The present paper investigates the behaviour of a polymer matrix beam reinforced with graphene and carbon fibres at nano and micro level reinforcements, respectively, to study mainly the strength aspects for structural applications. However an attempt has also been made to use a combination of both micro and nano level fillers in both individual and combined forms as reinforcements. The addition of graphene and carbon fibres in the control beams was varied from 0.1 to 0.4% percent by weight of polymer matrix. Dispersion of graphene was carried out using ultrasonic energy. Composite beams were tested under flexural in order to evaluate their mechanical property such as load-deflection criteria. These results were then compared with those obtained from plain polymer beams. The present work also investigates the optimum percentage of graphene and carbon fibres as individual and combination fillers that gave the best results in terms of enhanced mechanical properties and economical aspects as well. Scanning electron microscopy and energy dispersion X-ray spectroscopy was conducted to examine the interfacial surface adhesion between the fillers and the polymer matrix. Reinforcement of polymer beams with graphene alone by weight of the polymer matrix showed enhanced results when compared to carbon fibres alone while the use of combined nano and micro reinforcements showed performance lying in between nano and micro fillers in the polymer. Flexural strength is enhanced by 35% compared to plain control beams when graphene was used as reinforcement fillers in the polymer matrix.

GA has been considered as one of the effective reinforcement nanoparticles for polymer-based composites owing to their outstanding mechanical properties as well as their high surface area (Wong, Sheehan, & Lieber, 1997; Yu et al., 2000). However, reinforcing them in a polymer matrix so far has no yielded good results as revealed by many researchers and this could be due to two main issues: (1) the difficulty of dispersing nano fillers in the polymer matrix, and (2) interfacial adhesion between the fillers and the polymer matrix. It has been identified since long time that the mechanical properties of polymer materials can be enhanced by fabricating composites that are imbibed with different volume fractions of one or more reinforcing phases. Recently, the practical realization of composites for structural applications with use of nano-scale reinforcement is gaining prominence when compared to micro-scale fillers. This is mainly because of the unique blending of mechanical, chemical and physical properties associated with the use of nano-fillers fillers preferably with a characteristic dimension typically below 50nm. Apart from this, study on the combination of fillers usage at both micro and nano level is scantily reported in the literature and this area needs to be rigorously explored to realize the benefits of such reinforcements. The idea of dispersing nanoparticles is mainly due to their large enhancement in the specific surface area and interfacial area they provide to the matrix phase.

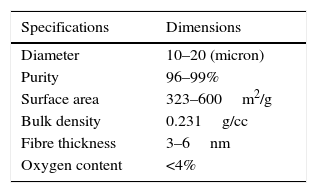

As traditional composites with natural fibre reinforcement use over 35wt% of reinforcing phase, the dispersion of just a few milligrams of nanoparticles into polymeric matrix could lead to drastic changes in their mechanical properties with added functionalities. Increase in the viscosity of the holding matrix because of micro scale fillers can be greatly reduced by using nano scale fillers leading to the reduction in the brittlement of the holding matrix. Fibre-reinforced composites have emerged as a major class of structural materials and are either used or being considered as substitutions for metals in many weight-related critical components in aerospace, automotive and other industries. In this work, a method has been proposed to reinforce the adhesive layer through the homogeneous dispersion of only a small fraction of GA. Carbon fibres are regarded as one of the most promising reinforcement materials for the next generation of high-performance structural and multifunctional composites (Endo, Hayashi, Kim, Terrones, & Dresselhaus, 2004). These molecular scale platelet areas of GA have outstanding mechanical, thermal and electrical properties. In fact, some GAs are stronger than steel, lighter than aluminium and more conductive than copper as reported by Moniruzzaman and Winey (2006). Theoretical and experimental studies have shown that GA exhibit extremely high tensile modulus (>1000GPa) and strength (>5GPa). In addition, CFs can exhibit high flexibility, low density (0.231g/cc) and large surface area (323–600m2/g). Because of this unique combination of physical and mechanical properties, GAs have emerged as excellent candidates for use as reinforcing agents in polymeric materials to yield the new generation nanocomposites. Perhaps the most remarkable improvement in the tensile modulus and yield strength of a polymer through the dispersion of GA was reported by several investigators (Liu, Phang, Shen, Chow, & Zhang, 2004). By dispersing only 2wt% of carbon fibres in a polymer matrix an increase of approximately 214% in the tensile modulus and 162% in the yield strength was reported. They attributed these impressive improvements in the stiffness and strength due to a uniform and fine dispersion of the carbon fibres and good interfacial adhesion between the GA and matrix which were assessed using SEM. Lu, Liang, Gou, Leng, and Du (2014) reported an effective approach of significantly improving electrical properties and recovery performance of shape memory polymer (SMP) nanocomposites with reduced graphene oxide (GOs) self-assembled and grafted onto carbon fibre in order to enhance the interfacial bonding with the SMP matrix via van der Waals force and covalent bond, respectively. In the work reported a layer of Ag nanoparticles synthesized from Ag+ solution was chemically deposited onto GO assemblies. From the experimental results it was reported that the electrical conductivity of the SMP nanocomposite significantly improved. The study focused on the electrically induced shape memory effect of the SMP nanocomposites in which the temperature distribution in the SMP nanocomposites was recorded and monitored. Lu, Yao, Huang, and Hui (2014) discussed an effective approach to significantly improve the electrical properties and recovery performance of shape memory polymer (SMP) nanocomposites that show Joule heating triggered shape recovery. In the work presented, reduced graphene oxide (GO) was self-assembled and grafted onto the carbon fibres to enhance the interfacial bonding with the SMP matrix via van der Waals and covalent crosslink, respectively. From the exhaustive experimental results, it is reported that the electrical properties of SMP nanocomposites were significantly improved via a synergistic effect of GO and carbon fibre. A simple method was demonstrated to produce electro-activated SMP nanocomposites that are applicable for Joule heating at lower electrical voltages.

