This paper presents the design, development and tests made to a fiber optic pressure sensor using the multimodal interference methodology (MMI) thus, we propose an alternative sensor to the ones available which are limited by high robust environments where the use of them is a potential hazard (explosive gases, corrosion and even electromagnetic fields). The range of work for this sensor is 0 to 0.36 psi, the arrangement used is formed by a laser diode, a sensing element, an electronic amplifying circuit, a data acquisition board and a computer. The sensing element used is a SMS fiber optic structure (singlemode–multimode–singlemode, where a multimode fiber is embedded between two singlemode fibers) placed within the contact surface (diaphragm) made of a polymeric material; the body of the sensor was made of nylamid. The bending produced in the diaphragm by the pressure inside the body of the sensor generates changes in the transmitted power response carried inside the fiber.

Se presenta el diseño, fabricación y pruebas realizadas a un sensor de presión de fibra óptica utilizando la metodología de interferencia multimodal (MMI), proponiendo así un sensor alternativo a los sensores existentes los cuales son limitados por ambientes de alto riesgo donde su uso es un peligro latente (gases explosivos, corrosión e inclusive campos electromagnéticos). El rango de trabajo para este sensor es de 0 a 0.36 psi, el arreglo utilizado está conformado de un diodo láser, elemento de sensado, circuito electrónico amplificador, tarjeta de adquisición de datos y una computadora. Como elemento de sensado se utilizó una fibra óptica SMS (por sus siglas en inglés singlemode–multimode–singlemode, formada por una fibra multimodo unida entre dos secciones de fibra monomodo) colocada dentro de una superficie de contacto (diafragma) hecha de material polimérico, el cuerpo del sensor está construido de nylamid. La deflexión producida en el diafragma por la presión dentro del cuerpo del sensor generará cambios en la respuesta de potencia transmitida a través de la fibra.

Currently, there are many systems or sensors used for the measurement of any variable that you can imagine, although some of them can be expensive due to its components, level of precision or security required while functioning under certain work environments. The development of new devices for their use in high risk places (or not) is necessary, thus, we present an alternative to the electronic devices available. The development of this investigation is oriented to the sensors used to measure pressure, you can find many kinds such as: Resistive, capacitive, generator, inductive and electromagnetic. All of which have a common element: They all use electricity to function and to send signals. Currently, optoelectronics and optic fiber technology have reached a level of technological maturity, quality and have become cost effective that are by far better than the sensors available [1, 2]. The tendency of the current pressure sensors is to use interferometric systems and most of them use Bragg grating using as a transduction element, a diaphragm. Optic fiber sensors presents technological base that can be applied in multiple in many fields where sensing is required. They have many specifications that make their use very attractive for sensing: They are not electric, can be used in hostile environments, are small in size and light in weight. They can have a great geometric versatility and among other things are immune to electromagnetic interference [3, 4]. Recently, the effects of the MMI in a fiber with a SMS structure were studied and used to develop sensing applications and signal processing [5, 6, 7, 8]. These optic devices offer a solution based totally on fiber with the advantages of its easy fabrication, packaging and interconnection with other types of optic fiber through a system based on intensity measurements [9].

2Theoretical backgroundIn this section, we describe the basis in which this work is developed. “A sensor is a device that given the energy of the environment where it is measured, a transductive exit signal is given in function of the measured variable” [10]. “The most appropriate area to work with the optic fiber is found within the near-infrared spectrum (0.8μm y 1.7μm), because in this spectrum the propagation properties are optimum” [3].

