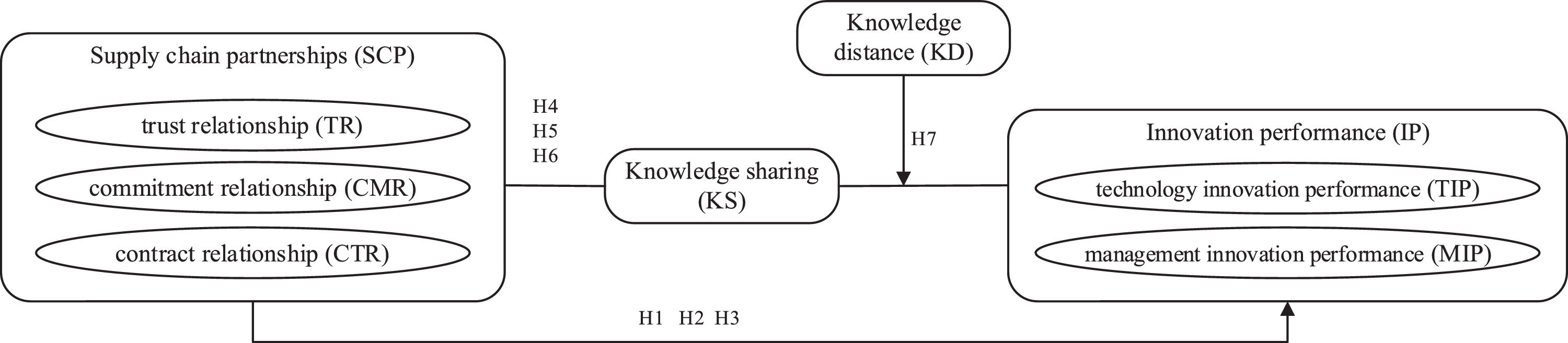

Affected by complicated issues, such as regional conflicts, trade wars, and the COVID-19 pandemic, manufacturing firms face enormous challenges in reconstructing the global supply chain landscape to form new cooperative innovation mechanisms. This study investigates the relationship between supply chain partnerships (SCP) and innovation performance (IP) from a knowledge-management perspective. A multi-factor conceptual model of this relationship was proposed, considering the mediating effect of knowledge sharing (KS) and the moderating effect of knowledge distance (KD). SCP is measured in three dimensions: trust relationship (TR), commitment relationship (CMR), and contractual relationship (CTR). IP is measured in two aspects: technological innovation performance and management innovation performance. An empirical study was conducted to test the hypotheses using data from 417 valid questionnaires. Confirmatory factor analysis and structural equation modeling were applied to test the hypotheses. The results demonstrate that (1) KS plays a significant mediating role in how SCP impacts IP and that the indirect effect of TR through KS on IP is greater than that of CTR or CMR. (2) KD between supply chain partners plays a significant negative moderating role between KS and IP; that is, the smaller the KD, the higher the IP achievable through sufficient KS. These findings shed new light on building collaborative innovation mechanisms for supply chain management.

The coronavirus disease (COVID-19) pandemic, regional conflicts, and trade wars have brought enormous uncertainty to global economies and societies. In this context, supply chain partnerships (SCPs) formed over time have experienced tremendous challenges that significantly impact the continuous innovation activities and performance of manufacturing companies. Between February and March 2021, the Economist Intelligence Unit and Citigroup jointly investigated the impact of COVID-19 on supply chain firms. A survey was conducted with 175 supply chain managers from different industries, including information technology, automotive, clothing, food and beverage, health-care, pharmaceuticals, and biotechnology. The survey results show that about 51.7% and 43.3% of the respondents in the automotive industry and the footwear and clothing industry, respectively, consider that the supply chain interruption was “very serious.” Manufacturers face pressing issues, such as production interruptions, freight obstructions, labor shortages, customs clearance delays, order reductions, customer losses, and tight cash flows. In this regard, many manufacturing firms will inevitably reconstruct the global supply chain landscape and develop new reliable supply chain partnerships. However, it is notoriously difficult to forge sustainable partnerships in complex supply chain organizations (Yang & Lien, 2018). Reshaping supply chain partnerships to form new cooperative innovation mechanisms is even more complicated in this dynamic and uncertain environment.

Supply chain collaborative innovation is an essential solution for firms to respond to unpredictable changes. It is the main driving force for enhancing supply chain flexibility and sustainable performance (Shan, Li and Shi, 2020), as well as offering new or enhanced products or services (Koufteros,Cheng & Lai, 2007). Innovation performance (IP) is a collection of innovation outputs and the input-output conversion efficiency (Huang & Hou, 2019). IP is typically reflected in products, services, processes, markets, strategic innovation, and other aspects (Wang & Ahmed, 2004; Lin,Chen & Chiu, 2010).

Many scholars have focused on the interactions between partnerships and supply chain performance. Early studies primarily considered partnership trust and commitment as independent variables, supply chain capability and information sharing as mediating variables, and competitive advantage and supply chain cooperation performance as dependent variables (Kwon & Suh, 2005; Sáenz, Aramburu & Blanco, 2012; Binz & Truffer, 2017; Ezhei & Ladani, 2017; Sahebjamnia, Torabi & Mansouri, 2018; Huang & Hou, 2019; Shan, Li and Shi, 2020). Some believe that, in the long run, a lack of reliable trust relationships between partner companies may lead to an inability to achieve the desired technological innovation performance goals (Gao,Lee & Zhang, 2006; Inderfurth, Sadrieh & Voigt, 2013; Ganesh, Raghunathan & Rajendran, 2014). Others show that contract and commitment relationships reached by close partnerships among supply chain companies might have negative influences, leading to reluctance toward innovative practices or low improvement in innovation performance (Ezhei & Ladani, 2017; Sahebjamnia et al., 2018; Shan, Li and Shi, 2020).

Knowledge is the most dynamic and essential factor, as well as the core element of innovative activities for manufacturing companies (Li,Liu & Yue, 2019). Lee and Cavusgil (2006) discovered that stabilizing interfirm partnerships and facilitating knowledge sharing (KS) have a positive impact on enhancing alliance performance under environmental turbulence. Existing research on inter-firm knowledge mainly focuses on the impact of different knowledge categories (such as tacit and explicit knowledge) or KS behaviors on co-operation performance. KS is a critical form of collaborative innovation and mutual exchange among supply chain partners. Learning and absorbing knowledge among partners in a supply chain can accelerate the generation of innovative ideas, products, or technical solutions; create supply chain synergies; enhance overall flexibility and efficiency; and improve innovation performance. In addition, because of the differences in knowledge accumulation, culture, roles, and capabilities of firms in a supply chain, knowledge distance (KD) is expected to arise among supply chain partners, which may affect the breadth, depth, speed, cost, and benefit of KS, and thus affect the innovation performance (IP) of supply chain partners (Gaffney, Karst & Clampit, 2016).

However, there is a lack of analysis from a knowledge perspective in terms of KS and KD to study the relationship between supply chain partnerships and innovation performance. To the best of our knowledge, no previous studies have considered KS as a mediating variable or KD as an adjustment variable to investigate the interactions between SCP and IP. Therefore, this study aims to bridge this research gap by addressing the following three research questions: (1) What types of SCP can lead to positive effects on the IP of manufacturing companies? (2) What roles does KS play in the relationship between SCP and IP? (3) What is the effect of the KD? In this regard, an empirical study based on structural equation modeling was conducted. Bootstrap and hierarchical regression methods were further employed to study the mediating effect of KS and the moderating effect of KD. As a result, the relationship between supply chain partnerships and innovation performance from a knowledge management perspective is revealed, and managerial implications are discussed.

The remainder of this paper is organized as follows. Following a brief introduction in Section 1, a literature review and research hypothesis development are presented in Section 2. Section 3 introduces the research methodology, including the questionnaire design, data acquisition, and reliability and validity testing. Section 4 adopts a structural equation modeling approach to test the hypotheses and analyzes the results based on an empirical study. Finally, Section 5 summarizes the research findings and discusses future research directions.

