In the present work, the treatments using sodium hydroxide, flame retardant chemical and combination of both sodium hydroxide and flame retardant changed the physical properties thus reduced the mechanical properties of woven hemp fabric and fabricated composites. However, the treatments increased the fire retardant properties of fabricated composites as indicated by the burning tests, thermogravimetry analyses and limiting oxygen index tests. An assessment based on woods and engineered wood products have shown that the fabricated composites are suitable to be used for building infrastructure materials as an alternative to wood products.

Natural fibre reinforced composites have taken the interest of many researchers since the last two decades due to their potential such as reduction in weight, possible overall cost reduction, reduction in construction time and production of multifunctional components [1,2]. Nevertheless, it should be understood that the characterising these materials towards targeted applications is challenging and applications are found mainly in non-structural parts due to their limitation in mechanical and other properties [3,4]. Looking at the targeted applications such as materials for construction or infrastructure and automotive industries, safety issues especially on their ability to inhibit fire has become a priority for these materials to remain relevant to be used.

There are lots of work done on the fire retardancy and thermal stability of natural fibre reinforced composites [5–16]. Dorez et al. [5] studied the thermal and fire behaviour of natural fibres (hemp, flax, sugar cane and bamboo) reinforced polybutylene succinate (PBS) biocomposites and found that the incorporation of fibres in PBS reduced the thermal stability as well as the time to ignition of composites but increased the mass residue corresponding to the formation of a char barrier. Later, the addition of fire retardant agent, ammonium polyphosphate (APP) to flax fibres led to a hot hydrolysis of PBS and phosphorylation of fibres thus retarded the fire by formation of barrier layer on the biocomposites due to the charring of the matrix and preservation of the fibre skeleton. Kandare et al. [6] studied the fire reaction properties on flax/epoxy laminates and balsa as a core of sandwich composites. Incorporation of ammonium phosphate as a fire retardant agent improved the fire retardant properties of their composites. Lazko et al. [7] studied the effect of several kinds of fire retardant agents (melamine phosphate (MMP), melamine borate (MMB), zinc borate (ZB) and aluminium trihydroxide (ATH)) on the semi-rigid panels. The semi-rigid panels were composed of flax short fibres and pea protein binder. They found that the treatments improved flame resistance and the best result was obtained by incorporating melamine borate (heat release reduced up to 50% and ignition time increased six times from the reference sample). However, the incorporation of flame retardant materials tended to reduce the semi-rigid panels’ mechanical properties.

Another quantitative measurement to evaluate fire retardant of a material is by implementing limiting oxygen index (LOI) test. It shows the minimum amount of oxygen in oxygen–nitrogen mixture required to support complete combustion of a vertically held sample that burns downward from the top. The higher the LOI value, the more effective the flame-retardant treatment [8,9]. Shukor et al. [8] used ammonium polyphosphate in different concentration in their kenaf/PLA mixture and they found that the LOI value increased with the increment of ammonium polyphosphate concentrations. Xu et al. [9] treated hemp fibre with various solutions (nitrogen, phosphorus and boron) with various mixture percentages. They found that the LOI of treated samples increased compared to untreated ones, and the value were different among treated samples. All the composites treated with fire retardant exceeded of surpass the LOI’s minimum value of 28 which is generally classified as a fire retardant material [10]. Thus, a composite material which has higher LOI value than 28 indicates the better fire retardant properties.

Commonly, the method of incorporating fire retardant agent is by adding it during the mixing process between fibre and matrix. However, there are fewer works on applying fire retardant agent to reinforcement directly (especially on hemp fabric) and effect of this treated reinforcement on the composite materials. Therefore, the aim of this work was to investigate the fire retardant properties of the vinyl ester reinforced with woven hemp fabric. The fabrics were firstly treated with sodium hydroxide (NaOH), commercial fire retardant (FR) chemical and the combination of both NaOH and FR (NaOH + FR). Investigation on fire retardant properties was done by means of burning tests, thermogravimetry analyses and limiting oxygen index tests. The characterisation of treated woven hemp fabric and fabricated composites' mechanical properties was also done to analyse the effect of the chemical treatments. An assessment on their mechanical properties was performed in order to analyse the feasibility and readiness of the composites as building construction materials.

2Materials and methods2.1MaterialsA commercial heavy fabric grade woven hemp fabric in plain weave fabric structure was supplied by Hemp Wholesale Australia. The commercial grade of sodium hydroxide (NaOH) supplied by Science Essential Australia and commercial flame retardant (FR) chemical was supplied by Cyndan Chemicals, Australia. According to the supplier, the main active ingredient in this flame retardant is ammonium polyphosphate. Information from the technical and material data sheet says this chemical is water-based, not classified as hazardous, and environment friendly.

2.2Chemical treatments of woven hemp fabricWoven hemp fabrics were treated with sodium hydroxide (NaOH), fire retardant (FR) and combination of both chemicals (NaOH + FR). For the first treatment, fabrics were soaked in NaOH solutions (10% concentration) for 3 h at room temperature. The fabrics were then washed with distilled water for several times to remove excessive alkali from the fabrics. The washed fabrics were dried at room temperature for 8 h, and then oven dried in an electric oven at 100 °C for another 6 h. The dried fabrics were stored in a sealed plastic bag to avoid atmospheric moisture absorption prior to chemical and thermal analyses.

For the FR treatment, according to the supplier, the FR can be used as it is by spraying or dipping, while drying is not necessary. However, in this work, `dip and nip’ method was employed to treat the fabrics. For reference, `dip and nip’ method is generally used in textile and other industries. The nipping process was set carefully so that the chemical uptake was consistently maintained at the range of 100–105%. The treated fabric was then left to dry at room temperature for 8 h.

Whilst for the combination of NaOH + FR, the fabrics was firstly treated with NaOH followed by FR. The treatments were conducted according to the procedures as mentioned above. The abbreviations for woven hemp fabric; untreated, treated with sodium hydroxide, treated with FR chemical and treated with sodium hydroxide combined with FR are UT, NaOH, FR and NaOH + FR, respectively.

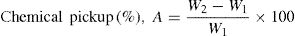

2.3Characterisation of woven hemp fabricIt was predicted that the woven fabrics physically change after the treatments. Therefore, the characterisation on their physical properties was done in order to investigate the composites’ properties later. The chemical uptake or pick-up for all treated woven hemp fabrics were calculated using Eq. (1) [17,18].

where W2 is the weight of fabric after treatment and W1 is the weight of fabric before treatment and both should be in the dry condition.The density of the treated fabric was measured to determine the changes before and after treatment. The density of the hemp fibres was determined by Multipycnometer MVP D160E. Helium gas was used as a displacement medium. The helium was added to the fibres under vacuum conditions to ensure that all interior air cavities in the submerged fibres (e.g. the fibre lumen) were filled with helium. The data reported are the average and standard deviation of 3 measurements.

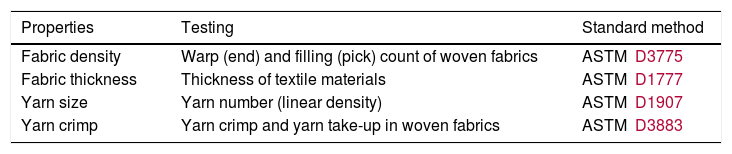

Woven hemp fabric properties were characterised for their thickness and fabric density/fabric count while their yarn was characterised for their yarn size (linear density) and crimp (for warp and weft). All tests were conducted employing several textile materials standard methods as stated in Table 1. These standard methods are commonly used in the textile industry for characterisation as well as product quality determination purposes. Detail measurements on this can be found from previous communication [19].

In order to measure the weight of fabric precisely, the weight of each fabric (untreated and treated) was calculated by calculating the total weight of warp and weft yarn [19]. The weight was measured using Eq. (2) as follows:

where N is the yarn size calculated from Eq. (2), C is the yarn crimp percentage while subscripts 1 and 2 refer to warp and weft yarn respectively. P is the yarn spacing in mm. The measurement and calculation procedures for the yarn size (N), yarn crimp percentage (C) and yarn spacing (P) of the woven hemp fabric are shown in the work by Misnon et al. [19].2.4Composite fabricationMethyl ethyl ketone peroxide (MEKP) was added into vinyl ester with 1:44 ratio by weight to prepare the resin. By applying hand lay-up technique, this resin was then used on 10 fabric layers of 300 × 300 mm. The fabrics were layered in warp and weft alternately. The wet fabrics were then laid in between thick glass plates of 400 × 400 × 10 mm, which were coated with a polymer mould release. This assembly was compressed with a weight placed on top to remove the excessive resin. The calculated pressure applied to this assembly was 4.360 kPa. The assembly was left for the curing at room temperature for 24 h followed by post curing in an oven for 4 h at 80 °C. Four types of composites were fabricated as shown in Table 2.

List of manufactured composite samples.

| Sample abbreviation | Treatment |

|---|---|

| HVE*-UT | Untreated |

| HVE-NaOH | Sodium hydroxide (10%) |

| HVE-FR | Commercial fire retardant chemical |

| HVE-NaOH + FR | Combination of NaOH and FR |

The density of the fabricated composites was determined using similar method and apparatus as discussed in Section 2.3, whilst the constituent contents of the fabricated composites (weight percentage and volume fraction) were determined according to ASTM D3171 test method II. Test method II can be employed since the distribution of fibres in the fabric form (in this case hemp) is acceptably consistent. By the densities and weights of woven hemp fabric, vinyl ester and their fabricated composites are known; the reinforcement and matrix contents were calculated.