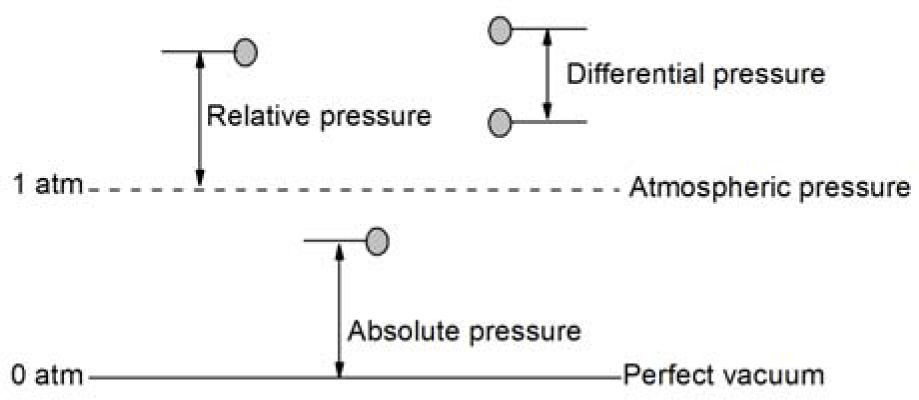

2.1PressureThe pressure measurements can be done in different forms depending on the variable that has to be quantified. The absolute pressure is the value of the pressure of a certain point with relation to the absolute zero pressure (emptiness or vacuum). Sometimes this value is of no interest and what we need to know is the magnitude of the difference in pressure between two given points, this measurement is known as differential pressure. A typical case is the loss of pressure that happens to fluids that run through pipes. A different form to measure the magnitude of the pressure that is similar to the differential pressure, but here one of the points is the atmospheric pressure and the other point is a given value; this form of measurement is known as gauge pressure. The most common use of this type of pressure measurement is that of the blood pressure. Another form to measure pressure is that of vacuum or emptiness; emptiness is described as a negative differential pressure with respect to that of the atmospheric pressure [3]. Figure 1 describes de types of pressure, taking as reference the atmospheric pressure and that of emptiness.

2.2Classification of optic fiber sensorsThe classification of optic fiber sensors can be done attending the following criteria [3, 4]:

- •

According to the function given to the optic fiber:

External use: A deep guide that transports the electromagnetic radiation from de source of radiation to the sample. Subsequently, the transmitted radiation is reflected or emitted by the same sample and driven to the detector. They do not need a transducer. They are easy to design but their application field is limited.

Internal use: Optic fiber exercises the functions of both, acting as a transducer and driving the electromagnetic radiation. In the intrinsic sensors some properties of the optic guides (refraction index, absorption), are modified by the action of the environment. They have a mayor area of application in the field of physic sensors (temperature, pressure, etc.).

- •

By the type of optic modulation employed:

Amplitude or intensity modulation: The amount of light detected is due to external disturbances. They use optic and simple circuitry. They are generally associated with shifting or some physic disturbances that interact with a transducer blinded to the fiber. These are the optic fiber sensors that are more spread out in the market.

Phase of modulation: Employ interferometric techniques to detect the magnitude to measure (pressure, rotation, magnetic field, etc.). The laser source of light has a beam that exits and divides, hence, the light travels through the fiber of reference in a simple way and through the sensing fiber, which is exposed to a perturbed environment. If the light in the sensing fiber and the light in the reference fiber are exactly in phase when/once combined, they interfere in a constructive way with the increment of the light intensity. If they are out of phase, destructive interference occurs and the intensity of the light is low.

- •

According to the nature of the parameter to quantify:

Physical: Determine physical parameters (temperature, pressure, shift or movement, flow, rotation, etc.).

Chemical: Respond to a particular chemical type.

Biomedical: Glucose measurement, blood analysis, etc.

- •

According to the type of interaction with the element:

Reversible: Those that do not consume reagent with the element (pH sensors).

Irreversible: Those that consume reagent, they can be subdivide in renewable and nonrenewable, whether or not they are capable of going back to their original state with the adequate reagent.

- •

According to the nature of the measured optic property:

Absorbance, reflectance, luminescence, Raman dispersion or refraction index.

- •

According to the configuration (sensor external form):

Sounding type: A union between the sensing phase and the optic fiber is needed. This union can be done through a chemical connection or by its confinement with a membrane; they can work either in a continuous or in discrete form.

