This study proposes a novel production function of digital empowerment. It constructs a theoretical framework to analyze the digital enabling process for enterprises from the production factor and economic activity aspects. It uses data mining technology to measure the degree of digitalization, extracts a typical relationship model between digitalization degree and enterprise performance, and digs out the association rules among traditional factors, digital factors, and economic activities under different relationship models. The results show that the digitalization degree and the digitalization enabling the level of mechanical and electronic enterprises are higher than those of light textile enterprises and resource-processing enterprises. The substitution elasticities and the association rules among factors and activities also have enterprise heterogeneity, which leads to differences in the digital transformation paths of different types of enterprises.

The digital economy era is approaching with the development of artificial intelligence, big data, cloud computing, Internet technology, and other new generations of information technology (Amuso, Poletti & Montibello, 2019; Novikov & Sazonov, 2020). Different from the previous industrial revolution, which mainly relied on material resources (such as labor, capital, and energy (Rifkin, 2011), digital knowledge and information, digital technology, and a highly skilled labor force are the driving force for economic growth in this revolution (Azmeh, Foster & Echavarri, 2019; Ojanperä, Graham & Zook, 2019). The IDC (Reinsel, Gantz & Rydning, 2018) forecasted global data would increase from 33ZB in 2018 to 175ZB in 2025. The new generation of information technology has been infiltrating the real economy, changing the original industrial production organization mode, the law of value creation, and distribution (De Reuver, Sørensen & Basole, 2018). It connects products, people, and devices with the virtual world, making the information transfer between enterprises in the value chain more convenient and cooperation more effective than previously (Cheng, Zhang, Tao & Juang, 2020). The application of digital technology and the flow of digital knowledge and information can increase information transparency, enabling enterprises to obtain information needed at low cost and with high efficiency; to better meet the needs of upstream and downstream enterprises and customers and help partners understand the processing status in real-time (Tao, Zhang, Liu & Nee, 2018). The deep integration of digitalization with the real economy has transformed the driving force of economic growth, thereby improving the quality and efficiency of economic development (Amuso et al., 2019). The IDC (IDC, 2018b) research shows that global big data and business analysis revenue will increase by at least $100 billion from 2018 to 2020, with an average annual growth rate of 11.9%. Accenture (2019) predicted that the industrial Internet would bring over $15 trillion of growth to the global economy by 2030.

Therefore, many real enterprises hope to seize the new opportunities brought by the digital economy and make changes to enterprises to realize the continuous growth of enterprise profits (Banerjee & Ma, 2012; Li, Su, Zhang & Mao, 2018). Additionally, the impact of digitalization is no longer limited to developed economies. It has a profound impact on middle-income and low-income countries (Foster & Azmeh, 2019). Some small and medium-sized enterprises (SMEs) in developing countries have used complex digital technologies such as intelligent enterprise resource planning, artificial intelligence, the Internet of Things, digital design, and smart manufacturing to improve the competitiveness of enterprises in the digital economy era (Ghobakhloo & Azar, 2018; Tortorella & Fettermann, 2018).

However, the effect of enterprise digital transformation is unideal. Some enterprises, especially SMEs, lack sufficient capital and high-skilled talents (Hong & Ghobakhloo, 2013; Müller, Buliga & Voigt, 2018). They usually have limited access to information (Madrid-Guijarro, Garcia & Auken, 2009) and rarely use big data and digital technology for financial analysis, prediction, and project management (Ghobakhloo, Arias-Aranda & Benitez-Amado, 2011). The IDC (2018a) surveyed 2000 transnational enterprises and found that the failure rate of digital transformation of traditional industries was as high as 70%–80% in 2018. As the world's second-largest economy, the Chinese government has attached great importance to integrating the real economy and digital technology. It has introduced a series of policies and regulations to encourage the transformation and upgrading of traditional enterprises (State Council, 2017), but the effect is not optimistic. According to statistics, in 2019, only 9% of Chinese enterprises achieved remarkable results in digital transformation, and they achieved over half of the total revenue from new businesses. In contrast, most enterprises have not achieved digital transformation, or the results are insignificant (Accenture, 2019).

In the digital economy, big data, cloud computing, artificial intelligence, and other digital technologies have accelerated the coupling and restructuring of digital and traditional resources. This phenomenon has changed the relationship and combination of production factors and stimulated inefficient resources to release increased value-creation potential by improving productivity. It has promoted profound changes in production methods worldwide and digital transformation to become an inevitable enterprise trend development. Whether enterprises choose digital transformation largely depends on whether the digital transformation can improve the value-creation ability of enterprises. In contrast, the success of the digital transformation is related to the transformation path. Globally, the digital transformation of Chinese enterprises is at a medium and low level (Alikberova & Alikberov, 2020). This study seeks to promote the digital transformation of Chinese enterprises by investigating the effect of digitalization on enterprise value creation and whether the path of digital transformation for different types of enterprises differs.

By analyzing the above issues, we attempt to reveal the mechanism of digitalization on enterprise value creation, identify the digital transformation path of different types of enterprises in China and provide a theoretical basis for the government to formulate policies to solve the bottleneck of digital transformation of Chinese enterprises. The remaining study is organized as follows. Section 2 is the literature review, reviewing the existing studies on digital transformation. Section 3 constructs the theoretical framework to analysis the impact of digitalization on value creation of enterprises. Section 4 is the empirical analysis of Chinese manufacturing enterprises. Section 5 is the discussion of the findings and contributions, and the conclusions and limitations are shown in Section 6.

Literature reviewConcept of digitalizationThe digital economy is a concept closely related to digitalization, which is the development and extension of the information economy. Machlup (1962) realized the particularity of information products and services earlier and pointed out that enterprises providing information products or services to the market were an important economic sector. Although his perception of the information economy has exceeded the technical level, the essence of the information economy has not yet been explained. Don Tapscott (1996) studied the effect of information technology on the economy and formally proposed the concept of a digital economy for the first time. The Group of Twenty Summit (2016) pointed out that the essence of the digital economy is a series of economic activities that take digital knowledge and information as key production factors, modern information networks as the important carriers, and information and communication technology as a main driving force for efficiency improvement and economic structure optimization. Xu, Ge, Wang & Skare, 2021 used bibliometric analysis methods and visualization software to explore technology adoption, and found that technology adoption has a variety of applications in digital fields such as online shopping, mobile learning, mobile banking, and e-learning, which shows that the integration of digital technology and traditional field has become an important development trend. The overall digitalization of China is in the middle of the range globally, but China has emerged as a global leader in some key digital industries such as e-commerce, fintech, cloud computing and ICT exports (Alikberova & Alikberov, 2020). In the industrial sector, the advanced manufacturing sector is more digitalized (L. Zhang & Chen, 2019).

