It is well known that the global climate change is the largest challenge for the society of the 21st century. For managing the resulting consequences, innovative materials become more and more important. Open cell metal foam contributes promising solutions to light-weight design, battery applications and renewable energy harvesting. Still, challenges are present concerning the cutting into a defined shape. Remote laser cutting offers a solution for decreasing the production costs as well as the needed component accuracy. Our investigations reveal that this technique has a high potential concerning cutting speed of open cell aluminum foam, which was increased by more than 500% compared to state-of-the-art laser separation. Furthermore, different material thicknesses up to 20mm were investigated. Additionally, the limit of the possible contour wall width was decreased to less than the size of one pore. This paper offers insight into the viability of remote laser cutting in overcoming the challenges dealing with mechanical milling or grinding. Investigating the process concerning thermal stress input as well as particle attachments will be the next steps in the future.

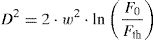

In the last several years, innovative materials such as open cell metal foams deliver the opportunity to be the solution for upcoming challenges in light-weight design [1]. For pushing the possibilities, open cell foams were utilized in various fields of application such as heat exchangers, battery systems or medical implants [2–11]. Note that manufacturing open cell metal foam into a define shape is still challenging due to the utilization of mechanical processes like milling or grinding, as shown in Fig. 1[9]. An innovative approach in overcoming these challenges is the application of laser technology [12].

Laser technology is a new approach for cutting metal foam due to the fact that it is a wear-free and highly flexible process [13]. Several experiments were carried out using laser fusion cutting [14,15]. This is an established separation technique in various fields of industrial applications. The basic principle is well known as the laser beam is absorbed at the surface of the material and melts the entire bulk at once. A coaxial high pressure gas stream (for example N2, Ar, or air) ejects the molten material to the bottom side of the specimen [12]. Due to melting the entire bulk in the cut kerf at once, a thermal stress is induced. Consequently, several investigations dealt with induced thermal stress into the foam material in order to determine and evaluate the cutting parameters as well as the geometry of the contour [13]. Additionally, the property of the open cell structure decreases combustion of the process gas. Nevertheless, dross attachments as well as thermal stress are the biggest challenges that have to be investigated in more detail.

Therefore, several investigations concerning laser fusion cutting of open-cell metal foam were carried out. Nevertheless, meld attachments as well as the possible thicknesses, still limits the possibilities. In conclusion, laser cutting possesses the ability to increase the cutting speed and the quality of the parts generated from foam material [16–18].

In order to overcome those limitations a novel laser cutting technology was implemented and successfully tested [19–21]. Our previous investigations showed that remote cutting is a promising approach in sizing with laser. Moreover, it has the possibility to reduce the thermal induced stress. Furthermore, the open cell structure will be kept as well as the preferred contour outline. The investigation verifies the novel remote laser cutting technique for open cell foams. Relevant core themes of the research are achievable separation velocity, edge geometry, achievable component tolerances and minimal wall thickness.

The second section will give an introduction into the experimental setup. Explaining the basic principle of remote laser cutting as well as the methodology are the major subjects in the section. A special focus is put on the imaging process and how it can be used for getting reliable results. The third section focusses on material characterization and cutting process parameters. Finally, the fourth section illustrates the results regarding the four major core themes.

