In this study, a novel space holder is used for the fabrication of Si foams. The space holder is a graphite composite (GC) with regular spheroidal cells. Conventional space holder materials are not suitable for casting Si foams. The main issue in this context is the differences between the melting point of the foam's base material and the one of common space holders. GC offers many advantages as e.g. low cost, good dissolution by oxidation, high melting point and non-toxicity. This type of space holder is chemically stable when being in contact with liquid and solid Si, and it is, hence, suitable for a melt metallurgical processing route. Si foams are manufactured by applying replication casting. The resulting foam geometry and its surface are analyzed using LM and SEM. XRD measurements are performed to investigate the quality of the Si foam in terms of contamination by graphite or oxygen.

Metal foams are a special type of engineering materials. The combination of base metal and cellular structure shows great potential for a wide range of applications in energy absorption [1], thermal engineering [2] and lightweight constructions [3]. Common manufacturing techniques for metal foams are: sintering, using a blowing agent, investment casting and replication casting [4–6]. A melt metallurgical processing route is usually used for fabrication of open-pore metal foams. Primarily the porosity and morphology of the open-pore foam is defined by a perform. In the case of investment casting, typically a reticulated polymer foam is used as precursor. It is embedded in a ceramic slurry, burned out and infiltrated with molten metal [7–10]. However, this method requires a high effort in time and material. Another melt metallurgical processing route is the replication casting technique. A space holder material is placed in a mold that gets infiltrated with the molten metal. In a next step, the space holder is removed leaving an open-pore metal foam. The space holder has to be insoluble and unreactive with the molten and solid metal while showing good solubility in a solvent or acid that does not react with the metal [10–12].

Energy-efficiency and energy-storage are mayor research fields in science, engineering, and technology in the future [13]. Si has been the most promising candidate for the next-generation anode materials, expressing a theoretical specific capacity of 4200mAhg−1, which is much higher than the commercial graphite anode. Hence, there are currently many developments using Si foams for energy applications [14–16]. Another very promising application for Si foams is the thermoelectricity. Thermoelectric materials show outstanding properties due to their ability to convert waste heat into electricity [17–19]. Of many different alloys and compounds belonging to this class of materials, Mg2Si is a promising candidate. A new manufacturing approach requires Si foam as a precursor that is infiltrated by molten Mg followed by a thermal treatment to form the thermoelectric material Mg2Si [20]. These examples in application show the need of the porous Si structures. The aim of the present study is to investigate the manufacturing process of open-pore Si foams by the melt metallurgical route. For this purpose, we investigate graphite as a space holder to produce replicated open-pore Si foams.

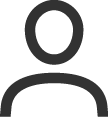

2Material and methodsIn this study, pure graphite (99.8%) spheres (Fig. 1(a)) and graphite based composite (GC) were used as space holder materials. Both types of space holder have a spheroidal shape and a size of 4mm in diameter. The fabrication of GC was performed using graphite particles (purity of 99.8%) in a range of 0.2mm<d<0.5mm (supplied by Thielmann Graphite GmbH & Co. KG, Germany) that were blended with an inorganic binder. This mixture was put in silicone spheroidal and 4mm diametric molds to achieve the desired shape of the space holders. Subsequently, the mixture of graphite and inorganic binder was dried out. Fig. 1(b) shows the final GC after the removal of the mold in comparison to pure graphite spheres.