Literature analysis and hypothesis developmentSupply chain partnership (SCP) and innovation performance (IP)Since research on SCP was initiated in Japan in the 1950s, it has become a key component of supply chain management (SCM) and attracted extensive attention. It is commonly believed that SCP is a long-term cooperation agreement reached by upstream and downstream companies in sharing benefits and risks through effective communication of information and KS to achieve common goals and maintain strategic partnerships (Katz, 1996; Herzog, 2001). Morgan and Hunt (1994) indicated that a good partnership must be established based on mutual trust and commitment between the two parties so that they can maintain a long-term and stable cooperative relationship. Based on this argument, a partnership framework can be constructed using the dimensions of trust and commitment. Thereafter, many scholars have studied supply chain partnerships in these two dimensions (Kwon & Suh, 2005; B. Ramasamy,Goh & Yeung, 2006; Singh & Power, 2009; Rezaei,Ortt & Trott, 2018). In the literature, price relation contracts or quantity relation contracts have also been proposed, with most focusing on high-tech industries such as electronics and semiconductor manufacturing (Taylor & Plambeck, 2007). Therefore, in this study, the SCP is divided into three aspects: trust relationship (TR), commitment relationship (CMR), and contractual relationship (CTR).

Trust relationship and innovation performanceTrust is often regarded as the willingness to have confidence in a partnership, reliance on partners, sharing benefits and risks, and maximizing the overall benefits of the partnership (Chopra & Meindl, 2002; Johnson,Cullen,Sakano & Takenouchi, 2003; Anderson & Narus, 2018). As a result, trust among partners is the soul and backbone of supply chain management (Fu,Han & Huo, 2017). Trust relationship (TR) is reflected by the degree to which partners perceive each other to be credible, honest, and benevolent, the strength of partners’ collective interest in taking risks, and partners’ willingness to rely on each other to resolve issues through mutual benefits (Shin,Yoo & Kwon, 2020). Trust is the cumulative result of various factors that drive a relationship during its development (Abosag & Lee, 2013).

The key mediating variable model of the trust-commitment relationship pioneered by Morgan and Hunt (1994) emphasizes that trust has a promotional influence on IP in the context of cooperation. Thanki and Thakkar (2018) mentioned that trust and dependence among supply chain partners significantly affect companies’ performance in an integrated environment. From a long-term development perspective, a lack of trust between partner companies may result in failure to achieve the desired technological innovation performance (Panteli & Sockalingam, 2005). IP is a collection of innovation outputs and the conversion efficiency of input-output (Huang & Hou, 2019). Based on sudden changes in global uncertainties in recent years, this study focuses on two aspects of IP: technological innovation performance (TIP) and management innovation performance (MIP). It is hypothesized that the correlations between TR and TIP and between TR and MIP would be positive.

H1

TR positively affects the IP.

H1a

The effect of TR on TIP is positive.

H1b

The effect of TR on MIP is positive.

Commitment relationship and innovation performanceCommitment relationships (CMR) can be used to measure the positive attitude that an organization expects to maintain a synergistic relationship with others in a common goal or pursuit (Morgan & Hunt, 1994; Abosag & Lee, 2013; Fu et al., 2017; Dwyer,Schurr & Oh, 2018). Moore (1998) defines CMR in supply chains as the attitude of partners towards developing and sustaining stable relationships. The long-term commitment of partners is conducive to safeguarding the social and commercial interests that partners enjoy. A partner's commitment strengthens the partnership by escalating the commitment to maintain the relationship (Abosag & Lee, 2013). The CMR is a useful relationship mechanism that can effectively control opportunism, promote cooperation between buyers and sellers, and improve innovation, operations, and financial performance (Yam & Chan, 2015; Mandal & Sarathy, 2018). Studdard (2004) indicated that the higher the level of commitment between network entities, the more beneficial it is for resource acquisition in the innovation process. Ramaseshan et al. (B., 2006) confirmed that high-level CMR is significantly positively correlated with high strategic performance. Yang,Wang,Wong and Lai (2008), based on the analysis of a large sample questionnaire survey, showed that CMR with suppliers in supply chain alliances can play a positive role in achieving good performance. As a result, we propose the following hypotheses regarding the relationship between the CMR and IP:

H2

CMR positively impacts IP.

H2a

CMR has a positive influence on TIP.

H2b

CMR has a positive influence on MIP.

Contractual relationship and innovation performanceThe contract relationship (CTR), based on legal guarantees, clarifies the responsibilities and obligations of the collaborating parties in a supply chain so that it can curb opportunism effectively and maintain long-term cooperative relations. A relational contract specifies the terms for the buyer and supplier, and whether both sides are willing to abide by the promised terms during the special cooperative period. The purpose of CTR is to reduce transaction costs and improve transaction efficiency so that the transaction process can be followed with evidence (Williamson, 2002). Simultaneously, it is beneficial to build a market transaction base with partners and target trusted companies to develop products and services (Yan,Chong & Mak, 2010).

The CTR needs to be self-enforcing to protect the trust relationship between partners and the performance of future collaborations (Taylor & Plambeck, 2007). Poppo and Zenger (2002) believed that alliance companies can control and coordinate their trading behavior and punish violations through contracts, which can effectively maintain the reliability of the alliance's trading relationship and the predictability of partner behavior, and stipulate the boundary of knowledge transfer between firms to improve cooperation performance. Contractual cooperation has higher sensitivity and adaptability and lower organizational costs; thus, firms can cooperate with lower costs and higher efficiency. Simultaneously, firms can respond quickly to changes in the market and external environment, thereby improving cooperative firms’ innovation performance. As a result, the following hypotheses regarding CTR and IP were established based on a literature analysis:

H3

CTR positively affects IP.

H3a

CTR has a positive influence on TIP.

H3b

CTR has a positive influence on MIP.

Mediating effect of knowledge sharing on supply chain partnership and innovation performanceKnowledge is often characterized as a non-depleted hidden resource that helps realize innovation through its spread, diffusion, and application. Therefore, it is crucial to manage and utilize knowledge efficiently (Lee & Wong, 2015). Knowledge management involves the acquisition, sharing, integration, and utilization of knowledge resources. According to (Wang & Noe, 2010), successful knowledge management activities mostly rely on KS, which includes not only the exchange of knowledge but also the absorption and utilization of shared knowledge by the knowledge acquirer (Reinholt,Pedersen & Foss, 2011). Firms need to conduct knowledge exchange activities to achieve win-win cooperation with their partners (Ritala,Olander,Michailova & Husted, 2015). KS significantly contributes to the relationship between a company and its partners (Scott-Kennel & Saittakari, 2020), and can enhance the innovation capability of partner firms (Delbufalo, 2017).

A high-level trust relationship between supply chain partners can promote efficient KS among companies, thereby improving their innovation performance. Brahm and Tarzijan (2016) indicated that trust between collaborative companies in a supply chain can help build a responsive sharing platform when facing dynamic changes in the external environment, thereby achieving a virtuous circle of synchronous decision making and knowledge sharing. Sáenz et al. (2012) pointed out that KS can promote cooperation and exchange between organizations and improve the innovation performance of firms by creating new knowledge. TR is one of the many factors critical to the success of KS or transfer (Yang,Chen & Hao, 2019). Briefly, the above analysis of KS, TR, and IP leads to the following hypotheses:

H4

KS plays a positive mediating role between TR and IP.

H4a

TR positively impacts KS.

H4b

KS has a positive mediating effect between TR and TIP.

H4c

KS has a positive mediating effect between TR and MIP.

Cummings and Teng (2003) suggested that a commitment relationship (CMR) can promote further cooperation among supply chain partners, thereby providing greater convenience for any partner to share knowledge and information. Van den Hooff and De Ridder (2004) indicated that an effective CMR can significantly affect KS behavior. Chen,Wan and Wang (2017) discovered that CMR among supply chain nodes can not only promote more flexible cooperation on technologies, products, and services but also coordinate conflicts of interests and tasks between partners. Thus, the potential risks of opportunistic behavior and the bullwhip effect can be avoided, and the sharing of knowledge and information is promoted. Ganesh et al. (2014) show that CMR between organizations is beneficial for information sharing in complex supply chains. As a result, the following hypotheses regarding KS, CMR, and IP are proposed:

H5

KS plays a positive mediating role between CMR and IP.

H5a

CMR positively impacts KS.

H5b

KS has a positive mediating effect between CMR and TIP.

H5c

KS has a positive mediating effect between CMR and MIP.

Additionally, a contractual relationship (CTR) between supply chain partners can ensure long-term and stable cooperation. Lee and Cavusgil (2006) found that governance based on CTR could reduce the risk of cooperation, promote the transfer and exchange of knowledge, and improve cooperation performance. Ha and Tong (2008) indicated that CTR is an important driver of information-sharing value in contracts and information sharing under supply chain competition. Zhang-Sheng (2012) mentioned that if cooperative firms establish a contractual relationship, the cost and difficulty of knowledge transfer and exchange between partners will be reduced, and the efficiency of acquiring and utilizing knowledge will increase to provide a certain guarantee for firms to achieve their expected performance. The above analysis implies that establishing CTR among supply chain partners can promote KS and ultimately contribute to improving cooperative innovation performance. As a result, the following hypotheses regarding KS, CTR, and IP were developed:

H6

KS plays a positive mediating role between CTR and IP.

