The transparent relaxor ferroelectric ceramics of the system lanthanum modified lead magnesium niobate (PLMN-13PT) have been investigated for a variety of electro-optic, properties; good electro-optic switching times and modest half-wave voltages. In this work, the dependence of microstructural, structural, dielectrical, optical, and electro-optical properties in function of Rare Earth (RE=Tm3+, Nd3+, Yb3+, Er3+ and Ho3+) has been reported. PLMN-13PT:RE with excellent properties were obtained, highlighting the electrical, optical, and electrooptical properties, suitable for the fabrication of multifunctional devices. The most prominent or important feature is the largest quadratic Electro-optic coefficient achieved ((9.37±0.39)×10−16m2/V2) corresponding to PLMN-13PT:Ho transparent ceramics. This result in addition to the electrical and photoluminescence properties becomes a promising alternative to building multifunctional devices.

Las cerámicas ferroeléctricas relajantes transparentes del sistema niobato de plomo y magnesio modificado con lantano (PLMN-13PT) han sido investigadas por una variedad de propiedades electroópticas; buenos tiempos de conmutación electroóptica y modestos voltajes de media onda. En este trabajo se ha informado de la dependencia de las propiedades microestructurales, estructurales, dieléctricas, ópticas y electroópticas en función de las tierras raras (RE=Tm3+, Nd3+, Yb3+, Er3+ y Ho3+). Se obtuvieron cerámicas del sistema PLMN-13PT:RE con excelentes propiedades, destacando las eléctricas, ópticas y electroópticas, aptas para la fabricación de dispositivos multifuncionales. La característica más destacada o importante es el mayor coeficiente electroóptico cuadrático alcanzado ((9,37±0,39)×10-16m2/V2) correspondiente a la cerámica transparente PLMN-13PT: Ho. Este resultado, además de las propiedades eléctricas y de fotoluminiscencia, convierte a este sistema en una alternativa prometedora para la construcción de dispositivos multifuncionales.

Lead magnesium niobate Pb(Mg1/3Nb2/3)O3 (PMN), as one of the most widely investigated relaxors ferroelectric with a perovskites structure, was first synthesized in the late 1950s [1]. Later on, a novel methodology was devised to stabilize perovskites structure by adding stable normal PbTiO3 (PT). The formation of the solid solution increases the tolerance factor and electronegativity difference, leading to the stabilization of the perovskites structure and the enhancement of the dielectric property of the relaxor ferroelectric [2].

Present applications take advantage of PMN-PT's singularly excellent dielectric and high electrostrictive properties, which make them promising for applications in multilayer capacitors, piezoelectric transducers, actuators, and optical devices [3,4]. However, the PMN-PT ceramics are extremely difficult to fabricate without the appearance of the pyrochlore phase, which deteriorate the dielectric properties [5]. This is very important because the influence of the earth rare element in the perovskite structure of PMN-PT can increase or decreases the formation of the pyrochlore phase [6] and change the material properties as reported by Zhang et al. [7]. In the same way, it has been proved that the strength and toughness of some structural ceramics can be improved greatly by adding rare earth oxides. These are added as a stabilizers and sintering aids and, consequently, to reduce the sintering temperature and production costs. Meanwhile, rare earth oxides also play a very important role in functional ceramics, such as sensors, microwave dielectric and, piezoelectric ceramics [8,9].

In previous studies, PMN-PT ceramics were prepared by doping with lanthanum. La addition to PMN-PT has been shown to promote densification and through hot uniaxial pressing, optically transparent materials have been achieved, allowing the determination of various optic and electro-optic properties [10–12]. The electro-optic interaction with optical amplification in rare-earth-doped ferroelectric oxide is an interesting topic for developing new active devices. The intrinsic capability of the perovskite structure to host ions of different sizes, in special, the effects of RE addition has been studied in PMN-PT ceramics [6,13,14]. When doping with lanthanum, the PMN-PT transparent host material has excellent properties: good optical transmittance and large electro-optic effect. This is important for the fabrication of electro-optical devices, however, nowadays, the need for modern applications is integrating different functions in one material is a fundamental challenge, thereby, the rare earth doped PLMN-PT ceramics can be interesting for obtaining multifunctional materials. However, no published work on the effect of RE in the PLMN-13PT properties is encountered. Therefore, the purpose of this work is to report the microstructural, structural, dielectrical, optical, and electro-optical properties of PLMN-13PT doped with RE, (RE=Tm3+, Nd3+, Yb3+, Er3+ and Ho3+) as well as to analyze the possible applications in multifunctional devices.

Materials and methodsThe powder was synthesized by the columbite or two-stage calcining method [15]. The batch formulae were (0.87)[Pb(1−y)Lay(Mg1/3Nb2/3)O3]–0.13PbTiO3, with y=0.01 and doped with 0.5% mol of rare earth, RE, (RE: Tm, Er, Nd, Yb, and Ho), PLMN-13PT:RE.

The starting materials were Lanthanum Oxide, La2O3 (Aldrich, >99% purity), Niobium Oxide, Nb2O5 (Alfa Aesar 99.9+% purity), Magnesium Carbonate Hydroxide Pentahydrate, (MgCO3)4·Mg(OH)2·5H2O (Aldrich 99% purity), Lead Oxide, PbO (MGK 99%), Titanium Oxide, TiO2 (Alfa Aesar, 99.8% purity), Neodymium (III) Oxide, Nd2O3 (Aldrich, 99.99% purity), Ytterbium (III) Oxide, Yb2O3 (Aldrich, 99.99% purity), Holmium (III) Oxide, Ho2O3 (Aldrich, >99.999 purity), Erbium (III) Oxide, Er2O3 (Aldrich, >99.99% purity) and Thulium (III) Oxide, Tm2O3 powders. The (MgCO3)4Mg(OH)2·5H2O was carried up to 1100°C, for 4h, to drive off CO2 and H2O and obtain the correct amount of MgO for a stoichiometric reaction with Nb2O5. In the first stage, MgO and Nb2O5 powders were ball-milled and pre-reacted at 1100°C for 4h, in air, to form the columbite phase (MgNb2O6). In the second stage, the synthesized (MgNb2O6) (MN) was ball-milled in isopropanol, for 24h, with appropriate amounts of PbO, TiO2, La2O3, Rare Earth and heated at 900°C, for 4h, in an oxygen atmosphere, at a controlled pressure of 200kPa. The calcined powders were pressed into pellets 14mm in diameter and 10mm in thickness with the addition of an appropriate amount of polyvinyl alcohol (PVA) binder. The pellets were sintered in hot uniaxial pressing in O2 atmosphere followed for 4h at 1260°C, and 6MPa.