Measurement of digitalization degreeScholars have used different methods to measure the degree of digitalization. Based on the maturity model, Schumacher, Erol and Sihn (2016) used the Likert Scale method to evaluate the importance of digitalization degree from 62 indicators in 9 dimensions. They divided the enterprise digital transformation into five levels, from never realizing digitalization to fully realizing digitalization. Schuh, Anderl, Gausemeier, Hompel and Wahlster (2017) analyzed four modules of resources, information systems, organizational structure, and culture by radar chart. They divided the enterprise digital transformation into six levels: computerization, connectivity, visibility, transparency, prediction ability, and adaption. Additionally, Marinko Škare and Małgorzata Porada-Rochon’(2021) constructed a summary index using the standardized inverse-covariance weighted average of growth of capital services provided by computers and information technology (ICT) assets, the contribution of capital services provided by (ICT) assets to GDP, and share of (ICT) capital compensation in the gross domestic product (GDP) to test the digital convergence of 129 countries. They identified digital leaders and followers by log t convergence test. Skare and Riberio Soriano (2021) also proposed the digital adoption index (DAI) from three dimensions, DAI Business, DAI People, and DAI Governments, to measure the digital adoption of 183 countries.

Overview of the impact of digitalization on enterprisesDigitalization has realized the decentralization of industrial structure, the digitalization of economic activities, and the connection of social life with the Internet of Things (Besson & Rowel, 2012; Tan, Pan, Lu & Huang, 2015). It is a resource available to enterprises and the derivation of enterprise capabilities (McAfee & Brynjolfsson, 2012). Some scholars think that the significance of digitalization to the real economy lies in the renewal of the organizational mind, which emphasizes the reconstruction of traditional industries by digitalized thinking (H. Li, Tian & Li, 2014). Digitalization endows enterprises with four new capabilities: information acquisition and integration capabilities based on the Internet of Things, cloud computing, data mining, artificial intelligence, and other new-generation information technologies (Basole & Park, 2019; Wang & Wang, 2020), market perception ability generated by the direct interaction between enterprises and consumers owing to the “disintermediation” function of the Internet (Dey, Yen & Samuel, 2020), relationship integration ability resulting from enterprise information transparency and the digital connection between enterprises (Zhao, Wu & Liu, 2019), and advanced prediction ability generated by real-time processing and application of super large data in mobile Internet (McAfee & Brynjolfsson, 2012). Digitalization forms more and faster “new competitive means” by giving enterprises new capabilities. Subsequently, it subverts the original value-creation process of enterprises.

Digitalization can promote the innovation ability of enterprises. Digital information and knowledge can be generated, shared, and exchanged among enterprises at low cost, rapid, and real-time via various digital platforms (Menon, Kärkkäinen & Wuest, 2019); it enables enterprises to obtain increased information at a reduced cost, increases knowledge stock, and accumulates additional knowledge for innovation (C. Zhang, Xue & Dhaliwal, 2016). Additionally, digital technology allows the accelerated diffusion and dissemination of knowledge within enterprises, making it easier for information and knowledge to be transformed into high-quality innovation results, thus promoting enterprise innovation (Paunov & Rollo, 2016). The inherent dynamism and plasticity of digital technologies may drive knowledge combinations, which leads to new digital knowledge generation and digital innovation (Hanelt, Firk, Hilebrandt & Kolbe, 2020). Kaufmann, Lehner and Tödtling (2003) empirical analysis of Australian enterprises showed that as a typical representative of digital technology, Internet technology has a significant positive effect on enterprise innovation cyberspace expansion. Purdy, Qiu and Chen (2017) have shown that digital technology could improve the innovation ability of enterprises.

Another significant impact of digitalization on enterprises is that it can effectively reduce the cost of enterprises. With the help of digital platforms, enterprises can use free knowledge, information, and low-paying or even zero-paying public power to reduce the cost of enterprise information acquisition (García, Guillot, Zimányi & Langman, 2012). Digital technology has transformed “information scarcity” into “information democracy” (Dey et al., 2020). The connection function of digital technology can reduce the information asymmetry between consumers and producers (Cappellini & Yen, 2013), remove unnecessary intermediate channels, and accurately connect the consumers and producers, which can reduce the information search cost (García-Dastugue & Lambert, 2003) and transaction cost of both consumers and producers (Howe, 2008). Additionally, in the digital economy era, everyone is self-Media; the media-based marketing behavior of consumers can effectively reduce the marketing cost of enterprises (Dan, Qu, Liu, Zhang & Zhang, 2014).

Digitalization can also improve productivity. Brynjolfsson, Hitt & Kim, 2011 used the survey data of 179 large listed enterprises to analyze the effect of data and business analysis on enterprise productivity. They found that the average productivity of enterprises making decisions using big data and business analysis was high. The empirical analysis of Tunisian enterprises by Mouelhi (2009) showed that using information and communication technology could promote the production efficiency of manufacturing enterprises. Forero(2013) proposed that Internet technology development can improve a technical efficiency of a country.

Mechanism of value creationThe production function is a functional model that reflects the value-creation process by describing the relationship between input and output (Ackerberg, Caves & Frazer, 2015). Marshall(1920) constructed the first gross production function. He proposed that the commodity value could be created jointly by labor, capital, land, and entrepreneurs. However, he did not provide the specific form of the function. Subsequently, Cobb and Douglas(1928) introduced technical factors into the relationship between input and output and proposed the Cobb-Douglas (C-D) production function, which has become the most widely used production function in economics. The C-D production function was further developed into the CES (Qian & Wu, 2020), the VES (Gamlath & Lahiri, 2018), Stochastic Frontier (Banker, Natarajan & Zhang, 2019; Kumbhakar & Tsionas, 2006), and trans-log production functions (B. Lin & Raza, 2020). The main difference between these kinds of production functions lies in the different settings of the elasticity of substitution. The early C-D production function assumes that technological progress is neutral and the elasticity of substitution is equal to 1. However, many subsequent studies have shown that technological progress was not necessarily neutral(Hicks, 1932a), and biased technical progress was proposed (Acemoglu, 2002, 2007). Subsequently, Arrow, Chenery, Minhas & Solow, 1961 thought that the elasticity of substitution in actual production is not equal to 1. Furthermore, they proposed the CES production function, whose elasticity of substitution is a constant greater than 0.

The initial production function focused on the relationship between various kinds of physical capital (machines, buildings) and labor factors (Berndt & Christensen, 1973). However, some scholars have subsequently, studied the alternative relationship between agricultural production factors (Shumway, 1995) and the relationship between energy and other production factors (Popp, 2002). Recent studies have paid more attention to the alternative relationships among skilled labor, unskilled labor, and physical capital (Acemoglu & Restrepo, 2018, 2019) and have also introduced digital factors into the production function (Meng & Wang, 2021).The production function has developed from two factors to multi-factors, such as the nested CES production function, to meet the increase in factor types (Henningsen, Henningsen & van der Werf, 2019).

