Valorization of waste plastic as concrete aggregates has become an opportunity. Some advantages are plastic waste recycling, consumption reduction of natural aggregates and improvement of concrete properties. This paper presents a review on addition of recycled plastic waste to cement composites and influence on their properties. Forty five international papers were selected from scientific peer-reviewed journals. The critical items analyzed were: plastic characteristics, mix proportion design and concrete properties. The last item includes fresh and hardened concrete properties, durability performance and thermal conductivity. Although some properties were negatively influenced by the plastics, this paper focuses on the variables that mitigate these effects. The improvement of insulation properties with plastic is widely analyzed, but further research is recommended. As conclusion, application of plastic waste would be useful on both, technical and environmental dimensions and this paper could be used as a helpful tool for studying and designing mortars and concrete composites with recycled plastic.

Solid waste valorization provides a possibility to take advantage of the resources contained in it as supplies or raw materials, within the framework of a Circular Economy. Since concrete is one of the most commonly used construction materials in the world, the use of recycled materials as substitutes of its components, particularly coarse and fine aggregates, has become an opportunity. Plastic is one of those potential waste materials and there are three possible ways of including it in concrete and mortar. The first one is as resin, to produce polymer concrete and mortar after being depolymerised [1]. The second one is as a binder, after being melted with sand and clay [2]. The third one is as particles, fibres or pellets, as a replacement of fine or coarse aggregate. The last one presents the largest research background and it will be the aim of the present review. Indeed, some authors have already published reviews on this use of recycled plastic.

Siddique et al. published an analysis on physical and mechanical properties of concrete with plastic aggregates, such as bulk density, air content, slump, compressive strength, splitting tensile strength, modulus of elasticity, impact resistance, permeability and abrasion resistance [3]. It is worth mentioning that the authors based their research on eleven published papers only and important properties such as thermal insulation were not analyzed. Finally, only the addition of plastic as fibres was considered.

Pacheco-Torgal et al. presented a review on concrete with tyre rubber and PET bottle waste material [4]. From the 99 papers included, just 16 are from the last ten years. The authors also briefly studied some properties of concrete but they did not consider the types and processes of the plastic to be added.

Saikia and de Brito reviewed the same topic [5]. They conducted a complete analysis of mechanical and thermal properties, durability and fire resistance, but they only took into account twenty research works. Moreover, the papers they analyzed are dated until year 2010 and many meaningful studies have been published since then.

Subsequently, Yin et al. presented a review on the use of macro plastic fibres in concrete [6]. Though the authors considered a large number of studies, less than fifteen were about the mechanical and thermal properties of concrete with plastic waste aggregate. The rest of the papers studied other topics, like aggregation of virgin plastic to concrete, plastic recycling processes or reinforced concrete. Another important point is that the review does not analyze the addition of plastic particles.

Finally, it should be noted that Sharma and Pal Bansal published a review on different aggregate shapes of recycled plastic waste in concrete, such as particles (shredded and melted) and fibres [7]. However, two important gaps in this research are the analysis of types and process of plastic waste and the cementitious mix design. The last one is very important because it includes plastic dosage and its relation with the mechanical and thermal properties of cement composites. Furthermore three research works were considered on material thermal insulation, but they were not related to the others properties studied, which resulted in a thermal conductivity analysis that was incomplete and not linked to the rest of the review.

In accordance with the above mentioned information, it can be observed that even though there is a review background on concrete and mortar with plastic aggregates, weak points have been found in each case. Finally, it is worth mentioning that even though cement composites thermal properties have been considered in some reviews, a wider analysis is possible.

The purpose of this paper is to thoroughly study the development of knowledge, over the last ten years, on the addition of waste plastic to cement composites. For that purpose, forty five papers specifically referring to the addition of recycled plastic to concrete and mortar and its influence on mechanical and thermal properties have been selected for this research work. The conclusions will be relevant both for future original research works and for practical application in the construction industry.

2MethodologyThe methodology adopted for the review was:

- 1.

Gathering of international literature, specifically of research papers on the use of recycled plastic waste as an aggregate to concrete and mortar. The search was conducted on the basis of two consecutive criteria:

- •

Keywords: “Plastic recycling”, “Plastic waste”, “Aggregate”, “Concrete”, “Cement mortar”, “Fibre-reinforced concrete” and “Fibre-reinforced mortar”. A list of papers was obtained, among which relevant reviews and specific research works were found.

- •

Relevant articles quoted on the papers obtained were included in the list.

- •

- 2.

Paper selection according to the following requirements:

- •

Research works published between 2007 and 2017, with the purpose of covering ten years of findings.

- •

Research works published in scientific peer-review journals included in recognized databases.

- •

Research works on the addition of recycled plastic particles and fibres, as concrete and mortar aggregate.

- •

After this selection, forty five papers were collected.

- •

- 3.

Definitions of points to be examined. Six relevant issues were identified for the present review.

- •

Plastic type: HDPE, LDPE, PS, PET, PP, PVC, melamine, nylon.

- •

Shape and size of plastic aggregate.

- •

Processes to prepare plastic waste: washing, shredding, melting, extruding, conforming.

- •

Mix design proportion: cement, coarse aggregate, fine aggregate, water/cement ratio, plastic.

- •

Plastic fibre properties: melting temperature, crystallization temperature, compressive strength, splitting tensile strength, flexural strength, total deformation, yield strength, hardness, elasticity modulus, surface degradation.

- •

Properties of fresh and dried concrete and mortar. In the case of fresh material, the properties are air content and slump and in the case of dried material, the properties are bulk density, compressive strength, tensile strength, flexural strength, elasticity modulus, homogeneity, fibre pull-out resistance, durability (water absorption, carbonization, alkaline environment resistance, acid environment resistance, drying shrinkage, abrasion resistance, gas permeability, freezing and thaw resistance) and thermal insulation.

- •

- 4.

Information processing.

- 5.

Discussion of results and drawing of conclusions.