Several research investigations have been reported in the literature regarding the use of different polymer systems with various reinforcements in micro, nano and combination of micro-nano fillers to develop polymer-based composites. However, the reinforcement of fillers like graphene (nano) and carbon fibre (micro) in polymer-based matrix for structural applications has been less investigated. In the present work, the mechanical performance of a polymer beam reinforced with graphene, carbon fibres, a combination of graphene and carbon fibres is studied and the results were compared with that of plain beams such as load v/s deflection criteria. From the exhaustive study based on the performance it can be concluded that the polymer reinforced beam yielded best results as compared to plain beams. This could be due to the high strength offered by GA at the polymer interface.

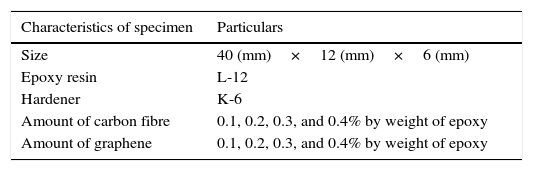

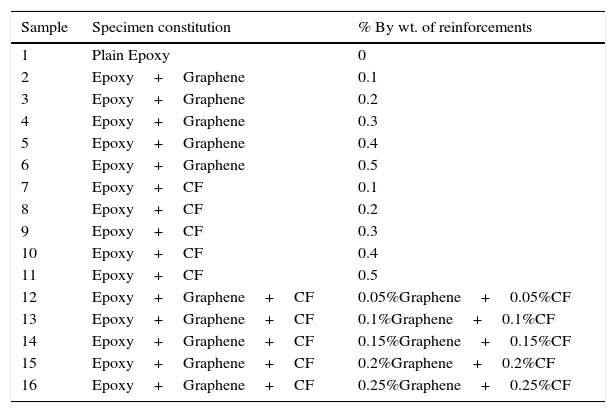

2Experimental programmeThe properties of the GAs used in this case are given in Table 1 and they were of industrial grade with a purity greater than or equal to 95 percent. The specimen characteristics are mentioned in Table 2. The specimen reference has been mentioned in Table 3. Uniform dispersion of carbon fibre against their agglomeration due to Vander Waals bonding is the first step in the processing of nano-composites. Dispersion is a critical issue while mixing carbon fibres in either water or organic solvents. As the hydrophilic nature of fillers could lead to reduced interfacial adhesion between the fillers and the holding matrix, method of sonication adopted, duration of sonication and method of casting, the specimens were maintained uniformly throughout. Different predefined amounts of CF and GA were added to the polymer matrix as shown in Table 3, and the whole mixture was kept in an ultra sonicator for 60min to achieve uniform dispersion in the matrix.

Details of the test specimen.

