Bacteria are important sources of cellulases with various industrial and biotechnological applications. In view of this, a non-hemolytic bacterial strain, tolerant to various environmental pollutants (heavy metals and organic solvents), showing high cellulolytic index (7.89) was isolated from cattle shed soil and identified as Bacillus sp. SV1 (99.27% pairwise similarity with Bacillus korlensis). Extracellular cellulases showed the presence of endoglucanase, total cellulase and β-glucosidase activities. Cellulase production was induced in presence of cellulose (3.3 times CMCase, 2.9 times FPase and 2.1 times β-glucosidase), and enhanced (115.1% CMCase) by low-cost corn steep solids. An in silico investigation of endoglucanase (EC 3.2.1.4) protein sequences of three Bacillus spp. as query, revealed their similarities with members of nine bacterial phyla and to Eukaryota (represented by Arthropoda and Nematoda), and also highlighted of a convergent and divergent evolution from other enzymes of different substrate [(1,3)-linked beta-d-glucans, xylan and chitosan] specificities. Characteristic conserved signature indels were observed among members of Actinobacteria (7 aa insert) and Firmicutes (9 aa insert) that served as a potential tool in support of their relatedness in phylogenetic trees.

Glycoside hydrolases or glycosidases are enzymes that hydrolyze O-, N- and S-linked glycosides, which have diverse industrial applications. Cellulases are glycoside hydrolases that hydrolyze O-linked glycosides, i.e. the β-1,4-glycosidic bonds between two glucose residues of cellobiose units in cellulose. They form a synergistically functioning enzyme system, that chiefly consist of endoglucanase (EC 3.2.1.4), exoglucanase/cellobiohydrolase (EC 3.2.1.176/EC 3.2.1.91) and beta-glucosidase (EC 3.2.1.21). Cellulases have important industrial applications in textile processing, as detergent components, as part of macerating enzymes in food processing, in production of animal feed, for removing bacterial biofilms, and more recently in biorefinery for production of value-added chemicals and biofuels from renewable biomass feedstocks.1,2 Majority of the cellulases are commonly obtained from fungi, but bacteria are considered important because of their high growth rate, production of effective complex enzymes and ease of genetic engineering for enhancing enzyme production.3 Among various sources, an excellent cellulolytic environment is the cattle rumen which contains a very dense and complex mixture of cellulolytic bacteria (in majority), fungi and protozoa.4 The bacterial species able to utilize crystalline cellulose are known frequently from the phyla Firmicutes, Actinobacteria and Proteobacteria.5 Within Firmicutes, most species of Bacillus are known to be endoglucanase producers, in that, they are able to hydrolyze amorphous forms of cellulose like carboxymethyl cellulose. However, relatively only few strains of Bacillus are known to utilize crystalline forms of cellulose and produce multiple cellulase enzymes.3,6,7

In addition to the use in industrial fermentations, the prefatory potential of such microorganisms in other areas like bioremediation could also be studied for their multiple applications. Organic solvents are often used in the manufacture of pharmaceutical products, paints, varnishes and adhesives, and they cause significant air and water pollution, and land contamination.8 Microorganisms that are tolerant to the destructive effects of solvents have been explored for their potential in industrial and environmental biotechnology to carry out bioremediation and biocatalytic processes.9 Moreover, pollution due to the heavy metals from mining and industrial wastes, vehicle emissions and fertilizers have negative consequences on the hydrosphere, and one of the best procedures considered in removing the toxic metals from the environment is using metal tolerant bacteria.10,11 Thus, it is required to find microorganisms that apart from being representatives for production of a number of economic products i.e. enzymes, are also capable of tolerating environmental pollutants.12

Conserved signature indels (CSIs) in protein sequences, characterized by their defined size and being flanked on both sides by conserved regions, are rare and specific genetic changes that provide useful phylogenetic markers for understanding evolutionary relationships among different organisms.13 Presently, relationship of cellulolytic bacteria among different phyla is not well known. One way of establishing this is by studying protein sequences among various organisms, which can indicate specific patterns occurring in a particular or several group of species. CSIs specific for different lineages can provide definitive means of differentiation of organisms of these groups, while those shared among different taxa enable the determination of phylogenetic relationships based on multiple protein sequences.14

Thus, in the present study a cellulase producing bacterial strain of Bacillus sp. SV1 was isolated from a cattle shed soil. Its tolerance to different environmental pollutants including toxic heavy metals and organic solvents was checked. Factors effecting cellulase production, different cellulose substrate hydrolyzing capacity of the extracellular cellulase and cellulase gene detection were studied. Cellulase sequences from three species of Bacillus were used as query to analyze phylogenetic relationships and occurrence of CSIs among different taxa.

Materials and methodsChemicalsChemical reagents of analytical grade were obtained from Sigma–Aldrich (St. Louis, MO, USA), Hi-Media laboratories (Mumbai, India) and Fisher Scientific (Mumbai, India).

Isolation of cellulolytic bacteriumSoil sample was collected in sterile vials from a cattle shed (located in Sonia Vihar, New Delhi – 28.70743° N and 77.25993° E) and stored at 4°C. One gram soil was suspended in 50mL of sterilized liquid medium IV (pH 7.0) containing (g/L): NaNO3 – 1; K2HPO4 – 1; KCl – 1; MgSO4 – 0.5; yeast extract – 0.5; sodium carboxymethylcellulose (Na-CMC, 1500–3000cP) – 10.15 Actidione (100ppm) was included to prevent fungal growth. Enrichment of cellulolytic bacteria was done at 37°C and 180rpm in an incubator shaker (Kuhner LT-X) for 48h. This suspension after serial dilution in 0.87% (w/v) NaCl solution was spread (100μL) on nutrient agar (NA) (g/L: peptone, 5; sodium chloride, 5; beef extract, 1.5; yeast extract, 1.5; agar, 15) plates and incubated at 37°C for 48h, from which ten discreet colonies were selected and purified on NA. Each of the ten isolates were then point inoculated on solid medium IV (pH 7.0) containing (g/L): NaNO3, 1; K2HPO4, 1; KCl, 1; MgSO4, 0.5; yeast extract, 0.5; sodium carboxymethylcellulose (Na-CMC, 1500–3000cP), 10; agar, 16, and incubated at 37°C for 48h, followed by Congo red (1mg/mL) staining–NaCl (1M) de-staining and measurement of cellulolytic index (CI) (ratio of the diameter of the clearing zone around the colony to the diameter of colony).16 Hemolytic behaviors of the isolates were examined by streaking them on sterile sheep blood agar plates and incubating at 37°C for 24h.17 Out of ten, one isolate, designated as SV1, was selected for further study based on CI and non-hemolytic nature.

