Stage I of the enlargement of Atocha Railway Station aimed primarily to adapt the facility to a new operating model, raising the station's capacity essentially by separating arriving and departing passenger traffic.

This article describes the project background, scope and justification, as well as the main structural members and most significant works involved in the enlargement, distinguishing between construction in platforms and tracks and existing facility restructuring.

In light of the complex geometry of the new roofs over Atocha Station, computational fluid dynamics (CFD) techniques were deployed to verify the pressure coefficients initially adopted for the new platform canopies by extrapolation from the existing legislation. The structural engineering involved is addressed.

Lastly, logistics and planning are discussed, with an account of all the possible scenarios and the challenge of performing many activities simultaneously on a tight schedule in limited quarters (power outages, track beds, high voltage works,…). The exceptional constraints inherent in the need to maintain high-speed train (“AVE”) service during the works intensified the overall complexity.

El proyecto de Ampliación del Complejo Ferroviario de Atocha Fase I se desarrolla con el principal objetivo de permitir la puesta en servicio de un nuevo modelo de explotación ferroviaria a fin de incrementar la capacidad de la Estación de Puerta de Atocha, separando los flujos de llegadas y salidas.

Se describen a continuación los antecedentes, el ámbito de la ampliación y los motivos de la misma, así como los principales elementos estructurales y las actuaciones más significativas realizadas dentro del proyecto de ampliación, distinguiendo entre las intervenciones realizadas en las vías y las llevadas a cabo sobre la estructura del edificio ya existente.

Asimismo, se detallan algunas consideraciones sobre las acciones aplicadas en el cálculo de las nuevas marquesinas y sobre los análisis realizados mediante cálculo dinámico de fluidos para verificar los coeficientes de presión adoptados inicialmente a partir de extrapolaciones de normativas de acciones vigentes, dada la compleja geometría de las nuevas cubiertas de la estación de Atocha.

Por último, se describen la logística y la planificación realizadas durante la ejecución de las obras, teniendo en cuenta todos los escenarios posibles y la necesidad de simultanear una gran cantidad de actividades en un espacio y tiempo limitados (cortes de tensión, cajas de vías, trabajos con líneas de alta tensión…). La complejidad de este estudio ha sido enorme, considerando las excepcionales limitaciones derivadas de las necesidades de explotación de la estación de AVE durante la fase de ejecución del proyecto.

Atocha may well be one of the stations that best mirrors the nearly constant change that many such facilities have undergone throughout their history. Sited in the heart of Madrid's urban core, it houses local, medium- and long-distance and high-speed train service.

Atocha Station, or “Mediodía” (“south” in Spanish) Station as it was called for many years, was opened with the launch of the Madrid-Aranjuez line on 9 February 1851. Its five tracks all terminated inside the station building. Passengers boarded from Embarcadreo (“boarding” in Spanish) Square and exited across Méndez Álvaro courtyard. The station was partially destroyed by fire in 1864. In a first enlargement in 1857, the yards and platforms were roofed with simple trusses.

In light of growing service needs, a design for a new station was commissioned from architect Alberto de Palacio. Work began in 1888 and the new station, which consisted of a vaulted bay covering six tracks and their respective platforms, was completed in 1892. The station was the terminal for trains run by the MZA (Madrid-Zaragoza-Alicante) railway company, later absorbed by RENFE (Spanish national railways). These lines connected Madrid to eastern Spain.

A further enlargement was finished in 1992 to meet a number of complex objectives. With its hypostyle hall, the design authored by architect Rafael Moneo created a new space for medium- and long-distance trains, while accommodating new tracks for the Madrid-Seville high-speed line. A car park was also built, together with a local train station with connections to the city's underground. The former station building was converted into a lobby and greenhouse for tropical plants. The roof over the hypostyle hall consists of 16 m × 16 m steel modules resting on very tall columns.

The underground local train facility that forms part of the Atocha complex, commissioned in the nineteen seventies, was built in the nineteen thirties at the end of the tunnel connecting Atocha and Chamartín Stations.

The steep growth in both long-distance and local traffic led to the enlargement discussed hereunder.

2. New enlargementOn the occasion of the 1992 enlargement, the most ambitious to date, the long-distance trains running on Renfe gauge track were replaced with international gauge high-speed trains. In the interim, high-speed traffic has grown exponentially in Spain, with the concomitant saturation of Atocha Station and the need for further enlargement.

Atocha Station cannot grow sideways, for it is limited on one side by the local train station and on the other by Méndez Álvaro Street. Over the years, the city has encircled the facility. The enlargement project planned was consequently divided into several stages, given the volume and complexity involved.

1. The first stage, commissioned in late 2010, consisted of separating the arrival and departure areas, nearly doubling station capacity.

2. The second will entail building an underground station beneath Méndez Álvaro Street for the high-speed trains arriving at Atocha and travelling to Chamartín Station along the new Serrano Street tunnel. At this time, trains travelling south, east and northeast depart from Atocha Station, while trains travelling northwest depart from Chamartín. This second stage of the works will provide greater flexibility in present and future high-speed train departures.

3. The third stage will include a new arrivals lobby over the local station tracks, with direct outdoor access across a multi-storey car park alongside the local train tracks.

ADIF (Spanish railway infrastructure authority) commissioned the Atocha enlargement design from Rafael Moneo, guarantee the aesthetic quality of the complex by harmonising the architecture with the preceding enlargement. The structural design was authored by CARLOS FERNANDEZ CASADO, S.L., and the works were performed by a joint venture chartered by DRAGADOS and TECSA. INECO provided technical assistance. During the works, two engineering firms, CESMA and MC2, furnished the joint venture with technical assistance and many construction solutions.

3. Project description: Stage IThe Stage I works were commissioned on 19 December 2010, when the east corridor reached the capital city. The objective was to change the station's operating configuration by separating arrival and departure passenger traffic to optimise the existing, while building new, facilities.

The works had a substantial social impact, accommodating the passengers and services generated by the country's eastern and other future high-speed lines. The station presently handles 16 million passengers yearly, a figure that is expected to grow to 35 million by 2025.

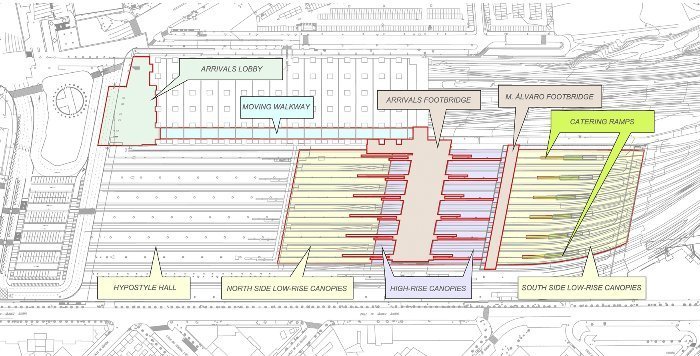

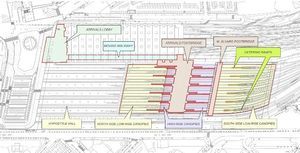

Passenger redistribution called for the following (see Figure 1).

• An arrivals footbridge had to be built over the tracks. It is located at approximately mid-length on the platforms, which it divides in two: the north side for departures and the south for arrivals.

• The entire platform area was roofed. Construction of the 20-metre tall high-rise canopy or roof covering the footbridge involved enormous complexity, for it had to be built without interrupting normal train service in either the local or the high-speed station. North and south of the high-rise structure, the platform was roofed with low-rise canopies.

• A moving walkway was also built to connect the arrivals footbridge to the new arrivals lobby. Its four travelators run parallel to the tracks, from south to north underneath one of the rows of domes on the west side of the local station car park.

• The travelators empty onto the new arrivals lobby, from which passengers can access the rest of the station's various levels, as well as urban transportation and the car park.

• The Méndez Álvaro footbridge was also built.

• The catering ramps were remodelled.

Figure 1. Plan view of elements involved in the station remodel.

The most prominent railway works included converting four tracks into the international gauge and installing nineteen devices and four scissors crossovers to handle more moving and parked rolling stock.

The platforms were also raised, to 76 cm, to comply with European standards.

Other actions undertaken included rerouting traffic around the bus interchange shelter to further collective transport by widening the bus dock and taxi stand. Embarcadero Square and the Méndez Álvaro taxi courtyard were also remodelled.

4. New structuresThe main structural changes called for in the Atocha Station enlargement are described below.

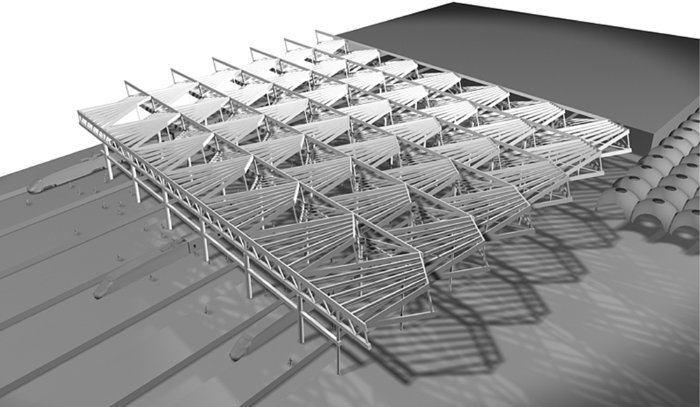

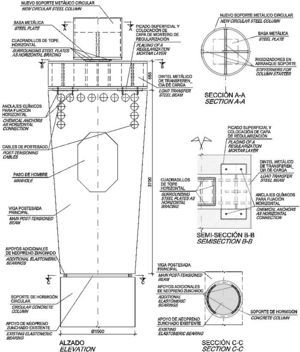

4.1. High-rise canopyThe high-rise canopy is unquestionably the most singular element in Moneo's design. Located on the south side of the station, it covers the arrivals and Méndez Álvaro footbridges and their respective accesses. At its highest, the canopy towers 20 m over the platforms bordering the station's 13 long distance tracks. It consists of 42 modules that measure 17.66 m long crosswise and 16.60 m lengthwise to the tracks. Taken together, the modules form a roof spanning 99.60 m north-south and 123.62 m east-west, skewed at a 10.68° angle with respect to a line perpendicular to the tracks. Its columns are designed as a continuation of the columns in the hypostyle hall.

Overall, the canopy rests on 42 circular steel columns 1 m in diameter and 14 m high, positioned at the corners of each module. The six eastern-most modules cantilever in that direction, and are consequently supported at only two vertices on each module. The six western-most modules follow the same pattern. These outer moduli, cantilevered in this stage of the enlargement, will rest on columns in future stages.

Crosswise to the tracks, seven 5.50 m deep trusses are constrained by a set of six columns (see Figure 2). All the upper and bottom chords as well as the diagonal lacings are made of 0.25 m wide box members. The upper chords are 0.88 m deep, while the bottom chords measure 1.20 m and the diagonal lacings 0.70 m.