| Sample | Specimen constitution | % By wt. of reinforcements |

|---|---|---|

| 1 | Plain Epoxy | 0 |

| 2 | Epoxy+Graphene | 0.1 |

| 3 | Epoxy+Graphene | 0.2 |

| 4 | Epoxy+Graphene | 0.3 |

| 5 | Epoxy+Graphene | 0.4 |

| 6 | Epoxy+Graphene | 0.5 |

| 7 | Epoxy+CF | 0.1 |

| 8 | Epoxy+CF | 0.2 |

| 9 | Epoxy+CF | 0.3 |

| 10 | Epoxy+CF | 0.4 |

| 11 | Epoxy+CF | 0.5 |

| 12 | Epoxy+Graphene+CF | 0.05%Graphene+0.05%CF |

| 13 | Epoxy+Graphene+CF | 0.1%Graphene+0.1%CF |

| 14 | Epoxy+Graphene+CF | 0.15%Graphene+0.15%CF |

| 15 | Epoxy+Graphene+CF | 0.2%Graphene+0.2%CF |

| 16 | Epoxy+Graphene+CF | 0.25%Graphene+0.25%CF |

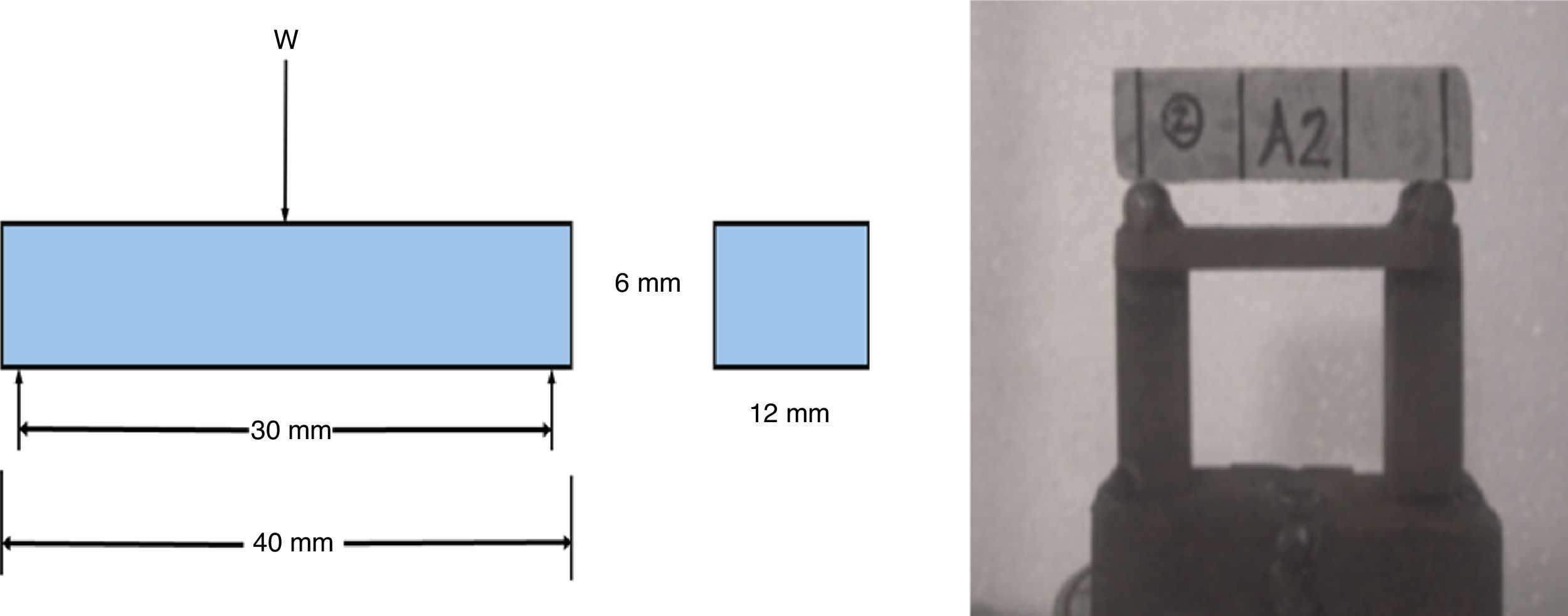

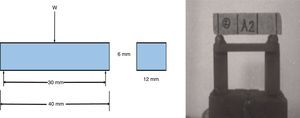

In the first stage of the experiment, small-scale experimental testing was conducted to investigate the efficiency of uniformly dispersed, randomly oriented GA as reinforcement in epoxy composites. Single-point bending tests on 40mm×12mm×6mm beams were carried out as per the ASTM D2344M standard to compare the load v/s deflection responses of plain epoxy beams and GA reinforced epoxy beams.

3Preparation of specimensThe GA employed in this work were of industrial grade with a purity of 95wt% and accordingly a concentration of 0.1, 0.2, 0.3 and 0.4% by the total weight of the epoxy matrix were used. Hardener added was 10% by the weight of the epoxy matrix to initiate the crystallization of the epoxy resin. The final product was then placed in 40mm×12mm×6mm aluminium moulds. The specimens were then cured in a room for 24h before being removed from the moulds.

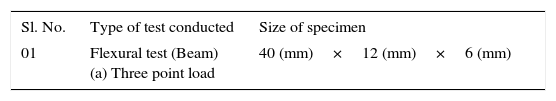

4Three-point load test on beamsThe mechanical performance of the hybrid nanocomposite material reinforced with carbon fibres and graphene, and their combination in polymer-based matrix, was evaluated by a fracture mechanic test. A specimen beam of size 40mm×12mm×6mm were tested by three-point loading test as shown in Figure 1. Six replications were made for each micro/nano-composite specimen tested in order to increase the statically accuracy. A hydraulic closed-loop testing machine was used. In order to achieve experimental accuracy, ASTM D2344M was followed to obtain the average value of the flexural strength of the polymer beams. The equipment used for the three-point load test is shown in Figure 2. The specimen size and type of test conducted is shown in Table 4.