H6a

CTR positively affects KS

H6b

KS has a positive mediating effect between CTR and TIP.

H6c

KS has a positive mediating effect between CTR and MIP.

Moderating effect of knowledge distance on knowledge sharing and innovation performanceCummings and Teng (2003) proposed that KD measures knowledge similarity between knowledge providers and receivers. Liyanage and Barnard (2003) and Mandrinos and Nik Mahdi (2016) regarded KD as the degree of similarity or difference in basic knowledge between organizations. Qian,Liang and Dang (2009) defined KD as the difference in the knowledge structure presented on the premise that different subjects have the same knowledge base. Similarly, Schulze and Brojerdi (2012) suggested that KD is the degree of difference between partners in a specific knowledge element. In short, KD can be summarized as the difference in the knowledge structure, understanding, and application of the upstream and downstream firms of a supply chain with the premise of the same knowledge base.

Owing to the existence of KD, the mediating effect of KS between SCP and IP may differ, even if the direction of the effect could change. When companies involved in KS do not have sufficient overlapping knowledge, there is an obvious KD, and thus, KS will be difficult (Tortoriello,Reagans & McEvily, 2012). Phelps,Heidl and Wadhwa (2012) indicated that even knowledge providers can improve the observability of knowledge through various means and that KD creates certain obstacles to innovation performance. Schulze and Brojerdi (2012) studied 53 collaborative development projects and concluded that a small KD benefits IP. KS among supply chain partners is expected to improve IP smoothly. Through KS, firms can combine their own knowledge with external knowledge more effectively, realize new combinations and matching of knowledge, and promote and stimulate innovation performance (Zhou & Li, 2012). Conversely, a large KD leads to large obstacles to communication and exchange, making it difficult for supply chain partners to acquire the necessary knowledge. Therefore, the following hypotheses are proposed:

H7

KD has a negative effect on the relationship between KS and IP.

H7a

KD negatively impacts the relationship between KS and TIP.

H7b

KD negatively impacts the relationship between KS and MIP.

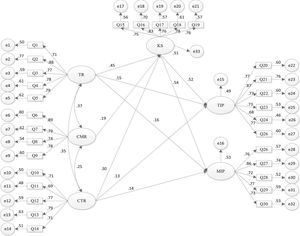

Research methodologyBased on the hypotheses developed in Section 2, this study constructs a conceptual model to discuss the mediating effect of KS and the moderating effect of KD on the SCP and IP of manufacturing firms. As shown in Fig. 1, the considerations for SCP include TR, CMR, and CTR, while those for IP include TIP and MIP. To verify the proposed conceptual framework and hypotheses, an empirical study was conducted based on a questionnaire survey, which can help generalize the results and facilitate the simultaneous investigation of a large number of factors.

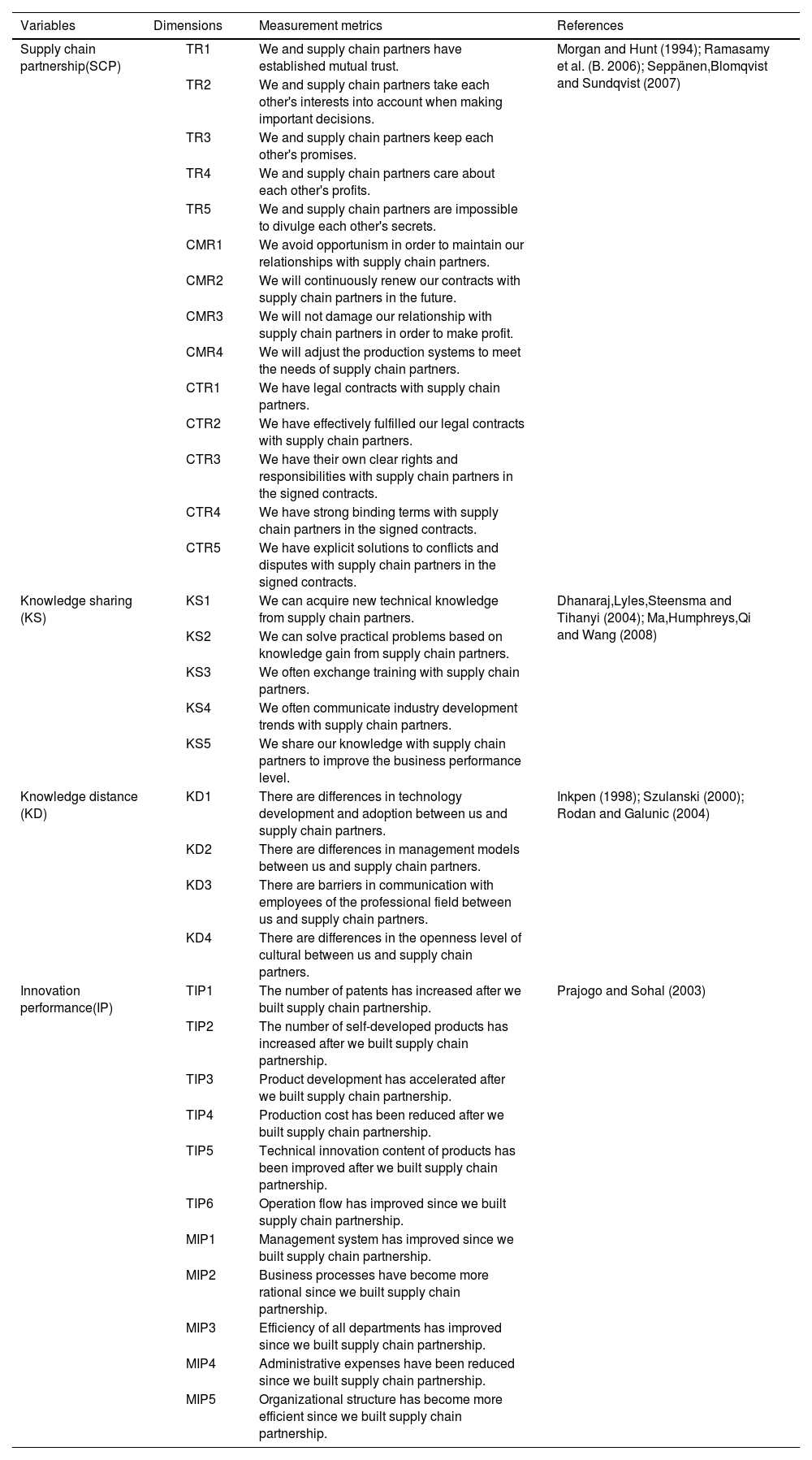

Questionnaire designThe measurement indicators were developed and revised in multiple rounds to form a preliminary questionnaire based on the above critical literature analysis and expert advice. It was then distributed to 60 professionals invited for pre-investigation, and 44 valid responses on the questionnaire design were recovered. Questionnaire items with redundant information were eliminated based on the respondents’ feedback. In addition, semantic modification and expression simplification were performed so that the respondents could clearly understand the survey questions. This effort led to the development of a final questionnaire for mass distribution. In the final version, the TR, CMR, and CTR aspects of SCP were measured using five, four, and five indicators, respectively. The TIP and MIP aspects of IP were calculated using six and five metrics, respectively. KS has five measuring instruments, and KD has four. Table 1 summarizes these 34 metrics. Each questionnaire item was measured on a five-point Likert scale ranging from “strongly disagree” (1) to “strongly agree” (5).