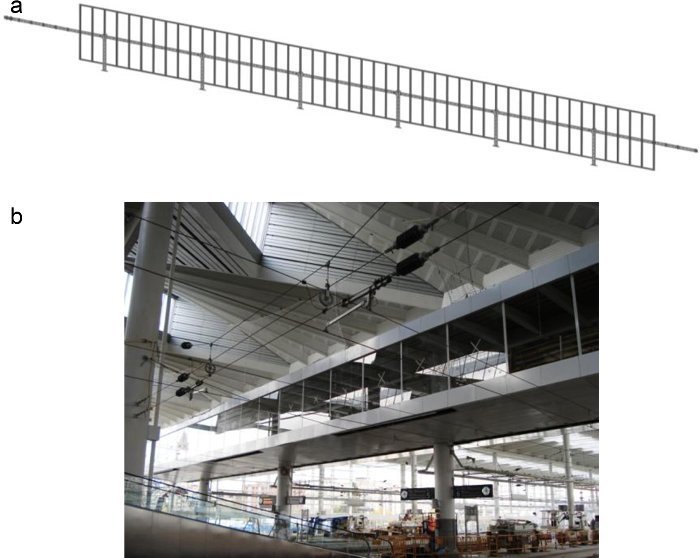

Figure 2. High-rise canopy.

The canopy modules, positioned in between the trusses, are arrow-shaped in the plan view. Each module consists of a hyperbolic paraboloid resting on two generators, with a triangular plane projecting outward from one of its sides. The edge beams that bound each module have a box section measuring 0.70 or 0.90 m deep by 0.25 m wide, with the exception of the two sides formed by the diagonal bridging in the trusses.

The curved surface, a hyperbolic paraboloid, is generated by the slant on the purlins between the top beam in the skylight and the bottom chord on the adjacent truss, which together form a right angle in the plan view. That surface is framed by perimetric box members with the same width as the truss chords and a depth of 0.88 or 0.90 m. In the I-section purlins, in turn, the bottom flange consists of a structural tube, while the top flange accommodates the curved plane. Their web is vertical (Figure 3).

Figure 3. Indoor view of the finished high-rise canopy.

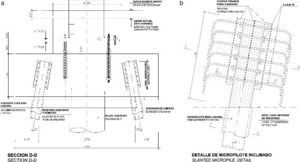

The new foundations built in the high-rise canopy area are capped micropiles. The existing foundations were disconnected from the vertical loads on the structure and re-used to bear horizontal loads only.

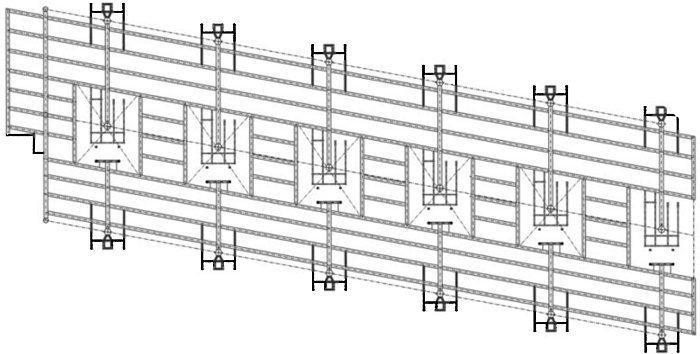

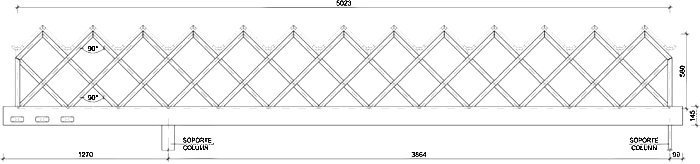

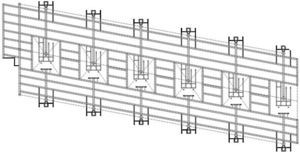

4.2. Low-rise platform canopiesOn the north side of the track yard, the low-rise platform canopies, which replace the ones built in 1992, are positioned between the hypostyle hall and the new high canopy. In the south platform area, they are an extension to the new roof. The new canopies are made entirely of steel and positioned 4.50 m higher than the former structures, i.e., around 10 m above platform level. The columns are distributed as in the former structure. The foundations under the former north side canopies were re-used and the concrete supports demolished.

The canopies comprise a series of portal frames forming a 79° angle with the platforms and spanning a total of 17.66 m over the tracks. The main beams, parallel to the tracks, rest on steel columns spaced at 16.60 m. Their steel box section is 1.00 m deep and 0.25 m wide. The welded I-section cross-beams measure 0.165 m wide by 0.440 or 0.655 m deep and are positioned transversely to the tracks where they rest on the main beams at 4.15-m intervals.

Natural lighting is provided by continuous roof lights along the track centrelines. These skylights rest on longitudinal box section purlins measuring 0.30 m deep by 0.15 m wide, arranged over the I-section cross-beams (see Figure 4).

Figure 4. North side low-rise canopies.

4.3. Arrivals footbridgeThe new arrivals footbridge, which crosses the platforms at nearly mid-length and a height of 9 m, is roofed by the high-rise canopies. Passengers access the bridge via movators (two per platform), escalators (two per platform), lifts or conventional stairways. Its purpose is to channel passenger traffic from the arriving trains to the moving walkway that empties onto the arrivals lobby.

The footbridge, 33.15 m wide by 103.7 m long, spans two bays. The stairwells and lifts are located in line with the central columns. Passengers accessing the footbridge from the ramps leading up from the platforms will in future be able to exit the station across the footbridge connecting to Méndez Álvaro Street, located on the south side of the high-rise canopies on the same elevation as the arrivals footbridge.

The composite beams that form the structural framework for the footbridge support a likewise composite deck slab (Figure 5). In this framework, the loads borne by the composite deck slab are received by the longitudinal beams and transferred to the cross-beams, in turn connected to the columns that support the canopy.

Figure 5. Plan view of arrivals footbridge.

The I-section steel shapes in the composite beams measure 1.00 m deep and are topped by a 0.16 m thick composite deck, whose steel plate is 58 mm deep and 1.25 mm thick.

The footbridge may be accessed from the platforms on escalators, movators or lifts, or traditional stairways, fully cantilevered for architectural reasons (Figure 6).

Figure 6. Stairway from platform to footbridge.

4.4. Méndez Álvaro footbridgeThe Méndez Álvaro footbridge was built as a pedestrian connection from Méndez Álvaro Street to the future thoroughfare to be built between Ciudad de Barcelona Avenue and the station, connecting the Delicias and Pacífico quarters. Although the bridge is not accessible at this time, it was built in this stage because it forms part of the new canopies over the platforms.

This structure is on the same elevation as the arrivals footbridge and separates the high- from the low-rise canopies on the south side. It is 9.65 m wide and is supported only along its centreline. It is roofed and fully enclosed on the sides with glazed walls.

It spans 17.66 m bays. Its steel structure is characterised by a bottom box girder 0.80 m deep and 0.60 m wide and a top box girder measuring 0.80 by 0.40 m that serves as the bottom chord for one of the high-rise canopy trusses. I-section beams measure with a depth ranging from 0.60 m at the restraint to 0.30 m at the end cantilever off these main box girders. The bottom beams support a composite corrugated steel sheet and concrete deck slab 0.16 m deep, while a suspended ceiling hangs from the top beams, connected to secondary shapes that support the high-rise canopy (Figure 7a and b).

Figure 7. (a) Méndez Álvaro footbridge, plan view. (b) Méndez Álvaro footbridge, photograph taken during construction.

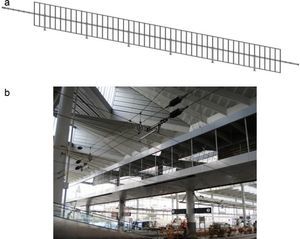

4.5. Moving walkwayThe gallery housing the travelators that carry passengers from the arrivals footbridge to the new lobby runs along the entire existing local station car park in the area closest to high-speed track 1. To ensure aesthetic continuity between the domes roofing the passageway and the car park domes, the largest possible number of shapes were maintained and strengthened (Figure 8).

Figure 8. View of domes over the moving walkway during construction.

4.6. Arrivals lobbyStage I of the Atocha Station enlargement included converting part of the station near the present local train station car park into a new lobby. This irregularly shaped space is located at the end of the arrivals passageway and provides access to the local train station and, from its ground storey, to a car park. The upper storey, connected by a conventional stairway, movators and a lift, exits directly to the outdoor taxi stand and bus shelter.

At elevation 628 (pavement level) the lobby has a 0.20 m deep composite slab resting on 0.65 m deep cellular steel beams with circular openings spaced at approximately 1.90 m. The 400 mm diameter voids in the beams are spaced at 600 mm, centres. This slab rests on the former slab and a lattice truss positioned parallel to the present outdoor pavement. The service ways for the new lobby run through the voids.

The truss has a 1.00 m wide, 1.45 m deep bottom chord and is crowned, instead of by an upper chord, by a crest formed by the diagonal bridging in the trusses.

The roof over the lobby slab rests on the aforementioned lattice truss whose crests determine its geometry. The roof's hips and valleys are L-shapes connected on one plane of the crest by 200 mm × 180 mm parallel steel tubes running perpendicular to the beam, and on the other plane by 180 mm × 180 mm tubes forming a lattice truss. The distance between hips and valleys is approximately 1.90 m. This roof cantilevers 14.40 m, with a maximum of 23 m between the bearing plate and the truss (see Section 6.2.1).

4.7. Catering rampsThe catering ramps rise to the platforms from a crosswise underground gallery at the south end. Prior to the enlargement, this posed no problem at all because the trains were parked primarily at the north end of the platforms. With the new arrangements, however, in which the arriving trains park in the south, changes had to be made to comply with the existing legislation.

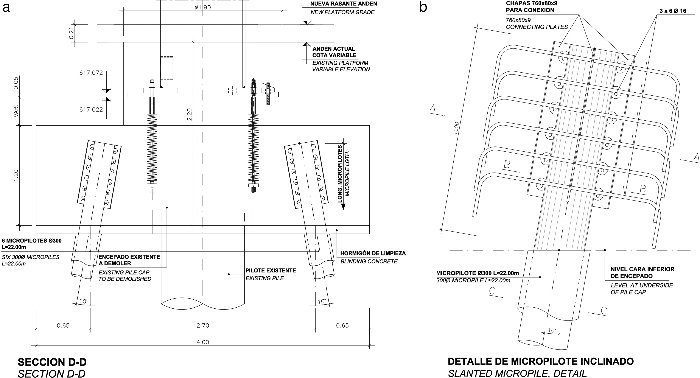

The new and slightly narrower ramps occupy the same position as the former ramps. As the exits were shifted slightly northward, the underground stretch and the sealing slab had to be lengthened. To avoid having to vary the slope or the vertical clearance, the slab was built with a variable depth. The sections were narrowed by lining the existing walls with new ones (see Figure 9).

Figure 9. Catering ramps while under construction.

The initial position of the low-rise canopy columns interfered with the ramp openings. The solution was to build steel portal frames that span the ramp as springings for the columns (Figure 10). The portal frame columns, which rise from the new roof slabs in the ramps, were dimensioned from the outset bearing that circumstance in mind. Lastly, some of the new canopy columns were built on the roof over the existing cross-wise gallery. To prevent the transmission of loads to the existing structure, load transfer beams were built on the roof slabs supported by micropile foundations.

Figure 10. Finished catering ramps.