Flow cell type: Its main characteristic is that they are integrated in a flow system. The sensing phase is arranged in the detection system, for this reason the processes of reaction on the reactive phase and the detection are simultaneous; but unlike the sounding types of sensors, there is not a connection between the reactive phase and the optic fiber, they even can lack of it. These flow cell sensor work only in a continuous form.

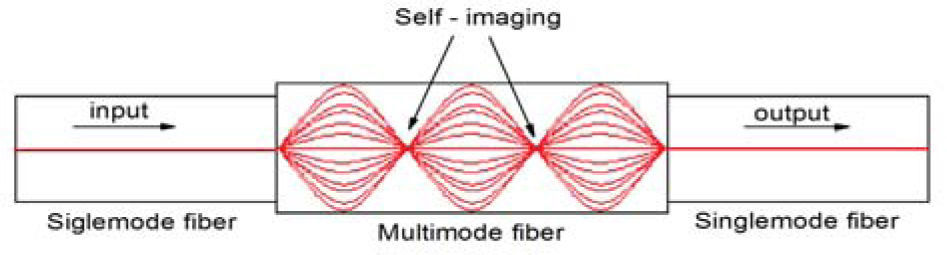

Interference is defined as the superposition of two or more waves and their combination to form one single wave. The main principle in which the MMI technique is based, is called the self-imaging phenomenon. Which can be defined as: “the property of the multimodal wave guides in which the profile of the entrance field is reproduced in one or multiple images in periodic intervals along the direction of the propagation of the wave guide” [11]. The image reproduction is due to both, the constructive, and to the destructive interference that is present all along the guide wave. The self-images generation in flat wave guides can be analyzed using the modal propagation analysis, MPA [11], under a hybrid method [12]; as well as using the beam propagation method, BPM [13].

Figure 2, shows the typical SMS structure (singlemode–multimode–singlemode), where the input profile can be produced in the interface between the monomode wave guide and the multimode wave guide, it will replicate in the interface that lays in the monomode wave guide and the multimode wave guide.

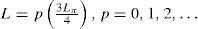

The multimode section of the fiber (MMF) is capable of carrying many guided modes, for this reason, an entrance field coupled to the MMF section can be reproduced in a single or multiple self-image in periodic interval along the MMF. With the object of obtaining a single image, the difference in phase between all the modes of propagation have to be a whole number that is a multiple of 2π, hence, all the modes can interfere in the phase and in that way the field of entrance can be reproduced. This effect has been widely researched [14] and the distance (length, L) where the self-images will form are given by:

Where Lπ is the width of the pulseIn Equation 2nMMF y DMMF correspond respectively to the refraction index and to the nucleus diameter of the MMF section, with λ0 as the specific wave longitude to which the SMS structure is desired to set and p represents the number of self-images that is desired. In the case p=0 (first self-image). The fiber used works with a wavelength of 1555 nm, the MMF section has a diameter of 125μm and a refraction index of 1.44 and a length of 14.55mm.

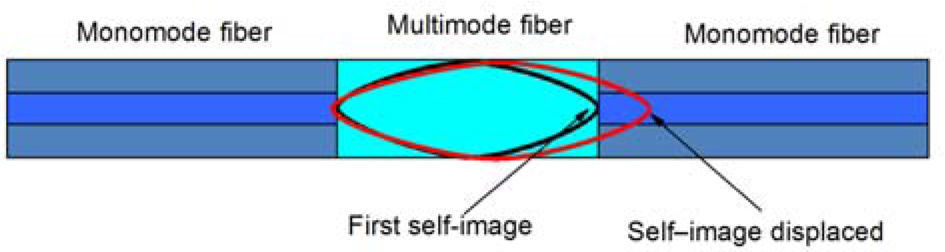

Figure 3, is an example of the type of MMI fiber used in the research, which is designed so as to the beam is coupled to the core of the monomode fiber, when the MMI fiber is subjected to a physical action, the self-image is shifted and as a result of this action different results are obtained in the transmitted intensity.