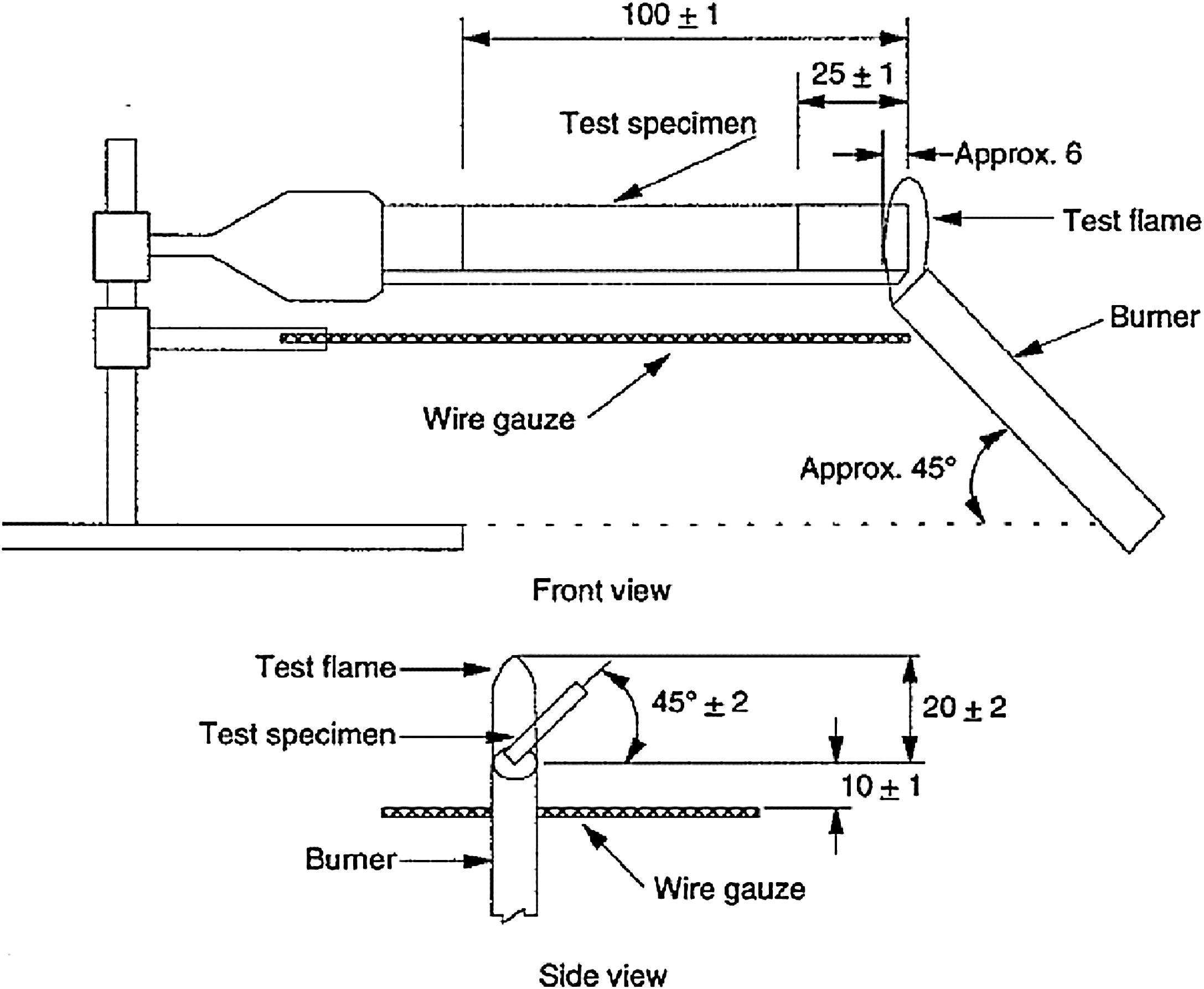

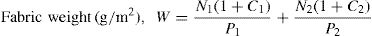

2.6Fire retardant testsThe fire retardant test was carried out according to ASTM D635. This fire response test method was used to compare the relative linear rate of burning of composites in the form rectangular specimen in the horizontal position. Fig. 1 shows a schematic illustration of the flame retardant test fixture. The gas was supplied with a technical grade methane and the measured data were the rate of burning for the material. The burning rate was calculated according to the formula;

where V is the burning rate (in mm/min); L is the burning length (mm); and t is the time (s) for the flame to travel L (mm). The burning rate data reported were the average of five replicated experiments.Test fixture for burning test in accordance with ASTM D635.

Thermogravimetric analyses (TGA) were carried out on a TA Instruments Model TGA Q500, operating under nitrogen and air atmosphere using a platinum pan. The runs were performed over a temperature range between 30 and 600 °C at 10 °C/min heating rate and 20 ml/min flow.

Limiting oxygen index (LOI) is a method to determine the minimum oxygen concentration in an oxygen/nitrogen mixture that sustains the flame. It is a convenient, reproducible, and inexpensive way of determining the tendency of a material to sustain flame. The LOI testing was carried out using an LOI instrument model number of M606 in accordance with ASTM D2863. A test sample of 150 × 50 mm was placed in a transparent test chamber and ignited at the top. The oxygen concentration in the mixture of oxygen and nitrogen was increased slowly until the sample sustained burning. The volume fraction of the oxygen in the gas mixture was reported as the LOI.

2.7Mechanical testsTensile and flexural tests were performed on a universal testing machine (MTS Alliance RT/10). The tensile properties were characterised following ASTM D638. Specimens with dimension of 250 × 25 × 5 mm3 were prepared from the fabricated samples. Cross-head speed for the tensile testing was 2 mm/min. Laser extensometer was used for measuring the axial strain. Ten specimens were tested from each sample and tensile modulus was measured from the initial slope for each specimen.

Flexural test was conducted as per ASTM D790 for evaluating flexural properties of the composites. A three-point bending fixture with cylindrical supports of 5 mm radius was mounted. The span length in this study was 80 mm. The specimen dimension employed in this test was 100 × 12 × 5 mm3. The cross-head speed was 2 mm/min during applying the load. Similar to tensile test, ten specimens were tested for each sample. Specimens were monitored until fibre rupture occurred and at this point, the load was taken to calculate the flexural stress. The flexural modulus was calculated as the slope in the linear range of the stress vs. strain between points at a deflection just above zero.

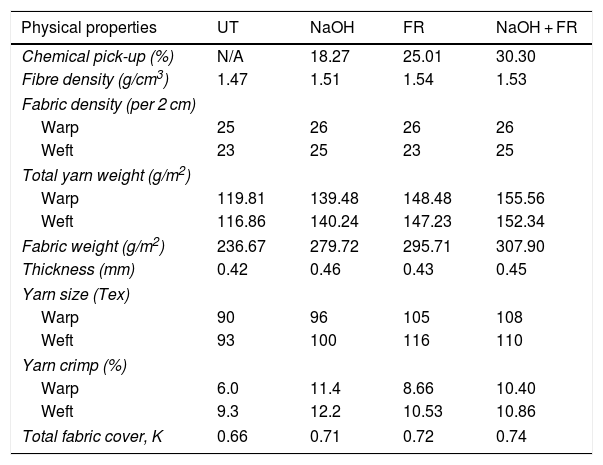

3Results and discussion3.1Effects of fire retardant treatments on the physical properties of woven hemp fabricsChanges of the physical properties of woven hemp fabrics before and after chemical treatment are shown in Table 3. The chemical pick-up of the fabrics was measured based on the changes in weight before and after treatment with the assumption that there was no yarn loss when the treatment was done. Some 18.18% of weight was added to the woven hemp fabric treated with NaOH whilst fabric treated with FR was recorded higher, which was 24.94%. Woven hemp fabric treated with NaOH and FR was recorded even higher obviously due to the deposition of both treatments, which was 30.10%. The density of all treated woven hemp fabrics increased drastically compared to the untreated fabric most probably due to the effect of treatment applied on them. The densities of treated woven hemp fabrics were significantly increased in comparison with untreated samples. The differences of density among treated fabrics were small and can be said insignificant.

Physical properties of all woven hemp fabrics.