5. Works on tracks: platform canopies5.1. Design specifications5.1.1. RequirementsEssentially two objectives are pursued in the design, construction, use and maintenance of a structure. On the one hand, it must be afforded sufficient strength and stability to ensure that no unacceptable risks are taken ([1], [2], [3]) (assuming that the boundary between acceptable and unacceptable risk is known). On the other, its in-service performance must be suited to user needs, established on the grounds of the planned use. The reliability of a given structural solution ([5]) in pertinent risk scenarios can be verified either with implicit procedures, applying standardised rules based on the partial safety factor method, or by explicitly proving that the risks inherent in a given structure lie within the accepted threshold ([4]).

The qualitative analysis stage is of vital importance, for risks or scenarios that go undetected there will be ignored in the rest of the process. If all the objectively known risks and scenarios are identified, subsequent alleviation by adopting the most suitable measures is fairly straightforward and lowers the residual risks associated with a given solution while at the same time optimising costs ([6]).

5.1.2. Actions and effectsTwo categories of hazards were identified for the canopies on the Atocha Station enlargement: the natural environment and human activities. The following hazards fall under the first category:

– relative deviations from the models applied for wind, snow or temperature action;

– structural overloads induced by hailstorm or rainwater, concurring with a collection system failure;

– deviations from the soil strength values assumed;

– chemical reactions.

The second category includes the following hazards:

– structural overloads induced by maintenance operations;

– human error, such as deviation from the assumed values for manufacturing imperfections, mechanism deterioration for want of maintenance, or actions or effects not taken into consideration.

The measures adopted in the platform canopies forming part of the Atocha Station enlargement to mitigate wind and snow action are described below. They consisted of developing realistic models by establishing the theoretical and experimental parameters defining such actions. These models were subsequently used for partial safety factor method-based structural engineering. That procedure affords the structure sufficient stiffness and strength to reliably meet the existing requirements (see Section 5.1.1), provided that planning, construction and test assessment, as well as the theoretical premises, are in keeping with the safety requisites laid down in the applicable legislation ([7]).

5.1.3. Wind5.1.3.1. GeneralThe distribution and value of the pressure exerted by the wind on a building and the resulting forces depend on the size and shape of the structure, its surface characteristics and permeability, wind direction and intensity and the gust effect. These forces can be determined as the sum of the local pressure acting on the various areas of the external (1) and internal (2) surfaces of a building, where positive pressure represents a force per unit of area acting on the surface:

cpe ; cpi internal and external exposure factors, respectively; ce exposure factor; qb basic velocity pressure.The rules for actions on structures, such as described in the Spanish Technical Building Code ([8]), contain sufficiently precise information both for the basic velocity pressure value, with depends on basic wind velocity, and for exposure factors. On the contrary, neither the rules nor the specialised literature on wind loads define exposure factors for geometries such as in the roof over Atocha Station. In such cases, where warranted by construction costs and the singularity of the structure involved, wind tunnel tests are recommended.

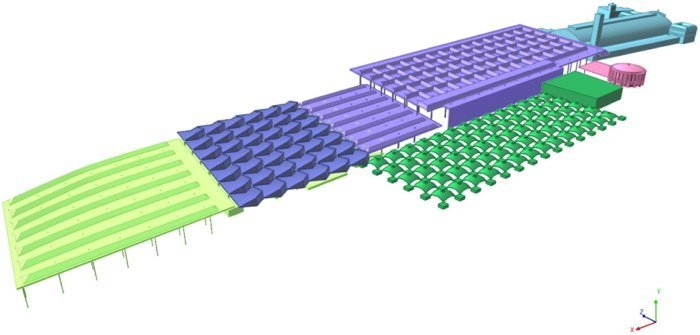

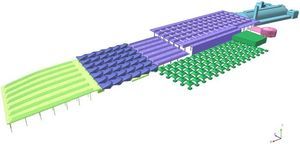

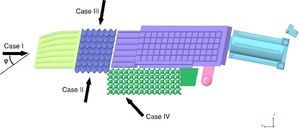

5.1.3.2. Numerical simulationInstead of traditional wind tunnel testing, computational fluid dynamics (CFD) ([9]) modelling was used to analyse the station as a whole, including both the new elements and the station volumes prior to the enlargement (Figure 11). A number of simulations were run with this model, in which four representative angles were assumed for wind action: one longitudinal (φ = 0°), two cross-wise (φ = 79°; 259°) and one diagonal (φ = 135°) (Figure 12). In each case, the internal and external exposure factors on every surface were analysed, along with the overall drag and lift force coefficients for the whole structure. Once the aforementioned coefficients were defined, the static forces equivalent to the wind action could be calculated for each surface of the roof (Section 5.1.3.3).

Figure 11. Numerical model for simulating wind action [9] .

Figure 12. Angles of incidence assumed for the wind study [9] .

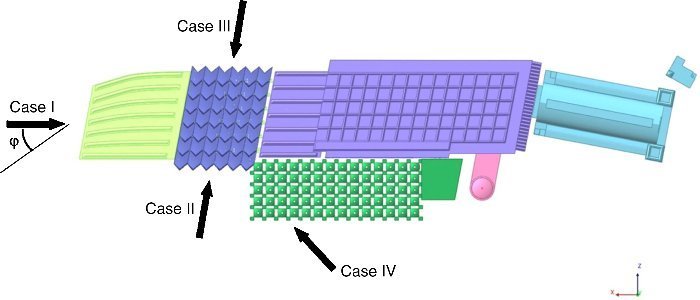

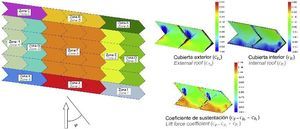

5.1.3.3. ResultsFor the intents and purposes of representing the exposure factors obtained with the numerical model, the high-rise canopy was divided into regions, each grouping modules for which exposure conditions were comparable. By way of example, Figure 13 shows the internal and external exposure factors found for the northeastern modules (Region A). The lift force coefficients, i.e., the vectorial sum of the internal and external exposure factors, are shown for the same modules. Moreover, the force coefficients were obtained by integrating the lift force coefficients over the entire area of the structure. The components of these coefficients are generally represented on orthogonal coordinates.

Figure 13. Plan view of the areas of the high-rise canopy used to represent exposure factors: results for Region A [9] .

When the angle of wind incidence was φ = 0°, the highest lift force coefficient was observed for the modules in the southernmost bay (Regions I, J, K):

cl,max maximum lift force coefficient.When the angle assumed was φ = 135°, the same peak value was found for the north bay modules (Regions A, B, C). Positive lift force coefficient values denote a downward force (pressure) per unit of area. Using the aforementioned value in conjunction with the basic velocity pressure value and the exposure factor determined as specified in the existing codes ([8]) yields the following characteristic value for the peak local velocity pressure on the slanted surfaces on the north and south modules:

characteristic value of the peak local velocity pressure found with numerical analysis.Analogously, the minimum lift force coefficients can also be extrapolated from the numerical model results. The minimum value was found with an angle of wind incidence of φ = 259° for the west side bay on the high-rise canopy (Regions C, G, H). This value, whose negativity denotes an upward (suction) force per unit area, together with the basic velocity pressure value and exposure factor, yields the characteristic value of the minimum local pressure on the slanted surfaces of the aforementioned modules:

characteristic value of the minimum local velocity pressure (suction) found with numerical analysis.Further to the foregoing, the slanted surfaces of the northwestern modules (Region C) may be affected by both the maximum and minimum (suction) local velocity pressure, depending on the angle of wind incidence. While this region is on a corner of the roof where wind loads are often extreme, wind action was likewise found to be extreme in other modules at some distance from the corners: namely Regions B, J (pressure) and G (suction).

The overall wind load on the structure is found by multiplying the aforementioned force coefficients by the reference area, in this case the plan view projection of the high roof, as well as by the basic velocity pressure and the exposure factor. This force can be decomposed using the same system of coordinates as for the force coefficients. Given the portal frame design for the platform canopies, the determinant for structural performance and safety is the horizontal component of the wind force. The least favourable situation is found for an angle of wind incidence of φ = 259°, whose characteristic value is:

characteristic value of the horizontal component of the wind force found with numerical analysis.The values obtained for the other two angles of incidence studied, while smaller, were on the same order of magnitude. Lastly, contrary to the aforementioned local pressures, which have a heavy impact on the dimensioning of structural and non-structural elements with small areas of influence, the vertical component of the wind force is of very limited relevance to the structural performance and safety of the system as a whole.

5.1.3.4. BenefitsAlthough the codes on actions affecting building structures contain no information on pressure coefficients or force for roofs such as in the Atocha Station enlargement (Section 5.1.3.1), the local pressures and overall forces induced by wind loads can be estimated from standardised rules ([8], [10]) and assumptions based on analogy and likelihood.

Comparing the wind loads found in that way to the action deduced from numerical analysis is an illuminating exercise. In this case, the former approach was found to be conservative, except for local wind pressure: a prudent interpretation of the standardised rules ([8], [10]) yields a characteristic value for the side modules essentially equal to the value found with numerical analysis (Eq. (4)). Side module suction and the horizontal component of the overall wind force on the high-rise canopy, however, were 55% and 80% lower, respectively, when computed with numerical analysis than with standardised rules. Such reductions led to indisputable benefits in the dimensioning of roof members, particularly the purlins, the nodes (which must be stiff enough to ensure portal frame stability), and the deep micropile foundations (which are highly sensitive to horizontal forces). Moreover, smaller wind suction values may also have a beneficial effect on roof plating and clamp dimensions.

5.1.4. Snow5.1.4.1. GeneralThe distribution and intensity of snow loads on any structure in general and on roofs in particular depend on climate, topography of the surrounding terrain, the proximity of other buildings or obstacles, building shape and site, wind effects, roof characteristics and the thermal exchange on its surface. Structural analysis of the snow load on a roof should explicitly cover at least the effect of altitude, regional climate, roof shape and building exposure.

Most of the models available to determine snow loads are only applicable to roofs exposed to normal wind conditions, with a natural depth of snow. Such is the case of the models set out in the Spanish Technical Building Code ([8]) and the Eurocode ([11]), according to which the snow load on a roof, qs, can be found from the following expression:

s snow load on horizontal ground; μi snow load shape coefficient; Ce exposure coefficient; Ct thermal coefficient.The snow load on horizontal ground protected from the wind and representatively located on the building site provides the information needed to determine the effect of regional climate and altitude. Further to codes ([8], [11]), the load should be assumed to be the characteristic value, sk, for a 50 year return period, i.e., the value with a 2% likelihood of being exceeded in any given year.

The snow load shape coefficient of a roof, μi, provides a measure of the ratio between the snow load on the roof and on horizontal ground near the building site. Since snow may fall with or be followed by wind, the snow depth on the roof may be irregular. For this reason, codes ([8], [11]) introduce two families of snow load shape coefficients for roofs exposed to normal wind conditions to be able to determine snow loads assuming the following distributions:

– Undrifted snow load with no wind-induced redistribution.

– Drifted snow load due to wind.

In buildings with multi-span roofs at different elevations, consideration must be given to the possible slippage of snow from the upper to the lower levels.

With the exposure coefficient, Ce, the model accommodates the effect of a number of factors on the snow load, including topography, proximity of structures or obstacles, wind conditions and solar radiation. Finally, the thermal coefficient, Ct, factors in the effect of the thermal properties of the roof and the indoor thermal conditions on the snow load.