Existing research has analyzed the effect of digital technologies on innovation capacity, cost, and enterprise productivity. However, some deficiencies still exist. First, existing studies lack a unified theoretical framework to systematically study the digital transformation of enterprises and fail to uncover the black box of the process of digitally enabling enterprises. Second, regarding the measurement method of the digitalization degree, most researchers use the comprehensive indicator method and maturity model, which results in measurement results strongly dependent on the coverage, integrity, and comprehensiveness of the indicator data. However, owing to the lag and unavailability of statistical data, comprehensive and complete indicator data that can reflect the degree of digitalization cannot be obtained in many cases, which affects the accuracy of measurement results. Third, most studies on the impact of digitalization on enterprises usually use econometric models for analysis. The econometric model has high requirements for the quantity and distribution of data, and the data needs to meet several assumptions (Coester, Hofkes & Papyrakis, 2018). In the digital economy, massive data has been continuously emerging, creating higher requirements for data collection and processing and model function construction (Georgiadou, Angelopoulos & Drake, 2020), which inevitably highlights the limitations of the econometric model.

In response to the above problems, this study puts forward the production function of digital empowerment to construct a theoretical framework, and analyzes the digital enabling process for enterprises from the production factor (that is logical starting point of value creation) and the economic activity (that is value converter). Then, this study utilizes text mining technology and big data analysis to identify the key information reflecting the degree of digitalization from the massive data to measures the degree of digitalization of enterprises, and extracts the relationship model between the degree of digitalization of various enterprises and enterprise performance. The use of these digital technologies makes up for the incompleteness and lag of statistical data to a certain extent. Finally, the association rule analysis method with the characteristics of making full use of big data information and without assumptions is used to excavate the hidden association rules between various production factors and economic activities under different relationship models, which overcomes some shortcomings of econometric models.

Theoretical modelProduction function of digital empowermentProduction factors are the logical starting point of value creation. It is necessary first to clarify the composition of the production factors involved in enterprise value creation to study the impact of digitalization on the value creation of enterprises. In the early stage, the production factors involved in value creation mainly included all kinds of material capital (machinery, construction), labor, and energy. With the development of science and technology, labor was further subdivided into skilled and unskilled labor. The change in the interrelation between labor and physical capital has become an essential factor affecting the value creation of enterprises (Acemoglu & Autor, 2011; Acemoglu & Restrepo, 2018, 2019). In the digital economy, digital information and knowledge have become the key production factors. The composition and interrelation of production factors involved in value creation have changed again. Digitalization has infiltrated traditional labor (Lt) and traditional capital (Kt) to form digital labor (Ld) and digital capital (Kd). They jointly create the value, Y = f (Lt, ALLd, Kt, AKKd). Digital labor and digital capital have been involved in value creation, changing the relationship among production factors by replacing or supplementing traditional production factors and endowing energy to production factors to stimulate their value creation potential.

Substitution, supplement, and other associated matching relationships among production factors are usually expressed by substitution elasticity, which refers to the ratio of the change rate of the factor input ratio to its relative price change rate(Hicks, 1932b). Therefore, the elasticity of substitution between the digital and traditional factors can be expressed as:

where xd and xt represent the input of the digital and traditional factors, respectively. pd and pt represent the price of the digital and traditional factors, respectively. If the rise of pd causes xt to decrease, then xd and xt complement each other. If the rise of pd causes xt to increase, then xd and xt replace each other.The CES production function effectively analyzes the substitution elasticity among production factors and its impact on value creation. This study explores how digitalization can influence the relationship between traditional and digital factors through empowerment, thus affecting the value creation of enterprises. Therefore, the production function of digital empowerment with multi-factor and multi-level nesting is constructed.

It is assumed that the production factors mainly include traditional labor (LtT) and capital (KtT) and digital labor (LdT) and capital (KdT). The production function of digital empowerment is expressed as:

where, T is the year, YT is the output of the enterprise in T year, and C, C1and C2 are the parameters of the generalized technical level. Formula (1) is the first stage of the CES production function composed of labor combination (YLT) and capital combination (YKT). Formula (2) is the second stage of the CES production function composed of traditional labor (LtT) and digital labor (LdT), traditional capital (KtT), and digital capital (KdT). ALTd,AKTd are the enabling level of digitalization to digital labor (LdT) and digital capital (KdT), respectively; they are related to the product of total digital enabling level AT∈(1,+∝) and the distribution parameter of digital empowerment g∈(0,1). α,β, and γ∈(0,1) are distribution parameters, and ε,θ, and η∈(0, +∝) are the substitution elasticity of labor combination (YLT) and capital combination (YKT), traditional labor (LtT) and digital labor (LdT), and traditional capital (KtT) and digital capital (KdT).The digital enabling level is mainly determined by the digitalization degree and the influence of digitalization on enterprises.

where, digitalT is the digitalization degree indicating the digital integration and utilization level of the enterprise, DT is the digital influence coefficient.Because the transformation and upgrading of innovation, production systems, and supporting equipment compatible with digitalization need some time to complete, the popularization of digitalization in enterprises at the initial stage is relatively slow, giving digitalization a minor role of in enterprise promotion. However, eventually, digitalization will significantly promote the development of enterprises (Brynjolfsson, Rock & Syverson, 2017). Some scholars have proposed that the influence of digitalization on economic development presents a trend of “first convex then concave” (Lin, Chen, Chen & Chen, 2020). Considering that the logistic function satisfies both the characteristics of “convex first, then concave” and the existence of upper and lower limits (Chiyo, Mizukami & Yokota, 2020; Van Loon, Fokkema, Szabo & de Rooij, 2020), this study uses the logistic function to describe the impact of digitalization on the enterprise. Therefore, the digital influence coefficient (DT) can be expressed as follows:

where DT is the digital influence coefficient in T period. D0 is the starting value of the digital influence coefficient, which is in the range of [0–1], and D¯ is the limit value of the digital influence coefficient.ξ is the curvature of the change trend of the digital influence coefficient, and h is the time node from convex to concave.Association rule mining for the digital development of enterpriseBased on the above production function of digital empowerment, the substitution or complementary among production factors can be obtained, which is an essential factor affecting the digital development of enterprises. As a value converter, economic activities are also the key factors that determine the digital development of enterprises. The digital development of enterprises is reflected in the degree of digitalization and performance of enterprises. Only when the degree of digitalization and performance are both high the digital development of enterprises improves. Therefore, it is necessary to identify the relationship between the degree of digitalization and performance and excavate the association rules between production factors (including traditional and digital factors) and economic activities under different relationship models.

