Se ha realizado el estudio del comportamiento de una arcilla de la formación Guayabo del Área Metropolitana de San José de Cúcuta al ser mezclada con corindón; este trabajo es la continuación de otros realizados con anterioridad. En esta materia prima los minerales dominantes son, la caolinita y los micáceos; posee cuarzo, carbonatos y óxidos de hierro libres, además de una excelente plasticidad y una buena distribución granulométrica. Se realizaron tres mezclas con porcentajes de 5% (M5), 10% (M10) y 20% (M20) de corindón, utilizando la técnica de prensado para el conformado y registrando el control de proceso en el secado. Se sinterizo en un horno mufla a 1.200 °C y 1.250 °C y se realizaron pruebas para determinar su comportamiento tecnológico, como fueron contracciones, densidad aparente, absorción de agua, porosidad abierta, resistencia mecánica a la flexión y resistencia a la abrasión profunda. Los resultados de la investigación dejaron ver que al adicionarle corindón al material arcilloso, mejora sus propiedades tecnológicas, permitiendo así que este residuo sea utilizado dentro de los procesos industriales y minimizando la contaminación generada por este.

A study about the behaviour of a clay from the Guayabo formation in the Metropolitan Area of San José de Cúcuta when mixed with corundum was conducted; this work is a continuation of others previously performed. In this raw material the dominant minerals are kaolinite and mica; it has quartz, carbonates and free iron oxides, as well as excellent plasticity and a good particle size distribution. Three mixtures with percentages of 5% (M5), 10% (M10) and 20% (M20) of corundum were made using the press technique to form and record control in the drying process. It was sintered in a muffle furnace at 1200 °C and 1250 °C and tests were performed to determine their technological behaviour, as contractions, bulk density, water absorption, open porosity, mechanical resistance to bending and to deep abrasion. The research results showed that when corundum was added to the clay material, it improves its technological properties, allowing this residue to be used in industrial processes and minimizing the pollution generated by this.

Nowadays, the city of San José de Cúcuta and its metropolitan area have grown industrially in the ceramic sector due to its excellent clays which are exploited by all sides of the city, this fact makes Cucuta one of the cities with more inflows of this material at national and international levels, and that is the reason why excellent building materials are fabricated and exported to several cities on the planet.

In this region we find clays of three geological formations such as the Carbonera, the Lion and the Guayabo, clays from the Carbonera formation are distinguished by their dark appearance, the León ones are characterized by its grayish appearance while clays group Guayabo have more reddish colours1, the latter is the one used the most in this sector not only because of its material wealth but also due to their excellent mineralogical, chemical and physical properties that make it a pioneer in the manufacture of products made of clay to be used in construction. Considering the advancement in technology there is the need to seek for other markets where you can enter, taking advantage of the ease of manipulation that this clay has during any ceramic material process to which it is exposed.

It is for this reason that this work, which is the continuation of two previously performed is presented. In this study the behavior of a clay is shown when the same is mixed with the residue of corundum after the test of resistance to deep abrasion of unglazed tiles according to the norm NTC 4321-6; the main objective is to observe the technological properties of the material and its possible application in other areas of industry, as well as to look for ways to minimize the pollution generated by this type of material in which the corundum is not meant to be reused during the abrasion test, causing it to be thrown as waste, generating pollution.

In this research the results of different mineralogical, chemical, physical and technological studies are presented. Then the results obtained in the latter part of the work are discussed.

Materials and methodsMaterialsClay

It is a material from the municipality of Zulia, Norte de Santander and is part of the Guayabo formation, clay has a reddish tonality and a plastic texture.

Corundum

It is the residue of the test according the NTC 4321-6 norm, is a material made of alumina and silica, with coarse texture and particle size of 80 mesh ASTM.