The information provided in the codes for determining the parameters on which the snow load on the roof depends (Eq. (7)) is conservative, by and large. This is true of Spain's Technical Building Code ([8]). While in the framework of structural engineering design, the snow load shape, exposure and thermal coefficients cannot be changed, the characteristic value of the snow load on the ground can be modified fairly simply, providing a weather station located close to the building site and itself protected can furnish a sufficiently long and reliable historical data series. A temperature and rainfall observatory in Retiro Park, located in the vicinity of Atocha Station, meets those requirements. The snow load on the ground was consequently determined from the records on file in that observatory.

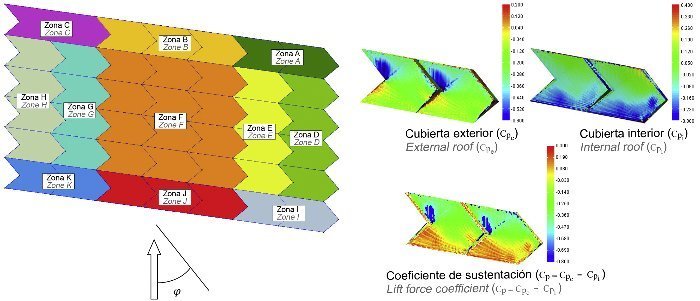

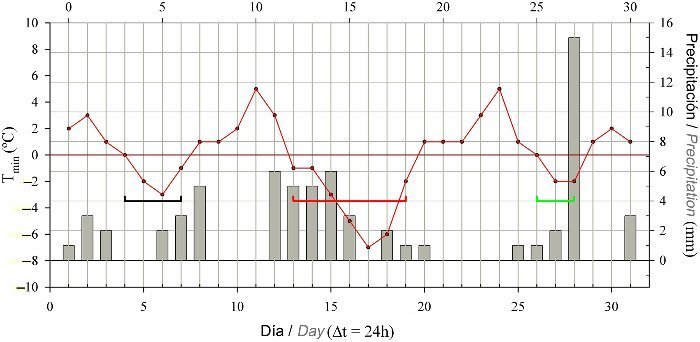

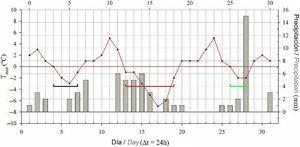

5.1.4.2. MethodologyInasmuch as the weather stations forming part of the State Meteorology Agency (Spanish initials, AEMET) do not directly record snowfall depth or density, the study was based on an indirect assessment of the water equivalent of the snow cover ([12]). The precipitation accumulated in a series of consecutive days with low temperatures of 0 °C or under was found from the meteorological records available at a given station (see Figure 14). The maximum snowfall for each month was calculated from the value found for each such series, assuming that the snow melted in the intervals between any two consecutive series. Since the measure was the water equivalent of accumulated snow, there was no need to factor the coefficient for altitude conversion into the gravity load calculations.

Figure 14. Procedure used to determine maximum monthly snowfall [12] .

The value of the snow load on horizontal ground with a 2% likelihood of occurrence is found from the data on record at a given station, established as in the above procedure. A number of studies used for these intents and purposes, such as ([13]), have shown that yearly extreme hydrological values provide a suitable fit to the so-called Gumbel distribution ([14]).

The 50-year return period value is found from the mean, μx, and standard deviation, σx, for the yearly maximum snow load determined from the series of maximum values for the station in question and assuming the aforementioned distribution ([14]). Further to codes ([8], [11]), this value is the characteristic value of the snow load on horizontal ground at the station analysed.

5.1.4.3. ResultsThe Retiro weather station has records for the period running from 1901 to 2002. Using only the values for winters when snow was recorded, the statistical method described in the preceding item yielded a characteristic value for the snow load on the ground of sk,Retiro = 0.24 kN/m2. Characteristic values were also found for other weather stations in Madrid with sufficiently long historical series, more specifically Madrid Chamartín, sk,Chamartin = 0.295 kN/m2 and Puerta de Hierro, sk,PuertaHierro = 0.27 kN/m2. Based on those findings, the characteristic value for snow load on the ground at Atocha Station was (conservatively) adopted as:

Assuming a value of ρ = 1.5 kN/m3 for the specific weight of the snow during the maximum load season, the aforementioned characteristic snow depth value found was 0.2 m, a subjectively credible number.

5.1.4.4. BenefitsFor a given place, the characteristic value for the snow load on the ground obtained from reliable experimental data as explained in the preceding sections can be compared to the characteristic value found by applying the legislation in effect ([8]). For Atocha Station, using Madrid weather station records proved to be enormously beneficial, for the snow load found was on the order of 50% lower than calculated with the standardised method ([8]). That difference, which led to considerable savings in the dimensioning of purlins and other roof elements, structural and non-structural, might seem surprising, given that the data from the aforementioned three stations were also used to define the formulas for calculating the snow load on the ground set out in the code ([8]). A rational explanation is at hand, however, given the wide scatter in the 1024 series of maximum yearly snow load values ([12]) that the model proposed in the code attempted to accommodate ([8]).

5.2. Structural approach5.2.1. Curtain wallThe southward extension of the platform canopies called for building a new curtain wall to protect users from the elements (Figure 15). That wall begins at the same point as the south side low-rise canopies and runs to the opposite end of the roof along the entire wall that separates the high-speed from the local train tracks.

Figure 15. Curtain wall during construction.

The curtain wall, with uprights positioned at 4.5 m intervals and interconnected with crossbars, rests on a trapezoid section beam, in turn supported by circular steel columns spaced at 16.60 m and aligned with the columns that bear the canopy roof. The purlins on that side of the roof afford the wall horizontal support while transferring to it the respective vertical load.

The uprights are 0.30 m × 0.17 m rectangular tubes and the crossbars 0.12 m diameter circular tubes. The width of the 0.80 m deep trapezoid beam ranges from 0.40 to 0.50 m, the latter concurring with the diameter of the circular columns.

5.2.2. FoundationsFoundations, an essential part of any structure, in this case called for particular attention due to two needs: to work in an environment conditioned by previous remodels and to customise the design of the foundations under each column. Several conditioning factors and specific problems had to be addressed in each. Moreover, due to the existence of any number of service ways and galleries whose exact location would not be known until work began, the foundations had to be adapted to each member individually. The result was foundations “à la carte” in which standardised detailing was not feasible.

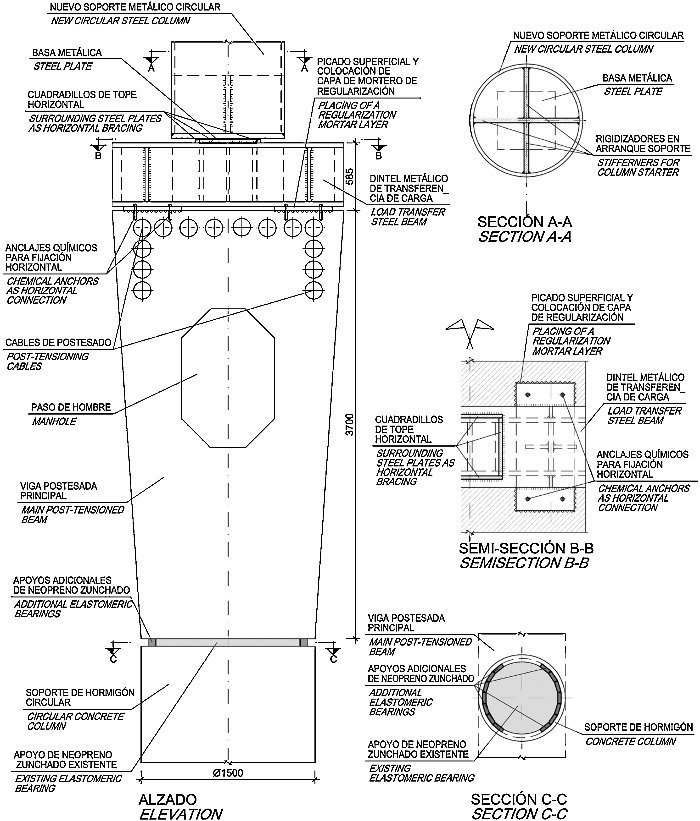

The existing foundation piles were re-used for the north low-rise canopies, to whose caps the new steel columns were simply anchored with starter bars (see Figure 16).

Figure 16. North side low-rise canopy foundations.

New deep foundations were built using micropiles for the high-rise canopy, the south side low-rise canopy and the curtain wall. The use of micropiles throughout, even for the huge loads to be transferred by the high-rise canopy, was imposed by the constraints on worksite accessibility, given the smaller size, greater mobility and higher performance of the machinery involved.

The S335 structural steel used in the 200 and 300 mm diameter built-up micropiles was wholly apt for welding the gussets needed to transfer sizeable loads from the cap to the micropile (Figure 17).

Figure 17. Pile cap for the north side low-rise canopy and detail of connection to the micropile.

5.3. Construction details5.3.1. High-rise canopies nodesNode design and dimensioning were essential to the present enlargement, for in addition to adapting to the complex connections deriving from the geometry involved, they had to provide the structure with sufficient stiffness and strength to transfer forces among members, while at the same time ensuring simple assembly so the structure could be built without interfering with train or station service (see Figure 18).

Figure 18. High-rise canopy node during assembly.

Given the structural modularity characterising the enlargement and the concomitant presence of standardised elements, the initial intention of casting these elements in steel moulds was ultimately ruled out for reasons of timing, despite the inherent economic and structural advantages.

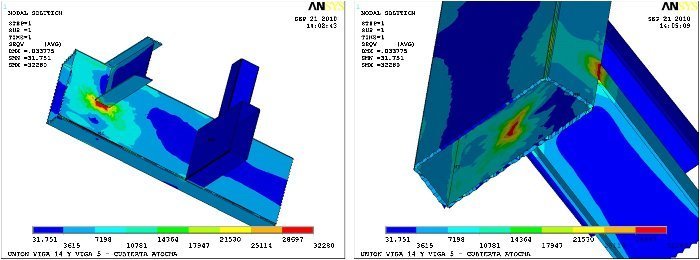

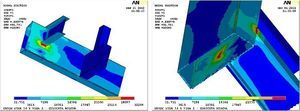

The option adopted instead was to weld the nodes, while simplifying the construction details to the utmost by conducting an in-depth study of the forces and moments involved, inter-element stress transfer and the paths followed by the forces crossing the joint. The result was the use of only the number of stiffeners strictly necessary and the selection of the most appropriate welding typology for each case. Where no stiffeners were positioned inside the box shapes, finite element analysis was performed, in which both geometric and material non-linearity were entered into the model to establish the actual yield criteria for the detail and validate their suitability (Figure 19).

Figure 19. Analysis of an unstiffened node.

5.3.2. Column restraintDepending on the angle of incidence of the wind, a given area of the roof may be exposed to pressure or suction (Section 5.1.3). Moreover, the interaction between the wind and the roof can also generate dynamic effects. All that translates into variable and repeated stress on the anchorages between the base of the columns and the pile caps (see Figure 16, Figure 17). Since the essential parameter on which the fatigue strength of a given construction detail depends is the difference between stresses, that difference must be minimised in anchorages by prestressing the elements involved. The prestressing force is determined in a way such that the maximum fatigue load induces no detachment whatsoever between the base plate and the pile cap concrete. With this arrangement, the variation in the force stressing the anchorages is much smaller than it would be if the joint were not prestressed. Depending on the case, stress may be on the order of 90 or even 95% lower, thereby preventing any possible repetitive variable load-induced deterioration.