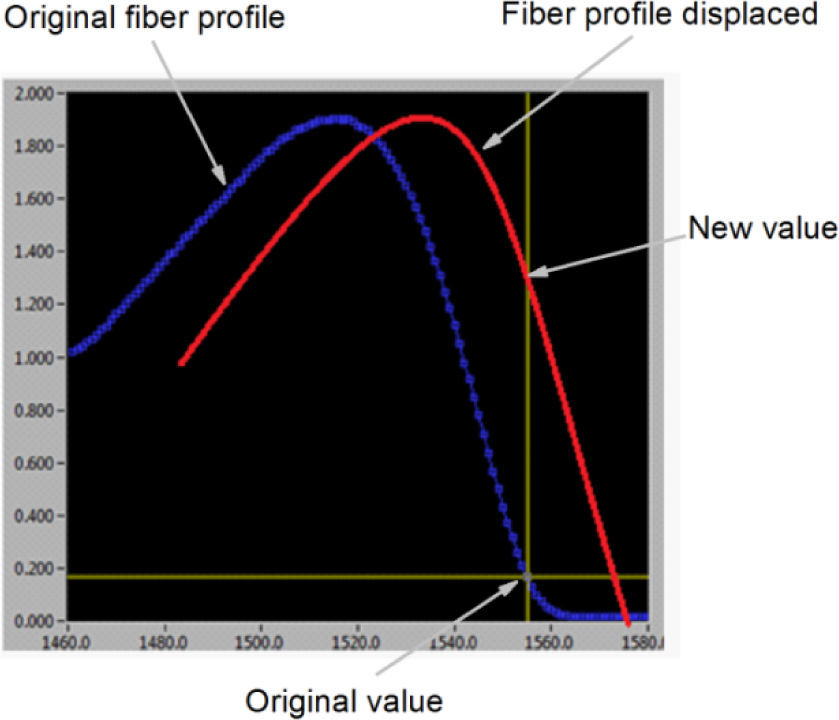

In figure 4, a MMI fiber profile in an operating wavelength of 1555 nm is shown, when exerting physical action on the optic fiber, a displacement the profile of intensity is achieved towards the direction of the wave guide propagation and the following lectures of higher intensity are obtained.

3Materials and methods3.1Membrane elaborationThe material used to elaborate the membrane (diaphragm) is PDMS (polidimetil siloxano sylgard 184, Dawn Corning), an elastic polymerous based on silicon. The manufacturing of the membranes made with this polymerous material is relatively easy. The use of this building material reduces time and complexity in the elaboration of prototypes, avoiding the use of sophisticated equipment [15, 16]. The PDMS also has a high transparency, a null toxicity and a low cost [17], which makes it ideal for the use in the area of optic technology [18]. The membrane to be used in the tests has a thickness of 10mm with a catalyst relation of 15%, that is, for each gram of PDMS used, 0.15 grams of catalyst was added. The MMI fiber is placed in the middle of the membrane before drying the PDMS, a plastic mold is used, because it is difficult to remove the PDMS from metal or glass surfaces, once the mixture is poured into the mold, it is allowed to dry during 48 hours.