| Physical properties | UT | NaOH | FR | NaOH + FR |

|---|---|---|---|---|

| Chemical pick-up (%) | N/A | 18.27 | 25.01 | 30.30 |

| Fibre density (g/cm3) | 1.47 | 1.51 | 1.54 | 1.53 |

| Fabric density (per 2 cm) | ||||

| Warp | 25 | 26 | 26 | 26 |

| Weft | 23 | 25 | 23 | 25 |

| Total yarn weight (g/m2) | ||||

| Warp | 119.81 | 139.48 | 148.48 | 155.56 |

| Weft | 116.86 | 140.24 | 147.23 | 152.34 |

| Fabric weight (g/m2) | 236.67 | 279.72 | 295.71 | 307.90 |

| Thickness (mm) | 0.42 | 0.46 | 0.43 | 0.45 |

| Yarn size (Tex) | ||||

| Warp | 90 | 96 | 105 | 108 |

| Weft | 93 | 100 | 116 | 110 |

| Yarn crimp (%) | ||||

| Warp | 6.0 | 11.4 | 8.66 | 10.40 |

| Weft | 9.3 | 12.2 | 10.53 | 10.86 |

| Total fabric cover, K | 0.66 | 0.71 | 0.72 | 0.74 |

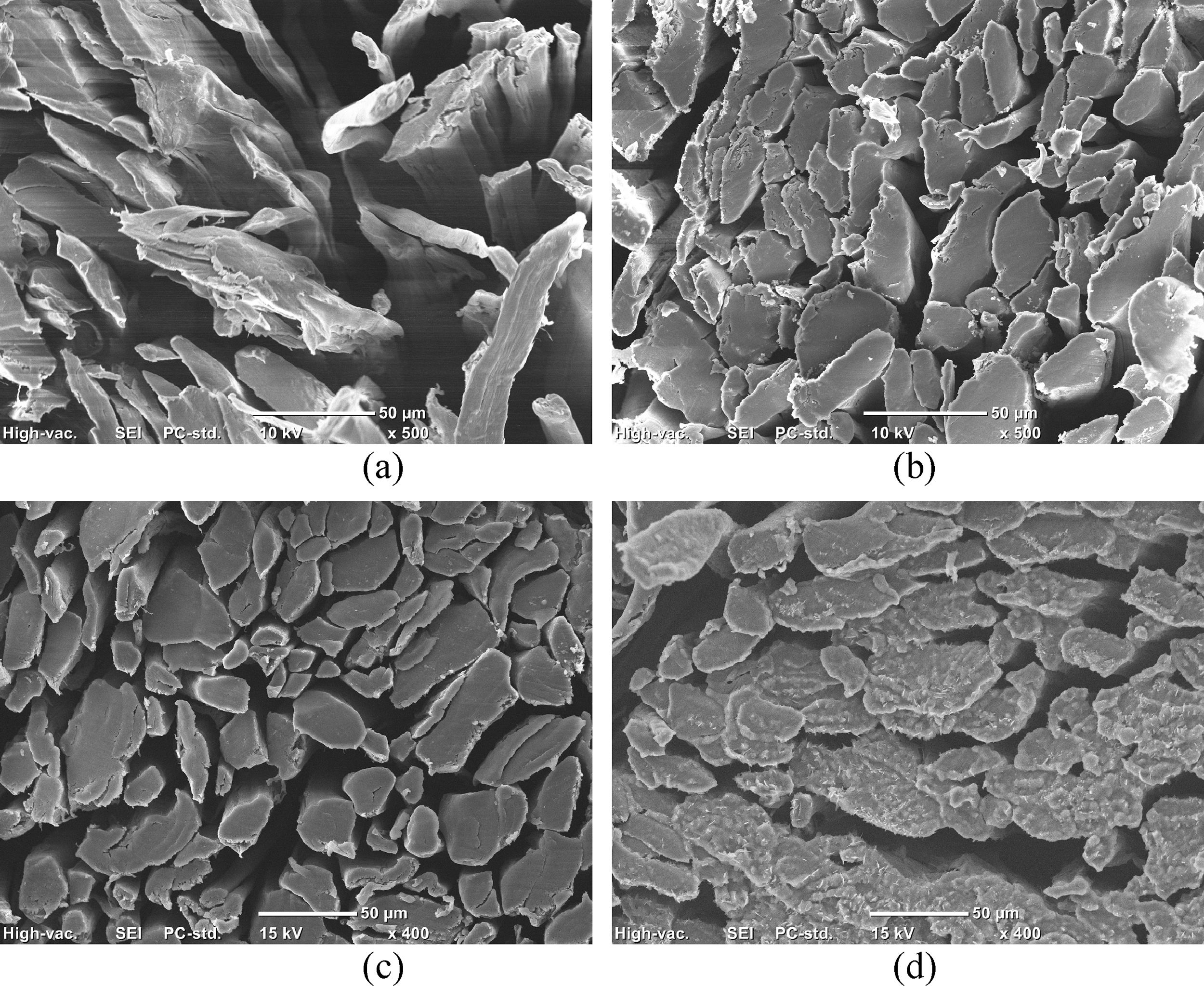

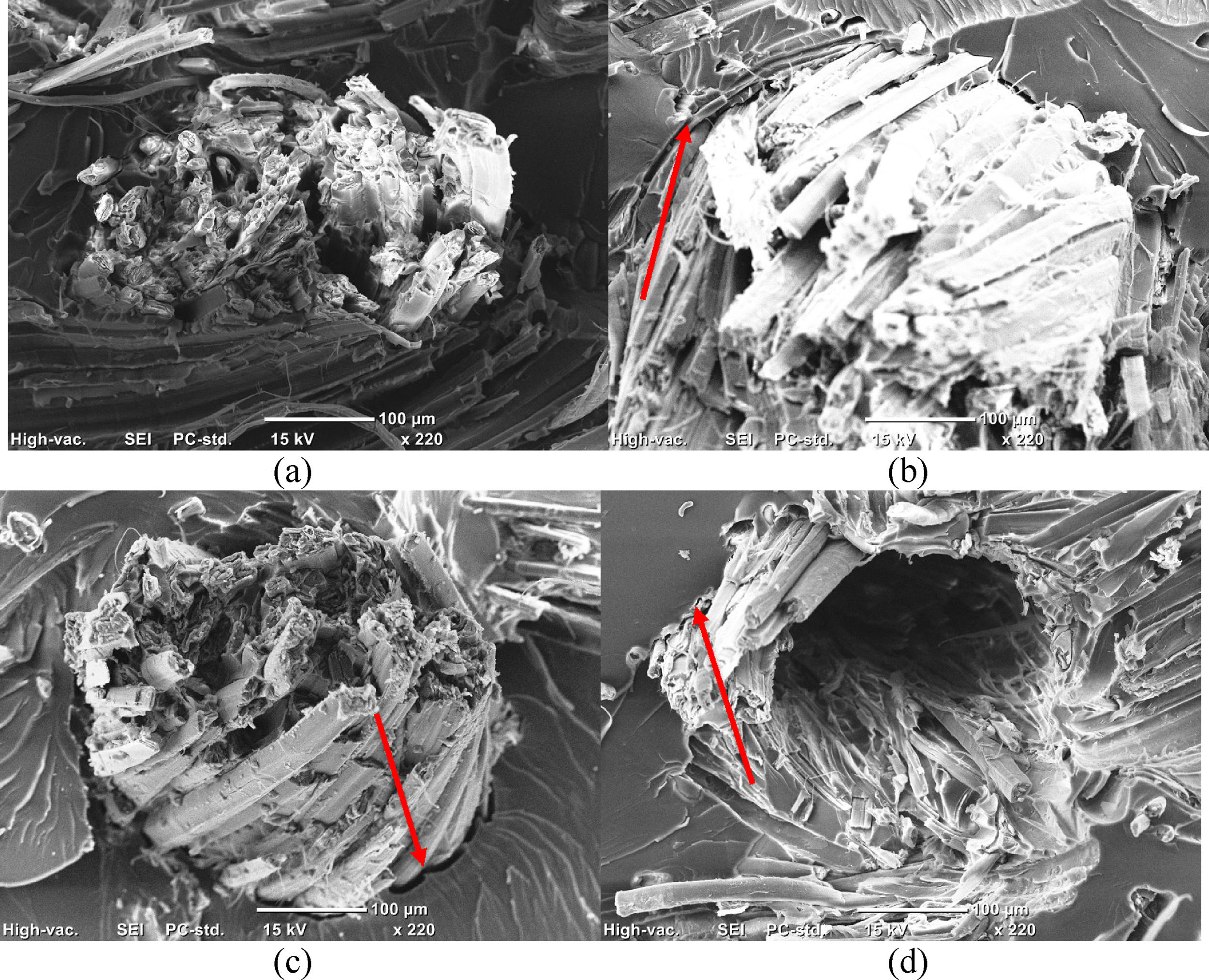

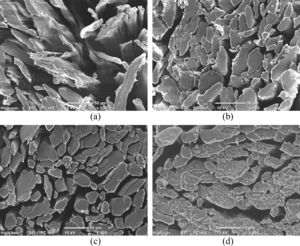

In terms of alkali treatment, this treatment is similar to the `mercerisation’ process of cotton fabric where concentrated alkaline is applied to the cotton fabric meant to increase lustre, hygroscopicity, strength as well as dye affinity of the cotton fabric [20,21]. Since cotton and hemp are categorised under natural textile fibres, similar effect is expected happened to hemp fabric. That means, the removal of hemicellulose and lignin as well as structural modification are happened on the hemp fibres [21,22]. The reduction of hemicellulose and lignin is the reason why the fibre density was increased to 1.51 g/cm3 because when this two compounds decreased, the content of cellulose became higher thus increased the density of fibre [23]. The modification by alkali treatment led to formation of alkali cellulose, physical reaction, to intensive swelling of fibres and structural reactions. When the fibre swelled, its volume underwent considerable changes; increased in water absorption due to the increase of pore size and then led to the increase in cross-section of fibre by 40–50% [20,21]. Scanning electron microscopic image in Fig. 2(a) shows physical aspect of untreated fibres which were thin and in lenticular shape. In contrast to UT, NaOH treated fibres in Fig. 2(b) show that the fibre cross-section became rounder suggesting that the fibres were swollen.

In the case of FR treatment, since the main chemical in FR is ammonium polyphosphate, the presence of phosphorus (or sulphur) derivatives is able to generate acid or acid-forming agents [24]. This acid could also remove some hemicellulose and lignin thus made the hemp fabric increased in its fibre density besides the chemical deposition on the fibres (25.01%) during the treatment. However, the acid is not strong enough to rough the fibres as what happened to the cotton fibre treated with fire retardant in the work by Lam et al. [25]. The treatment also resulted to the swollen fibres and increased the fibre diameter as shown in Fig. 2(c).

The hemp fibre was also swollen when treated with combination of NaOH and FR (NaOH + FR) and this can be seen from Fig. 2(d). This sample exhibited the highest chemical pick-up (30.30%) as a result of the combined treatment with NaOH and FR chemicals. Other than that, the fibres' surfaces were sputtered most probably with salt due to the reaction between the generated acid and pure alkali from FR and NaOH respectively. In addition to the consequences of the treatment, the elimination of hemicellulose and lignin on top of addition of salt on the fibre surface latter caused the increment of the fibre density of this sample.

With reference to Table 3, as a consequence of the swollen fibres, all the treated hemp fabrics experienced some increment on their yarn crimps because the yarn released tension which was developed during yarn spinning, fabric weaving and fabric finishing [25]. This also led to increase in thickness and density of fabric because when the yarn crimped, the whole fabric shrunk due to strict yarn interlacement thus made the fabric thicker and contracted more yarn per area. The total fabric cover also increased due to the fabric shrinking and yarn contraction. The increment in fabric weight was not only due to the yarn crimping which made it shrunk and became thicker but also due the deposition of chemical treatment on the yarns and fibres.

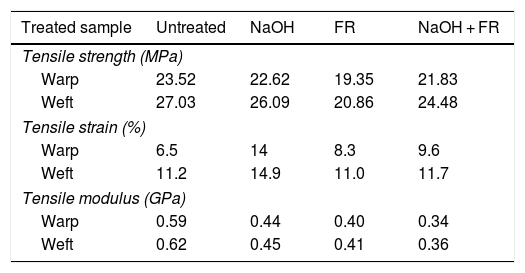

3.2Effects of fire retardant treatments on the mechanical properties of woven hemp fabricsTable 4 summarises the average tensile properties for each woven hemp fabric. The strain percentages were varied due to the different yarn crimp percentage as shown in Table 3. The yarn crimp phenomena have been discussed in Section 3.1. In the warp direction, the hemp fabric sample treated with NaOH exhibited the highest yarn crimp percentage, followed by the fabric treated with NaOH + FR. The lowest yarn crimp was possessed by the fabric treated with FR. For the sample which has higher yarn crimp percentage, it took more time for the yarn to be straightened thus affecting the overall strain percentage of each sample (Table 4).

Summary of tensile properties for all woven hemp fabrics in this work.

| Treated sample | Untreated | NaOH | FR | NaOH + FR |

|---|---|---|---|---|

| Tensile strength (MPa) | ||||

| Warp | 23.52 | 22.62 | 19.35 | 21.83 |

| Weft | 27.03 | 26.09 | 20.86 | 24.48 |

| Tensile strain (%) | ||||

| Warp | 6.5 | 14 | 8.3 | 9.6 |

| Weft | 11.2 | 14.9 | 11.0 | 11.7 |

| Tensile modulus (GPa) | ||||

| Warp | 0.59 | 0.44 | 0.40 | 0.34 |

| Weft | 0.62 | 0.45 | 0.41 | 0.36 |

In terms of tensile strength, the highest was possessed by the untreated hemp fabric and then decreased when the chemical treatments were applied on them. The NaOH treatment removed hemicellulose and lignin partially from the fibres resulting in easy deformation of the cellulose microfibrils during tensile test [22,26]. In the case of hemp fabric treated with FR, some amount of cellulose in the hemp fibre was hydrolysed during the fire retardant treatment which caused minor degradation resulting in the decrease in its strength [25,27,28]. Ammonium polyphosphate compound is an inorganic salt of polyphosphoric acid and it might be dissolved or hydrolysed in acid solution [29,30]. In terms of NaOH + FR treatment, since the fabric was firstly treated with NaOH, the strength was reduced due to the reason discussed above. It was then further decreased a bit due to the FR treatment but since the fibres had already been deposited by NaOH, the FR (ammonium polyphosphate) reacted majorly with NaOH to produce salt. Therefore, the tensile strength of the hemp fabric treated with NaOH + FR was a bit higher than the sample treated with FR.

In terms of tensile modulus in the warp direction, in Table 4, it shows that all treatments reduced the tensile modulus of woven hemp fabric. Apart from the increment of yarn crimp percentage which latter increased the yarn crimp percentage thus decreased the stiffness of fibres, there was another suggestion on this. According to Christian and Billington [31] higher tensile modulus was attributed to the higher fibre density in fabric. Nevertheless, the mechanical properties of woven hemp fabric especially tensile modulus did not entirely agree with the statement made by Christian and Billington [31] because they did not perform any treatment on their hemp fabric. In this work, even though the densities of all treated woven hemp fabrics were higher than untreated sample [28], the treated woven hemp fabrics exhibited lower tensile modulus. This was because all the treatments employed in this work eliminated some hemicellulose and lignin and hence reduced stiffness of woven hemp fabric as other than tensile strength, the stiffness of the hemp fibre was depended on these two compounds [32].

In terms of the weft direction, all the mechanical properties shown in Table 4 followed the similar trend with warp direction except for the tensile strain. The original yarn crimp for weft yarn was longer (9.3%) than warp (6%) (refer Table 3). Nevertheless, it is normal for weft yarn to have a higher yarn crimp than warp yarn due to the tension arrangement during the process of weaving [19,29,33].

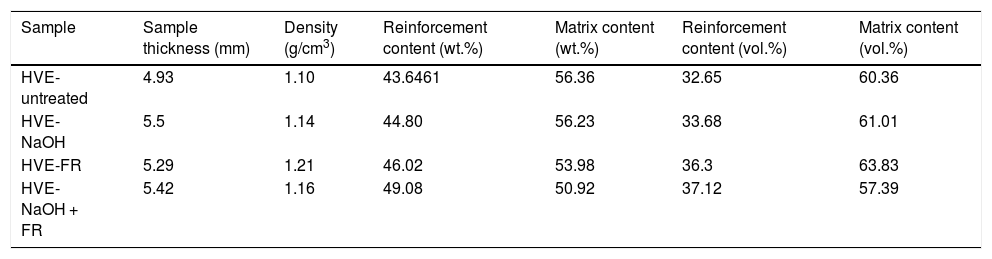

3.3Physical properties of fabricated woven hemp fabric compositesTable 5 shows the results of constituent content of all fire retardants treated woven hemp fabric reinforced vinyl ester composites fabricated in this study. The differences in the density of the samples were due to the higher densities of all treated woven hemp fabrics than the untreated fabric sample (refer Table 3) while the density of vinyl ester resin remained the same which was 1.027 g/cm3. The differences in treated woven fabrics' density, as mentioned above, were due to the swollen fibre as well as the deposition of chemical particle on the fibre and this affected the density and the composition of fabricated composites as shown in Table 5.