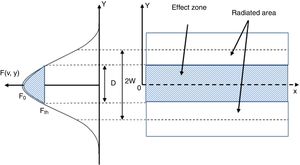

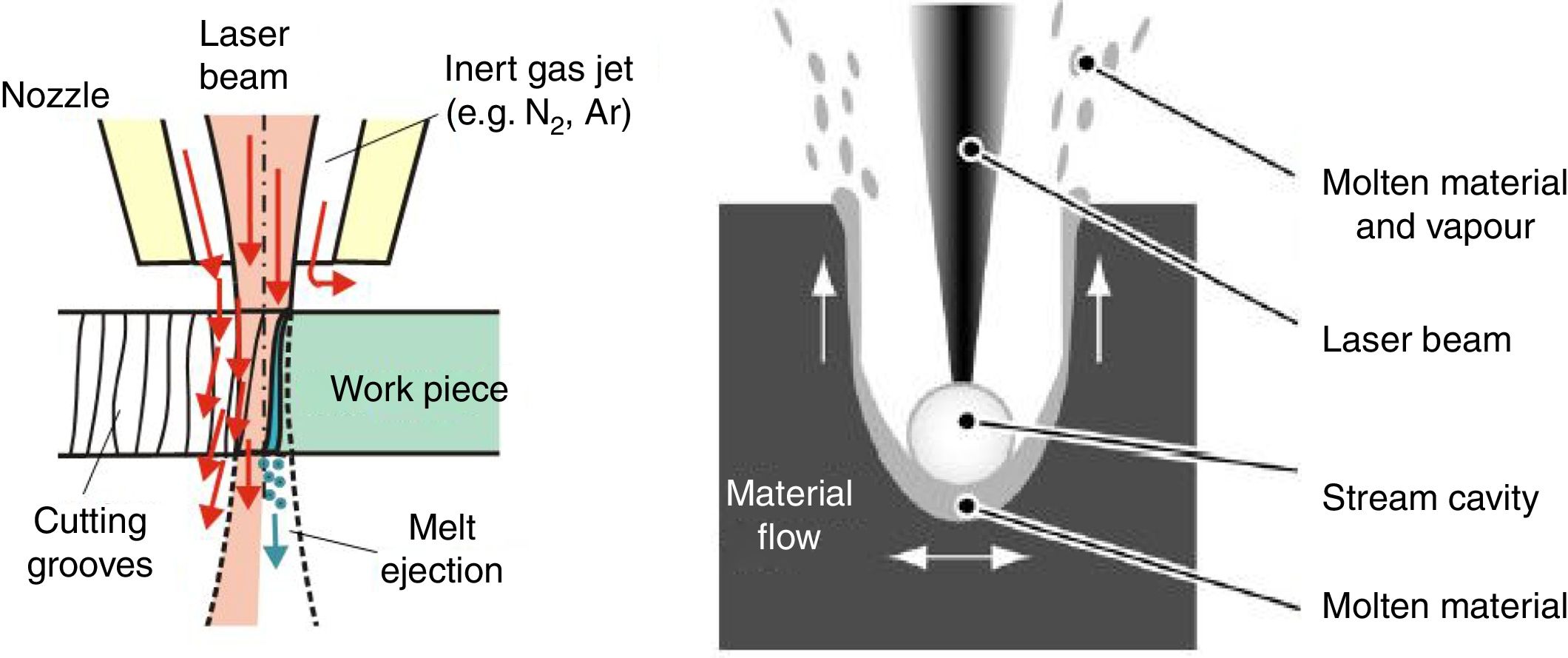

2Experimental setupSince the basic physical principle is not generally known, this section will describe remote laser cutting in more detail. The laser beam is absorbed at the surface and melts only a small volume of the irradiated area. Next to the molten part, a small amount of material is vaporized, shown in Fig. 2. This vapor is called steam cavity and consists of a high pressure, which ejects the molten material. For achieving the steam cavity in the cut kerf, a high intensity of the laser beam is required. It is known that this could be achieved by using small spot sizes in the focal plane. The cut kerf is created in a gradual ablation. Moreover, the melt and vapor is ejected to the top side of the specimen. Consequently, small spot sizes (Øspot<100μm) at large working distances require a high beam parameter product (BBP). Accordingly, a single mode fiber laser was utilized for the following investigations [22].

Theoretical work principle of laser fusion (left image) and laser remote (right image) cutting [13].

The word “remote” in the sense of laser cutting describes the beam manipulation system, which focuses and deflects the laser radiation. Hence, the beam gets deflected over mirrors, which are attached on highly dynamic galvanometric drives. Typically, a larger distance (up to 650mm) to the material surface is adjusted than other laser cutting technologies (0.5–1.5mm). Summarizing the different separations techniques, the basic principle of the remote laser cutting and fusion cutting is illustrated in Fig. 2.

Laser remote cutting as an alternative separation technique for metal foams will be discussed in terms of four main criteria; achievable cutting speed, edge shape, thermal damage and oxygen distribution. Due to the fact that the laser beam is deflected by mirrors, cutting speeds of up to 1200m/min are possible. Furthermore, stepwise ablation of the material during remote cutting offers an opportunity to manipulate specific process parameter (idle time between cycles, cross jet pressure, scan velocity). Moreover, optimizing these can reduce the thermal damage zone.

As already mentioned, for the remote laser cutting technique high brilliant beam sources are indispensable. For the following investigations, a single mode fiber laser with a maximum output power of 5000W is utilized. Due to the fact that the beam size has a significant influence on the spot size, a collimator with a focal length of 200mm is used [18]. As a beam manipulation system a scanner with an aperture of 20mm and a focal lens (340mm focal length) was considered. The results of the optical components are measured with a laser beam diagnostic system and shows spot value of 61μm.

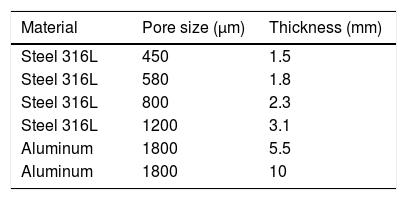

In this report, open cell foam out of steel-316L and aluminum were investigated. The foams were provided from the companies “Mayser” (aluminum foam) and “Alantum” (steel 316L foam). Table 1 presents the most important material parameters.

