Bi2Ca2−xNaxCo2Oy materials with x=0≤x≤0.125, have been prepared either by sintering through the classical ceramic method, or textured using the laser floating zone technique. XRD results have shown that Bi2Ca2Co2Oy phase is the major one, independently of the Na content, in both kind of samples. SEM studies have shown a drastic microstructural modification between sintered and laser-textured materials. Na-doping increases density and grain sizes in sintered materials, while it enhances grain alignment in laser-grown materials. Moreover, it decreases secondary phase content in all cases. Electrical resistivity is also drastically reduced through texturing, when compared to the sintered samples, and Na-doping further decreases it. The lowest values determined in the laser-textured samples (26mΩcm at 650°C) are around 40% lower than the best in sintered materials. On the other hand, S has been only slightly affected for Na-doping or processing method for all samples. Consequently, the highest power factor at 650°C (0.18mW/K2m) has been obtained in laser-grown 0.075Na-doped samples, which is around 20 and 70% higher than the measured in undoped laser-textured samples, and sintered ones, respectively.

Se han preparado materiales de composición Bi2Ca2-xNaxCo2Oy, con x=0 ≤x ≤0,125, por el método de estado sólido, además de texturarlos mediante la técnica de zona flotante inducida por láser. Los resultados de XRD han mostrado que la fase Bi2Ca2Co2Oy aparece como la mayoriraria, independientemente del contenido de Na, en ambos tipos de muestras. Los estudios SEM han encontrado una drástica modificación microestructural entre materiales sinterizados y texturados. El dopado con Na aumenta la densidad y el tamaño de grano en materiales sinterizados, mientras que mejora la orientación de los granos en materiales texturados. Además, disminuye el contenido de fases secundarias en todos los casos. La resistividad eléctrica disminuye drásticamente con el texturado, en comparación con las muestras sinterizadas, mientras que el dopado con Na la disminuye aún más. Los valores más bajos determinados en muestras texturadas (26mΩcm a 650°C) son alrededor del 40% menor que los mejores datos publicados en materiales sinterizados. Por otro lado, S solo se ha visto afectado levemente, tanto por el dopado como por el método de procesado. En consecuencia, el máximo factor de potencia a 650°C (0,18mW/K2m) se ha obtenido en muestras dopadas con 0,075Na y texturadas, que es alrededor de un 20 a un 70% superior al medido en muestras texturadas sin dopar y sinterizadas, respectivamente.

Since the early years of thermoelectricity, many different families of materials with thermoelectric (TE) properties, have been discovered [1–3]. The main purpose of developing these materials is based on their ability to transform heat into electric power provided by the Seebeck effect [4]. The efficiency of this process is usually evaluated based on the materials properties using the dimensionless Figure-of-Merit (ZT) calculated through [5]:

where S, ρ, κ, and T are Seebeck coefficient, electrical resistivity, thermal conductivity, and absolute temperature, respectively. In the above equation, the S2/ρ relationship is called TE Power Factor (PF).For practical purposes, it has been established that TE materials should have ZT≥1 to be considered for applications. Until now, the materials presenting the highest ZT values are intermetallic materials, such as PbTeSe [1] or SnTe [6]. The main drawbacks of these materials are that they work properly at low-medium temperatures due to oxidation processes at high temperature under air, and their high costs [4], and low abundance in the earth crust [7]. Other promising materials are silicides [8] but, in spite of the large abundance of silicon in the earth crust [7], the best performances are obtained in compounds including high costs elements [4]. On the other hand, oxide materials with relatively high TE performances were discovered in 1997 [3]. These materials combine high thermal stability and working temperatures, low costs, and relatively high abundance in the earth crust [4,7]. This discovery, and these advantages of oxide materials, led to new families with attractive TE properties, such as Bi2AE2Co2Ox (AE: alkaline earth) [9,10]. The main concern about these materials was their typically low TE performances, showing ZT values below 1, but the interest about them was increased when ZT values of 1.2 in Bi2Sr2Co1.8Ox whiskers were reported [11]. However, despite the many works performed on TE oxides, bulk polycrystalline materials have not yet reached these ZT values. Consequently, one of the most important objectives is the enhancement of their TE performances before they can be used in practical applications. Among the different strategies for enhancing TE properties of these oxide materials, some like using soft chemistry methods [12,13], texturing [14,15], or doping [16,17] can be highlighted.

Other studies about the crystallographic structure of these CoO-based materials have shown that they can be described using a monoclinic structure, which is formed by two alternatively stacked layers. These layers can be, in turn, described as a conductive CdI2-type hexagonal CoO2 layer, and a rock-salt-type (RS) one. Both sublattices possess common a- and c-axis lattice parameters and β angles but different b-axis length, causing a misfit along the b-direction [18]. As a consequence of this structure, it has been found that cationic substitution in the RS layer using a lower oxidation cation, increases the charge carrier concentration in the conduction band due to the partial promotion of Co3+ cations to Co4+ in the conducting layer [19]. On the other hand, as the thermoelectric parameters are linked each other, a decrease of Seebeck coefficient, is also produced [20]. This effect can be produced in CoO-based materials by partially substituting an alkaline earth with an alkaline element, as previously reported [21,22].