Characterization and phylogeny of the cellulolytic isolateMorphological, physiological and biochemical characters for the isolate SV1 were studied. Genomic DNA was extracted using a Fermentas GeneJET genomic DNA purification kit. The universal primer pair, 27f (5′-AGAGTTTGATCCTGGCTCAG-3′) and 1492r (5′-GGTTACCTTGTTACGACTT-3′) was used to amplify 16S rRNA gene.18 PCR parameters adopted were: initial denaturation at 94°C (3min), followed by 30 cycles of denaturation at 94°C (30s), annealing at 55°C (30s) and extension at 72°C (2.5min), with the final extension at 72°C (6min). Amplified region was sequenced with an Applied Biosystems (ABI) Prism 310 Genetic Analyzer. The obtained sequence was used to blast in the EzTaxon-e server, followed by multiple sequence alignment of the retrieved closest neighbors reference sequences.19 Based on lowest calculated Bayesian information criterion scores, Kimura 2-parameter model was used for constructing a maximum likelihood phylogenetic tree (with the bootstrap test of 1000 replicates).20 The non-uniformity of evolutionary rates among sites were modeled using a discrete gamma distribution (+G) with 5 rate categories and by assuming that a certain fraction of sites are evolutionarily invariable (+I). All evolutionary analyses were conducted in MEGA6.21

The 16S rRNA gene sequence was submitted to the GenBank database using the BankIt submission tool, and the obtained accession number is KJ024372.

Antibiotic susceptibility patternThe susceptibility of the isolate SV1 to various antibiotics was tested using the standard disc diffusion method.12 Bacterial culture (0.1mL of 1.5 OD600) in nutrient broth (NB) (g/L: peptone, 5; sodium chloride, 5; beef extract, 1.5; yeast extract, 1.5) was spread on NA plates, and then single antibiotic discs were placed on the surface, followed by incubation at 37°C for 24h. The antibiotics used were (μg/disc or units/disc) were: Streptomycin (10), Ciprofloxacin (5), Erythromycin (10), Ofloxacin (5), Norfloxacin (10), Ampicillin (10), Carbenicillin (100), Penicillin-G (2units/disc), Tetracycline (10), Cefazolin (30), Cefaclor (30), Cefotaxime/Cephotaxime (30), Amikacin (30), Cefuroxime (30), Chloramphenicol (30), Rifampicin (30), Ceftriaxone (30), Gentamicin (10), Kanamycin (5) and Ceftazidime (30). The diameters of growth inhibition zones inclusive of the diameter of discs were measured, and categorized as susceptible (≥21mm), intermediate (16–20mm) or resistant (≤15mm).12

Tolerance against environmental pollutantsHeavy metal tolerance of the isolate SV1 by measurement of minimum inhibitory concentration (MIC), was determined by growing bacteria on NA plates incorporated with different heavy metals (μg/mL), followed by incubation at 37°C for 24h.12 The heavy metal ions (salts, μg/mL) used were: Pb2+ (lead nitrate, 0–500), Cu2+ (cupric sulphate, 0–200), Hg2+ (mercuric chloride, 0–100), Cr3+ (chromium chloride hexahydrate, 0–600), Zn2+ (zinc chloride, 0–200), Co2+ (cobaltous chloride hexahydrate, 0–200) and Ni2+ (nickel (II) chloride, hexahydrate, 0–300).

The tolerance of the isolate SV1 to organic solvents of different logPow was also examined. Bacterial growth was monitored in NB containing different solvents (10%, v/v) at 37°C, 180rpm for 48h.22 The organic solvents used were methanol, ethanol, acetone, n-propanol, isopropanol, ethyl acetate, butanol, benzene, chloroform, toluene, p-xylene, n-hexane, 1-decanol and isooctane. NB without any solvent was used as the control.

Preparation of inoculum and extracellular crude cellulaseIsolate SV1 was sub-cultured in NB at 30°C, 200rpm for 48h, and the obtained broth culture (OD600 about 1.5) was used as inoculum at 1% (v/v) in all fermentation runs, carried out in 250-mL Erlenmeyer flasks. After fermentation, culture aliquots (1–2mL) were centrifuged at 5000×g for 15min at 4°C (Thermo Scientific, Heraeus FRESCO 21), and the obtained supernatant was used as crude cellulase.

Different media and physiological parameters effecting growth and cellulase productionThe effects of seven different media on cell growth and cellulase production at 37°C and 180rpm for 48h were estimated. The media (g/L) with initial pH 7.0 used were:

- I

(NH4)2SO4 – 1; K2HPO4 – 1; MgSO4 – 0.5; NaCl – 0.1; CMC – 10.23

- II

KH2PO4 – 4; Na2HPO4 – 4; tryptone – 2; MgSO4 – 0.2; CaCl2 – 0.001; FeSO4·7H2O – 0.001; CMC – 10.24

- III

Yeast extract – 2.5; K2HPO4, NaCl – 1; MgSO4 – 0.2; (NH4)2SO4 – 0.6; CMC – 10.25

- IV

NaNO3 – 1; K2HPO4 – 1; KCl – 1; MgSO4 – 0.5; yeast extract – 0.5; CMC – 10.15

- V

MgSO4 – 0.2; K2HPO4 – 1; KH2PO4 – 1; NH4NO3 – 1; FeCl3·7H2O – 0.05; CaCl2 – 0.02; CMC – 10.26

- VI

(NH4)2SO4 – 1; KH2PO4 – 3; MgSO4 – 0.1; K2HPO4 – 7; trisodium citrate – 0.5; yeast extract – 0.2; CMC – 10.27

- VII

Yeast extract – 7; KH2PO4 – 4; Na2HPO4 – 4; MgSO4 – 0.2; CaCl2 – 0.001; FeSO4·7H2O – 0.004; CMC – 10.28

The optimization of physiological conditions, including pH (6.0–9.5), temperature (25–40°C) and agitation rate (0–250rpm) on bacterial growth and production of cellulases was then investigated through the one-factor-at-a-time (OFAT) approach in medium VII.