The phases were determined by X-ray diffraction (XRD) using a Rigaku diffractometer, with CuKα radiation. The measures were performed at room temperature. The relative amount of pyrochlore phase was determined with the Eq. (1):

where Iperov and Ipyro are the higher intensities of the perovskite diffraction and the pyrochlore diffraction peaks, respectively [16].Apparent densities were determined by the Archimedes method. The microstructural features of the samples were investigated by scanning electron microscopy (SEM), using a Jeol JSM 5800 LV. The grain sizes were calculated from the SEM images of the polished thermally etched surfaces by the linear-intercept method. For dielectric measurement, gold electrodes were deposited on both faces of the disk samples (5mm diameter and ∼1.0mm thick). The relative permittivity, ε′ was measured by impedance analysis (HP4194A). Variations in the shape of ε′ in the function of temperature curves was related to the diffuseness coefficient, Δ, calculated from the Santos Eiras Eq. (2)[17],

In Eq. (2)ε′max is the maximum of the dielectric permittivity and Tmax its related temperature. In Eq. (2), ξ indicates the character of the phase transition. Besides, Δ is considered as an empirical diffuseness parameter that indicates the degree of the diffuse phase transition, being certainly related to the dielectric permittivity peak broadening [17].

The optical transmittance was measured with a spectrophotometer (Micronal, model B582), the instrument that covers the 200nm to 1100nm wavelength in optically polished samples with 500μm thick. The electro-optical characterization is based on the Senarmont compensated measurements [18]. In equation (3) is presented the relation between birefringence and electric field for a medium with a linear and quadratic electro-optic response.

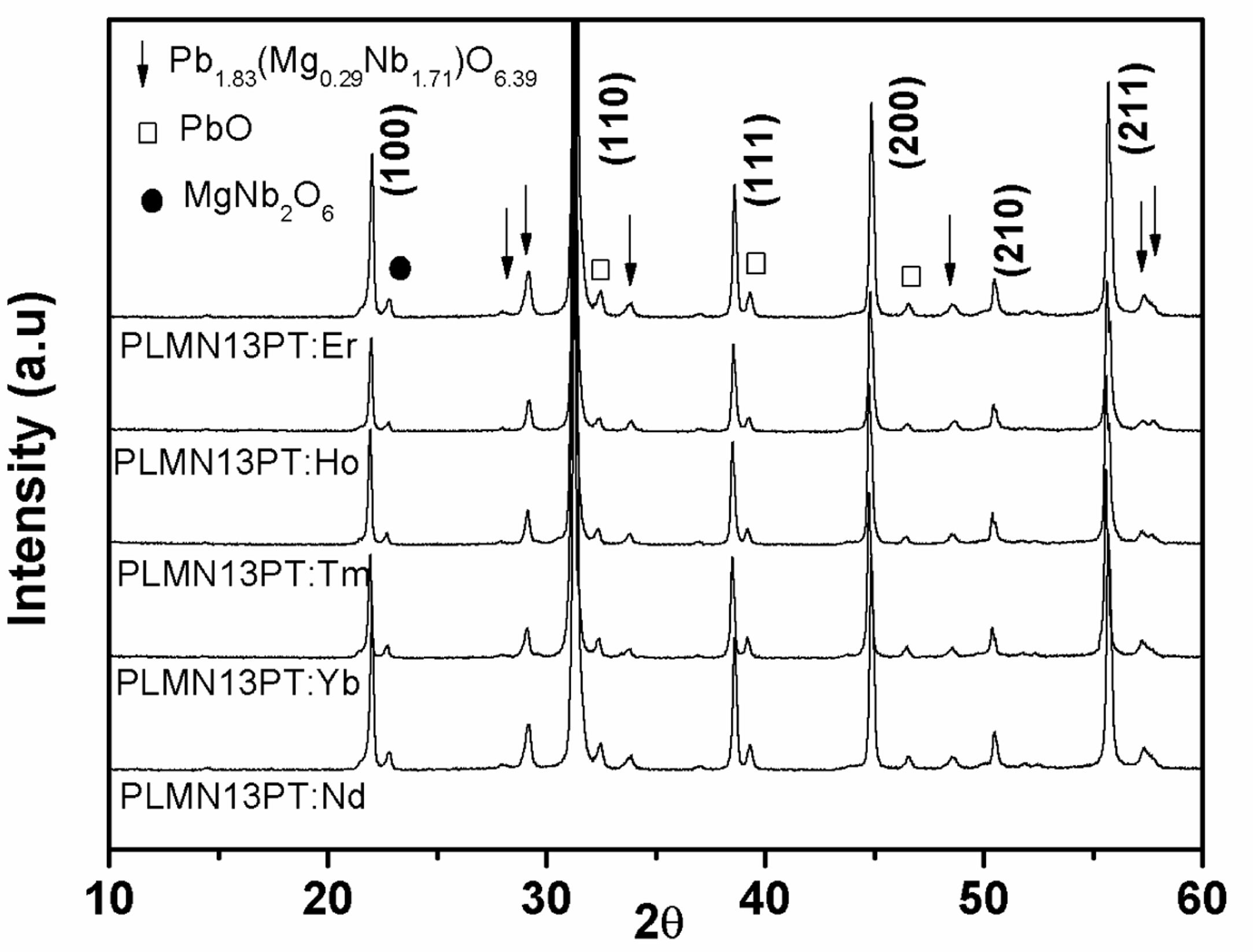

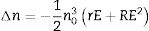

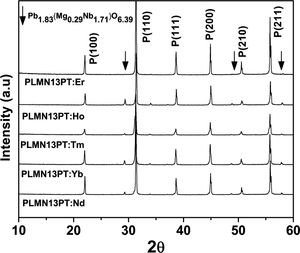

where Δn is the birefringence induced for the electric field E, n0 is the natural birefringence of the medium, r and R are the linear (Pockels) and quadratic (Kerr) electro-optic coefficients, respectively.Results and discussionThe XRD patterns from PLMN-13PT:RE powders calcined in function of rare earth are shown in Fig. 1. The main peaks show a predominant cubic perovskite structure (JCPDS 391488). Small peaks of pyrochlore phase (JCPDS 330769) and other secondary phases, such as PbO (massicot) and MgNb2O6. (orthorhombic structure) can be found.

