This work presents the production of expanded clay aggregates (EA) by firing at 1300°C (EA/1300), a high temperature for EA production. Therefore, the material was produced in an attempt to maximize lightness. Initially, it was characterized the natural clay and the expanded clay aggregate. The EA/1300 had a density of 0.56kg/dm3 and a strength of 0.13MPa, reaching an expansion of 645%, while the EA/1250, clay aggregate fired at 1250°C and produced for comparison, had a density of 0.85kg/dm3, a strength of 0.80MPa, and an expansion of 415%. Subsequently, it was made a lightweight concrete (LC/1300) evaluating its physical and mechanical properties. The LC/1300 had an average compressive strength of ∼4MPa, and a density of 1.22kg/dm3. The LC/1250 had a density of 1.43kg/dm3 and a compressive strength of ∼10MPa. Despite the strength reduction, it was concluded that EA/1300 can be a viable material for the production of lightweight concrete (LC), particularly as concrete artifacts, non-structural blocks, void filling, and in thermal and acoustic insulation applications. This novel material showed low density, with a reduction of 15% in relation to the LC/1250, maintaining the properties of lightweight concrete with EA – chemical inertness and fireproof – and with a strength higher than commercial lightweight concrete with polymeric aggregates.

Este trabajo presenta la producción de áridos ligeros de arcilla expandida (EA) mediante cocción a 1.300°C (EA/1300), una temperatura alta para la producción de EA. Por lo tanto, el material se produjo en un intento de maximizar la ligereza. Inicialmente, se caracterizaron la arcilla natural y el árido ligero. El EA/1300 tuvo una densidad de 0,56kg/dm3 y una resistencia de 0,13MPa, alcanzando una expansión de 645%, mientras que el EA/1250, producido con el árido ligero de arcilla cocido a 1.250°C, tuvo una densidad de 0,85kg/dm3, una resistencia de 0,80MPa y una expansión del 415%. Posteriormente se elaboró un hormigón ligero (LC/1300) y se evaluaron sus propiedades físicas y mecánicas. El LC/1300 tenía una resistencia a la compresión promedio de ∼4MPa y una densidad de 1,22kg/dm3. A modo de comparación, el LC/1250 tenía una densidad de 1,43kg/dm3 y una resistencia a la compresión de ∼10MPa. A pesar de la reducción de la resistencia, se concluyó que el EA/1300 puede ser un material viable para la producción de, particularmente como elementos prefabricados de hormigón, bloques no estructurales, relleno de huecos y en aplicaciones de aislamiento térmico y acústico. Este nuevo material mostró una baja densidad, con una reducción del 15% en relación al LC/1250, manteniendo las propiedades del hormigón ligero con EA – inercia química e ignífugo – y con una resistencia superior al hormigón ligero comercial con áridos poliméricos.

The growing global interest in the sustainable economy of raw materials and the savings in transport costs, associated with the reduction of the weight of materials, has stimulated attention to the use of lightweight concrete, which should be produced preferably closer to the consumption centers.

Several materials are used for the production of lightweight aggregates. The best known natural aggregates, some have been successfully used since the ancient Roman times, are rocks of volcanic origin – pumice, volcanic slag, and perlite [1,2]. In addition to these materials, many studies have also investigated the use of diatomaceous earth [3]. Industrial residues, such as coal ash and blast furnace slag [4], and aggregates of recycled materials, such as bricks and crushed glass [5], are interesting alternatives to obtain lightweight concrete and among them, some stand out as eco-friendly raw materials. Although there are many opportunities for the study and the industrial use of these aggregates, the most critical problem is often the distance from where the materials are extracted/obtained to the cement plant, and the reliability in the quantity and quality of the materials – what can be a determining factor for the selection of clays due to its abundance.

Lightweight concrete (LC) formulated with expanded clay aggregates (EA) and without structural function has successful application in several segments. For instance, void filling, thermal and acoustic insulation applications, floor tiles, concrete artifacts such as vases and precast benches, non-structural blocks, and precast plates for bridges [6]. Developing LC by increasing its lightness, without significantly reducing the mechanical strength, represents a challenge for researchers. Interesting studies have shown the development of expanded carbon fiber aggregates that have been tested on lightweight concrete [7,8].

According to many authors, LC using EA must have a density lower than 2.00kg/dm3[9,10]. This represents a reduction of ∼20%, compared to conventional concrete (2.40kg/dm3) [9]. Usually, non-structural LC has a strength in the order of 3.4MPa to 17MPa, structural LC has a minimum strength of 18MPa, and conventional concrete ranges from 20 to 50MPa [9,11–13].

The transformation process of a clay with expansive properties for the EA considers as main factors: maximum firing temperature; heating/cooling rate; furnace type/production process; additives; chemical and mineralogical composition of the clay; dimension and amount of water in the unfired aggregate [14]. The choice of temperature is the most important factor in the production of the expanded clay aggregate, since gas expansion produces the increase of the body [15,16]. Recently, a studied showed that the proper temperature/viscosity is more important than gas generation for EA expansion [17]. The increase in temperature leads to a higher gas pressure inside closed pores. This gas pressure can cause pore enlargement and volume expansion of the body – the macroscopic effect being “bloating”, which is strongly dependent on glassy phase viscosity and surface tension [18].

Therefore, a firing temperature can be selected to obtain a lighter clayey material, maximizing the expansion of the aggregate. At the same time, this process can maintain the qualities of this type of aggregate, such as chemical resistance, fire resistance and a strength superior to lightweight concrete with polymer, e.g., expanded polystyrene (EPS) [19]. Lightweight concretes with EPS with diameters from 1 to 2mm, as a substitute for sand, usually, have many pores, low strength and should not have a structural function [20]. The utilization of EPS beads as partial replacement of coarse aggregates in concrete showed a considerable loss of strength, although it is an interesting alternative for EPS recycling [21,22].