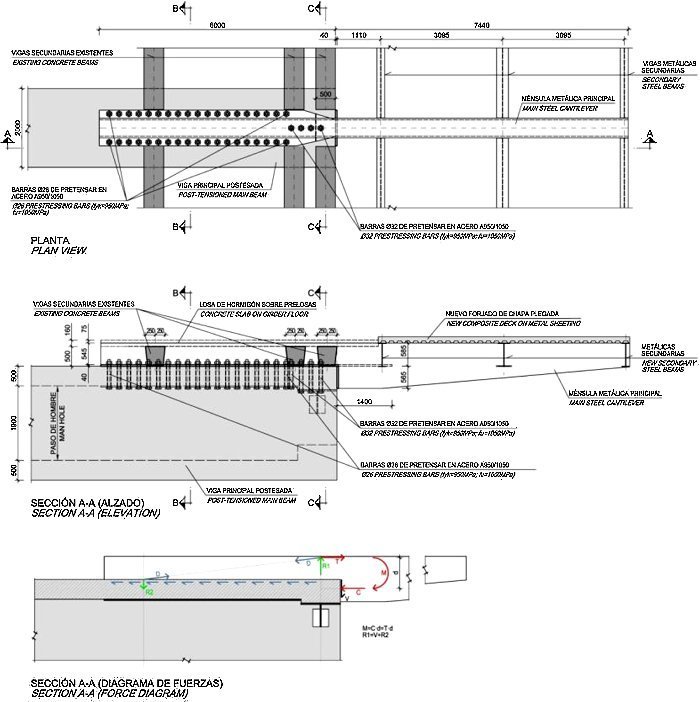

6. Works on the building6.1. Works affecting the structure of the existing building6.1.1. Description of the existing structures affected by the remodelOne of the key elements on the existing structure impacted by the enlargement was the roof slab over the local train platforms, which had to be strengthened and broadened to connect into the arrivals footbridge, i.e., the structure that spans perpendicularly across the high-speed tracks to the moving walkway that carries passengers to the new arrivals lobby.

The roof slab over the local train platforms consists of the following structural systems.

• One area is characterised by a continuous 60 cm deep ribbed slab whose 180 cm wide main ribs, together with a series of rectangular or square section concrete columns, form double-bay portal frames with spans of up to 14.00 m. Its 60 cm wide secondary ribs run perpendicular to the portal frames and alternately span 9.10 or 5.20 m.

• In another, a 16 cm thick solid slab rests on a grid of concrete beams, including: (a) primary double-bay post-tensioned beams with 2 m × 38.50 m spans, spaced at 15.00 m intervals; and (b) built-up secondary beams measuring 13.50 m long.

Inside the new arrivals lobby, the ribbed slab that roofs the local train platforms (elevation 628) was adapted to install a new transformer station and communication cores (lifts, stairways, ramps) between the moving walkway and the upper storey outdoor exit near the lantern-shaped bus shelter and interchange.

The basic criterion that governed all the structural solutions adopted was to minimise modifications to the existing structure and avoid user inconvenience as far as possible. The ribbed slab was found to be unable to bear significant load increases other than its own self-weight and other dead loads. The strengthening required to meet code specifications was therefore tailored to distinguish between areas where local loads would not be significantly greater than prior to the remodel and the areas where they would.

6.1.2.1. Areas with no significant load increasesThe as-built drawings available defined the geometry of the reinforcement in the ribbed slab with sufficient accuracy. In addition, the trial pits drilled in the initial stages of the works confirmed the reinforcement ratio shown on the drawings. These findings made it possible to conduct a detailed study of the stress and strain that would be borne by the slab after the remodel. That analysis showed that the secondary ribs would suffice to bear minor load increases, albeit with a close fit to the safety factors defined in the existing legislation. Those factors declined substantially in the main portal frame ribs, however. The fact that no perceptible cracking was observed during the original works was no guarantee of good final stage performance, for the design live loads were never applied to the area analysed and the dead loads specified on the drawings were never reached.

The escalators for accessing the local train platforms are located in the area underneath the ribbed slab delimited by pairs of portal frames spaced at 5.20 m. The main ribs that needed to be strengthened are positioned above recesses in the partitions on each side of the escalator. Given these highly favourable geometric arrangements, slender steel columns could be positioned at mid-span of the ribs in highly efficient and speedy operations performed at night during the hours when no local trains run, i.e., with no impact whatsoever on station use. These new intermediate columns did not have to be actively loaded with hydraulic jacks. Consequently, the permanent loads present when they were installed continue to be borne by the original main ribs, while the additional dead and live loads are borne by shorter span continuous beams. Hence, no moment inversion takes place in the bearing sections where the main ribs rest on the new steel columns; rather, the mid-span positive moment declines.

6.1.2.2. Communication core support areaModerately sized pits, albeit significantly larger than the cells in the ribbed slab, were needed at the points where the ramps in the new arrivals lobby spring from the slab. Drilling those pits into the slab would have entailed cutting through the main and secondary ribs and building many columns on the lower level, a solution ruled out by the station layout.

The architectural design accommodated that conditioning factor with a slightly slanted build-up between the end of the moving walkway and the spring line for the pedestrian ramps and stairways in the lobby. With that solution, the pits could be positioned above the ribbed slab. To minimise the action on the existing structure, gridded steel beams and a shallow composite slab were built above and clear of the ribbed slab, so that when in service it would only bear its own self-weight.

The photo in Figure 20 shows the aforementioned grid prior to concrete casting. The corrugated sheet steel composite slab is flush with the upper flange on the steel beams to keep the depth shallow.

Figure 20. Construction of the steel grid prior to casting the concrete for the composite slab.

6.1.3. Modification of the solid slab over the concrete beam grid6.1.3.1. Main post-tensioned beamsThe main post-tensioned beams did not need any manner of strengthening, for the load increases were negligible.

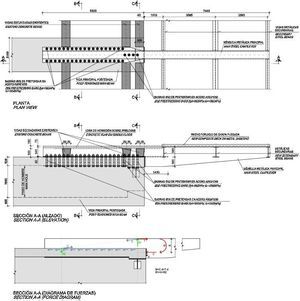

A series of structural modifications were necessary, however, in connection with the bearing plate where the main column on the new arrivals lobby steel roof rests on one of the aforementioned beams. That column transfers an axial load of 8500 kN and shear stress of 1100 and 450 kN in the longitudinal and transverse direction of the beam, respectively, to the underlying concrete structure (design values). In light of such large values, the roof column had to be positioned over the mid-span column in the post-tensioned beam. As Figure 21 shows, the new column springs from a steel load transfer beam that distributes the local reaction between the two side webs of the post-tensioned beam. This solution avoided having to strengthen the central opening with diaphragms, making it possible to maintain the manhole.

Figure 21. Bearing plate where the steel roof column rests on the post-tensioned beam, detail.

The mid-span bearing on the main beam, positioned on a circular section concrete column 1500 mm in diameter, consisted of a 1250 mm diameter elastomeric bearing. In light of the 40% increase in the vertical load, the existing elastomeric bearing had to be encircled with others. By increasing the area of the elastomeric bearing by around 200 cm2, the normal and tangential stresses were limited to 15 and 0.7 MPa, respectively, i.e., less than the characteristic total loads. Neither the concrete column nor the main beam had to be strengthened.

6.1.3.2. Secondary reinforced concrete beamsThe secondary existing beams along the moving walkway only had to be strengthened in a few specific instances, where the new local loads modified their stress state significantly.

On the one hand, the edge beams on the local train platform roof had to be strengthened to bear the loads from the new low-rise canopies. Here it sufficed to raise their bending strength by applying carbon fibre to the bottom and lower rim of the sub-vertical surfaces of the webs, as illustrated in Figure 22.

Figure 22. Carbon fibre flexural strengthening for secondary beams.

More intense action was required on the beams around the new lift shaft in the arrivals lobby. Since the shaft is located in an area not clearly allocated to public use, work could be performed underneath the slab. So as not to affect the existing clearances, however, a very tight solution was adopted consisting of fitting the lift shaft strictly to the height defined by the depth of the concrete beams on that storey. To that end, a steel enclosure of sufficient size and stiffness to resist impact due to the possible detachment of the lift car was hung from the two beams on each side. Figure 23 shows plan and cross-section drawings of the shaft.

Figure 23. Steel enclosure for lift shaft (plan and cross-section).

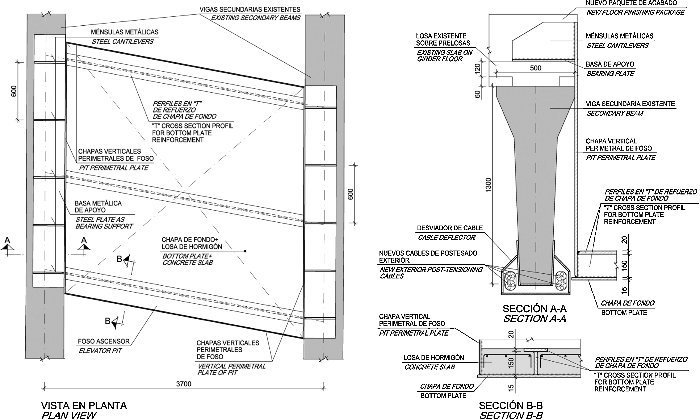

As the existing secondary beams were unable to bear the self-weight of the steel enclosure for the shaft and the service and impact loads from the lift, they were strengthened by external post-tensioning ([15]) (see the photograph in Figure 24). The reactions induced by the steel enclosure are concentrated in the middle section of the secondary beams. Consequently, the post-tensioned cable layout was adapted to the respective moment diagram to ensure that the strengthening would effectively offset the aforementioned reactions (Figure 25).

Figure 24. Existing beam strengthened with external post-tensioning.

Figure 25. External post-tensioning cable layout.

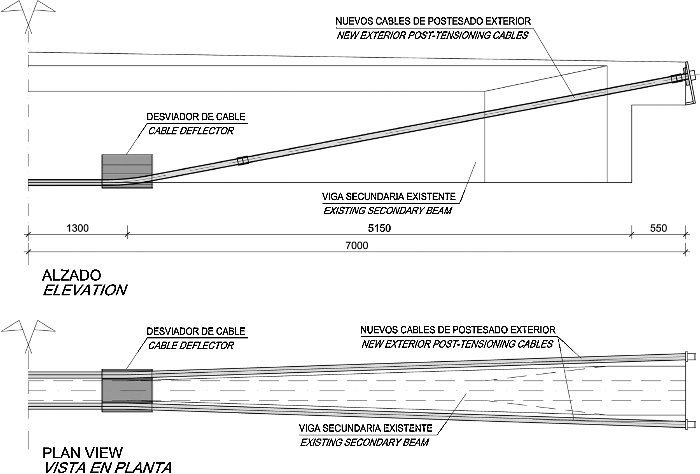

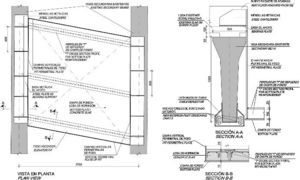

6.1.4. Cantilevered connection (by-pass) between the local train platform roofs and the new arrivals footbridgeThe architectural design called for locally widening the roofs over the local train platforms in the eastern area of the arrivals footbridge to shorten the distances to be travelled by arrivals passengers.