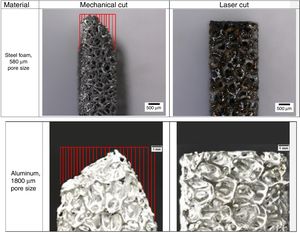

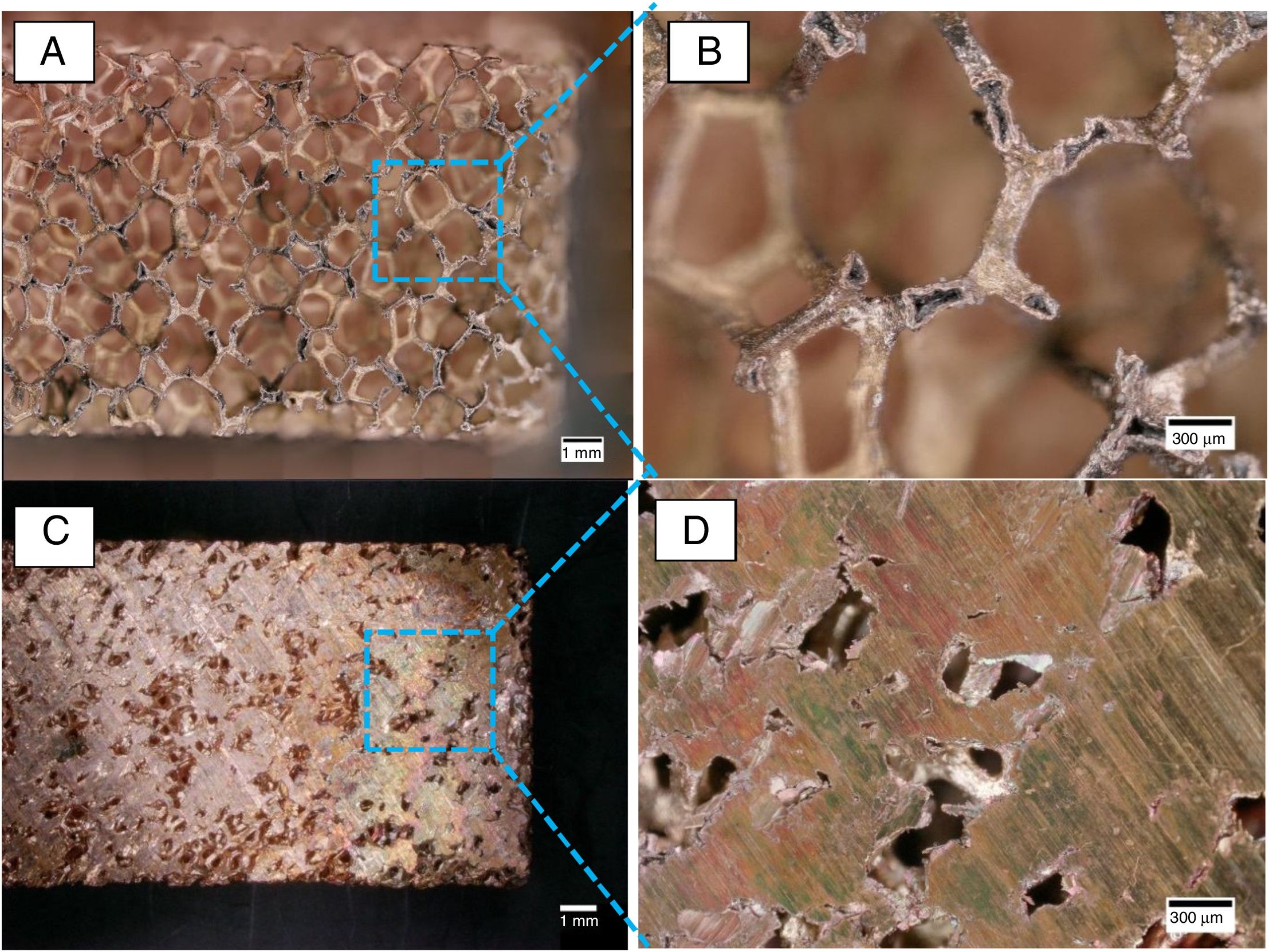

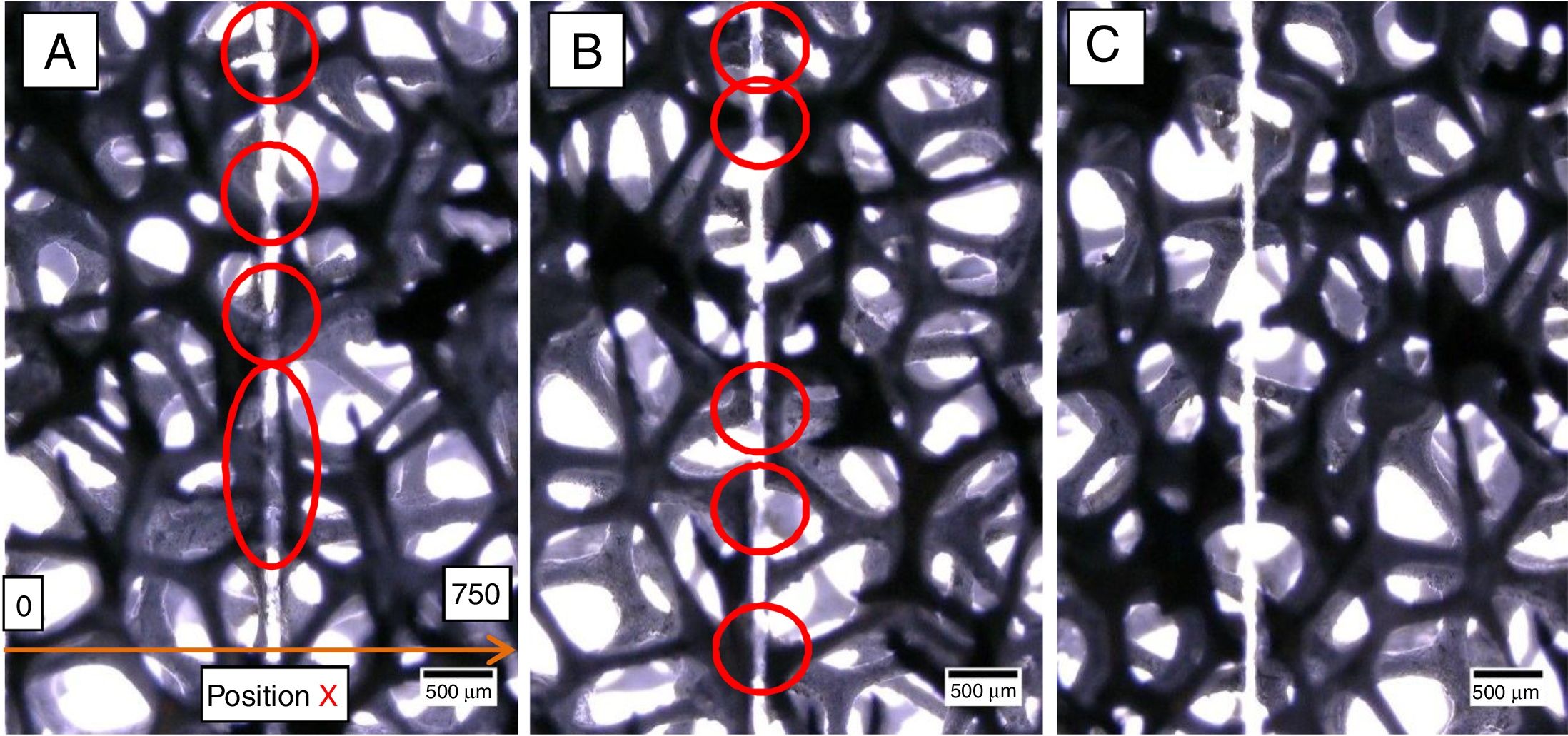

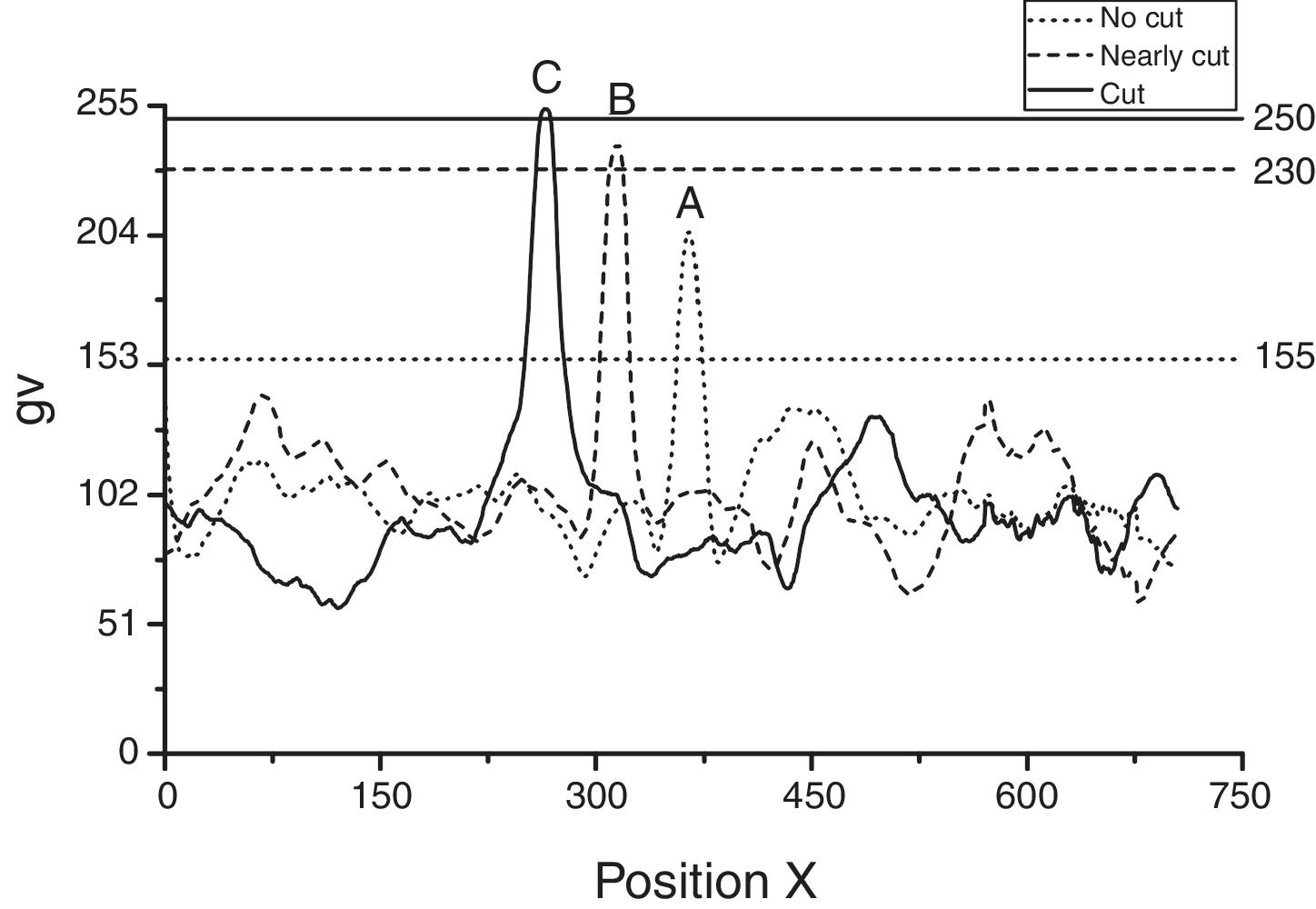

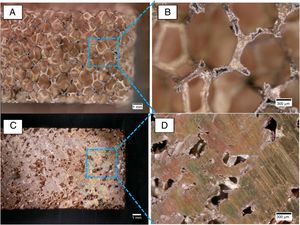

For determining the possible cutting speed, the results had to be categorized into three different groups. All samples were analyzed via microscopy (Keyence VHX 5000) and defined as “cut”, “nearly cut” and “no cut”. A sample, which is located in the “cut” category possess a complete and clear kerf without any struts, as illustrated in Fig. 3 left. While a “nearly cut” offers some remaining and a “no cut” shows multiple incomplete sections in the kerf (Fig. 3). Moreover, with this cut categorization the possibility to determine the cutting velocity for both setups and foams are given.

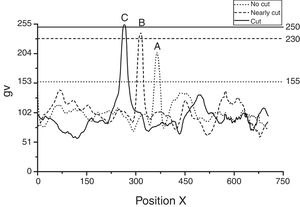

At first, an image of the surface as in Fig. 4 of the sample was taken and segmented into vertical lines. Consequently, the background of the images was white, which represents a gray value of 255. The average gray value of these vertical lines (0<Igv<255) were calculated and recorded. If a gray value is above 250, the sample was set into the “cut” category. A gray value between 230 and 250 represent the “nearly cut”. All remaining results can be seen as a “no cut”. This process is shown in Fig. 4.

Concerning the determination of tolerance, all data were taken by a standardized and gauged measuring machine. This machine has the opportunity to gather the data non-destructive via an optical measuring tool (Fig. 5).

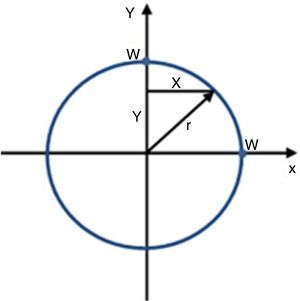

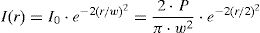

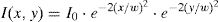

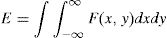

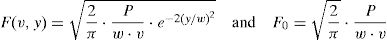

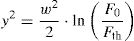

The laser beam has a Gaussian beam profile and moves with the constant velocity v over the surface of the specimen. Each point of the material, which was influenced by the beam, gets a pulsed like load of intensity. Duration and strength of this load defines the fluence:

F is the fluence, I represent the intensity of the used laser beam and t depicts the interaction time between the base material and the laser beam.The beam shows a Gaussian intensity distribution:

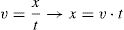

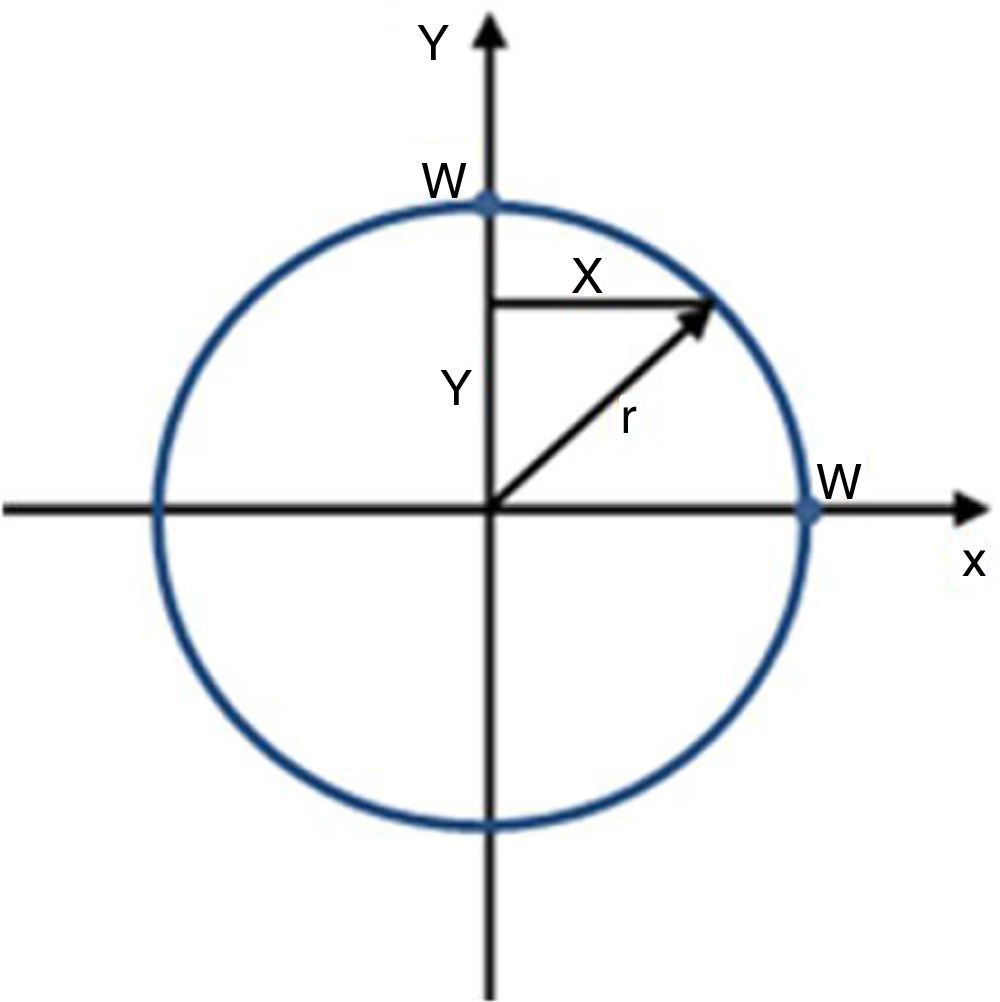

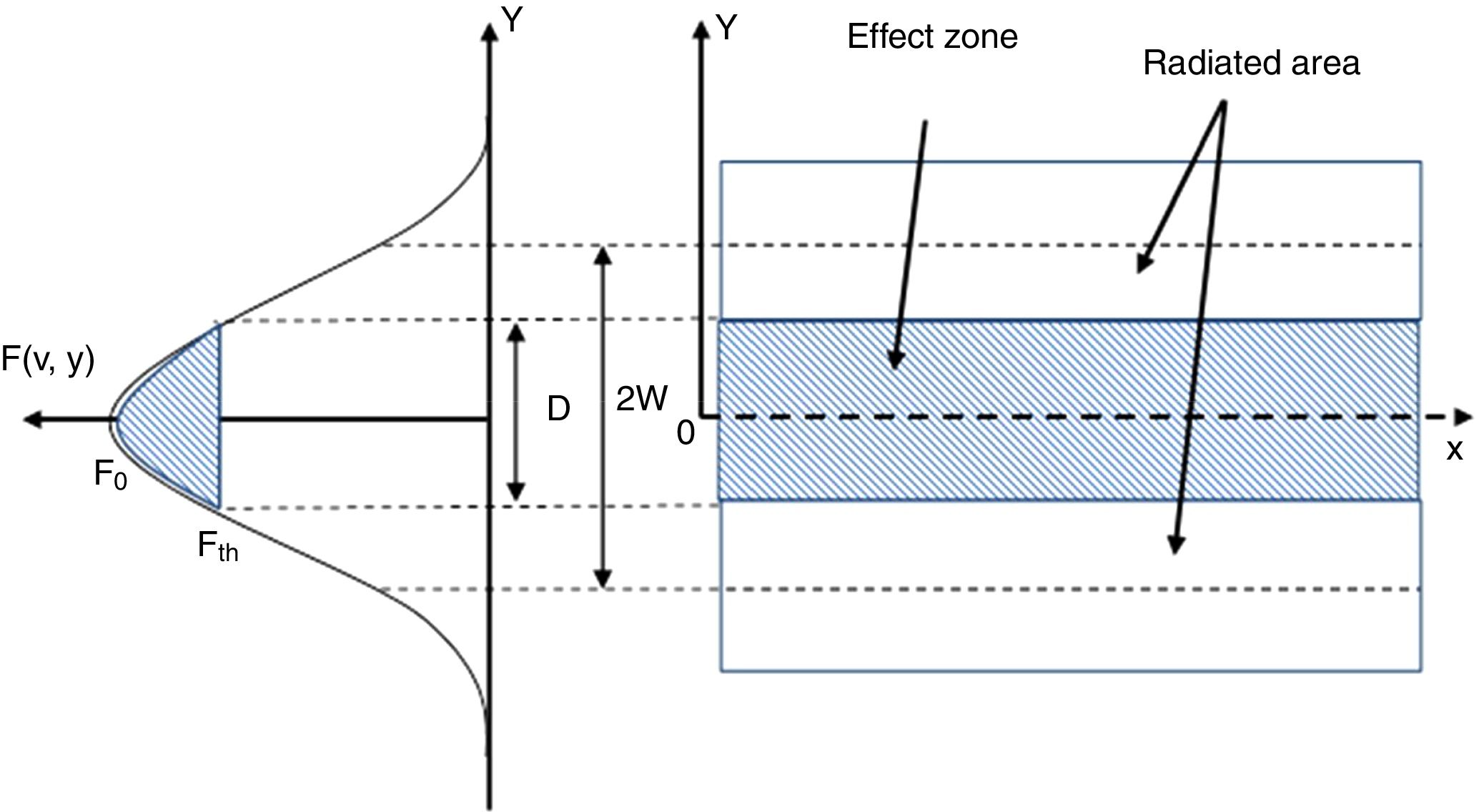

P shows the values of the used laser power and v represents the velocity of laser beam on the material surface. The radius of the laser beam on the material surface is defined by w.A beam with a fluence distribution F(r) moves with a constant velocity v in the x-direction. If the maximum fluence F0 is larger than the effect threshold Fth materials changing appears in strips as shown in Fig. 6.