The doping with Rare Earth in PLMN-13PT powders increases lightly the quantity of the pyrochlore phase (∼15%) when comparing with PLMN-13PT powders [19]. This indicates that doped with RE could promote the loss of lead oxide that could generate the formation of pyrochlore phase, for example, Nd3+ and Ho3+ (large ionic radius) replaces Pb2+ at the A site and to maintain the charge neutrality it introduces Pb2+ vacancies in the lattice. On the other hand, Tm3+, Er3+ and Yb3+, (small ionic radius) replaces atoms at the B site and to maintain the charge neutrality it introduces O2− vacancies in the lattice. The ionic occupancy is ruled by its atomic radius, determined by the geometric analysis of Pauling rules for structural stability [20]. The other Pauling rules is not considered in this work because, there are not differences between the state oxidation of the dopants [20].

In particular, the peaks corresponding to Nb2O5 (bcc structure) and MgO (hcp structure) are not observed, revealing that the Nb2O5 has completely reacted with MgO. This is attributed to the formation of MgNb2O6 (MN) by columbite method [21].

The relative density of PLMN-13PT:RE ceramics (Table 1) are greater than 97% of the theoretical density, which is especially suitable for electronic industry application [22]. The relative density exhibits a decreasing tendency as the ionic radius is greater. This can be attributed to the loss of PbO in the densification process (control atmosphere of PbO was not used in this work) [23]. It is could be associated with the occupation of RE3+ atoms in Pb2+ sites, implying the appearance of vacancies in the A and B sites in different quantities [19]. Possibly, the vacancies in A-site increase upon increasing the ionic radius size in PLMN-13PT:RE ceramics, leading to greater loss of lead and therefore a decrease in density.

Variation of relative density and ionic radius as a function of RE dopant in PLMN-13PT:RE ceramics.