The objective of this work is evaluating the modifications in structural, microstructural, and thermoelectric properties of Bi2Ca2Co2Ox materials through partial substitution of Ca2+ by Na+. These modifications will be evaluated in laser-textured materials using as reference classically sintered samples with the same composition.

ExperimentalBi2Ca2−xNaxCo2Oy precursors, with x ranging between 0 and 0.125, were obtained from commercial Bi2O3 (98+%, Panreac), CaCO3 (98.5%, Panreac), CoO (99.99%, Sigma–Aldrich), and Na2CO3 (99.8%, Panreac) starting powders. They have been weighed in the respective stoichiometric proportions, and ball milled in an agate ball-mill, using water media, at 300rpm for 30min. These suspensions were then totally dried under IR radiation, and calcined using a two-steps process, at 750°C for 12h, and 800°C for another 12h, with an intermediate manual milling, to produce a fine powder. Following this thermal procedure, Ca and Na carbonates are mostly decomposed and the different oxides start to react, as previously reported [23]. Part of these powders has been cold uniaxially pressed into pellets under 400MPa applied pressure, and sintered at 810°C for 24h with a final furnace cooling. The other part of precursors has been cold isostatically pressed in form of cylinders (∼3mm diameter) under 200MPa, and used as feed in a laser floating zone (LFZ) device described elsewhere [24]. The molten zone has been induced by a Nd:YAG laser radiation (Spectron Laser Systems, λ=1024nm), and the growth conditions were fixed at 30mm/h. Moreover, the seed has been rotated at 3rpm to keep the cylindrical geometry while the feed has been oppositely rotated at 15rpm to maintain the compositional homogeneity in the molten zone. After this process, cylindrical laser-textured materials (∼2mm diameter), have been obtained. However, these Bi-containing compounds typically show incongruent melting, leading to a complex mixture of secondary phases in the bulk material after solidification [10,14]. Consequently, following texturing process, it is necessary to perform an annealing procedure at 800°C for 24h to obtain the thermoelectric phase from the secondary ones [14].

Powder X-ray diffraction (XRD) data of all prepared samples were recorded at room temperature in a Rigaku D/max-B X-ray powder diffractometer (Cu Kα radiation), with 2θ ranging between 10° and 40°, in order to identify the phases in the sintered and laser-textured materials. SEM characterization has been performed in a Zeiss-Merlin field emission scanning electron microscope (FESEM), associated to an energy-dispersive spectroscopy (EDS) system used for qualitative elemental analysis. Samples were analysed, using backscattered electrons, on longitudinal polished sections to determine the microstructural and compositional modifications induced by Na doping and texturing process.

Electrical resistivity and Seebeck coefficient were simultaneously determined between room temperature and 650°C, under He atmosphere. For this purpose, the standard dc four-probe configuration, in steady-state conditions, has been used in a LSR-3 system (Linseis GmbH). The measurements have been performed on heating, with a dwell time of 30s before each measurement, and setting a fixed temperature gradient of 30°C between the ends of the samples. The samples were measured along the growth axis, which coincides with the conducting plane of Bi2Ca2Co2Oy phase. Finally, from these electrical resistivity and Seebeck coefficient data, the thermoelectric performances of samples, evaluated through their PF, have been calculated to stablish the influence of Na-doping and texturing on the thermoelectric characteristics of these materials. Moreover, these values will be also compared to the best results presented in literature.