The present work shows the study of expanded clay aggregates firing at 1300°C (EA/1300) in a laboratory kiln. Initially, the physical and chemical properties of the clay raw material and the produced aggregates were evaluated. The choice of the firing temperature (1300°C), well above the temperature generally utilized in industrial manufacture, aimed to provide the maximum lightness of the aggregate. Subsequently, a non-structural lightweight concrete (LC/1300) was made, with due characterization. The properties of the EA/1300 and LC/1300 were compared to the EA fired at 1250°C (EA/1250) and the lightweight concrete with this aggregate (LC/1250).

Materials and methodsThe expansive clay used in this study comes from the Arroio Grande-RS deposit (Brazil). This clay has never been used to the production of expanded clay aggregates. Because of its geographical strategic position, this deposit can serve the markets of the south of the country, including countries such as Uruguay and Argentina. In Brazil, there is only one expanded clay aggregate producer, which is 1500km away from the referred deposit.

The clay was dried in a laboratory oven at 110°C, disaggregated in mortar/pestle and all of it passed to the sieve mesh 325 (opening of 45μm). The clay was humidified until it reached the plasticity to be shaped manually (∼20% of water), forming small spheres as testing bodies. These remained at room temperature for 24h and placed in a muffle at 50°C.

After drying, the clay bodies (unfired pellets) were put into the kiln (with spacing between them on a refractory alumina wool) with a heating rate of 5°C/min to a temperature of 1300°C, with a level of 20min so that the entire cycle lasted 4h and 40min. The kiln used was the TB-9665 Jung model, static, and electric heating system with silicon carbide resistors. After that time, the material was cooled slowly inside the furnace for approximately 12h. Although recommended by some authors [7], thermal shock was not tested during cooling, because of operational safety. The fired product (expanded clay aggregate) was denominated EA/1250 and EA/1300, according to the maximum firing temperature. The first was produced at the temperature normally used industrially and will be used to compare properties with EA/1300. It should be noted that clays have its optimal firing temperature according to their physical-chemical properties and the characteristics of the kiln used. In any case, the chosen temperature difference (50°C) between the materials produced is considerably large.

In the industry, the previously prepared clay is extruded to form cylinders or rods of 2cm with a diameter of 1cm, which are dried and fired in a rotating kiln of 60m with a small degree of inclination. As this kiln rotates, the clay moves, increasing its volume and defining the final shape. Upon exiting, it is incandescent and is quickly cooled by fans [23]. Therefore, the reader must consider the differences between the process in the laboratory and in the industry, so that the investigated parameters, for their applicability, need the scale-up study, which was not addressed here.