| Ceramics | Relative density (%) | Ionic radius (A) [24] |

|---|---|---|

| PLMN-13PT:Yb | 99.2±0.2 | 0.86±0.01 |

| PLMN-13PT:Tm | 98.8±0.1 | 0.87±0.01 |

| PLMN-13PT:Er | 98.4±0.1 | 0.88±0.01 |

| PLMN-13PT:Ho | 98.2±0.2 | 1.22±0.01 |

| PLMN-13PT:Nd | 97.7±0.3 | 1.28±0.01 |

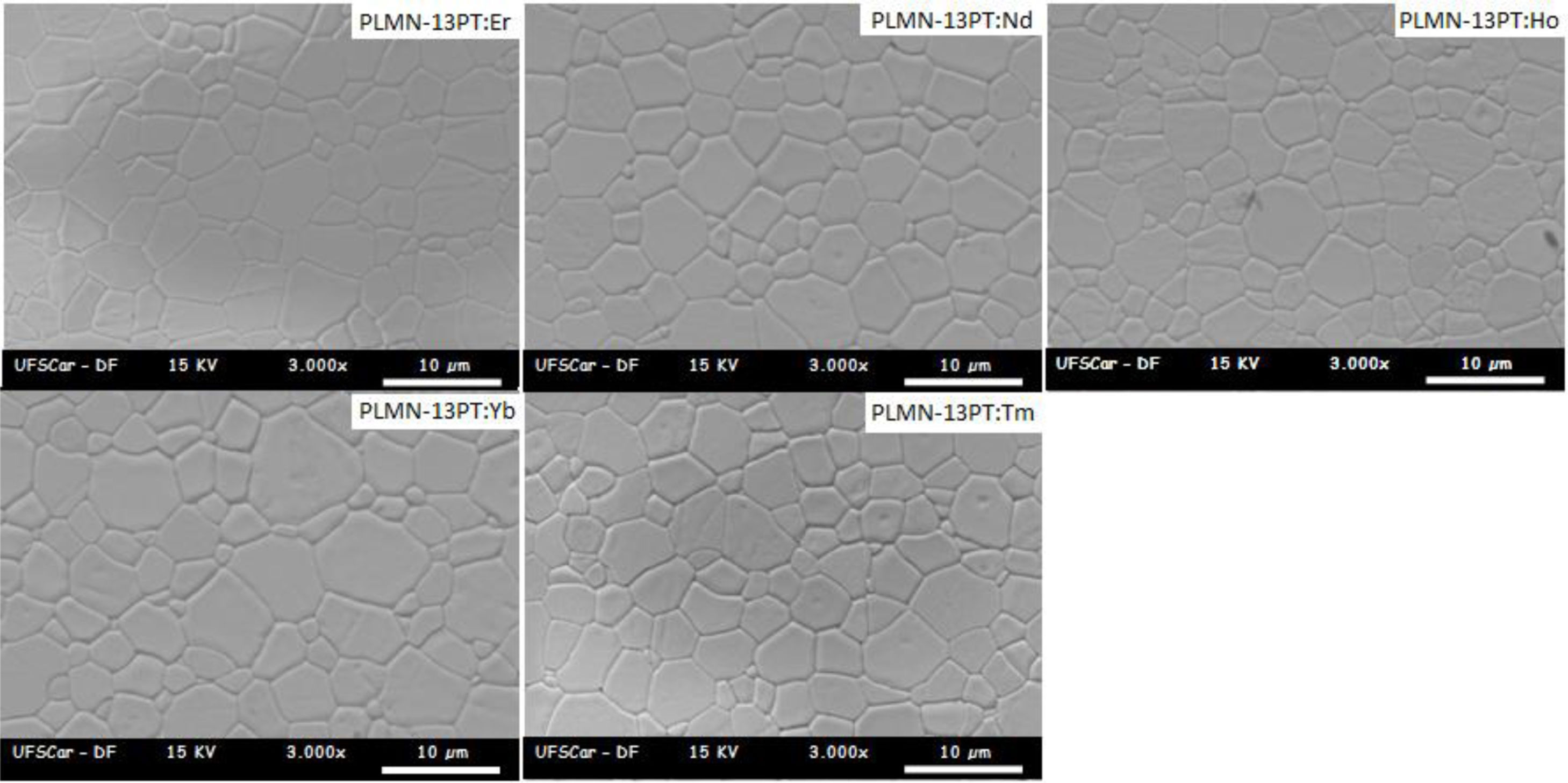

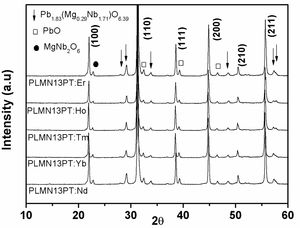

The high densification of PLMN-13PT:RE ceramics is further confirmed by micrographs of the polished and thermally attacked surface of PLMN-13PT:RE, which is shown in Fig. 2. All ceramics exhibited a similar porous-free microstructure with an average grain size between 5.5μm and 6.5μm. The grain boundary is thin, and the grains are crystallized very well. It is also thought to be beneficial for the improvement of material transparency.

The high densification could be attributed to the combination of oxygen atmosphere sintering and hot-pressing sintering process. It has been reported that oxygen has high solubility and diffusivity in PMN–based systems, and the pores in ceramics filled with oxygen are easily removed through the diffusion of vacancies formed by PbO evaporation. Alike, the hot-pressing sintering process gives a squeezing force between the grains, which is beneficial to eliminating pores in lead ceramics (e.g. PLT, PLZT, PMN-PT) [25,26].

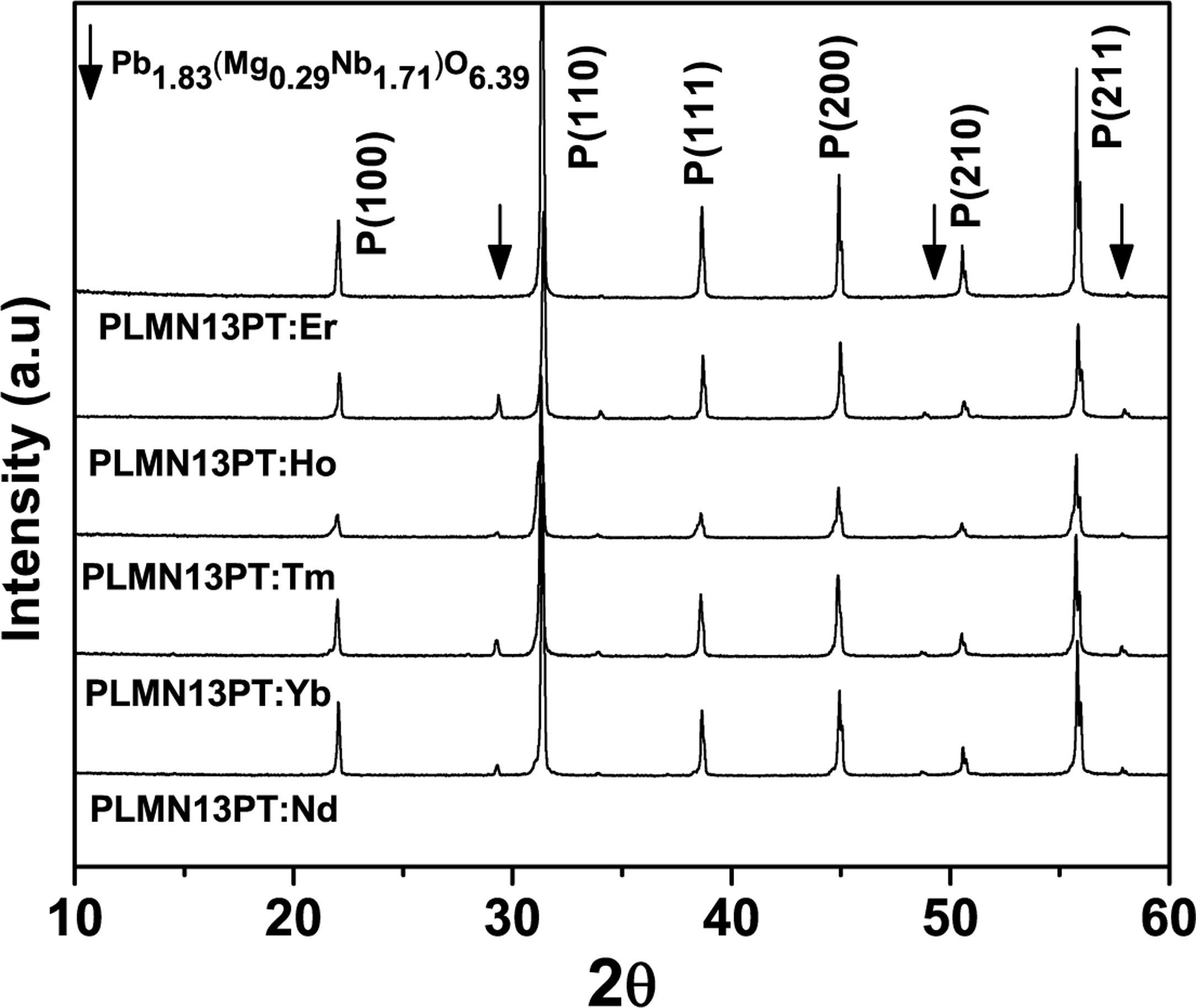

The XRD patterns of PLMN-13PT:RE ceramics with different are RE doped are presented in Fig. 3. A complete perovskite structure (JCPDS 391488) is formed and a small amount of pyrochlore phase was detected. Other second phases were not detected. All ceramics shown by well-resolved peaks at (100), (110), (111), (200), (210), (211) planes. The relative amounts of perovskite and pyrochlore phase were determined by measuring the major XRD peak intensities of the perovskite and pyrochlore phase (Eq. (1)).

