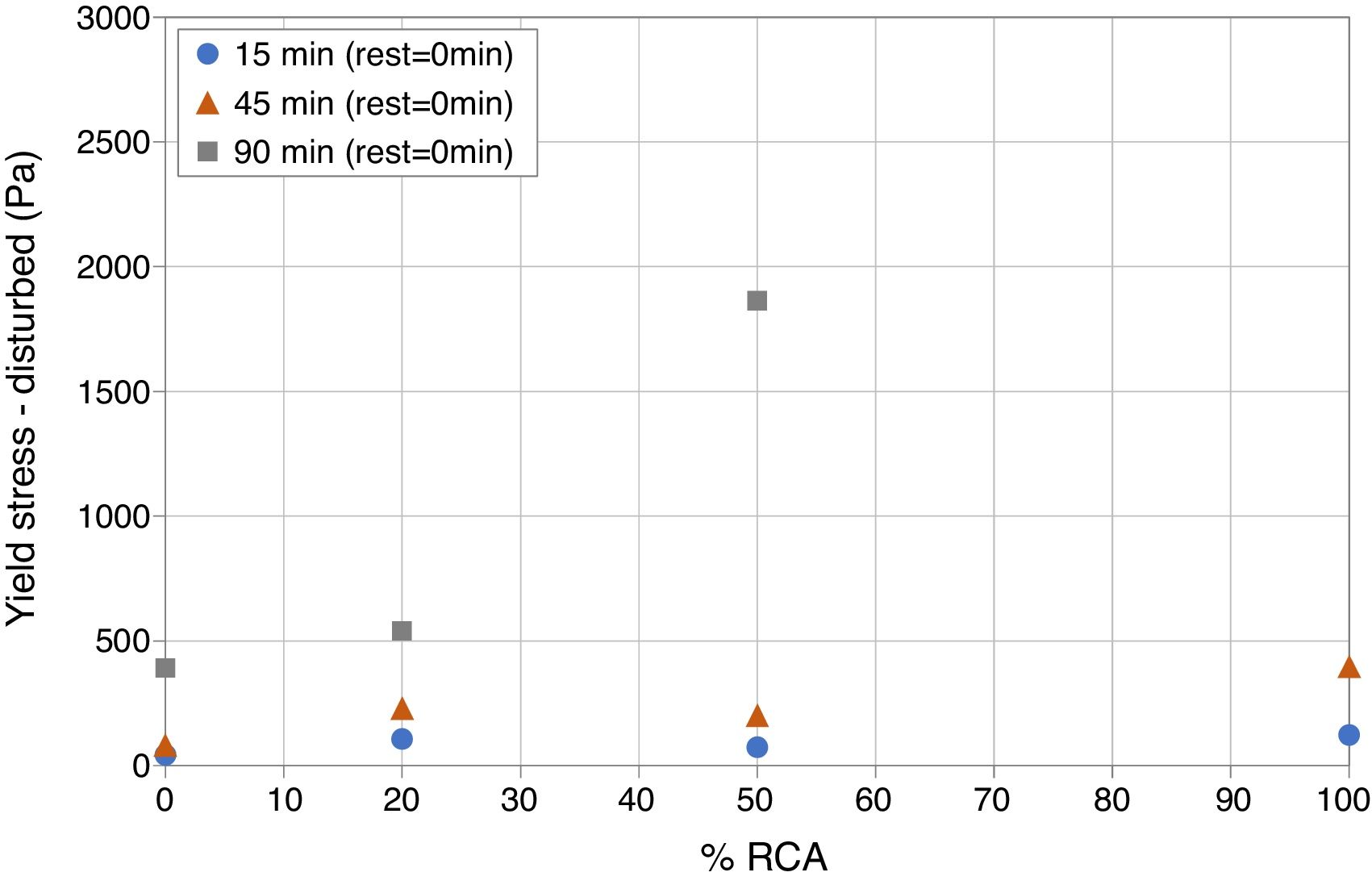

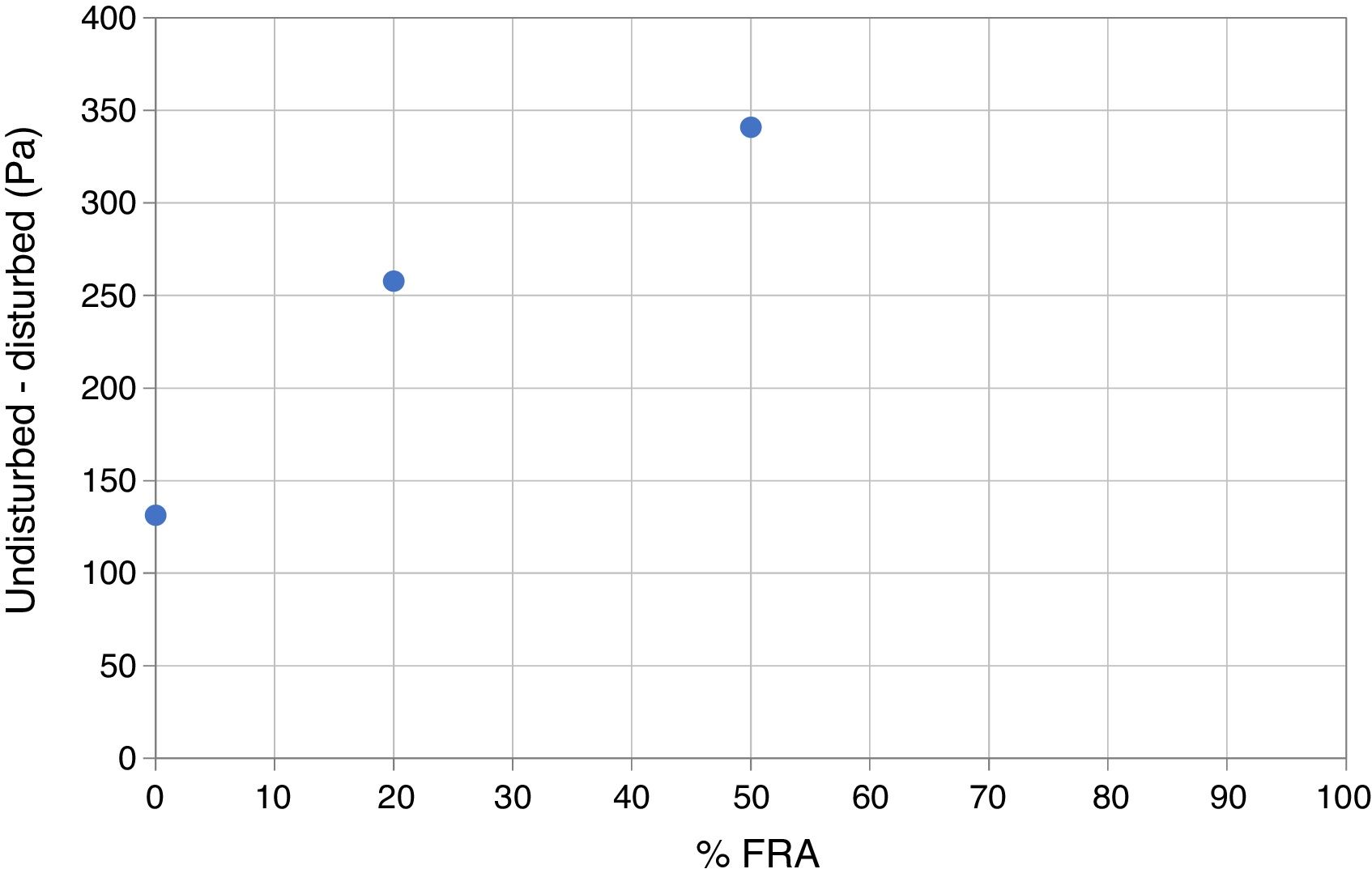

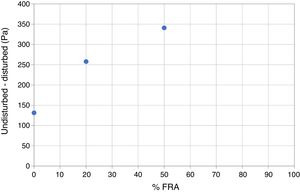

where R1 is the vane radius (m), R2 is the outer container radius (m), h is the vane height (m), G is the y-intercept on the flow curve (Nm) and H is the slope of the flow curve (Nms).The findings on all rheological parameters are shown in Figs. 11–14.

