Characterization of the holographic material composed by adhesive polymer Norland Optical Adhesive 72® (NOA 72®) was studied. With a wavelength of 457nm from an Ar laser, real time phase holographic gratings under different parameters such as energy, frequency and thickness were recorded. The diffraction efficiency of the recorded holographic gratings was measured and some experimental results are shown. Furthermore, the material was used to record Fourier holograms.

The research of photosensitive materials is an active field where the main goal is to find materials with desirable characteristics for optical data storage. Some of these special characteristics are high sensibility, high resolution and width spectral range, low cost, between some others (Smith, 1969). There are many kinds of materials that have been used for this purpose, such as silver halide, photoresist, dichromated gelatin, photopolymers, thermal recording materials, photo thermoplastics, photochromics, and photorefractive crystals (Bjelkhagen, 1996; Hariharan, 1980; Kang, Kim, & Bae, 2004; Kostuk, 1999) and recently the most used are photopolymers.

The photopolymers has excellent holographic characteristics, such as high refraction index modulation, real time recording and low cost. The response of these materials depends of parameters such as incident beam intensity, monomers concentration, polymerization velocity, humidity, temperature and thickness (Adhami, Lanteigne, & Gregory, 1991; Gallegos et al., 2005; Gleeson, Kelly, O’Neill, & Sheridan, 2005). There are some papers where the thickness of the photopolymer film is of great importance (Neipp et al., 2003; Ortuño, Gallego, García, Neipp, & Pascual, 2003). The spectral sensibility of these materials can be easily modified if the photopolymers are mixed with dyes (Luna-Moreno, Olivares-Peréz, & Berriel-Valdos, 1997; Luna-Moreno, Olivares-Pérez, Berriel-Valdos, & Osorio-Alarcón, 1998; Ortiz-Gutiérrez, Alemán, Pérez-Cortés, Ibarra-Torres, & Olivares-Perez, 2007).

Some of the photopolymer employed in optical storage are given in Budinski and Budinski (1999), Fernández et al. (2006), Ibarra and Olivares-Pérez (2002), Martin, Leclere, Renotte, Toal, and Lion (1994), Naydenova, Sherif, Mintova, Martin, and Toal (2006). One of these polymers is an adhesive called Norland Optical Adhesive No. 65® (NOA 65®). Pinto-Iguanero and co-workers reports the use of NOA 65® in its natural form to record computer generated Fourier holograms by microlithography techniques (Pinto-Iguanero, Olivares-Pérez, & Fuentes-Tapia, 2002).

In this paper the use of Norland Optical Adhesive 72® (NOA 72®) as photosensitive material is proposed. This is cured with ultraviolet light between 315 and 400nm and visible light between 400 and 450nm. The wavelengths of maximum absorption are 320, 365 and 420nm. The complete curing process requires 5J of energy in the range from 315 to 450nm (Norland Products, 2015). To characterize the photosensitive material phase holographic gratings (PHG) using a light beam with an argon laser wavelength of 457nm were recorded. Diffraction efficiency (DE) of holographic gratings recorded using a beam of He–Ne laser was measured. The material does not require preparation processes or developing processes. An important property of the adhesive is its transmittance spectrum in the range 400–1200nm, which makes this material ideal for manufacturing diffractive phase elements. Also in this paper, the results obtained when recording Fourier holograms of binary objects are also presented.

2NOA 72® propertiesThe typical applications of this polymer is for putting lenses in metal mounts, bounding plastic to glass and cold blocking by means of the cured process. Some properties of polymer NOA 72® are described in Norland Products Incorporate (1999).

The polymer-cured process depends of the intensity and the wavelength of UV radiation. Before exposure the polymer to UV radiation, the adhesive is in liquid state because the monomers and photo initiators will not react with each other. When is exposed to UV the photo initiators undergo a change creating free radicals that react with monomers creating monomer chains. In the cured state, the monomer chains convert to cross-linked polymer chains. In Norland Products Incorporate (1999) appear typical answers of pre-cure and full cure process of the NOA 72®.

