The objective of this research was to describe the types of business networks formed to meet the requirements established by the new bidding law, the Differential Public Procurement Regime, the innovations of this bidding system and the effect on the construction supply chain. This is a descriptive study based on a qualitative–quantitative analysis of a case study of road works on BR-381/MG, in Minas Gerais, Brazil. The units of analysis were the bidding documents, respective contracts, and the construction sites. The results showed that 40 companies took part in the bidding process in 13 cooperative consortia, 8 of which were vertical and horizontal networks, and 5 were vertical networks. An incremental innovation related to the project delivery method was identified between the government and construction companies in Brazil by means of integrated design and build procurement, which changed relationships within the construction supply chain by moving the design supplier into the contractor consortium and improved supply chain management. Moreover, inversion of stages by the new bidding law has increased agility in procurement of public works, as prices are analyzed prior to the other documents.

Internationalization of the economy has caused changes in management of businesses that seek organizational configurations adapted to a newly established reality. Forming business networks is one of the strategies adopted to obtain the new productivity and quality standards required. This cooperative business network allows for the creation of strategic alliances, such as consortia. With these, companies aim to complement the skills of one another in order to enter markets within the new world scenario (Olave & Amato Neto, 2001).

Companies participate in cooperative networks in order to enter new markets and maintain or improve their position in established markets (Quandt, 2012). Thus, they create competitive advantages by boosting their partners’ skills (Araújo & Guerrini, 2012; Jorde & Teece, 1989; Miranda, 2010). The existence of so many cooperative alliances, such as joint ventures, consortia, minority interests, and research or production cooperation agreements is no surprise (Lastres & Cassiolato, 2003; Wernerfelt & Karnani, 1987).

The Differential Public Procurement Regime [Regime Diferenciado de Contratação] (DPPR) came into force in August 2011, aimed at contracting sporting infrastructures for the competitions beginning in 2013, with the Confederations Cup, and ending in 2016, with the Olympic Games, held in Rio de Janeiro, which allows for the formation of business consortia.

The National Transportation Infrastructure Department [Departamento de Infraestrutura de Transporte] (DNIT, 2013) employs the Differential Public Procurement Regime (DPPR) widely in their bidding processes, including the case under study, tender notice No. 165/2013. The object of this tender notice is to increase traffic capacity on the BR-381/MG highway, in the Metropolitan Region of Belo Horizonte – one of the Brazilian cities hosting the Confederations Cup and the World Cup, and the headquarters for the United Kingdom's Olympic team.

The objective of this research is to describe the types of business networks formed to meet the requirements set out by the DPPR, the innovations of the DPPR bidding system, and the regime's effect on the construction supply chain.

Literature reviewBusiness cooperative strategyBusiness networks are types of relationships whose objective is to provide some kind of benefit for its members (De Lima & Campos Filho, 2009). Companies can cooperate in many ways, from a simple business connection involving the exchange of money for products to a complex integration of goods, services, financing, and systematically managed information (Eiriz, 2001).

The network typology can be constructed by analyzing the position of a company in relation to the others. According to the position occupied by companies in a network, their vertical location upstream or downstream in the supply chain can be identified, as well as its horizontal location at the same operational level of the focal firm (Britto, 2000).

Competing companies can constitute consortia of horizontal cooperative networks due to mutual gaps of complementary skills required to attain certain objectives they would otherwise fail to meet, or in order to create a synergy between their isolated skills (Andrade & Hoffmann, 2010). There are also consortia of vertical cooperative networks, when non-competing companies established at different levels of the supply chain form an alliance (Britto, 2000; Masquietto, Sacomano Neto, & Giuliani, 2011; Moro & Glitz, 2013).

Civil construction business networks are formed with the purpose of obtaining complementary skills and improving the position of its members in relation to the industry competition (Barbosa, Zilber, & Toledo, 2009). Constituting business networks in the production chain can bring about competitive advantages, to attract new ventures for the network members, or to improve the development of construction in progress (Casarotto, 2002).

In Brazil, Law No. 6.404, of 15 December 1976, regulated formation of consortia for the building sector. “Consortium means an association of companies, by means of a contract, which aims to perform a specific enterprise” (Miranda, 2010, p. 4).

Bidding systemHeinen (2014) states that the Differential Public Procurement Regime (DPPR) is an attempt to change the current procurement process for supply of goods and services. The DPPR's innovations are practices found in public and private international organizations and in the Brazilian private sector. However, the regime is groundbreaking compared to General Bidding Law No. 8.666/1993. “The State is giving the private sector a task that has traditionally been theirs, i.e. drawing up of the basic designs” (Heinen, 2014, p. 40).

The new bidding regime set out by Law No. 12.462/2011 allows for the transfer of responsibilities around technical engineering projects to firms contracted to execute the works. Bidders submit the preliminary designs of the desired end product, with companies being responsible for preparing the executive designs. This transfers to them many of the risks that were previously the responsibility of contracting parties (Dotti & Junior, 2013; Schwind, 2014).

Also noteworthy are the bidding systems used in procurement processes, which cover three key domains: the bidding type, the execution regime, and the project delivery method, all of which must be mutually supporting (Darrington & Lichtig, 2010).

According to Ferreira and Santos (2012), Bicalho (2013), Heinen (2014), and Quintella (2014), the potential innovations in the processes of contracting infrastructure works are related to the criteria of bidding type (company selection), execution regime (form of measurement and payment of services rendered), and delivery method (project scope).

Each construction project requires appropriate choices for the project delivery system. The project delivery system includes the bidding type, the type of contract and the project delivery method (Azevedo, 2005; Thomsen, Darrington, Dunne, & Lichtig, 2013).

The bidding type is related to the selection criteria that determine winning bidder, e.g. the lowest price model, the qualitative criterion model – such as the best technical merit – and a combination of technical merit and lowest price type. It is the granting criterion (Chaovalitwongse, Wang, Williams, & Chaovalitwongse, 2012; El Wardani, Messner, & Horman, 2006; Safa, Yee, Rayside, & Haas, 2016).

The execution regime is the type of contract, which specifies how to measure and compensate the contractor for services rendered, e.g. lump-sum, unit price, guaranteed maximum price (GMP) and cost-plus-a-fixed-fee contracts (Pakkala, 2012; Thomsen et al., 2013).

The project delivery method refers to the project scope, which encompasses the scope of the product to be delivered and how to manage it and the relationship with its owner, e.g. design-bid-build (DBB) and design-build (DB) (Vellalos & Gordon, 2012).

The DBB is the traditional project delivery method. In this method, first the owner prepares or hires a designer company to produce construction drawings and specifications. Then, through a bidding process, they hire a contractor for the construction works (El Wardani et al., 2006; Martin, Lewis, Petersen, & Peters, 2016; Yu, Shen, & Shi, 2016).

In the DB method, the owner hires one single company or consortium to deliver both the design and construction. Upon conclusion, the owner is responsible for the operation and conservation of the product delivered (El Wardani et al., 2006; Ghadamsil & Braimah, 2016; Yu et al., 2016).

Integration of supply chain companies is an innovation in the project delivery method. Horizontal and vertical integration of supply chain participants provides an opportunity to improve agility in project delivery (Naoum & Egbu, 2016).

Government strategy: innovation in the integrated DPPRIn 1993, the Brazilian federal government enforced General Bidding Law No. 8.666/1993, which addresses public procurement processes, including contracting of companies for deployment of basic infrastructures (Brazil, 1993).

The DPPR applied to contracting of road works allows contracting of companies to prepare technical engineering (design) and building (production) projects of the enterprise to be included as the object of bidding documents (Morano, 2013). Article 2 of DPPR Law No. 12.462/2011 provides for the possibility of contracting the executive engineering project and the construction works in an integrated manner, including the building works needed to relocate families occupying the public spaces where road works would be performed (Brazil, 2011).

The DPPR is a law created to complement and present innovative alternatives to Law No. 8.666/1993 (Ferreira & Santos, 2012). The existence and simultaneous enforcement of Laws No. 8.666/1993 and No. 12.462/2011 is imperative (Quintella, 2014). In 2014, a reform of this law was proposed, which aimed to encompass, in general terms, its application scope (Almeida, 2014).

Supply chain and boundaries of organizationsMany organizations define their boundaries based on their skills and relationship with agents upstream and downstream their supply chains. Establishment of a company's boundaries is associated with its core skills and its decisions regarding internal production or purchase from suppliers. Boundaries are determined as the internal activities that create more added value for the client are defined, with the objective of gaining a sustainable competitive advantage (Hamel & Prahalad, 1990; Quinn and Hilmer, 1994).

Focal firms began to focus on their supply chain, aiming to create partnerships with their suppliers and buyers upstream and downstream, respectively, in order to adapt to the competitive reality established in globalized markets, with the intention of increasing competitiveness, which sometimes creates competition among supply chains (Di Serio & Sampaio, 2001; Kaare & Koppel, 2012; Tiwari, Shepherd, & Pandey, 2014).

Concept and types of innovationInnovation is defined as the ability to create new value at the intersection of business and technology (Cane, 2005). Companies combine changes in technology and in the business model. In addition to technological innovations in products and services, enabling processes and technology, organizational innovations in the business model take place in the way companies are managed (Schumpeter, 1943; Tigre, 2006).

Innovation comprises changes to one or more of the six components of two levers: technology (product and service offerings, process technologies, enabling technologies) and business model (value proposition, supply chain and target customer). Innovation is incremental when it leads to small improvements in existing products and business processes. It is semi-radical when it includes little or no changes to one of the innovation levers and substantial changes to the other. On the other hand, it is radical when it includes substantial changes to the levers in both technology and business model (Davila et al., 2006).

With regard to the technology levers, the product or service is what a company offers in the market, process technologies are related to how products are manufactured, and enabling technologies to information and communication technologies and how fast they are incorporated. In the business model levers, the value proposition is what is sold and delivered to the market, the supply chain is how it is created and delivered to the market, and the target customer is to whom it is delivered (Alves, Freitas, & Rolon, 2014; Davila et al., 2006).

MethodologyThis is a descriptive research which aims to identify the types of business networks formed in the bidding process of the DPPR, the bidding system and its effects on the supply chain. Direct observation was done at working sites, and contracts signed between consortia and DNIT were studied. It is a case study of the bidding process of road infrastructure works by the analysis of the DNIT tender process No. 165/2013 (Brazil, 2013) and the worksites.

This study falls within the qualitative and quantitative approach. The qualitative aspect of this study lies in its intention to describe the type of network formed among companies stemming from the use of the DPPR in the procurement process and to devise the factors that influence consortia formation. The quantitative approach lies on the use of a Likert scale, in which the research participants were asked to express their agreement or disagreement with the statements provided in a questionnaire applied based on a pre-defined scale. The measurement instrument proposed by Likert aims to evaluate participants’ level of agreement with regard to a series of statements (Sanches et al., 2011).