Equipment usedA powder diffractometer, Bruker brand model D8 Advance was used, a equipment of X-ray fluorescence Panalytica Axios, hammer laboratory mill brand Servitech model CT-058, a rapid laboratory mill with capacity for three jars of 1 liter each with grinding bodies of alumina, a laboratory press 20-40 T with rectangular mold, stainless steel stove with natural ventilation from a range of 0 ¿ C to 300 ¿C, a muffle furnace volume of 64 liters, a wood heating, a press pressure (Crometro) and CAP/3 Abrasion, Pfefferkorn all brand Gabbrielli Technologhy was used to measure plasticity, OHAUS branded digital scale 1500 g capacity adventurer sensitivity 0.01 g, thermobalance Ohaus MB45 and sensitivity 0.0001 g, 152 H and gauge digital hydrometer Mitutoyo brand and sensitivity 0.01 g. In the Fig. 1, Fig. 2 the equipment used is shown.

Fig. 1. Equipment required for the research.

Fig. 2. Equipment required for the study of technological properties.

MethodsThe raw material for different characterization tests outlined above were preparded by the international standards ASTM D422, ASTM C323-56, ASTM C324-01, ASTM C325-81, NTC 4113-2, 4321-3 NTC, NTC 4321-4 and NTC 4321-6.

Sample preparation

The mousier content of the sample collected in situ by the sampling applying the NTC 4113-2 standard was determined, then the drying process was performed at 110 ¿C (±5 ¿C). After drying the sample, a manually pre-grinding was performed until a size of 10 mm was reached. It was then put into a hammer mill to a size not exceeding 2 mm, in order to obtain a homogeneous and uniform particle size. It was then sieved to 10 mesh ASTM (2.00 mm), with the ground sample four mixtures were made: PATTERN (Clay 100%), M5 (95% clay and 5% corundum), M10 (90% clay and 10% corundum) and M20 (80% clay and 20% corundum).

Test procedure

Once the mixture was prepared, the wet grinding for each was performed in order to obtain an industrial waste between 3% and 9%, the slurry was dried at 110 ¿C and the powder for pressing was prepared with a humidity of 5,7% (±0.1%). Table 1 shows the preparation data.

Table 1. Preparation data of the samples under study.

| Sample | Retained on sieve | Industrial waste | Humidity in pressing | Post-press expansion |

| (%) | (%) | (%) | (%) | |

| STANDARD | 4,87 | 3,95 | 5,61 | 0,492 |

| M5 | 10,80 | 4,30 | 5,66 | 0,486 |

| M10 | 15,40 | 6,10 | 5,71 | 0,463 |

| M20 | 25,90 | 9,00 | 5,74 | 0,460 |

Rectangular specimens 55 mm * 110 mm were made at a pressure of 26.17 bars equivalent to 240 Kg/cm2 of specific pressure at industrial level, the test pieces were dried in an oven at 110 ¿C for 6 hours, once the pieces were dried the shrinkage, loss of weight, bulk density and mechanical resistance to bending were determined. Table 2 shows the results observed.

Table 2. Drying data of the samples.

| Sample | Drying shrinkage | Weight loss | Dry bulk density | Mechanical resistance |