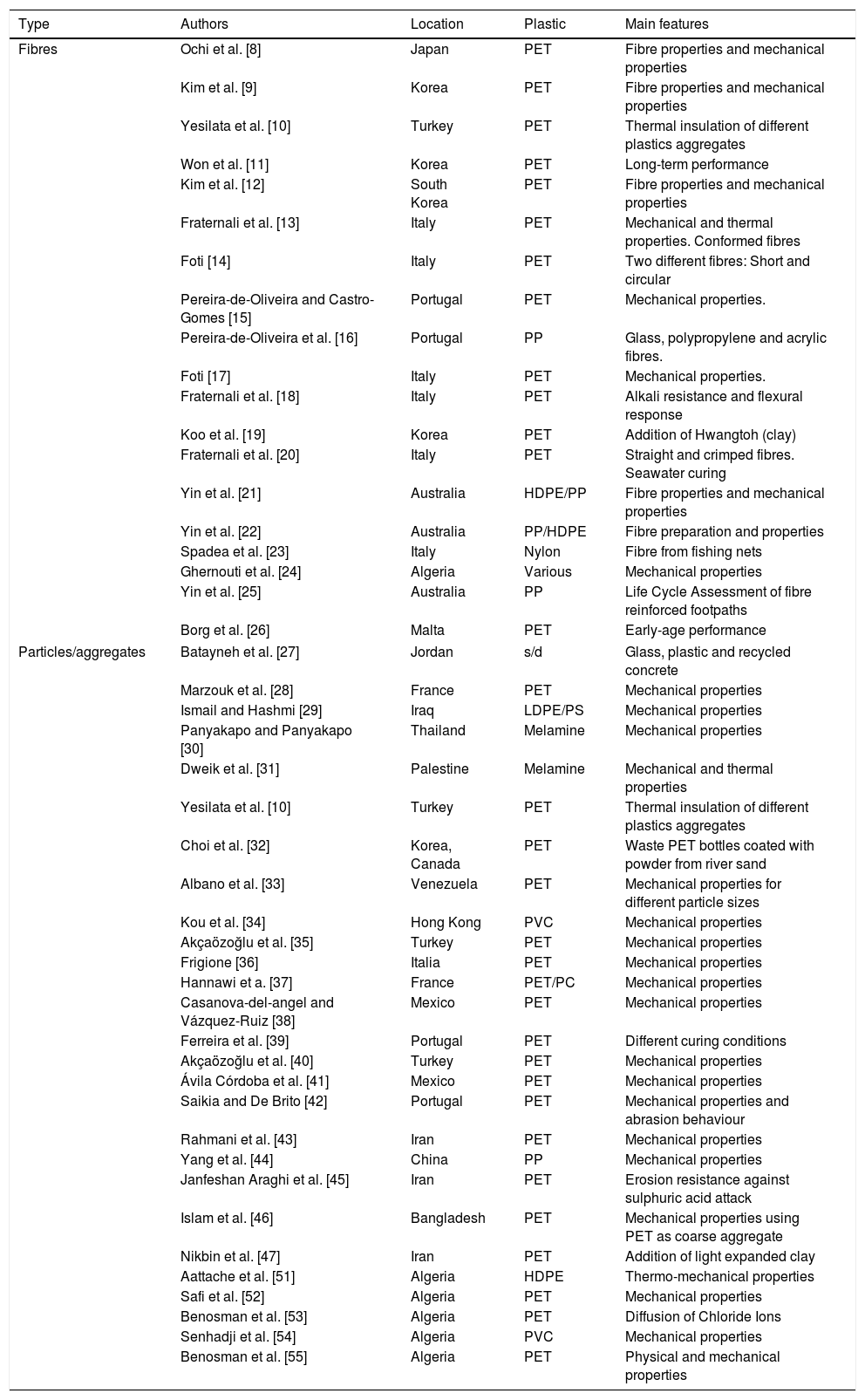

The results obtained for the plastic types used, as well as the shape and size of the plastic aggregates are unified and summarized in Table 1. The table shows the list of papers analyzed, divided by the plastic aggregate type (particles or fibres). The last column indicates the particularities studied in each research work. It is important to point out the large number of research works including PET (thirty two), the results of which agree with those presented by Saikia and de Brito [5]. Furthermore, the geographical distribution of the papers was analyzed, resulting in more than 80% of papers originated in Asia and Europe, which illustrates the necessity to promote more contribution from Latin America research works.

Papers found on concrete and mortar with recycled plastic particles and fibre aggregate.

| Type | Authors | Location | Plastic | Main features |

|---|---|---|---|---|

| Fibres | Ochi et al. [8] | Japan | PET | Fibre properties and mechanical properties |

| Kim et al. [9] | Korea | PET | Fibre properties and mechanical properties | |

| Yesilata et al. [10] | Turkey | PET | Thermal insulation of different plastics aggregates | |

| Won et al. [11] | Korea | PET | Long-term performance | |

| Kim et al. [12] | South Korea | PET | Fibre properties and mechanical properties | |

| Fraternali et al. [13] | Italy | PET | Mechanical and thermal properties. Conformed fibres | |

| Foti [14] | Italy | PET | Two different fibres: Short and circular | |

| Pereira-de-Oliveira and Castro-Gomes [15] | Portugal | PET | Mechanical properties. | |

| Pereira-de-Oliveira et al. [16] | Portugal | PP | Glass, polypropylene and acrylic fibres. | |

| Foti [17] | Italy | PET | Mechanical properties. | |

| Fraternali et al. [18] | Italy | PET | Alkali resistance and flexural response | |

| Koo et al. [19] | Korea | PET | Addition of Hwangtoh (clay) | |

| Fraternali et al. [20] | Italy | PET | Straight and crimped fibres. Seawater curing | |

| Yin et al. [21] | Australia | HDPE/PP | Fibre properties and mechanical properties | |

| Yin et al. [22] | Australia | PP/HDPE | Fibre preparation and properties | |

| Spadea et al. [23] | Italy | Nylon | Fibre from fishing nets | |

| Ghernouti et al. [24] | Algeria | Various | Mechanical properties | |

| Yin et al. [25] | Australia | PP | Life Cycle Assessment of fibre reinforced footpaths | |

| Borg et al. [26] | Malta | PET | Early-age performance | |

| Particles/aggregates | Batayneh et al. [27] | Jordan | s/d | Glass, plastic and recycled concrete |

| Marzouk et al. [28] | France | PET | Mechanical properties | |

| Ismail and Hashmi [29] | Iraq | LDPE/PS | Mechanical properties | |

| Panyakapo and Panyakapo [30] | Thailand | Melamine | Mechanical properties | |

| Dweik et al. [31] | Palestine | Melamine | Mechanical and thermal properties | |

| Yesilata et al. [10] | Turkey | PET | Thermal insulation of different plastics aggregates | |

| Choi et al. [32] | Korea, Canada | PET | Waste PET bottles coated with powder from river sand | |

| Albano et al. [33] | Venezuela | PET | Mechanical properties for different particle sizes | |

| Kou et al. [34] | Hong Kong | PVC | Mechanical properties | |

| Akçaözoğlu et al. [35] | Turkey | PET | Mechanical properties | |

| Frigione [36] | Italia | PET | Mechanical properties | |

| Hannawi et a. [37] | France | PET/PC | Mechanical properties | |

| Casanova-del-angel and Vázquez-Ruiz [38] | Mexico | PET | Mechanical properties | |

| Ferreira et al. [39] | Portugal | PET | Different curing conditions | |

| Akçaözoğlu et al. [40] | Turkey | PET | Mechanical properties | |

| Ávila Córdoba et al. [41] | Mexico | PET | Mechanical properties | |

| Saikia and De Brito [42] | Portugal | PET | Mechanical properties and abrasion behaviour | |

| Rahmani et al. [43] | Iran | PET | Mechanical properties | |

| Yang et al. [44] | China | PP | Mechanical properties | |

| Janfeshan Araghi et al. [45] | Iran | PET | Erosion resistance against sulphuric acid attack | |

| Islam et al. [46] | Bangladesh | PET | Mechanical properties using PET as coarse aggregate | |

| Nikbin et al. [47] | Iran | PET | Addition of light expanded clay | |

| Aattache et al. [51] | Algeria | HDPE | Thermo-mechanical properties | |

| Safi et al. [52] | Algeria | PET | Mechanical properties | |

| Benosman et al. [53] | Algeria | PET | Diffusion of Chloride Ions | |

| Senhadji et al. [54] | Algeria | PVC | Mechanical properties | |

| Benosman et al. [55] | Algeria | PET | Physical and mechanical properties | |

Regarding the analysis of the processes to obtain the plastic aggregate, a classification of publications according to size of the aggregate was prepared, and mechanical and thermal processes used for plastic recycling were indicated. The last item is very important, because the manufacturing processes may modify the performance of the final mix and production costs vary according to the processes involved.