Also, it is possible establishing that, the rare earth doped in PLMN-13PT ceramics causes changes in the position (200) peaks [19]. That is because RE3+ occupies the A-site by replacing Pb2+ in PMN-13PT ceramics. This occupation leads to lattice distortion and reduces the interplanar spacing d. According to Bragg equation 2dsinθ=λ, when interplanar spacing d decreases, θ will increase, which means diffraction peaks shift to higher angles, for example, XRD patterns of the samples obtained from Nd3+ and Ho3+ doped ceramics presented a major increase in θ, when compared with Er3+, Tm3+ and Yb3+ doped ceramics, this analysis can be indicative that Nd3+ and Ho3+ ions replace atoms localized in A sites, however, this is not analyzed in detail in this work.

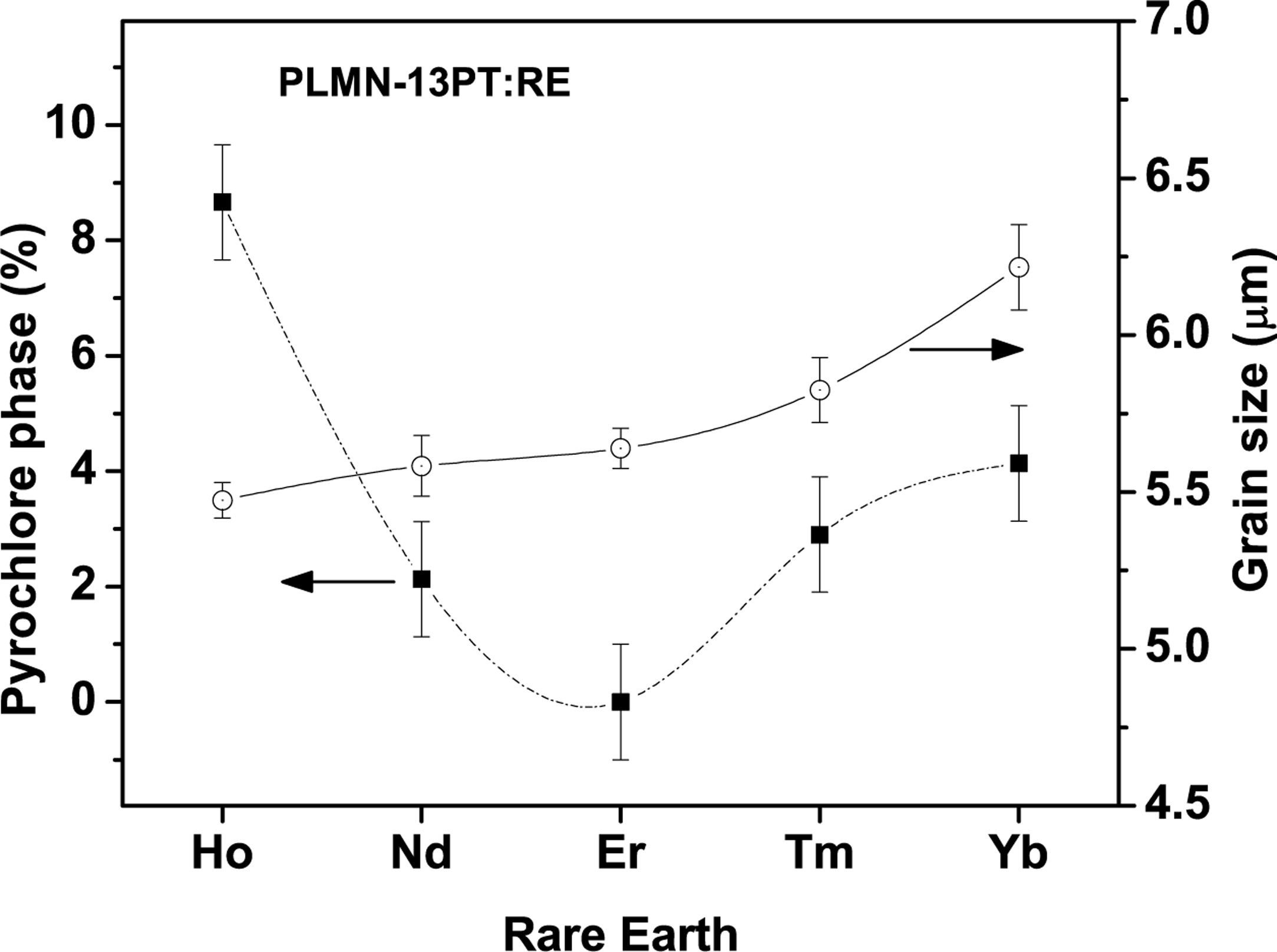

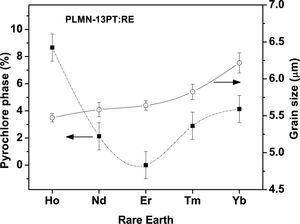

The variation of pyrochlore phase and grain size in function of RE3+ are shown in Fig. 4. Rare-earth doped PLMN-13PT:RE resulted in a decrease in grain size when compared with PLMN-13PT[19]. Similar suppression of RE-doping on grain growth was also observed in lead ceramics and was explained in terms of the lower diffusivity of rare-earth ions [27].

The pyrochlore phase in PLMN-13PT:RE (RE: Er3+, Nd3+, Tm3+, and Yb3+) ceramics is between 0 and 3%, and PLMN-13PT:Ho is around 8% (Fig. 4). This is because the pyrochlore phase would be formed due Pb2+ is replaced by Ho3+ and this might lead to the agglomeration of Pb2+ at the grain boundary [28]. The pyrochlore phase is less in Er3+, Tm3+, and Yb3+ doped ceramic because in this case the O2− vacancies prevail. However, the pyrochlore phase in PLMN-13PT:RE powders decreases after of densification process as can be deduced from Figs. 1 and 3.