The relationship between the degree of digitalization and enterprise performance can be divided into four types according to the degree of digitalization and enterprise performance: high digitalization-high performance (Hd-Hp), high digitalization-low performance (Hd-Lp), low digitalization-high performance (Ld-Hp), and low digitalization-low performance (Ld-Lp).

The association rule mining technology extracts the association rule between production factors and economic activities under different relationship modes.

Association rule analysis is an algorithm mining association relationships between transactions hidden in massive data(Agrawal, Imielinski & Swami, 1993). It identifies the combination with high frequency from big data, analyzes the dependence among different factors, and explores the emergence rule of each factor.

Digital degree, enterprise performance, the input proportions of production factors, and economic activities constitute the item set I={TL0–10-TL90–100, DL0–10-DL90–100, TK0–10-TK90–100, DK0–10-DK90–100, CP0–10CP90–100, CS0–10CS90–100}. Where the input proportions of various production factors in the range of [0, 100] are divided into 10 grades from large to small, i.e., traditional labor (TL0–10-TL90–100), digital labor (DL0–10-DL90–100), traditional capital (TK0–10-TK90–100), and digital capital (DK0–10-DK90–100). Economic activities mainly include production and sales activities, in which production and sales activities are represented by the production cost and sales expense rates, respectively. Similarly, they are equally divided into 10 grades in the range of [0, 100], production cost rate (CP0–10CP90–100), and sales expense rate (CS0–10CS90–100). T={t1, t2, t3, …, tn} is the set of transactions, ti⊆I. If X→Y satisfies X⊂I, Y⊂I, and X∩Y≠Φ, then X→Y is the association rule in T.

The mining process consists of two stages: the first is identifying all frequent item sets; we use the most classic Apriori algorithm (Agrawal et al., 1993) to search frequent item sets. The second is the mining association rules in these frequent item sets. Association rules are usually measured by support and confidence. Support refers to the probability of occurrence of an item set (X→Y) in the whole data set, representing the frequency of rules. The calculation formula is:

Generally, a support threshold is set; when the support of an item set exceeds this value, it will be considered worthy of attention. Such an item set is called a frequent item set.

Confidence is a conditional probability; under the condition that X occurs, the probability of Y derived from X indicates the strength of the rule. The confidence of X → y is defined as:

In addition to the support and confidence, we introduce the lift as the standard of rule selection. Lift refers to the ratio of the confidence of the rule to the probability of the occurrence of the consequent, reflecting the positive and negative correlation between the antecedent and consequent.

By adding a lift to the measurement framework of rules, we can remove the rules with less relevance from the rules mined by support and confidence. If the lift is greater than 1, and the higher the lift is, the higher the positive correlation is; if the lift is less than 1, and the lower the negative correlation is, the higher the negative correlation is, and if the lift is equal to 1, it means there is no correlation.

Empirical analysisVariable selection and data sourceThis study takes 988 A-share listed manufacturing enterprises in Shanghai and Shenzhen stock markets from 2019 to 2021 as the research object, and 862 listed companies are finally selected for the research excluding 126 samples with missing data. Since the impact of digitalization on value creation is characterized by enterprise heterogeneity, we firstly classify manufacturing enterprises into light textile enterprises, resource processing enterprises and mechanical and electronic enterprises based on the operation characteristics and product attributes of enterprises (W. Wang & Niu, 2019).

The variables involved in the production function of digital empowerment mainly include: output of enterprise (Y) is expressed by the total output of listed enterprise(H. Wang, Gao & Zhang, 2019). Digital labor (Ld) is represented by the total number of R & D personnel and operators of digital equipment, while traditional labor (Lt) is represented by the number of general personnel, that is, the difference between the total number of personnel and the number of digital labor. Digital capital (Kd) refers to total investment of R & D, digital devices and platforms, while traditional capital (Kt) refers to net fixed assets including plant construction, general equipment, raw materials. The digitalization degree (digitalT) is reflected by the digitalization behavior of the enterprise, which can be obtained by using text mining to identify the number of keywords related to digitalization, such as artificial intelligence(AI), big data, cloud computing, digitization, Information, intelligence, network, Internet +, Internet of Things, e-commerce, platform economy, sharing economy, online and offline, O2O, B2B, C2C, B2C, C2B. (Meng & Wang, 2020). The performance of enterprise can be expressed by the return on assets(Chang & Rhee, 2011; Hsu, Lien & Chen, 2013). All data are from CSMAR database.

Parameter settingThe parameters of the generalized technical level C,C1, and C2 are set to 1 to simplify theoretical analysis and estimation (Acemoglu, 2002, 2003)

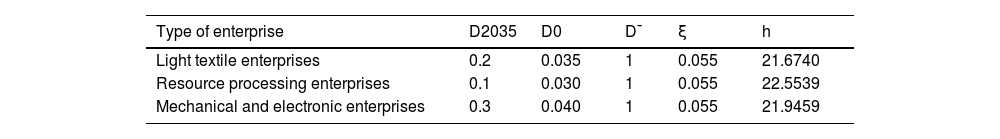

In the function of the digital influence coefficient (DT), {D¯,ξ,and h} are determined by the evolution track of digitalization enabling. The existing studies provide the basis for their values. Purdy et al. (2017) and Purdy, M and Daugherty (P, 2017) predicted the influence of digital technologies on labor productivity in the United States, Japan, China, and other countries. They found that by 2035, the digital technique would increase labor productivity in the United States and Japan by 11%–41% and in China by 27%. Based on the above research, this study uses the labor productivity increase brought by digitalization to express a digital enabling coefficient. It assumes that the digital enabling coefficients of resource processing, light textile, and mechanical and electronic enterprises in 2035 are 0.10, 0.2, and 0.3, respectively, which is consistent with the assumption that digital technology will increase China's labor productivity by 27% in 2035. The OECD (2015) pointed out that since 2000, the average growth rate of labor productivity of industries using digital frontier technology has been 3.5%. Based on this, this study sets the initial digital enabling coefficients of resource processing, light textile, and mechanical and electronic enterprises to 0.03, 0.035, and 0.04, respectively. Referring to the research of Chen, Lin & Chen, 2019, the change curvature of the digital enabling coefficient ξ is set to 0.055, and then h can be calculated. The relevant parameters of the digital enabling coefficient of the three types of enterprises are shown in Table 1.

The parameter setting of the digital enabling coefficient function.

Therefore, the calculation formula of the digital enabling coefficient of light textile enterprises is:

D1t=0.035+0.965/[1+e−0.055(t1−21.674)].

The calculation formula of the digital enabling coefficient of resource-processing enterprises is:

D2t=0.03+0.97/[1+e−0.055(t2−22.5539)].

The calculation formula of the digital enabling coefficient of mechanical and electronic enterprises is:

D3t=0.04+0.96/[1+e−0.055(t3−21.9459)].