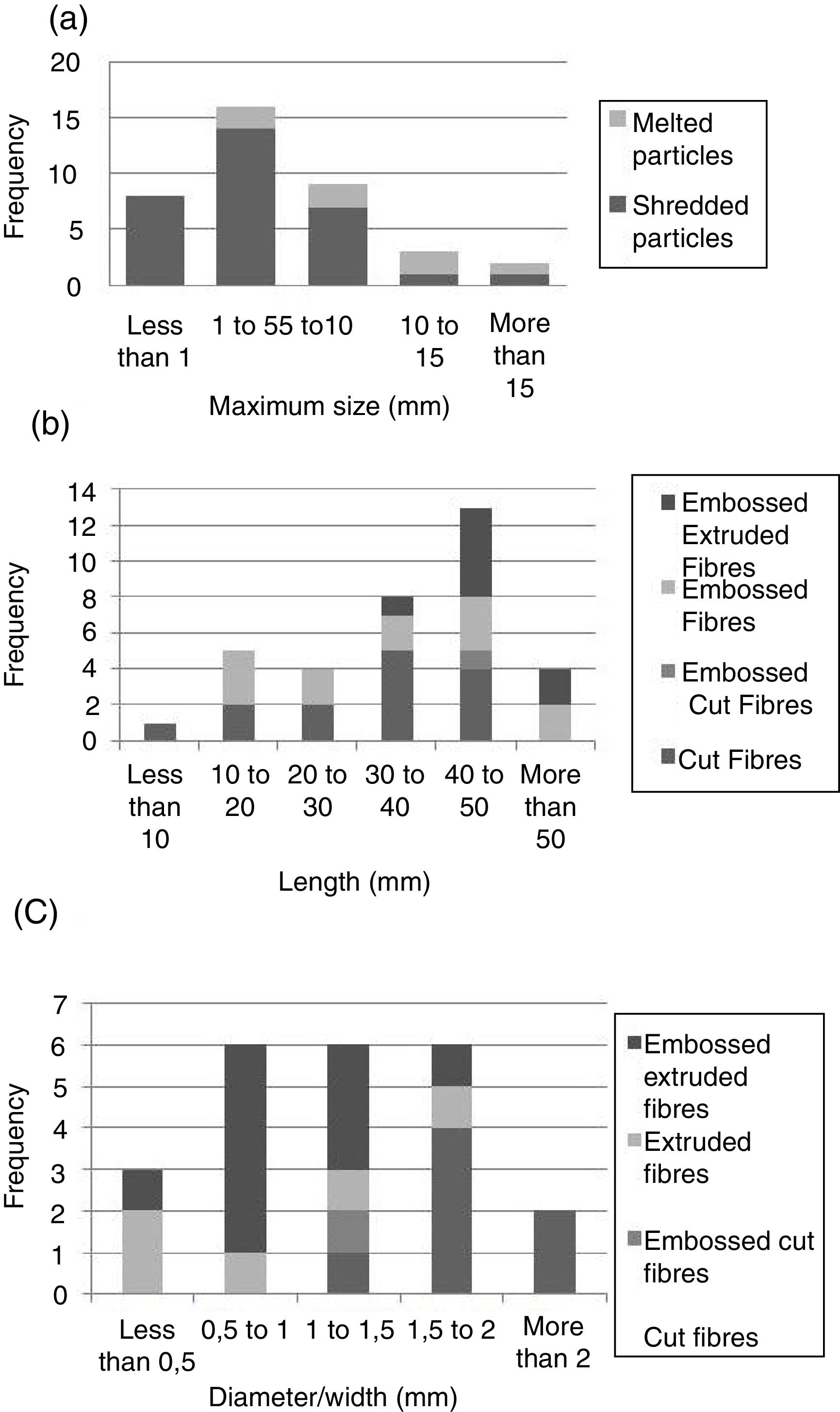

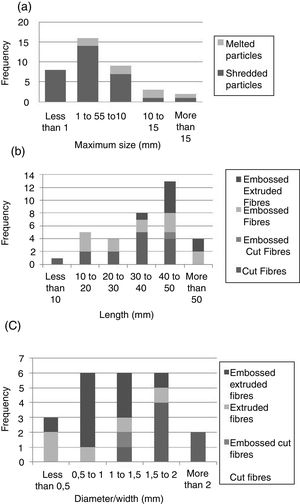

Fig. 1(a) shows the relation between particle size and the process applied to plastic to obtain such particles: shredding and melting. Fig. 1(b) shows the length of fibres in relation to their obtainment processes: cutting, extrusion and embossing. Fig. 1(c) shows the width/diameter ratio of fibres with the extrusion and cutting processes. The three figures show the frequency at which plastic aggregates appear in publications. The horizontal axis was divided into ranges since studies, in general, have used an interval to define the size of aggregates.

From the interpretation of Fig. 1 the following deductions are obtained:

- •

The particle size range mostly used was 1–5mm. The shredded particles have been studied more thoroughly than melted ones, and production costs could be the reason.

- •

Shredded particles were tested in all ranges, while melted ones, just for sizes larger than 1mm. That might be related to the difficulties in the melting process due to the potential amalgamation of particles.

- •

Most studied fibre length is between 40 and 50mm and it was the only range which has presented background in embossed cut fibres. Because of that, future researches would be necessary in order to describe the performance of this fibre type.

- •

In the case of fibre width, a high dispersion was observed in the results. An interesting fact was that cut fibres were always larger than 1mm, since smaller widths are difficult to obtain.