Estimation of inducible nature of cellulase synthesisInducible nature of cellulase synthesis was investigated in medium VII (initial pH 7.5, at 30°C, 200rpm, 48h): (a) in the absence/presence of CMC, (b) by replacing CMC with other carbon sources (monosaccharides, disaccharides, polysaccharides and sugar alcohols), and (c) by supplementing CMC with other carbon sources (monosaccharides, disaccharides, polysaccharides and sugar alcohols) as co-substrates.15

Various nutritional factors effecting bacterial growth and cellulase productionEffects of different organic nitrogen (casein hydrolysate broth, corn steep solid, beef extract, tryptone, peptone, glycine and bacto casamino acids) sources at 0.7% (w/v) in place of yeast extract, and of different concentrations of CaCl2 (fused, 0–5g/L) and FeSO4·7H2O (0–2.9g/L), on bacterial growth and cellulase production in medium VII were studied at initial pH 7.5, 30°C and 200rpm for 48h.

Analytical methods and statistical analysisCellulases (CELs) were assayed using the following substrates, (a) for CMCase/endoglucanase activity: 1.8mL of 1% (w/v) Na-CMC prepared in phosphate buffer (0.05M, pH 7), (b) for FPase/total cellulase activity: Whatman grade 1 filter paper strip (1×3cm) in 1.8mL phosphate buffer (0.05M, pH 7), and (c) for β-glucosidase activity: 2mL of 0.15g/L pNPG (p-nitrophenyl-β-d-glucopyranoside) in phosphate buffer (0.05M, pH 7). For reaction, 0.2mL of crude cellulase (replaced by phosphate buffer in control) was mixed with substrates and incubated at 40°C for 1h. The reducing sugars (glucose equivalent) for CMCase and FPase activities were estimated at 575nm, using 3mL of freshly prepared dinitrosalicylic acid reagent (g/100mL: sodium hydroxide – 1; dinitrosalicylic acid – 1; crystalline phenol – 0.2; sodium sulfite – 0.05), followed by keeping in a boiling water bath for 15min, and then adding 1mL of 40% (w/v) solution of potassium sodium tartarate (Rochelle salt) prior to cooling.29 For β-glucosidase activity, the reaction was terminated by 1M Na2CO3 solution (2mL) and p-nitrophenol released was estimated at 400nm in a UV–visible spectrophotometer (Shimadzu 250 1 PC, version 2.33).30 One unit of CELs activity was expressed as 1μM of glucose (for CMCase and FPase) and p-nitrophenol (for β-glucosidase) liberated per mL crude cellulase per minute. The formula used for calculating the activities of CELs is

where μM of glucose/p-nitrophenol released is obtained from the standard curve, total assay volume is 2mL (CMCase and FPase activities)/2.2mL (β-glucosidase activity), volume of crude cellulase used is 0.2mL, volume in cuvette is 1mL and incubation time is 60min.All experiments were performed in triplicate, and values are presented as the mean±standard error of the mean (SEM). The statistical analysis of data by one-way ANOVA, followed by Duncan's multiple-comparison test (p<0.05) was done using the SPSS 16.0 software (SPSS Inc., Chicago, IL, USA).

Detection of cellulase geneTwo pair of primers were used, pair 1: BsFw (forward primer: 5′-GGAATTCCATATGAAACGGTCAATCTC-3′) and BsRv (reverse primer: 5′-TGCGGCCGCCTAATTTGGTTCTGTTCCC-3),31 and pair 2: CelBF (forward primer: 5′-CCATGGATCATGAGGATGTGAAAACTC-3′) and CelBR (reverse primer: 5′-CTCGAGTGAATTGGTTGTCTGAGCTG-3′).32 The PCR reactions were carried out in a final volume of 25μL containing genomic DNA (2μL), 10× NH4 buffer (2.5μL), 50mM MgCl2 (2μL), 10mM dNTPs (1μL), 10mM of each forward/reverse primer (1μL each), 10U taq DNA polymerase (0.3μL) and sterile double distilled water (15.2μL). PCR amplifications were performed with the following parameters: initial denaturation at 94°C (3min), followed by 30 cycles of denaturation at 94°C (30s), annealing at 52.7°C (30s) and extension at 72°C (2min), with the final extension at 72°C (7min). The PCR products were loaded and run on 1.0% agarose gels.

In silico investigation of the evolutionary divergence in endoglucanase of Bacillus spp.The protein sequence of endoglucanase component (EC 3.2.1.4) of cellulases from three species of Bacillus: Bacillus agaradhaerens (UniProt accession – O85465, 400 aa), Bacillus cellulolyticus (UniProt accession – E6TWN7, 488 aa) and Bacillus subtilis (UniProt accession – P07983, 499 aa) was taken as query. Each sequence was used to blast in the UniProtKB database, with default parameters of E-Threshold value (0.01), matrix (auto), filtering (none), gapped (yes) and hits (500).33 The obtained 500 protein reference sequences from each blast were retrieved in FASTA format, from which fragmented, hypothetical, redundant and uncharacterized sequences were deleted, while the remaining reference sequences were then aligned by MUSCLE using MEGA6. Within the alignment, presence of conserved signature indels (CSIs) that were surrounded by conserved regions were studied. The neighbor-joining phylogenetic trees with 1000 bootstrap replications were constructed by computing the evolutionary distances using the Poisson correction method,34 corroborated by the Jones–Taylor–Thornton (JTT) matrix-based model, and were in the units of number of amino acid substitutions per site.35 The rate variation among sites was modeled with a gamma distribution (shape parameter=1) for the JTT model. Further, complete deletion of gaps, homogeneous pattern among lineages and uniform rates among sites were used. The propensity (total frequencies of occurrence) of amino acids was calculated among the references in MEGA6.