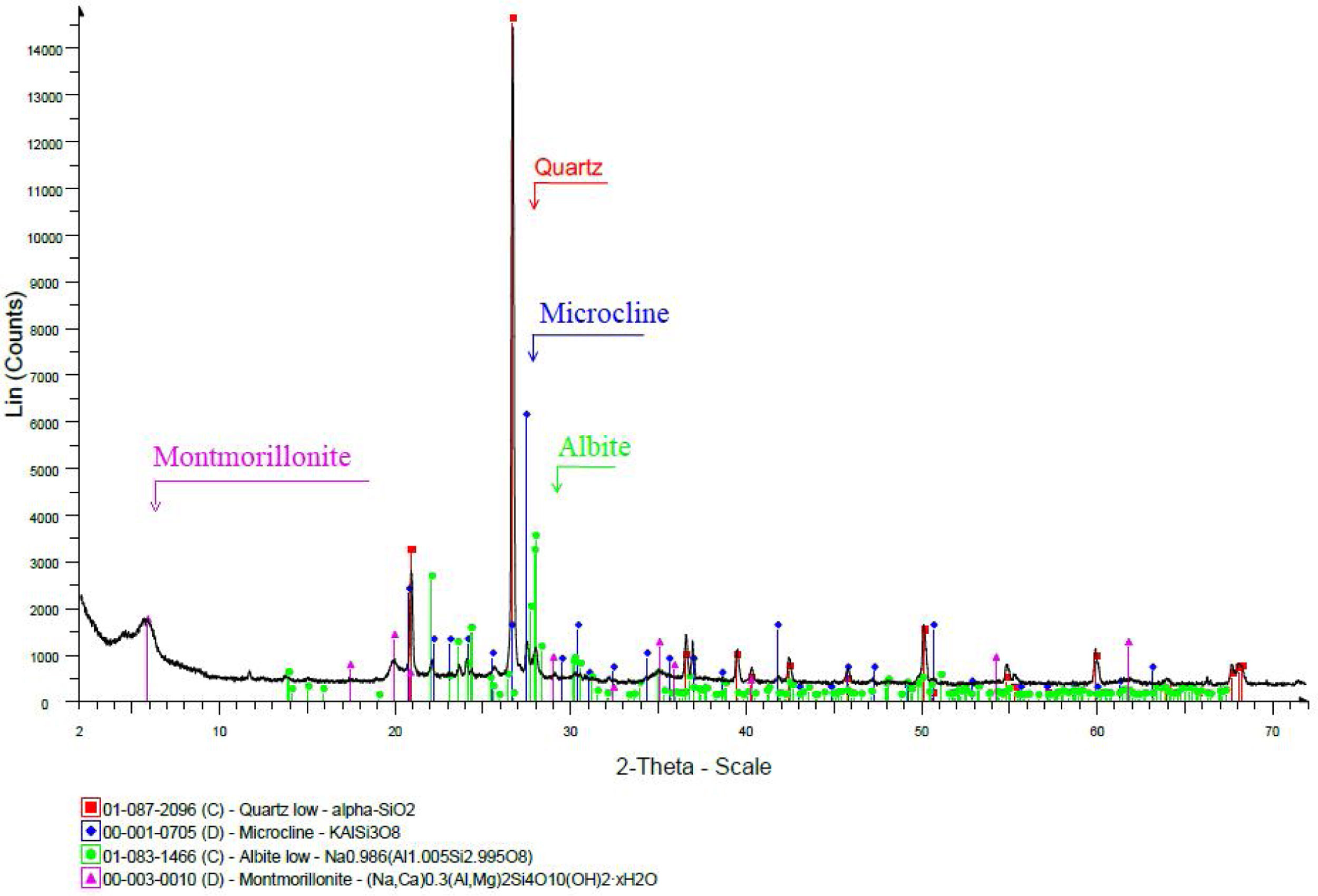

The materials were characterized by the following assays: X-ray fluorescence, Shimatzu model XRF-1800; laser particle size distribution, Cilas model 1180; and optical microscope. The chemical composition and the identification and quantification of the crystalline phases were realized in the Senai Institute of Technology. The quantification was performed using the Rietveld method with GOF=3.67 and Rwp=14.52. The equipment is a Bruker-D8 diffractometer with theta goniometer. Radiation is Ka in copper tube in the conditions of 40kV and 40mA. The speed and the scan interval of the goniometer were from 3s to 0.02° and from 2° to 72° 2 theta, respectively.

The plasticity index was calculated according to the standards [24,25] using Atterberg's method and Casagrande apparatus. Water absorption was determined by immersion in tap water at room temperature for 24h. The expansion index of the clay balls (expandability) was calculated by the difference in diameters before and after firing, using the average of 12 spheres in different diameters (12.5mm; 9.5mm; 6.3mm and 4.8mm). The results showed a good relationship when the volumetric expansion was calculated by inserting the sphere before and after firing in a graduated cylinder with a powdered material (fused alumina with particle size<180mm). For EA compressive strength test, the aggregates were layered inside a mold and surrounded by a 1:1 mass cement mixture (cement:water), just to promote a slight bond between the aggregates. The cement is only for a slight adherence between the aggregates without actually influencing the resistance according to [19]. EA density was measured by the Archimedes method.

For the production of lightweight concrete, Portland cement was used with high initial strength (CPV-ARI), density of 3.12kg/dm3 and surface area of 5480cm2/g (Blaine method). Lightweight concrete was produced with lightweight aggregates EA/1250 and EA/1300, which received the name LC/1250 and LC/1300, respectively.

A quartz sand from deposits close to the Jacuí River (the same state where the clay deposit is located) was used, since river sands tend to provide greater fluidity, due to the high sphericity of the particles [26]. The sand was characterized by means of particle size distribution, using 6.30mm sieves; 4.75mm; 2.36mm; 1.18mm; 0.6mm; 0.3mm; 0.15mm, with a 2.4 fineness module, as suggested by some authors [27]. Tap water was used in concrete formulations. The samples prepared with the cementitious matrix (mortar) had a strength of ∼23MPa (measured with water/cement=0.7).

The initial studies with EA/1300 indicated that it was unnecessary to perform a pre-absorption of water (AA) of the aggregates for application in the concrete, since its average absorption in 24h was less than 10%, what is in accordance to the recommendations of literature [9,19]. ACI 211.2 [28] presents two methods of formulation for lightweight concretes. The first, called “mass method” or “weight dosage”, which was used initially in the present work, is indicated for concretes with fine aggregates with normal density (sand) and lightweight coarse aggregates (expanded clay aggregates). The second, called the “volumetric method”, is recommended for concretes with coarse and small lightweight (expanded) aggregates. This last method is necessary for comparison of concretes formulated with aggregates of different densities. Therefore, LC/1250 was formulated following the volumetric method to be comparable with LC/1300.

For the production of LC/1300, a matrix of 1:4 (1:m) was established with an initial trace of 1:2.4:1.6:0.8 following the order of cement, sand and expanded clay aggregate, with water/cement factor of 0.8. This ratio is slightly higher than that normally used in civil engineering constructions, due to the higher water absorption of expanded aggregates compared to gravel. The consistency of the LC produced was evaluated empirically, that is, the workability was considered “good” when molding the bodies. The EA/1300 water absorption was 4.2% in a 24-h period, so the real water/cement was 0.72, what is a little higher than the maximum allowed for structural lightweight concrete – 0.65 according to Ref. [29]. On a volumetric basis, the LC/1300 concrete unit mix was 1:1.63:3.33:0.72, which was used as a reference for the production of LC/1250. The EA/1250 were immersed in water and after 72h they were removed and dried superficially for use in the formulation of the LC/1250. Table 1 shows LC/1300 formulation.

Presentation of concrete formulation LC/1300 with EA/1300. Weight and volume bases.

| LC/1300 | Cement | Sand | EA/1300 | Water | Total |

|---|---|---|---|---|---|

| Weight basis trace | 1 | 2.4 | 1.6 | 0.72 | |

| Dosage (for 1m3) (kg) | 208 | 499 | 333 | 150 | 1190 |

| Dens. (kg/dm3) | 3.12 | 2.58 | 0.56 | 1 | |

| Vol. dosage (dm3) | 66.7 | 193.4 | 594.6 | 150 | 1005 |

| Vol. (%) | 6.64 | 19.24 | 59.16 | 14.93 | 99.97 |

| Packing Dens. (kg/dm3) | – | 1.47 | 0.48 | 1 | |

| Volume basis trace | 1 | 1.63 | 3.33 | 0.72 |

The main objective of this work was to produce lightweight concrete, prioritizing lightness, but with a mechanical strength higher than the minimum required for LC with expanded clay aggregates. Pre-results confirmed that this was possible. Six bodies were molded with a dimension of Ø5cm×10cm, which were tested after 28 days of cure. The maximum expanded aggregate size was 12.5mm, which is in accordance with the standards [30]. The LC were characterized according to the Brazilian Standards [31–35]: compression strength, density, water absorption (w.a.); and a comparable efficiency factor (strength/density), which is a parameter suggested by Rossignolo [9].