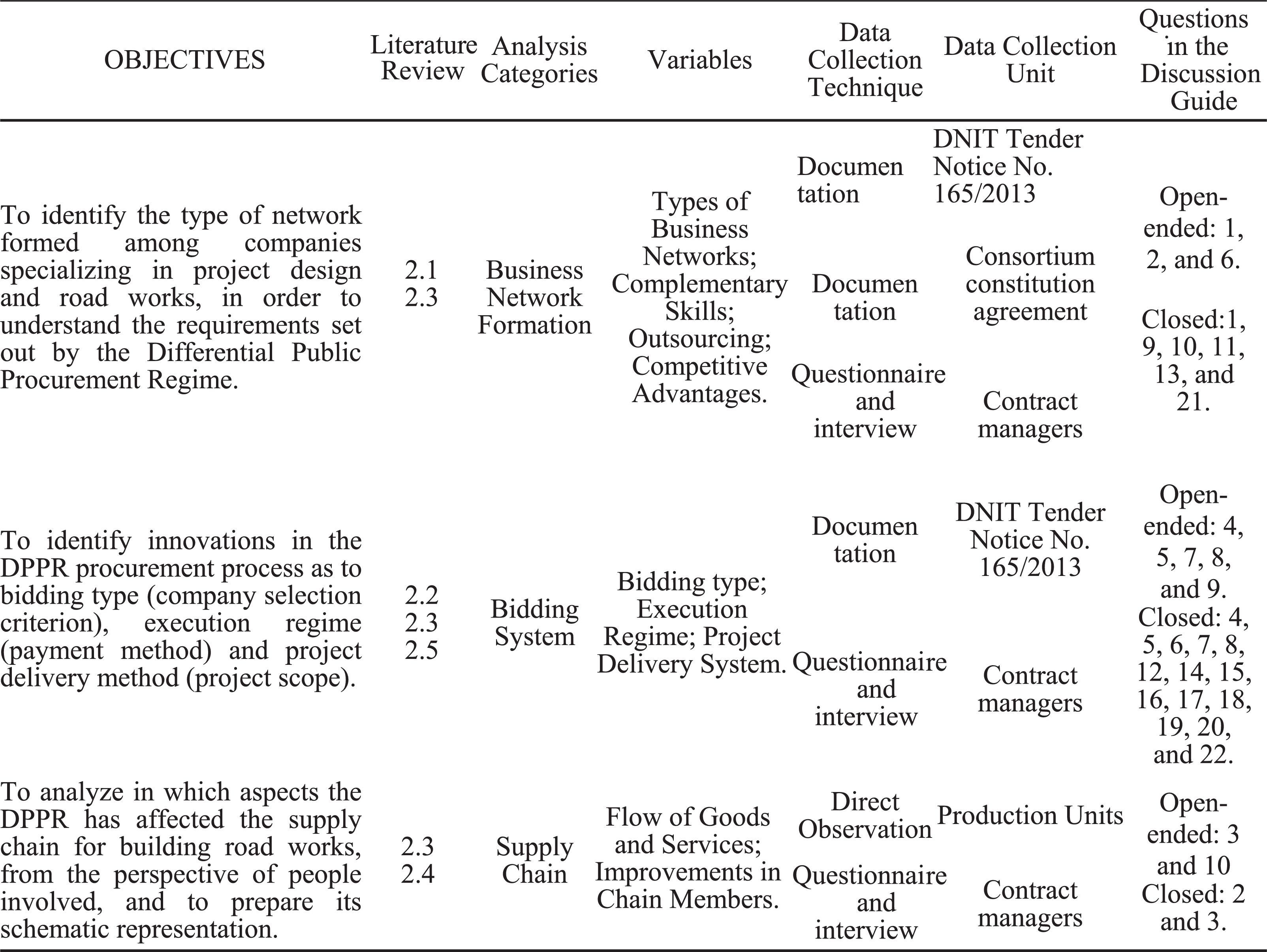

Data collection instruments and research executionThe data collection instrument was a questionnaire with open-ended questions and one with closed questions. The questionnaires were prepared with questions regarding the analysis categories indicated in Chart 1, directly related to the specific objectives of this study and used as a guide to collect data for this essay.

The names of respondents and their organizations have been kept confidential. The questionnaires were sent to the professionals of the companies taking part in the bidding process and to the professionals of companies and offices involved in matters relative to DNIT tender notice No. 165/2013.

All of the professionals were contacted by telephone, e-mail, or in person. In spite of the restriction posed by the confidentiality of companies, consortia and managers’ identities, the research was fully adhered to. It is worth noting the interest shown by respondents throughout the entire data collection process.

Data collection by means of questionnaires and interview was performed with managers of construction companies and designers of the works under study, DNIT managers, managers of companies taking part in the bidding process – even the ones that have been outbid – and law firms that provided support for the companies during the bidding process.

The professionals who took part in the research are widely representative in their field of knowledge, well-known for their publications and research in their field, as well as in the market.

During the data collection stage, a semi-structured questionnaire with 10 open-ended questions was applied to 11 groups of respondents consisting of managers of the companies in the consortia originally constituted for participation in the bidding process, including those who were terminated after having been outbid, as well as the group of managers of the contracting organization (DNIT). Respondents from terminated consortia, even when physically apart, established communication among them in order to form a group of respondents for the open-ended questionnaire.

Additionally, an interview was carried out with one of the contract managers of the case study construction work. This interview was conducted at the headquarters of the company participating in the consortium. The interview was carried out in accordance with the case study protocol, using the same structure of the open-ended questions in the questionnaire applied. It was digitally recorded by the respondent himself, who arranged for its transcription and, subsequently, sent the typed text to the interviewer. A few statements deemed relevant were noted at the time of the interview by a person authorized by the respondent. The interview generated ten pages when transcribed.

It was possible to identify and highlight standard answers from participants from the answered questionnaire with open-ended questions. Although the answers to the open-ended questions represented the opinion of the majority of each group, we chose to apply a questionnaire with 22 closed questions to each member of the 11 groups formed, aiming to verify the level of agreement with the open-ended questions.

Altogether, 50 questionnaires with closed questions were applied to the members of the 11 groups of open-ended question respondents and, in the end, 42 questionnaires with properly answered closed questions were returned.

The questionnaire's closed questions were deliberately formulated so as to relate to the standard inferred from the analysis and interpretation of answers to the open-ended questions, aiming to verify agreement of respondents with the inferences. Chart 1 presents the list of open-ended and closed questions associated with each specific objective.

The closed questions were designed using the 7-point Likert scale corresponding to the following levels of agreement: Strongly Agree (SA), Agree (A), Somewhat Agree (SWA), Neither agree nor disagree (NAD), Somewhat disagree (SWD), Disagree (D) and Strongly Disagree (SD). The option Insufficient Knowledge (IK) was also available for respondents who considered themselves unable to provide an opinion.

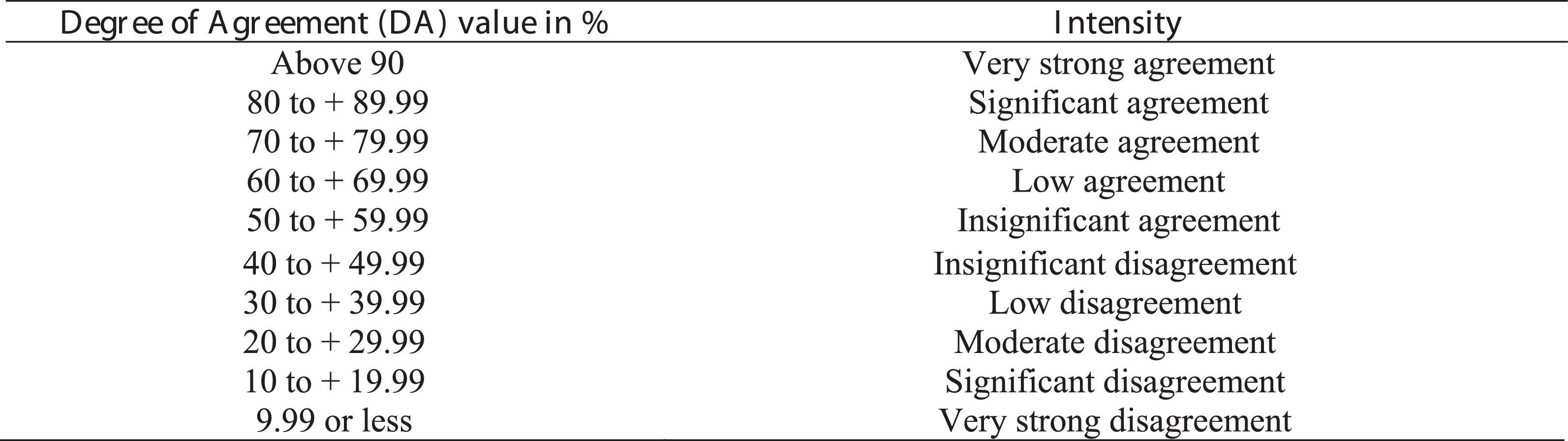

The results of the closed-question questionnaires on the Likert scale allowed us to determine the Observed Median, the respondents Disagreeing with the Statements (Ds), the ones Agreeing with the Statements (As), and the Degree of Agreement with the Statements (DAs).

The observed median is the column inside the interval Likert scale used in this study, where the participant representing 50% of respondents is found; Ds=Disagreeing with the statement refers to the number of respondents who disagreed with the statement given by equation SWD+D+SD+NAD/2; As=Agreeing with the statement refers to the number of respondents who agreed with the statement provided by equation As+A+SA+NAD/2; (Sanches et al., 2011).

The degree of agreement with the statement (DAs) corresponds to the percentage of respondents agreeing with the statements (As), in the case of statements with direct meaning. For statements with reversed meaning, i.e. built so that the desired value is found in the Strongly Disagree (SD) column, the degree of agreement refers to the percentage of respondents disagreeing with the statement (Ds) (Sanches et al., 2011). In the end, the degree of agreement was calculated for each of the 22 closed questions.

Inferences were obtained from the analysis of the open questions. Since these inferences are correlated with a particular group of closed questions, the average degree of agreement of the closed questions group determines the inference's degree of agreement.

Once the relationships between open and closed questions were established, it was possible to show the average degree of agreement of the closed statements related to a particular inference of the open question.

The calculated Degree of Agreement was interpreted according to the framework defined by Davis (1976), based on the scale of intensity of the degree of inference agreement, as presented in Chart 2.