Variable dimensions and their measurement instruments.

| Variables | Dimensions | Measurement metrics | References | |

|---|---|---|---|---|

| Supply chain partnership(SCP) | TR1 | We and supply chain partners have established mutual trust. | Morgan and Hunt (1994); Ramasamy et al. (B. 2006); Seppänen,Blomqvist and Sundqvist (2007) | |

| TR2 | We and supply chain partners take each other's interests into account when making important decisions. | |||

| TR3 | We and supply chain partners keep each other's promises. | |||

| TR4 | We and supply chain partners care about each other's profits. | |||

| TR5 | We and supply chain partners are impossible to divulge each other's secrets. | |||

| CMR1 | We avoid opportunism in order to maintain our relationships with supply chain partners. | |||

| CMR2 | We will continuously renew our contracts with supply chain partners in the future. | |||

| CMR3 | We will not damage our relationship with supply chain partners in order to make profit. | |||

| CMR4 | We will adjust the production systems to meet the needs of supply chain partners. | |||

| CTR1 | We have legal contracts with supply chain partners. | |||

| CTR2 | We have effectively fulfilled our legal contracts with supply chain partners. | |||

| CTR3 | We have their own clear rights and responsibilities with supply chain partners in the signed contracts. | |||

| CTR4 | We have strong binding terms with supply chain partners in the signed contracts. | |||

| CTR5 | We have explicit solutions to conflicts and disputes with supply chain partners in the signed contracts. | |||

| Knowledge sharing (KS) | KS1 | We can acquire new technical knowledge from supply chain partners. | Dhanaraj,Lyles,Steensma and Tihanyi (2004); Ma,Humphreys,Qi and Wang (2008) | |

| KS2 | We can solve practical problems based on knowledge gain from supply chain partners. | |||

| KS3 | We often exchange training with supply chain partners. | |||

| KS4 | We often communicate industry development trends with supply chain partners. | |||

| KS5 | We share our knowledge with supply chain partners to improve the business performance level. | |||

| Knowledge distance (KD) | KD1 | There are differences in technology development and adoption between us and supply chain partners. | Inkpen (1998); Szulanski (2000); Rodan and Galunic (2004) | |

| KD2 | There are differences in management models between us and supply chain partners. | |||

| KD3 | There are barriers in communication with employees of the professional field between us and supply chain partners. | |||

| KD4 | There are differences in the openness level of cultural between us and supply chain partners. | |||

| Innovation performance(IP) | TIP1 | The number of patents has increased after we built supply chain partnership. | Prajogo and Sohal (2003) | |

| TIP2 | The number of self-developed products has increased after we built supply chain partnership. | |||

| TIP3 | Product development has accelerated after we built supply chain partnership. | |||

| TIP4 | Production cost has been reduced after we built supply chain partnership. | |||

| TIP5 | Technical innovation content of products has been improved after we built supply chain partnership. | |||

| TIP6 | Operation flow has improved since we built supply chain partnership. | |||

| MIP1 | Management system has improved since we built supply chain partnership. | |||

| MIP2 | Business processes have become more rational since we built supply chain partnership. | |||

| MIP3 | Efficiency of all departments has improved since we built supply chain partnership. | |||

| MIP4 | Administrative expenses have been reduced since we built supply chain partnership. | |||

| MIP5 | Organizational structure has become more efficient since we built supply chain partnership. | |||

Note: TR = trust relationship; CMR = commitment relationship; CTR = contractual relationship; TIP = technological innovation performance; MIP = management innovation performance.

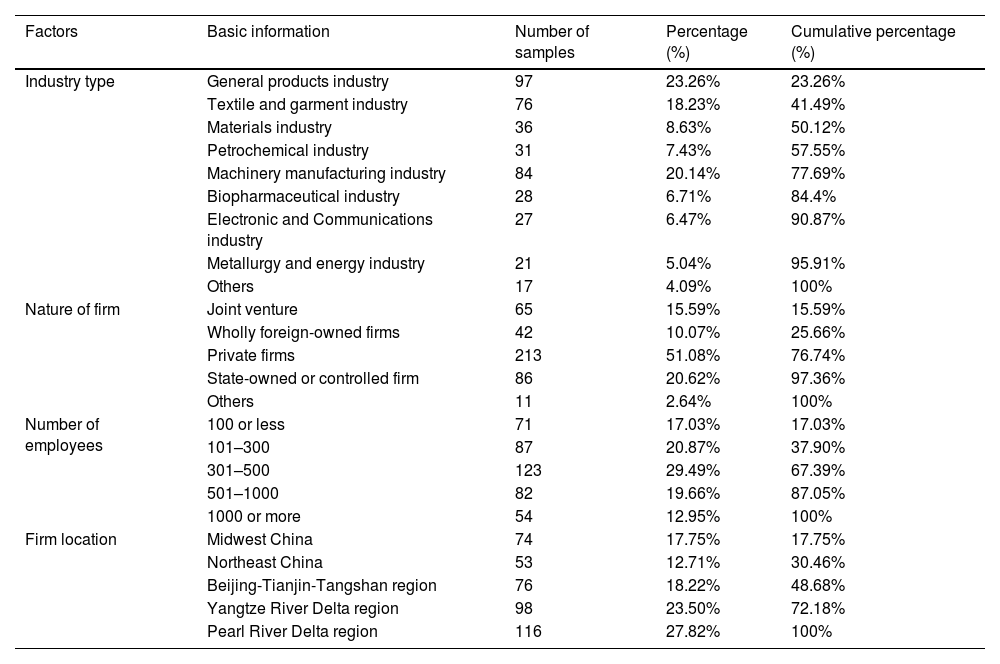

The empirical study was conducted in China mainly because the industry in China produces approximately 29% of the global manufacturing output, and Chinese manufacturing firms have established in-depth cooperative relations with global partners and become key nodes in the global supply chain and innovation network. Thus, the results obtained are expected to be significant and impactful. The questionnaire was distributed to supply chain professionals and managers working in manufacturing firms through reputable survey platforms in 2020 and 2021. In total, 650 electronic questionnaires were distributed, and 482 were recovered, representing a recovery rate of 74.2%. After excluding questionnaires with incomplete answers and those with single-answer or patterned responses, 417 valid questionnaires were retained. This represented an effective recovery rate of 86.5%. The basic information on the questionnaires is presented in Table 2.

Descriptive statistics of the collected samples.

| Factors | Basic information | Number of samples | Percentage (%) | Cumulative percentage (%) |