Constituent content results of all treated woven hemp composites.

| Sample | Sample thickness (mm) | Density (g/cm3) | Reinforcement content (wt.%) | Matrix content (wt.%) | Reinforcement content (vol.%) | Matrix content (vol.%) |

|---|---|---|---|---|---|---|

| HVE-untreated | 4.93 | 1.10 | 43.6461 | 56.36 | 32.65 | 60.36 |

| HVE-NaOH | 5.5 | 1.14 | 44.80 | 56.23 | 33.68 | 61.01 |

| HVE-FR | 5.29 | 1.21 | 46.02 | 53.98 | 36.3 | 63.83 |

| HVE-NaOH + FR | 5.42 | 1.16 | 49.08 | 50.92 | 37.12 | 57.39 |

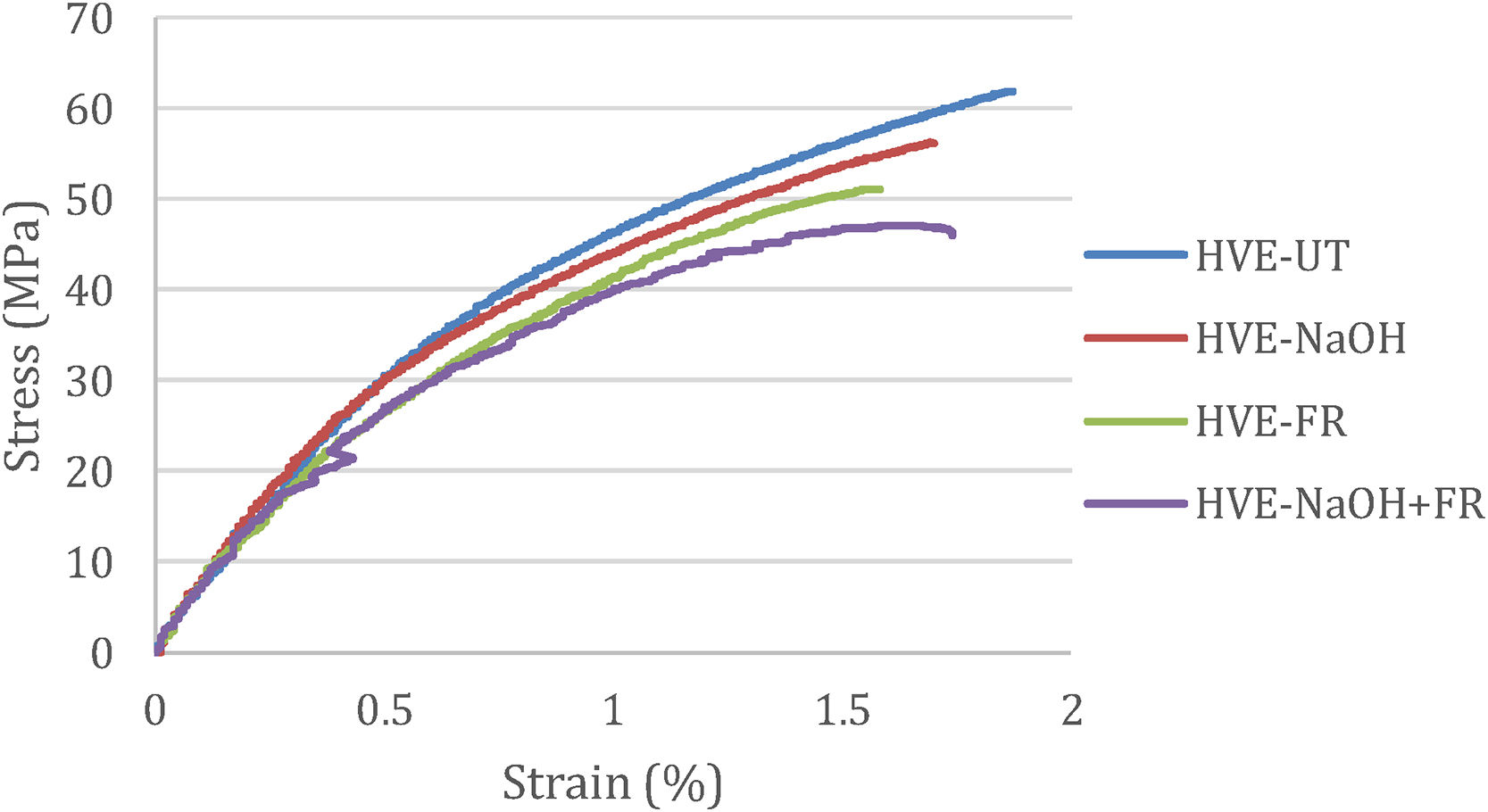

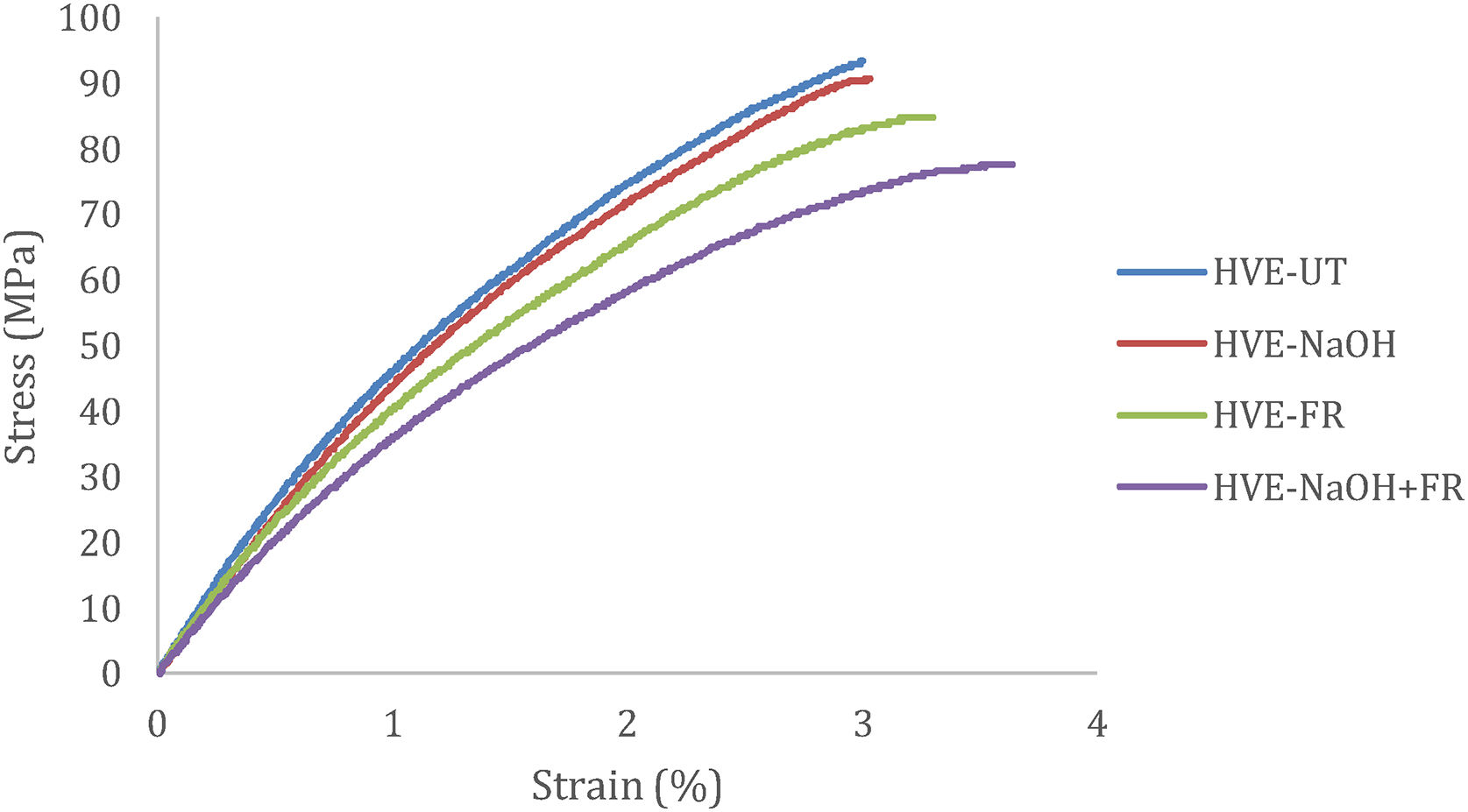

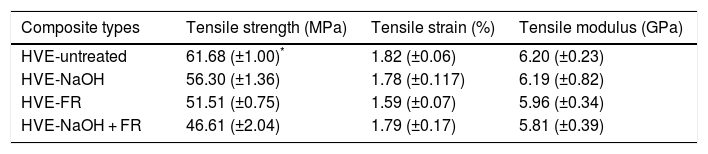

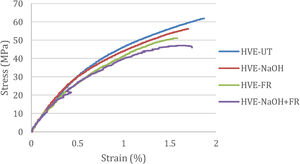

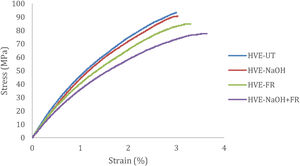

Table 6 shows the average tensile properties for all fabricated composite samples. It is worth mentioning that, it was observed from each sample that the stress–strain behaviour of all specimens cut from a plate were consistent. The typical tensile stress–strain response for each sample is shown in Fig. 3. As it will be discussed further, the typical behaviour showed the linear trend in the earlier stage (strain <0.5%) then became non-linear as the acting tensile force got higher and this was attributed to nonlinear behaviour of the vinyl ester. Unlike thermoplastic, vinyl ester is the thermoset type of resin which is well known to be more rigid and brittle. Therefore, the tensile strain of composite fabricated in this work is likely less than 3%.

Results of tensile properties of all fabricated woven hemp composites.

| Composite types | Tensile strength (MPa) | Tensile strain (%) | Tensile modulus (GPa) |

|---|---|---|---|

| HVE-untreated | 61.68 (±1.00)* | 1.82 (±0.06) | 6.20 (±0.23) |

| HVE-NaOH | 56.30 (±1.36) | 1.78 (±0.117) | 6.19 (±0.82) |

| HVE-FR | 51.51 (±0.75) | 1.59 (±0.07) | 5.96 (±0.34) |

| HVE-NaOH + FR | 46.61 (±2.04) | 1.79 (±0.17) | 5.81 (±0.39) |

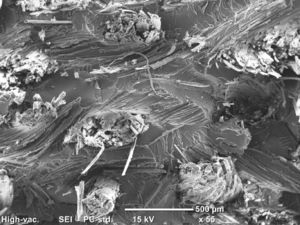

It was observed that when the all specimens were subjected to tensile loading, the specimens faded and lightened in colour (for instance, from light brown to whitish brown) within the gauge length. This was more likely due to the crazing of the matrix, but no cracking was visually observed. No significant cracking was observed between all the samples. Since the fibres were covered by resin, the failure normally happened to start from the resin followed by reinforcement failure [34,35]. The crazing that happened during the tensile loading showed a failure initiation on the vinyl ester resin before the woven hemp fabric.