| % | % | G/cm3 | N/mm2 | |

| STANDARD | 0,208 | 5,180 | 1,857 | 1,544 |

| M5 | 0,263 | 4,890 | 1,946 | 1,561 |

| M10 | 0,323 | 3,177 | 1,965 | 1,984 |

| M20 | 0,278 | 10,499 | 2,038 | 1,769 |

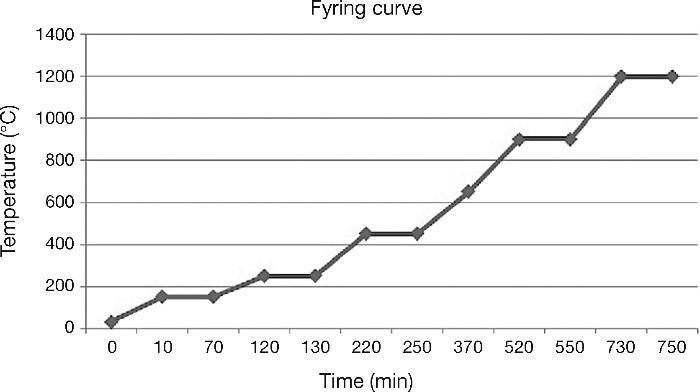

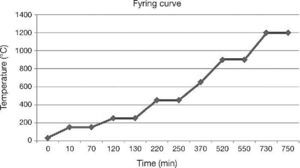

Baking was carried out at two final temperatures of 1200 ¿C and 1250 ¿C in a muffle furnace; the firing curve is shown in Fig. 3. When the material was sintered the shrinkage and bulk density were determined, in addition to the properties described in Section “Evaluation of the technological properties of the clay”.

Fig. 3. Fyring curve.

Methods used for the mineralogy identification of the clay sample.

• Chemical analysis. The chemical composition was determined by X-ray fluorescence (XRF) according to the ASTM C323-56 standard “Standard Test Methods for Chemical Analysis of Ceramic Whiteware Clays”, obtaining the percentage of oxides present in the sample, this technique is normally used for this type of work.

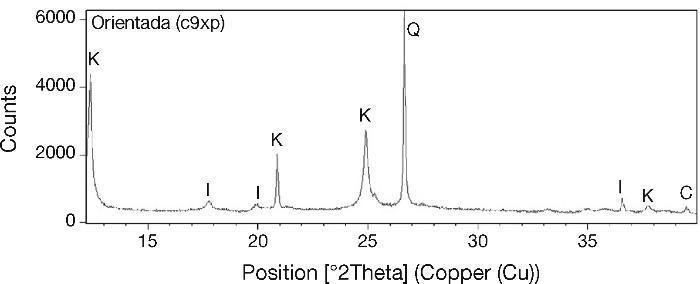

• X-ray diffraction. The mineralogical composition of the samples was performed by X-ray diffraction (XRD) in a brand powder diffractometer Bruker D8 Advance model under working conditions of 0-40 degrees 2θ. The diffractogram from the natural oriented sample was obtained.

Physical measurements of the clay sample.

• Retained on sieve. The clay/quartz ratio was determined in the sample of 200 g on a dry basis, this method (ASTM C325-81 “Standard Test Method for Wet Sieve Analysis of Ceramic Whiteware Clays”) was performed by washing the material on ASTM 230 mesh (63 microns).

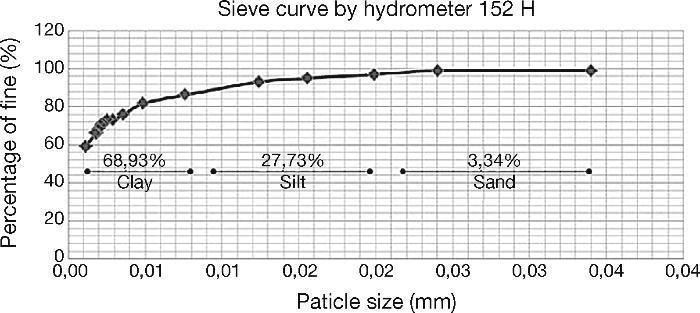

• Sieve analysis by hydrometer 152 H. Analysis of textural fractions was performed by the technique of hydrometer 152 H (ASTM D422 “Standard Test Method for Particle-Size Analysis of Soils”).

• Plasticity. The study of this property was performed by the Pfefferkorn method.

Evaluation of the technological properties of the clay

• Contraction in firing. Was determined by the ASTM C326 – 03 standard “Standard Test Method for Drying and Firing Shrinkages of Ceramic Whiteware Clays”.

• Bulk density. Determined by the dimensional method.

• Water absorption. Was determined by the method according to the NTC boiling 4321-3 standard “Determination of water absorption, apparent porosity, apparent relative density and bulk density”.

• Mechanical resistance to flexion. The study of this property has been determined by the NTC 4321-4 “Determination of modulus of rupture and breaking strength”.

• Resistance to deep abrasion. The study of this property has been determined by the NTC 4321-6 standard “Determination of resistance to deep abrasion for unglazed tiles”.