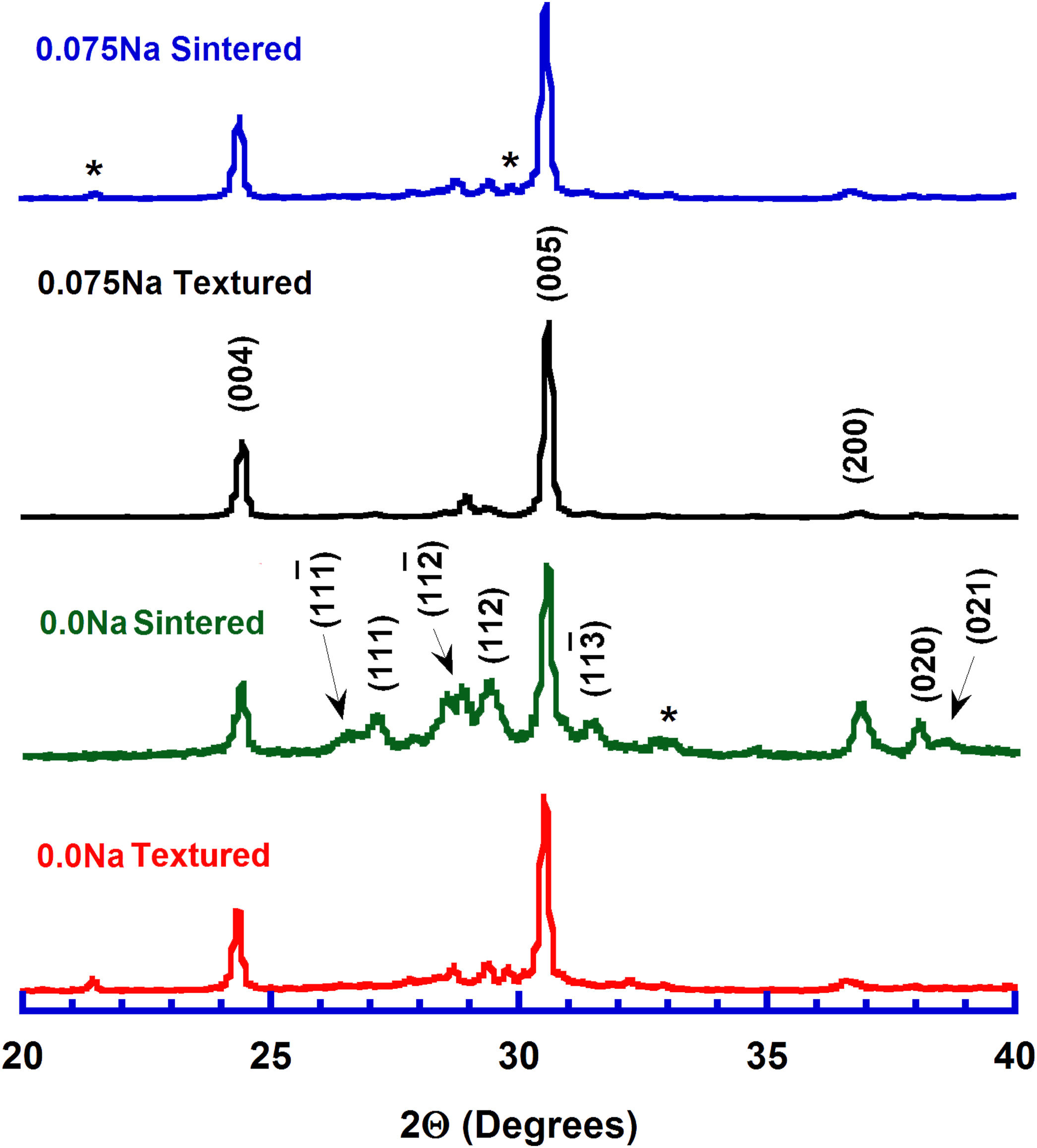

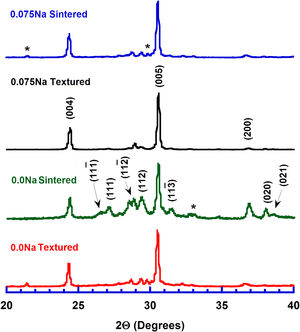

Results and discussionRepresentative XRD patterns obtained on grinded Bi2Ca2−xNaxCo2Oy samples are shown in Fig. 1. In this plot, it can be observed that most of the peaks (indicated by their diffraction planes) can be associated to the thermoelectric Bi2Ca2Co2Oy phase, as the major one independently of the processing technique, in agreement with previously reported data [23]. Moreover, the * shows the Co-free Ca4Bi6O13 secondary phase [25], which should be in small proportions due to the low intensity of its diffraction peaks. From these data, it can be easily deduced that all samples are formed by nearly single Bi2Ca2Co2Oy phase. On the other hand, it can be seen that undoped samples show slightly higher amount of Co-free secondary phase than doped ones, and that laser-grown samples also possess lower amount than sintered ones. Consequently, it can be established that laser-texturing decreases the secondary phase content, which is further decreased by Na doping. Furthermore, detailed observation of the different patterns has shown that no shift is produced in the thermoelectric phase diffraction peaks, independently of the Na content, or the processing route. Besides Lotgering factor (LF) is a useful parameter to quantify variation of grain orientation which defines as LF=(P−P0)/(1−P0), where P indicates the fraction of the summation of the peak intensities of preferred orientation and P0 is the P of the samples with a non-oriented distribution [26]. The calculated values for sintered and laser-textured samples are displayed in Table 1. From these results, it can be easily observed that LFZ process, together with Na-substitution clearly raises grain orientation, when compared to the sintered materials.