ResultsCellulolytic bacterial characterization and phylogenetic analysisThe isolated strain SV1 showed a very high cellulolytic index (CI) of 7.89 on the plate assay (Supplementary Fig. 1). It also showed non-hemolytic pattern on the sheep blood agar plate (Supplementary Fig. 2). The morphological, physiological and biochemical characters were studied for the strain SV1, which have been given in Supplementary Table 1.

The obtained 16S rRNA gene sequence (1375bp) of strain SV1 in the EzTaxon-e blast gave maximum pairwise similarities with Bacillus spp., including Bacillus korlensis (99.27%), Bacillus beringensis (98.61%), Bacillus kyonggiensis (97.58%), Bacillus circulans (96.85%), Bacillus nealsonii (96.78%), Bacillus firmus (96.72%) and Bacillus eiseniae (96.63%). In the maximum likelihood phylogenetic tree, strain SV1 formed a monophyletic group with B. korlensis and B. beringensis (Supplementary Fig. 3). The estimated major fatty acid components of strain SV1 were iso-C15:0 (34.02%), C16:1 ω11c (18.11%) and anteiso-C15:0 (11.80%), which was close to its nearest neighbor B. korlensis (Supplementary Table 2). Hence, based on these results, strain SV1 was designated as Bacillus sp. SV1.

From the two primer pair of cellulase gene, pair 1 (BsFw and BsRv) was able to detect the presence of cellulase gene of about 1000bp in Bacillus sp. SV1 (Supplementary Fig. 4).

Antibiotic susceptibility pattern and tolerances to heavy metals and organic solventsStrain SV1 was susceptible to all the antibiotics tested and showed an intermediate resistance against ceftazidime (Supplementary Table 1). It showed tolerance to multiple heavy metal ions, as inferred from bacterial growth. The minimum inhibitory concentration (MIC) of heavy metals (μg/mL) was: Pb2+ (100), Cu2+ (100), Hg2+ (50), Cr3+ (400), Zn2+ (50), Co2+ (150) and Ni2+ (200). It also showed high tolerance against the organic solvents which had logPow >2.0 including isooctane, n-hexane, benzene and p-xylene (Table 1).

The tolerance of the cellulolytic strain SV1 to organic solvents of different logPow values.

| Organic solvent | LogPowa | Growth (O.D. at 600nm)b |

|---|---|---|

| Control | – | 0.31±0.11 |

| Methanol | −0.77 | 0.01±0.00 |

| Ethanol | −0.58 | 0.01±0.00 |

| Acetone | −0.23 | 0.01±0.00 |

| n-Propanol | 0.25 | 0.01±0.00 |

| Isopropanol | 0.26 | 0.01±0.00 |

| Ethyl acetate | 0.73 | 0.01±0.00 |

| Butanol | 0.88 | 0.02±0.00 |

| Benzene | 2.13 | 0.39±0.00 |

| Chloroform | 2.24 | 0.02±0.00 |

| Toluene | 2.73 | 0.01±0.00 |

| p-Xylene | 3.1 | 0.18±0.01 |

| n-Hexane | 3.5 | 0.76±0.11 |

| 1-Decanol | 4.1 | 0.05±0.01 |

| Isooctane | 4.7 | 0.61±0.03 |

SEM, Standard error of the mean.

The varied effects of different media on bacterial growth and cellulase production are shown in Supplementary Fig. 5. It was observed that medium VII supported maximum growth (of 3.6 times) and cellulase production (of 1.5 times CMCase, 1.1 times FPase and 1.6 times β-glucosidase) than the enrichment medium IV, respectively. However, in other media, both growth and cellulase production were very low. Maximum growth occurred at pH 7.0, 30°C and 100rpm, while maximum cellulase production occurred at pH 7.5, 30°C and 200rpm in medium VII (Supplementary Fig. 5b–d).