According to the results of chemical analysis, which are shown in Table 3, the K2O content of this sample is 1.63%, a fact that suggests the existence of micaceous minerals in relatively high proportions, however, the existence of other laminar minerals cannot be ruled out. The low proportion of CaO whose value are at 0.22% and 0.75% MgO, indicate that the material will form the glassy phase at high temperatures and may generate a property of semirefractories, these oxides are in the form of carbonates and because they are in very small proportions, they do not generate high porosity in the item2.

Table 3. Chemical composition of the clay (FRX).

| Composition | ||

| Formula | Name | Mass % |

| SiO2 | Silicon oxide | 64,87 |

| Al2O3 | Aluminum oxide | 20,56 |

| Fe2O3 | Iron oxide | 4,75 |

| Na2O | Sodium oxide | 0,15 |

| K2O | Potassium oxide | 1,63 |

| CaO | Calcium oxide | 0,22 |

| MgO | Magnesium oxide | 0,75 |

| SO3 | Trioxide sulphur | 0,04 |

| Loss of ignition | 0,99 | |

| Unrated | 6,04 | |

| Total | 100,00 | |

| Molar ratio (SiO2/Al2O3) | 5,40 | |

On the other hand, the results of the chemical analysis with the ones from the X-ray diffraction indicate that the existing carbonate in the sample is calcite. Meanwhile, the proportion of Al2O3, more than 20% and SiO2, worth 64.87%, suggest the existence of one or more laminar minerals and the free quartz in varying proportions, plus a dimensional control stable, high refractoriness and decreased breakage of firing3. The high content of Fe2O3, a value of 4.75% allows to foresee the presence of free iron oxides and red coloration in the final product. As it is seen, the values of the SiO2/Al2O3 molar ratio are within 5.40; foreseeing a high cation exchange capacity (CEC) and an increase in binding energy between the particles. Finally, the loss on ignition is low due to the low presence of carbonates4.

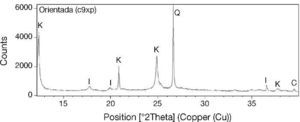

As shown in Fig. 4, the X-ray diagram of clay obtained in the oriented sample presents kaolinitic minerals, mica minerals, mainly illite and quartz diffractions some calcite weak5; first, the diffraction characteristics of the kaolinitic minerals are present in the diffractogram 7.14; 4.24; 3.57; 2.38 Å; There are also diffractions illite: 4.97; 4.47; 2.45 Å, quartz: 3.34 Å and 2.28 Å calcite. Diffraction analysis conducted was qualitative, since the importance of study was based primarily on the final properties of the mixture, but taking the data obtained in testing X-ray fluorescence and X-ray diffraction semiquantitative calculations were performed with the to take approximate weight percentages of each crystal structure and know what we faced during the investigation19, 20; these data were approximately 41% quartz, 36% kaolinite, 16% illite, calcite remaining 5% and 2% are possibly traces of other components which were not detected by the assay. All this leads to the inferring that the material in a high percentage is plastic and refractory by the predominance of structures such as kaolinite and illite.

Fig. 4. X-ray diffractograms of the clay (DRX).

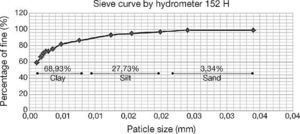

Physical studyThe values of the index of plasticity, studied by the method of Pfefferkorn, showed a value of 28.30%; plasticity of this sample therefore reaches a high value according to their mineralogy and grain size constitution6; as detailed in the results of sieve analysis (Fig. 5), which indicate that in general this is a silty clay sample with abundant fraction less than 2 μm and low percentage of particles larger than 2 mm (3.34%). Grain size is therefore suitable for all kinds of ceramic uses. Therefore this material was chosen for this study, considering its excellent mineralogical, chemical and physical properties, the material was suitable for different mixtures analysing its technological behaviour aiming to give it another use to the contaminant residue corundum remaining after the deep abrasion test according to the EN 4321-6 NTC standard.