|---|---|---|---|---|

| Industry type | General products industry | 97 | 23.26% | 23.26% |

| Textile and garment industry | 76 | 18.23% | 41.49% | |

| Materials industry | 36 | 8.63% | 50.12% | |

| Petrochemical industry | 31 | 7.43% | 57.55% | |

| Machinery manufacturing industry | 84 | 20.14% | 77.69% | |

| Biopharmaceutical industry | 28 | 6.71% | 84.4% | |

| Electronic and Communications industry | 27 | 6.47% | 90.87% | |

| Metallurgy and energy industry | 21 | 5.04% | 95.91% | |

| Others | 17 | 4.09% | 100% | |

| Nature of firm | Joint venture | 65 | 15.59% | 15.59% |

| Wholly foreign-owned firms | 42 | 10.07% | 25.66% | |

| Private firms | 213 | 51.08% | 76.74% | |

| State-owned or controlled firm | 86 | 20.62% | 97.36% | |

| Others | 11 | 2.64% | 100% | |

| Number of employees | 100 or less | 71 | 17.03% | 17.03% |

| 101–300 | 87 | 20.87% | 37.90% | |

| 301–500 | 123 | 29.49% | 67.39% | |

| 501–1000 | 82 | 19.66% | 87.05% | |

| 1000 or more | 54 | 12.95% | 100% | |

| Firm location | Midwest China | 74 | 17.75% | 17.75% |

| Northeast China | 53 | 12.71% | 30.46% | |

| Beijing-Tianjin-Tangshan region | 76 | 18.22% | 48.68% | |

| Yangtze River Delta region | 98 | 23.50% | 72.18% | |

| Pearl River Delta region | 116 | 27.82% | 100% |

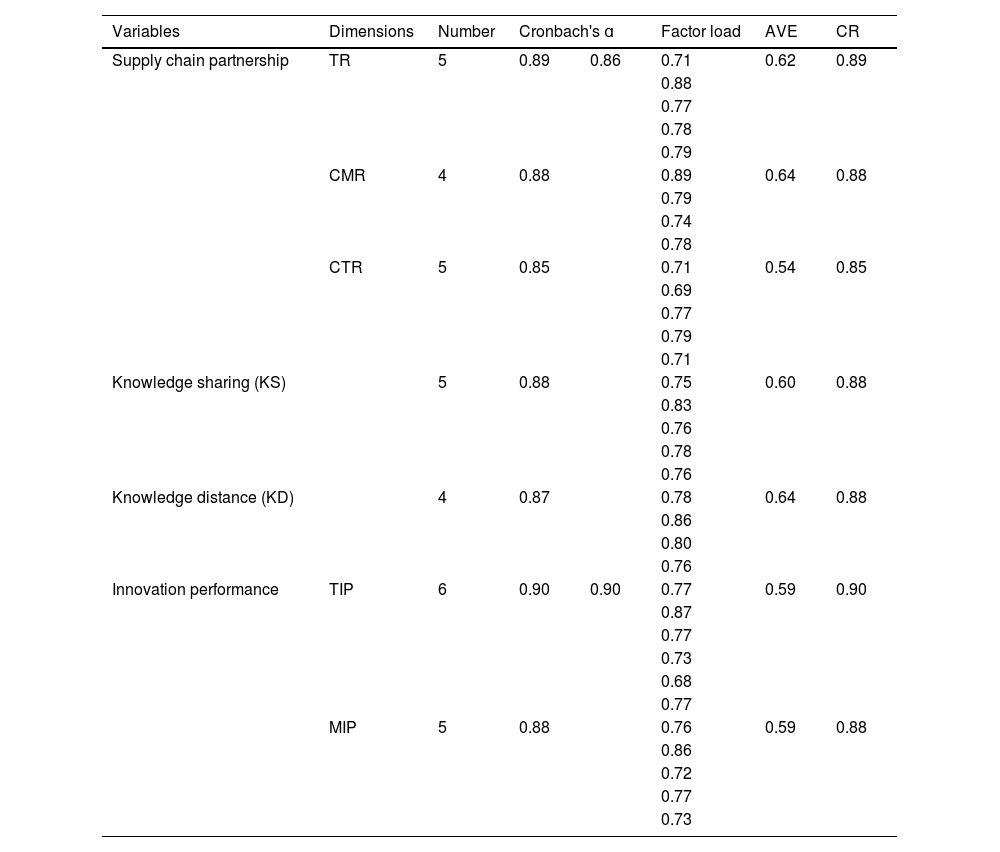

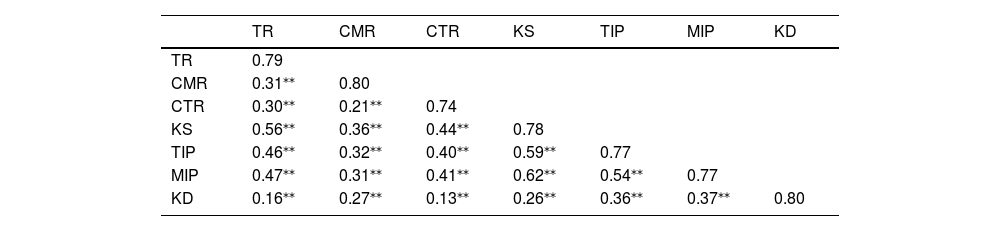

To examine the reliability and validity of the data, software tools of SPSS 24.0 and AMOS 24.0 are employed to conduct the tests. It can be seen in Table 3 that Cronbach'sα values are all greater than 0.8, which shows an ideal consistency between the variables and questionnaire items. The composite reliability (CR) was also greater than 0.8, indicating that the reliability of the measurement variables was high. Data validity was reflected in convergent and discriminant validity. Convergent validity can be verified using three parameters: factor load, average variance extracted (AVE), and CR. Generally, the values of the three items must be greater than 0.5; Table 3 shows that this requirement is met. The discriminant validity test assumes that the square root of the AVE of every measured variable is higher than the correlation coefficient between the measured variables (Table 4). Moreover, when the square root of the AVE is above 0.7, the model is regarded as having good discriminant validity (Bagozzi & Yi, 1988). Additionally, the correlation coefficient between each variable was less than 0.8, implying that no multicollinearity existed between the variables.

Results of data reliability and validity.

| Variables | Dimensions | Number | Cronbach's ɑ | Factor load | AVE | CR | |

|---|---|---|---|---|---|---|---|

| Supply chain partnership | TR | 5 | 0.89 | 0.86 | 0.71 | 0.62 | 0.89 |

| 0.88 | |||||||

| 0.77 | |||||||

| 0.78 | |||||||

| 0.79 | |||||||

| CMR | 4 | 0.88 | 0.89 | 0.64 | 0.88 | ||

| 0.79 | |||||||

| 0.74 | |||||||

| 0.78 | |||||||

| CTR | 5 | 0.85 | 0.71 | 0.54 | 0.85 | ||

| 0.69 | |||||||

| 0.77 | |||||||

| 0.79 | |||||||

| 0.71 | |||||||

| Knowledge sharing (KS) | 5 | 0.88 | 0.75 | 0.60 | 0.88 | ||

| 0.83 | |||||||

| 0.76 | |||||||

| 0.78 | |||||||

| 0.76 | |||||||

| Knowledge distance (KD) | 4 | 0.87 | 0.78 | 0.64 | 0.88 | ||

| 0.86 | |||||||

| 0.80 | |||||||

| 0.76 | |||||||

| Innovation performance | TIP | 6 | 0.90 | 0.90 | 0.77 | 0.59 | 0.90 |

| 0.87 | |||||||

| 0.77 | |||||||

| 0.73 | |||||||

| 0.68 | |||||||

| 0.77 | |||||||

| MIP | 5 | 0.88 | 0.76 | 0.59 | 0.88 | ||

| 0.86 | |||||||

| 0.72 | |||||||

| 0.77 | |||||||

| 0.73 | |||||||

Note: CR = composite reliability, AVE = average variance extracted.

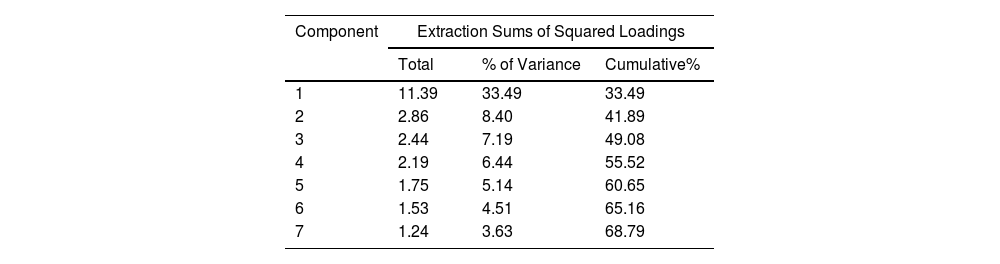

Harman's single-factor test was used to identify common method variance in the collected data. As shown in Table 5, the unrotated exploratory factor analysis results extracted seven factors with a characteristic root greater than one, consistent with the set factors. The maximum factor variance explained rate was 33.49% (less than 40%), and the cumulative percentage of the first factor was less than 50% of the cumulative percentage of all extracted factors, that is, 33.49% < 68.79% × 0.5. Therefore, common method bias was not significant in this study.