Interpretation of intensity of degree of agreement with statement

The documentary research and direct observations began in April 2015 and were concluded in January 2016. The interview and application of the questionnaire to the managers took place between December 2015 and January 2016.

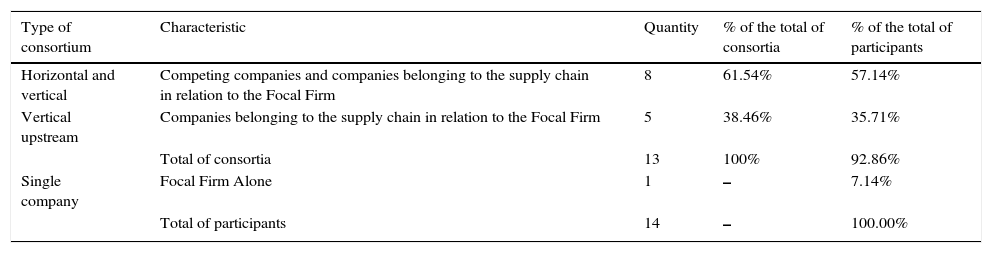

Analysis and interpretation of resultsAnalysis category 1: types of networks among companiesIt was verified that 40 companies participated in the bidding process of DNIT tender notice 165/2013, grouped into 13 networks in consortium format, whereas 5 were constituted by vertical business networks upstream the supply chain, 8 by simultaneously vertical and horizontal business networks. A single isolated company also participated.

Table 1 presents the percentage analysis of the types of consortia constituted as to the partnerships formed among competing companies of the building works field and the partnerships with companies specializing in designing and delivering technical engineering projects.

Percentage of the types of consortia formed.

| Type of consortium | Characteristic | Quantity | % of the total of consortia | % of the total of participants |

|---|---|---|---|---|

| Horizontal and vertical | Competing companies and companies belonging to the supply chain in relation to the Focal Firm | 8 | 61.54% | 57.14% |

| Vertical upstream | Companies belonging to the supply chain in relation to the Focal Firm | 5 | 38.46% | 35.71% |

| Total of consortia | 13 | 100% | 92.86% | |

| Single company | Focal Firm Alone | 1 | – | 7.14% |

| Total of participants | 14 | – | 100.00% |

There is a predominance of consortia of simultaneously vertical and horizontal companies, representing 61.54% of the total of consortia formed. This shows that the focal firms have sought to form networks in a consortium format with the design companies belonging to the construction supply chain and, at the same time, with companies that usually compete in the construction market, seeking to complement their assets.

It is also evident that 38.46% of the total of consortia constituted were of the vertical type, formed by the focal firm and a company supplying technical engineering projects belonging to a construction supply chain. This characterizes the type of vertical network upstream the flow of goods and services of the supply chain, as defined by Britto (2000).

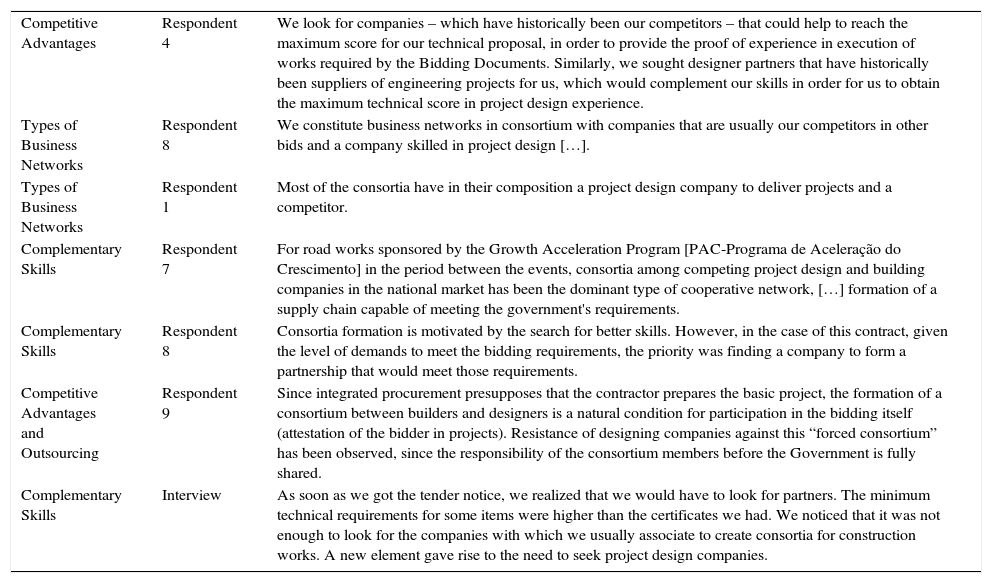

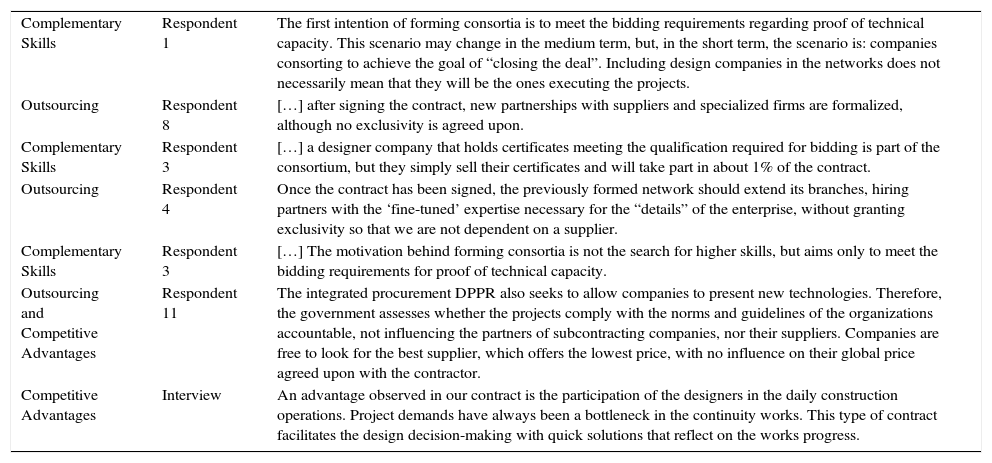

Answers provided to the questions asked of the managers of the companies involved in the bidding process have confirmed and complemented the information obtained from the documents analyzed.

The content of the questionnaires answered was analyzed, whose open-ended questions on this topic were questions 1, 2, and 6, while the closed questions were 1, 9, 10, 11, 13, and 21.

In open-ended Question 1, respondents were asked about the types of business networks formed to meet the requirements set out by the DPPR, during the bidding stage, with regard to partnerships with competing and supplying companies for infrastructure works bidded by the government, whose most representative answers are reproduced below:

| Competitive Advantages | Respondent 4 | We look for companies – which have historically been our competitors – that could help to reach the maximum score for our technical proposal, in order to provide the proof of experience in execution of works required by the Bidding Documents. Similarly, we sought designer partners that have historically been suppliers of engineering projects for us, which would complement our skills in order for us to obtain the maximum technical score in project design experience. |

| Types of Business Networks | Respondent 8 | We constitute business networks in consortium with companies that are usually our competitors in other bids and a company skilled in project design […]. |

| Types of Business Networks | Respondent 1 | Most of the consortia have in their composition a project design company to deliver projects and a competitor. |

| Complementary Skills | Respondent 7 | For road works sponsored by the Growth Acceleration Program [PAC-Programa de Aceleração do Crescimento] in the period between the events, consortia among competing project design and building companies in the national market has been the dominant type of cooperative network, […] formation of a supply chain capable of meeting the government's requirements. |

| Complementary Skills | Respondent 8 | Consortia formation is motivated by the search for better skills. However, in the case of this contract, given the level of demands to meet the bidding requirements, the priority was finding a company to form a partnership that would meet those requirements. |

| Competitive Advantages and Outsourcing | Respondent 9 | Since integrated procurement presupposes that the contractor prepares the basic project, the formation of a consortium between builders and designers is a natural condition for participation in the bidding itself (attestation of the bidder in projects). Resistance of designing companies against this “forced consortium” has been observed, since the responsibility of the consortium members before the Government is fully shared. |

| Complementary Skills | Interview | As soon as we got the tender notice, we realized that we would have to look for partners. The minimum technical requirements for some items were higher than the certificates we had. We noticed that it was not enough to look for the companies with which we usually associate to create consortia for construction works. A new element gave rise to the need to seek project design companies. |

In open-ended Question 2, research participants were asked about the types of business networks formed to meet the working requirements, in its execution phase, as to partnership with competing and supplier companies, whose most representative answers are reproduced below:

| Complementary Skills | Respondent 1 | The first intention of forming consortia is to meet the bidding requirements regarding proof of technical capacity. This scenario may change in the medium term, but, in the short term, the scenario is: companies consorting to achieve the goal of “closing the deal”. Including design companies in the networks does not necessarily mean that they will be the ones executing the projects. |

| Outsourcing | Respondent 8 | […] after signing the contract, new partnerships with suppliers and specialized firms are formalized, although no exclusivity is agreed upon. |

| Complementary Skills | Respondent 3 | […] a designer company that holds certificates meeting the qualification required for bidding is part of the consortium, but they simply sell their certificates and will take part in about 1% of the contract. |

| Outsourcing | Respondent 4 | Once the contract has been signed, the previously formed network should extend its branches, hiring partners with the ‘fine-tuned’ expertise necessary for the “details” of the enterprise, without granting exclusivity so that we are not dependent on a supplier. |

| Complementary Skills | Respondent 3 | […] The motivation behind forming consortia is not the search for higher skills, but aims only to meet the bidding requirements for proof of technical capacity. |

| Outsourcing and Competitive Advantages | Respondent 11 | The integrated procurement DPPR also seeks to allow companies to present new technologies. Therefore, the government assesses whether the projects comply with the norms and guidelines of the organizations accountable, not influencing the partners of subcontracting companies, nor their suppliers. Companies are free to look for the best supplier, which offers the lowest price, with no influence on their global price agreed upon with the contractor. |

| Competitive Advantages | Interview | An advantage observed in our contract is the participation of the designers in the daily construction operations. Project demands have always been a bottleneck in the continuity works. This type of contract facilitates the design decision-making with quick solutions that reflect on the works progress. |