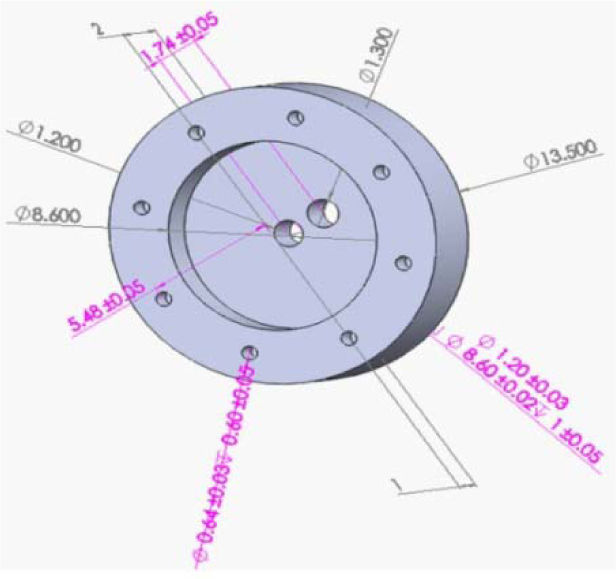

3.2Sensor bodyOnce we have the dimensions of the membrane, the sensor body prototype is designed. It is made of nylamid due its properties (light weight, resistance to great stress and easy plotting). Figure 5 describes the sensor body: Two entries for the air connections, 8 threated holes to hold the membrane to the nylamid body.

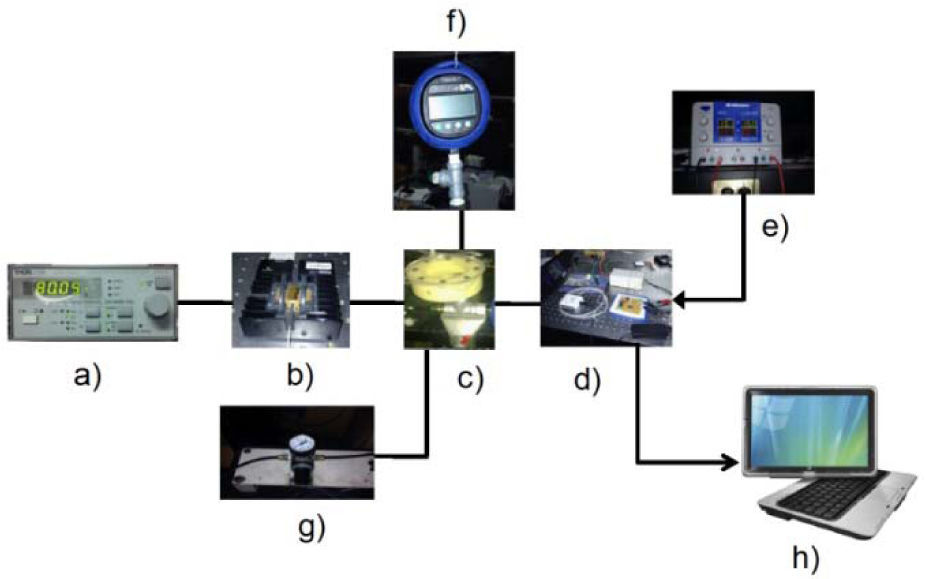

3.3Experimental arrangementThe proposed experimental arrangement (Figure 6) consist of the following: a) diode laser controller, b) diode laser (1555nm), c) sensor (nylamid + PDMS), d) data acquisition (photo detector, signal amplifying electronic circuit, data acquisition board USB-6259 National Instruments), e) power source, f) Crystal pressure gauge (300 psi), g) pressure regulator from the power line of 0 to 1422 psi and h) graphic interface designed in LabView.

With this arrangement we are able to detect the power variation carried inside through the MMI fiber produced by the pressure wielded on the membrane. One of the extremes of the SMF fiber is connected to (b), while the other is attached to the photo detector (d) to process the results (h). With (g), we control the air pressure inside the body of the sensor and with (f) the changes of pressure in the system are monitored, and a needle valve is connected at this point to empty the system.