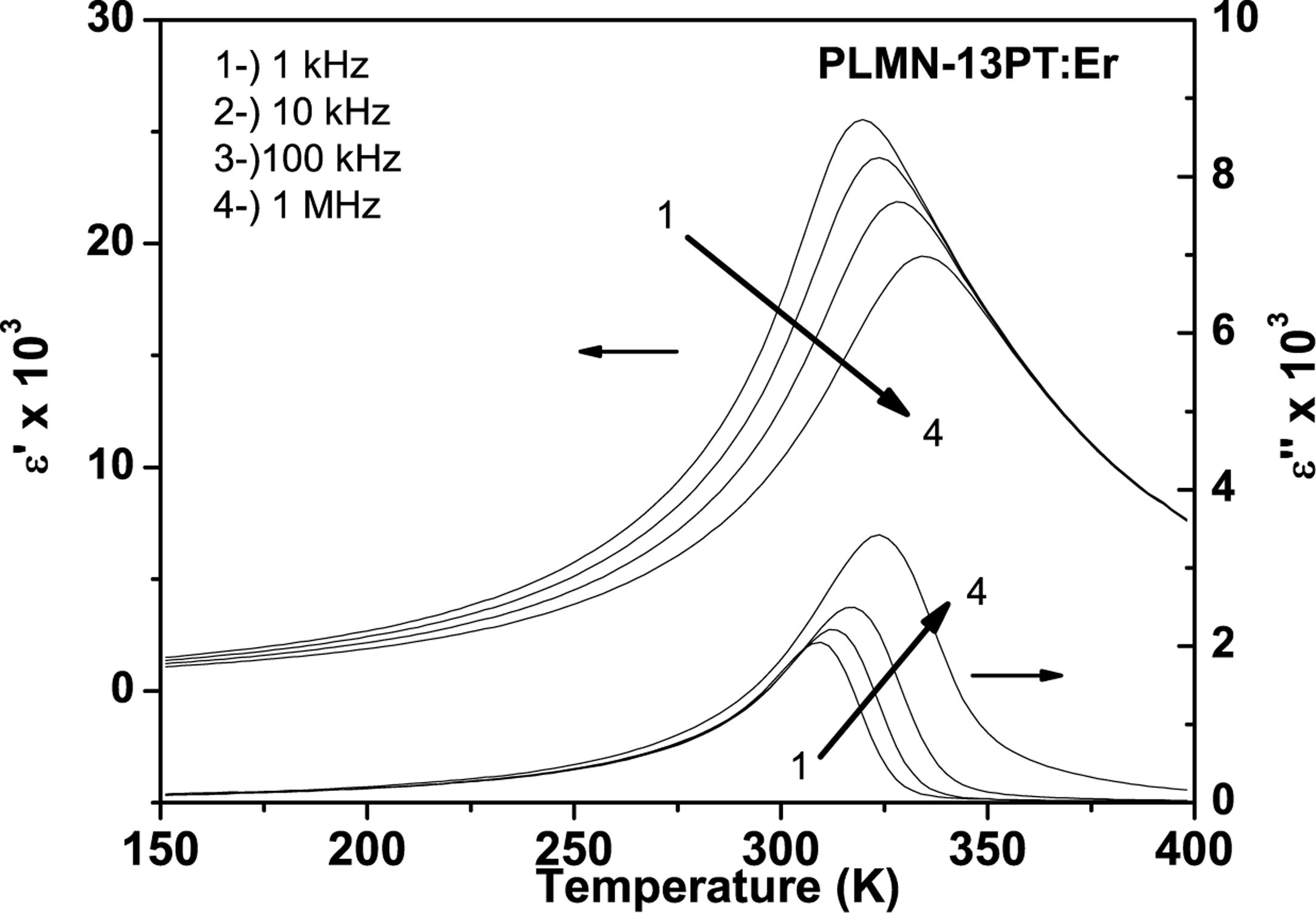

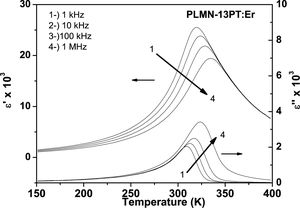

A typical example of measurements carried out in this work of the real, ε′, and imaginary, ε″, permittivity (measured between 1kHz and 1MHz in the temperature range 150–400K) is presented in Fig. 5 for sample PLMN-13PT:Er. All the samples (not shown here) exhibit typical relaxor behavior with the magnitude of ε′ decreasing with increasing frequency, and the maximum real permittivity, ε′max shifting to higher temperatures. As can be deduced from Table 2, the values of ε′max and Δ (diffuseness parameter) changes in PLMN-13PT:RE ceramics, indicating that the values of maximum permittivity are closely related to the extent of order-disorder, which is described with the diffuseness parameter.

Dielectric properties of PLMN-13PT and PLMN-13PT:RE ceramics 1KHz.

| Ceramics | ε′max | Tmax (K) | Δ | ξ | tan δ |

|---|---|---|---|---|---|

| PLMN-13PT | 25,200 | 305 | 1.63±0.00 | ||

| PLMN-13PT:Yb | 21,524 | 319 | 54.35±6.12 | 1.48±0.43 | 0.02 |

| PLMN-13PT:Tm | 27,611 | 324 | 46.70±5.92 | 1.50±0.43 | 0.03 |

| PLMN-13PT:Er | 25,557 | 320 | 46.59±5.26 | 1.57±0.41 | 0.04 |

| PLMN-13PT:Ho | 29,202 | 316 | 50.47±5.10 | 1.52±0.44 | 0.04 |

| PLMN-13PT:Nd | 24,488 | 302 | 50.54±4.40 | 1.66±0.33 | 0.05 |

The change of ε′max might be contributed to several factors, grains boundary phase, porosity, domain structure, perovskite formation, grain size, secondary phases. Since there are not grain boundary phases, and low porosities due to high relative densities in all samples, the effect of those on dielectric properties could be neglected. Therefore, it is reasonable to think that the variations of ε′max would be contributed to grain size, domain structure, secondary phases, and order-disorder ratio in the present work.