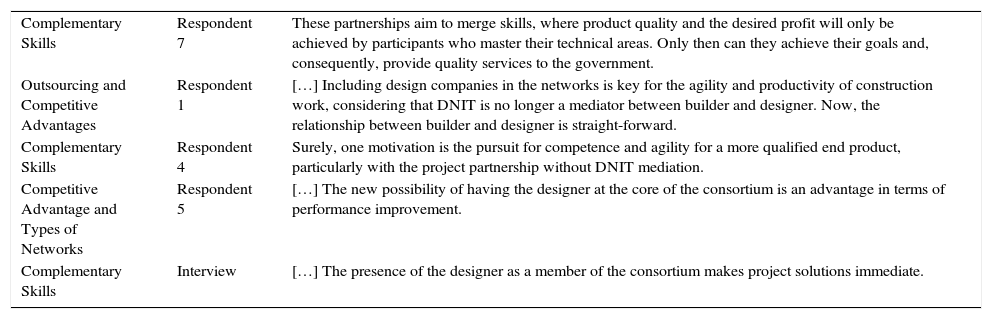

Open-ended Question 6 asked respondents about how consortia can influence the quality and agility of services provided for infrastructure works signed with the government. The most representative answers are found below:

| Complementary Skills | Respondent 7 | These partnerships aim to merge skills, where product quality and the desired profit will only be achieved by participants who master their technical areas. Only then can they achieve their goals and, consequently, provide quality services to the government. |

| Outsourcing and Competitive Advantages | Respondent 1 | […] Including design companies in the networks is key for the agility and productivity of construction work, considering that DNIT is no longer a mediator between builder and designer. Now, the relationship between builder and designer is straight-forward. |

| Complementary Skills | Respondent 4 | Surely, one motivation is the pursuit for competence and agility for a more qualified end product, particularly with the project partnership without DNIT mediation. |

| Competitive Advantage and Types of Networks | Respondent 5 | […] The new possibility of having the designer at the core of the consortium is an advantage in terms of performance improvement. |

| Complementary Skills | Interview | […] The presence of the designer as a member of the consortium makes project solutions immediate. |

It was evidenced in the answers that the types of networks, in the form of consortia, were vertical and horizontal in relation to the Focal Firm. Consortia were established among competing companies and project suppliers.

An important aspect to be observed is the perspective of the designer who felt compelled to participate in a consortium in order to get the project design contract, and was subsequently jointly and severally liable for the work execution: “There has been a resistance of designer companies regarding this “forced” consortium, since the liability of consortium members before the government is joint and several” (Respondent 11).

Notably, respondents indicated that the primary concern of the networks’ focal firms was around meeting the bidding requirements in order to attain the maximum technical score.

The construction work executive project may or may not be drawn up by the consortium's designer company. However, the importance of the designer in constituting the consortium during the execution of construction work was clear, even if it acts as project outsourcing manager.

It was also observed that, during execution of works, the consortium originally constituted cannot be modified. New partnerships are made through supply contracts and contracting of specialized companies without, however, signing an exclusive contract with new partners.

Analysis of the responses clearly indicates that participation of designer companies in consortia constitution improved agility in solutions toward adapting projects, which eliminates work stoppages due to potential uncertainties related to technical issues.

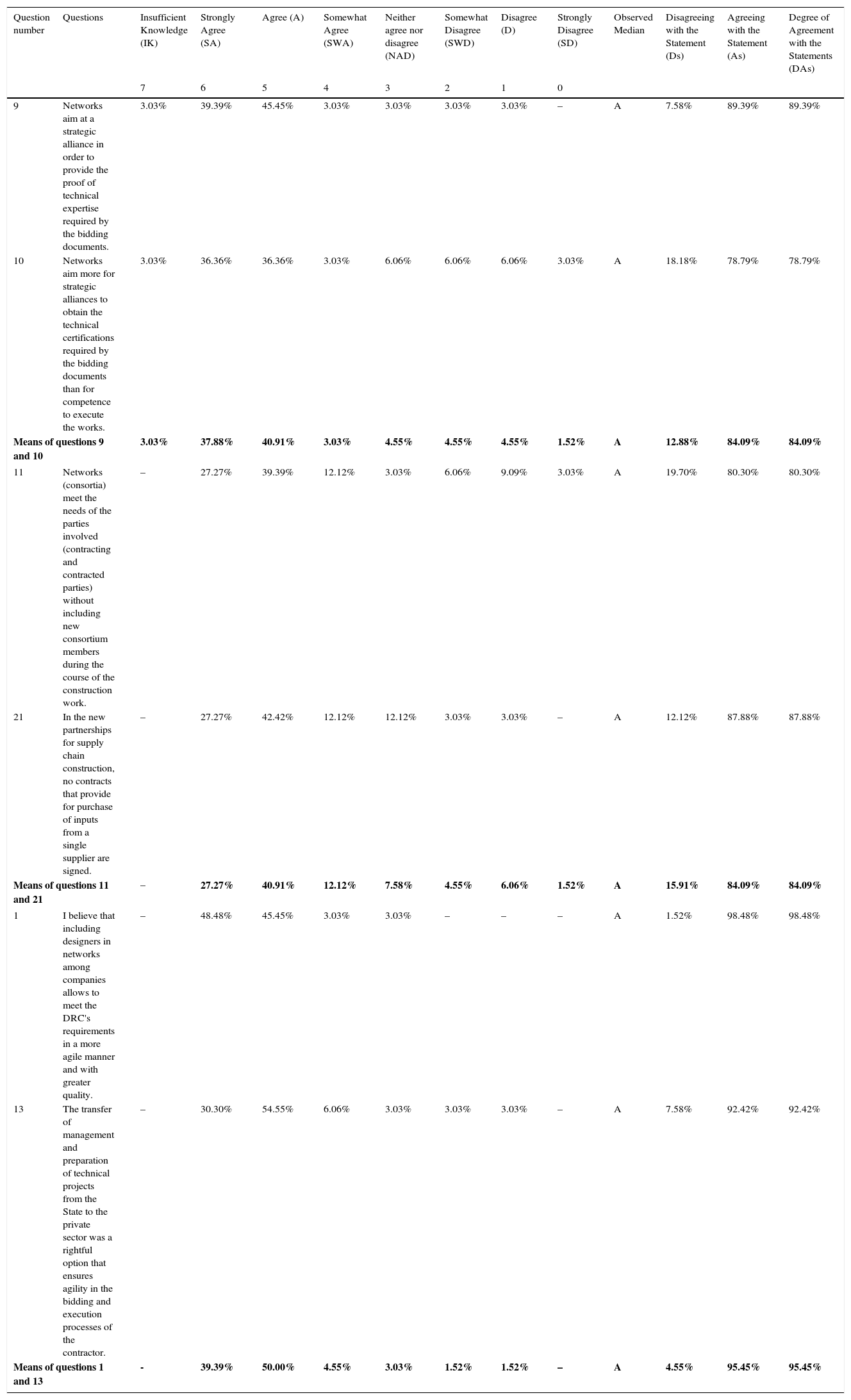

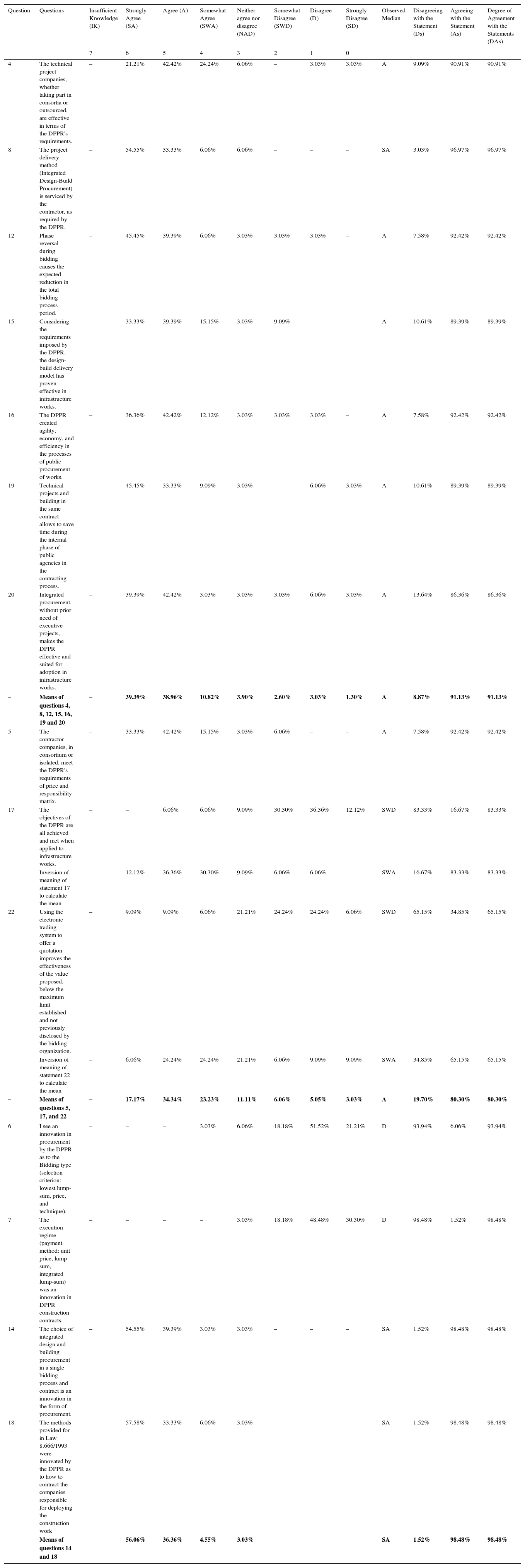

In that vein, closed questions number 1, 9, 10, 11, 13, and 21 were analyzed. Table 2 presents the closed questions addressing topics related to cooperative networks among companies and the study analysis on these questions.