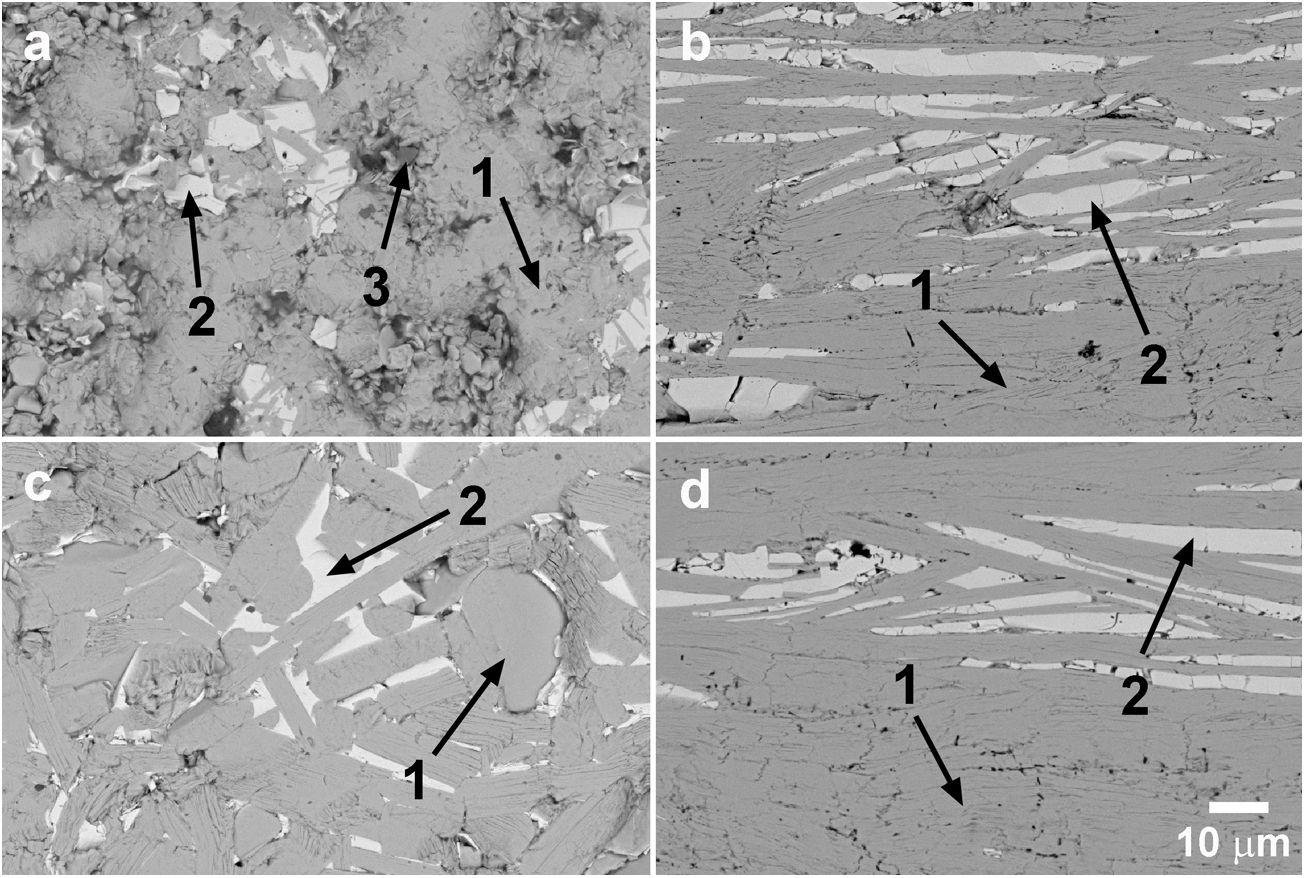

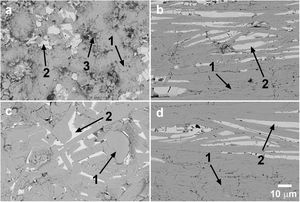

Fig. 2 presents SEM micrographs performed on the longitudinal polished surface of representative Bi2Ca2−xNaxCo2Oy samples. In these micrographs, three different contrasts can be observed (identified in the pictures for clarity). These contrasts have been associated through EDS to different phases: #1 (grey) corresponds to the thermoelectric phase, while #2, and #3 (light and dark grey) have been identified as Bi-Ca oxide, and Co oxide, respectively. Moreover, the drastic microstructure modifications between sintered (Fig. 2a, and c) and laser-grown (Fig. 2b, and d) samples can also be seen. Sintered samples display randomly oriented grains, and a small amount of Co oxide in the undoped samples. When Na is added, it induces a decrease of porosity, and the amount of Co oxide, while increasing grain sizes. On the other hand, laser-textured samples present longer grains, aligned along the growth direction, with much lower amount of porosity and Co oxide phase, when compared to the sintered ones. Furthermore, Na addition slightly increases grain alignment and decreases the amount of both secondary phases. The microstructural modifications produced by Na doping in the sintered and laser-grown samples can be associated to the formation of a Bi2O3-Na2CO3 eutectic, as it has been found that melting point of Na-doped samples is slightly decreased when compared to the undoped ones, in agreement with previous works in similar systems [21]. The presence of this eutectic can explain the large grain growth produced in Na-doped samples when compared to the undoped ones (see Fig. 2a, and c), due to the enhancement of cation mobility, and the better alignment observed in Na-doped laser-textured samples (see Fig. 2b, and d).