Since new columns could not be built on the platforms, the enlargement, measuring approximately 41.00 m × 7.50 m, had to be cantilevered off the main beams in the local train roof. In the design this structure was called the “cantilevered by-pass”. The existing secondary beams in the roof were found to be unsuitable for the enlargement because of their geometry and because their bearing capacities were very tightly designed to the pre-existing loads.

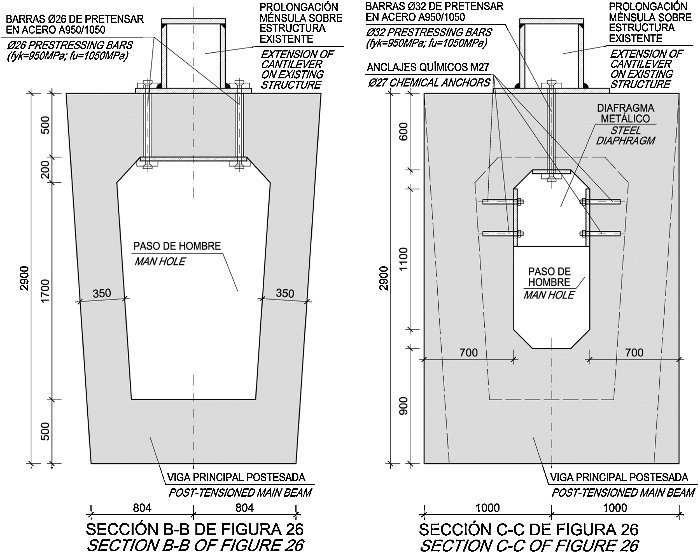

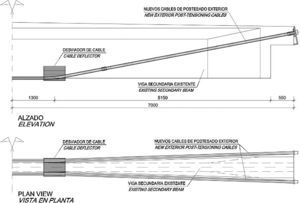

The modification to the existing structure was therefore confined to cutting through a fairly small area of the solid slab along the main beams and anchoring three powerful variable depth (hmax = 1150 mm) steel cantilevered members to the main post-tensioned beams. After sawing through the solid slab in the space in between the secondary beams initially used to drain the roof, a 6 m length of each member was positioned over the existing main beam to ensure that the vertical reaction and restraint moment would be correctly transferred. The elevation drawing in Figure 26 shows the cantilevered and anchored lengths of such a member. The free body diagram is also shown.

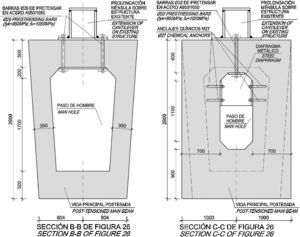

• The vertical reaction (R1), i.e., the sum of the shear force on the cantilever (V) and the lever effect (R2), is resisted by a transverse diaphragm whose dimensions were calculated to allow for the manhole, as shown in Figure 27. To transfer the vertical reaction to the webs of the existing concrete beam, the diaphragm was welded a posteriori to steel plates connected to the webs with anchorage bars.

Figure 27. Anchored length of cantilevered by-pass (cross-sections).

• The horizontal compression component (C) (associated with the restraint bending moment, M) is transferred directly to the top of the concrete beam at the end of the post-tensioned beam.

• The upper tensile component (T), together with the upward vertical lever reaction (R2), are transferred to the top of the beam along the anchored length of the cantilevered member. To that end, 38 prestressed bars were installed to connect the bottom flange in that length to the top of the concrete beam. The 22 bars closest to the edge of the roof, with 32 mm ∅, transfer shear force, primarily by friction. The other sixteen 32 mm ∅ bars essentially transfer axial tensile force.

Figure 26. Cantilevered by-pass (plan and elevation). Cross-sections B-B and C-C in Figure 27 .

The platform roof enlargement, resting on the three cantilevered members described, consists of a 6 + 10 cm thick composite slab laid on sheet steel supported by a lattice of 600 mm deep composite beams (Figure 28).

Figure 28. View of cantilevered by-pass from high-speed tracks.

6.1.5. Restoration and strengthening of steel car park domesBased on the analysis of the need to strengthen the domes over the moving walkway and the advisability of maintaining their aesthetics, the shapes circling the centre skylight and the perimetric arches in the domes were maintained and strengthened, replacing only the ribs that constitute their skeleton. In addition, the bearing plates, which had been weathered and manipulated since their construction many years ago, had to be retooled and strengthened.

6.2. New construction in the existing building6.2.1. New storey for the arrivals lobbyThe arrivals lobby ramps, stairways and lift carry passengers from travelator elevation 624 to street level at elevation 628. The architectural design included the construction of a courtyard open on one of the two sides of the lobby roof as a continuation of the pedestrian entrance. That entailed building a new deck slab adjacent to the ribbed hollow-core slab on which the street rests. The solution chosen was a 16 cm thick (6 + 10 cm) composite slab on sheet steel connected to 690 mm deep steel beams with spans varying from 13.60 to 22.15 m. All these members are I-beams, with the exception of the beam that receives the ramps and stairways, where a box configuration was used to resist the torque generated by the eccentricity of the reactions. Circular openings 400 mm in diameter and spaced at 600–1000 mm, centres, were provided to accommodate the necessary service ways. Larger sized rectangular openings (“racecourses”) were made where necessary (Figure 29). The composite beams were dimensioned by first assuming a solid web with no openings, and then successively thickening the webs based on the strain equivalence between two finite element models, one for a solid web and the other for a thicker web with openings.

Figure 29. Composite beams with circular openings and “racecourses”.

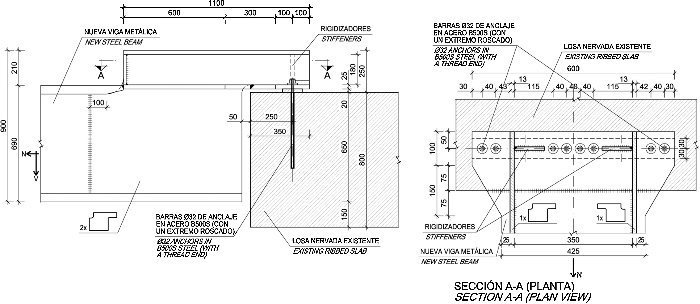

Some of the composite beams rest on the bottom chord of the large truss in the lobby (Section 6.2.2) across a fixed-hinged bearing plate angle-welded to the web and slightly over-engineered to bear the parasitic moment inevitably induced by the restraint.

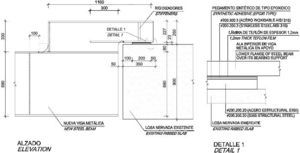

At the opposite end, the beams rest on the existing 80 cm deep hollow-core slab. The short beams rest on the edge of that slab, supported by a receiving plate anchored a posteriori to the bars. The long beams are rabbeted to the top of the existing slab. This fixed-hinged connection consists of a steel bearing plate and vertical anchor bars installed a posteriori (see Figure 30).

Figure 30. Rabbeted fixed-hinged bearing.

Nonetheless, due to the relative positions of the expansion joints on the existing and new slabs, some beams rest on an area of the existing slab where thermal effects or shrinkage may induce differential horizontal displacements. That circumstance called for designing skid-shoes consisting of 1.2 mm thick Teflon membranes (Figure 31, Figure 32).

Figure 31. Rabbeted skid shoe (elevation).

Figure 32. Rabbeted skid shoe (during construction).

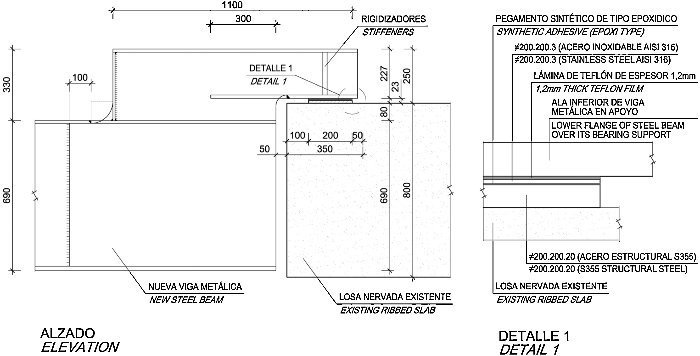

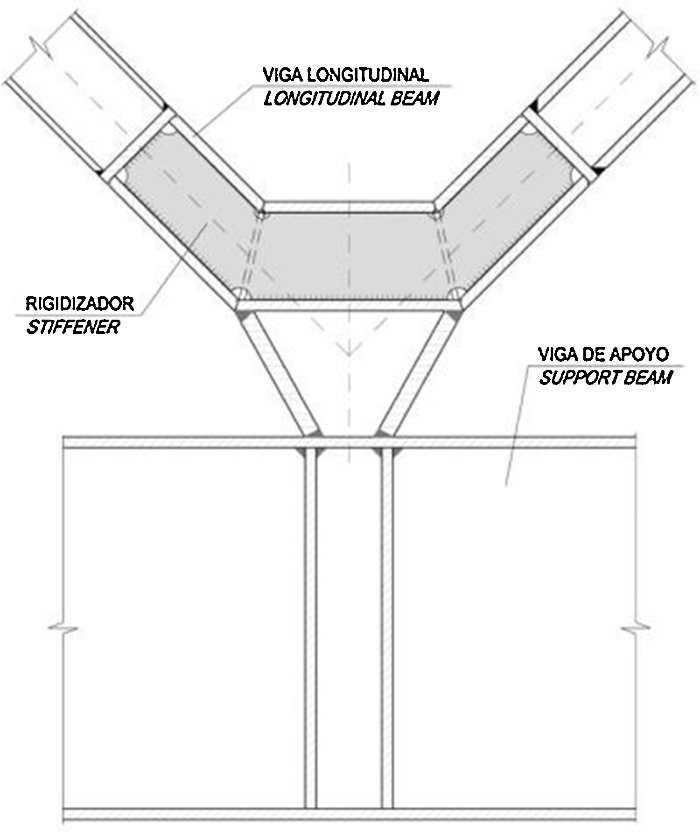

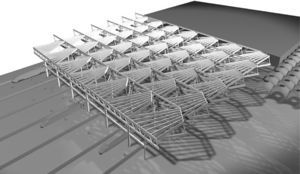

6.2.2. Roof on new arrivals lobbyThe new arrivals lobby roof is a three-dimensional truss consisting of longitudinal beams and continuous transverse members. The cross-section of the roof as a whole forms a series of crests whose geometry accommodates the spans that need to be crossed.

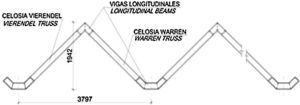

Built-up, V-shape longitudinal beams are positioned in the hips and valleys of the crests. They are spaced at 1654 mm, centres, and inter-connected by means of alternating Warren and Vierendeel trusses that work jointly to ensure the continuity and stiffness of the planes (Figure 33).