On the other hand, the value of Tmax in PLMN-13PT:RE is observed to shift to higher values (Table 2) as compared to PLMN-13PT (305K) [19]. However, the Tmax values are lowers when the ceramics is doped with Nd3+ and Ho3+ (incorporation into A site). Higher increase of Tmax is observed in doped ceramics with Er3+ Tm3+ and Yb3+. This phenomenon could be explained by the changes in structural distortions induced by doping with ions of different sizes.

The downtrend of ξ in PLMN-13PT:RE (Table 2), when compared with PLMN-13PT (ξ=1.63) [19], verifies that RE doping can strengthen the long-range coupling interaction among the BO6 octahedrons and increase the dielectric properties of these materials [26].

The PLMN-13PT ceramic doped Yb3+ with a small grain sizes show small value of ε′max, and Ho3+ modified PLMN-13PT ceramic with large grain size shows the high value of ε′max. But the values in ε′max for Tm3+, Er3+, and Nd3+ doped PLMN-13PT ceramics cannot be explained in terms of grain size. Thus, the variation of ε′max cannot be absolutely explained in terms of grain size in PLMN13PT:RE ceramics.

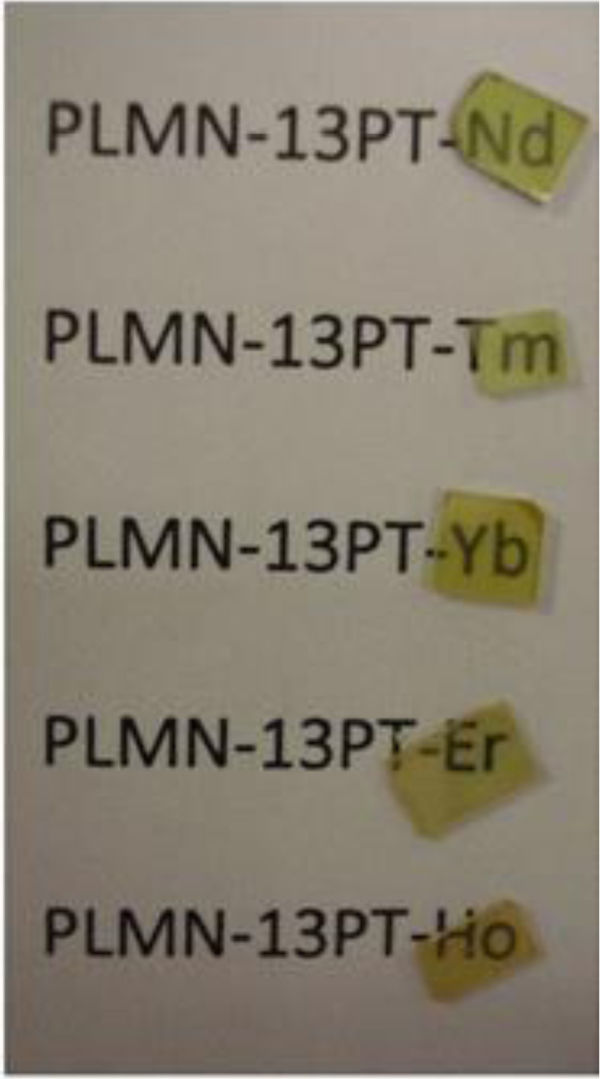

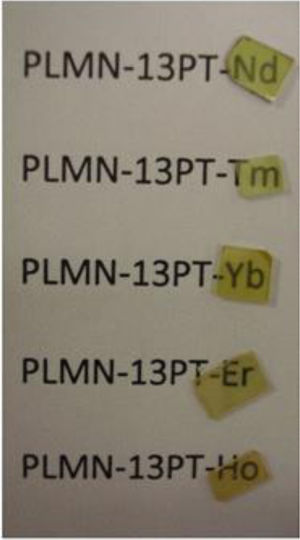

Photography of the obtained transparent PLMN-13PT:RE ceramics (with a thickness of samples 0.5mm) is shown in Fig. 6. One can see that possibility of clearly seeing and legibility of the text underneath samples confirms their transparency. Also, it can be seen small changes in color of the ceramics in function of dopant. This is possible because of luminescence properties of dopants ions and their interaction with the matrix ceramic.