Representative SEM micrographs performed longitudinal polished surfaces of (a and c) sintered; and (b and d) textured samples, with composition Bi2Ca2Co2Oy (a, and b); and Bi2Ca1.925Na0.075Co2Oy (c, and d). Grey contrast (#1) corresponds to the thermoelectric phase, light grey (#2) to the Co-free one (BiSrO), and black one (#3) to Co-oxide.

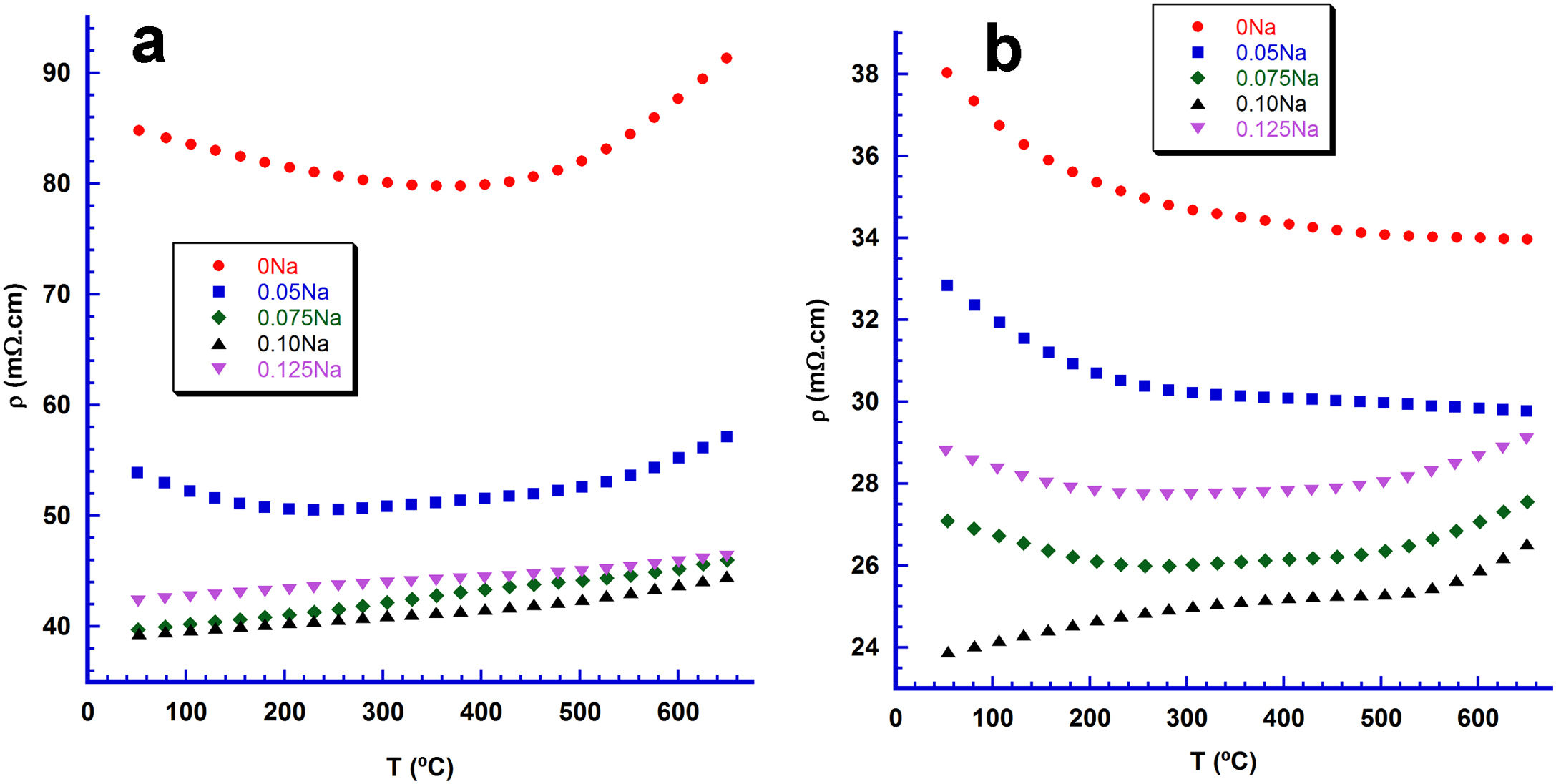

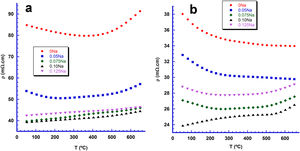

Electrical resistivity evolution with temperature, as a function of Na content, for both types of samples, is displayed in Fig. 3. In the graph, it can be easily observed that the sintered samples (Fig. 3a) possess higher electrical resistivity than laser-textured ones (Fig. 3b), in the whole measured temperature range. This behaviour clearly reflects the different microstructure previously discussed, as long and well oriented grains, together with much lower porosity, lead to decreased resistivity values in the laser-grown materials. Moreover, the minimum resistivity values have been obtained in 0.10Na-doped samples in both cases, evidencing the favourable effect of grain orientation on the electrical conduction. The main difference between both types of samples, besides the magnitude of the electrical resistivity, is its evolution with temperature. In this regard, undoped sintered samples show semiconducting behaviour (dρ/dT<0) from room temperature to around 400°C, being metallic one (dρ/dT>0) at higher temperatures (see Fig. 3a). When Na is added to these samples, the transition temperature between semiconducting and metallic behaviour is decreased to about 300°C for 0.05Na-doped samples, and lower resistivity variations. Further Na-doping leads to metallic behaviour in the whole measured temperature range. Furthermore, as previously mentioned, electrical resistivity is decreased when the amount of Na is increased up to 0.10, increasing for further Na addition. This evolution is in agreement with the fact that substituting Ca2+ with Na+ lead to