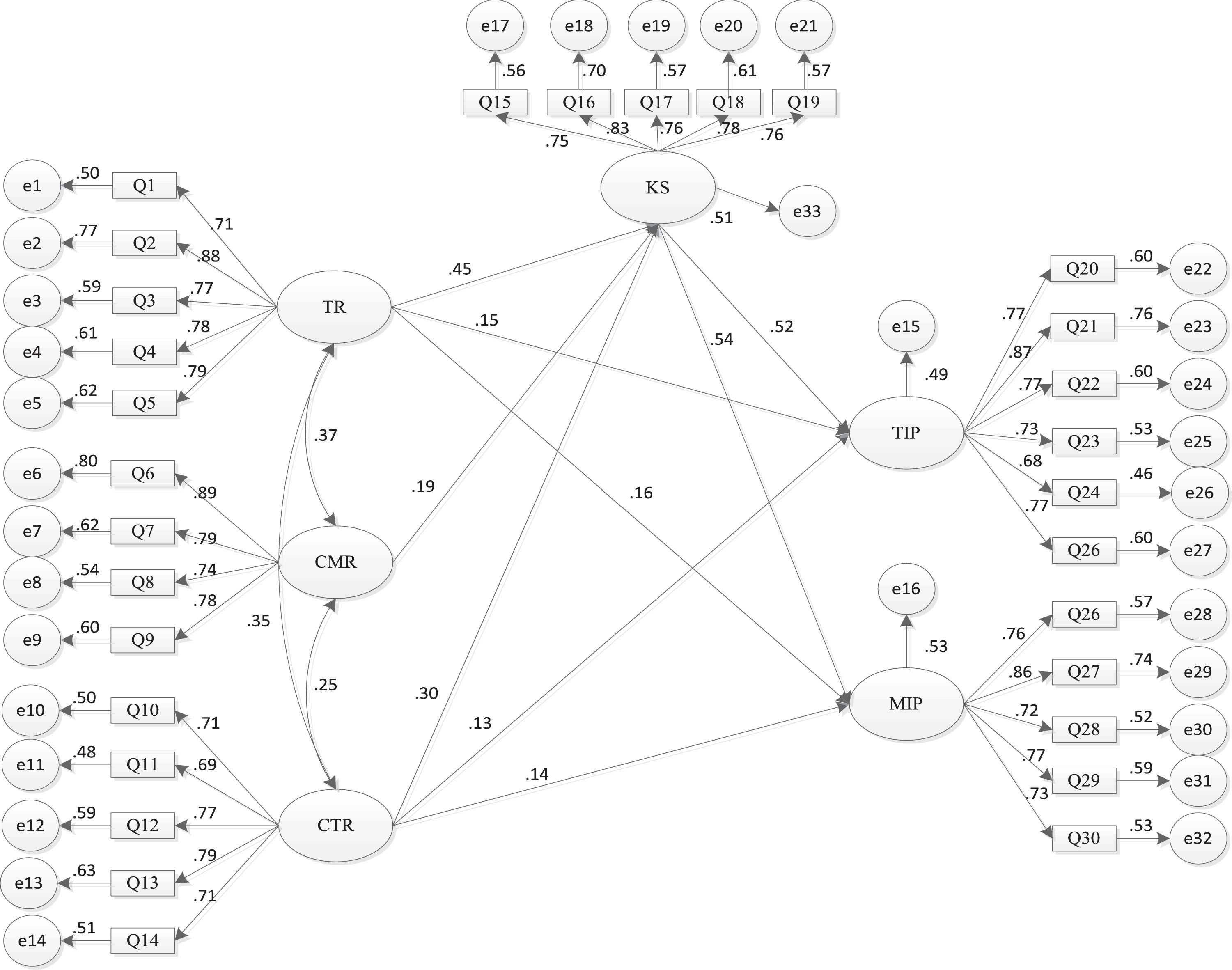

Hypothesis testing and resultsModel verification and path analysisTo verify the overall model fitness and influence path of the various variables, this study employed structural equation modeling (SEM) and confirmatory factor analysis (CFA) to test the hypotheses using AMOS24.0 software. First, a CFA was conducted to eliminate insignificant paths. The number of valid questionnaires after data cleaning was 417, which exceeded the general requirement of the minimum sample size of CFA – at least 200 samples or five times the number of measurements (scale questions). According to the criteria of C.R. value < 1.96, there was no statistical significance at P < 0.05. In this regard, the two paths of “TIP←CMR” and “MIP←CMR” are deleted, and a revised structure equation model is obtained, as shown in Fig. 2.

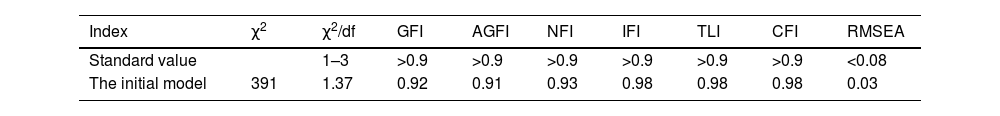

The fitting results of the modified model are presented in Table 6. There was no significant difference in the degree of fit compared with the initial model. Specifically, χ2/df is 1.37, which meets the criterion of less than 3, and GFI, AGFI, NFI, IFI, TLI, and CFI are all greater than 0.9, which means that the overall fitness of the model is satisfactory.

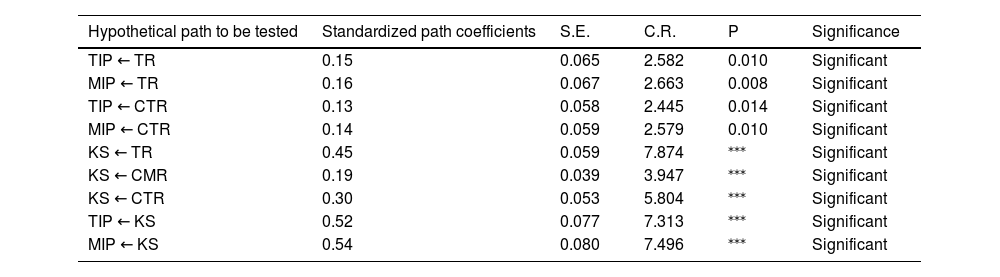

From the perspective of model fitness, the paths with insignificant P values are deleted according to the test results of the initial model, so the fitting degree of the obtained new model is improved. Each path of the modified model is statistically significant at the level of CR value greater than 1.96 with P < 0.05 (see Table 7). In addition, it can be found that after deleting the two paths of “TIP←CMR” and “MIP ← CMR,” the path of “TIP ← CTR” also becomes significant.

Path test results of the modified model.

| Hypothetical path to be tested | Standardized path coefficients | S.E. | C.R. | P | Significance |

|---|---|---|---|---|---|

| TIP ← TR | 0.15 | 0.065 | 2.582 | 0.010 | Significant |

| MIP ← TR | 0.16 | 0.067 | 2.663 | 0.008 | Significant |

| TIP ← CTR | 0.13 | 0.058 | 2.445 | 0.014 | Significant |

| MIP ← CTR | 0.14 | 0.059 | 2.579 | 0.010 | Significant |

| KS ← TR | 0.45 | 0.059 | 7.874 | ⁎⁎⁎ | Significant |

| KS ← CMR | 0.19 | 0.039 | 3.947 | ⁎⁎⁎ | Significant |

| KS ← CTR | 0.30 | 0.053 | 5.804 | ⁎⁎⁎ | Significant |

| TIP ← KS | 0.52 | 0.077 | 7.313 | ⁎⁎⁎ | Significant |

| MIP ← KS | 0.54 | 0.080 | 7.496 | ⁎⁎⁎ | Significant |

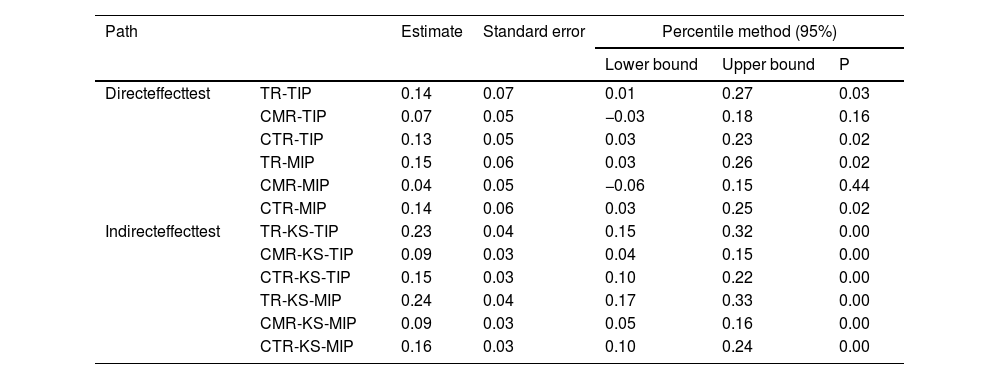

The bootstrap method was employed to further explore the mediating role of KS. Compared with the traditional causal stepwise regression test, the bootstrap method has advantages in terms of high efficiency and suitability for relatively small sample sizes. This is also a well-known method for testing mediating effects. The principle is that if the confidence interval does not contain zero, the mediating effect can be considered true; otherwise, it is considered false. After 2000 bootstrap calculations, the test results were obtained, as shown in Table 8. The direct effects of TR on TIP and MIP were 0.14 and 0.15. The 95% confidence intervals are [0.01, 0.27] and [0.03, 0.26], respectively, and the confidence interval does not include zero, proving that the direct effects of TR among supply chain firms on TIP and MIP are significant. In addition, TR has indirect effects on TIP and MIP; in fact, its indirect effects on TIP and MIP, obtained as 0.23 and 0.24, respectively, are even more significant than its direct effects. Moreover, the CMR shows insignificant direct effects on TIP and MIP because their confidence intervals contain 0, but the indirect effects on TIP and MIP are significant. Additionally, both the direct and indirect effects of CTR on TIP and MIP are meaningful, although the indirect impacts of CTR on TIP and MIP are greater than the direct impacts. Thus, the mediating effect of KS was not negligible.