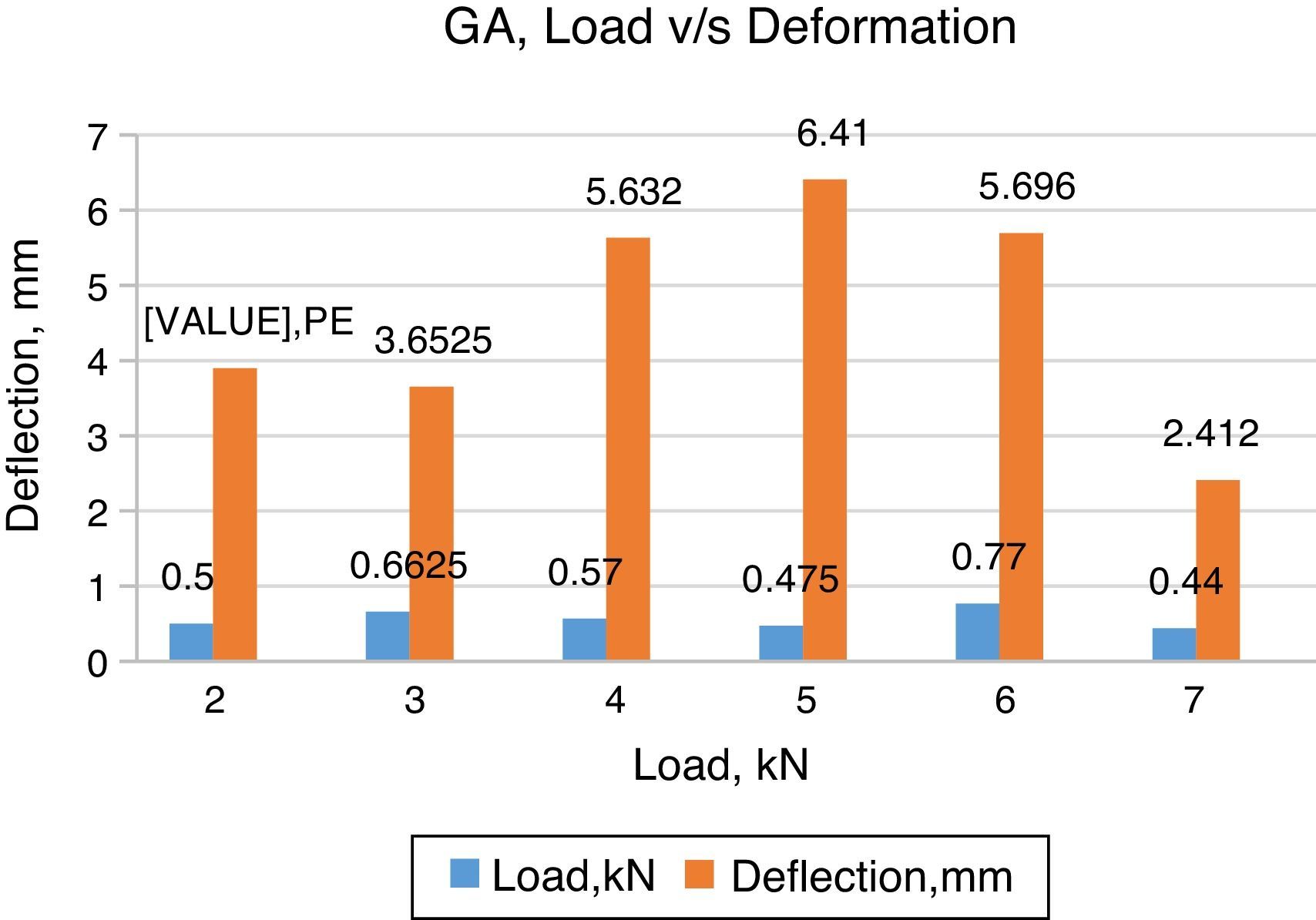

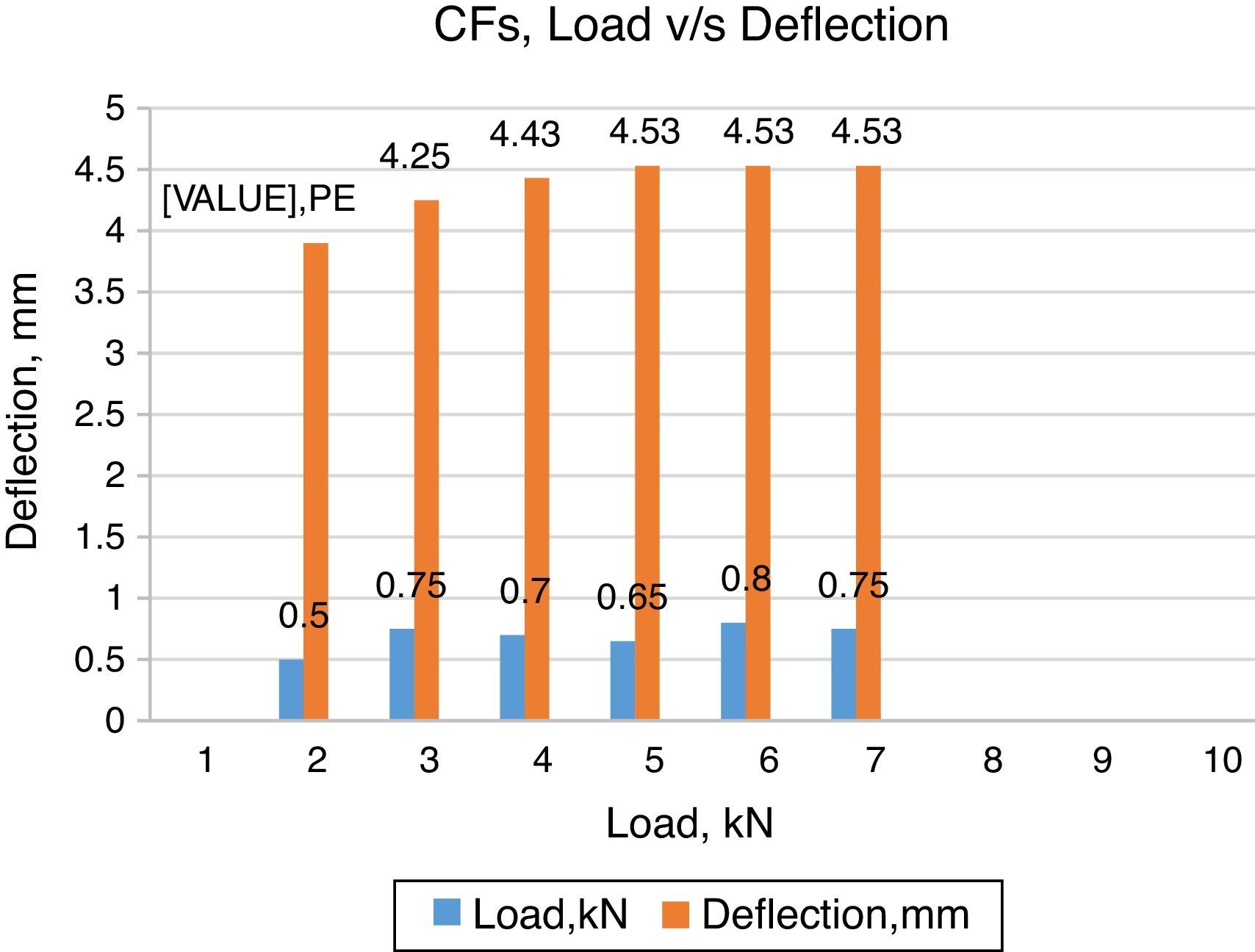

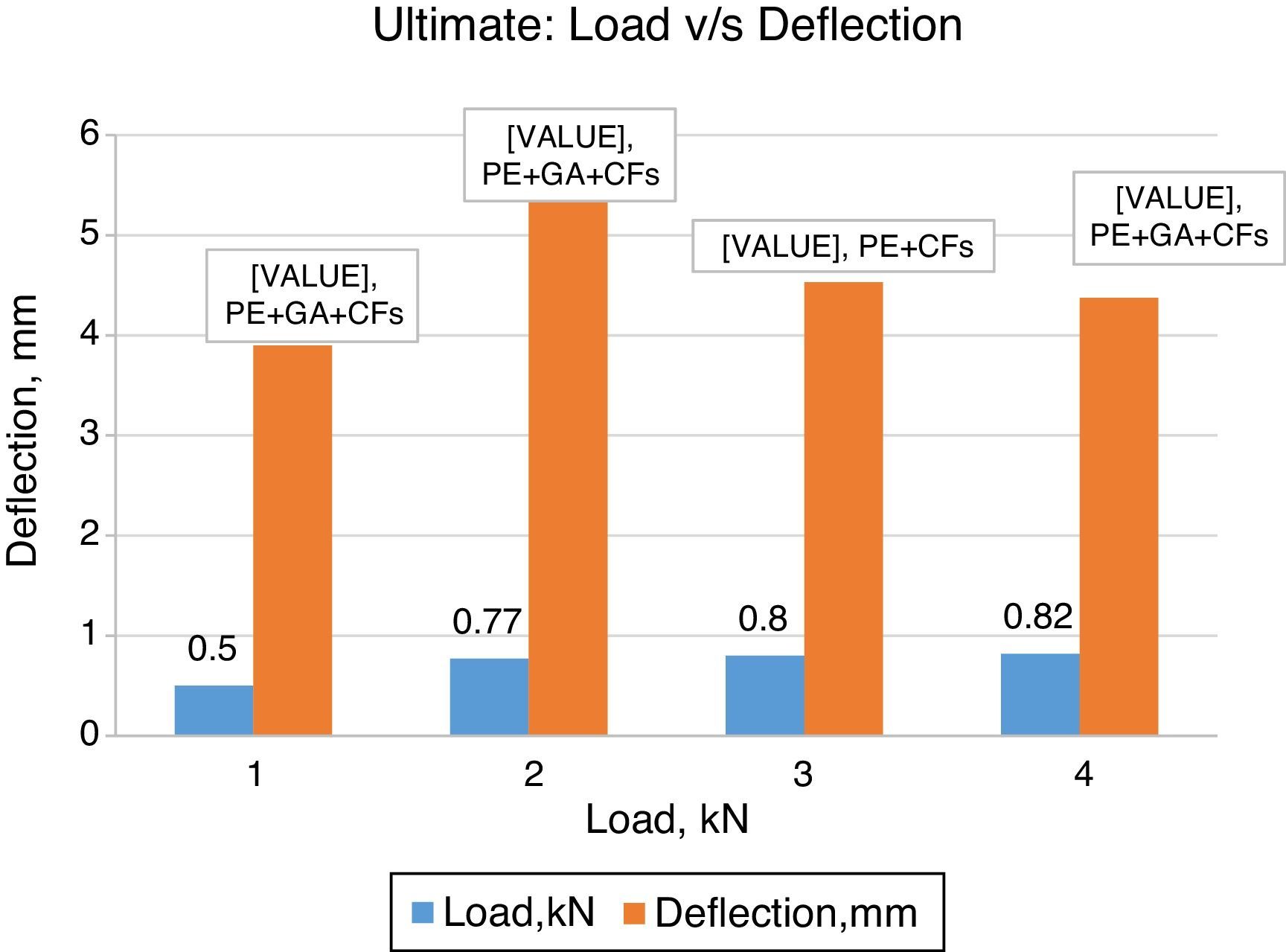

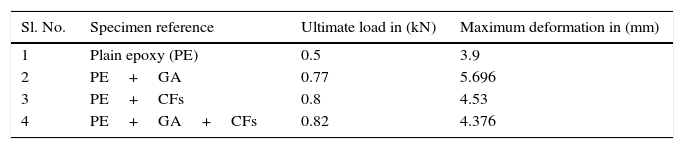

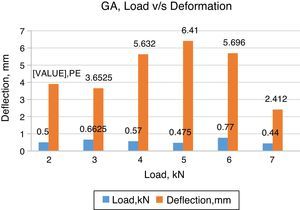

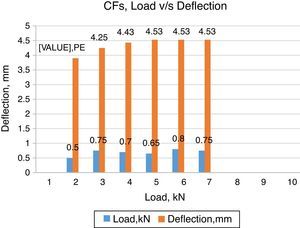

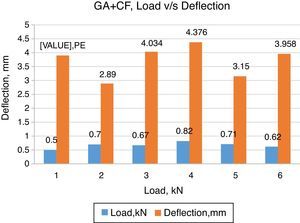

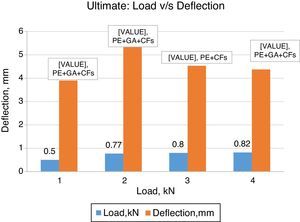

5Results and discussionsThe evaluation of the optimum percentage of carbon fibres and graphene and the combination required for reinforcing in plain epoxy beams was studied based on the three-point loading tests conducted. The optimum percentage of carbon fibres and graphene by wt% of epoxy required to reinforce