reduces the total charge in the RS layer which, in turn, increases the oxidation state of Co3+ to Co4+ in the conducting layer. This process increases the charge carrier concentration in the conduction band, reducing electrical resistivity. However, the slightly different ionic size of Ca2+ and Na+ lead to a decrease of charge carrier mobility, tending to increase electrical resistivity. Consequently, the observed behaviour of these samples can be explained by a combination of these two previously discussed effects, increasing or decreasing resistivity as a function of the predominant one.

When considering the evolution of laser-textured samples (Fig. 3b), undoped and 0.05Na-doped ones present semiconducting behaviour in the whole measured temperature range, 0.075 and 0.125Na-doped change to metallic at around 400°C, and 0.10Na samples are metallic at all temperatures. This evolution can be explained taking into account the same discussion made for the sintered samples, but adding new parameters: the drastic grain alignment, and the LFZ technique, which produces a high number of oxygen vacancies in the thermoelectric phase, usually not totally filled after the annealing procedure. As a consequence of these vacancies, Co4+ in the conduction layer is reduced to Co3+, as previously observed in related systems [26,27], tending to increase electrical resistivity. The lowest resistivity values at 650°C (26mΩcm) have been determined in 0.10Na substituted laser-textured samples, which is about 40% lower than those obtained in undoped laser-textured samples, and around 80% lower than the lowest value obtained in sintered samples in this work. Moreover, these values are much lower than the best reported sintered materials prepared through solution methods (50mΩcm) [28], and in the order of textured materials using hot uniaxial pressing process (28mΩcm) [29]. These results clearly agree with the large grain sizes and orientation, and the decrease of porosity in LFZ grown samples.