Business networks: relationship between open-ended and closed questions and degree of agreement.

| Question number | Questions | Insufficient Knowledge (IK) | Strongly Agree (SA) | Agree (A) | Somewhat Agree (SWA) | Neither agree nor disagree (NAD) | Somewhat Disagree (SWD) | Disagree (D) | Strongly Disagree (SD) | Observed Median | Disagreeing with the Statement (Ds) | Agreeing with the Statement (As) | Degree of Agreement with the Statements (DAs) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 7 | 6 | 5 | 4 | 3 | 2 | 1 | 0 | ||||||

| 9 | Networks aim at a strategic alliance in order to provide the proof of technical expertise required by the bidding documents. | 3.03% | 39.39% | 45.45% | 3.03% | 3.03% | 3.03% | 3.03% | – | A | 7.58% | 89.39% | 89.39% |

| 10 | Networks aim more for strategic alliances to obtain the technical certifications required by the bidding documents than for competence to execute the works. | 3.03% | 36.36% | 36.36% | 3.03% | 6.06% | 6.06% | 6.06% | 3.03% | A | 18.18% | 78.79% | 78.79% |

| Means of questions 9 and 10 | 3.03% | 37.88% | 40.91% | 3.03% | 4.55% | 4.55% | 4.55% | 1.52% | A | 12.88% | 84.09% | 84.09% | |

| 11 | Networks (consortia) meet the needs of the parties involved (contracting and contracted parties) without including new consortium members during the course of the construction work. | – | 27.27% | 39.39% | 12.12% | 3.03% | 6.06% | 9.09% | 3.03% | A | 19.70% | 80.30% | 80.30% |

| 21 | In the new partnerships for supply chain construction, no contracts that provide for purchase of inputs from a single supplier are signed. | – | 27.27% | 42.42% | 12.12% | 12.12% | 3.03% | 3.03% | – | A | 12.12% | 87.88% | 87.88% |

| Means of questions 11 and 21 | – | 27.27% | 40.91% | 12.12% | 7.58% | 4.55% | 6.06% | 1.52% | A | 15.91% | 84.09% | 84.09% | |

| 1 | I believe that including designers in networks among companies allows to meet the DRC's requirements in a more agile manner and with greater quality. | – | 48.48% | 45.45% | 3.03% | 3.03% | – | – | – | A | 1.52% | 98.48% | 98.48% |

| 13 | The transfer of management and preparation of technical projects from the State to the private sector was a rightful option that ensures agility in the bidding and execution processes of the contractor. | – | 30.30% | 54.55% | 6.06% | 3.03% | 3.03% | 3.03% | – | A | 7.58% | 92.42% | 92.42% |

| Means of questions 1 and 13 | - | 39.39% | 50.00% | 4.55% | 3.03% | 1.52% | 1.52% | – | A | 4.55% | 95.45% | 95.45% | |

The criteria and equations described by Sanches et al. (2011) were used to determine the degree of agreement with the statement (DAs) for each question answered by respondents, as is also described in the chapter on the methodology.

Analysis category 2: innovation in the bidding systemThe documents analyzed pertain to the bidding process governed by DNIT tender notice No. 165/2013. The aforementioned document describes the criteria established for the bidding system, i.e. bidding type, the execution regime and the project delivery method.

The professionals participating in the study found that the greatest driver for adoption of the DPPR was agility in the bidding phase, contract execution, drawing up of the executive projects, and in the execution and conclusion of the construction work. Eliminating the executive projects’ contracting and drafting phase represented a procedural economy allowed by the DPPR. The respondents stated that the lump-sum execution regime and the risk and responsibilities matrix of the parties were the most relevant aspects of the contract.

Regarding the execution regime, respondents stated that the types provided by the DPPR are part of the payment criteria already enforced by Law 8.666/1993. Thus, no innovations regarding the contract execution regime were observed.

With regard to the project delivery method, respondents identified an innovation in the procurement system through the new project delivery method using integrated design-build (DB) procurement, which changed relationships in the construction supply chain by moving the project supplier into the consortium contracted. They also reported that the design-build (DB) project delivery method was the driver for formation of vertical networks between the focal firm and the project supplier company.

Regarding the bidding type, the study participants reported that there was no innovation in the DPPR procurement process, i.e. in the selection criterion of the company with the most cost-effective proposal by the lump-sum method, the best technique, and the combination of best technique and lowest cost.

The content of the questionnaires answered was analyzed, whose open questions on this topic were numbers 4, 5, 7, 8, and 9, and closed questions were numbers 4, 5, 6, 7, 8, 12, 14, 15, 16, 17, 18, 19, 20, and 22.

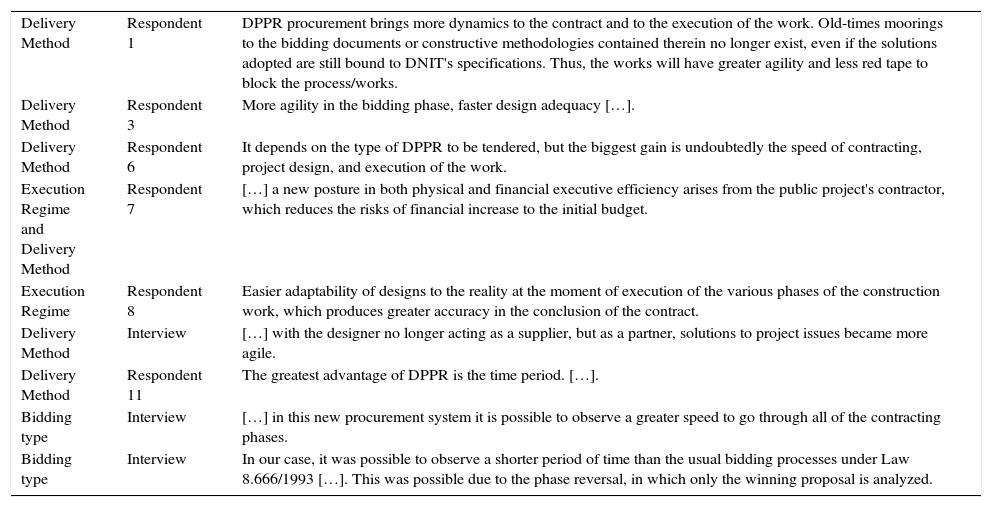

Open-ended Question 4 asked what was the most relevant motivation or differential which made the DPPR the most appropriate option for the infrastructure work contracts signed with the government. The main responses were:

| Delivery Method | Respondent 1 | DPPR procurement brings more dynamics to the contract and to the execution of the work. Old-times moorings to the bidding documents or constructive methodologies contained therein no longer exist, even if the solutions adopted are still bound to DNIT's specifications. Thus, the works will have greater agility and less red tape to block the process/works. |

| Delivery Method | Respondent 3 | More agility in the bidding phase, faster design adequacy […]. |

| Delivery Method | Respondent 6 | It depends on the type of DPPR to be tendered, but the biggest gain is undoubtedly the speed of contracting, project design, and execution of the work. |

| Execution Regime and Delivery Method | Respondent 7 | […] a new posture in both physical and financial executive efficiency arises from the public project's contractor, which reduces the risks of financial increase to the initial budget. |

| Execution Regime | Respondent 8 | Easier adaptability of designs to the reality at the moment of execution of the various phases of the construction work, which produces greater accuracy in the conclusion of the contract. |

| Delivery Method | Interview | […] with the designer no longer acting as a supplier, but as a partner, solutions to project issues became more agile. |

| Delivery Method | Respondent 11 | The greatest advantage of DPPR is the time period. […]. |

| Bidding type | Interview | […] in this new procurement system it is possible to observe a greater speed to go through all of the contracting phases. |

| Bidding type | Interview | In our case, it was possible to observe a shorter period of time than the usual bidding processes under Law 8.666/1993 […]. This was possible due to the phase reversal, in which only the winning proposal is analyzed. |

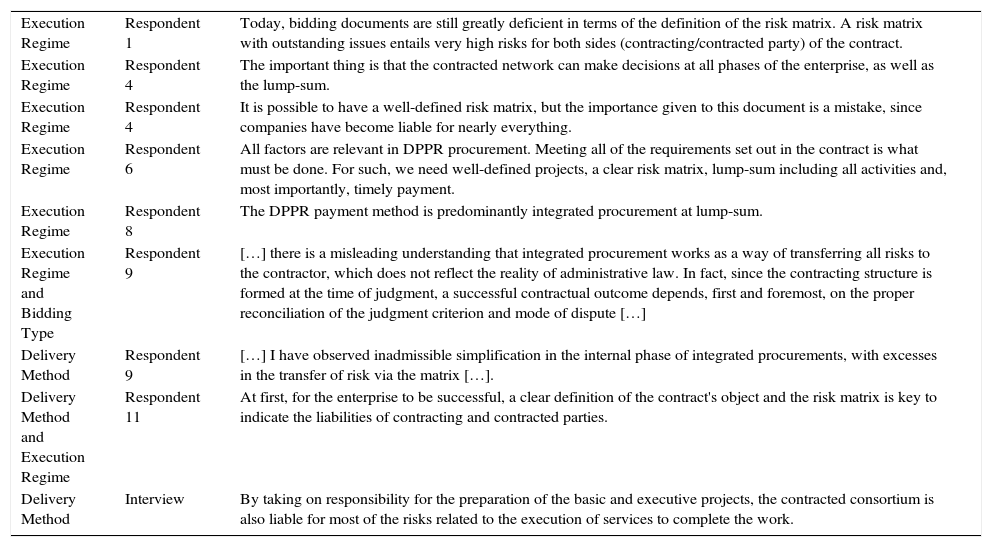

In open-ended Question 5, participants were asked to state what the most relevant requirements of the DPPR were in the execution of an infrastructure work. The main responses were:

| Execution Regime | Respondent 1 | Today, bidding documents are still greatly deficient in terms of the definition of the risk matrix. A risk matrix with outstanding issues entails very high risks for both sides (contracting/contracted party) of the contract. |

| Execution Regime | Respondent 4 | The important thing is that the contracted network can make decisions at all phases of the enterprise, as well as the lump-sum. |

| Execution Regime | Respondent 4 | It is possible to have a well-defined risk matrix, but the importance given to this document is a mistake, since companies have become liable for nearly everything. |

| Execution Regime | Respondent 6 | All factors are relevant in DPPR procurement. Meeting all of the requirements set out in the contract is what must be done. For such, we need well-defined projects, a clear risk matrix, lump-sum including all activities and, most importantly, timely payment. |

| Execution Regime | Respondent 8 | The DPPR payment method is predominantly integrated procurement at lump-sum. |

| Execution Regime and Bidding Type | Respondent 9 | […] there is a misleading understanding that integrated procurement works as a way of transferring all risks to the contractor, which does not reflect the reality of administrative law. In fact, since the contracting structure is formed at the time of judgment, a successful contractual outcome depends, first and foremost, on the proper reconciliation of the judgment criterion and mode of dispute […] |

| Delivery Method | Respondent 9 | […] I have observed inadmissible simplification in the internal phase of integrated procurements, with excesses in the transfer of risk via the matrix […]. |

| Delivery Method and Execution Regime | Respondent 11 | At first, for the enterprise to be successful, a clear definition of the contract's object and the risk matrix is key to indicate the liabilities of contracting and contracted parties. |

| Delivery Method | Interview | By taking on responsibility for the preparation of the basic and executive projects, the contracted consortium is also liable for most of the risks related to the execution of services to complete the work. |