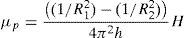

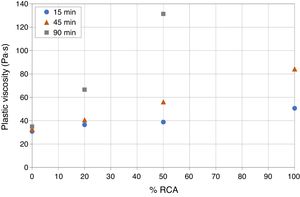

As the content of recycled fine aggregate increases, all rheological parameters increase (Figs. 11–14). One of the reasons that explains these results is the evolution of the water absorption of recycled fine aggregate. When high replacement ratios are used, this evolution modifies more significantly the effective water to cement ratio, reducing it and damaging the rheological behaviour of these concretes, especially at long ages. On the other hand, the more irregular shape and the rougher texture of recycled fine aggregates also affect rheology. Moreover, some fines of the FRA are basically old adhered mortar and they can present hydraulic, also affecting rheology.

Regarding the time-dependent evolution, at an age of 45min, all recycled mixes show more workability loss than the reference concrete (Fig. 14). This loss is greater for high replacement ratios. At an age of 90min, the 20% replacement concrete shows a similar workability loss to that of the reference concrete but a higher degree of thixotropy (Fig. 13). For high replacement concretes (50% and 100%), the self-compacting behaviour is lost, and even it was no possible to make the tests in the case of the total substitution (Figs. 11–14).

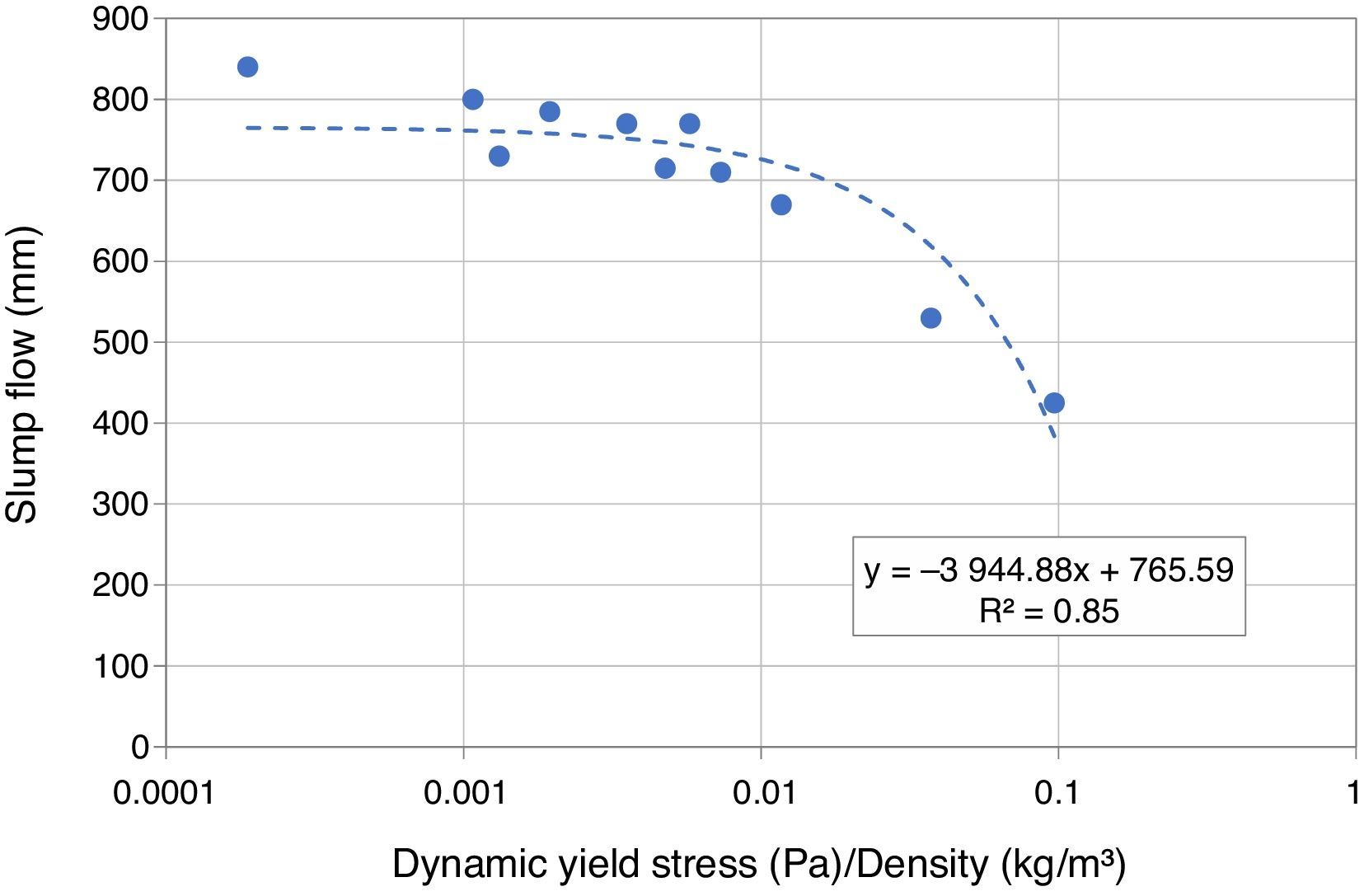

Moreover, an analysis of the data in Fig. 15 shows that a similar tendency to that reported in the literature [29] between empirical (slump flow) and rheological (dynamic yield stress) results can be obtained.

Finally, concrete thixotropy was assessed as the difference between the peak shear stress in the two stress growth tests (undisturbed and disturbed) at 45min (30min of resting time). The greater difference between undisturbed and disturbed yield stress, the higher the thixotropy is. It can be observed in Fig. 16 