Results and discussionsClay characterizationTable 2 shows Arroio Grande (AG) clay characterization. Comparing the chemical composition of AG clay with expansive clays from other works [36–39], the composition of all clays varies considerably in terms of the type and content of oxides present. However, AG clay has a higher amount of SiO2, due to the high amount of quartz. All clays showed a significant content of fluxing oxides, such as alkalis, alkaline earth, and iron oxide.

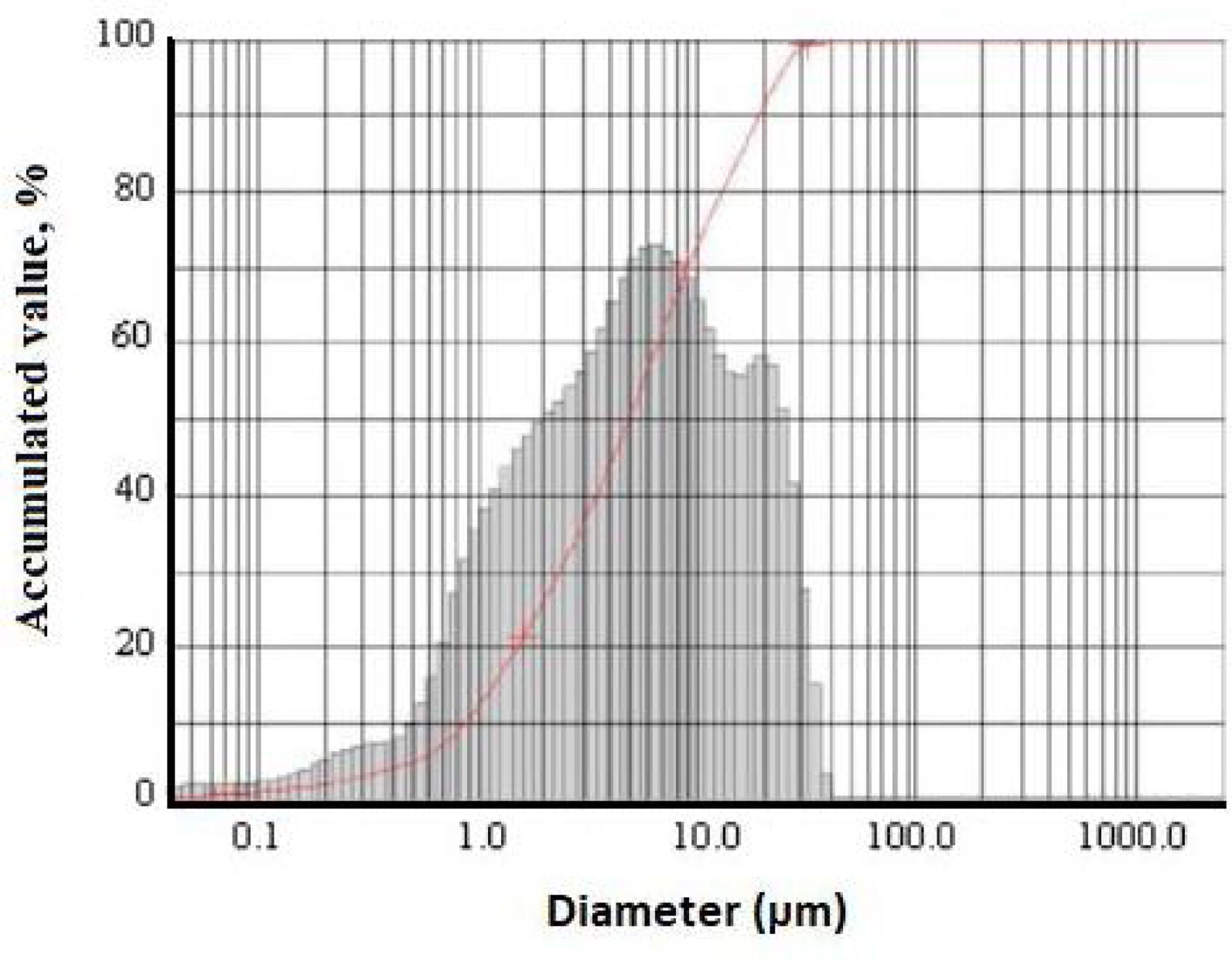

Arroio Grande (AG) clay. Chemical composition, phase quantitative analysis (Rietveld – DRX), particle size distribution and plasticity index (PI).

| Chemical composition | (%) | Phase analysis | (%) | Particle size distribution | Diameter (μm) |

|---|---|---|---|---|---|

| SiO2 | 75.05 | Quartz | 55.68 | 10%< | 0.87 |

| Al2O3 | 10.95 | Microcline | 12.94 | 50%< | 4.48 |

| Fe2O3 | 3.55 | Montmorillonite | 20.94 | 90%< | 19.19 |

| K2O | 1.94 | Albite | 10.43 | Mean diameter | 7.51 |

| TiO2 | 0.64 | ||||

| CaO | 0.59 | Plasticity | |||

| SO3 | – | LL | 53.3 | ||

| Na2O | 0.98 | PL | 22.1 | ||

| MgO | 0.83 | PI | 33.2 | ||

| Others | 0.67 | ||||

| Loi | 4.80 | ||||

| Total | 100 | ||||

The studied clay did not undergo previous mineral processing, being used directly from the deposit. Therefore, it naturally presents good workability and relatively fine particle size. This makes its cost more attractive than processed clays. On the other hand, a beneficiation step, such as sieving, air flotation, etc., could increase the purity and reactivity of AG clay, whose quartz is associated with the coarsest particle size fraction. Fig. 1 shows that the material retained in 200-mesh sieve is mainly quartz.