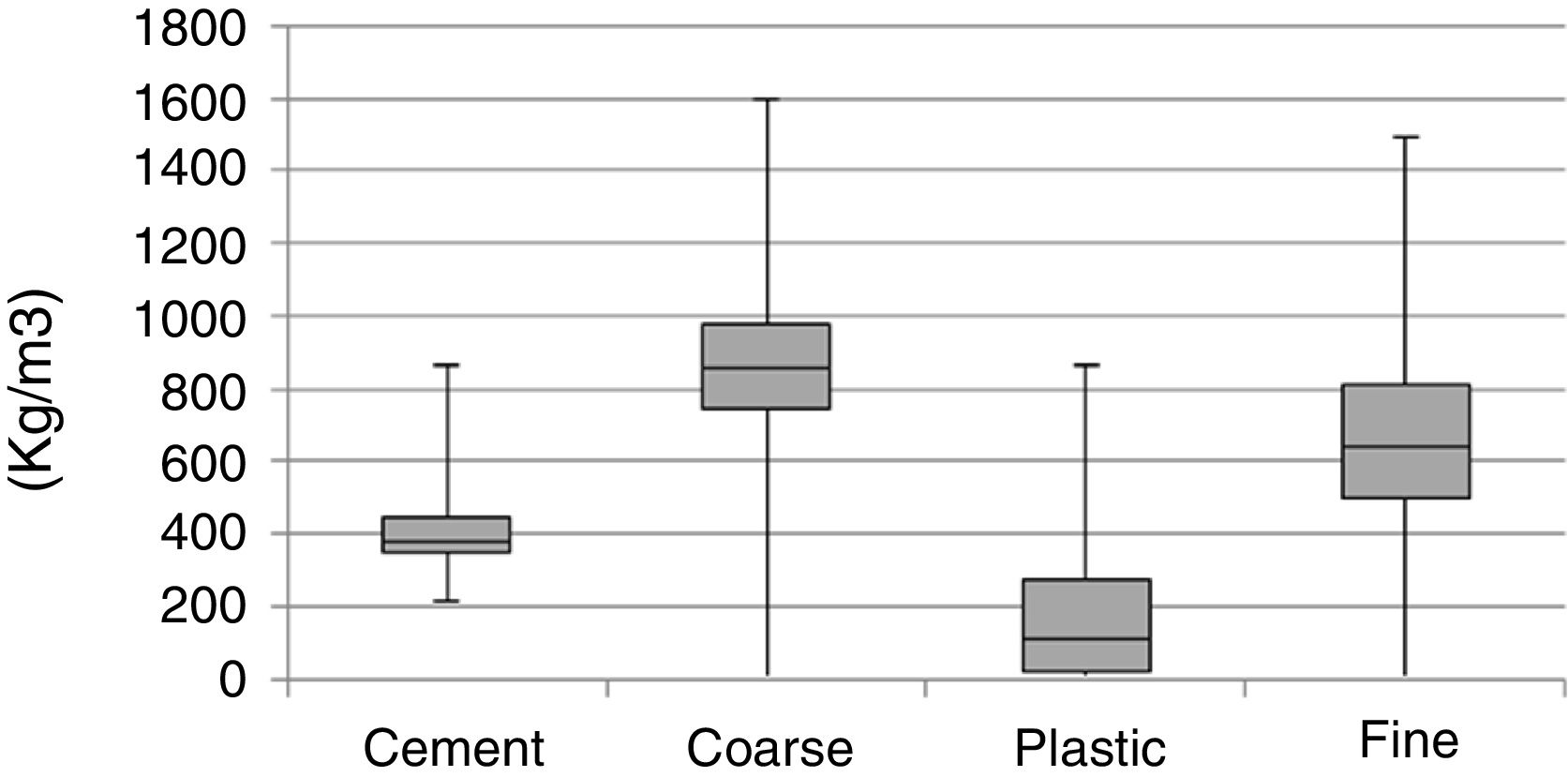

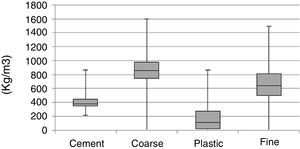

An important gap in previous reviews was the analysis of the mix design. Mix design includes the determination of quantities for cement, coarse and fine aggregate (usually expressed as kg/m3 of concrete), water/cement ratio, and recycled plastic. Although there are standards and rules which regulate the design of cementitious mixes and their application in construction, a large variability of results was observed. Studied papers present several combinations in terms of the content of each component, and diverse plastic particle or fibre sizes. Publications studied include other components, such as blast-furnace slag, aluminium dust and admixtures, among others but this analysis does not consider that in the design of the cementitious mix.

As it can be observed in Fig. 2, the median is 380kg/m3 for cement, 857.91kg/m3 for coarse aggregate and 643.50kg/m3 for fine aggregate. As regard plastic content, a greater disparity can be observed, with a median of 107.25kg/m3, a minimum of 0.45kg/m3 and a maximum of 843kg/m3.

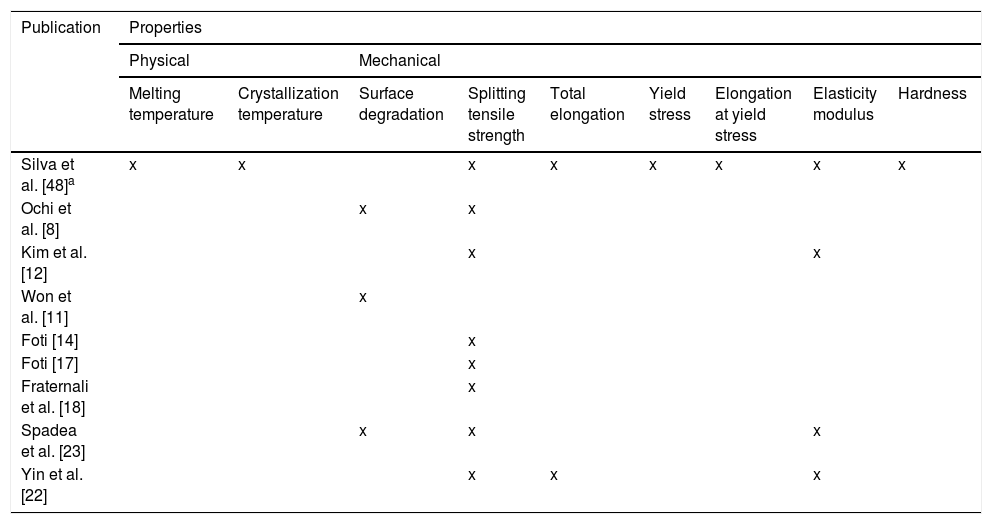

3.3Properties of plastic fibresThe properties of plastic fibres are summarized in Table 2. According to the results presented in Table 1, PET fibres predominate in seven of the nine researches of fibres.

Recycled plastic fibre properties.

| Publication | Properties | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Physical | Mechanical | ||||||||

| Melting temperature | Crystallization temperature | Surface degradation | Splitting tensile strength | Total elongation | Yield stress | Elongation at yield stress | Elasticity modulus | Hardness | |

| Silva et al. [48]a | x | x | x | x | x | x | x | x | |

| Ochi et al. [8] | x | x | |||||||

| Kim et al. [12] | x | x | |||||||

| Won et al. [11] | x | ||||||||

| Foti [14] | x | ||||||||

| Foti [17] | x | ||||||||

| Fraternali et al. [18] | x | ||||||||

| Spadea et al. [23] | x | x | x | ||||||

| Yin et al. [22] | x | x | x | ||||||

It can be observed that most of the studies on fibres were focused on splitting tensile strength. That is because the principal use of fibres in concrete and mortar is as a reinforcing mechanism against shrinkage. Yin et al. shows the different failure mechanisms related to such fibres [22].

The study of surface degradation carried out by Ochi et al. is important; in it, they concluded that alkaline environments affect PP to a larger extent than PET fibres [8]. Won et al. reported that concrete with PET fibres has a better performance in freezing-thawing cycles than a traditional concrete [11]. However, when recycled PET fibre-reinforced cement composite was exposed to an alkaline environment, progressive deterioration was observed on the PET fibre surface as the ageing time increased. Spadea et al. concluded that nylon fibres present adequate alkali resistance according to the ASTM D543-06 standard [23].