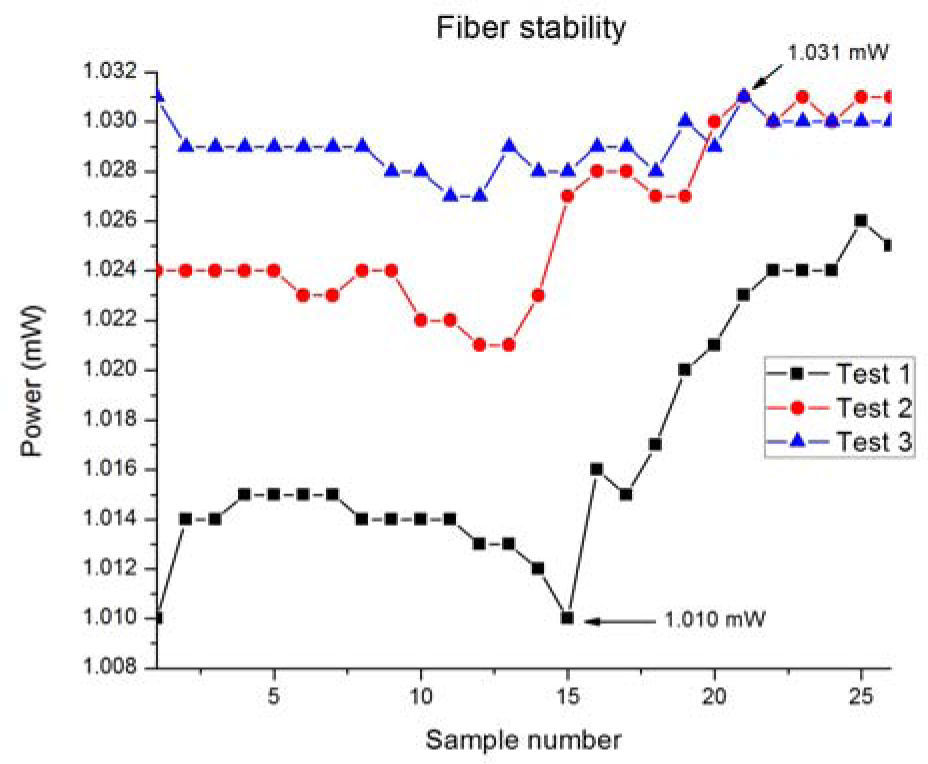

4Experimental results and analysisFirst, we monitor the power values transmitted by the SMS fiber within the membrane without applying pressure; with the aim of verifying that the fiber is not fractured. The initial potency value is set at 1.038mW. Figure 7 shows the power values obtained in time intervals (5 seconds) from three tests carried out. The difference between the highest and the minimum potency value is 0.021mW, the obtained value shows that the fiber is in good operating conditions.

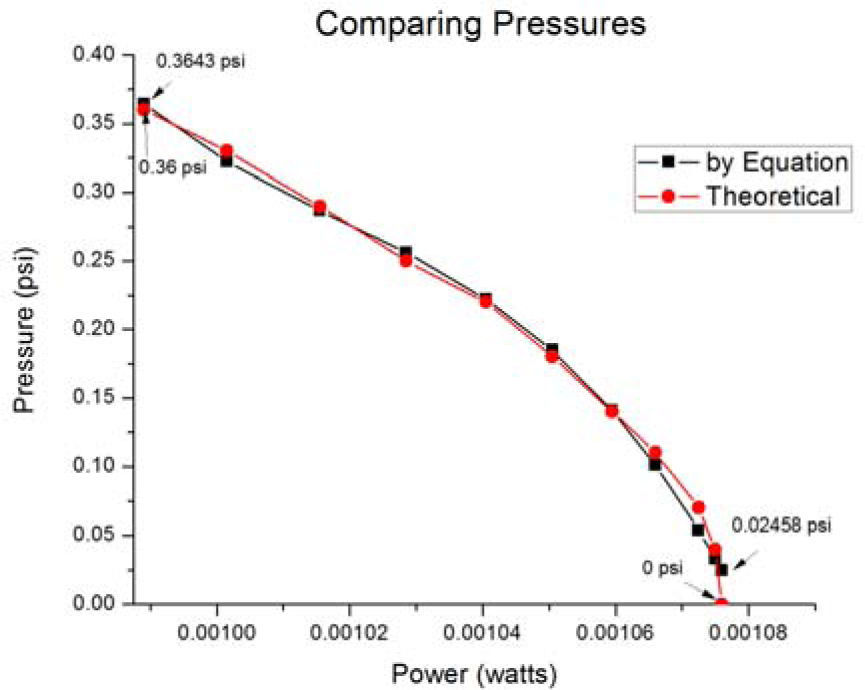

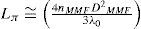

Once the stability of the fiber has been verified, a test is run to obtain the initial values of reference (Figure 8), using them, a linear adjustment of third degree is made, obtaining the following equation with a correlation factor (R2) of 0.988.