Figure 33. Roof cross-section.

The vertical loads are transferred to the bearings across the slanted planes of the two types of trusses: the longitudinal beams serve as chords and the trusses transfer shear forces, while the horizontal components of the slanted planes are counterbalanced at each node to form a likewise balanced whole. The end members had to be heavily strengthened, because while they have a single truss and hence weaker anti-buckling bracing, they form the front line of exposure to the wind.

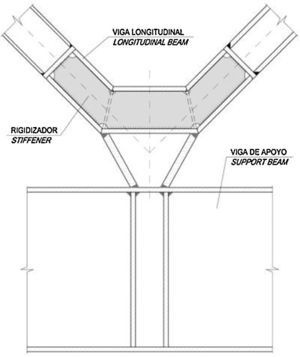

Given its shape and structural design, the roof can rest on only two lines of support spaced at 23 metres, with a cantilever of nearly 14 metres outward from the station. The first line, on the cantilever side, is a beam that rests in turn on the façade columns. On the opposite end, the roof rests on a truss made of welded tubular web members and a box beam bottom chord 1.00 m wide and 1.45 m deep (Figure 34).

Figure 34. Truss, elevation view.

The box beam in the truss serves as a bottom chord, receiving predominantly axial forces, while the crest-based geometry at the top is not clearly an upper chord, but rather a member that receives axial forces and significant parasitic bending moments. Lastly, this truss rests on two columns, one circular and the other rectangular.

The parameters addressed in the numerical model included snow, wind, temperature and the loads on the elevation 628 slab beams that rest either on the box beam in the truss or the ties that hang from the roof. The roof was assumed to be statically indeterminate with the columns and truss, while the short columns that support the crests, elements subjected to significant bending moments, were studied in detail (see Figure 35).

Figure 35. Short columns, detail.

The lack of horizontal bracing led to engineering the roof as a sway frame, applying non-linear analysis and adding the initial overall imperfections. The second order effects were observed to raise stress and strain by an insignificant 5%. The Euler load was found for members liable to buckling to determine their effective buckling length.

7. Construction processAs noted above, the present enlargement constitutes Stage I of a broader remodel of Atocha Station. That conditioned construction typology and processes in certain elements, to the extent that in some cases the new construction is merely provisional, to be replaced by the permanent solutions in subsequent stages.

7.1. LogisticsConstruction in the urban core of a large city is always complex, but more so when the works are to be performed in the country's largest high-speed train station and its capital's largest local train station, without interrupting service in either. The outcome of all these conditioning factors translated into limited worksite accessibility and on-site mobility, absence of on-site storage space, need for strict safety measures both for workers and the station's thousands of daily users, and considerations around the impact on station services, facilities and even structures in permanent use in the station as well as on area traffic and residents. Site location was, then, a key conditioning factor that governed both the choice of construction processes and the types of ancillaries ultimately used.

Another of the basic determinants for the remodel project was the construction deadline for works that involved modifying tracks that were continually in use and existing buildings with heavy flows of pedestrian traffic.

One last project requisite was to ensure uninterrupted commercial operation of the high-speed and local stations. As a result, much of the work had to be performed at night, since the power had to be removed from the overhead wires for safety reasons. That in turn meant establishing special environmental measures, in particular in connection with noise control, given the existence of nearby residential buildings.

7.1.1. Environmental factors and protective measuresA detailed logistics and safety plan had to be drafted to meet all the aforementioned requisites. A system was implemented to separate and even isolate the work areas from train traffic, passenger flows and train services (such as catering) with “provisional protection tunnels” (Figure 36).

Figure 36. Provisional tunnels to protect tracks.

The provisional protection tunnel system consisted essentially of dividing the platforms in three, with an inner worksite area flanked by two outer lanes for passenger traffic. This division included roofing the track bed with its overhead wires and the outer passenger traffic lanes. As a result, only the worksite area was unroofed, while the train and passenger traffic areas were completely closed off and protected.

Thanks to these provisional protection tunnels, work could be performed on the platforms regardless of whether they were in use and whether or not traffic had been interrupted in the adjacent tracks. This proved to be vital to meeting construction deadlines.

The tunnels were built using part of the steel structure on the low-rise canopies that were to be demolished. More specifically, the IPE-400 variable depth steel beams that supported the overhead wires were braced with steel columns and used to build portal frames, subsequently enclosed on the sides with corrugated sheet steel. The structure was then roofed with materials removed from the existing canopies. The resulting tunnels protected the overhead wires from the accidental impact of construction materials (Figure 37).

Figure 37. Inside view of provisional tunnels.

The workspace between the walls of the provisional tunnels on each platform was only around 7 m wide. That clearance had necessarily to suffice for the equipment and machinery required to demolish the existing canopies, drive the new foundation micropiles, open the trenches, lay the steel and cast the concrete for the pile caps, and erect the columns and superstructure for the new canopies (Figure 38).

Figure 38. Working space on platforms after tunnel assembly.

In addition, the existence of nearby buildings on Méndez Álvaro Street called for installing fixed and portable noise screens to be able to work at night without inconveniencing nearby residents. These screens were positioned on continuous footings built at platform 8 (see Figure 39).

Figure 39. Noise screens.

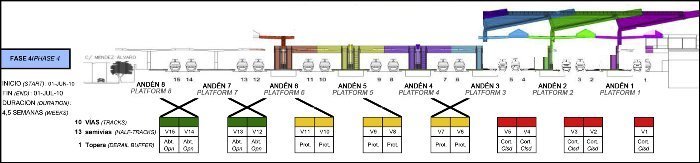

7.1.2. Work sequenceMuch of the work had to be conducted at night, when power outages, which at times were limited to three-hour periods, would not interfere with train service. That, in turn, often made it difficult to finish tasks in a single workday, leading to continuous rescheduling. For reasons of railway operation, at times power could not be removed from some or even any of the tracks.

The first task was to adapt four of the station's tracks (12–15) to standard gauge so the remaining tracks could be consecutively withdrawn from and returned to service. Construction advanced from track 1 to 11 by groups of three or four tracks. Consequently, for much of the time, tracks were in service on both sides of the works, rendering ancillary logistics and the type of activities that could be performed particularly complicated.

The diagram in Figure 40 illustrates one of the work sequences, showing the respective track service and power outages and interruptions to train circulation and parking.

Figure 40. Phase diagram and outage sequences.

7.1.3. Demolition and foundationsDemolition works were undertaken once the provisional protection tunnels were built over the tracks adjacent to the platform where work was to be performed. The sequence, illustrated in the figures, was as follows:

• Partial sectioning of the steel beams on the existing canopies and removal from the platform (Figure 41).

Figure 41. Demolition of canopies between provisional track protection tunnels.

• Bracing of the reinforced concrete beams on the existing canopies for subsequent division into 4 m lengths with a circular saw and removal on carts to the south end of the platform (Figure 42).

Figure 42. Demolition of canopies between provisional track protection tunnels.

• Sectioning and removal of concrete columns.

As noted earlier, the design pile-based foundations had to be replaced with micropiles, which required smaller scale machinery that could access and work in the scant space available on the platforms more readily (Figure 43).

Figure 43. Micropile and pile cap construction between provisional track protection tunnels.

Lastly, once work was completed in the platform at issue, the protective tunnels over the adjacent tracks were demolished (see Figure 44).

Figure 44. Demolition of provisional tunnels.

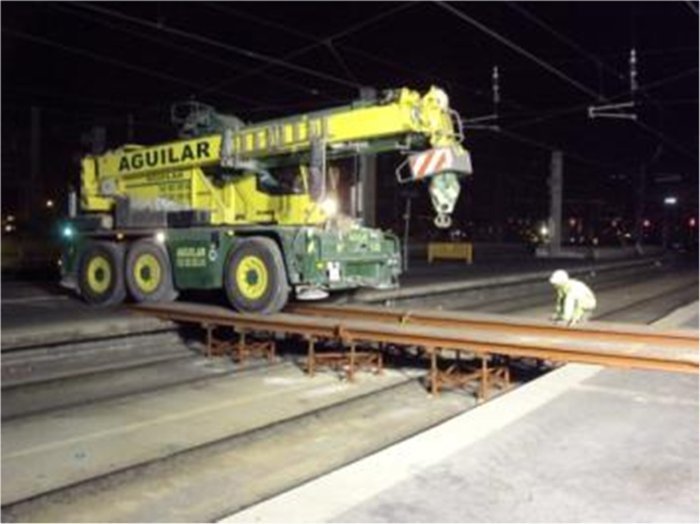

7.1.4. Machinery: site access and on-site mobilityWhen service was interrupted on a pair of tracks, most of the work to be done involved the platforms and the track itself. A number of solutions were in place to reach those areas with the machinery and materials, although most were confined to the use of small-scale equipment at night only.

Depending on the stage of the works, material was delivered through the station entrance on Méndez Álvaro Street or in-station roads for internal traffic. In the latter case, given the difference in elevation, additional hoisting resources in the form of tower cranes or heavy duty mobile cranes were required to position the material where it was needed (Figure 45).

Figure 45. Platform access for machinery.

Where small volumes were involved, the existing underpass (catering gallery) was used to move materials and machinery inside the station. The platform elevations were lowered to accommodate large-scale machinery and heavy materials (mobile cranes, hydraulic platforms) and ensure uninterrupted travel while respecting the clearance to the overhead wires. With that solution, most machines were able to access the platforms from the Méndez Alvaro Street entrance at night. During the day, however, the platforms had to be kept at the proper elevation for arriving passengers in any of the tracks in service. To that end, lightweight, portable modular footbridges were built that were manually assembled every morning and dismantled every night.

Another method for moving materials and machinery was to lay beams across the track bed to form temporary bridges and thereby create a grade crossing without affecting the existing platform (Figure 46).

Figure 46. Inter-platform machinery traffic.

After the work was completed, platform elevations and finishes were restored.

One of the major challenges was coordinating the use and on-site circulation of the many machines involved (see Figure 47), for given the paucity of available space, relocating a single machine could entail moving half a dozen others (with their respective personnel and ancillaries).

Figure 47. Coordination of machinery traffic.

Moreover, every pair of tracks was fitted with an asymmetric scissors crossover. These devices lay in the very midst of all other actions: alongside the arrivals footbridge and in the area between the high-rise and low-rise canopies. While they consequently occupied a space needed to work, they also needed to be scrupulously protected. To that end, the crossovers were covered with sheet steel resting on steel shapes and stiff enough to bear all manner of machinery (Figure 48).

Figure 48. Protection for scissors crossovers.

7.2. AncillariesThe site and nature of the works largely conditioned the type of ancillary resources that could be used.

Only two tower cranes were erected to move materials, due to the lack of space. One was sited over foundations consisting of a large micropile cap on platform 8 alongside Méndez Álvaro Street (Figure 49).

Figure 49. Erecting crane on platform 8.

The other tower crane was sited between the local and high-speed lines on a large concrete portal frame that spanned an in-station roadway so as not to obstruct emergency service access. That called for building a powerful raised bedframe for the crane that rested on walls with micropile foundations (see Figure 50).

Figure 50. Portal frame for tower crane between local and high-speed lines.