Fig. 5. Grain size distribution of the clay.

Technological studiesAccording to the analyses of the sample, it is observed that the determination of the drying shrinkage of the samples showed the following values: 0.208, 0.263, 0.323 and 0.278% for the pattern, M5, M10 and M20 respectively, showing that the best performance was recorded for the pure clay sample. This is due to its mineralogical constitution and low granulometry after wet milling, as it can be detailed in the industrial waste percentage, which is 3.95%.

In reference to other features (Table 2), such as the post-pressing, the best performances comes from the M20 sample with 0.460%, indicating that it will generate less stress at the time of removal of the product from the socket Press . The dry strength ranges between 1,544 and 1,984 N/mm2, with the M10 performing the best, even when the best densification registered is from the M20 sample with 2.038 g/cm3, this is because the material is evenly compact7.

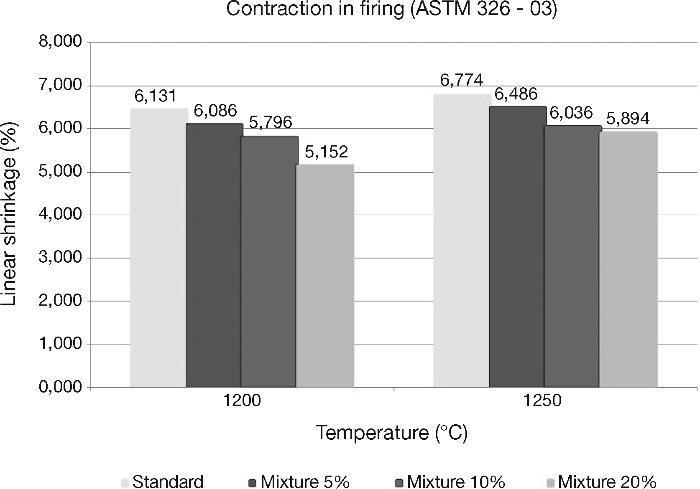

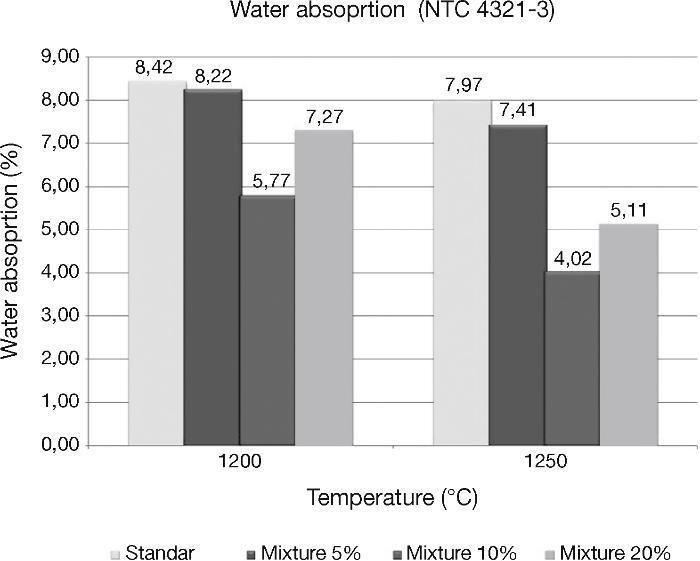

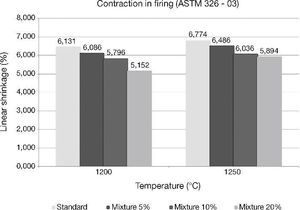

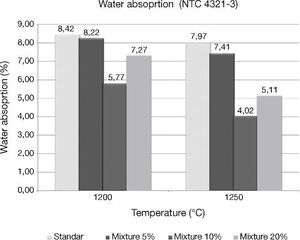

The shrinking suffered after the cooking (Fig. 6) is generally moderate and decreases as the percentage of clay corundum is increased, indicating that this percentage is controlled and reduced, helping to reduce cracks and pyroplastic deformation in the material7. In general, it is lower for the samples M10 and M20, which are the ones containing more of corundum. In Fig. 7, the results of the determination of water absorption of the samples under study are shown; these vary between 5.77 and 8.42% when cooked at 1200 ¿C and between 4.02 and 7.97% when cooked at 1250 ¿C.