3Photosensitive film fabrication3.1Preparation of the photosensitive cellsThe NOA 72® is deposited in cells manufactured by two glass plates separated by two acetate plastic films placed at its side ends. Different cells were manufactured by changing the thickness of the separator film. The thickness of the plastic film used was 110, 220 and 330μm and were measured with digital micrometer from Mitutoyo model IP65. Cells are clamped by two of its lateral ends leaving open top and bottom. The cell is positioned vertically to allow the polymer to be placed at the top, and by gravity, the polymer fills the cell.

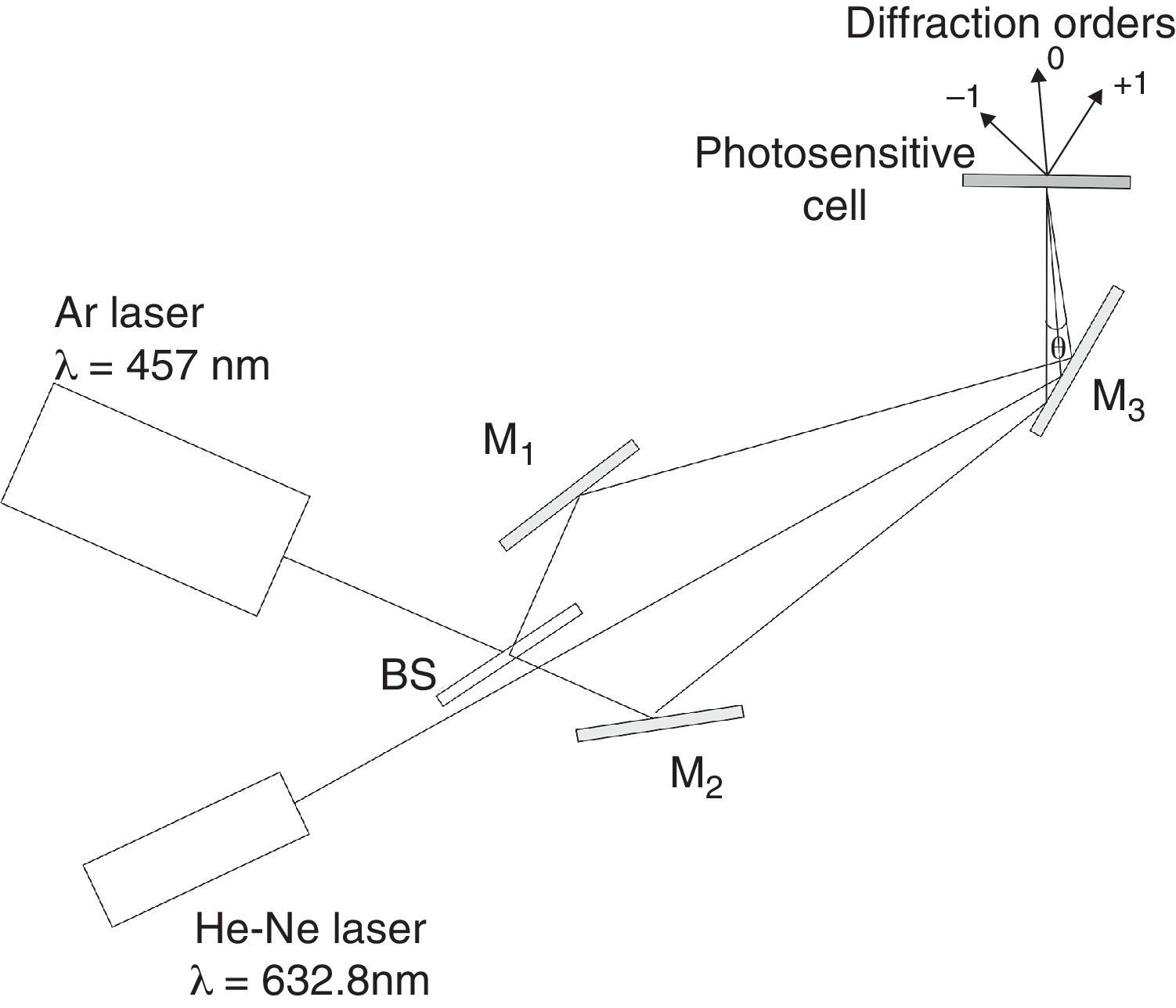

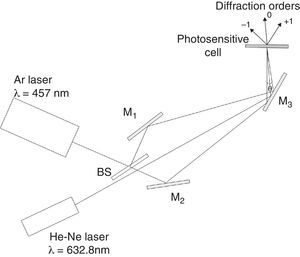

3.2Experimental setupTo record the PHG in photosensitive cell, the experimental arrangement shown in Figure 1 is used and, as noted, a beam of light from an Ar laser passes through a beam splitter (BS) and sent two beams of light to the mirrors M1 and M2. The M1 and M2 mirrors deflect the beams toward the mirror M3. This mirror placed at 45° from the horizontal deflects the beams toward the photosensitive cell where they overlap and generate an interference pattern that is recorded. The photosensitive cell is placed horizontally to avoid damage from possible runoff of the polymer.

Optical setup employed to record holographic grating. A beam from Ar laser creates an interference pattern on the photosensitive film. The beam from He–Ne laser reads the grating and diffracts three light spots called diffraction orders and with the photo detector the DE is measured.

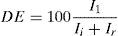

To measure the DE of PHG recorded a beam of light from a He–Ne laser is used. Figure 1 shows that the laser beam incident on the area in which the grating is recorded produces diffraction pattern which consists of bright spots called diffraction orders. The central bright spot is called zero-order, side bright spots are called diffraction orders +1 and −1. DE, expressed as a percentage, is defined as the ratio of the intensity of the +1 (or −1) diffraction order and the intensity of the incident beam as shown in the following equation.

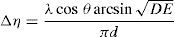

where I1 is the +1 diffracted order intensity, Ii the incident beam intensity and Ir is the reflected beam intensity. In this equation we are considering the Fresnel losses because of the reflection on the photosensitive cell.3.3Modulation of the refraction index by Kogelnik's theoryBased on the DE measured values, the modulation amplitude of the refraction index Δn can be calculated using the Kogelnik theory (Kogelnik, 1969) according to the next equation