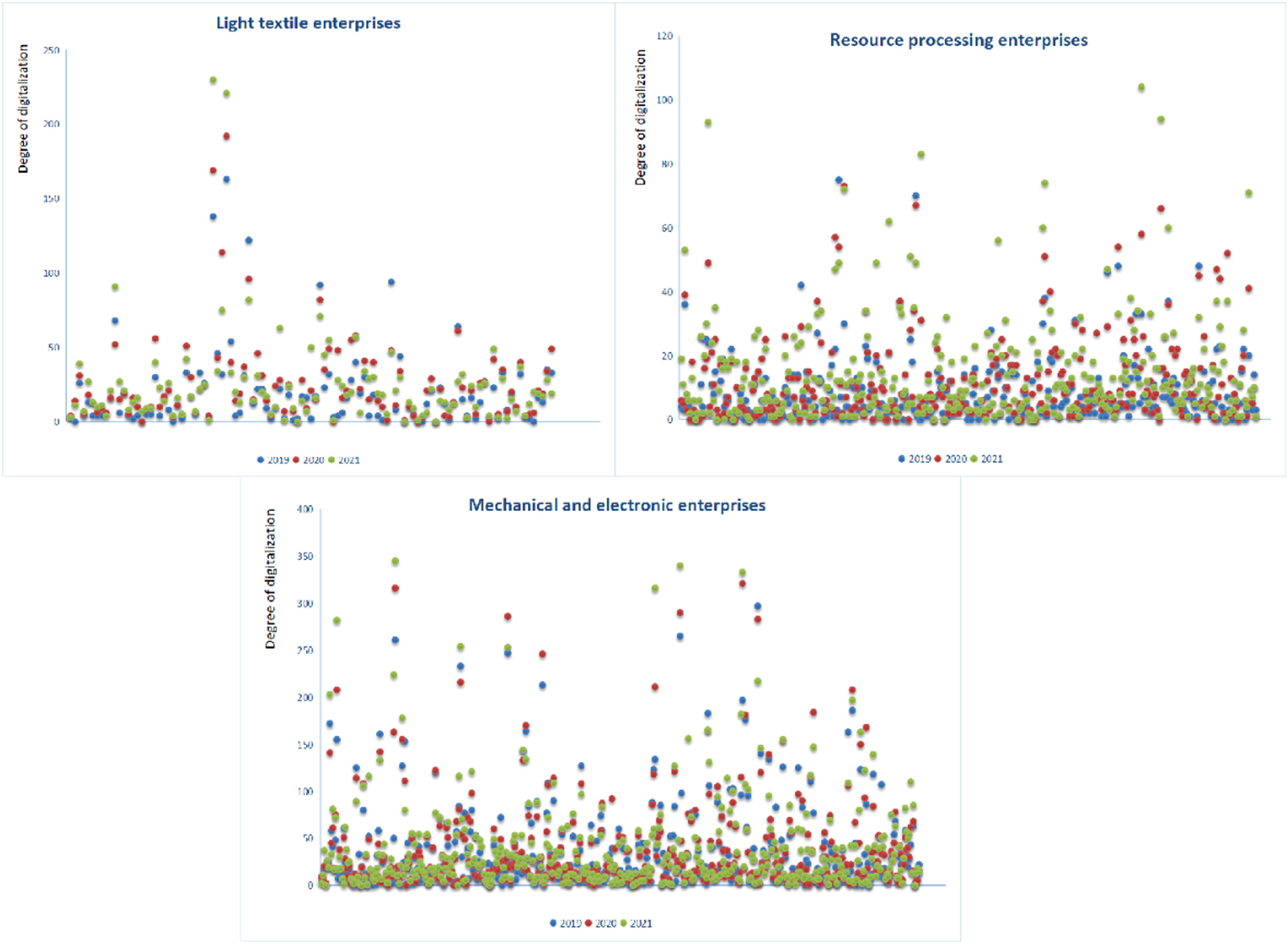

The results of the digitalization degree are shown in Fig.1. The digitalization degree of the three types of enterprises shows an increasing trend from 2019 to 2021. For light textile enterprises, the average digitalization degree increased from 19.17 in 2019 to 24.58 in 2020, with a 28% growth rate. The average digitalization degree of resource processing and mechanical and electronic enterprises also increased by 74.52% and 14.33%, respectively.