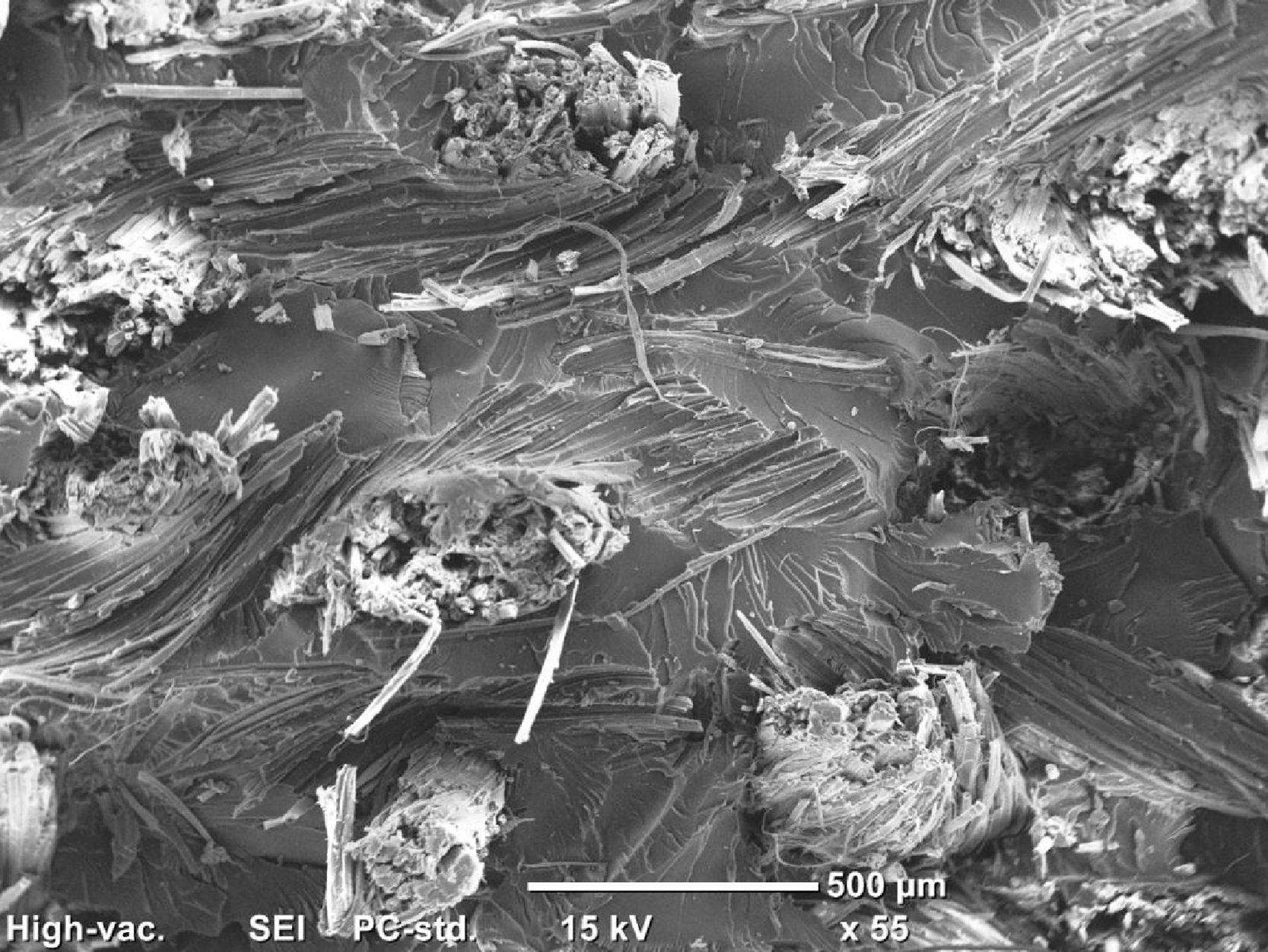

The scanning electron microscopic image in Fig. 4 shows the fracture surface of the composite specimen. The figure confirms the failure mode. While the fibres within the yarn ruptured, the yarn was pulled-out from the matrix at the failure surface of the specimen.

Table 6 shows that the tensile strength of the composite fabricated with treated woven hemp fabrics were lower than sample HVE-UT. Besides the lower tensile strength exhibited by all treated woven hemp fabrics (Table 4), it is believed that the decrement in treated composites' strength was attributed to the poor compatibility between the added treatment and vinyl ester resin. Not only that, the tensile modulus of composite made of treated hemp fabric also exhibited to be lower than the composite made of untreated hemp fabric.

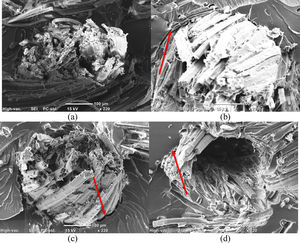

In the case of HVE-NaOH sample, the tensile properties decreased because the hemp fabric was treated with high concentration of alkali (10%). According to Mwaikambo and Ansell [36], a very high concentration of NaOH would certainly damage the fibre and consequently reduced the strength of the fibre. Kenaf composite made by Shukor et al. [8] experienced similar situation with fabricated composites in this work when its strength reduced by the treatment of 9% alkali. They claimed the reduction was due to cell wall thickening, which led to poor adhesion with the matrix. As for the composites made of hemp fabric treated with FR chemical and NaOH + FR, the decrease in their tensile properties was also due to poor compatibility between the fibres which deposited with ammonium polyphosphate deposition and vinyl ester resin [8]. Shumao et al. [37] found that the loading of ammonium polyphosphate on the polylactic acid and ramie fibres resulted to the incompatibility between the fibre and polymer matrix. Fig. 5 shows the tensile fracture surfaces of all fabricated samples in this work that indicated the poor compatibility between reinforcement and matrix (indicated with arrow) to all samples fabricated with treated fabrics. Therefore, based on these results shown in Table 6 and Fig. 5, the chemical treatments applied on the woven hemp fabric degraded the tensile properties of all fabricated composites.

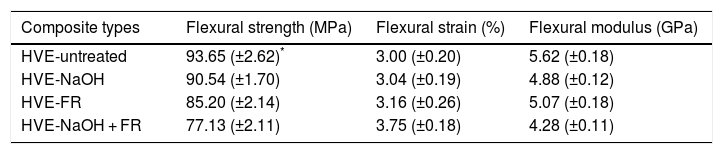

The flexural properties are summarised in Table 7. The typical stress–strain relation for each composite sample achieved from flexural test is shown in Fig. 6. The difference between the samples' response was dependent on different treatment done on the hemp fabrics. The response was similar to tensile one in which the linear parts of the typical behaviour were less than 0.6%, and then they became non-linear as the loading increased, which was attributed to non-linear behaviour of the vinyl ester. All specimens failed in a single crack located at mid-span.

Flexural properties results of all fabricated composites.

| Composite types | Flexural strength (MPa) | Flexural strain (%) | Flexural modulus (GPa) |

|---|---|---|---|

| HVE-untreated | 93.65 (±2.62)* | 3.00 (±0.20) | 5.62 (±0.18) |

| HVE-NaOH | 90.54 (±1.70) | 3.04 (±0.19) | 4.88 (±0.12) |

| HVE-FR | 85.20 (±2.14) | 3.16 (±0.26) | 5.07 (±0.18) |

| HVE-NaOH + FR | 77.13 (±2.11) | 3.75 (±0.18) | 4.28 (±0.11) |

The flexural properties in Table 7 shows the decrement in strength of the fabricated composites made of treated hemp fabric in comparison with sample HVE-UT and this scenario was similar to tensile strength. Again, similar reason with tensile properties, this was attributed to the poor adhesion between the reinforcement with matrix and this incompatibility was due to the treatments applied to the fibres. However, the decrement in flexural properties was about 3.3–17.64% compared to the reduction in tensile properties which was about 8.7–24.43%.