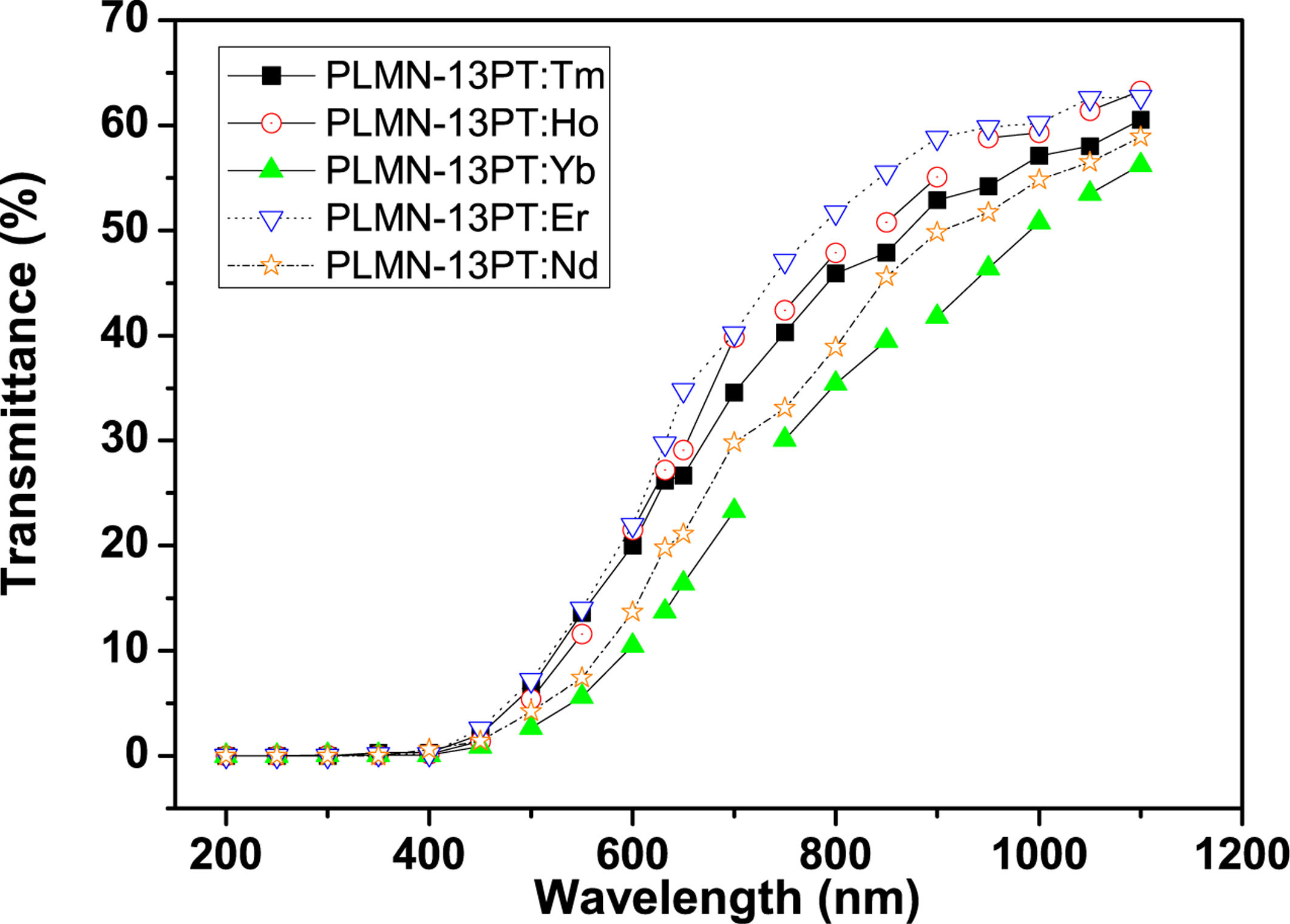

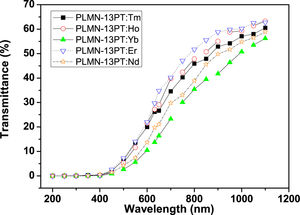

The optical transmittance of PLMN-13PT:RE ceramic is plotted against wavelength in Fig. 7. The ceramics are transparent from visible to the near-infrared region and they became completely absorbing around 400nm, indicating an optical absorption edge in near UV. This is like what is absorbed for most oxygen-octahedral perovskites [6,12]. The measurements of transmission spectra were extended to 1.1nm and no absorption was observed. Also, the transparency of all ceramics obtained in this work is higher than 40% at 800nm and 50% in near-infrared wavelength, which is slightly less to the data reported in the published literature. It can be assumed that light scattering due to multiple reflections by the domain boundaries of randomly oriented grains is the main cause of the fall in optical transmittance. When the incident light passes through the ceramic, those domain boundaries cause multiple scattering and generate larger scattering losses. On the other hand, PLMN-13PT:RE exhibited pyrochlore, which are expected to be detrimental to the optical transmittance.

Table 3 shows the Quadratic electro-optical coefficients, R, at room temperature of PLMN-13PT:RE ceramics. These coefficients are smaller than those found for the PLMN-13PT [19]. The PLMN-13PT:RE (RE=Ho3+ and Nd3+) present smaller values of electro optic coefficient when compared with PLMN-13PT [19] due to the creation Pb2+ vacancies [29]. It is also observed that the ionic radius of the dopant has influence on electro optic coefficient, e.g., the ceramics doped with Nd+3 and Ho+3 (larger ionic radius) have higher Kerr coefficient that the ceramics doped with Er+3, Tm+3 and Yb+3 (lower ionic radius). This observation could be explained by the mobility of domain walls [30]. In order to increase the electro-optical coefficient PLMN-13PT:RE the level of commercially used ceramics, studies are in process and will be presented in a future paper.

The intensity of the light transmitted through the crossed polarizers in the Sénarmont compensated measurements for PLMN-13PT:RE ceramics increases and reaches the first maximum with the increase of the electric field because of the electro-optic effect (not shown here). The light intensity, however, does not return to zero as the electric field keeps increasing, in other words, there is residual light intensity. This phenomenon can be attributed to the light scattering effect brought by the growth of the ferroelectric domains in sizes and numbers caused by the increasing electric field. This observation agrees with the dielectric properties especially with Δ and ξ values, previously presented. This also suggested that the material with smaller size domains would exhibit a larger quadratic EO effect, because respond easily and quickly to the electric field applied [31]. From this, it can be deduced that grains and grain boundaries in all these transparent ceramics should not be the main reason for the differences in their transparency. This observation agrees with the conclusion drawn earlier that the relatively low transparency is due to the light scattering effect caused by large domains existing in PLMN-13PT:RE ceramic.

ConclusionsPerovskite-type structure PLMNT transparent ceramics with dense microstructure and high transparency were fabricated by a uniaxial hot-press sintering method. The optical transmittance of PLMNT ceramics decreases markedly, because of the weakened symmetry of crystal structure resulting from the earth's rare doped. The dielectric constant decreases and the diffusivity coefficient increases with the rare earth doping, which are thought to effectively degrade the EO effect.

In this study, the largest quadratic EO coefficient achieved is (9.37±0.39)×10−16m2/V2 corresponding to PLMN13PT:Ho transparent ceramics. The PLMN-13PT:RE ceramics developed in this work are suitable for being applied in electro-optical modulators and high-speed electro-optical switches. These outstanding properties in addition to the electrical properties become a promising alternative to building multifunctional devices.

The microstructure, phase transition, and electrical properties of PMN–13PT can be significantly influenced by rare-earth element doping. However, the transparency of PMN–PT ceramics is not yet good enough to satisfy the need for electro-optic devices up to now. Thus, an optimal RE-doping concentration needs to be determined for PLMN–0.13PT:RE by further investigation.

Conflict of interestsThe authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

This research was partially supported by Brazilian Agencies: CAPES, CNPq and FAPESP and Colombian Agencies: CODI, University of Antioquia.