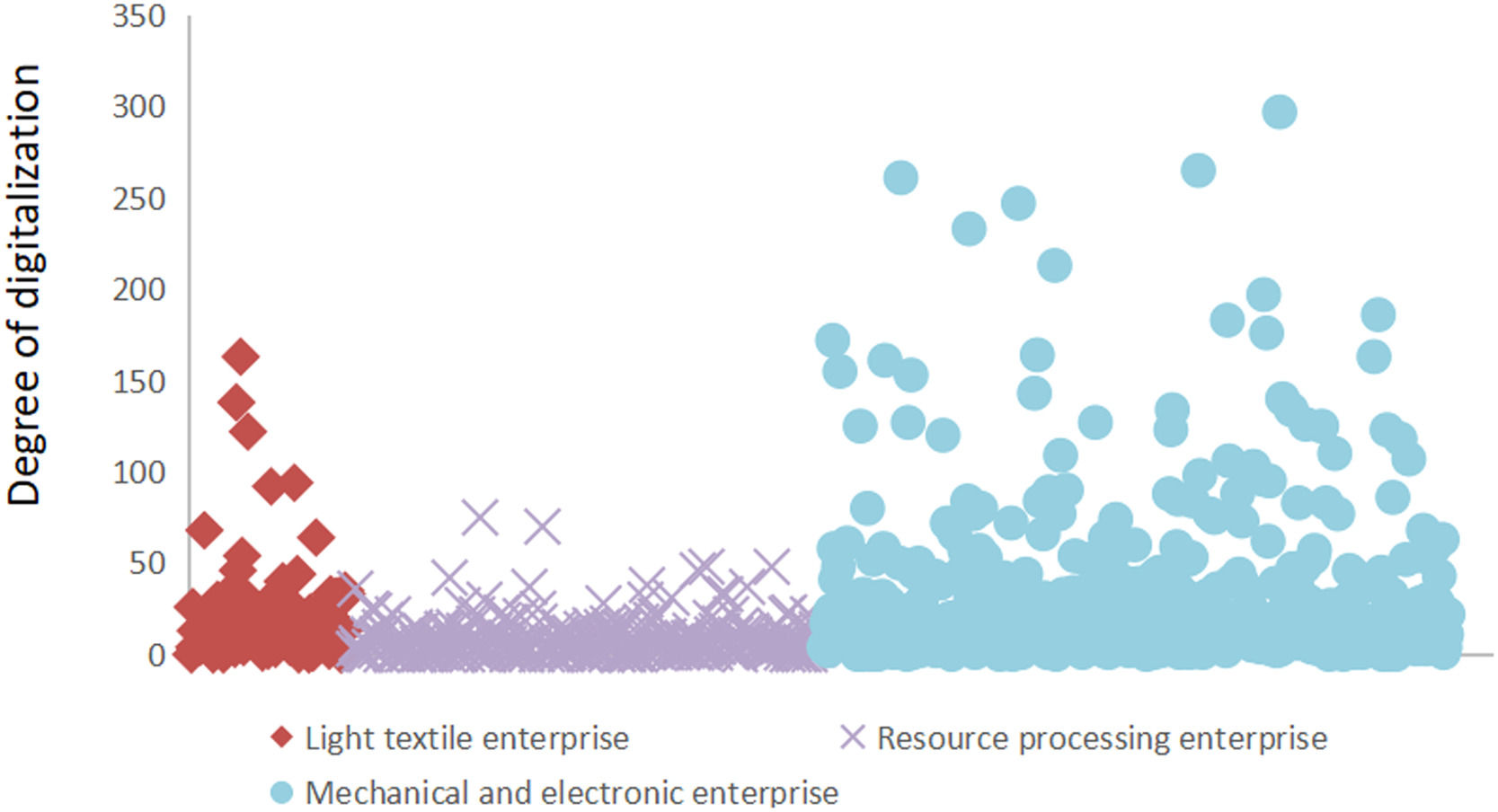

By comparing the average digitalization degree of the three types of enterprises (Fig.2), it can be seen that mechanical and electronic enterprises have the highest digitalization degree (35.92), followed by light textile enterprises (22.8); the digitalization degree of resource-processing enterprises (11.12) is the lowest.

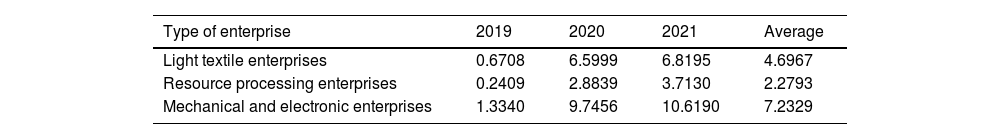

Digitalization enabling level of enterprisesBased on the formula (5), the digitalization enabling level is obtained, as shown in Table 2. From 2019 to 2021, the digital enabling level of light textile, resource processing, and mechanical and electronic enterprises all show a growing trend. Mechanical and electronic enterprises have the highest digitalization enabling level, over three times and over twice that of resource-processing enterprises and light textile enterprises. However, although resource-processing enterprises have the lowest digitalization enabling level, they have the highest growth rate.

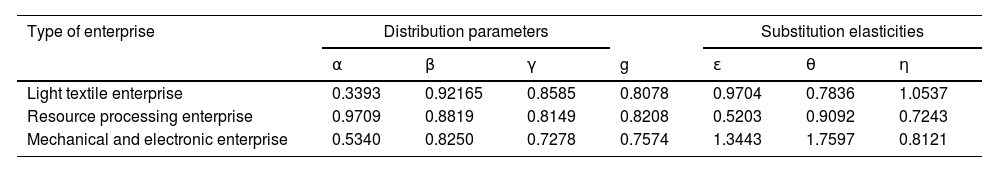

Elasticity of substitutionAccording to formulas (1) and (2), the substitution elasticities of the two-stage nested CES production function of three types of enterprises are estimated by nonlinear econometrics. The results are shown in Table 3.

The substitution elasticities and other related parameters.

For light textile enterprises, the substitution elasticities of labor combination-capital combination and traditional labor-digital labor are respectively 0.9704 and 0.7836, indicating that labor combination and capital combination, and digital labor and traditional labor are complementary. The substitution elasticity of traditional capital-digital capital is 1.0537, showing that an alternative relationship exists between digital and traditional capital. For resource-processing enterprises, ε, θ, and η are less than 1, which means that the labor combination-capital combination, digital and traditional labor, and digital and traditional capital are all complementary. For mechanical and electronic enterprises, the substitution elasticities of labor combination-capital combination and traditional labor-digital labor are 1.3443 and 1.7597, respectively; they are mutually substituted, traditional capital and digital capital are complementary, and the substitution elasticity is less than 1.