Chart comparing the theory power values and the values obtained through Equation 3.

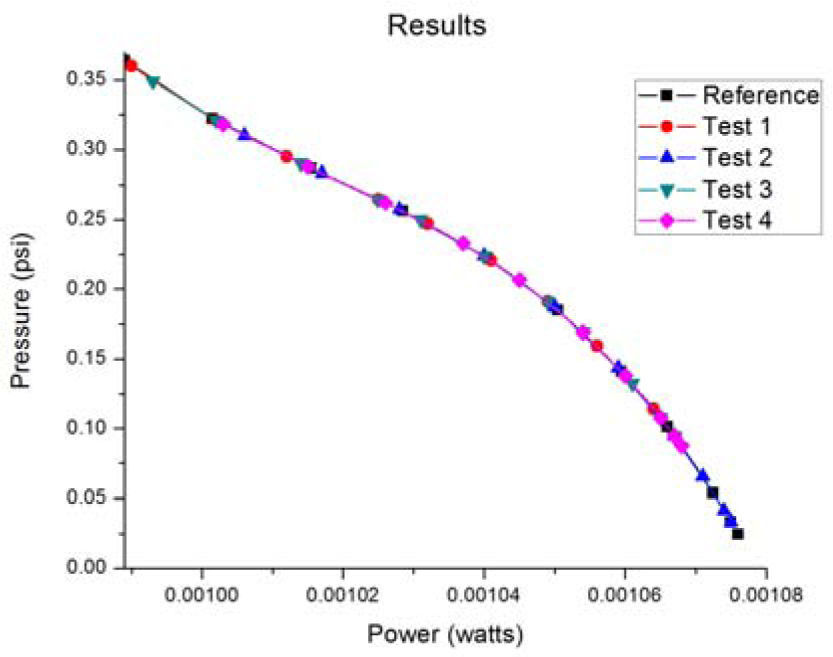

Four tests are run obtaining power values, all of which were introduced in Equation 3 and became pressure values in a range of work of 0 to 0.36 psi. Figure 9 shows the values of pressure that resulted from these tests.

From Figure 9, it is observed that starting from 0 psi, the power reference value reaches a maximum of 1076μW and when we applied 0.36 psi the value of the power decreases to 989μW.

The differences among pressure values of the four test are due to the power values obtained, in other words, only some of the values of each test coincide with some other test.

The results obtained from the tests, using the proposed sensor, showed confident results; the pressure variations are fast and controlled. The measurements “in situ” are easier because the reduced amount of equipment used for the tests.

5ConclusionsThe power variation transmitted inside the MMI fiber responds linearly to the wielded pressure in the system, the increase of pressure generates a reduction of power, otherwise the power increases. We got good results using the MMI techniques. Using air as a work fluid, a uniformed pressure was wielded inside the sensor body producing a bending on the central part of the membrane, where the sensing part is located (MMI fiber). An improvement was obtained in the elaboration technique of the membranes bases in PDMS regarding the drying time, mixing of the formula and the catalyst percentages according to the desired thickness and hardness. Another alternative is proposed within the area of pressure sensors based on characteristics such as: Low manufacturing cost, easy manufacturing, low requirements of equipment and mobility for the tests in situ. One of the most important advantages that the developed sensor offers is that because of the use of optic fiber, the sensor is not limited to work in normal environments. It can also work in high risk environments where corrosion, flammable gases, electromagnetic fields could be present, because it changes from using electricity to natural light for the transmission of signals. A new methodology is under research for the elaboration of PDMS membranes.

This work was supported by “Consejo Nacional de Ciencia y Tecnología of México (Project: 169197)