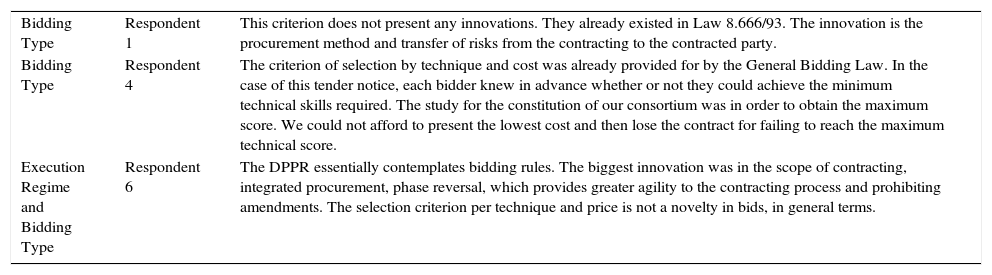

Open-ended Question 7 addresses the bidding type adopted by the bidding documents and asked respondents to identify the innovations introduced by the DPPR as to the bidding type (company selection criterion). The main statements were:

| Bidding Type | Respondent 1 | This criterion does not present any innovations. They already existed in Law 8.666/93. The innovation is the procurement method and transfer of risks from the contracting to the contracted party. |

| Bidding Type | Respondent 4 | The criterion of selection by technique and cost was already provided for by the General Bidding Law. In the case of this tender notice, each bidder knew in advance whether or not they could achieve the minimum technical skills required. The study for the constitution of our consortium was in order to obtain the maximum score. We could not afford to present the lowest cost and then lose the contract for failing to reach the maximum technical score. |

| Execution Regime and Bidding Type | Respondent 6 | The DPPR essentially contemplates bidding rules. The biggest innovation was in the scope of contracting, integrated procurement, phase reversal, which provides greater agility to the contracting process and prohibiting amendments. The selection criterion per technique and price is not a novelty in bids, in general terms. |

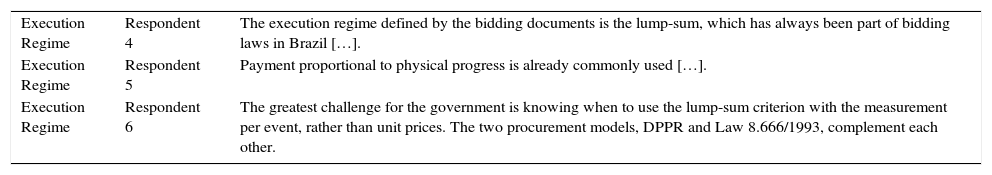

Open-ended Question 8 addresses the execution regime adopted by the tender notice. The study participants were asked to identify the innovations introduced by the DPPR procurement process as to payment method, as follows:

| Execution Regime | Respondent 4 | The execution regime defined by the bidding documents is the lump-sum, which has always been part of bidding laws in Brazil […]. |

| Execution Regime | Respondent 5 | Payment proportional to physical progress is already commonly used […]. |

| Execution Regime | Respondent 6 | The greatest challenge for the government is knowing when to use the lump-sum criterion with the measurement per event, rather than unit prices. The two procurement models, DPPR and Law 8.666/1993, complement each other. |

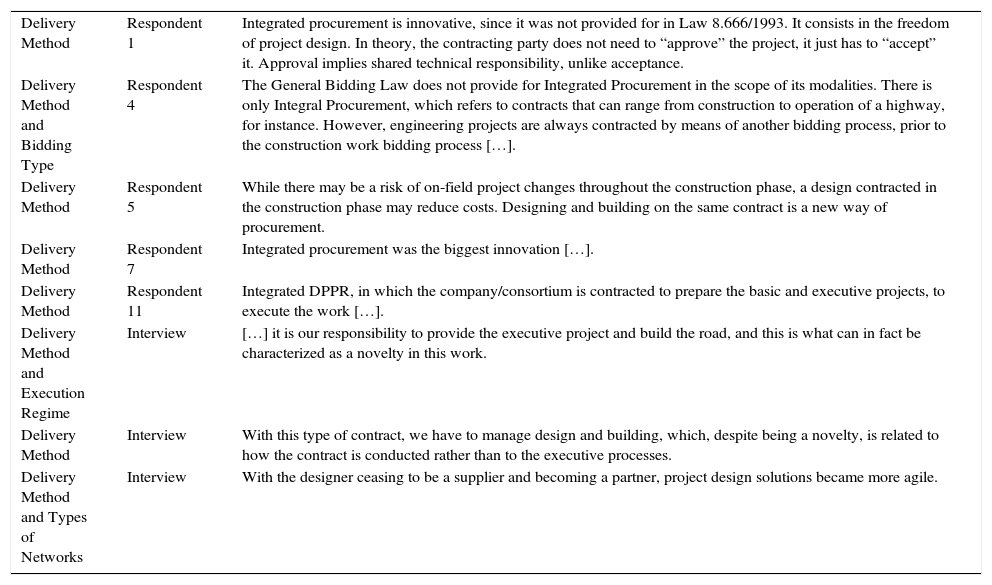

Open-ended Question 9 addresses the delivery method of the object contracted that was adopted by the tender notice. Respondents were asked to identify the innovations introduced by the DPPR regarding the project delivery method (project scope), whose main manifestations were:

| Delivery Method | Respondent 1 | Integrated procurement is innovative, since it was not provided for in Law 8.666/1993. It consists in the freedom of project design. In theory, the contracting party does not need to “approve” the project, it just has to “accept” it. Approval implies shared technical responsibility, unlike acceptance. |

| Delivery Method and Bidding Type | Respondent 4 | The General Bidding Law does not provide for Integrated Procurement in the scope of its modalities. There is only Integral Procurement, which refers to contracts that can range from construction to operation of a highway, for instance. However, engineering projects are always contracted by means of another bidding process, prior to the construction work bidding process […]. |

| Delivery Method | Respondent 5 | While there may be a risk of on-field project changes throughout the construction phase, a design contracted in the construction phase may reduce costs. Designing and building on the same contract is a new way of procurement. |

| Delivery Method | Respondent 7 | Integrated procurement was the biggest innovation […]. |

| Delivery Method | Respondent 11 | Integrated DPPR, in which the company/consortium is contracted to prepare the basic and executive projects, to execute the work […]. |

| Delivery Method and Execution Regime | Interview | […] it is our responsibility to provide the executive project and build the road, and this is what can in fact be characterized as a novelty in this work. |

| Delivery Method | Interview | With this type of contract, we have to manage design and building, which, despite being a novelty, is related to how the contract is conducted rather than to the executive processes. |

| Delivery Method and Types of Networks | Interview | With the designer ceasing to be a supplier and becoming a partner, project design solutions became more agile. |

The perceived innovation was not understood by the respondents as a radical change from the previous format. Improvements have been reported in the supply chain constraint component, which has not been treated as something that could modify or create new markets characteristic of the radical innovations described, according to Davila et al. (2006). An incremental innovation was observed in the supply chain, in the business model leverage, by moving the project supplier into the contracted consortium to deliver the completed work.

All of the inferences made from the answers to the open-ended questions were confirmed by a set of closed questions, with the purpose of verifying the degree of agreement of all respondents.

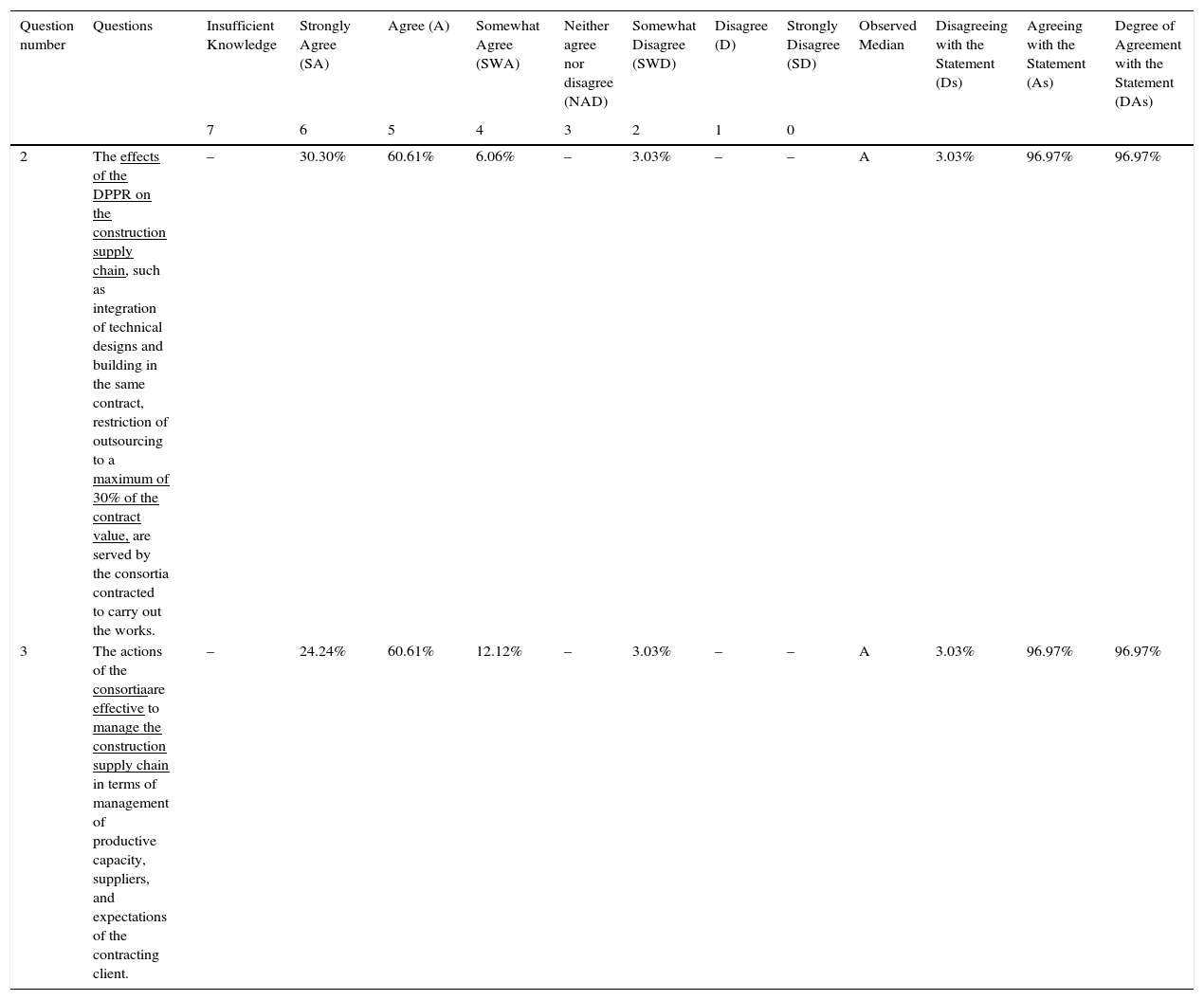

Table 3 indicates the degree of agreement of the respondents to each of the inferences made about the bidding system predicted by the DPPR, arising from the means of each group of closed questions that confirm the inferences.