Fig. 2 shows that clay phases are quartz, montmorillonite, microcline and albite, as described in Table 2. The main property of an expansive clay is plasticity (workability), therefore, the presence of montmorillonite (∼21% in Table 2) is important, since this phase is normally associated with high plasticity. This is in accordance to the calculated plasticity index (PI=33.2% in Table 2). XRD of the Arroio Grande clay after firing showed the presence of stable phases such as mullite, quartz and cristobalite, which are usually found in high temperature firing products – porcelains and porcelain stoneware. These phases are associated with a high mechanical strength [40]; however, the high porosity of an expanded clay aggregate make its strength very low (as discussed later).

The particle size distribution of AG clay is indicated in Table 2 and in Fig. 3. The mean diameter is 7.51μm and this clay has a significant number of fine particles (10%<0.84μm). A high percentage of fine particles is an important property of a clay, as this characteristic favors the development of a high plasticity and is associated with a lower firing temperature.

Based on the properties of Arroio Grande clay, shown above, it can be said that the chosen clay has a good potential to be used in the production of lightweight aggregates. The clay has a significant level of fluxing oxides (Na2O, K2O, Fe2O3, etc.), is fine, has a good plasticity (presence of phases such as montmorillonite and high plasticity index) and a high workability to produce clay balls. It should be noted that mainly chemical composition and particle size of a clay determine the bloating during firing.

Expanded clay aggregates (EA)Firing expansion and morphology of aggregatesIn the firing of the clay balls (unfired pellets), the increase in temperature promotes the softening of the siliceous phases, forming the liquid phase (or “vitreous phase”). This phenomenon is well known in the so-called liquid phase sintering in ceramic products [41]. The viscous flow fills the porosity and brings the particles closer together, due to the capillarity effect, which leads to the firing retraction of the body (or clay ball). The viscous flow mechanism is strongly dependent on the viscosity and surface tension of the vitreous phase. The increase in temperature leads to the rise of the pressure of the gas inside the pore. At the same time, the reduction in viscosity (and surface tension) at higher temperatures facilitates the growth of pore size and bloating of the part. A more detailed explanation can be found in Refs. [17,18].