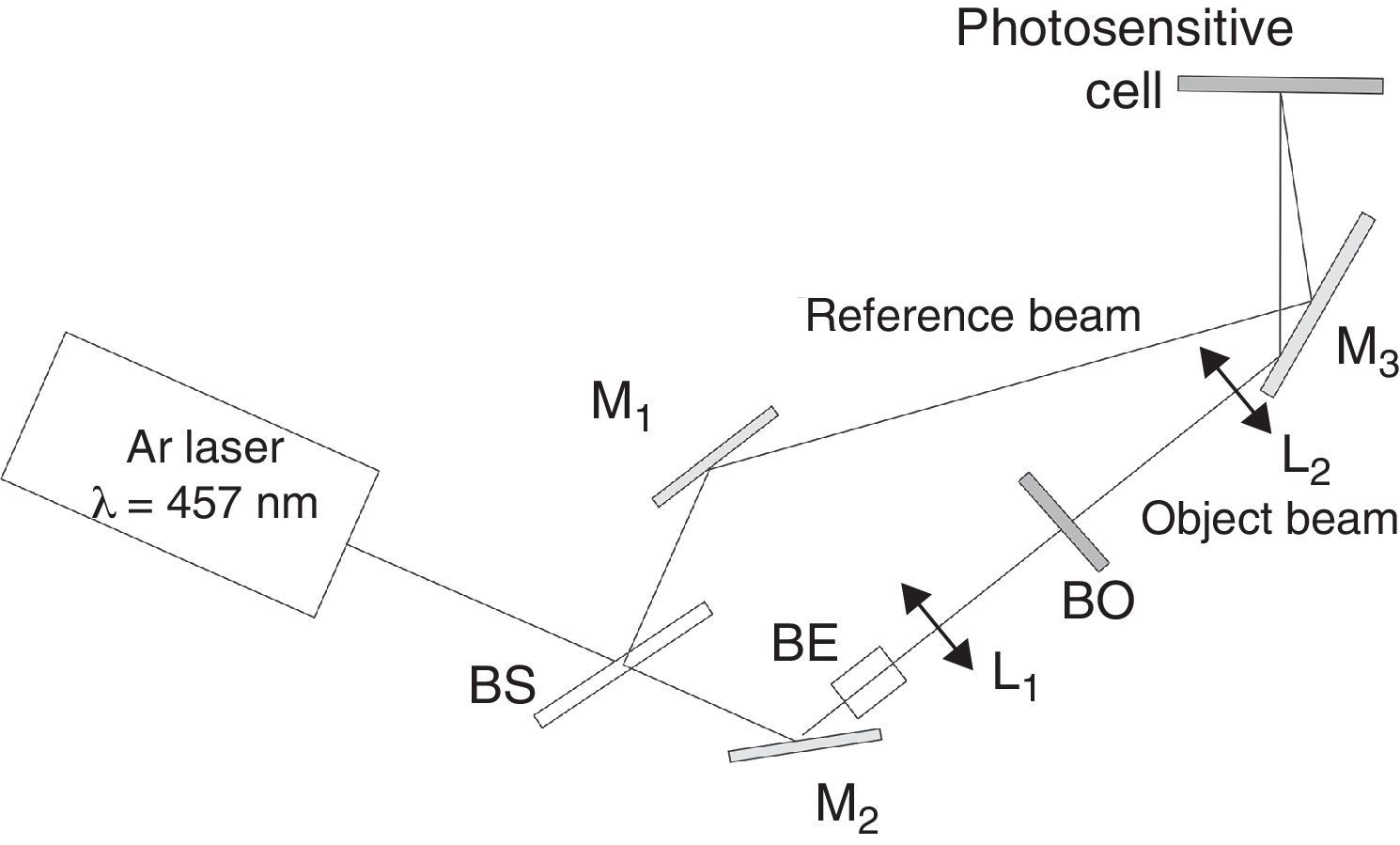

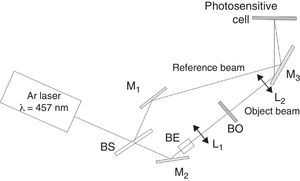

where d is the grating thickness, λ is the reading beam wavelength and θ is the incident angle of the reading beam.3.4Fourier hologramsAlso Fourier holograms were recorded in this material with good results. Figure 2 shows the experimental setup for recording Fourier holograms that are formed by the interference of two light beams, one of them called reference beam comes directly from a laser, and the other beam called object beam, is the Fourier transform of a binary object illuminated by a plane wave. The light beam reflected in the mirror M2 passes through a beam expander BE to generate spherical wave. This wave is collimated by the lens L1 placed at its focal length of the BE and generates a plane wave. This plane wave illuminates the object located in the focal plane of the lens L2 and performs the Fourier transform on the plane where the photosensitive cell is placed and generates the interference pattern with the reference beam.