Fig. 6. Contraction in firing.

Fig. 7. Water absortion determination using the boiling method (NTC 4321-3).

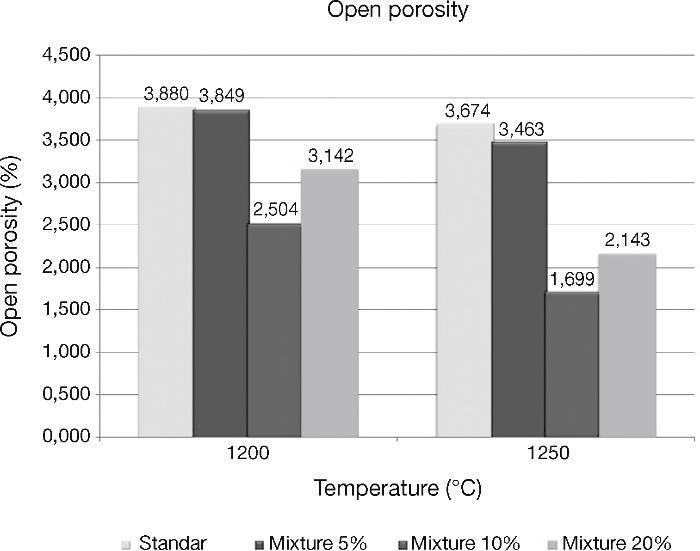

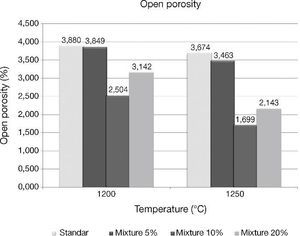

For the two firing temperatures there is only one capacity, relatively high, of water absorption for the standard sample, suggesting that when the corundum is added to the clay the material raises generate more glassy phase propagation reducing pores within their structure, as seen in the Fig. 8.8, 9 According to these results, and considering that the lower the water absorption is best mechanical performance of the product is achieved, the M10 is the lower porosity shown in the two firing temperatures used.

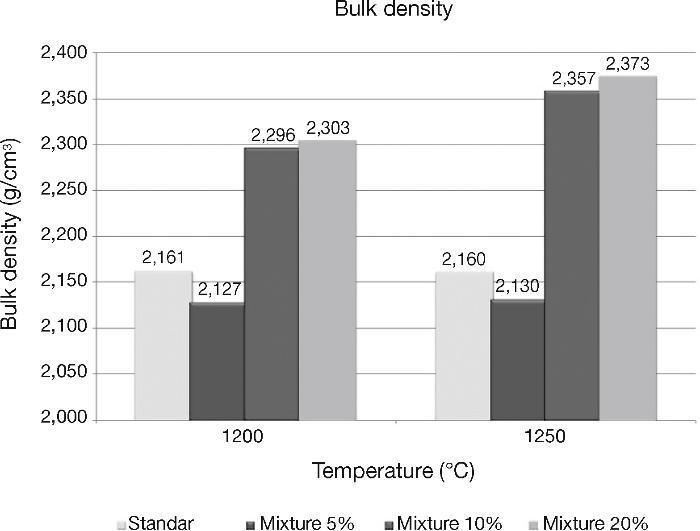

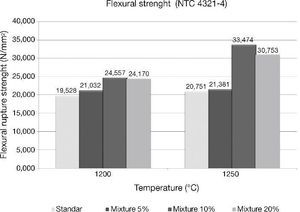

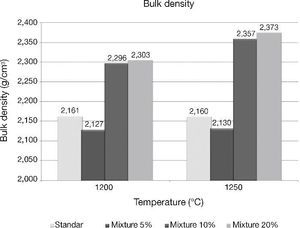

Fig. 8. Open porosity.