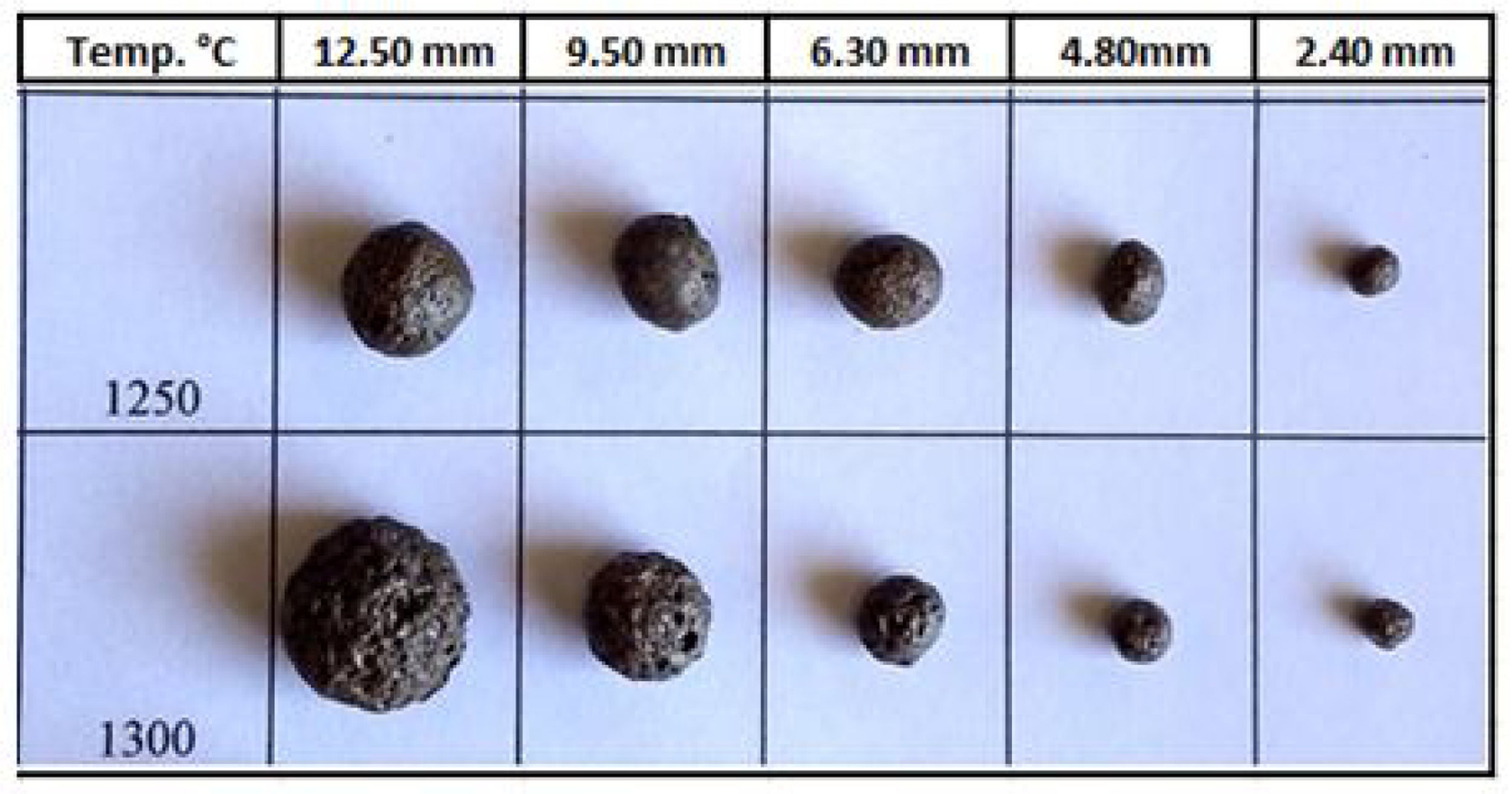

The data presented in Table 3, illustrated in Fig. 4, shows EA/1300 expansion of 645%, which is considerably higher than the expansion achieved at 1250°C (415%). In the work of Ozguven and Gunduz [14], for example, an expansion of 550% was obtained. Other authors pointed out that aggregates can expand up to 7 times their initial volume [9,14,20].

The increase in temperature provided a significant expansion and, as a consequence, a decrease in density (Table 3). It is important to emphasize no air incorporator was used. Additives may be one of the factors to enhance the expansion of aggregates, but the cost and the potential release of toxic gases in firing, must be considered.

Fig. 5 shows a comparison of the set of aggregates retained in sieves, whose mesh opening is presented (12.5mm, 9.5mm, etc.) in this figure, showing the morphological differences at the two firing temperatures. The firing at 1300°C left the surface with a more irregular texture, compared to EA/1250, but the spherical shape remains. In view of this, it is possible to produce the aggregate at 1300°C, taking advantage, therefore, of the high expansion and low density (Table 3), without significant changes in other properties.

Water absorption of aggregatesTable 4 shows a significant advantage for EA/1300 when compared to EA/1250, since its absorption is only 4.2% in a 24-h period, practically 1/3 of the total absorption of EA/1250, which continues to absorb water from the system after 24h. EA/1300 was immersed in water and after 3h reached 80% of total water absorption. The lower absorption of EA/1300 can be explained by the higher sintering that occurs on the surface of the aggregate, reducing the open porosity, even with a more irregular texture (showed in Fig. 5), as a consequence of the higher firing temperature.

On occasion, corrections should be made in the formulating of concrete in the fresh stage, considering the EA water absorption and the time in which this absorption occurs. Otherwise, the amount of concrete mixing water may vary. Some researchers demonstrated that EAs, in the period of 24h, absorb 5–20% in relation to its dry mass. The EA is of good quality when it does not exceed an absorption of 15%, but other authors consider 10% [9,42]. This limit is recommended because pre-absorption is not a practical method (leaving the aggregates at rest immersed in a water vessel for 24h) to be used at the construction site [9,19]. Thus, according to Table 4, the use of EA/1300 allows better and easier technological control than the EA/1250.

However, pre-humidification of aggregates is recommended to facilitate the composition of the concrete, according to some studies [10,27]. In this case, a humidification period of just 5h should be sufficient to the utilization of EA/1300; nevertheless, after 24h of immersion in water, both EA/1300 and EA/1250 reach ∼100% of absorption.

Density and mechanical strength of aggregatesEAs density and mechanical strength are shown in Table 5. EA/1300 showed a low compressive strength (0.13MPa), which is a consequence of its low density (0.56kg/dm3) and high porosity due to its higher firing expansion. This density is much lower than the EA/1250 density (0.80kg/dm3) which corresponds to a higher strength of 0.80MPa. In the British standard [43], the density of a lightweight aggregate must be less than 2kg/dm3, therefore, the density of both aggregates can be considered good. Commercial lightweight aggregate usually has a density of ∼1.00kg/dm3[23].

When comparing the EA/1300 with the EA/1250, an increase of 50°C provided a density reduction of 34%. This is a substantial value to produce lightweight concrete. Another factor, because of EA/1300 lower density and higher porosity, is the improvement of thermoacoustic properties, which will be evaluated in future works. Conversely, the mechanical strength of the aggregate has been reduced by ∼84%; therefore, it is important to evaluate these parameters well in the application of LCs.

Lightweight concrete (LC)Water absorption of LCTable 6 shows the water absorption of concrete after 24h and 72h of immersion, an important criterion for checking the durability of the concrete exposed to the weather. The water absorption (w.a.) of the LC/1300, after 24h, was 5.56%, equivalent to 95% of its total absorption capacity (5.88% after 72h). Therefore, the LC/1300 exhibited the same behavior as conventional concretes.

In Table 6, the LC/1250 had an absorption higher than the LC/1300. This result was expected, since the EA/1250 has a higher water absorption than the EA/1300 (Table 4), consequently, the higher open porosity of the EA is influencing the open porosity of the concrete. This makes sense because LC/1300 and LC/1250 were formulated with the same volume of EAs. Therefore, a higher firing temperature for the production of EA/1300 can be an interesting alternative to decrease the concrete water absorption.

Density and mechanical strength of LCTable 7 presents density, compressive strength, and efficiency factor (strength/density ratio) for the studied LCs.

The LC/1300 reached a density of 1.22kg/dm3, i.e., ∼15% lower than the density of the LC/1250 (Table 7). When compared with conventional concretes, density ∼2.4kg/dm3[9,19], the difference is ∼50%. Thus, the utilization of LC/1300 represents an increase in economic savings in terms of handling and transportation costs, in addition to a reduction of the corresponding environmental impact of these activities. However, a remarkable advantage is the decrease of construction building weight and, consequently, in the cost of structure materials. These benefits must be evaluated considering the higher production temperature of EA/1300.