Other challenges were posed outside the track areas: construction of the arrivals lobby, for instance, was largely conditioned by the low bearing capacity of the existing deck slabs. That ruled out the use of a tower crane and necessitated the design and construction of a strong bedframe to distribute the loads generated by the mobile crane used to erect the structure.

The use of bridge cranes as ancillaries in the assembly of elements on both the low- and high-rise canopies proved to be instrumental for works progress. They were installed on the steel structure for the new roofs, on occasion conditioning their dimensions (Figure 51).

Figure 51. Bridge cranes over the high-rise canopies.

7.3. Construction in track areasThe most prominent features of the construction work performed in the track yard are described below.

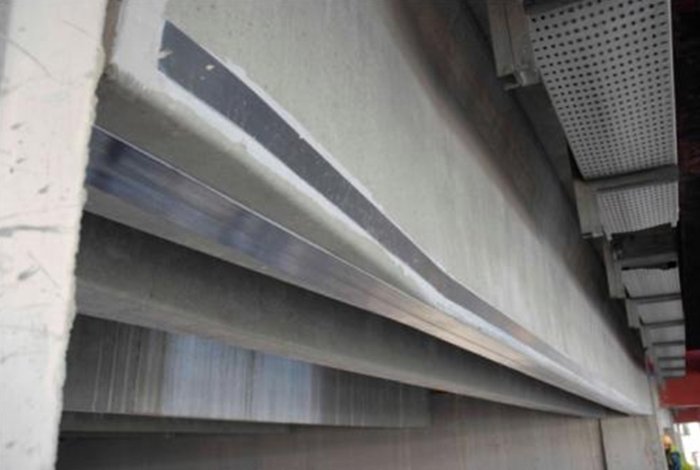

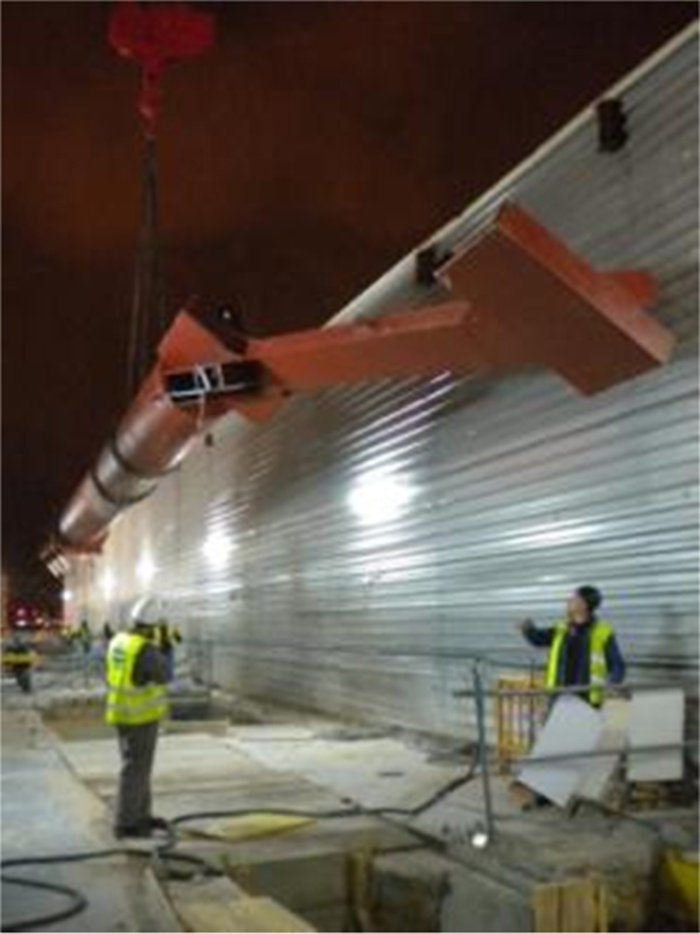

7.3.1. High-rise canopiesThe high-rise canopy was erected sequentially. The assembly process followed in all 42 modules began with the columns, to which the upright was shop-welded. A span length of shop-assembled transverse truss was then positioned between two columns. The beams forming the longitudinal portal frames were erected next, and the bracing elements and the enclosures were built over the paraboloid frame. Lastly, the triangular and paraboloid purlins were set into position as it can be seen in Figure 52.

Figure 52. Assembly of the first high-rise canopy module.

Assembly progressed transversely from platform 1 to platform 7. The geometry in the modules in platforms 1 and 6 varies significantly from the others, for they have a single line of columns. As a result, provisional shoring towers springing from the local track area, at a distance of nearly 30 m in the case of platform 1, had to be erected during construction (Figure 53). On the opposite end, in platform 7, the 14 m tall shoring towers rested on the platform itself, springing from bed frames (Figure 54).

Figure 53. Shoring towers in the local train area.

Figure 54. Shoring towers on platform 7.

The roof cantilever was unbraced with the aid of hydraulic jacks installed at the top of the shoring towers. The finishes were added as module construction progressed. Since cantilever stability was logically very sensitive to the actual loads, calculations were performed to analyse their stability and determine safety during unbracing. Since that analysis ultimately showed that at least two full rows of modules were needed to offset the loads on cantilevers spanning over 18 m, the shoring could be removed from the end cantilevers once that milestone was reached.

Roof finishes, which ensure thermal and acoustic insulation as well as noise absorption, were also conditioned by the need to work over tracks in service, which called for dry solutions. In other words, concrete had to be ruled out, for its use might have originated moisture on the overhead wires or the trains themselves.

The high-rise canopies finishes were installed both from above with the aid of the bridge cranes (Kalzip roofs, curtain walls and outdoor smoke vents) and from below, working from man lifts (painting, suspended ceilings and indoor smoke vents). Flexible sequencing of these finishes was vital to works progress, for each task could be performed indistinctly before or after any other and advance independently.

7.3.2. Low-rise platform canopiesAfter the former roofs were demolished in the north platforms, the new low-rise canopies were built over the existing foundations, to which the new columns were anchored. In the south, new foundations were built using slanted micropiles: given the scant on-site space available, other solutions were ruled out due to the larger scale machinery required. These canopies were also erected sequentially, worksite conditions permitting, and always avoiding interference with train service. The structure was positioned on the columns and provisionally stabilised by connecting it to them (Figure 55). The transverse beams were inter-connected later, when the tracks were clear for working. Works therefore progressed longitudinally along each platform, while transverse progress was conditioned by the timing of station-governed track interruptions. When the respective area became available, the beam sections were joined and the canopy finishes applied, in this case entirely from above using the aforementioned bridge cranes (Figure 56).

Figure 55. Low-rise canopy construction.

Figure 56. Finished low-rise canopies.

7.4. Construction in the existing buildingsTwo of the most prominent modifications on the existing station buildings included the construction of a new arriving passengers terminal one storey above the present local station and the remodel of one of the lines of domes over present car park P2, which was conditioned for passenger traffic from the platforms.

The conditioning factors in these works were the urban surrounds and the heavy flows of railway system users. While train circulation did not constitute a constraint, works progress was conditioned by the usual uncertainty around the existing structure with which the new buildings would be fully integrated.

7.4.1. Arrivals lobby and roofThe most characteristic element in this part of the works is the huge steel truss on the south façade on whose 1 m deep welded box profiles much of the building rests. This truss spans more than 38 m between two new columns. One springs from the steel load transfer beam embedded in the existing deck slab, and the other from an existing column in the local station, whose foundations had to be injection-strengthened to accommodate the substantial load increase.

A deck slab with composite beams that rest on the bottom chord of the truss and the existing hollow-core slab with rabbeted supports was built as a continuation of the existing pavement. Part of this slab hangs from the singular dogtooth roof. It has box girders in hips and valleys and a three-dimensional structural system that is the result of the Vierendeel-like triangulated trusses positioned along the slopes.

Several solutions were studied for truss construction: the earliest options called for modules with a maximum weight of 300 kN, welded on site that would be assembled with no need for provisional bracing. Nonetheless, given the crest-like shape of the truss, these modules needed secondary elements, such as transverse ties or provisional chords, to offset the unbalanced forces on the joints and reduce the strain on the element during assembly. These circumstances raised the cost of the solution considerably. One alternative studied consisted of positioning the modules without strengthening and applying the forces required with a system of jacks to re-establish the theoretical unstrained configuration and an acceptable stress state before welding the modules to one another. Finally, however, the solution adopted was to use shoring towers as provisional supports at the cantilevered end of the roof and at mid-span in the main bay, in addition to the two permanent bearing points. As the photograph in Figure 57 shows, the provisional supports for the roof modules comprise, from left to right, the truss, the mid-span shoring towers and the façade beam. The shoring towers for the cantilever are not shown.

Figure 57. Modular roof construction.

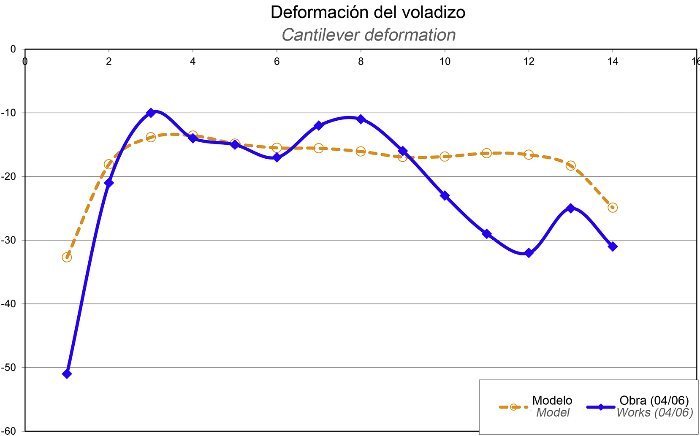

The roof modules, with a maximum weight of 300 kN, were assembled by stages, welding each to the one preceding it (Figure 58). At the same time, an incremental model that simulated the geometry and loads in each construction stage was developed for the structure. The model was then used to monitor the global movements measured on site against the movements predicted in the numerical model as well as to verify the forces and moments and strain on the structure, for under self-weight, the construction stages modified the stress state predicted by the numerical model.

Figure 58. Roof module on the worksite.

Unbracing at the two temporary points of support was also monitored. With all the roof modules welded, the shoring towers were removed first from the cantilever and then from the mid-span positions. A comparison of the model and on-site measured movements yielded wholly satisfactory results (Figure 59).

Figure 59. Comparison of cantilever movements after roof de-bracing.

8. ConclusionsWith the conclusion of Stage I of the enlargement of Atocha Railway Station, a new operating model could be implemented that has raised the station's capacity by separating arriving from departing passenger flows. As noted earlier, the fact that the enlargement described is the first stage of a more ambitious project conditioned the construction solutions and processes for a number of elements. Indeed, some of the new construction is provisional and will be replaced by permanent elements in later stages.

The many factors that conditioned these works – site, timing and imperative non-interference with railway operations, among others – called for highly detailed planning, in which all possible scenarios and the need to conduct a considerable number of activities simultaneously in limited space and time (power outages, track beds, high voltage work…) had to be addressed. The enormous complexity of the project stemmed from the exceptional constraints inherent in the need to work with the high-speed train station in service.

Project highlights include the construction of the new high-rise and low-rise canopies that extend the hypostyle hall lengthwise, and the remodel of the existing building to construct a new arrivals lobby.