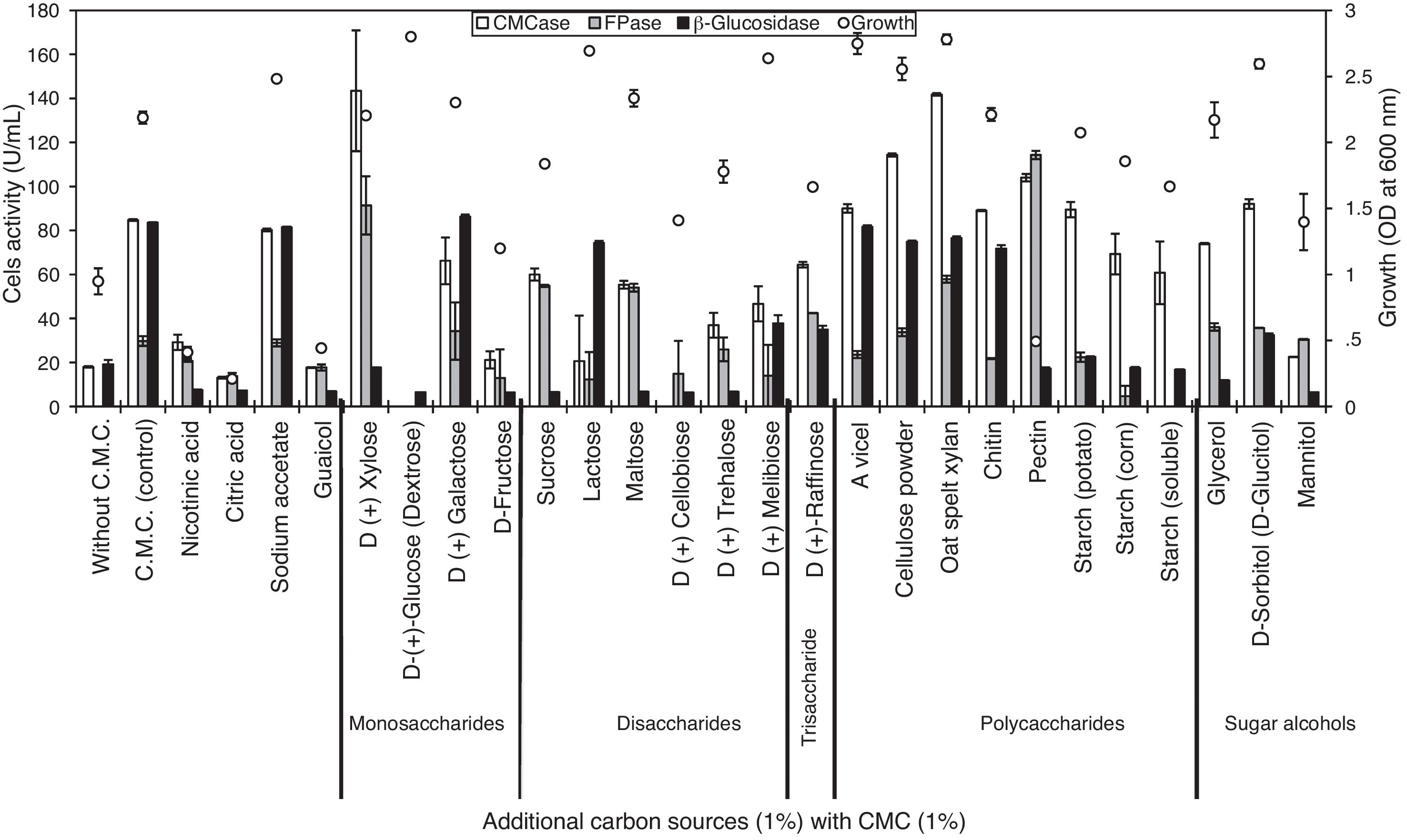

Inducible nature of cellulase synthesisCellulase production was higher in presence of CMC than in its absence (3.3 times CMCase, 2.9 times FPase and 2.1 times β-glucosidase) or replacement (Fig. 1). The observed pattern of cellulase production was different in conditions when CMC was replaced (Fig. 1) or used as co-substrate (Fig. 2) with different carbon sources. When CMC was replaced, raffinose, avicel and xylan promoted higher β-glucosidase production than CMCase; galactose completely suppressed CMCase and FPase productions (Fig. 1). Among co-substrates, xylose, xylan and pectin enhanced CMCase (1.7 times, 1.6 times and 1.2 times) and FPase (3.1 times, 1.9 times and 3.8 times) productions respectively, over the control containing only CMC (Fig. 2). However, nicotinic acid, citric acid, guaiacol, glucose, fructose and cellobiose as co-substrates were inhibitory. The presence of the co-substrates sodium acetate, chitin, starch (potato), glycerol and sorbitol did not significantly affect the CMCase production, while sodium acetate, galactose, lactose and chitin did not significantly affect the β-glucosidase production.

Effects of different additional carbon sources as co-substrates to CMC on cellulase production and bacterial growth of the cellulolytic Bacillus sp. SV1. All values are represented as mean of triplicate experiments±SEM, taken after 48h of bacterial culturing at 30°C, 200rpm in medium VII (initial pH 7.5).

Presence of an appropriate organic nitrogen source and of metals (CaCl2 and FeSO4·7H2O) was highly preferred for cellulase production, as was observed among different media. Hence, absence or presence of different organic nitrogen sources was investigated for their effects on cellulase production. Absence of organic nitrogen source (growth – 9.8%, CMCase – 10.8%, FPase – 18.8%, β-glucosidase – 9.8%) and presence of glycine (growth – 6.0%, CMCase – 11.0%, FPase – 0.0%, β-glucosidase – 9.7%) and bacto casamino acids (growth – 9.4%, CMCase – 5.9%, FPase – 38.1%, β-glucosidase – 10.5%) caused drastic decrease in both growth and cellulase production, than in the control containing yeast extract (Fig. 3A). In the presence of corn steep solids, growth (145.6%) and CMCase production (115.1%) was maximum, compared to the control. Presence of CaCl2 (up to 5mg/L) caused enhancement in β-glucosidase production (1.5 times) compared to its absence, while higher concentrations (>100mg/L) were inhibitory (Fig. 3B). The presence of FeSO4·7H2O (up to 36mg/L) was found to be essential for increasing productions of CMCase (of 1.5 times) and β-glucosidase (of 1.1 times) than its absence, whereas higher concentrations (>108mg/L) were inhibitory for both growth and cellulase production (Fig. 3C).

Effects of different organic nitrogen source (A), and concentrations of CaCl2 (B) and FeSO4·7H2O (C) on cellulase production and growth of Bacillus sp. SV1. All values are represented as mean of triplicate experiments±SEM, taken after 48h of bacterial culturing at 30°C, 200rpm in medium VII (initial pH 7.5). In (A), the production of cellulases is expressed as relative CELs activity, defined as the percentage of the activities observed with respect to the control (containing yeast extract).

The protein sequence blast of each Bacillus spp. cellulase query in the UniProtKB database included references that belonged to various taxa within the domain Bacteria and Eukaryota. Bacterial references belonged to phyla Proteobacteria, Bacteroidetes, Firmicutes, Actinobacteria, Spirochaete, Fibrobacteres, Ignavibacteriae, Planctomycetes and Verrucomicrobia. Eukaryota references included members of Arthropoda (Psacothea, Apriona, Anoplophora) and Nematoda (Ditylenchus, Heterodera, Radopholus, Aphelenchoides, Pratylenchus). Among the references, different enzymes including endo-1,3-beta-glucanase, endo-1,4-beta-xylanase and chitosanase were also present. The phylogenetic relationship of these references is indicated in the neighbor-joining trees for each query (Fig. 4; Supplementary Figs. 6 and 7). In all the three trees, similar taxa were found to be grouped together, and eukaryota references had a common ancestor with the members of the phylum Bacteroidetes.