The compressive strength of LC/1300 was ∼4MPa, significantly lower compared to LC/1250 (∼10MPa). When analyzing the efficiency factor, it is clear that the gain in terms of density reduction may not compensate for the decreasing of mechanical strength, especially in applications that require higher strength. The LC/1300 low strength can be directly related to the low strength of EA/1300 (Table 5).

It is interesting to note that the reduction of density of the concrete follows a certain proportionality, considering the content of ∼ 60% of lightweight aggregates (Table 1). The EA/1300 has a density 34% lower than that of the EA/1250 (Table 5); the LC/1300 has a density 15% lower than that of the LC/1250 (Table 7); and the cementitious matrix (mortar) showed approximately the same density in both concretes, 2.18 and 2.27kg/dm3 for LC/1300 and LC/1250, respectively.

The strength of the EA/1300 is approximately 6.5 times lower (a reduction of 83.7%) than that of the EA/1250, while the LC/1300 showed a strength 2.5 times lower (a reduction of 60.8%) than that of the LC/1250. The presence of lightweight aggregates reduces the strength of the concrete, since the mortar has a strength of ∼23MPa. In conventional concrete, with aggregates of basaltic gravel, the strength of the aggregate is higher than that of the mortar, so that the rupture occurs in the mortar and/or at the aggregate–mortar interface. In lightweight concrete, the rupture does not occur due to the difference between the deformations – different elastic deformation modules – of the aggregates and the mortar, but due to the collapse of the mortar, after the rupture of the aggregates [9]. The imposed stress is amplified by microcracks (the critical flaw) in the aggregates.

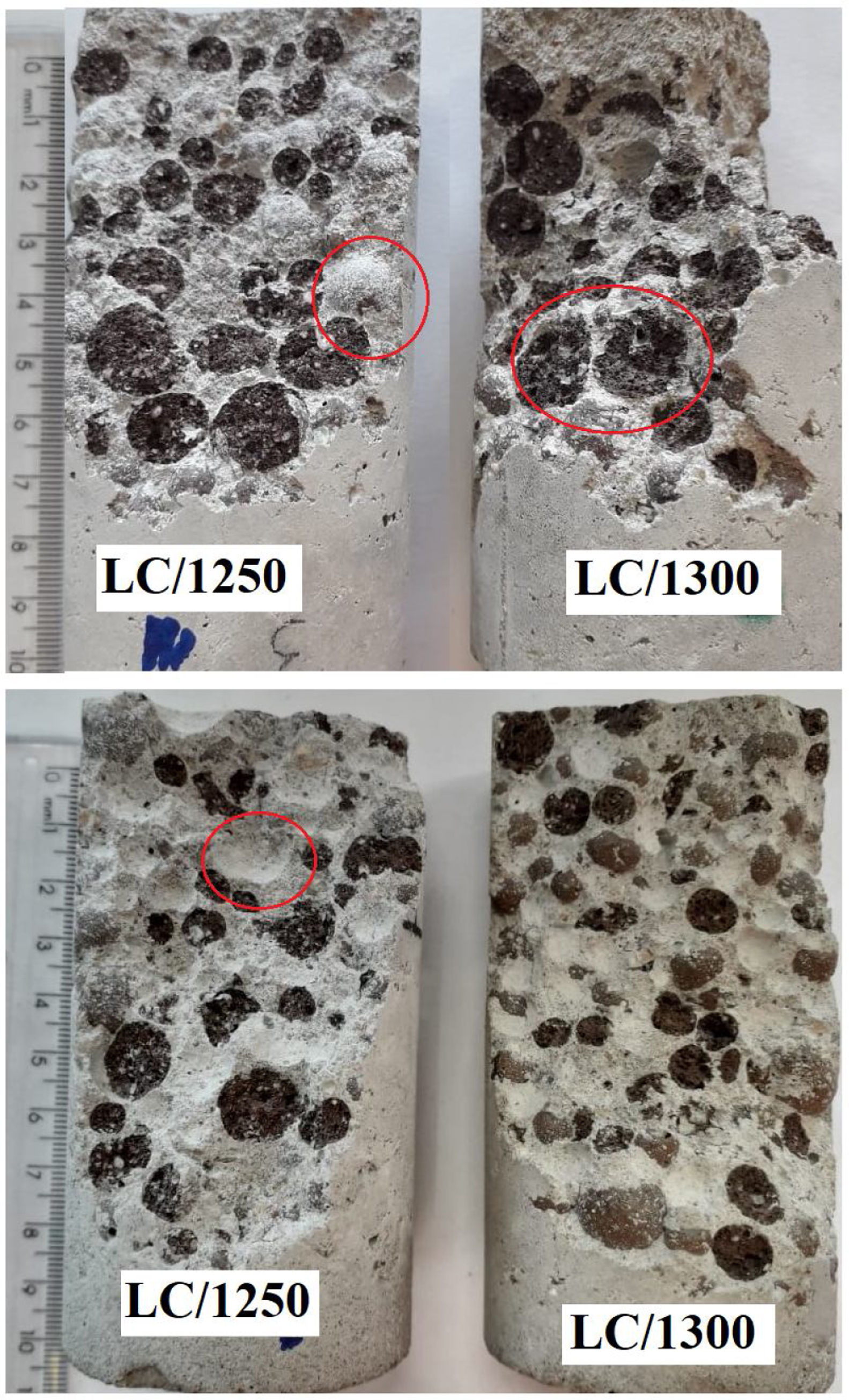

As can be seen in Fig. 6, an aggregate can be “easily” pulled out of the matrix or can be broken. Eventually, the crack path can deviate, which, in principle, leads to increased fracture toughness in a composite material [44]. There is no difference in behavior in relation to the rupture of the samples, that is, the higher strength of the EA/1250 is not enough to prevent (or apparently hinder) the fracture of the aggregates more effectively than with the EA/1300. There is also no difference in the so-called crack path. When comparing the fracture behavior of the LCs, as shown in Fig. 6, with the rupture of a conventional concrete, in the latter it is easily observable that most of the aggregates of gravel are intact, although some aggregates can be separated from the concrete matrix [45].