The width of the effect zone is D. In this section, the maximum fluence F0 exceeds the effect threshold Fth for a moved laser beam. Moreover, the width D depicts a fluence distribution F(v,y) at F(v, D/2)=Fth. Hence, the effect zone D can be calculated with Eq. (7)

At F(v,y)=Fth should the y=D/2, which concludes in:

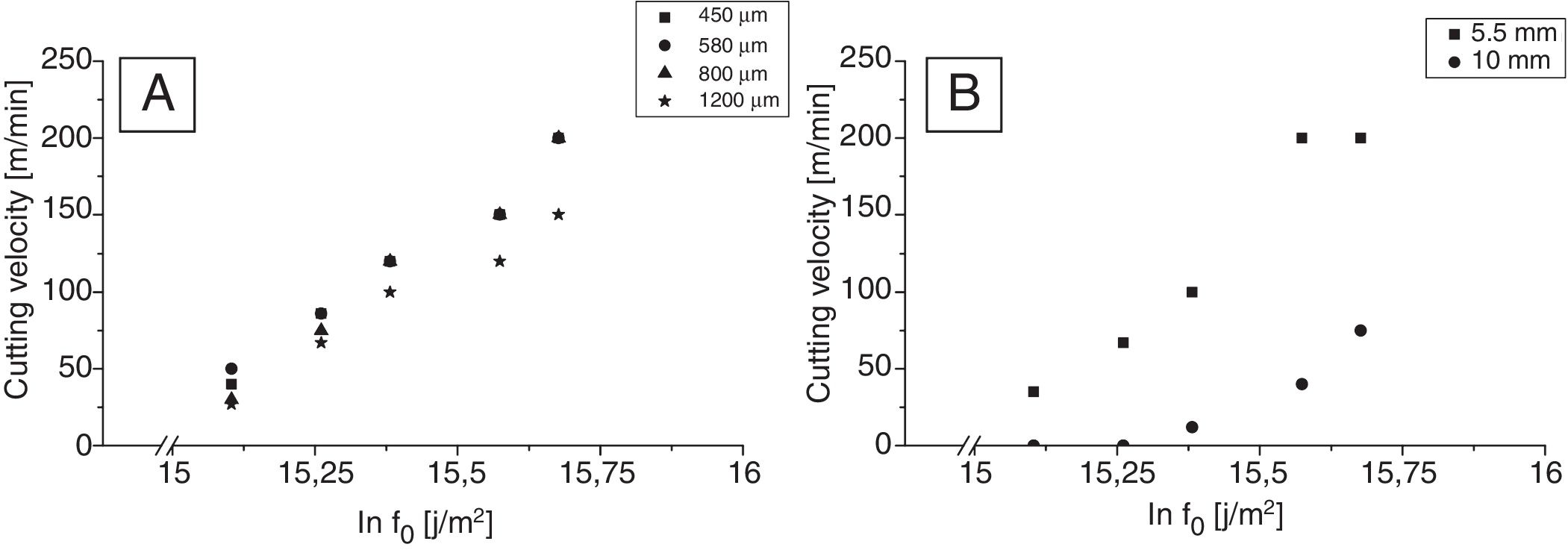

3Results3.1Separation velocityFor determining the cutting speed, the maximum laser power Plaser was linearly raised and the numbers of scan cycles were adapted to achieve a complete cut, respectively. Note that several laser and scanning parameters influences the results. For combining them into one overall parameter the maximal fluence F0 is introduced.

With increasing fluence the achievable cutting speed rise for all investigated foam materials, as it can be seen in Fig. 7. Moreover, foams with larger material thickness (10mm) such as aluminum exhibit slower cutting speeds due to the needed increase of scan cycles. The maximal cutting speed for steel (316L) foam is 200m/min for pore sizes of 450μm, 580μm and 800μm.