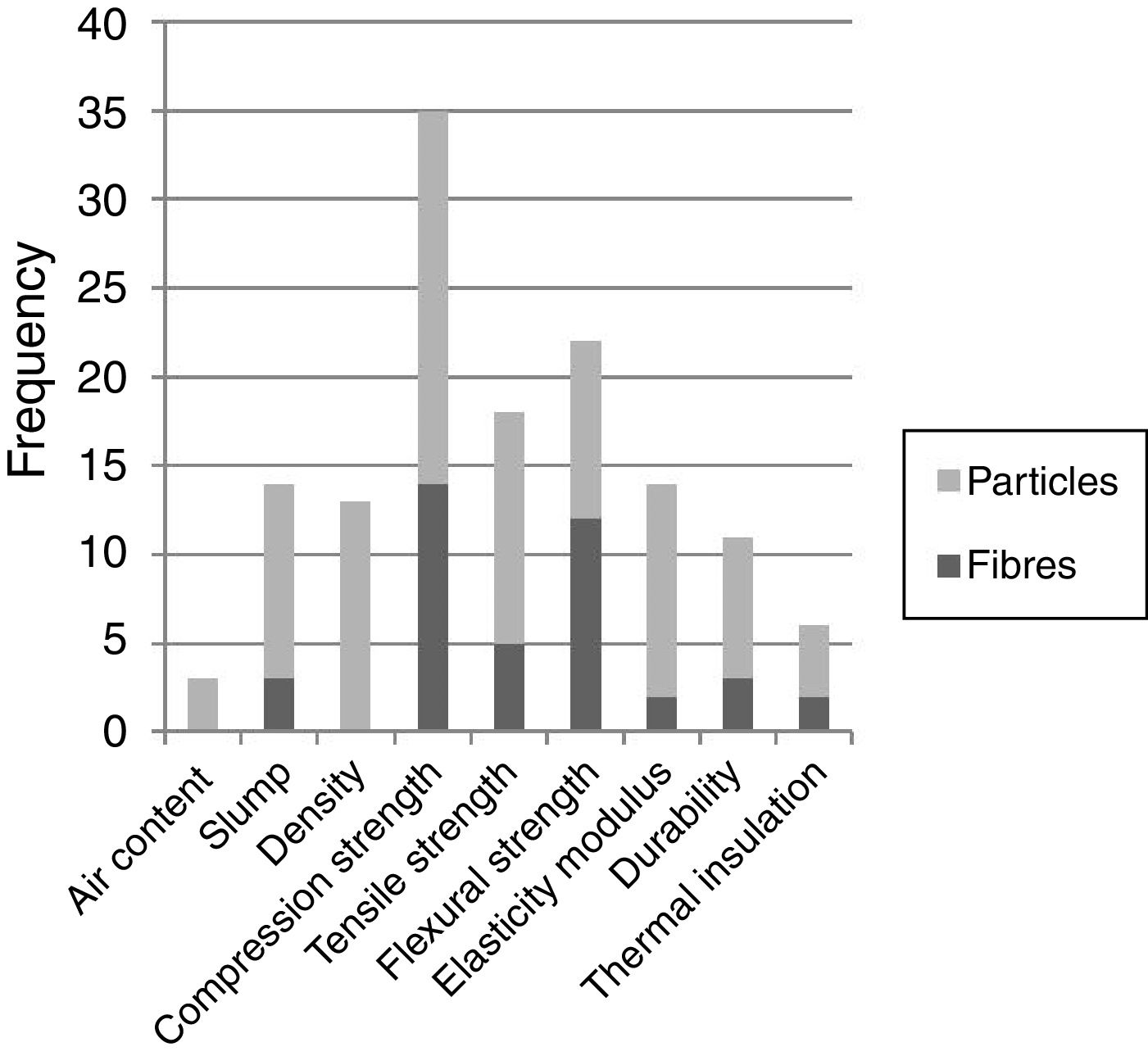

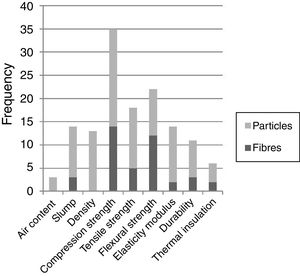

3.4Concrete and mortar propertiesIn Fig. 3, the number of publications which have considered each of the properties under study is presented. The figure shows a differentiation between plastic particles and fibres. As it can be seen, compression strength is the most frequent property, followed by tensile strength and flexural strength. A deeper discussion of each one is presented below.

3.4.1Fresh concrete and mortar properties3.4.1.1Air contentIt is the volume of air voids in the cement composites, excluding the pore space in the particles of the aggregates. Just two research works were found and both agreed that air content is moderately reduced with the aggregate of plastic particles [32,38].

3.4.1.2SlumpThis property is related to the workability of freshly mixed concrete and mortar. Workability makes reference to how easily cement composites can be mixed, transported, placed and finished without segregation [3].

A lower slump value was observed in many papers for concrete and mortar mixes with plastic particles, in comparison with conventional mixes [27,29,33,43]. This effect could be related to the angular and non-uniform shape of the shredded plastic which could result in a lower fluidity of the mix.

Other determinations related to concrete and mortar slump were performed with varied results. Saikia and De Brito and Ferreira et al. used different w/c values to achieve a constant slump value [39,42].

As they informed, a slightly lower w/c ratio for concrete with melted plastic particles and a much higher w/c rate for shredded plastic aggregates were needed, this rate being higher for coarse particles than for fine ones. Moreover, Albano et al. presented an inverse relation between water–cement rate and slump for the same plastic amount: slump is larger for a 0.5 w/c ratio than for a 0.6 ratio [33]. Choi et al., Yang et al. and Islam et al. reported a direct relation between the amount of plastic content and workability [32,44,46]. However, it is worth mentioning that melted particles were used in these research works. Few papers were obtained on the addition of fibres. Ghernouti et al. performed a slump test of concrete with aggregate of extruded fibres and they found a slump increase when fibre content rose [24].

Finally, it is necessary to discuss a result reported by Saikia and de Brito, Sharma and Pal Bansal and Senhadji et al. [5,7,54]. They presented an increase in the slump value as a result of the addition of plastic aggregate (either particles or fibres) and they concluded that such phenomenon occurred because of the presence of more free water in the mixes, since plastic particles do not absorb as much water as conventional aggregate.

3.4.2Hardened concrete and mortar properties3.4.2.1DensityAll the papers analyzed agree that the mix density decreases with the increment of plastic particle content [28,31,32,34,37,39,42,52,54]. Particularly, Hannawi et al. reported that for mixtures with more than 20% of plastic content, the dry density was lower than 2000kg/m3, which is the minimum dry density required for structural lightweight concrete according to the RILEM LC2 classification [37].

Furthermore, some authors have analyzed this detriment in relation with other variables. Saikia and De Brito analyzed the influence of particle size on density [42]. Natural aggregate was replaced by shredded plastic, and for the three replacement percentages tested (5, 10 and 15%), the cement composites with larger particles showed lower density. However, the difference never exceeded 0.6%, so it was not significant. Choi et al. reported that density decrease was more marked for smaller water/cement ratios [32]. Hannawi et al. found a larger reduction for PC than for PET [37]. Kou et al. assessed the density of the mix as it was normally hardened, air dried and oven dried, and they found that in all cases, it decreased with the increase of plastic content [34]. Finally, Dweik et al. studied the density of mortar and concrete for equal contents of plastic, and they reported a larger reduction for the first one [31].

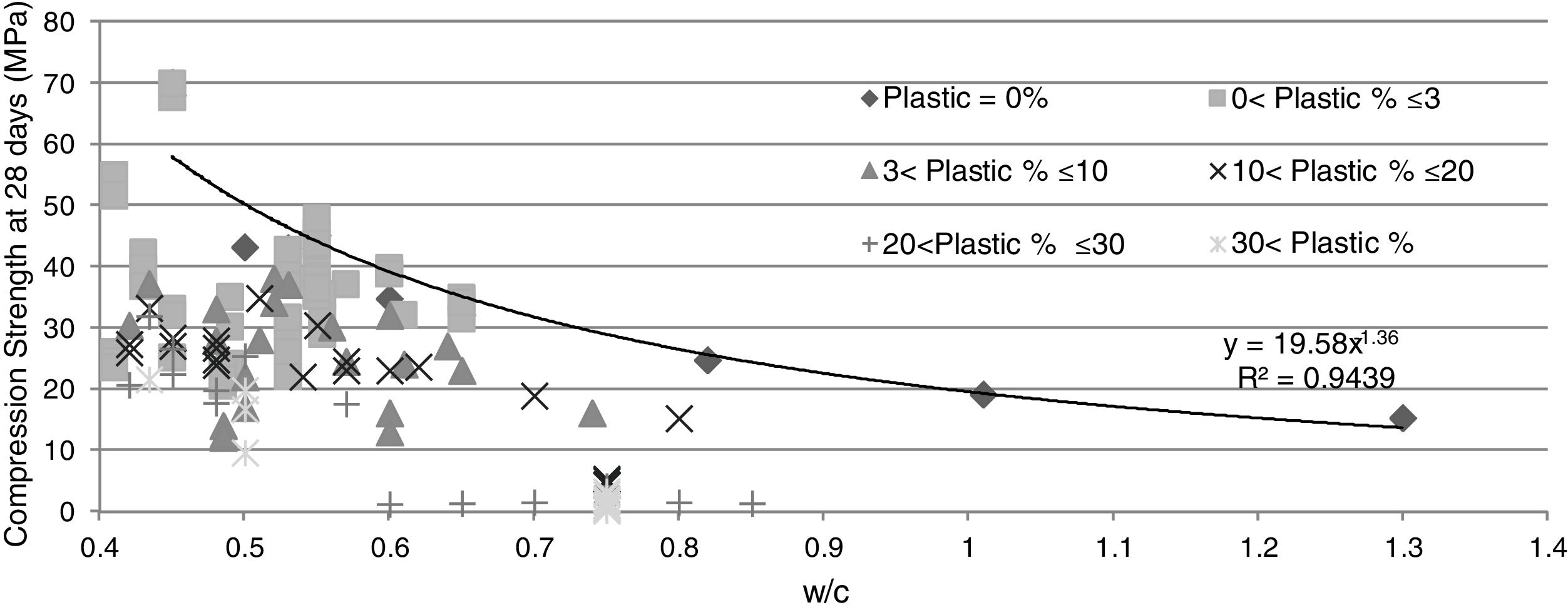

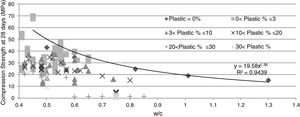

3.4.2.2Compression strengthThis property is determined as the maximum measured strength at 28 days of a specimen of concrete or mortar to compression axial load, and it is a fundamental property on which concrete is categorized. Fig. 4 represents compression strength at various water/cement ratios for different plastic contents. Only research works which include water/cement ratios, compression strength and plastic content have been considered for this graphic. Over 150 results from 23 publications are presented in the figure. The group of mixes that includes plastic considers any plastic type and any percentage, and fibres and particles do not get separated.