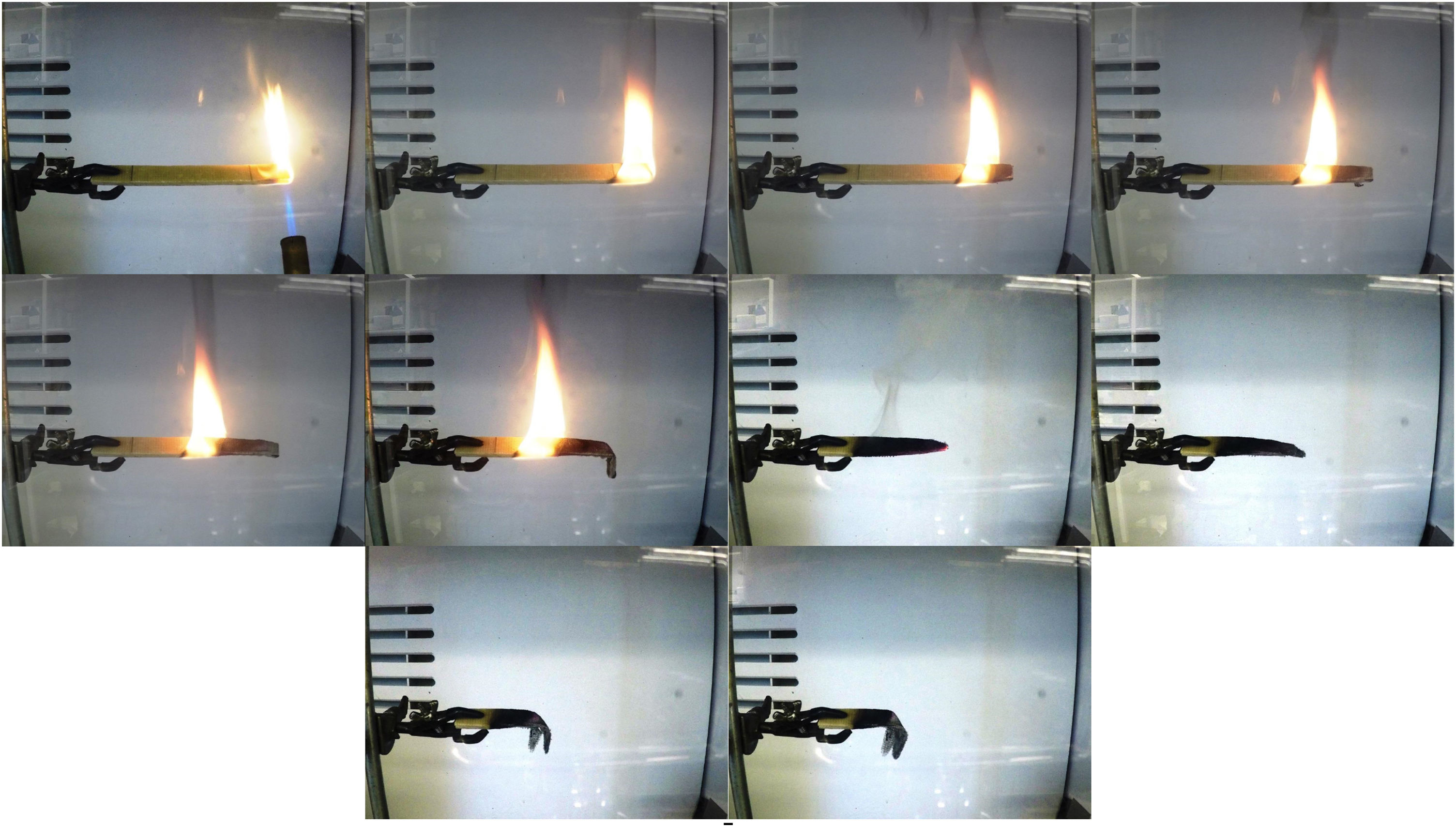

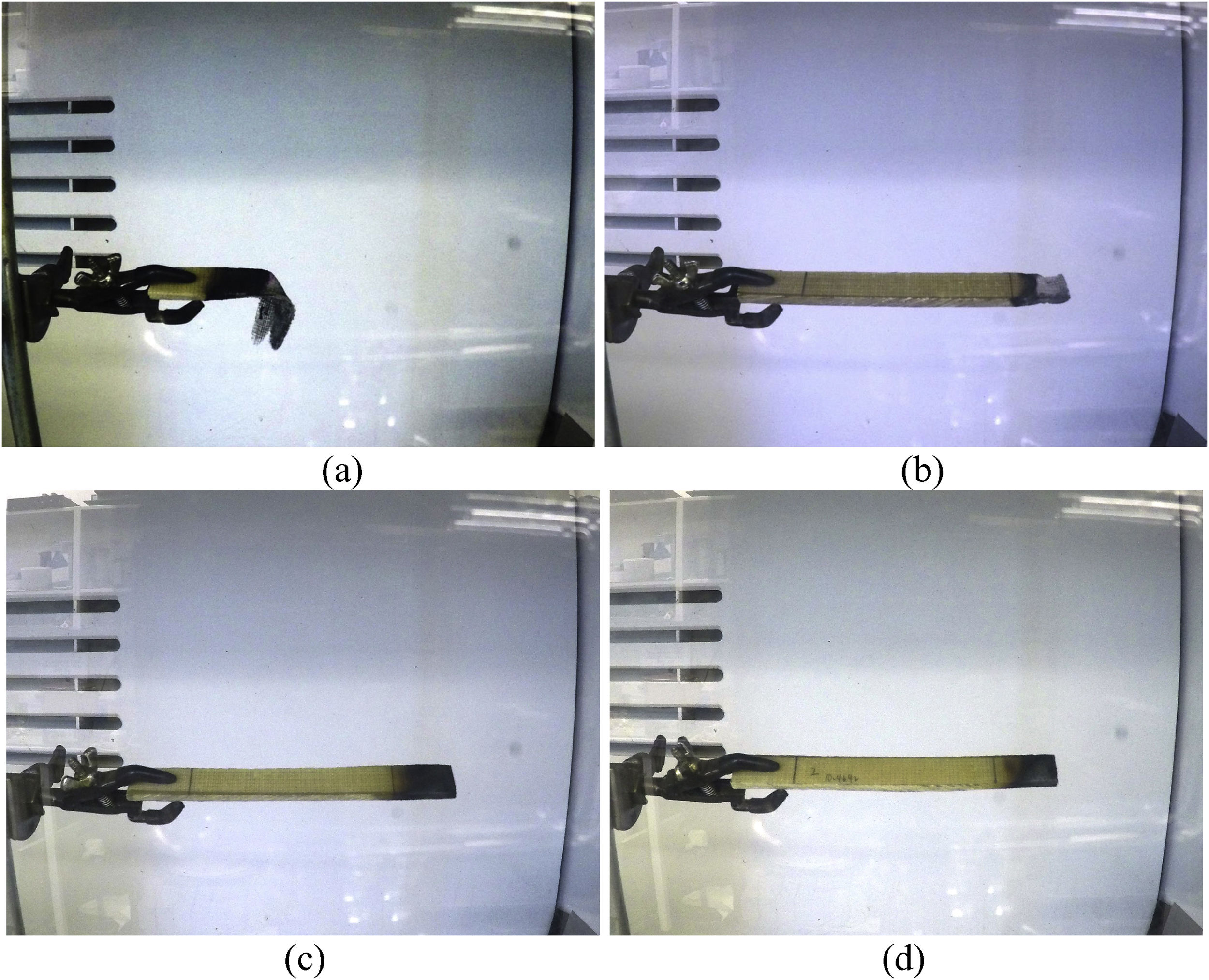

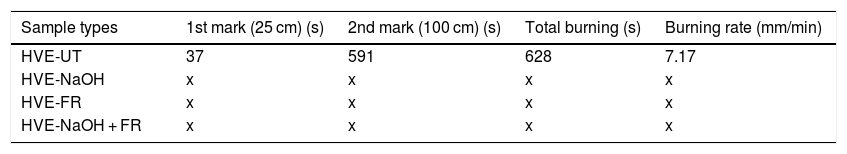

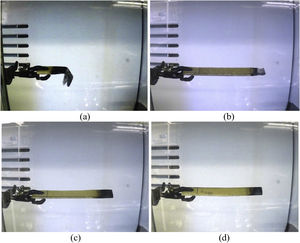

3.5Burning test results of fabricated woven hemp fabric compositesThe results of burning test in accordance with ASTM D635 are shown in Table 8. In this test, each sample was exposed to the flame source for 30 s. Only untreated sample was burnt and the flame had spread until it reached second mark. The total burning time for this sample was recorded as 628 s. It was also observed that the sample was burned in yellow flame and released black smoke and the smell was like the mix of light burnt paper and stronger burnt plastic might be due to the hemp fabric and vinyl ester resin correspondingly. The burning rate of this sample was recorded as 7.17 mm/min. As an example to the test, Fig. 7(a) shows time-elapsed photos of untreated composite sample (HVE-UT) during burning test. The sample was ignited when it was exposed to the flame source and burnt from the very beginning until the second mark (100 mm).

As for sample HVE-NaOH, it was observed that the samples were burning with a yellow flame and was kept burning for 10 s after the flame source was removed. The sample was not burnt even up to the first mark (25 mm). Therefore, according to ASTM D635 burning rate was not possible to measure for this sample. In addition to its burning characteristics, this sample was observed to produce smoke and odour similar to sample HVE-UT. The image of HVE-NaOH subjected to burning test can be seen in Fig. 8(b). From this image, we can see that there was just a small area which was affected by the flame and some part which was burnt by the smoulder and became ash. Based on the discussion above and comparative observation between images in Fig. 8(a) and (b), it is found that the NaOH treatment on the woven hemp fabric increases the fire retardant of the woven hemp composites.

In terms of sample HVE-FR, it shows the good properties against the fibre and this can be proved by the results from Table 8. It was observed that neither ignition nor flame was sparked on the sample after the flame source was removed. However, during the flame exposure, charring process happened in the area where the flame reached. Since the burning was stopped as soon as the flame source was removed, thus the burning did not reach to the first mark. Fig. 8(c) shows the images of sample HVE-FR after subjected to burning test which shows small burnt part of the sample. Similar condition was found in the sample HVE-NaOH + FR when the flame was extinguished as soon as the flame source was removed and the carbonaceous char did not reach the first mark. It was also witnessed that during the test, both samples released black smoke, intense smell plus burnt plastic, burning in a yellow flame and the residue was hard. Sisal fibre reinforced polypropylene composites mixed with ammonium polyphosphate fabricated by Jeencham et al. [38] were not burnt during the burning test (ASTM D635) as compared to untreated sample and they suggested that the fire retardant of this sample was improved. Duquesne et al. [39] fabricated composites using flax woven fabric and bio-based matrix and they found that with the addition of ammonium polyphosphate, their composites were not burnt during burning test. Therefore, based on the results in Table 8 and the images in Fig. 8(c) and (d), HVE-FR and HVE-NaOH + FR showed good resistance and retardancy against the fire due to the treatments imparted on the woven hemp fabric.