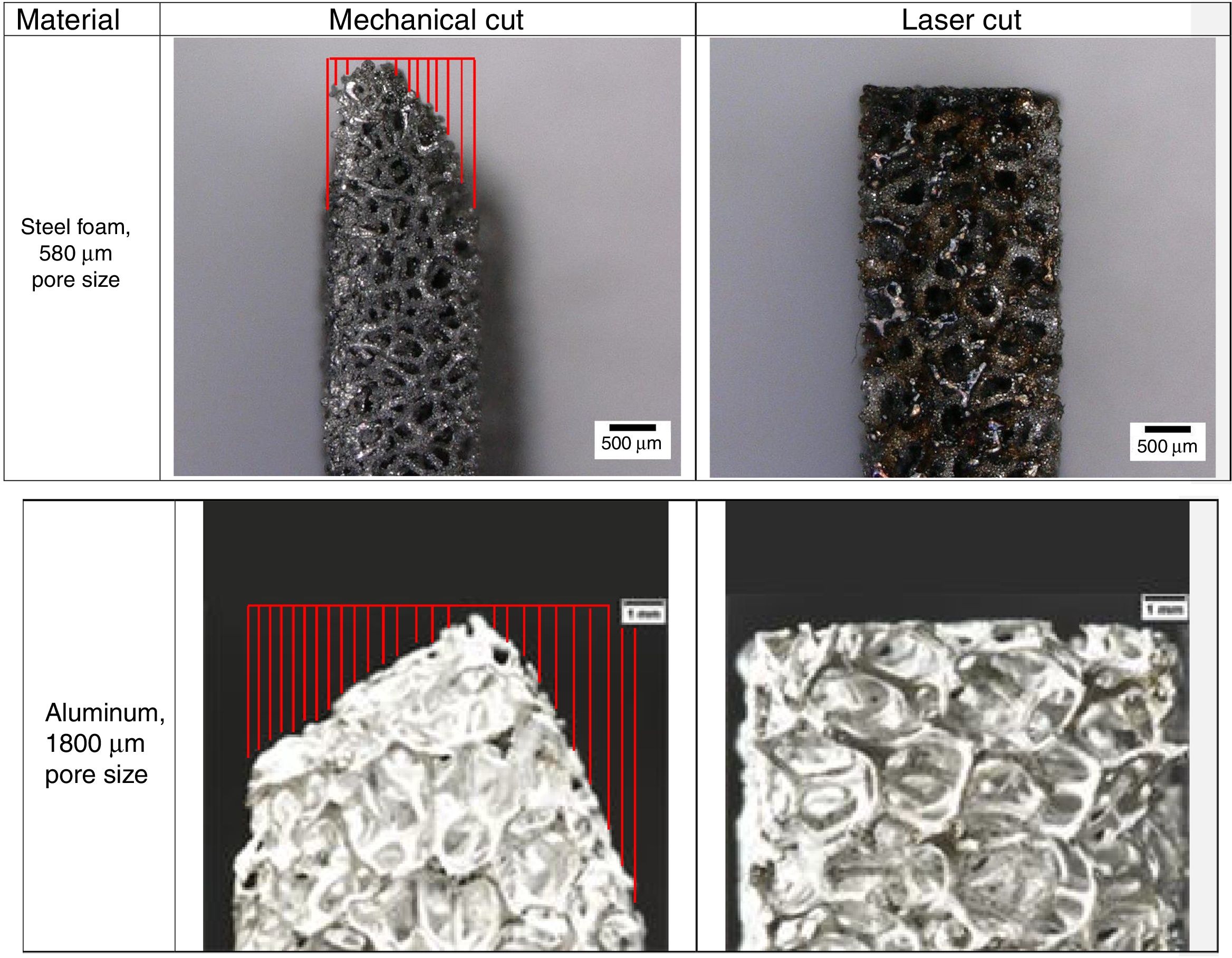

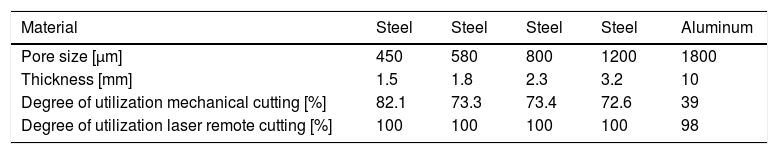

3.2Edge geometryA geometrical aspect of the cut area has to be investigated as well. As mentioned, state-of-the-art separation techniques like milling, grinding or punching are creating a disorientation of the edge. Especially punching influence the edge geometry due to a squeezing effect. Exemplarily, the determination of the degree of utilization is depicted in Fig. 8.

As demonstrated in Fig. 8 the hatched area represents the material loss. In conclusion, only 72.6% of the material at the edge is operative for the designed purpose. This remaining material defines the degree of utilization. Note that the material is getting squeezed into the remaining foam structure, which influences the pore size and distribution. In comparison, laser cutting shows no edge deformation or squeezing. For all different pore sizes the fraction of remaining material, the so-called degree of utilization, was calculated and illustrated in Table 3. As it can be seen, the degree of utilization for remote laser separated foam is at 100% whereas the mechanical cut creates values between 82% and 72%. This 100% degree of utilization could be explained by the forceless separation with laser beams. It is well known that with increasing pore size the material thickness is getting larger due to fabrication aspects [2]. A larger pore size and foam thickness leads to a greater foam area, which is effected by the cutting force. This is why an increase of pore size leads to a decrease of the degree of utilization. The results of all researched foam materials concerning the degree of utilization are shown in Table 2.

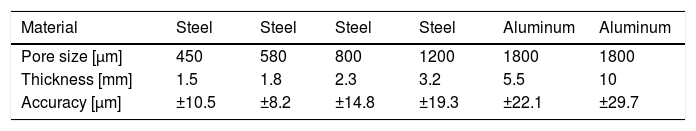

Next to the degree of utilization a significant result is the achievable accuracy. In the past the poor performance concerning the accuracy of parts made from foam leads to failures in functionality [3]. Therefore, one main issue of the investigations is the determination the cut accuracy of open cell metal foam. For determining the contour accuracy, round blank specimens were cut with a programmed diameter of 15mm. Moreover, for each porosity and their corresponding thickness, ten circles were manufactured. Each measured round specimen consists of 20,000 data points.

The results of the investigations dealing with the achievable contour accuracy show a tremendous increase compare to the state-of-the-art separation techniques [3]. In addition, values less than 20μm are reachable for steel foams. Open cell metal foams out of aluminum exhibit accuracy values less than 30μm. Moreover, a correlation between pore size and accuracy can be identified. As it can be seen, with increasing pore size the achievable accuracy is decreasing. This effect is not fully investigated in order to give an explanation. More research has to be conducted concerning this issue for identifying the parameters.