Relationship between open-ended and closed questions, and degree of agreement.

| Question | Questions | Insufficient Knowledge (IK) | Strongly Agree (SA) | Agree (A) | Somewhat Agree (SWA) | Neither agree nor disagree (NAD) | Somewhat Disagree (SWD) | Disagree (D) | Strongly Disagree (SD) | Observed Median | Disagreeing with the Statement (Ds) | Agreeing with the Statement (As) | Degree of Agreement with the Statements (DAs) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 7 | 6 | 5 | 4 | 3 | 2 | 1 | 0 | ||||||

| 4 | The technical project companies, whether taking part in consortia or outsourced, are effective in terms of the DPPR's requirements. | – | 21.21% | 42.42% | 24.24% | 6.06% | – | 3.03% | 3.03% | A | 9.09% | 90.91% | 90.91% |

| 8 | The project delivery method (Integrated Design-Build Procurement) is serviced by the contractor, as required by the DPPR. | – | 54.55% | 33.33% | 6.06% | 6.06% | – | – | – | SA | 3.03% | 96.97% | 96.97% |

| 12 | Phase reversal during bidding causes the expected reduction in the total bidding process period. | – | 45.45% | 39.39% | 6.06% | 3.03% | 3.03% | 3.03% | – | A | 7.58% | 92.42% | 92.42% |

| 15 | Considering the requirements imposed by the DPPR, the design-build delivery model has proven effective in infrastructure works. | – | 33.33% | 39.39% | 15.15% | 3.03% | 9.09% | – | – | A | 10.61% | 89.39% | 89.39% |

| 16 | The DPPR created agility, economy, and efficiency in the processes of public procurement of works. | – | 36.36% | 42.42% | 12.12% | 3.03% | 3.03% | 3.03% | – | A | 7.58% | 92.42% | 92.42% |

| 19 | Technical projects and building in the same contract allows to save time during the internal phase of public agencies in the contracting process. | – | 45.45% | 33.33% | 9.09% | 3.03% | – | 6.06% | 3.03% | A | 10.61% | 89.39% | 89.39% |

| 20 | Integrated procurement, without prior need of executive projects, makes the DPPR effective and suited for adoption in infrastructure works. | – | 39.39% | 42.42% | 3.03% | 3.03% | 3.03% | 6.06% | 3.03% | A | 13.64% | 86.36% | 86.36% |

| – | Means of questions 4, 8, 12, 15, 16, 19 and 20 | – | 39.39% | 38.96% | 10.82% | 3.90% | 2.60% | 3.03% | 1.30% | A | 8.87% | 91.13% | 91.13% |

| 5 | The contractor companies, in consortium or isolated, meet the DPPR's requirements of price and responsibility matrix. | – | 33.33% | 42.42% | 15.15% | 3.03% | 6.06% | – | – | A | 7.58% | 92.42% | 92.42% |

| 17 | The objectives of the DPPR are all achieved and met when applied to infrastructure works. | – | – | 6.06% | 6.06% | 9.09% | 30.30% | 36.36% | 12.12% | SWD | 83.33% | 16.67% | 83.33% |

| Inversion of meaning of statement 17 to calculate the mean | – | 12.12% | 36.36% | 30.30% | 9.09% | 6.06% | 6.06% | SWA | 16.67% | 83.33% | 83.33% | ||

| 22 | Using the electronic trading system to offer a quotation improves the effectiveness of the value proposed, below the maximum limit established and not previously disclosed by the bidding organization. | – | 9.09% | 9.09% | 6.06% | 21.21% | 24.24% | 24.24% | 6.06% | SWD | 65.15% | 34.85% | 65.15% |

| Inversion of meaning of statement 22 to calculate the mean | – | 6.06% | 24.24% | 24.24% | 21.21% | 6.06% | 9.09% | 9.09% | SWA | 34.85% | 65.15% | 65.15% | |

| – | Means of questions 5, 17, and 22 | – | 17.17% | 34.34% | 23.23% | 11.11% | 6.06% | 5.05% | 3.03% | A | 19.70% | 80.30% | 80.30% |

| 6 | I see an innovation in procurement by the DPPR as to the Bidding type (selection criterion: lowest lump-sum, price, and technique). | – | – | – | 3.03% | 6.06% | 18.18% | 51.52% | 21.21% | D | 93.94% | 6.06% | 93.94% |

| 7 | The execution regime (payment method: unit price, lump-sum, integrated lump-sum) was an innovation in DPPR construction contracts. | – | – | – | – | 3.03% | 18.18% | 48.48% | 30.30% | D | 98.48% | 1.52% | 98.48% |

| 14 | The choice of integrated design and building procurement in a single bidding process and contract is an innovation in the form of procurement. | – | 54.55% | 39.39% | 3.03% | 3.03% | – | – | – | SA | 1.52% | 98.48% | 98.48% |

| 18 | The methods provided for in Law 8.666/1993 were innovated by the DPPR as to how to contract the companies responsible for deploying the construction work | – | 57.58% | 33.33% | 6.06% | 3.03% | – | – | – | SA | 1.52% | 98.48% | 98.48% |

| – | Means of questions 14 and 18 | – | 56.06% | 36.36% | 4.55% | 3.03% | – | – | – | SA | 1.52% | 98.48% | 98.48% |

This analysis category identified what most influenced the construction supply chain as a result of using the DPPR by analyzing the information contained in the responses to the interview and questionnaires.

It can be inferred that the biggest effects caused on the supply chain arise from the restriction of 30% for subcontracting. In addition, it was observed that the DPPR influenced management of the flows of goods and services by moving the supplier of technical engineering projects into a consortium of companies by means of integrated design-build (DB) procurement. Integrated procurement of technical projects and construction was identified by participants as an innovation derived from the use of the DPPR.

It was observed that the presence of the designer in the daily operations of construction works provided agility to the correction actions of projects’ adjustment needs, as inferred by the analysis of participants’ answers and direct observation at the worksites.

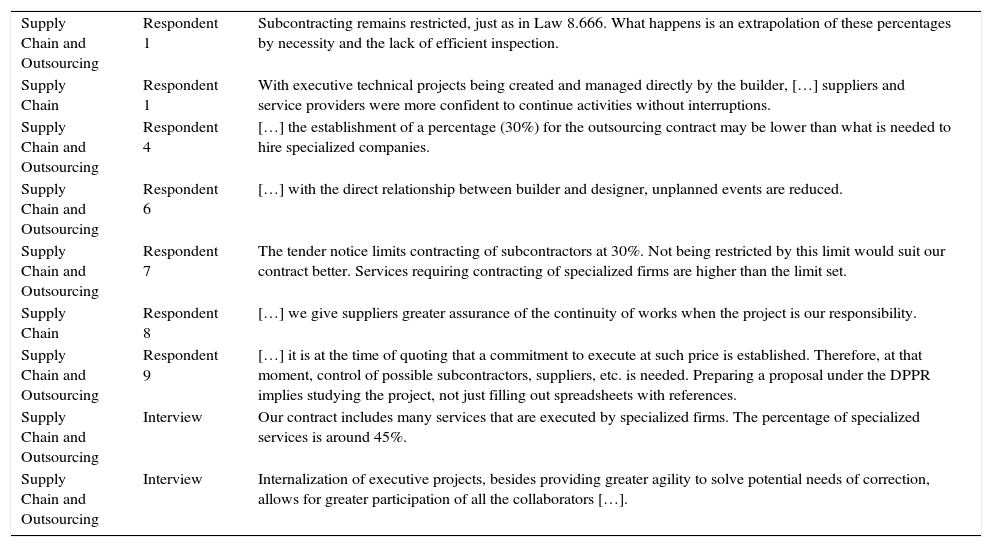

Open-ended Question 3 addressed the effects on the supply chain, and open-ended Question 10 addressed what influenced the supply chain, both effects and influences, as a consequence of using the DPPR. The closed questions related to the topic are questions number 2 and 3. The main statements are found below:

| Supply Chain and Outsourcing | Respondent 1 | Subcontracting remains restricted, just as in Law 8.666. What happens is an extrapolation of these percentages by necessity and the lack of efficient inspection. |

| Supply Chain | Respondent 1 | With executive technical projects being created and managed directly by the builder, […] suppliers and service providers were more confident to continue activities without interruptions. |

| Supply Chain and Outsourcing | Respondent 4 | […] the establishment of a percentage (30%) for the outsourcing contract may be lower than what is needed to hire specialized companies. |

| Supply Chain and Outsourcing | Respondent 6 | […] with the direct relationship between builder and designer, unplanned events are reduced. |

| Supply Chain and Outsourcing | Respondent 7 | The tender notice limits contracting of subcontractors at 30%. Not being restricted by this limit would suit our contract better. Services requiring contracting of specialized firms are higher than the limit set. |

| Supply Chain | Respondent 8 | […] we give suppliers greater assurance of the continuity of works when the project is our responsibility. |

| Supply Chain and Outsourcing | Respondent 9 | […] it is at the time of quoting that a commitment to execute at such price is established. Therefore, at that moment, control of possible subcontractors, suppliers, etc. is needed. Preparing a proposal under the DPPR implies studying the project, not just filling out spreadsheets with references. |

| Supply Chain and Outsourcing | Interview | Our contract includes many services that are executed by specialized firms. The percentage of specialized services is around 45%. |

| Supply Chain and Outsourcing | Interview | Internalization of executive projects, besides providing greater agility to solve potential needs of correction, allows for greater participation of all the collaborators […]. |