Neighbor-joining phylogenetic tree of cellulase (endoglucanase) references of Bacillus cellulosilyticus based on the amino acid sequences. Highlighted regions include clade between endoglucanase of Bacteroides ovatus and xylanase of Bacteroides xylanisolvens, clade between endoglucanase and 1, 3-beta glucanase of Paenibacillus polymyxa, and a 7 amino acid (aa) insert shared among members of Actinobacteria and Niastella koreensis (of Bacteroidetes). Symbols and abbreviations: Firmicutes (open circle), Proteobacteria (closed square), Spirochaete (open triangle), Ignavibacteriae (Ign.), Planctomycete (Pla.), Bacteroidetes (closed circle), Verrucomicrobiae (Ver.), Eukaryota (closed triangle), Actinobacteria (open square), Fibrobacteres (Fib.). Bar, 0.1 substitutions per nucleotide position.

During alignment of references obtained from blast of the three Bacillus spp. cellulase queries (B. agaradhaerens, B. cellulolyticus and B. subtilis), characteristic taxon-specific conserved signature indels (CSIs) were observed. Among B. cellulolyticus references, a 7 aa long insert, specific to Actinobacteria and to one Bacteroidetes member Niastella koreensis was found (Fig. 5A). N. koreensis also branched within the monophyletic group of Actinobacteria members (Fig. 4). Further, among B. subtilis references, an 8 aa long insert specific only to Actinobacteria members (Fig. 5B) and an 8 aa (Fig. 6A) and a 9 aa (Fig. 6B) long inserts specific to certain members of Firmicutes (species of Caldicellulosiruptor, Caldanaerobacter and Clostridium) were observed. A similar 9 aa long insert shared among these three members of Firmicutes was also observed in B. agaradhaerens references (Supplementary Table 3). Even in the phylogenetic trees, species of Caldicellulosiruptor, Caldanaerobacter and Clostridium formed monophyletic grouping (Supplementary Figs. 6 and 7). CSIs both specific to and shared among the members of Actinobacteria and Firmicutes were found within the references of B. agaradhaerens and B. subtilis cellulase queries (Supplementary Table 3).

Among the different amino acid residues, propensity of alanine, glycine and serine was high, whereas that of cysteine, methionine and histidine was very low, though variations were also observed in distribution of residues in different references (Supplementary Table 4). For instance, the distribution of the catalytic residue aspartate was low in the Cystobacter (Proteobacteria), Hymenobacter (Bacteroidetes) and the Actinobacteria Verrucosispora and Actinoplanes, but very high in Firmicutes members Coprococcus, Butyrivibrio and in the Actinobacteria Bifidobacterium.

DiscussionIn the present study, a cellulase producing bacterium was isolated from soil collected from a cattle shed area. The soil here is usually mixed with cattle dung, due to which different cellulolytic organisms from the cattle rumen might be available. It was considered to isolate cellulase producing bacteria not only based on high cellulolytic index (CI), but also on its non-hemolytic behavior which provides safer working conditions and lesser risk of therapeutic hurdles.15,17 Most of the bacteria that are reported for the production of cellulases, do not have information on the non-pathogenic behavior (in terms of non-hemolytic behavior) of the bacteria. Therefore, if this behavior of the bacteria is already studied, that makes the bacteria more safer to use, causing lesser obstacles for therapy and treatment if any infection is caused. Among the isolates, some had low growth with low CI, some had high CI but showed either α- or β-hemolytic behaviors on sheep blood agar plates, and some had low CI with γ (non-hemolytic) behavior on blood agar plates. Only the strain SV1 was considered as it had a very high CI (7.89) and non-hemolytic behavior. The CI known from cellulolytic bacteria (members of Proteobacteria, Actinobacteria, Firmicutes and Bacteroidetes) isolated from the gut of the larvae of Holotrichia parallela ranged from 1.1 to 9.0.36,37 The CI known for some of the cellulolytic bacteria are Bacillus megaterium RU4 (6.5),38Paracoccus yeei RA2 (3.0),38Bacillus sp. KC2 (6.86),39Bacillus sp. KC4 (4.37),39Bacillus sp. KC8 (3.95),39 actinomycetes (1.1–2.3).40 Strain SV1 was susceptible to all the antibiotics tested, which also suggests of its safe utilization for application in cellulase production. However, it showed an intermediate resistance against ceftazidime. It is considered that ceftazidime resistance in bacteria arise by either the horizontal acquisition of β-lactamases or from an altered expression of the chromosomal wide-spectrum class C β-lactamase.41,42 Due to its tolerance against the toxic heavy metals Cr, Ni, Co and other metals, some physiological mechanism might be involved, which may include their degradation into non-toxic forms. The different mechanisms, often plasmid-associated, known are active efflux, sequestration, complexation, biosorption, ionic interaction, changing toxic to non-toxic forms, enzymatic metal reduction, immobilization and precipitation.43,44 The reduction of Cr to non-toxic forms have been known from various bacteria like Bacillus, Pseudomonas, Escherichia coli, Exiguobacterium, Desulfovibrio and Microbacterium, while a Cr(VI) reducing Bacillus sp. FM1 was also found to be tolerant to multiple heavy metals including Cu, Co, Cd, Ni and Zn.45B. circulans EB1 has been used for the biosorption of Mn, Zn, Cu, Ni and Co, thus making it suitable for the bioremediation of metal contaminated aqueous systems.46 A nickel tolerant B. megaterium SR28C, that showed tolerance to other metals (Cu, Zn, Cd, Pb, Cr), was found to have plant growth promoting property by decreasing Ni toxicity in soils, which is useful for phytostabilization.47 Furthermore, all the organic solvents that the strain SV1 was tolerant to (isooctane, n-hexane, benzene and p-xylene) had a logPow value greater than 2.0, which indicates of their more hydrophobicity. Besides showing tolerance, the strain SV1 also had enhanced growth in the presence of the solvents n-hexane, isooctane and benzene, which suggests of its ability to either utilize or degrade these solvents. Similarly, the tolerance to organic solvents with higher logPow values has also been found in several species of Bacillus used for enzyme productions, some of which are Bacillus aquimaris (benzene, heptane),22Bacillus sphaericus (n-benzene, toluene, ethyl benzene and p-xylene),48Bacillus licheniformis PAL05 (benzene and toluene),49B. licheniformis YP1A (tetradecane and decane),50 and Bacillus cereus BG1 (hexane).51 Thus, the strain SV1 could be valuable for the bioremediation of multi-metal or organic solvent polluted areas.