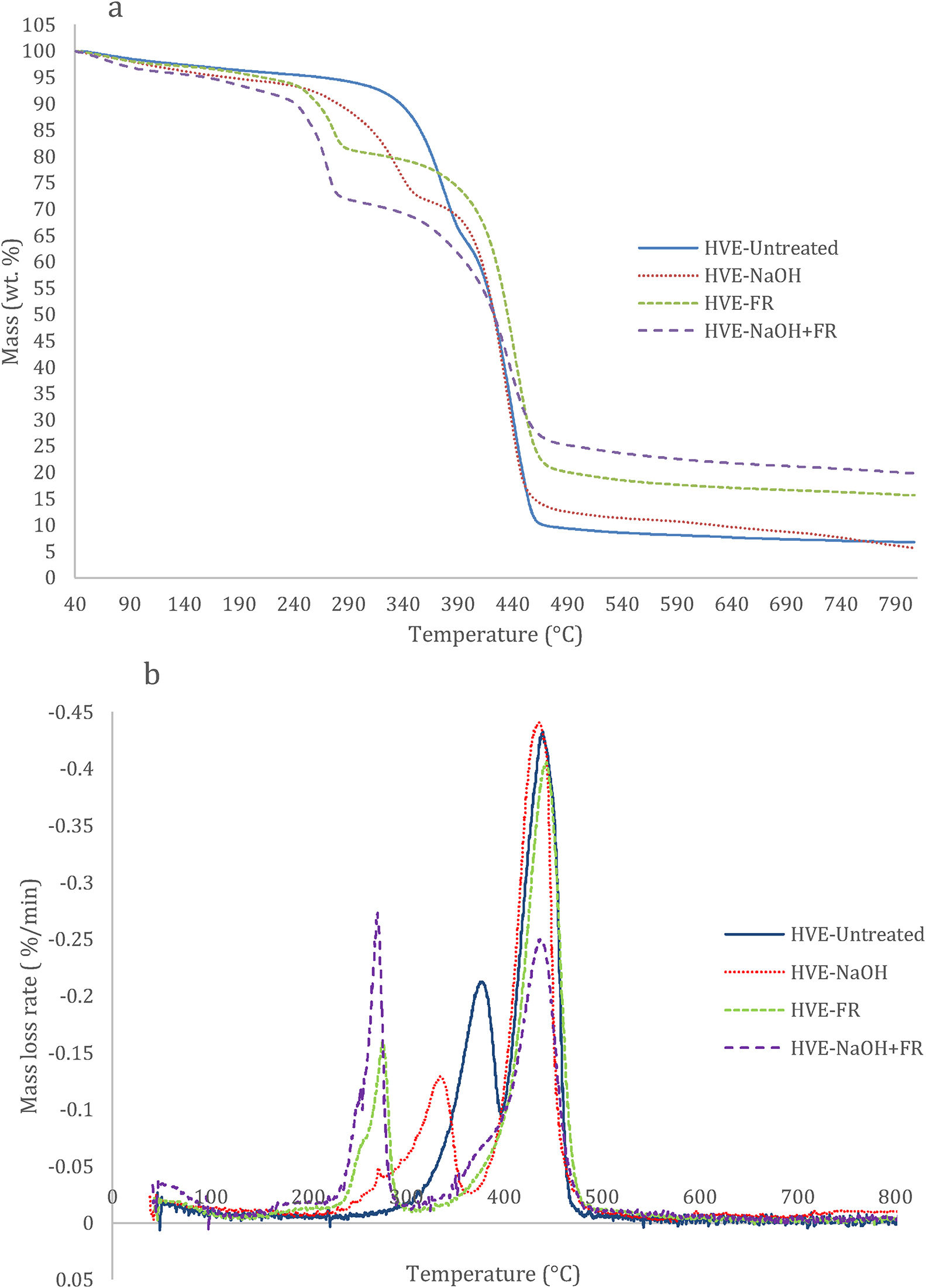

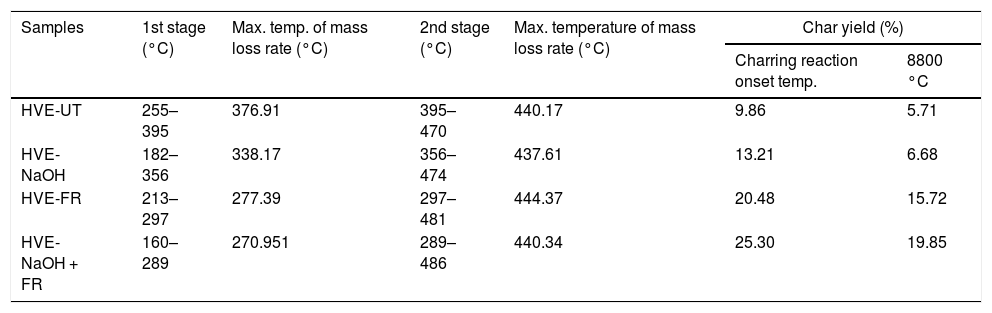

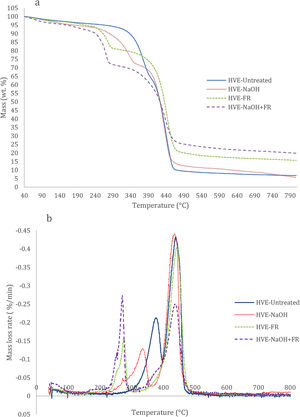

3.6Thermal properties of fabricated woven hemp fabric compositesAnalysis on the thermal decomposition of all treated fabric reinforced vinyl ester composites was carried out by thermogravimetric (TG) and derivatives thermogravimetric (DTG) analyses, and the curves are shown in Fig. 9. While Table 9 shows all thermal analysis data extracted from the TG and DTG curves which show the exact temperature ranges for the first and second stages, their maximum temperature of mass loss rate in each stage and char yield percentages for the present samples. Overall, the decomposition of all fabricated composite samples was divided into two stages. First stage is attributed to the pyrolysis of natural fibre [7,8,40]. According to Yang et al. [41] the decomposition of hemicellulose and cellulose happens at the temperature ranging from 215 to 400 °C. In a specific case of hemp fibre, the decomposition of hemicellulose and cellulose was recorded that ranges from 220 to 400 °C [19]. Thus, the first stage degradation was mainly due to the decomposition of hemp fibres. The second stage, according to Zhang et al. [40], is due to the decomposition of the matrix. The onset degradation temperature of vinyl ester was recorded as 370 °C in the works by Ehsani et al. [42] and Alhuthali et al. [43]. Therefore, it can be said that the degradation on the second stage is attributed mainly to the vinyl ester resin. The decomposition after second stage is due to the char pyrolysis which primarily happens above 400 °C. These two stages of decomposition was also witnessed by other researchers [8,37,38,40].

Data of thermal analysis extracted from TG and DTG curves.

| Samples | 1st stage (°C) | Max. temp. of mass loss rate (°C) | 2nd stage (°C) | Max. temperature of mass loss rate (°C) | Char yield (%) | |

|---|---|---|---|---|---|---|

| Charring reaction onset temp. | 8800 °C | |||||

| HVE-UT | 255–395 | 376.91 | 395–470 | 440.17 | 9.86 | 5.71 |

| HVE-NaOH | 182–356 | 338.17 | 356–474 | 437.61 | 13.21 | 6.68 |

| HVE-FR | 213–297 | 277.39 | 297–481 | 444.37 | 20.48 | 15.72 |

| HVE-NaOH + FR | 160–289 | 270.951 | 289–486 | 440.34 | 25.30 | 19.85 |

With regards to the HVE-UT, the first stage was happened from 255 to 395 °C while the maximum mass loss rate was happened at 376.91 °C (refer Table 9). The total mass loss during this stage was accounted as 35%. This mass loss, as what has been discussed above is attributed to the degradation of hemicellulose and cellulose in the sample [7,8,40,41,44]. Most of the pyrolysis products of cellulosic were produced in this stage and that included L-glucose as a major product and combustible gases [18]. Second stage was happened from 395 to 470 °C while the temperature of maximum mass loss rate at 440.17 °C. It was also observed that, the sample experienced rapid and higher total mass loss (55.2%) in the second stage as compared to the first stage. The behaviour of vinyl ester decomposition in the second stage for HVE-UT is consistent with the vinyl ester resin tested by Ehsani et al. [42] and Alhuthali et al. [43]. The char pyrolysis for HVE-UT was happened starting at 470 °C. Normally, during this process, dewatering and charring reactions are more dominant than of the dehydration of cellulose and decomposition of resin.

In the matter of sample HVE-NaOH, the first stage of decomposition was commenced at 70 °C earlier than the sample HVE-UT which was recorded from 182 to 356 °C. The maximum mass loss rate for this stage was at 338.17 °C with the total mass loss of 28%. The second stage was happened at the temperature starting from 356 to 474 °C while the temperature at the maximum mass loss rate was 437.61 °C and the mass loss was accounted as 59%. In both stages, the decomposition of HVE-NaOH became slow down by reason of the NaOH treatment on the woven hemp fabric in accordance with Mostashari et al. [20]. Hence, in the first stage, NaOH that remained intact with woven hemp fibres absorbed and dissipated the heat thus slowed down the decomposition of hemicellulose and cellulose compounds [45].

The incorporation of NaOH in hemp fibre made it capable to expel water vapour under burning condition. Therefore, it was able to barricade the oxygen accesses and this treatment could act as a dehydrating flame retardant agent. This situation is similar to the several flame retardant generated inert gasses such as CO2, SO2, H2O, NH3, etc. during thermal decomposition thus complicates fuel gas such as oxygen access into the flammable volatiles of combustion product [46]. This situation creates flame retardancy and this mechanism is also known as `gas dilution theory’ [47]. Consequently, slow degradation of vinyl ester in the second stage was caused by the inadequate fuel gas supply on the combustion due to the water vapour barricade which was expelled by the NaOH in hemp fibre.

In terms of sample HVE-FR, the first stage of decomposition was later than the sample HVE-NaOH yet earlier than untreated sample (HVE-UT) which was from 213 to 297 °C. However, the stage offset was earlier than HVE-NaOH and this made the mass loss of HVE-FR during the first stage to be 19%, which indicates that the dehydration of cellulose was happened rapidly thus the char could be formed earlier. The second stage of HVE-FR commenced from 297 to 481 °C with the temperature at maximum mass loss happened at 444.37 °C with the mass loss of about 61%. Char formation can reduce the mass of volatile combustible degradation fragment evolved by making the carbon and hydrogen stay in the condensed phase [48,49]. For this sample, since the reactive ingredient in the flame retardant chemical is ammonium polyphosphate, the char formation is attributed to the presence of ammonium polyphosphate, which promotes polyphosphoric acid that phosphorylates the C(6) hydroxyl groups of the glucopyranose units. In addition, they act as acidic catalysts for dehydrating the glucopyranose units [9,24,50,51]. This phosphorylation eventually avoids the formation of flammable volatiles (i.e. L-glucose) and thus ensures that the competitive char-forming reaction is the favoured pyrolysis pathway. In addition, the high dehydrating power of flame retardants such as ammonium polyphosphate justifies their tendency to form more aromatic chars with respect to organophosphorus molecules [24]. Slow degradation on the vinyl ester resin for sample HVE-FR is because of the FR chemical treatment in the woven hemp fabric. Ammonium polyphosphate may act in the gas phase in polymers. According to Chapple and Anandjiwala [3], phosphorus radicals are released from the polymer at temperatures below that required for decomposition of the polymer. The radicals terminate the combustion process by reacting with H and OH radicals in the flame. Furthermore, heavy volatiles which containing phosphorus may form a vapour-rich phase at the polymer surface that restricts fuel gas access. Thus, the slow decomposition of vinyl ester in the second stage is due to the phosphorus-containing volatiles on the resin surfaces which act as a barrier to the fuel gas released by the vinyl ester to reach with the flame radicals. This phosphorus-containing volatile is released from the first stage decomposition (lower temperature than the polymer decomposition) because the ammonium polyphosphate is applied on the woven hemp fabric.

Regarding the sample HVE-NaOH + FR, the first stage of decomposition was also commenced earlier than the sample HVE-UT which was recorded as 160–289 °C and this was also observed earlier than other treated composite samples (HVE-NaOH and HVE-FR). The mass loss at the first stage was 28% and the maximum mass loss at this stage was happened at 270.95 °C. The second stage was happened from 289 to 486 °C in which the maximum mass loss temperature was at 440.34 °C with the mass loss accounted as 46.7%. This suggests that the combination of NaOH and FR treatment increases the dehydration of cellulose even faster and increases thermal stability.

The char yield percentages for all fabricated composite samples were also extracted from the thermogravimetric curves and shown in Table 9 at the char reaction onset temperature (at the end temperature of second stage) and 800 °C. The char yield percentages at the char reaction onset temperature in high-to-low order were HVE-NaOH + FR, HVE-FR, HVE-NaOH and HVE-UT with the value of 25.30, 20.48, 13.21 and 9.86% respectively. Whereas, at the end of thermogravimetric tests (800 °C), similar trend of char yield for all samples in high-to-low order was found with the value of 19.85, 15.72, 5.68 and 5.71% respectively. The highest char yield possessed by NaOH + FR sample was most probably due to the synergistic between NaOH and FR which surpassed the effect of NaOH and FR alone on the woven hemp fabric. Xu et al. [9] suggested that the fire retardant properties increased with the increase of char yield. Thus, in terms of thermogravimetric analyses, combination of NaOH and fire retardant treatment could give highest thermal stability of the woven hemp fabric reinforced vinyl ester composite as well as char yield which suggesting the best fire retardant properties in comparison to all other samples. This was followed by sample HVE-FR, and lastly HVE-NaOH. Overall, it can be implied that all the treatments not only increase the thermal stability of woven hemp fabric but also the whole system of the composite.

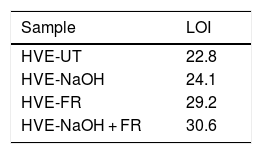

3.7Limiting oxygen index results of fabricated woven hemp fabric compositesLimiting oxygen index (LOI) measurement test is widely used to evaluate the flammability of materials. It shows the minimum amount of oxygen in oxygen–nitrogen mixture required to support complete combustion of a vertically held sample that burns downward from the top. The higher the LOI value, the more effective the flame-retardant treatment [8,9]. It is worth mentioning that there is no indication in ASTM D2683 about the level of fire retardant based on the LOI value. However, according to Kamath et al. [10] LOI value more than 28 is generally classified as fire retardant. In accordance with GB50222-1995 standard method (which is equivalent to ASTM D2683), (1) the value <24 indicates the material is flammable; (2) the value ≥24 and <27 indicates the material is combustible, and; (3) the value ≥28 indicates the material is fire retardant.

The LOI results shown in Table 10 can explain the fire retardant phenomenon discussed in Section 3.5. The highest LOI value was shown by sample HVE-NaOH + FR which was a bit higher than the sample HVE-FR due to the advantages from the combination of NaOH and FR treatments on the woven hemp fabrics. The significant reduction in the LOI values was recorded for the sample HVE-NaOH in comparison with two other treated composite samples, and untreated sample (HVE-UT) possessed the lowest value among all samples.

The LOI value for HVE-UT was lower than 21, thus the hemp fabric is classified as flammable material. That is why untreated hemp was burnt to the whole fabric and left very minimal residue in the burning test. Treatment with NaOH on the hemp fabric increased the LOI value of sample HVE-NaOH to 24.1 and this is clustered under combustible material. When the sample HVE-NaOH was subjected to burning test, the ignition of fire produced yellow flame. Even though the flame can be self-extinguished, the smoulder was produced and kept burning the char residue into ash (refer section 3.5 and Fig. 8(b)), thus it can still be burnt by the exaggeration of other fire sources.

Sample HVE-FR’s LOI value was more than 28, thus this sample is clustered as a fire retardant. During burning test, there was no ignition or smoulder had produced but the char after the flame was removed. The LOI of kenaf reinforced polylactic acid composite made by Shukor et al. [8] increased from 27.6 to 31.6 with the incorporation of ammonium polyphosphate. Similar results with the ramie reinforced polylactic acid was found by Shumao et al. [37] where the LOI increased ranging from 28.1 to 35.6. Therefore, it can be assumed that the ammonium polyphosphate content compound in the fire retardant chemical contributed to the higher LOI value to the fabricated composite in this work.