the plain epoxy beams was evaluated based on the higher structural efficiency in terms of load carrying capacity. Hence, the flexural behaviour of GA/CFs/GA+CFs reinforced in the epoxy beams was investigated. Composite beams were tested under flexure (three-point loading) to evaluate their mechanical properties such as strength, deflection criteria, among others. The results obtained were then compared with the results of the tests on the control beams. The ultimate load carrying capacity of all the different fillers is provided in Table 5. The load-deflection curves for different proportions of GA-reinforced epoxy composite beams subjected to the three-point loading test are shown in Figure 3. The load-deflection curves for different proportions of CF-reinforced epoxy composite beams subjected to the three-point loading test are shown in Figure 4.

Test results for CFs and graphene reinforced in epoxy composite beam subjected to the three-point loading test: Ultimate load and maximum deformation.

| Sl. No. | Specimen reference | Ultimate load in (kN) | Maximum deformation in (mm) |

|---|---|---|---|

| 1 | Plain epoxy (PE) | 0.5 | 3.9 |

| 2 | PE+GA | 0.77 | 5.696 |

| 3 | PE+CFs | 0.8 | 4.53 |

| 4 | PE+GA+CFs | 0.82 | 4.376 |

2,3,4 Note-wt. % w.r.t. to epoxy.