A tendency line corresponding to 0% plastic content was obtained, with a coefficient of determination (R2) of 0.9439, and a potential function was used, as it was the one with the best fit. As it can be seen in Fig. 4, most of the results are below the trend line of 0% plastic replacement, which means that plastic content decreases compression strength.

Plastic content ranges were fixed at intervals of 10 percentage points, except for the first range (0% to 3%), which was very significant and mainly used for fibre dosing.

Conversely, Yin et al., Pereira et al. and Koo et al. did not report differences in compression strength with the addition of fibres, maybe because of the low dosage used (less than 1.5% per volume) [15,19,21]. This result was not influenced by fibre conformation type (line or diamond indentation). Besides, Borg et al. and Ghernouti et al. checked that fibre length does not have a significant impact on compression strength [24,26]. Foti analyzed fibres cut from PET bottles in two shapes, lamellar and circular, and found that for the same amount of fibres the second ones presented a greater decrease in compression strength [14].

As regards the influence of the shredded PET particle size, the consulted authors have disagreed. For larger, particles a lower compression strength reduction is shown by Marzouk et al. [28], while Saikia and De Brito and Ferreira et al. reported exactly the opposite [39,42]. Cordoba et al. found constant compression strength up to 1.5mm of particle size, but a reduction occurred for larger sizes [41].

3.4.2.3Tensile strengthUsually tensile strength is closely linked to compression strength and both show similar behaviour [5]. Tensile strength is generally determined indirectly with tests such as diametric compression of a concrete specimen. Different plastics types have been analyzed and distinct results were reported in the available literature. Batayneh et al., Albano, Frigione, Saikia and De Brito, Casanova and Vazquez, Rahmani et al. and Ferreira et al. reported that tensile strength decreased with the aggregate of recycled PET either as particles or fibres [27,33,36,38,39,42,43]. Moreover, Kou et al. reported a reduction in this property with the addition of waste PVC particles [34]. In contrast with the conclusions in the previous paragraph, Ghernouti et al. found an increase of 74% in tensile strength with the addition of plastic bag fibres [24]. Yin et al. stated that the improvement of this property could be a consequence of the capacity of fibres to arrest crack propagation in concrete [6]. Yang et al. also reported an improvement on tensile strength for a 15% replacement of natural aggregate with recycled PP particles [44]. The melamine case presented by Dweik et al. reported a maximum tensile strength for approximately 20% replacement [31].

The effect of plastic particle size on tensile strength was analyzed by Saikia and De Brito [42]. Although a reduction in tensile strength was observed with an increase of PET particle dosage, for smaller particles, such reduction was lower. Fibre length did not seem to affect tensile strength [24]. An interesting fact presented by Albano was a reduction in tensile strength with an increase of w/c ratio [33]. Ferreira et al. studied the influence of curing conditions on this property and found better results for outdoor environmental curing than for wet chamber and laboratory curing, though differences were small [39].

3.4.2.4Flexural strengthFlexural strength is defined as the ability of a structural member to resist failure under flexural load. As regards plastic particle aggregate, Rahmani et al. found a maximum flexural strength for a 4% replacement of natural sand with plastic particles, though Yang et al. obtained a maximum for a 15% replacement [43,44]. A possible cause could be the type and shape of plastic; while the first authors used shredded PET particles, the second ones used recycled PP pellets.

Some authors have found that flexural strength dropped with an increment of plastic particle aggregate volume [27,29,37,38,42,52]. According to Marzouk et al., for more than 50% of natural aggregate substitution with plastic particles, flexural strength fell strongly [28]. The effect observed in those studies may be due to the elastic characteristics of plastic and its low bond with cement [5].

Regarding the size of plastic particles, interesting results were obtained by Marzouk et al. [28]. They compared three particle sizes (5mm, 2mm and 1mm) and observed that for the same substituted volume, the larger ones showed a more similar behaviour to the reference mortar. However, Saikia and De Brito studied the inclusion of three different particles shapes, two shredded particles (10mm and 5mm) and a melted one (4mm) [42]. In every case, flexural strength presented a decreasing trend when plastic content rose, although the most important decrease was obtained for large shredded particles, followed by the small ones and finally, the melted particles.

Particular determinations were reported in the analyzed publications. Albano et al. studied flexural strength for concrete with plastic aggregate which had been exposed to heat sources and discovered that no noticeable changes were observed at 200°C, while at 400°C and 600°C strength dropped [33]. Ismail et al. calculated the flexural tenacity index of concrete, which is determined by the area under the load-strain curve [29]. The tests showed an arrest of micro-crack propagation with the introduction of plastic particles into concrete, which implies an increment of material tenacity.

Regarding the impact of fibres on flexural strength, Ochi et al. reported a minimum flexural strength value for a plastic aggregate of 0.5% in volume [8]. For higher values, the authors observed an upward trend on flexural strength but it was followed by an increment in standard deviation. These results seem to be in accordance with the ones reported by Pereira de Oliveira and Castro-Gomes [15].

Some research works have studied the influence of fibre shape. Foti tested short laminar fibres and circular fibres, and the last ones showed a better behaviour [14]. Spadea et al. reported that longer fibres are more effective that shorter ones [23]. Despite that, Ghernouti et al. did not find any differences between 20, 40 and 60 mm-long fibres [24].

Finally, a residual flexural strength provided by fibres after concrete failure, was reported in some studies. Borg et al. observed that higher fibre volumes provided better residual strength [26]. Yin et al. found differences in the post-cracking performance between line and diamond indented fibres [21]. While the first ones were pulled out the second ones were broken, which indicates that diamond indented fibres have better bonding. Furthermore, Fraternali et al. detected a beneficial effect of fibre waviness in terms of flexural strength [20]. Crimped fibres had better flexural performance than straight ones.