Open-pore Si foams were produced by centrifugal casting (Vacutherm-3,3-Titan from Linn High Therm GmbH, Germany). This is carried out in five steps: (1) melting of Si, (2) infiltration of the mold filled by the space holder, (3) cooling, (4) removal of the space holder and (5) a chemical aftertreatment. The material used for the infiltration procedure was Si with a purity of ≥99.99% (supplied by ALD Vacuum Technologies GmbH, Germany). Melting of Si was carried out inductively in argon inert gas atmosphere under 0.5bar gauge pressure, after previous evacuation of the melting chamber to 0.1mbar. Inert gas was used to avoid any reaction of graphite with ambient air. Si was placed in a preheated crucible and heated to a temperature of ϑ=1600°C. Centrifugal casting velocity was 500rpm, achieving a flow pressure of the melt of approx. 33.7bar. Previous to infiltration, the space holder particles are placed into a two-piece mold made of graphite. This was pre-coated by boron nitride on the inner walls and preheated to ϑ=200°C for t=1h. After infiltration, cooling was carried out in 20°C ambient temperature. In order to remove the space holder material, a heat treatment of ϑ=800°C for t=4h in normal atmosphere was applied. In a following step, the open-pore foam is treated by aqueous Hydrogen Fluoride (7%) at a temperature of ϑ=35°C for t=240min, this is to ensure the removal of SiO2 layer on the surface of the Si foam. The geometry is examined using a digital microscope VHX500 (from Keyence, Japan) and a scanning electron microscope (SEM) of the type JEOL 840A. By X-ray diffractometry (XRD), the crystal structure was identified using a XRD 3000 TT (from Richard Seifert & Co., Germany). The samples for XRD were prepared by grinding the upper part of the Si foam into a fine powder.

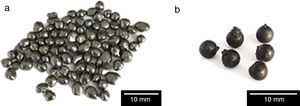

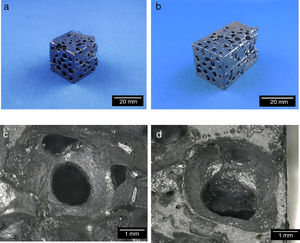

3Results and discussionBy the infiltration process, the voids between the spheroidal GC and graphite structures were filled with molten Si. The space holder was removed as mentioned in Sec. 2. Cellular foams of pure Si are shown in Fig. 2(a) and (b). Using both space holders open-pore foams can be created possessing an entirely high open-porosity. Furthermore, pore structures are homogeneous to a very high extend in combination with a high degree of interconnection between them, forming interconnected pores (Fig. 2(c) and (d)). The Si foam fabricated by GC space holder (Fig. 3(a) and (b)) show, a pore geometry of, circular to oval character corresponding to the shape of the space holder. In the replication-casting process, the space holder is essential for the final properties of the metallic foam. The porosities of the fabricated samples are approx. 70–74% for the GC and 64–71% for graphite space holder. The structural and mechanical properties strongly depend on the geometric properties of the space holder. It determinates the sizes and shape of pores and cells. Furthermore, the surface topology of the foam itself is prepossessed by the space holder smoothness surface. The smooth graphite spheroids lead to a smooth surface of the Si foam compared to the rough GC. The removal of the space holder by oxidation creates a filigree cellular open-pore structure. Hence, the Si struts are dense and have a triangle cross section combined with a high surface area. The surface has the typical casting structure. The remnant graphite on the surface implies an uncompleted oxidation (Fig. 3(c) and (d)). The X-ray diffraction profile of the sample is shown in Fig. 4. The crystal structure of the powder was identified as pure silicon and graphite. The Bragg angles of SiC or SiO2 are additionally indicated in the upper part of the diagram, demonstrating that only Si and graphite could be detected. This implies that the aftertreatment with hydrofluoric acid removed successfully SiC and SiO2 on the Si foam surface.

Open-pore Si foam with a cell size of 4mm was successfully produced by centrifugal casting. Graphite and graphite composite particles have proven as an alternative space holder material for the fabrication of Si foams. Removal of the space holder by oxidation creates a filigree cellular open-pore structure. The reason is the point contact between the graphite composites during the infiltration. Hence, the Si struts are dense and have a triangle cross section combined with a high surface area. The cell diameter is almost equivalent to the space holders. The process was set to reduce complexity and cost of Si foams. Pore diameter is a main parameter for variation of pores and cell size. A new approach of mixed use of space holders with different diameters and shape can modify porosity and lead to desirable foams for unique applications. Also a directed electrochemically treatment with high concentrated HF on the Si surface [21] could lead to a foam with a porous surface strut structure.

The authors acknowledge funding by the Ministerium für Wirtschaft, Arbeit und Wohnungsbau of the federal state Baden-Württemberg in the frame of the program “Technologischer Ressourcenschutz” (project number 7-4332.62-HSPF/3) and the financial support through the program “Mittelbau” at HAW. The authors would also like to express their gratitude to G. Erofeeva, A. Hausmann, M. Brodbeck B. Müller and G. Hildebrandt for assistance concerning experimental tasks.