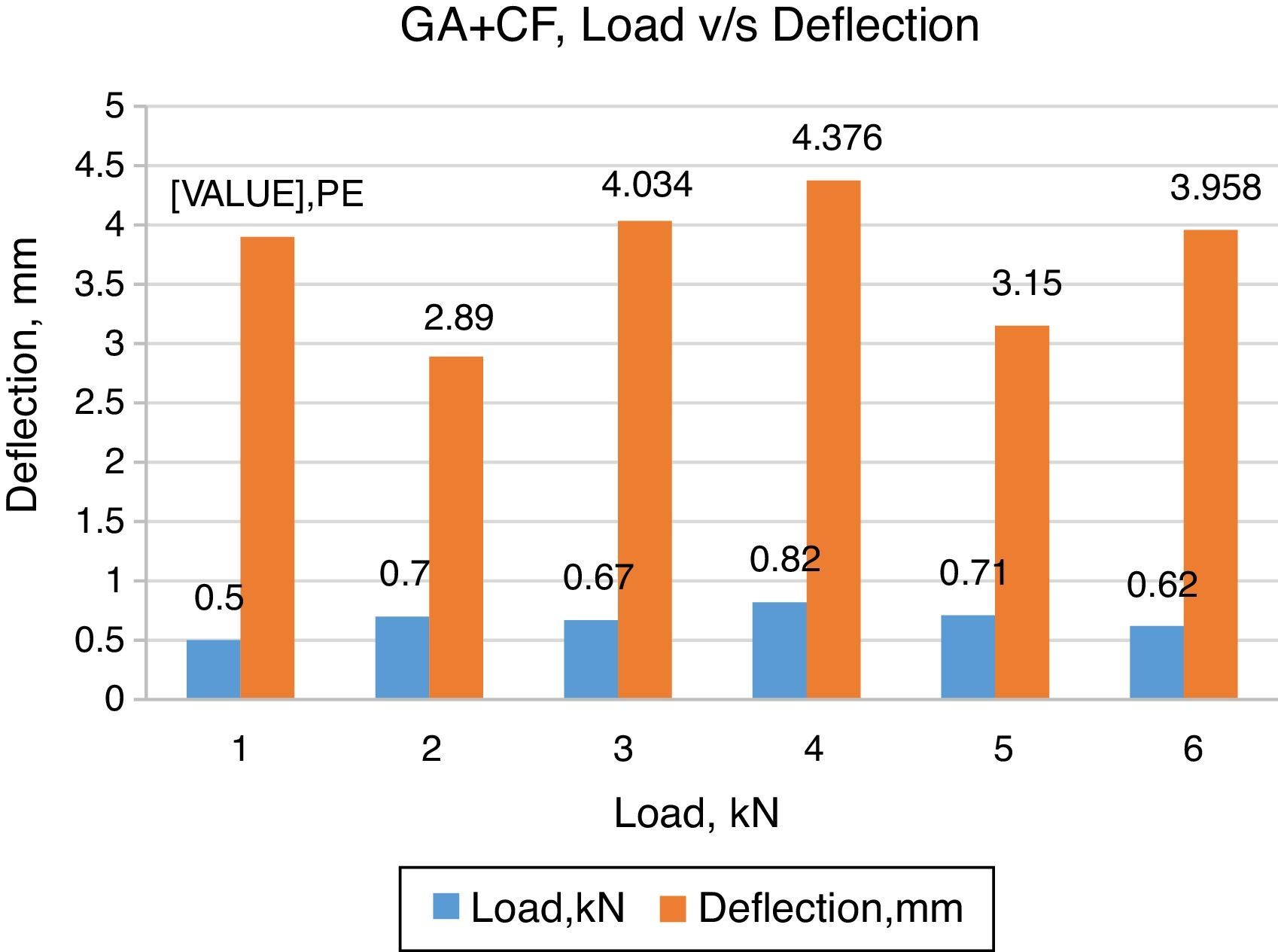

The load-deflection curves for different proportions of GA+CFs reinforced epoxy composite beams subjected to the three-point loading test are shown in Figure 5. The ultimate load-deflection curves for different proportions of GA, CFs, GA+CFs reinforced epoxy composite beams were than subjected to the three-point loading test are shown in Figure 6. Optimum percentage of CFs and GA as individual or combination dosage in the matrix that will lead to the ultimate load-carrying capacity of the epoxy beam under the three-point loading were arrived at. The variation of the ultimate load was studied keeping the PE beams as reference. The ultimate load followed an increasing trend of up to 0.2wt. % of carbon fibres that showed a maximum ultimate load, since the composite at greater CF contents has a tendency to undergo large deflections and thereby provide additional toughness to the composites developed. In case of GA as nano- filler, deflection observed is maximum for 0.4% graphene by weight of polymer matrix. The energy absorbing capacity of the composite has increased because of a greater amount of load carried by the carbon fibres and graphene which further resist the crack propagation. Therefore (epoxy+0.4%graphene) is considered to be optimum from both the deflection and strength criteria. Figure 6 shows a variation of load with deflection for various control beams considered in the study. From Figure 6 it follows that the GA-reinforced polymer beam showed higher resistance for deflection when compared to other reinforced and plain polymer beams as well. This could be due to the load transferring ability of the fibres that was found to improve because of the large surface area offered by GA at the polymer filler interface. As the % of carbon fibre and graphene increased in the polymer-based matrix, the strength further increased, this is observed till 0.1% by weight of carbon fibres and graphene and this could be due to the reinforcement offered at both nano and micro level to the holding matrix. Higher level of loading that is beyond 0.1% by weight of polymer matrix the strength decreased drastically and this could be due to an increase in the surface area of the particles attracting the polymer chains leading to the reduction in the polymer chain mobility which enhances the viscosity of the holding matrix causing brittleness.