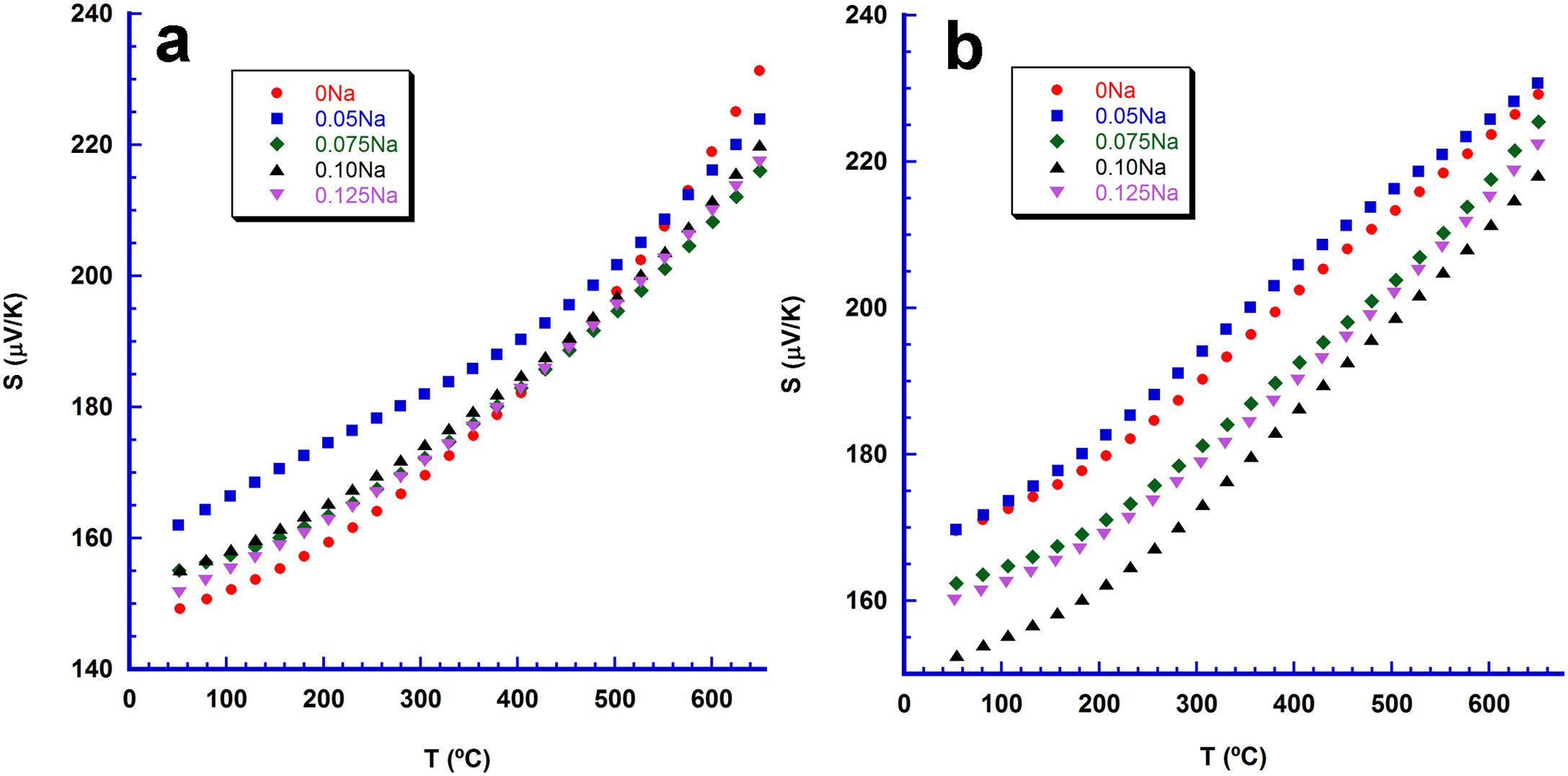

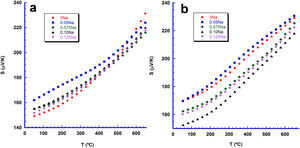

Fig. 4 displays Seebeck coefficient variation with temperature, and Na substitution for both kind of samples. In the graph, it can be seen that all samples present positive values in the whole measured temperature range, characteristic of hole-dominating transport mechanism. Moreover, S increases with temperature in all cases, which is the typical behaviour of a degenerate semiconductor, in agreement with previous works [26,28,29]. In general, laser-grown materials show higher S values at room temperature than the sintered ones, in agreement with the previous discussion showing that LFZ processing induces a large number of oxygen vacancies which are not totally filled by annealing. Consequently, the amount of Co3+ in the conduction layer is increased, leading to higher S values, in agreement with Koshibae's expression [20]. On the other hand, at high temperatures the S values are very similar for both kind of samples, being slightly higher for the samples which displayed higher electrical resistivity values, due to their lower Na content. The highest values (220μV/K) have been measured in undoped sintered, as well as in undoped and 0.05Na-doped textured, materials. These values are very similar to the obtained in sintered materials produced using solution methods (218μV/K) [28], or hot uniaxially pressed (230μV/K) [29]. On the other hand, they are much lower than the determined in LFZ as-textured materials (268μV/K) [23] due to their high content of oxygen vacancies.