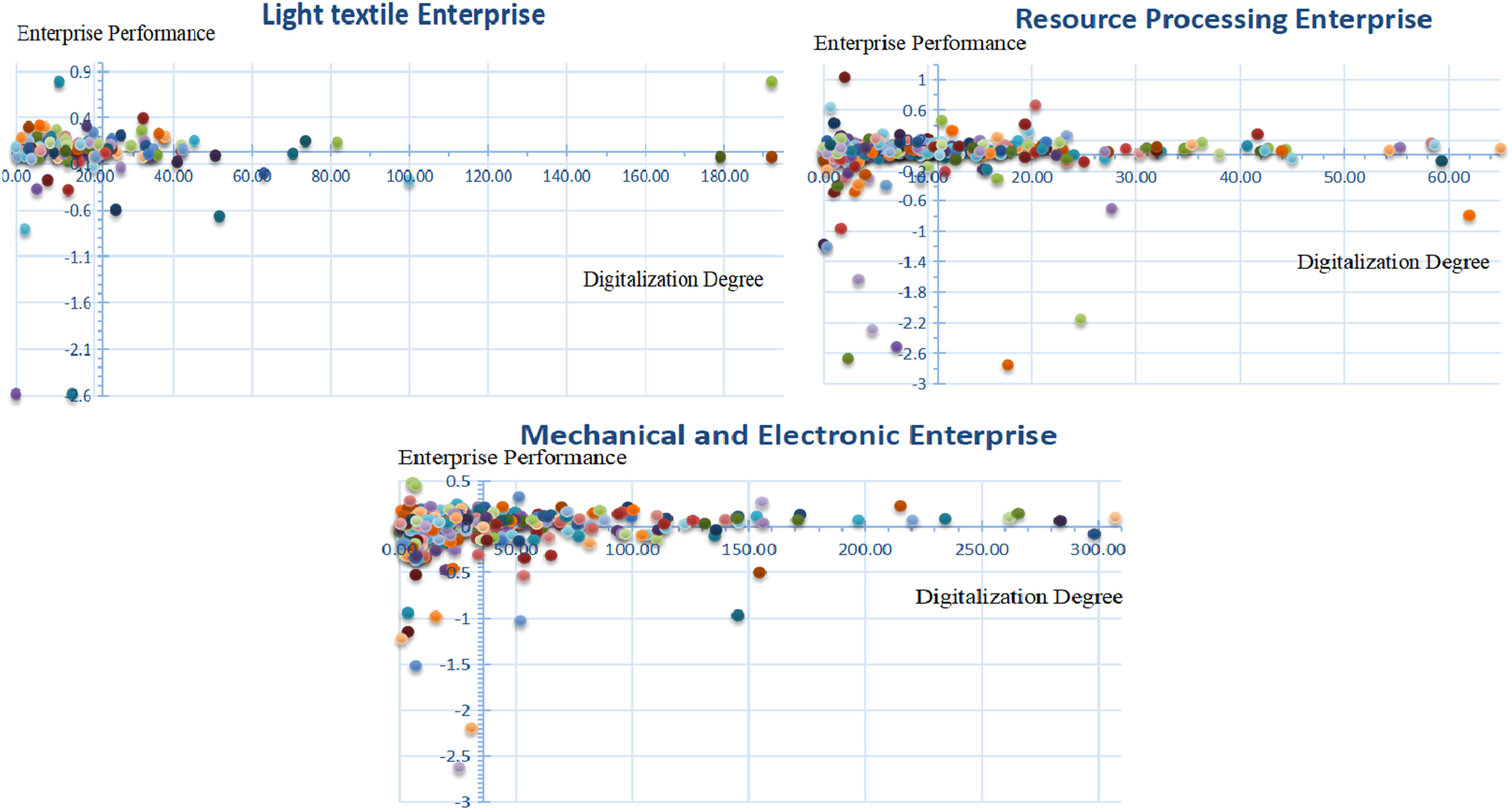

Association rule analysisThe relationship model between the digitalization degree and enterprise performanceThis study uses the return on assets to indicate corporate performance(Chang & Rhee, 2011; Hsu et al., 2013). The relationship between digitalization degree and enterprise performance can be divided into four models combined with the digitalization degree measured in Section 4.3.1, taking the average of enterprise performance and digitalization degree as the center point: high digitalization-high performance (Hd-Hp), high digitalization-low performance (Hd-Lp), low digitalization-high performance (Ld-Hp), and low digitalization-low performance (Ld-Lp), as shown in Fig. 3.

For the three types of enterprises, the proportion of enterprises belonging to the Ld-Hp relationship model is the largest, accounting for over 50%. Among them, resource-processing enterprises have the largest proportion of Ld-Hp mode (55.59%), and mechanical and electronic enterprises have the smallest proportion of Ld-Hp mode (51.51%). This finding indicates that most enterprises have a low digitalization degree and still mainly rely on traditional production and management methods for development. The number of enterprises in the Hd-Hp mode is the second largest. The proportions of light textile, resource processing, and mechanical and electronic enterprises belonging to the Hd-Hp mode are 19.27%, 23.40%, and 21.11%, respectively. This finding reflects that the deepening of digitalization has promoted the profitability of some enterprises. Additionally, some enterprises are at a low level of digitalization and performance. The number of these enterprises is slightly lower than that of enterprises in the Hd-Hp mode. The smallest proportion is in the Hd-Lp mode; light textile enterprises, resource-processing enterprises, and mechanical and electronic enterprises are 11.93%, 5.59%, and 8.12%, respectively.

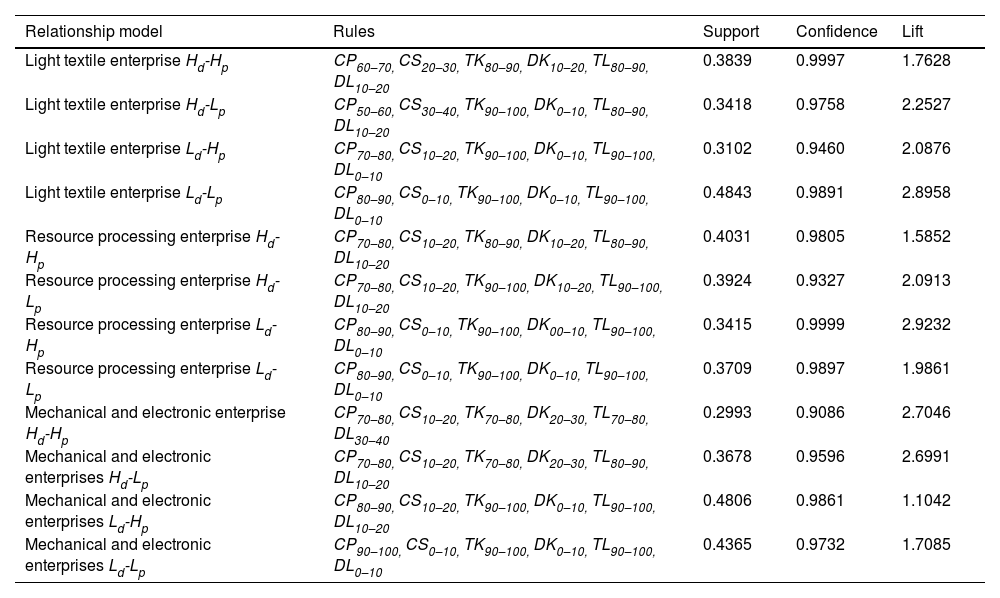

The results of the association rule analysisThe association rules of relationships between production factors and various economic activities of the three types of enterprises in different relationship models are obtained, as shown in Table 4. For the selected strongest association rules, the support is above 0.3, the confidence is greater than 0.88, and the lift is greater than 1, which indicates that the association rules between production factors and activities are reliable.

The results of association rule analysis.

Regarding the light textile enterprise, under the relationship model of Hd-Hp, the strongest association rule among production factors and activities is {CP60–70, CS20–30, TK80–90, DK10–20, TL80–90, and DL10–20}. Compared with the association rule of the Hd-Hp model, for the strongest association rule of the Hd-Lp relation model, the production cost rate reduces to 50%–60%, the sales expense rate increases to 30%–40%, the proportion of traditional capital increases to 90%–100%, and the proportion of digital capital is lower than 10%. For the strongest association rule in the Ld-Hp relation model, the production cost rate is higher than that of high digitization degree, which is in the range of 70% -–80%, while the sales expense ratio is reduced to 10%–20%. The proportions of traditional labor and capital are both large, ranging from 90% to 100%. The proportions of digital capital and labor are less than 10%. For the strongest association rule in the Ld-Lp relation model, the production cost rate is further increased to 80%–90%, and the sales expense ratio is lower than 10%.

For resource-processing enterprises, the strongest association rule of the Hd-Hp model is {CP70–80, CS10–20, TK80–90, DK10–20, TL80–90, and DL10–20}. The share of traditional capital and labor increased to 90%–100% for the enterprises under the Hd-Lp model. The association rules of the Ld-Hp and Ld-Lp models are similar; both are {CP80–90, CS10–20, TK90–100, DK0–10, TL90–100, and DL0–10}, compared with the Hd-Hp model, the production cost rate, traditional labor, and traditional capital have increased, and the digital labor and capital have reduced.