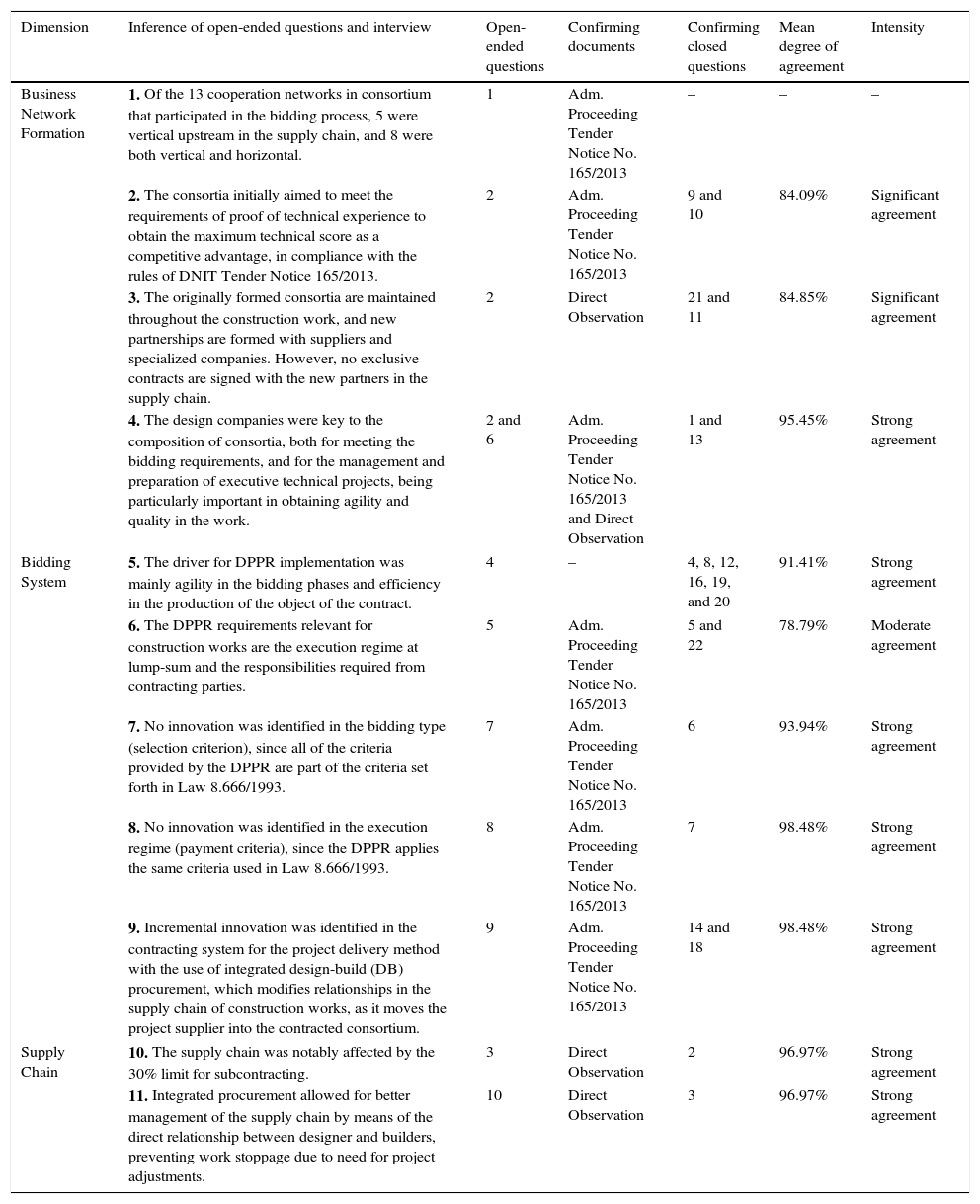

Table 4 shows the closed questions’ statements that address matters related to the supply chain of the case studied. Analysis of these questions was carried out using the criteria and equations described by Sanches et al. (2011) in order to determine the degree of agreement with the statement (DAs) of each of the statements answered by the respondents.

Supply chain: relationship between open-ended and closed questions and degree of agreement.

| Question number | Questions | Insufficient Knowledge | Strongly Agree (SA) | Agree (A) | Somewhat Agree (SWA) | Neither agree nor disagree (NAD) | Somewhat Disagree (SWD) | Disagree (D) | Strongly Disagree (SD) | Observed Median | Disagreeing with the Statement (Ds) | Agreeing with the Statement (As) | Degree of Agreement with the Statement (DAs) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 7 | 6 | 5 | 4 | 3 | 2 | 1 | 0 | ||||||

| 2 | The effects of the DPPR on the construction supply chain, such as integration of technical designs and building in the same contract, restriction of outsourcing to a maximum of 30% of the contract value, are served by the consortia contracted to carry out the works. | – | 30.30% | 60.61% | 6.06% | – | 3.03% | – | – | A | 3.03% | 96.97% | 96.97% |

| 3 | The actions of the consortiaare effective to manage the construction supply chain in terms of management of productive capacity, suppliers, and expectations of the contracting client. | – | 24.24% | 60.61% | 12.12% | – | 3.03% | – | – | A | 3.03% | 96.97% | 96.97% |

It was possible to identify correlations between the analyses of open-ended and closed questions. The questionnaire's closed questions were deliberately prepared in association with the open questions. Table 5 summarizes the results of this study.

Summary of inferences resulting from the analysis of evidences.

| Dimension | Inference of open-ended questions and interview | Open-ended questions | Confirming documents | Confirming closed questions | Mean degree of agreement | Intensity |

|---|---|---|---|---|---|---|

| Business Network Formation | 1. Of the 13 cooperation networks in consortium that participated in the bidding process, 5 were vertical upstream in the supply chain, and 8 were both vertical and horizontal. | 1 | Adm. Proceeding Tender Notice No. 165/2013 | – | – | – |

| 2. The consortia initially aimed to meet the requirements of proof of technical experience to obtain the maximum technical score as a competitive advantage, in compliance with the rules of DNIT Tender Notice 165/2013. | 2 | Adm. Proceeding Tender Notice No. 165/2013 | 9 and 10 | 84.09% | Significant agreement | |

| 3. The originally formed consortia are maintained throughout the construction work, and new partnerships are formed with suppliers and specialized companies. However, no exclusive contracts are signed with the new partners in the supply chain. | 2 | Direct Observation | 21 and 11 | 84.85% | Significant agreement | |

| 4. The design companies were key to the composition of consortia, both for meeting the bidding requirements, and for the management and preparation of executive technical projects, being particularly important in obtaining agility and quality in the work. | 2 and 6 | Adm. Proceeding Tender Notice No. 165/2013 and Direct Observation | 1 and 13 | 95.45% | Strong agreement | |

| Bidding System | 5. The driver for DPPR implementation was mainly agility in the bidding phases and efficiency in the production of the object of the contract. | 4 | – | 4, 8, 12, 16, 19, and 20 | 91.41% | Strong agreement |

| 6. The DPPR requirements relevant for construction works are the execution regime at lump-sum and the responsibilities required from contracting parties. | 5 | Adm. Proceeding Tender Notice No. 165/2013 | 5 and 22 | 78.79% | Moderate agreement | |

| 7. No innovation was identified in the bidding type (selection criterion), since all of the criteria provided by the DPPR are part of the criteria set forth in Law 8.666/1993. | 7 | Adm. Proceeding Tender Notice No. 165/2013 | 6 | 93.94% | Strong agreement | |

| 8. No innovation was identified in the execution regime (payment criteria), since the DPPR applies the same criteria used in Law 8.666/1993. | 8 | Adm. Proceeding Tender Notice No. 165/2013 | 7 | 98.48% | Strong agreement | |

| 9. Incremental innovation was identified in the contracting system for the project delivery method with the use of integrated design-build (DB) procurement, which modifies relationships in the supply chain of construction works, as it moves the project supplier into the contracted consortium. | 9 | Adm. Proceeding Tender Notice No. 165/2013 | 14 and 18 | 98.48% | Strong agreement | |

| Supply Chain | 10. The supply chain was notably affected by the 30% limit for subcontracting. | 3 | Direct Observation | 2 | 96.97% | Strong agreement |

| 11. Integrated procurement allowed for better management of the supply chain by means of the direct relationship between designer and builders, preventing work stoppage due to need for project adjustments. | 10 | Direct Observation | 3 | 96.97% | Strong agreement | |

Particularly with regards to inference 1 indicated in Table 5, related to the networks in consortia, the types observed were evidenced by the correlation between the theoretical framework and the documents analyzed, without the contribution of the study participants, given the theoretical and documentary nature used for this topic.

The inferences perceived by the researchers presented a high degree of agreement by respondents. The lowest degree of agreement was 78.79%, assigned to inference 6. The other inferences showed degrees of agreement above 84%.

Inference 8, which did not identify innovation in the execution regime (payment criteria), and inference 9, which identified incremental innovation in the project delivery method, presented a degree of agreement of 98.48%, indicating a strong intensity of agreement by the respondents.

Inferences 4, 5, 7, 10, and 11 also presented strong intensity of degree of agreement by the respondents, above 90%. For all the above, we verify strong adherence of the researchers’ interpretations to the answers given by the respondents and the interviewee.

Final remarksThis study does not intend to present generalized results for bidding processes, works contracted by means of the DPPR, and cooperative networks among companies in the form of consortium. However, it presents procedures and criteria that may be used in future studies.

According to the participants, prioritization of the maximum technical score, in compliance with the requirements of tender notice, to the detriment of complementary skills, in the search for partners to form consortia may be an indication that companies are failing to form partnerships with a potential to offer proposals with lump-sum costs lower than those presented in tender notice No. 163/2013.

From the reports resulting from the questionnaires and interviews, inadequacy was evident between the requirements of the tender notice for the formation of consortia and the possible partnerships among companies with complementary expertise. A set of liability criteria would be expected, which would naturally induce partnerships among companies that enhance their technical capabilities.

In the bidding system, there was innovation as to project delivery method through the use of integrated design-build procurement. No innovations were identified in the execution regime (service measurement and payment method) and in the bidding type (selection criterion for the best proposal).

Encompassing design and building in the same contract is a technological innovation in the product delivered, which allowed for a more comprehensive scope of design-build contracts, with the lump-sum execution regime and greater agility of the contracting processes and execution of works, which opens the possibility of reducing total costs of projects.

An innovation in the business model, in the supply chain, with the displacement of designers from their position of project suppliers to the interior of the consortium responsible for deploying works, was also characterized, which provided greater agility in the solutions for project adaptation to the needs of the work, with an effective reduction in the time period of the project goals.

The DPPR has created agile, economical and efficient forms for the processes of public procurement of works. In the bidding phase, phase reversal, in which prices are analyzed first, reduces the period of time of the contracting process. Integrated procurement eliminates the period of time for procedures necessary to contract design companies and effective preparation of the project before the construction bid. In the phase of work execution, integrated procurement makes the solutions of technical engineering project adaptations more agile.

The agility perceived in the procurement process by the DPPR is a fundamental factor that can sustain the continuity of its use and maturation. The other objectives pursued by the DPPR law, related to improvements in competitiveness, technological innovations, and the treatment of environmental liabilities, are aspects to be addressed with the maturation of the DPPR.

The respondents pointed out that the DPPR influences the supply chain by restricting subcontracting to 30% of the total contract value. It was verified that specialized services extrapolate the contractual limit of 30%, and that it is necessary to create internal skills to execute the production activities of the specialized services.

Based on the study performed, it was concluded that implementation of the DPPR can contribute to improve the effectiveness of public works procurement in general, not only for construction works related to the sporting events that gave rise to the DPPR.

Conflicts of interestThe authors declare that there is no conflict of interest.

Peer Review under the responsibility of Departamento de Administração, Faculdade de Economia, Administração e Contabilidade da Universidade de São Paulo – FEA/USP.