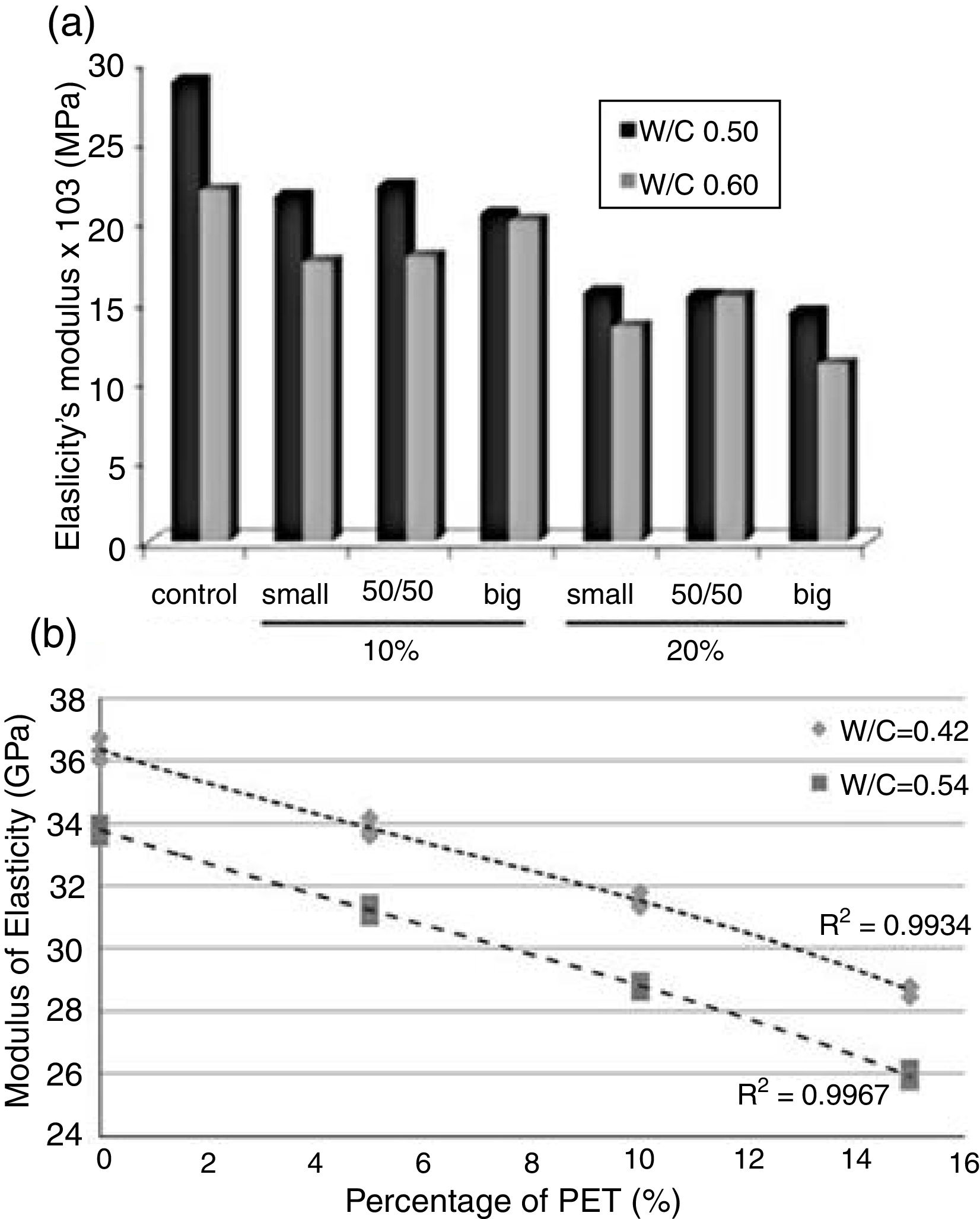

3.4.2.5Elasticity modulusThe elasticity modulus is defined as a stress to strain ratio value for hardened concrete according to ASTM C 469 and it can be influenced by the aggregate types. Tests performed by Koo et al. did not show important differences in the elasticity modulus when PET fibres were added to concrete [19]. However, Casanova and Vazquez and Ferreira et al. concluded that the elasticity modulus of concrete decreased when PET particles were added [38,39]. Such disagreement may be due to the differences on PET shape or on the dosage, while Koo et al. used around 0.5% in volume, Casanova and Vazquez used 17.5% and Ferreira et al. used 5 and 10% in volume [19,38,39].

Marzouk et al., Kou et al., Hannawi et al. and Yang et al. also reported a reduction in elasticity modulus with the addition of plastic particles [28,34,37,44]. Marzouk et al. attributed that to the reduction of composite bulk densities and to the decreasing celerity of ultrasonic wave propagation because of the disturbance produced by plastic presence [28]. At this point is important to mention that the authors reported they have studied many plastic types such as PET, PP, PC and PVC.

Some authors reported higher elasticity modulus for smaller water/cement ratios no matter the plastic amount included [33,43]. However, in both research studies the modulus observed for concrete with plastic aggregate was smaller than the concrete without plastic. These observations are presented in Fig. 5. In fact, Rahmani et al. reported an inverse linear relation when they plotted the elasticity modulus against PET percentage [43]. Some authors presented possible explanations for the elasticity modulus reduction. Albano et al., reported as a cause that PET is less resistant than sand and may deform to a lesser extent when an equivalent stress is applied, so shrinkage is partially related to the elastic deformation of the PET [33]. Rahmani et al. expressed the weak bond between the texture and PET particles can be mentioned as another reason for this phenomenon [43].

Albano et al. found that for a fixed particle size, a higher modulus is achieved with a smaller PET content [33]. In spite of that, Cordoba et al. reported a higher modulus for 2.5% of PET in volume than for 1% and 5%; that behaviour was observed for three different particle sizes (0.5mm, 1.5mm and 3mm) [41].

Some other important conclusions were found during the review. Saikia and De Brito studied the performance of three different plastic particle shapes, two sizes of shredded particles (10mm and 5mm) and one of melted particles [42]. In every case, the elasticity modulus showed a decreasing trend with an increment of plastic content; however, the strongest decrease was obtained for large shredded particles, followed by small ones and finally, by melted ones. Finally, Marzouk et al. compared different particle sizes (5mm, 2mm and 1mm) and found the highest modulus for the largest particle size [28].

3.4.2.6DurabilityWater absorption and available water. The water absorption establishes the suitability of a porous medium to be traversed by water. The increase in porosity is related to a greater vulnerability to aggressive agents. Albano et al. reported the water absorption percentage increased with the rise of content and size of PET particles [33]. Hannawi et al. reported the same behaviour when plastic particle content increased [37]. However, other researchers stated that volumetric substitutions of plastic aggregate decreased the rate of water absorption [28,52]. Finally, Akçaözoğlu et al. observed a higher water absorption in a mortar with only PET aggregates than in mortar with sand and PET aggregates; nevertheless, they concluded that in both cases the values were in the range corresponding to lightweight concrete [35]. All authors consulted seem to agree that aggregates have an influence on porosity, and therefore, this parameter could be important for the study of cement composite durability.

Carbonation. Carbonation is a slow process in which the slaked lime (calcium hydroxide) in the cement reacts with the carbon dioxide in the air to form calcium carbonate. Carbonation causes a drop in pH and that can lead to corrosion of the reinforcement and damage of the construction.

Koo et al. did not report significant differences in carbonation depth when recycled PET fibres were added to concrete [19]. Akçaözoğlu et al. studied two types of mortar, one with only plastic particle aggregate and another one with plastic particle and sand aggregate [35]. Carbonation depth was higher for the second one. Because of that, authors inferred that PET and sand do not combine sufficiently well as aggregates.

It was also concluded that carbonation depth may not be useful to characterize cement composite with plastic aggregates. Just two research works were found with a carbonation depth analysis, both included blast furnace slag as a replacement of a part of cement and no significant impacts were reported.

Alkali resistance. Mortar and concrete are highly alkaline, with a pH range from 12 to 13. Won et al. studied PET fibres in an alkaline environment [11]. They found that surface deterioration increased with time and that at 120 days the damage advanced throughout the whole section of fibres. Ochi et al. reported that alkaline environments affect PP fibres to a larger extend than they affect PET ones [8]. Spadea et al. also studied this property for nylon fibres, not observing signs of corrosion after 120h of immersion in sodium hydroxide solution [23].

Resistance to acid environments. Acids attack concrete by ion exchange. Due to moisture gradients, pH and concentration, the ions of the hydrated paste are replaced by the ones contributed by acids. These attacks produce mass loss, coherence loss, bonding capacity loss and non-removable efflorescence. Jafeshan Araghi et al. and Nikbin et al. studied the influence of the contact with sulphuric acid solution in concrete, with PET aggregate. They found a lower weight loss and better resistance of concrete to compression, with a higher plastic content (15%). That is the reason why they concluded that this percentage of dosage can be successfully used in acidic environments, such as sewers [45,47]. Benosman et al. also confirmed that the presence of PET aggregate lower the detrimental effects of acids on composites [55].