For mechanical and electronic enterprises, the strongest association rules in the Hd-Hp relationship model is {CP70–80, CS10–20, TK70–80, DK20–30, TL70–80, and DL30–40}. Compared with the Hd-Hp relationship model, under the Hd-Lp relationship model, the proportion of digital labor reduces to 10%–20%, while traditional labor increases to 80%–90%. The production cost rates in the Ld-Hp and Ld-Lp models increase to 80%–90% and 90%–100%, and the proportions of digital capital account for a relatively small amount (0–10%); the proportion of digital labor in the Ld-Lp model is smaller, as small as 0%–10%.

DiscussionDiscussion of the findingsBased on the above empirical results, this study proposes the digital transformation path of enterprises with different relationship models to promote the development of enterprises.

- (1)

For light textile enterprises, strengthening the cultivation and introduction of digital labor and increasing digital capital investment is the crucial path to improving the degree of digitalization and enterprise performance. Compared with the optimal relationship model (Hd-Hp), the main task of enterprises belonging to the Hd-Lp model is to increase the input of digital capital in sales links, such as the procurement of digital sales equipment, and investment in construction, operation, and maintenance of digital sales platform. For enterprises under the Ld-Hp and Ld-Lp relationship model, the production cost rates are higher than that of the Hd-Hp model, and the sales expense rate is lower than that of the Hd-Hp model. These enterprises should focus on both production and sales, and increase the digital labor input in the production link (such as digital equipment operators, hardware installation, and maintenance personnel), also increase the input of digital sales skills. Additionally, investment in digital equipment, technology research and development, digital platform construction, and other aspects of production and sales should also be strengthened.

- (2)

For resource-processing enterprises, it is necessary to increase the input of digital labor and capital in the production process, which has the greatest impact on its profitability. Compared with the Hd-Hp model, the production cost rate of the other three models is higher, and the proportions of digital labor and capital are relatively low. This indicates that increasing the investment and talents in the transformation of automation, informatization, digitalization, and intelligent in the production process can inhibit or reduce the dependence on traditional capital and low-skilled labor, to improve the digitalization degree and performance of enterprises.

- (3)

For mechanical and electronic enterprises, the cultivation and introduction of high digital technology labors and the financial support for research and development and the procurement of advanced digital equipment are very important. Mechanical and electronic enterprises belonging to the Hd-Lp model have relatively advanced digital equipment and highly skilled labor; the high-end and scarce talents who master AI, big data, cloud computing, 5 G, and other professional digital technologies are decisive factors for the digitalization degree and performance, which need special attention. However, enterprises in the Ld-Hp and Ld-Lp models still have a low degree of digitalization, and their primary task is to increase the input of labor and capital to support the informatization and networking of the basic business processes in the production process.

This study proposes several insights, which have three-fold theoretical contributions for the research on digital transformation of different types of enterprises.

Firstly, the production function of digital empowerment is proposed to analyze the influence mechanism of digitalization on value creation. Although there are some researches analyzing the of digital technologies on innovation capacity, production and sales costs and production efficiency of enterprises, these researches rarely consider the digital empowerment of production factors, and embody this empowerment mechanism in the model. The production function of digital empowerment theoretically analyzes the influence mechanism of digitalization on enterprise value creation, which includes the digital enabling level on each factor and the elasticities of substitution among the factors after introducing the empowerment. Thus, this study is an extension of previous studies, and offers a theoretical framework that may benefit future studies of digital transformation of enterprise.

Secondly, the association rules among the production factors and economic activities of enterprises is excavated. Production factors are the logical starting point of value creation, and economic activities are the conversion of factors into value. Digital resources and traditional factors accelerate the flow and reorganization in economic activities, which will bring about subversive changes to the internal and external environment and structure of enterprises (Bejakovic & Mrnjavac, 2020; Mueller & Grindal, 2019). Therefore, from the factor-activity aspect, this paper can fundamentally explore the impact of digitalization on enterprise value creation. This is a new perspective of research on enterprise value creation under the background of digital economy.

Thirdly, this study uses data mining techniques such as text mining, big data analysis and association rule analysis to conduct empirical analysis, which breaks through the limitations of high data requirements and preset assumptions in econometric models. Therefore, it is a supplement of the previous research methods.

Practical implicationsSeveral practical implications can be highlighted from this work, these insights may provide direction for the digital transformation of various enterprises in the future. First, enterprises with different scales, products and industrial types have different digital transformation paths due to different capital guarantee, technical support and business models. Despite some literatures have studied the effect of digitalization on many different types of enterprises, such as oil enterprises(Lu, Guo, Azimi & Huang, 2019), automobile enterprises (Forero, 2013; Mouelhi, 2009), food enterprises (Fernández-Uclés, Bernal-Jurado, Mozas-Moral & Medina-Viruel, 2019), most of them only analyze a certain type of enterprise, and there is a lack of comprehensive analysis on the differences of digital empowerment and digital transformation of different types of enterprises. We classify enterprises based on their industry characteristics and product attributes, and analyze the heterogeneous influence of digitization on different types of enterprises. Our research results will provide a reference for different types of enterprises to choose the appropriate path of digitalization transformation. Second, we analyze the association rules between production factors and economic activities of three types of enterprises in different digitalization- performance relationship model, which can help enterprises find the shortcoming in the process of digital transformation, and then guide different enterprises to reasonably allocate resources and organize various economic activities in the process of digital transformation. It provides decision support for the path design of improving enterprise performance through digital technology.

Conclusion and limitationsConsidering the empowering effect of digitalization on value creation of enterprises, this study proposes the production function of digital empowerment, and uses empirical data to analyze the differences of correlation and matching among production factors of various types of enterprises, as well as the enabling level of digitalization to factors. In addition, we also extract the relationship model between the digitalization degree and enterprise performance, and mine the strongest association rules among factors and economic activities under different relationship models, so as to provide basis for the design of the digital transformation path of various types of enterprises. This study provides a new perspective to study the impact of digitalization on the value creation of enterprises, and also contributes to the application of digital transformation.

This study also has limitations, which can be further improved in future studies. This study mainly focuses on the stimulation of digital technology on the value creation ability of the traditional production factors from the perspective of digital empowerment. In the next step, this study will integrate the value creation ability of digital technology, information and knowledge themselves into our research framework, and combine the multiplier effect of digitalization on original factors and its own incremental effect to study the impact of digitalization on enterprise value creation.

FundingThis paper was supported by the National Natural Science Foundation of China (Grant No. 71973023), the Major Project of Social Science Foundation of Jiangsu (Grant No. 19GLA003), Soft Science Project of Jiangsu (Grant No. BR2019043).