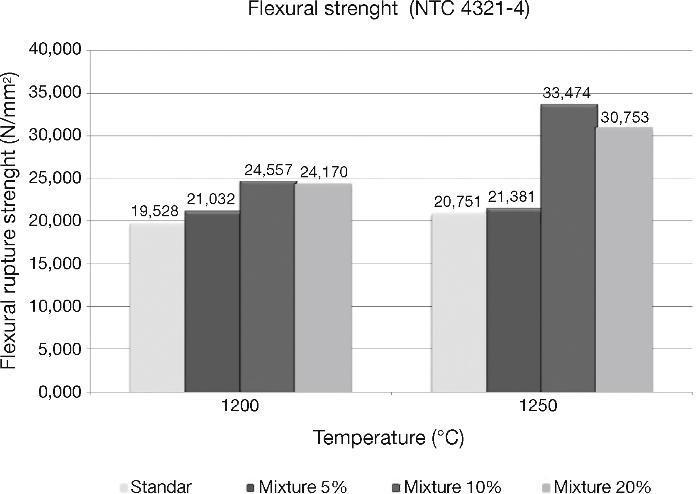

Fig. 9 shows that the flexural strength displayed by these samples according to cooking temperatures, is higher in the M10 for the two temperatures. This can be explained considering that being the corundum a silicoaluminous structure with predominance of Al2O3, it offers the ceramic microstructure an increase in their physical, mechanical and refractory properties, all with their relatively high content of kaolinite in the clay, to lower water absorption capacity and high densification of 2.296 g/cm3 and 2.357 g/cm3 to 1200 ¿C and 1250 ¿C respectively Fig. 10, gives excellent qualities for any ceramic product to be used in any industrial area10.

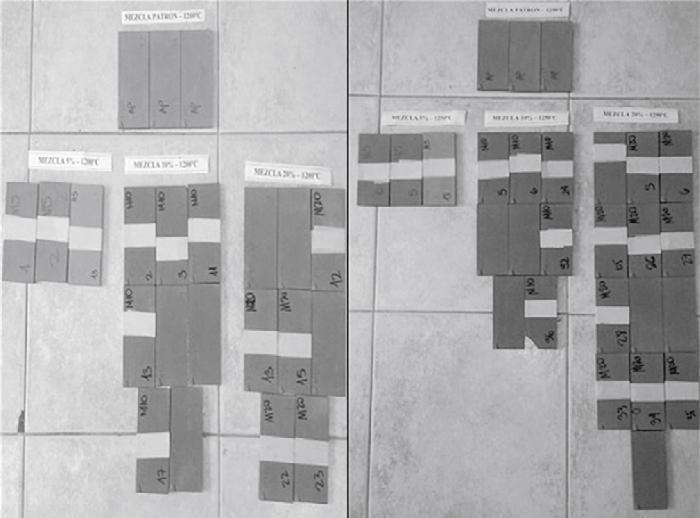

Fig. 9. Sintered specimens to 1200 °C and 1250 °C.

Fig. 10. Flexural strength (NTC 4321-4).