that the degree of thixotropy of SCCs with RFA is higher than that of the reference SCC. Moreover, as the replacement percentage increases, the concretes are more thixotropic. In the case of 100% RFA, the workability loss due to hydration processes is so significant that it would not be right to talk about thixotropy.

5ConclusionsThe study of the mortar phase in the design of the mixture proportions helps substantially. Also, it helps to understand the negative effects of the recycled sand. However, the comparability for the mixes – with SCC characteristics – is limited. It is impossible to compare in terms of fluidity and viscosity simultaneously, therefore it is not possible to comply with all recommendations for all replacement ratios.

With this mix design it was possible to produce self-compacting concrete with a substitution of up to 100% of recycled concrete sand. However, 50% and 100% mixes started to lose this behaviour after 60min.

The stress growth tests and flow curve tests confirmed the reduction of properties over time, and also all derived rheological parameters were increased. This loss of workability and finally of self-compacting concrete behaviour, seems to be produced by the absorption of the recycled aggregate.

The study is part of two projects entitled: (a) “Industrial Investigation about Concrete for a Sustainable Market (InHorMeS)” funded by the Innovation Galician Agency; (b) “Robust self-compacting recycled concretes: rheology in fresh state and mechanical properties (Ref: BIA2014-58063-R)” funded by MINECO. The research work was performed in the Centro de Investigación e Innovación Tecnológica en Edificación e Ingeniería Civil of Universidade da Coruña, A Coruña, Spain. The mortar phase was developed in the Laboratory of Construction of Instituto Superior Tecnico of Universidade de Lisboa in Lisbon, Portugal.