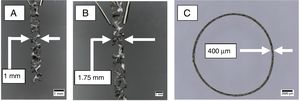

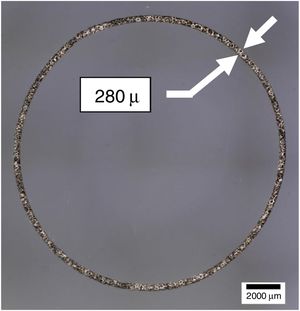

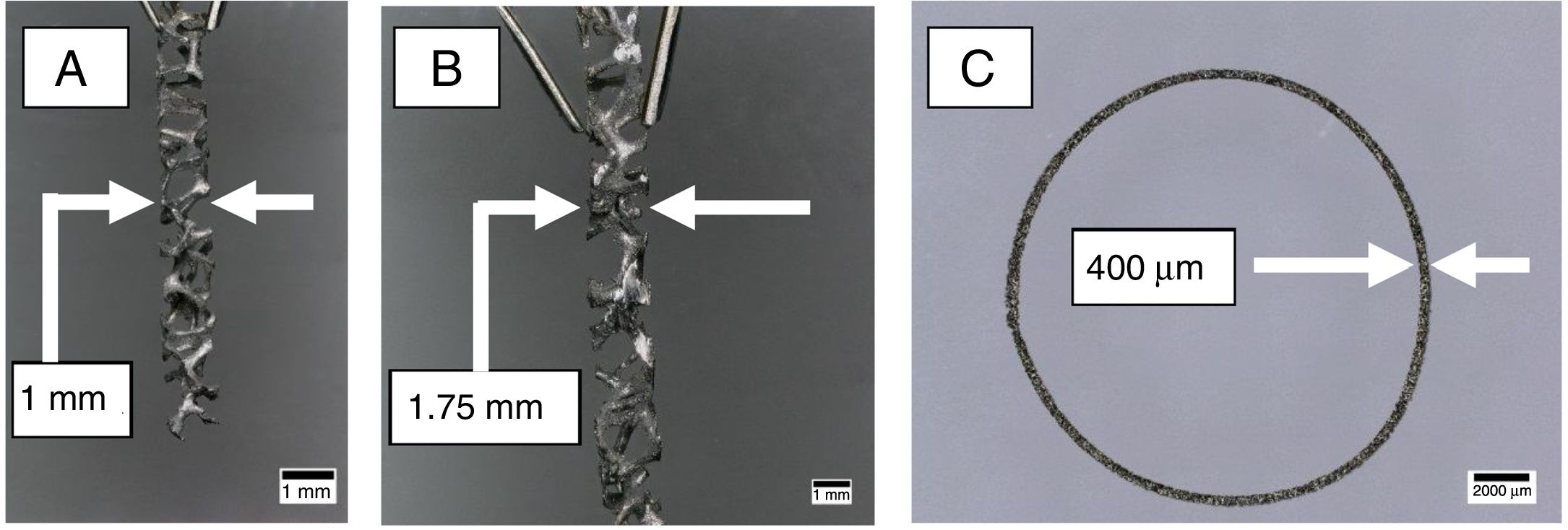

3.4Minimal wall thicknessLaser remote cutting offers the opportunity of a forceless separation technique. Therefore, the possibility is given to manufacture thin components out of foam. Consequently, several investigations concerning the achievable minimal wall thickness were conducted. For those experiments, open cell metal foam out of aluminum with a pore size of 1800μm and the related thickness of 5.5mm as well as steel foam with a pore size of 450μm were investigated. For determining the wall thickness optical microscopy was executed. The samples were single strips and circles, illustrated in Fig. 9.

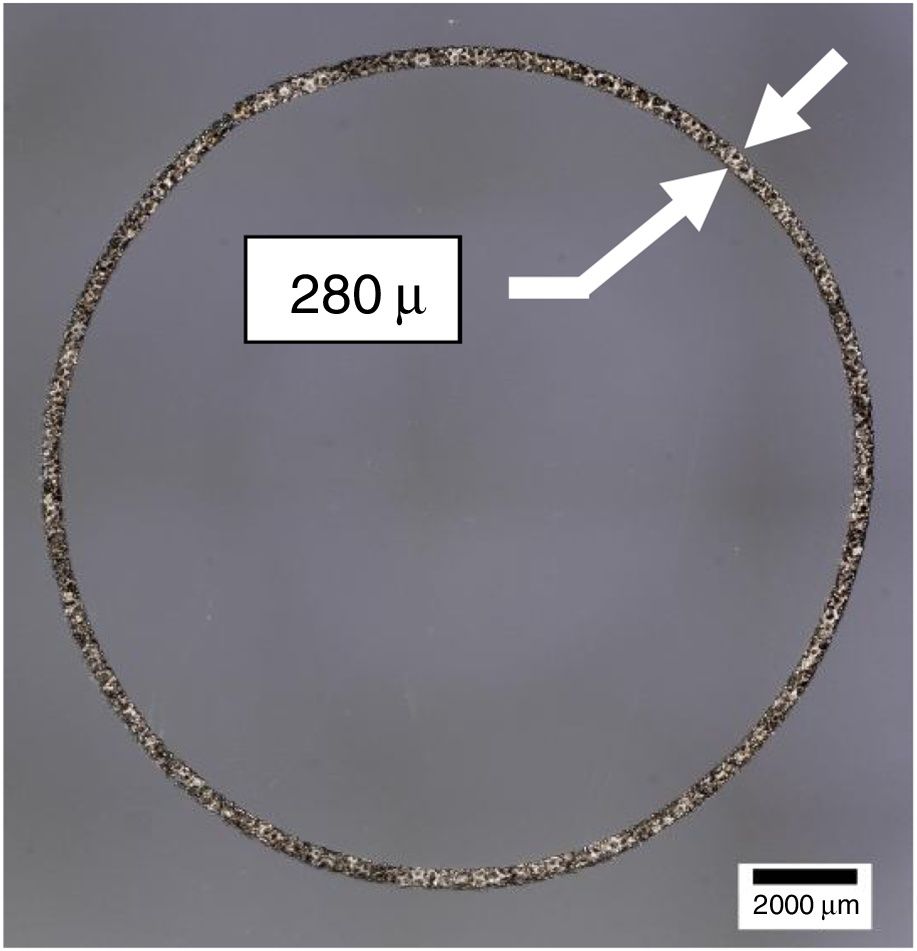

The possibility is given to achieve even smaller wall thicknesses. Nevertheless, it has to be ensured that enough foam material remains to creating a stable structure. Moreover, the investigations reveal that laser remote cutting open cell foam structures exhibit a wall thickness of at least 0.75 pore diameters. Otherwise producing a thin foam component is only feasible under probability. All in all it was possible to cut a specimen with a wall thickness of 280μm, which represents 0.62 pore diameters as shown in Fig. 10.

4ConclusionRemote laser cutting offers solutions for upcoming challenges concerning shaping of open cell metal foam out of steel and aluminum. An achievable cutting speed of up to 200m/min is possible. Note that with larger pore size the material thickness increased correspondingly, which results in a lower separation velocity. Tolerances of less than ±30μm, for some pore sizes ±8μm are reachable. A major leap forward was made concerning slicing the foam into thin components. Wall width with less than 0.75 pore sizes is achievable for several materials and porosities. Further investigations will consider an increase of material thickness as well as different materials such as nickel, titanium and certain alloys.

The authors gratefully acknowledge support and funding from the German Ministry of Research and Development (BMBF) grant no. 0325563A.

![Theoretical work principle of laser fusion (left image) and laser remote (right image) cutting [13]. Theoretical work principle of laser fusion (left image) and laser remote (right image) cutting [13].](https://static.elsevier.es/multimedia/26036363/0000003000000001/v1_201806280418/S2603636318300125/v1_201806280418/en/main.assets/thumbnail/gr2.jpeg?xkr=ue/ImdikoIMrsJoerZ+w96p5LBcBpyJTqfwgorxm+Ow=)