In the case of HVE-NaOH + FR, the increment of LOI value might be due to the synergistic effect between phosphorus-containing volatiles [3], and expelled water vapour by the NaOH release during the first stage of decomposition, which suggested that the fire retardant properties of this sample was increased. However, in terms of physical burning characteristics, there was no difference observed between samples HVE-NaOH + FR and HVE-FR.

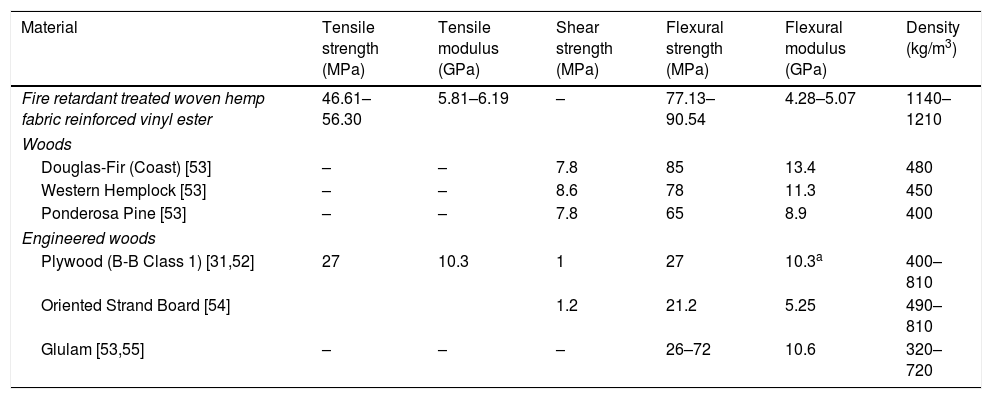

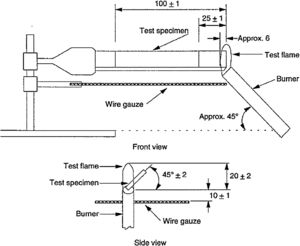

3.8Assessment on the applicationsAll Natural based composite materials have properties mostly similar to wood and engineered wood products [31]. A comparison is briefly presented here, focusing on properties of several woods commonly used as building infrastructure materials, namely Douglas Fir (coastal), Western Hemlock and Ponderosa Pine, and also to the engineered wood products such as plywood, oriented strand board (OSB) and glue laminated timber (glulam). Table 11 shows the ranges of the mechanical properties of all fire retardant woven hemp fabric reinforced vinyl ester composites (HVE-NaOH, HVE-FR and HVE-NaOH + FR) tested here, and some woods and engineered wood products used in construction. The mechanical properties of these woods and engineered wood products are emphasised on the flexural properties since infrastructure material prone to be exposed to flexure or compression load. Thus most of the results on the wood and engineered wood products in Table 11 do not expose the tensile properties of their products. It is also worth mentioning that the mechanical properties of wood and engineered wood product are tested in parallel in grain except for the flexural modulus of plywood.

Mechanical properties of fire retardant treated woven hemp fabric composites, wood and engineered wood products.

| Material | Tensile strength (MPa) | Tensile modulus (GPa) | Shear strength (MPa) | Flexural strength (MPa) | Flexural modulus (GPa) | Density (kg/m3) |

|---|---|---|---|---|---|---|

| Fire retardant treated woven hemp fabric reinforced vinyl ester | 46.61–56.30 | 5.81–6.19 | – | 77.13–90.54 | 4.28–5.07 | 1140–1210 |

| Woods | ||||||

| Douglas-Fir (Coast) [53] | – | – | 7.8 | 85 | 13.4 | 480 |

| Western Hemplock [53] | – | – | 8.6 | 78 | 11.3 | 450 |

| Ponderosa Pine [53] | – | – | 7.8 | 65 | 8.9 | 400 |

| Engineered woods | ||||||

| Plywood (B-B Class 1) [31,52] | 27 | 10.3 | 1 | 27 | 10.3a | 400–810 |

| Oriented Strand Board [54] | 1.2 | 21.2 | 5.25 | 490–810 | ||

| Glulam [53,55] | – | – | – | 26–72 | 10.6 | 320–720 |

Flexural strength of all treated composites is comparable to the woods and engineered wood products. In terms of flexural modulus, woven hemp fabric composite is roughly half or even lower than that of wood parallel to grain. Nevertheless, it is reported by Hurd [52] that the flexural modulus of wood perpendicular to the grain is about 11–35 times less than parallel to grain. Therefore, while the wood examples given in Table 11 are stronger and stiffer than all treated composites in one direction, these treated composites have more balanced bi-directional strength and stiffness, as expected.

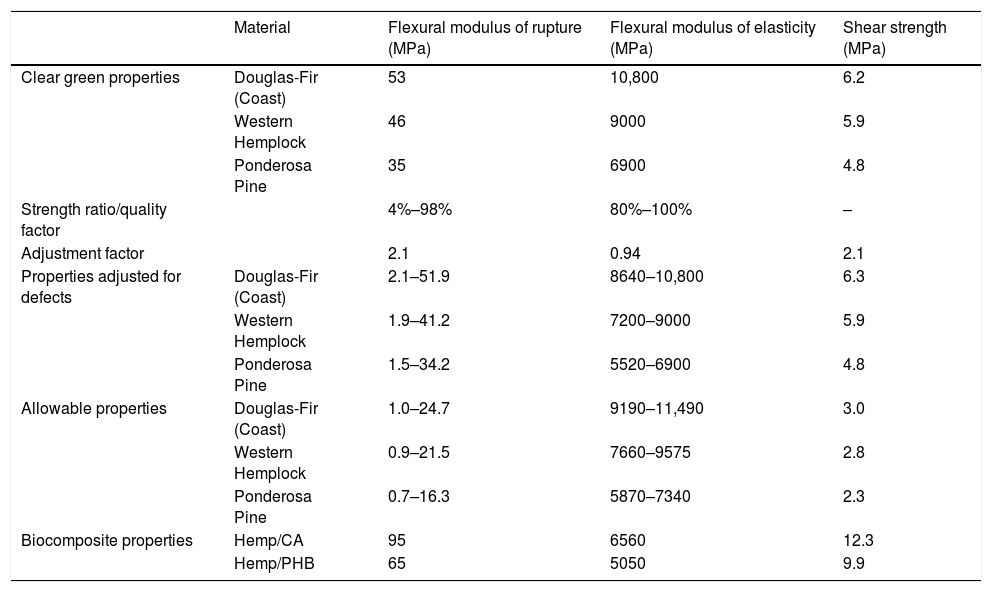

Table 12 shows the allowable mechanical properties used for design with the woods considered here in comparison with biocomposites made by Christian and Billington [31] as per ASTM D245. They expected that their biocomposites possess higher mechanical properties than the allowable wood design except their modulus of elasticity. Similar expectation can be made for the case of treated composites (fire retardant treated woven hemp fabric reinforced vinyl ester composites) fabricated in this study since its mechanical properties were recorded comparable (refer Table 11) to the biocomposites in Table 12.

Allowable design properties of several woods used in construction [31].

| Material | Flexural modulus of rupture (MPa) | Flexural modulus of elasticity (MPa) | Shear strength (MPa) | |

|---|---|---|---|---|

| Clear green properties | Douglas-Fir (Coast) | 53 | 10,800 | 6.2 |

| Western Hemplock | 46 | 9000 | 5.9 | |

| Ponderosa Pine | 35 | 6900 | 4.8 | |

| Strength ratio/quality factor | 4%–98% | 80%–100% | – | |

| Adjustment factor | 2.1 | 0.94 | 2.1 | |

| Properties adjusted for defects | Douglas-Fir (Coast) | 2.1–51.9 | 8640–10,800 | 6.3 |

| Western Hemplock | 1.9–41.2 | 7200–9000 | 5.9 | |

| Ponderosa Pine | 1.5–34.2 | 5520–6900 | 4.8 | |

| Allowable properties | Douglas-Fir (Coast) | 1.0–24.7 | 9190–11,490 | 3.0 |

| Western Hemplock | 0.9–21.5 | 7660–9575 | 2.8 | |

| Ponderosa Pine | 0.7–16.3 | 5870–7340 | 2.3 | |

| Biocomposite properties | Hemp/CA | 95 | 6560 | 12.3 |

| Hemp/PHB | 65 | 5050 | 9.9 |

From Table 11, all treated composites fabricated in this study have higher mechanical strength compared to the engineered wood products. However, flexural modulus of fabricated composites only comparable with the oriented strand board but lower than glulam. The flexural modulus of plywood stated in Table 11 is for a ply parallel to grain. However, in practice, the plies are always in a combination of parallel and perpendicular to grain thus make the modulus 35 times smaller than parallel to grain. Therefore, the modulus of treated composites can be considered comparable with plywood.

With the assessment shown in Table 11, the composite fabricated in this study can be used as an alternative to engineered wood products and woods. Christian and Billington [31] suggested that in order for these treated composites to be used in non-structural and structural components, increasing the moment inertia is the most priority, so as these materials are comparable to wood since the actual stiffness is a combination of the modulus of elasticity, E, and the moment of inertia, I. Some other advantages of these treated composites are, easy to tailor its properties and able to mould into structural shapes (including hollow sections). The only significant problem with the woven hemp fabric composite is its greater densities (1000–1100 kg/m3) as compared to the woods and engineered wood products (320–810 kg/m3). In order to replace wood products, a composite should be engineered to be lighter weight.

4ConclusionsSeveral composite materials were fabricated utilising woven hemp fabric treated with NaOH, a commercial fire retardant (FR) and combination of both chemicals to reinforce vinyl ester resin. Characterisation of the physical and mechanical properties was done in order to analyse the effect of the treatments on the woven hemp fabric as well as the fabricated composites. All the treatments increased fabric weight, yarn crimp, fabric thickness and density of fabric and fibre density due to the swollen hemp fibres, deposition of FR particles and salts on the hemp fibre surfaces. The treatments also decreased the mechanical properties of woven hemp fabric by elimination of hemicellulose and lignin during NaOH treatment and dissolution or hydrolisation of some amount of cellulose during FR treatment. The changes in the physical properties of the fabricated composites were due to the changes in the woven hemp fabric properties especially the increment of fibre density after the treatments.

SEM micrographs confirm that while the fibres within the yarn ruptured, the yarn was pulled-out from the matrix at the failure surface. The mechanical properties of woven hemp fabric composites were decreased after the treatments due to some reasons; the decrement of woven hemp fabrics' mechanical properties and the incompatibility or poor adhesion between the fibre and vinyl ester resin due to the treatments imparted. NaOH treatment thickened the cell wall of hemp fibre and the existence of ammonium polyphosphate on the fibre surface led to poor adhesion with the vinyl ester. However, the treatments increased the fire retardant properties of the composites and this was proven by the enhancement of their thermal stability and the increment on their limiting oxygen index values compared to untreated composite. In terms of the feasibility and readiness for the application in building infrastructure industry, the assessment by matching its mechanical properties with common wood products revealed that all treated composites were still comparable and can be used as an alternative to woods and engineered wood products.

Among all of the treated composites fabricated in this work, sample HVE-FR can be said to be the best, considering the good mechanical properties it possesses and the most important is, it exhibited good properties against the fire.

The authors would like to thank the Ministry of Higher Education, Malaysia and Universiti Teknologi MARA, Malaysia for providing the scholarship to the first author on doing this work.