The varied effects of different media on bacterial growth and cellulase production clearly reflected on the drastic effects that different components could have. Medium IV used for isolating the bacterium supported less cellulase production than medium VII. Both of these media had several compositional differences, the major being the increased concentration of yeast extract and presence of CaCl2 and FeSO4·7H2O in medium VII. Medium II also contained CaCl2 and FeSO4·7H2O, but had a different organic nitrogen source tryptone, which supported less cellulase production that was also confirmed in the study of different organic nitrogen sources that effected cellulase production. Medium I and V had no organic nitrogen source, due to which there was very less growth and cellulase production in them. Medium VI had very low concentration of yeast extract than medium III, and thus growth and FPase production observed was very low in medium VI than in medium III. The ratio of C/N, with both their type and relative concentration, can be important in the production of enzymes. Low level of nitrogen can be inadequate, while higher levels can be detrimental for enzyme production, which could also vary for different strains producing various enzymes.52 For strain SV1, the media I, II, IV, V and VII have a C/N ratio of 1.0, while media III and VI have the C/N ratio of 0.5. Moreover, when only the C source (Na-CMC) was provided and the organic nitrogen was removed, the production of cellulases were reduced. Similarly, the C/N ratio of 1.0 was found to give maximum production of another enzyme, amylase from B. licheniformis SPT 27.52 In contrast, for Trichoderma reesei ZU-02, the cellulase production was found to increase with increasing C/N ratio of up to 8.0,53 while for Penicillium occitanis, cellulase production was very high at a C/N ratio below 20.2.54 Thus, presence of the organic nitrogen yeast extract and the metals CaCl2 and FeSO4·7H2O were essential for both growth and cellulase production by the strain SV1. Yeast extract is a complex hydrolysate of yeasts, which provides nitrogenous compounds, carbon, sulfur, trace nutrients, vitamin B complex and other important growth factors.55,56 The organic nitrogen sources that promoted very low growth and cellulase production are among those that have simpler components containing either single amino acid (glycine) or mixtures of amino acid and peptides (casamino acids, tryptone, peptone and casein hydrolysate broth). However, beef extract (mixture of amino acids, peptides, organic acids, minerals and some vitamins) caused slightly more growth and cellulase production than glycine, casamino acids, tryptone, peptone and casein hydrolysate broth. Among the organic nitrogen other than yeast extract, only corn steep solids could enhance maximum growth and CMCase production. Corn steep solids are low-cost by-products that contain amino acids, vitamins and minerals, which has also been found to cause high CMCase production from Streptomyces malaysiensis,57Streptomyces drozdowiczii,58 and T. reesei.59 The enhanced production of cellulases in the presence of CMC than its absence or replacement by other carbon sources, and the suppressed CMCase production in presence of glucose and cellobiose (which are among the end-products of cellulose hydrolysis) indicated cellulase synthesis to be inducible and under catabolite repression, respectively. Thus, cellulase production was increased only for the requirement of the utilization of cellulose, but when simple sugars like glucose, fructose and cellobiose were present, bacteria utilized these easily metabolizable sugars and did not produce cellulase either due to its non-requirement (in condition when CMC was replaced) or for utilizing less complex sugars (in condition when CMC was a co-substrate with monosaccharides and disaccharides).60 Moreover, glucose and cellobiose are among the end-products of cellulose hydrolysis which also cause a catabolite repression of cellulase synthesis. Certain co-substrates did not significantly affect the production of cellulases, which indicated that cellulases might have been co-produced with other enzymes needed to utilize different substrates for supporting bacterial growth. The strain also utilized microcrystalline cellulose (avicel) for the production of different cellulases especially higher β-glucosidase than with CMC. Raffinose as a single carbon source enhanced β-glucosidase production. This trisaccharide comprising of galactose, glucose and fructose, has been used as an inducer for maximum production of another cellulase component CMCase from only B. subtilis AU-1, where it was suggested that raffinose was initially hydrolyzed into its component sugars, which then induced higher CMCase production.61 A combination of cellulolytic bacteria (Streptomyces, Cohnella and Cellulosimicrobium) have been used to reduce the soybean meal non-starch polysaccharide containing raffinose.62 However, raffinose has also been found to suppress the production of CMCase from Penicillium expansum.63 The enhanced cellulase production caused by the co-substrates xylose, xylan, pectin and cellulose powder might be attributed to the fact that plant cellulose is mostly in association with different polysaccharides of hemicellulose and pectin, due to which in order to get access to cellulose, the production of cellulolytic enzymes might be controlled not only in the presence of cellulose, but also hemicellulose (like xylan) and pectin.64 The optimal cellulase produced by strain SV 1 was 107.45±2.12U/mL (CMCase), 26.79±0.27U/mL (FPase) and 80.90±4.05U/mL (β-glucosidase), which is comparable to that observed in different strains of Bacillus sp., utilizing different cellulosic substrates (Table 2).