Results of mediating effect test.

| Path | Estimate | Standard error | Percentile method (95%) | |||

|---|---|---|---|---|---|---|

| Lower bound | Upper bound | P | ||||

| Directeffecttest | TR-TIP | 0.14 | 0.07 | 0.01 | 0.27 | 0.03 |

| CMR-TIP | 0.07 | 0.05 | −0.03 | 0.18 | 0.16 | |

| CTR-TIP | 0.13 | 0.05 | 0.03 | 0.23 | 0.02 | |

| TR-MIP | 0.15 | 0.06 | 0.03 | 0.26 | 0.02 | |

| CMR-MIP | 0.04 | 0.05 | −0.06 | 0.15 | 0.44 | |

| CTR-MIP | 0.14 | 0.06 | 0.03 | 0.25 | 0.02 | |

| Indirecteffecttest | TR-KS-TIP | 0.23 | 0.04 | 0.15 | 0.32 | 0.00 |

| CMR-KS-TIP | 0.09 | 0.03 | 0.04 | 0.15 | 0.00 | |

| CTR-KS-TIP | 0.15 | 0.03 | 0.10 | 0.22 | 0.00 | |

| TR-KS-MIP | 0.24 | 0.04 | 0.17 | 0.33 | 0.00 | |

| CMR-KS-MIP | 0.09 | 0.03 | 0.05 | 0.16 | 0.00 | |

| CTR-KS-MIP | 0.16 | 0.03 | 0.10 | 0.24 | 0.00 | |

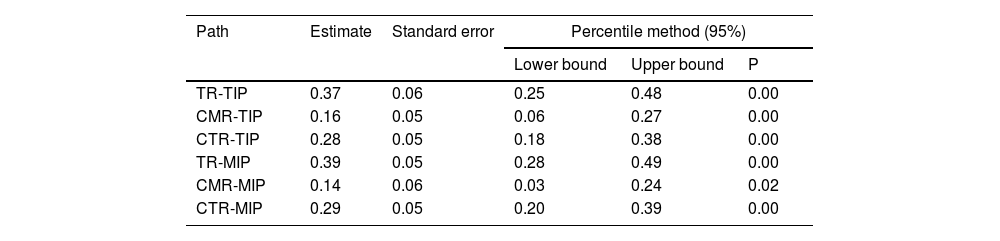

Generally, direct effects reflect the degree of correlation between variables. An indirect effect indicates that an independent variable affects a dependent variable through other mediating variables. The overall effect reflects the total influence of one variable on the other. The overall effect was calculated by adding the direct and indirect effects when each path was significant. According to the test results of the overall standardized effect shown in Table 9, TR had the most significant effect on TIP and MIP, followed by CTR and CMR.

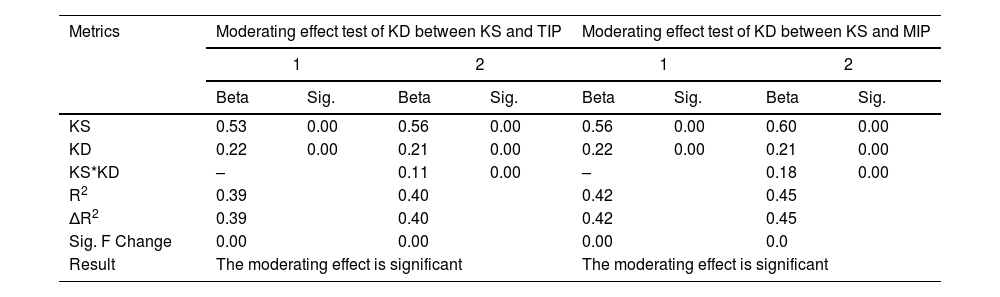

Moderating effect testThis study utilized the hierarchical multiple regression (HMR) method to test the moderating effect of KD between KS and IP. HMR is primarily concerned with analyzing causality through comparison rather than building econometric models. Therefore, it is suitable for meeting the needs of this study. The specific steps are as follows: (1) Perform a regression analysis of dependent variables (Y) on independent variables (X) and moderating variables (M), such that R12 can be obtained; (2) Perform a regression analysis of Y based on X, M, and X*M, and this yields R22; (3) Compare R12 and R22. If R22 is significantly larger than R12, the moderating effect is significant and vice versa. In this case, the moderating variable, KD, moderates KS and the two IP dimensions. Therefore, the independent variable is KS, and the dependent variables are TIP and MIP. Because all three variables were continuous, hierarchical regression was applied. The results are summarized in Table 10.

Test results of moderating effect of KD between KS and IP.

| Metrics | Moderating effect test of KD between KS and TIP | Moderating effect test of KD between KS and MIP | ||||||

|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 1 | 2 | |||||

| Beta | Sig. | Beta | Sig. | Beta | Sig. | Beta | Sig. | |

| KS | 0.53 | 0.00 | 0.56 | 0.00 | 0.56 | 0.00 | 0.60 | 0.00 |

| KD | 0.22 | 0.00 | 0.21 | 0.00 | 0.22 | 0.00 | 0.21 | 0.00 |

| KS*KD | – | 0.11 | 0.00 | – | 0.18 | 0.00 | ||

| R2 | 0.39 | 0.40 | 0.42 | 0.45 | ||||

| ΔR2 | 0.39 | 0.40 | 0.42 | 0.45 | ||||

| Sig. F Change | 0.00 | 0.00 | 0.00 | 0.0 | ||||

| Result | The moderating effect is significant | The moderating effect is significant | ||||||

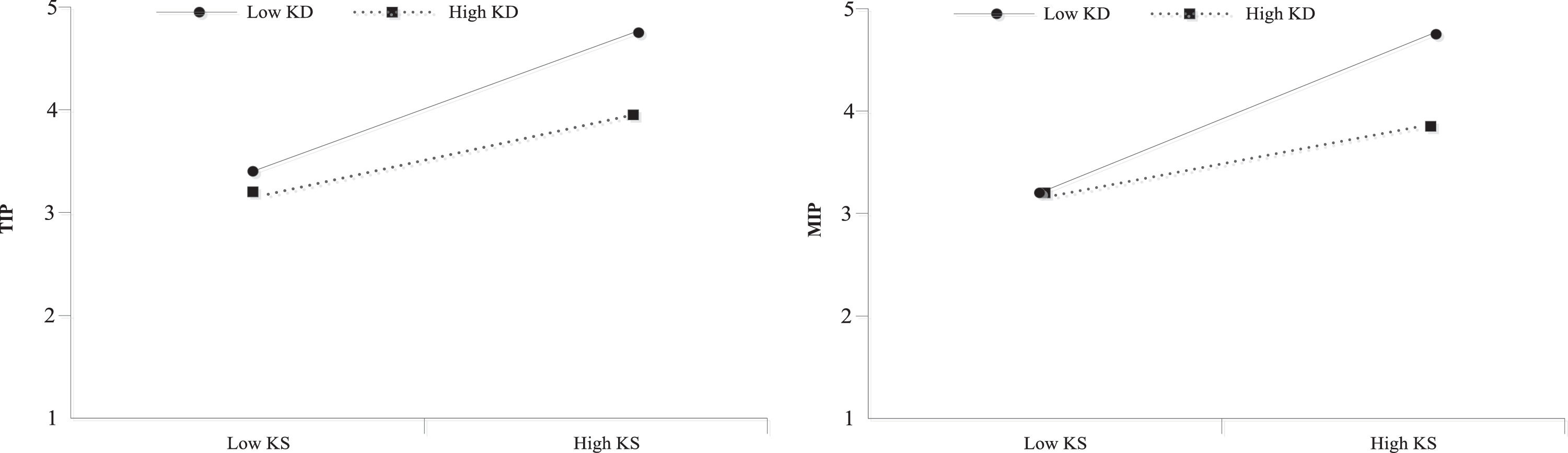

Based on the above steps, this study tested whether KD has a moderating effect on the relationship between KS and IP. As shown in Table 10, after adding KS*KD, R2 increased significantly, with all significances above 0.1. However, the Beta value decreased, indicating that the KD has significant adverse moderating effects on the relationship between KS, TIP, and MIP. Therefore, H7 was verified.