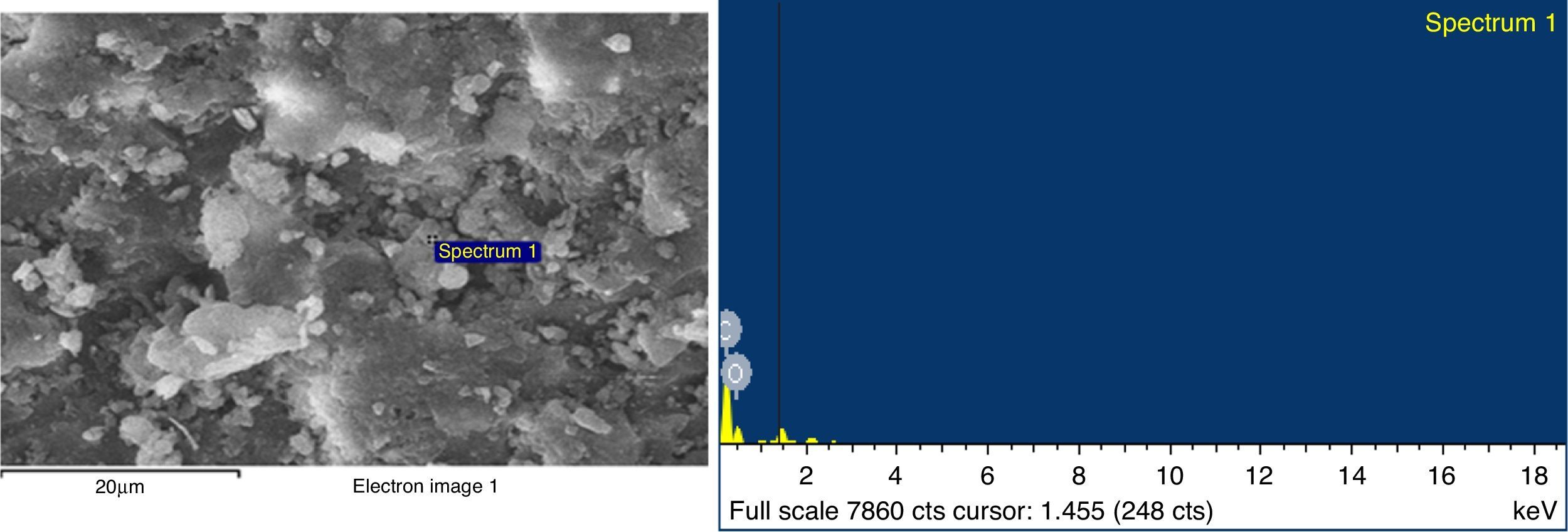

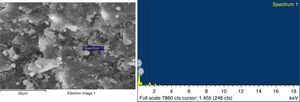

Figure 7 shows the SEM micrograph and EDS spectrum of the GA/epoxy composite with 0.4wt %, which shows high bonding strength that occurs between the GA and epoxy matrix achieved. This is consistent with other results published in the literature. Experimental observations revealed that the GA-reinforced epoxy composite beams showed increased strength compared with the plain epoxy beams. The nano-level reinforcement significantly improved the flexural strength of the beams. The results showed an increase in the load carrying capacity of the composite beams compared with the reference beams.

6ConclusionsPolymers reinforced with graphene and carbon fibre are an actively researched area and the hybrid composites thus developed have been used in different structural applications such as fuel systems components in cars, windmill blades, cables, tethers, beams, among others. From the above experimental results, it can be concluded that polymer beams reinforced with graphene and carbon fibre samples developed in-house showed optimum results for mechanical properties as compared to plain control beams. This could be due to the high surface area of nanoparticles which reduces the stress concentration at a particular point leading to the distribution of load over a large surface. Further work in this area involves the development of new hybrid composites using both nano and micro-materials that could address both micro/nano level aspects. Accordingly, the use of different nano-particles like carbon nano fibres (CNFs), graphene oxide at nano-level and carbon fibres (CFs) at micro level with natural fibres could also be effectively used for structural applications.

Conflict of interestThe authors have no conflicts of interest to declare.

Peer Review under the responsibility of Universidad Nacional Autónoma de México.