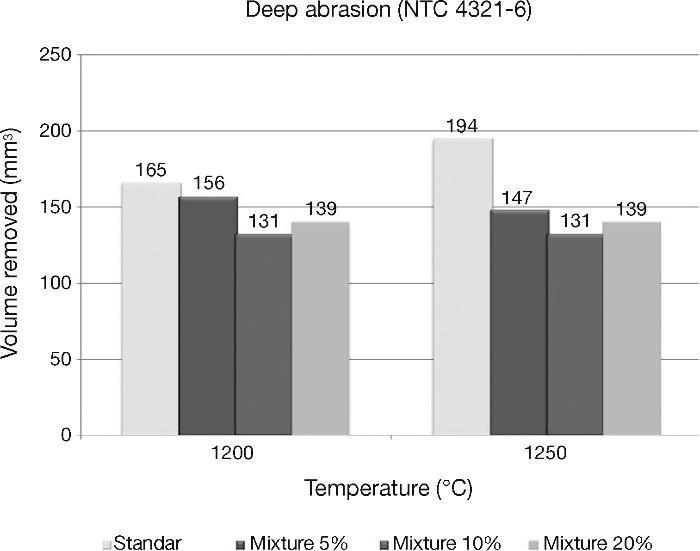

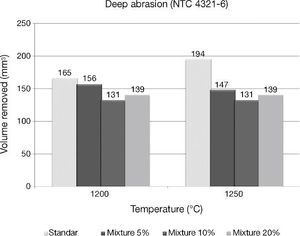

With the data obtained in Fig. 11, related to deep abrasion, it is shown that the material with corundum compared to pure clay undergoes less wear, which allows products to be used in any environment that generates environmental or physical degradation, which helps the material to be used not only for the production of construction but also in any industrial area where the abrasive environment is strong11, 12, 13, 14.

Fig. 11. Bulk density.

As shown in Fig. 12, almost all clays tested here gave pieces with quite dark shades, according to its high content of free iron oxides and high temperature cooking. Only the M5 and the pattern are those with less corundum and offer a little lighter products.

Fig. 12. Deep abrasion determination (NTC 4321-6).

The final results of technological tests conducted here allows some final considerations. According to their mineralogical constitution the clay is highly plastic, with contractions in cooking and high water absorption, mechanical strength for both, raw and low cooked, however, when mixing it with corundum these properties are improved, and ensure they do not suffer pyroplastic deformation synthetizing them above 1200 ¿C. Among these samples, most can be use in the manufacture not only of bricks, blocks, tiles but also for other products requiring high resistance temperatures and abrasive environments, without generating any damage to them15, 16, 17, 18.

ConclusionsThe worked clay is a complex mixture of minerals. Among laminar minerals, the kaolinite and illite dominate, micaceous minerals exist in a portion of about 15.93% and the kaolinitic minerals reach a value of 36.13%. These minerals are accompanied by quartz, carbonates and iron oxides.

The crystal structure from the carbonate is calcite and from the iron oxide is goethite as seen in the diffractogram, with weight percentages of 0.40% and 5.33% respectively. The free quartz is present in an amount of 40.85%.

The clay studied here is appropriate for the manufacture of baked clay, as shown by its size distribution and mineralogical constitution but should be placed attention and care to its plasticity considering that because of its high value generates a contraction in cooking which may cause excessive dimensional problems in the pieces and cracking. This problem can be minimise with the addition of corundum to the clay material.

Pure clay (pattern) has the highest water absorption and linear shrinkage of all the samples investigated at any temperature due to its low bulk density and high dry weight loss during the cooking phase.

Corundum, when added to the clay (raw material) shows that the changes are significant, because it remarkably decreases in linear shrinkage, water absorption and wear abrasion material; improving mechanical properties such as flexural strength on cooking. This behaviour is associated with the sintering mechanism generated by the corundum in the microstructure of the material, promoting better densification and reduction of porosity.

Even when the results of deep abrasion allow the classification of materials, they do not allow conclusions about their durability, it can be seen that, when the corundum is added to the clay material, the same improves wear resistance, increasing the chances that any clay material can be used in any industrial area if mixing properties are improved with this residue.

All M5, M10 and M20 are good raw materials for the manufacture of products based on clays or any product in which high resistance conditions abrasives are needed; but of the three samples investigated, the best performances recorded was for M10 which obtained the best results in reference to their technological properties such as water absorption, mechanical bending and deep abrasion resistance.

The use of corundum in clay materials generates improved material characteristics, becoming a good alternative to enhance or modify the technological properties thereof and, at the same time, a better use can be given to this wastage which generated pollution to the environment.

Acknowledgements

The authors express their gratitude to the Center for Ceramic Materials Research CIMAC of the Francisco de Paula Santander University, Cúcuta-Colombia, for their support conducting the tests.

Received 26 January 2015

Accepted 7 March 2015

Corresponding author. leoceli1406@hotmail.com