Shrinkage. Shrinkage can be quite significant in large cementitious areas but it is also important in smaller pieces, as it affects the element surface. To avoid that, steel reinforcing meshes have traditionally been used; however, in the latest years, they have been substituted by macro plastic fibres. Only a few research works were found on this topic. Kim et al. analyzed the influence of different fibre dosages and geometries in shrinkage cracking. They reported a significant reduction in shrinkage cracking for a 0.5% in volume of fibre content but below this dosage, there was no improvement [9].

The influence of plastic particles on drying shrinkage has also been reported in the available literature. Akçaözoğlu et al. observed a significant increase in drying shrinkage values of mortar with only PET aggregate with respect to mortar containing equal weight percentage of sand and PET [35]. They also reported a lineal relation between the amount of cement in the composite, and shrinkage. Moreover, Frigione noted that the replacement of sand with PET particles caused a slight increment in drying shrinkage [36]. He associated this behaviour with the elastic modulus, as when the elastic modulus is reduced, drying shrinkage increases. On the other hand, Kou et al. reported a decreasing trend of drying shrinkage with an increasing content of plastic and they justified this result considering that plastic particles do not absorb water and do not shrink, while sand actually does [34].

Abrasion resistance. It is the ability of a surface to resist wear by rubbing and friction. As it is well known, concrete with high compressive strength normally has high abrasion resistance. In spite of that, Saikia and De Brito observed a drop in compression strength and an improvement of abrasion resistance when plastic particles were incorporated [42]. They attributed the improvement to the high toughness and good abrasion behaviour of plastic, and also to the fact that fibres have a crack-arresting effect, which could be stronger than the reduction caused by compression strength.

Gas permeability. Gases, such as carbon dioxide or others with suspended ions may attack concrete, mortar and their steel reinforcing mesh. Hannawi et al. reported an increase in the permeability coefficient with the increment of plastic content and a greater effect for PET than for PC [37]. The reported conclusion was that such impact resulted from the weak bonding of cement and plastic.

Resistance to freezing and thawing. The effect of the freezing and thawing cycles is progressive and it affects the exposed surface (which is generally more porous) in the first place. The water that enters through pores freezes and increases its volume, thus generating tensions in the concrete. Won et al. reported that, under repeated freezing and thawing tests, concrete reinforced with recycled PET fibre showed better strength than concrete without plastic aggregate [11].

3.4.2.7Other propertiesThermal conductivity. Thermal conductivity is the unidirectional heat flow that is transmitted through a material, per length and temperature unit. Considering the International System of Units, it is given by Wm−1K−1. In the analyzed publications it is named in different ways, thermal conductivity, coefficient of thermal transmission, thermal transmittance and thermal insulation. The procedure for measuring this property is similar in the publications studied. It is done through an adiabatic box, which consists of a constant thermal source at one end and measures the temperature at the other end [49].

Fraternali et al. state that the reduction of the thermal conductivity of concrete reinforced with recycled fibres allows the production of structural components capable of reducing the environmental impact and improving the energy performance of buildings [13]. According to the results obtained, the percentage of improvement is 22% for PET and 27% for PP. Yesilata et al. also conclude that the addition of recycled materials (“square rubber”) improves up to 18.52% thermal insulation compared to traditional concrete [10]. The percentage of improvement with the addition of particles of PET bottles varies between 10.27% and 18.26%, depending on the geometry of the particles. Unlike previous authors, Dweik et al. incorporate melamine-formaldehyde (MF) as a substitute for sand in 20%, 40% and 60% [31]. When studying the behaviour of thermal conductivity, they observed that for the sample with 60% of MF, temperature was 30% lower than the control one. With 30% of MF, the temperature decreased by 15%. Benosman et al. also confirmed that the presence of PET was found to lower thermal conductivity [55].

Attache et al. analyses the behaviour of the aggregate of HDPE in low proportions 2, 4 and 6% (percentage in weight); at different ages of the samples (7, 14, 28, 90 and 120 days) and temperatures (20°C, 140°C, 250°C and 350°C). In all cases, the sample with the highest HDPE content showed a decrease in thermal conductivity [51].

All the publications analyzed agree on the fact that the addition of plastic material (PET, PP, MF, HDPE, etc.) to cement composite decreases thermal conductivity, resulting in more insulating materials for the same dimensions than without the addition of plastics. This result can be attributed to the low thermal conductivity of plastics (0.15Wm−1K−1) compared to natural sand (2Wm−1K−1) [40]. In the literature review by Ngo et al., thermal conductivities of various polymers are reported from 0.11 to 0.44Wm−1K−1; these values are significantly lower than the value of the natural aggregate [50].

4ConclusionsDuring the last decade, a lot of research works have studied the performance of cement composite with recycled plastic aggregate. The main purpose of this paper, which was the development of a review of scientific research works in that field, was achieved. Forty papers were analyzed in-depth and remarkable results were found and discussed. Hereunder, conclusions and recommendations for future research works are presented.

- 1.

PET is the most frequently studied recycled plastic and there is a lack of research works in developing countries, like the Latin American ones.

- 2.

As regards sizes and preparation processes of recycled plastic particles and fibres, the distribution of frequencies obtained by particle size is skewed towards downward values and shows that shredded particles are the mostly used ones.

- 3.

In the case of recycled fibres, more varied results are presented regarding frequency distribution according to width/diameter and length.

- 4.

The mix design statistical analysis conducted with the data reported in each of the publications analyzed presents a wide range on the proportion values of each component in the mix. This is very important because the mix design has an enormous effect on concrete and mortar final properties.

- 5.

Compression strength is a variable studied in almost all papers, and it is followed in importance by tensile and flexural strength and elasticity modulus. Slump is another relevant variable.

- 6.

A detriment has been observed at many cement composite properties with the aggregate of waste plastic, such as compression and tensile strength or elasticity modulus. These results agree with those presented in other reviews. However, many variables could be used to reduce that effect, such as water/cement ratio, and particle and fibre size and shape, which have been specifically analyzed on the present review.

- 7.

It is necessary to point out some benefits of the addition of recycled plastics on hardened concrete and mortar properties. Some of them are a lower density for plastic particle aggregate, or better flexural strength and residual flexural strength in the case of fibre aggregate.

- 8.

Durability is an important aspect, as some of its components show an improvement with the aggregate of recycled plastic, such as lower shrinkage with fibres or a higher abrasion resistance with particles. Despite that, only a few papers dealing with durability have been found. Consequently, further studies are necessary to improve the understanding of this property.

- 9.

Thermal conductivity was analyzed due to its contribution to the thermal efficiency of constructions. All the authors consulted agree on the fact that plastic aggregate decreases thermal conductivity. Therefore, further research in this line is recommended.

- 10.

The importance of this paper is that it can be used as a guide for designing specific mixes with plastic aggregates or fibres for different applications, including structural and non-structural building materials; such as bricks, panels, subfloors, etc.

This work was supported by the company OBRAS SRL [ARS 62.000,00] and the Secretariat of Science, Technical and Postgraduate [ARS 62.000,00] from the National University of Cuyo, Mendoza, Argentina.

![Modulus of elasticity for concrete with PET particles at various w/c values from references [33]: (a) and [43]: (b). Modulus of elasticity for concrete with PET particles at various w/c values from references [33]: (a) and [43]: (b).](https://static.elsevier.es/multimedia/26036363/00000030000000S1/v3_201903020710/S2603636318300599/v3_201903020710/en/main.assets/thumbnail/gr5.jpeg?xkr=ue/ImdikoIMrsJoerZ+w96p5LBcBpyJTqfwgorxm+Ow=)