The low strength of LC/1300 is a consequence of the low strength of EA/1300, as stated before. Theoretically, an increase of cement content in LC/1300 or the reduction of the amount of water in the mix the (changing the w/c ratio, but keeping a good fluidity) can lead to an increase in the strength. It is known from the Abrams Law [20] that the w/c factor is inversely proportional to the compressive strength of the concrete. For instance, a cement w/c=0.50 has compressive strength=34MPa, but a cement w/c=0.7 has compressive strength=21MPa [46]. On the other hand, an increase in cement content means a high cost in raw materials, and, as a rule, an increase of LC density.

Several interesting studies can be found in the literature for increasing the mechanical strength of a concrete, without, however, increasing its density. Fibers – metallic, polymeric and natural fibers – are widely used to improve mechanical properties of cement-based materials [47–49]. Also noteworthy is the use of hybrid fibers and nanofibers [50,51]. An interesting alternative is the use of supplementary cementitious materials (SCMs) that allows the reduction of the amount of cement, decreases carbon footprint, and, in general, with an increase in the strength of concrete or mortar [52,53]. These studies, fibers and SCMs, include the evaluation in lightweight concretes [54,55]. An alternative to the cement mortar improvement route is the use of carbon fiber in the lightweight aggregate with gains in concrete strength [8].

All of these works, described above, present outstanding study options that could include the use of EA/1300 as a way to develop a material with higher lightness and higher mechanical strength. The influence of EA/1300 in the fracture mechanics of LC/1300 and the evaluation of alternatives to the improvement of LC strength will be appreciated in a future work.

Despite the low strength of the LC/1300, it is still within the recommended range for the production of concrete blocks, since normally a minimum of 3.0MPa is required [55]. This strength can be used as a reference in several concrete artifacts and in the application of concrete for filling, aiming at durability. Nonstructural commercial LCs tend to have a compressive strength between 3.4 to 17MPa, so that the result achieved comply with this requirement [11].

Lightweight concrete with expanded clay aggregates always has a lower mechanical strength than convention concrete. This was the case in the present work. However, the low strength obtained is acceptable for a number of LC applications, maintaining all the advantages of clayey EAs. For example, in relation to lightweight concrete with polymer: higher mechanical strength, chemical inertness and incombustibility. It must be considered that EA/1300 has a higher production cost compared to EA/1250, due to the higher firing temperature. On the other hand, the reduction of 15% in the LC/1300 density leads to a number of advantages, such as a reduction in the cost of transportation and savings in structural design, as previously mentioned. Another point is the higher productivity of the EA/1300 due to its higher firing expansion. An economic and technical analysis (considering the feasibility of kilns to operate at higher temperatures) must be carried out. Nevertheless, it is interesting to note that even lower firing temperatures, compared to the one used here, can improve the properties of lightweight aggregates and, at least potentially, be beneficial to the concrete.

ConclusionsArroio Grande clay studied in the present work showed good qualities to the production of expanded clay aggregates. This clay showed good plasticity – fine particle size, presence of montmorillonite and high plasticity index – and adequate chemical composition (presence of fluxes) for the production of expanded clay aggregates (EA). By firing at 1300°C, a remarkable expansion was obtained (∼645%) without consuming any type of additive, and significantly higher than that firing at 1250°C; a comparable temperature normally used in industrial production.

The higher lightness of the expanded clay aggregate EA/1300 was a result of its high firing expansion achieving a density of 0.56kg/dm3 (EA/1250 density was 0.85kg/dm3); an increase of 50°C reached a density reduction of 34%. The increase in temperature propitiates a higher expansion due to two factors: an increase of gas pressure within the pore and the reduction of vitreous phase viscosity (and surface tension) at higher temperatures, what facilitates the growth of pore size and volume expansion of the aggregate. Therefore, temperature is a key parameter to design the desired EA density.

LC/1300 mechanical strength (4MPa) was significant lower in relation to LC/1250 (10MPa). The higher EA/1300 firing expansion, maximizing its porosity, means, intrinsically, a lower aggregate mechanical strength and, consequently, a lower strength of the LC/1300. There is no difference of the fracture surface aspect and the crack path of both LCs: some aggregates are separated from the concrete matrix, others are broken and few are intact. Therefore, considering the macrostructure, the difference of samples’ strength was a consequence of the lower strength of the EA/1300 (0.13MPa) compared to EA/1250 (0.80MPa).

The LC/1300 showed two important advantages compared to LC/1250. First, a weight reduction of 15%, what means a remarkable reduction in transportation costs and savings in structural design. Second, 31% of reduction in water absorption (w.a.), what is an important criterion for increasing the durability of the concrete exposed to the weather. This was a direct consequence of the lower w.a. of the EA/1300, which, in turn, reduces the pre-saturation time of the aggregates or, in some cases, allows the use of dry aggregates in the formulation of the concrete in situ.

The lightweight concrete (LC/1300) can be employed as filler, concrete artifacts, and lightweight precast structures, while maintaining the inherent qualities of this material – mechanical strength, chemical inertness, and incombustibility. Thus, the EA/1300 applied to concrete can be better than other lightweight materials, such as aerated concrete and lightweight concrete with polymer (e.g. expanded polystyrene). The variations of properties presented by LC/1300, in relation to LC/1250, i.e., lower density and lower strength, is the same when comparing lightweight concrete with conventional concrete. Consequently, the LC/1300 has, considering this laboratorial study, the properties and qualities necessary to find its place on the market, depending on the selected application.