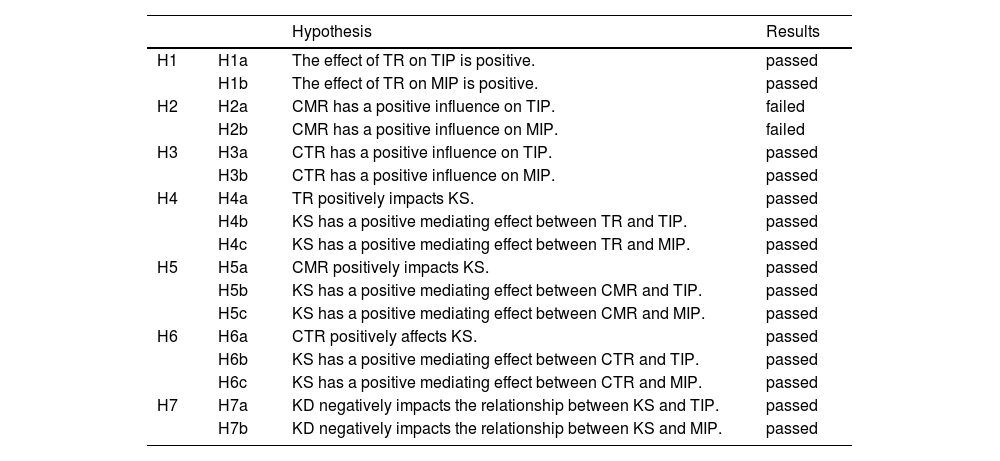

To further reflect the moderating effects of KD between KS, TIP, and MIP, this study takes the mean KD as the cut-off point and divides the samples into large and small KD groups by adding or deducting a standard deviation (< Z¯-δ, >Z¯+δ). Clearly, when KD is large (e.g., >Z¯+δ), KS among supply chain partners has a minimal effect on TIP or MIP. When KD is small (e.g., < Z¯-δ), both partners can obtain the required knowledge through KS. Therefore, the effects of KS on TIP and MIP were more significant, as shown in Fig. 3. In summary, all proposed hypotheses passed the verification test, except for H2. The verification results are presented in Table 11.

Summary of hypotheses tests.

| Hypothesis | Results | ||

|---|---|---|---|

| H1 | H1a | The effect of TR on TIP is positive. | passed |

| H1b | The effect of TR on MIP is positive. | passed | |

| H2 | H2a | CMR has a positive influence on TIP. | failed |

| H2b | CMR has a positive influence on MIP. | failed | |

| H3 | H3a | CTR has a positive influence on TIP. | passed |

| H3b | CTR has a positive influence on MIP. | passed | |

| H4 | H4a | TR positively impacts KS. | passed |

| H4b | KS has a positive mediating effect between TR and TIP. | passed | |

| H4c | KS has a positive mediating effect between TR and MIP. | passed | |

| H5 | H5a | CMR positively impacts KS. | passed |

| H5b | KS has a positive mediating effect between CMR and TIP. | passed | |

| H5c | KS has a positive mediating effect between CMR and MIP. | passed | |

| H6 | H6a | CTR positively affects KS. | passed |

| H6b | KS has a positive mediating effect between CTR and TIP. | passed | |

| H6c | KS has a positive mediating effect between CTR and MIP. | passed | |

| H7 | H7a | KD negatively impacts the relationship between KS and TIP. | passed |

| H7b | KD negatively impacts the relationship between KS and MIP. | passed | |

The results showed that TR positively affected both TIP and MIP and that the effect of TR on MIP was greater than that of TR on TIP. This finding is consistent with those of Lundin ((2006)) and Nyaga,Whipple and Lynch (2010). However, this study indicates that the CMR has no significant positive impact on TIP and MIP, which is inconsistent with the findings of Hansen (2016). This discrepancy may be attributed to differences in the study subjects. The supply chain firms in this study are broad and span multiple industries, while Hansen (2016) was limited to multiple departments of large electronics companies. In addition, CTR had significant positive effects on TIP and MIP at a significance level of 0.05. Among them, the impact of CTR on MIP was the most significant. Generally, CTR between supply chain partners has a positive effect on IP, which is consistent with the conclusions of Von Branconi and Loch (2004) and Rodríguez-López Diz-Comesaña and Mondragón (2017).

In terms of the mediating effect of KS, the results verify Hypotheses H4, H5, and H6; that is, each dimension of SCP has a significant positive effect on KS (P<0.001). TR had the most significant effect on KS, followed by CTR and CMR. This could be because the CMR has neither mutual recognition under TR nor a constraint and guarantee mechanism under CTR. Although supply chain companies promise to share knowledge, KS may be insufficient without corresponding assurances and penalties. Consequently, to promote deeper KS, supply chain partners can increase their degree of trust and establish reliable contractual relationships. The verification of H4, H5, and H6 also indicated that KS had a positive impact on the two dimensions of IP (P<0.001). By sharing knowledge, supply chain firms can continuously address deficiencies and supplement their original knowledge bases for technological and management innovations.

In addition, KD had a critical negative moderating effect on KS and IP. Moreover, the IP of manufacturing companies not only depends on supply chain partnerships and KS but is also affected by the moderating effect of KD. In other words, the larger the KD between supply chain partners, the more severe is the hindering effect on KS and firm innovation.

Managerial implicationsBased on the empirical analysis in this study, two managerial implications are obtained. First, in the actual operation of supply chain collaborative innovation, firms should strengthen their trust in the relationships with their cooperative partners. In the process of cooperation with partner enterprises, the trust mechanism not only simplifies the complicated cooperation process, thereby shortening transaction time and saving transaction costs but also promotes a more stable cooperative relationship between firms. At the same time, they should continuously enhance their supply chain partners’ cognition and recognition of collaborative goals and establish a harmonious, cooperative innovation atmosphere. They should strive to achieve zero-barrier communication, reduce unnecessary misunderstandings and friction, and prevent opportunistic risks. In addition, companies should be aware that effective contractual relationships can compensate for informal verbal commitments. Therefore, supply chain partners must establish corresponding remedies in contractual relationships, continuously improve contract performance and provide legal protection for long-term cooperation between partners.

Second, companies should attach great importance to the impact of knowledge management on their development. It is necessary to strengthen KS among supply chain cooperative companies and shorten the KD as much as possible. Companies can gradually broaden their communication channels with their supply chain partners by establishing a knowledge-sharing platform. Companies can continuously inject new knowledge through exchanges with partners. It is essential to keep up with market demand and competitive trends and quickly launch products or services that meet the market. Additionally, companies must be aware of the differences in knowledge accumulation between partners, which may, to some extent, inhibit KS between enterprises. Therefore, businesses must strive to eliminate KD when sharing knowledge. From the perspective of knowledge recipients, enterprises with a relatively low knowledge stock should pay more attention to acquiring and learning new knowledge and actively participate in knowledge exchange and sharing. Additionally, knowledge recipients should improve their learning abilities and consolidate their knowledge base to minimize the distance between high-knowledge stock companies.

ConclusionsThis research presents a multi-factor conceptual model between SCP and IP based on the perspective of knowledge management, in which SCP is measured using three explanatory variables: trust (TR), commitment (CMR), and contract (CTR). KS was introduced as an intermediary variable and KD as a moderating variable. This study also considers company IP in terms of TIP and MIP. An empirical study was conducted to verify the hypotheses by analyzing data from 417 valid questionnaires collected from manufacturing firms in China. The major findings are summarized as follows.

- (1)

Although TR positively impacts both TIP and MIP, the effect of TR on MIP is greater than that of TR on TIP. Moreover, CMR has no significant positive effect on TIP or MIP.

- (2)

CTR has significant positive effects on TIP and MIP, and the effect on MIP is more significant than that on TIP. In addition, CTR between supply chain partners has a significant positive impact on IP.

- (3)

Each dimension of SCP has a significant positive effect on KS. TR has the most significant effect on KS, followed by CTR and CMR. KS has a significant impact on TIP and MIP.

- (4)

KD shows a negative moderating effect between KS and IP, indicating that the IP of manufacturing companies not only depends on SCP and KS but is also affected by the moderating effect of KD.

Nevertheless, this study has certain limitations that present opportunities for further research. The research target in this study was limited to manufacturing companies in China; thus, the findings may not be applicable to other countries or regions. While China has been recognized as a major manufacturing-based economy, the boom in manufacturing activities in other countries and regions owing to supply chain restructuring in recent years has changed the global landscape. In future investigations, companies from different countries and sectors should be considered to cross-check the relationship between SCP and IP and the roles of KS and KD, thereby increasing the generalizability of the research findings. In addition, while a major innovation of this research is the introduction of KS as an intermediary variable and KD as a moderating variable, other factors could affect the relationship between SCP and IP in supply chain management practices. In the future, external environmental factors (e.g., incentive policies for enterprise innovation) can be considered as variables to enrich the conclusions.

The first author recognizes that the research was supported by the National Social Science Foundation of China (Grant No.21BJY216).