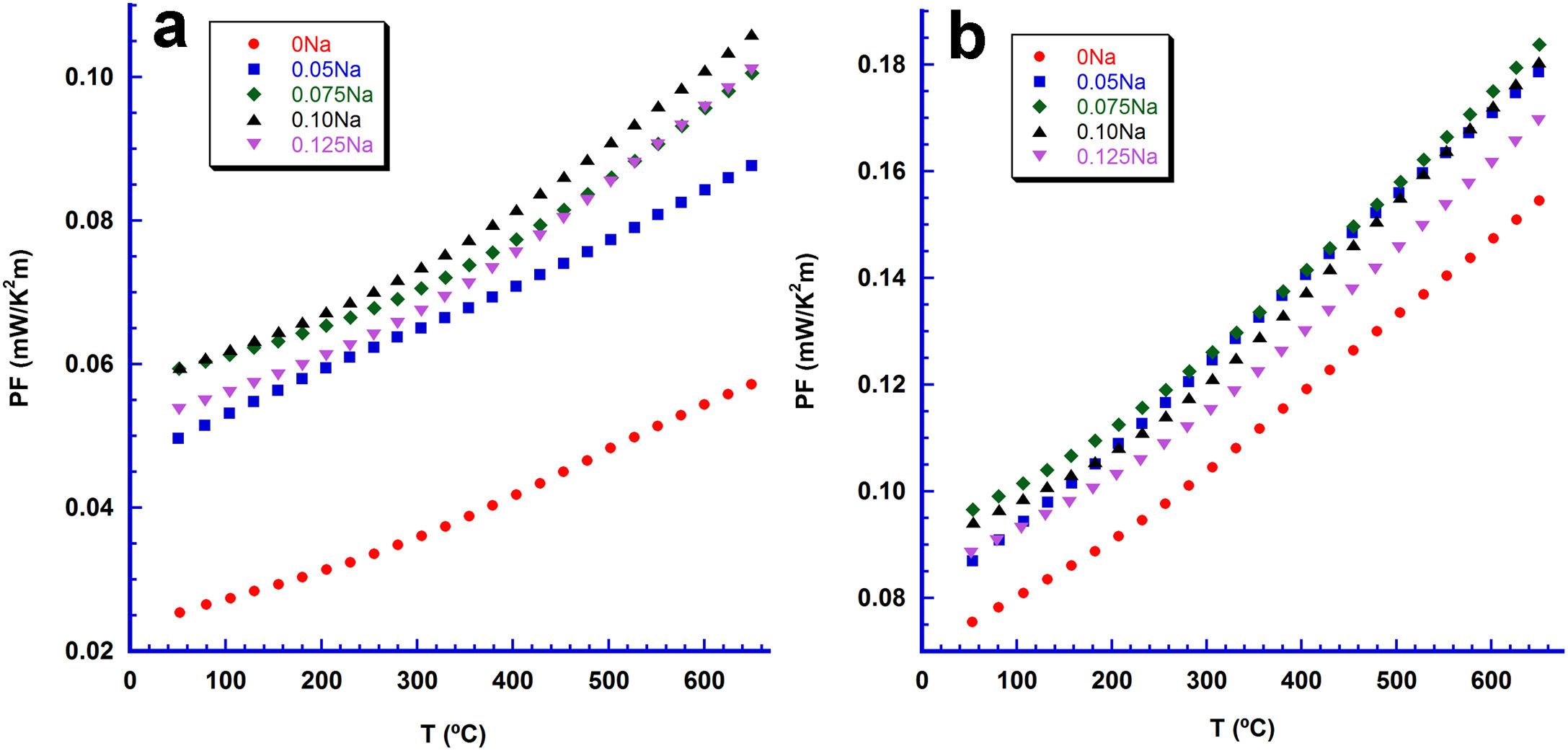

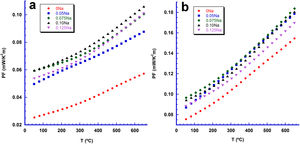

PF evolution with temperature, obtained from the electrical resistivity and Seebeck coefficient data, is presented in Fig. 5 for both types of samples. As it can be observed in the graphs, laser-textured samples show much higher PF values than the sintered ones, due to their lower electrical resistivity and similar S values. These results clearly show the beneficial effect of grain alignment and density over the amount of secondary phases, in the thermoelectric performances of these materials. In spite of these different values, the behaviour of all samples is very similar; PF grows with temperature in the whole measured temperature range, and the highest values in each type of samples are reached in medium Na content ones: 0.10 sintered, and 0.05, 0.075, and 0.10Na laser-textured samples. The highest value determined in laser-grown samples (0.18mW/K2m) is around 20 and 70% higher than the measured in undoped laser-textured samples, and sintered ones, respectively. Moreover, it is much higher than the reported for as-grown materials (0.085mW/K2m) [23], and sintered materials produced through solution methods (0.09mW/K2m) [28]. On the other hand, it is lower than the measured in hot uniaxially pressed materials treated for 50h (0.25mW/K2m) [29]. Despite of this slightly lower performances, the process to obtain the samples in this work is very simple and allows obtaining the samples with adequate geometry to be directly integrated in thermoelectric modules without further machining.

ConclusionsBi2Ca2−xNaxCo2Oy (0≤x≤0.125) thermoelectric ceramics have been successfully prepared through the classical ceramic route, and textured through the LFZ method. It has been found that Na substitution leads to a drastic grain growth in the sintered materials, and a slight improvement of grain orientation in the laser-textured ones. Moreover, it decreases secondary phases in both kind of samples. The microstructural differences between sintered and laser-grown materials have been reflected in a drastic decrease of electrical resistivity, with no significant reduction of Seebeck coefficient. On the other hand, Na-doping decreases electrical resistivity up to 0.10 in both types of samples. The increase of electrical resistivity in samples with higher Na content is associated to the raise of defects which act as electronic scattering centers. All these characteristics led to much higher power factor values in laser-textured samples, when compared to the sintered ones. Further increase is produced, in both cases, in Na substituted samples. These improvements, and the possibility to use these samples directly in thermoelectric modules, make them very interesting ceramic materials for practical applications.

This study was carried out within the scope of Cukurova University Scientific Research Projects Unit FBA-2020-13007. The authors wish to thank the Spanish MINECO-FEDER (MAT2017-82183-C3-1-R), and Gobierno de Aragón (Research Group T 54-20 R) for funding. The authors wish to acknowledge the use of Servicio General de Apoyo a la Investigación-SAI, Universidad de Zaragoza.