The comparison of the production of cellulases of strain SV1 with different cellulolytic strains of Bacillus, using various cellulosic substrates.

| Cellulolytic strains | Cellulosic substrate used | Production of cellulases (U/mL) | Reference |

|---|---|---|---|

| Bacillus sp. SV1 | Na-CMC | CMCase – 107.45, FPase – 26.79 and β-glucosidase – 80.90 | This study |

| Bacillus pumilus EB3 | CMC | FPase – 0.05, CMCase – 0.31 and β-glucosidase – 0.18 | 3 |

| Bacillus sp. SMIA-2 | Sugarcane bagasse | CMCase – 0.29 | 6 |

| Bacillus subtilis AS3 | CMC | CMCase – 0.57 | 65 |

| Bacillus thuringiensis var. israelensis | CMC | CMCase – 0.07, FPase – 0.01 | 66 |

| Bacillus thuringiensis var. thompsoni | CMC | CMCase – 0.06, FPase – 0.01 | 66 |

| Bacillus amyloliquefaciens SS35 | CMC | CMCase – 0.13–0.53 | 67 |

| Bacillus vallismortis RG-07 | Sugarcane bagasse | CMCase – 4105.00 | 68 |

| Bacillus pumilus EB3 | Oil palm empty fruit bunch | CMCase – 0.06 | 69 |

Na-CMC, Sodium-carboxymethyl cellulose; CMC, Carboxymethyl cellulose; CMCase, Carboxymethyl cellulase; FPase, Filter paper cellulase.

There are few cellulase producing bacterial species (though majority are fungi) that are used in the markets for the production and usage of cellulases. The species of Bacillus is one of them. Therefore, an evolutionary study of the cellulase amino acid sequence of different cellulolytic species of Bacillus was studied to know its relationship with other cellulolytic organisms. This was done by the use of phylogenetic trees and conserved signature indels. The protein sequence blast of each Bacillus spp. cellulase query (endoglucanase, EC 3.2.1.4) included references of almost nine bacterial phyla. Reference cellulases of Eukarya represented by Arthropoda and Nematoda indicated of their identity with the bacterial queries, which was supported by them having common ancestor with the bacterial phylum Bacteroidetes in the phylogenetic trees. Such similarity is suggested to be either due to the involvement of horizontal transfer of genes from symbiotic organisms or from a convergent evolution event which was passed on from a now extinct ancestor.70 The query cellulase, which causes endohydrolysis of (1,4)-beta-d-glucosidic linkages in cellulose, showed similarity in blast and formed clade in phylogenetic tree (Fig. 4) with another type of cellulase, endo-1,3-beta-glucanase (EC 3.2.1.6), which causes endohydrolysis of (1,3)- or (1,4)-linkages in beta-d-glucans. Their similarity might be attributed with a convergent evolution that occurred from the selective pressure of the abundant availability of cellulose. Cellulase query also showed similarity in blast and formed clade in phylogenetic tree (Fig. 4, Supplementary Figs. 6 and 7) with functionally different enzymes, endo-1,4-beta-xylanase (EC 3.2.1.8) and chitosanase (EC 3.2.1.132). Both are glycoside hydrolases, which either hydrolyze the beta-1,4 linkages between xylan (xylanase) or between d-glucosamine residues in a partly acetylated chitosan (chitosanase). This is highly indicative of a divergent evolution among these enzymes from a basic protein fold so as to incorporate different substrates.64

The sharing of the conserved signature insertions and deletions (CSIs) observed between N. koreensis (a Bacteroidetes member) and different members of Actinobacteria (Fig. 5A) was also supported by its branching within the monophyletic group of Actinobacteria (Fig. 4). This CSI of 7 aa insert must have been introduced in the cellulase of their common ancestor. The monophyletic grouping of the species of Caldicellulosiruptor, Caldanaerobacter and Clostridium (Supplementary Figs. 6 and 7) was supported by their sharing of an 8 aa (Fig. 6A) and 9 aa (Fig. 6B) (Supplementary Table 3) inserts, which must have been acquired and then later diverged from their ancestral species during evolution. CSIs observed to be specific to different bacteria phyla including Actinobacteria and Firmicutes (Supplementary Table 3) would be important tools for characterization and distinguishing of the members of their common evolutionary decent. Similarly, evolutionary relationships among cellulases, using CSIs are also known for various species of Archaea, Bacteria and Eukarya.71 From the different amino acid residues in cellulase, frequency of occurrence of alanine, glycine and serine were high, however the reason for very high and low variations observed in several references for certain residues is not known. Such variations were distributed among the members of Proteobacteria, Actinobacteria, Firmicutes, Bacteroidetes, Fibrobacteres, and in some Nematoda and one Arthropoda (Psacothea).

ConclusionA cellulolytic and non-hemolytic soil bacterium, Bacillus sp. SV1 showed susceptibility to various antibiotics, and tolerances to toxic heavy metals (Cr3+>Ni2+>Co2+>Pb2+=Cu2+>Hg2+=Zn2+) and organic solvents (n-hexane>isooctane>benzene>p-xylene). Extracellularly synthesized cellulases of the strain SV1 had endoglucanase, filter paper and β-glucosidase activities, which were increased in the presence of cellulose. CMC replaced by raffinose, avicel and xylan promoted higher β-glucosidase production, while xylose, xylan and pectin as co-substrates to CMC enhanced CMCase and FPase productions. The low-cost corn steep solids caused maximum growth and production of CMCase, which also required the presence of CaCl2 and FeSO4·7H2O. Therefore, the strain SV1 has potential in the production of complete cellulases in a cheaper medium, and also for prefatory bioremediation (of multiple heavy metals and organic solvents) applications. An evolutionary relationship of the cellulase of different species of Bacillus was studied using their protein amino acid sequences. The protein sequence blast of three Bacillus spp. cellulase (EC 3.2.1.4) showed that it had similarities with members of bacterial and eukaryotic phyla, with another cellulase enzyme (endo-1,3-beta-glucanase), and with two other hydrolase (endo-1,4-beta-xylanase and chitosanase) enzymes. Within the alignment of the reference cellulases for the queries, conserved signature indels were observed for the members of Actinobacteria and Firmicutes, which were in support of their evolutionary decent in phylogenetic trees.

Conflicts of interestThe authors declare no conflicts of interest.

Fellowships from C.S.I.R., New Delhi to Lebin Thomas, from U.G.C., New Delhi to Hari Ram, and the DST-purse and R & D grants from the University of Delhi are gratefully acknowledged.