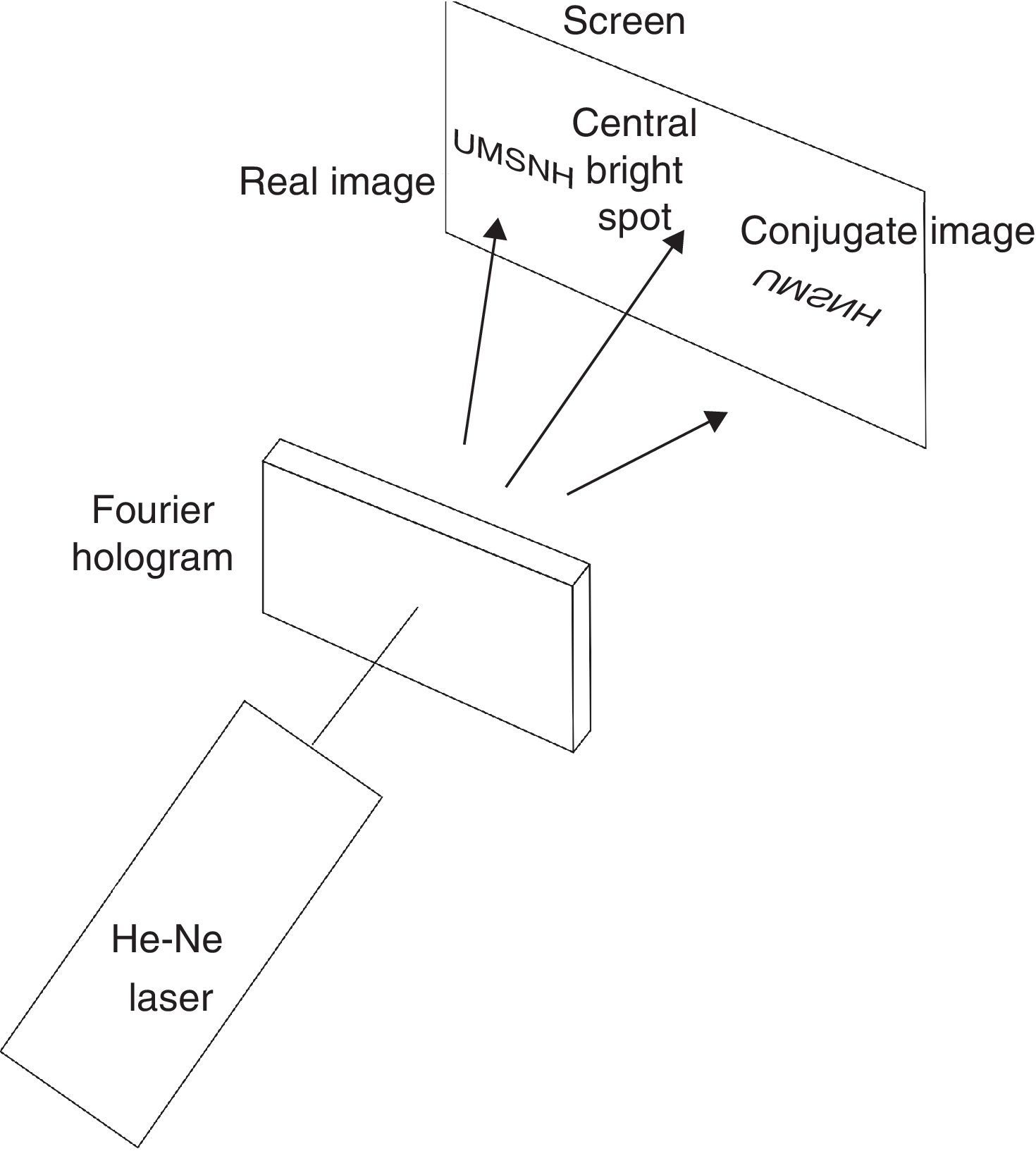

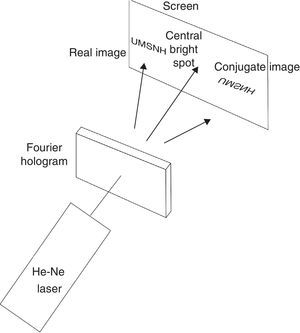

To reconstruct the image recorded in the Fourier hologram, it is illuminated with the same light beam was used as reference beam. In Figure 3 a scheme for reconstruction of Fourier holograms is shown. In this scheme a light beam from a He–Ne laser is incident on the photosensitive cell where Fourier hologram was recorded. The beam is diffracted as it passes through the material and in a remote display the real and conjugate images are formed.

4ResultsTo record the PHG in NOA 72® a light beam was used with λ=457nm of a multiline Ar laser. This line is used because it is the closest to the wavelength of maximum absorbance (420nm) (Norland Products, 2015). To measure the diffraction efficiency of holographic gratings laser He–Ne is used with λ=632.8nm. This emission line is used because the NOA 72® is not sensitive to this wavelength and thus does not affect the registration process. The two light sources are from Coherent; Ar laser has a variable output power and He–Ne laser has an output power of 5mW.

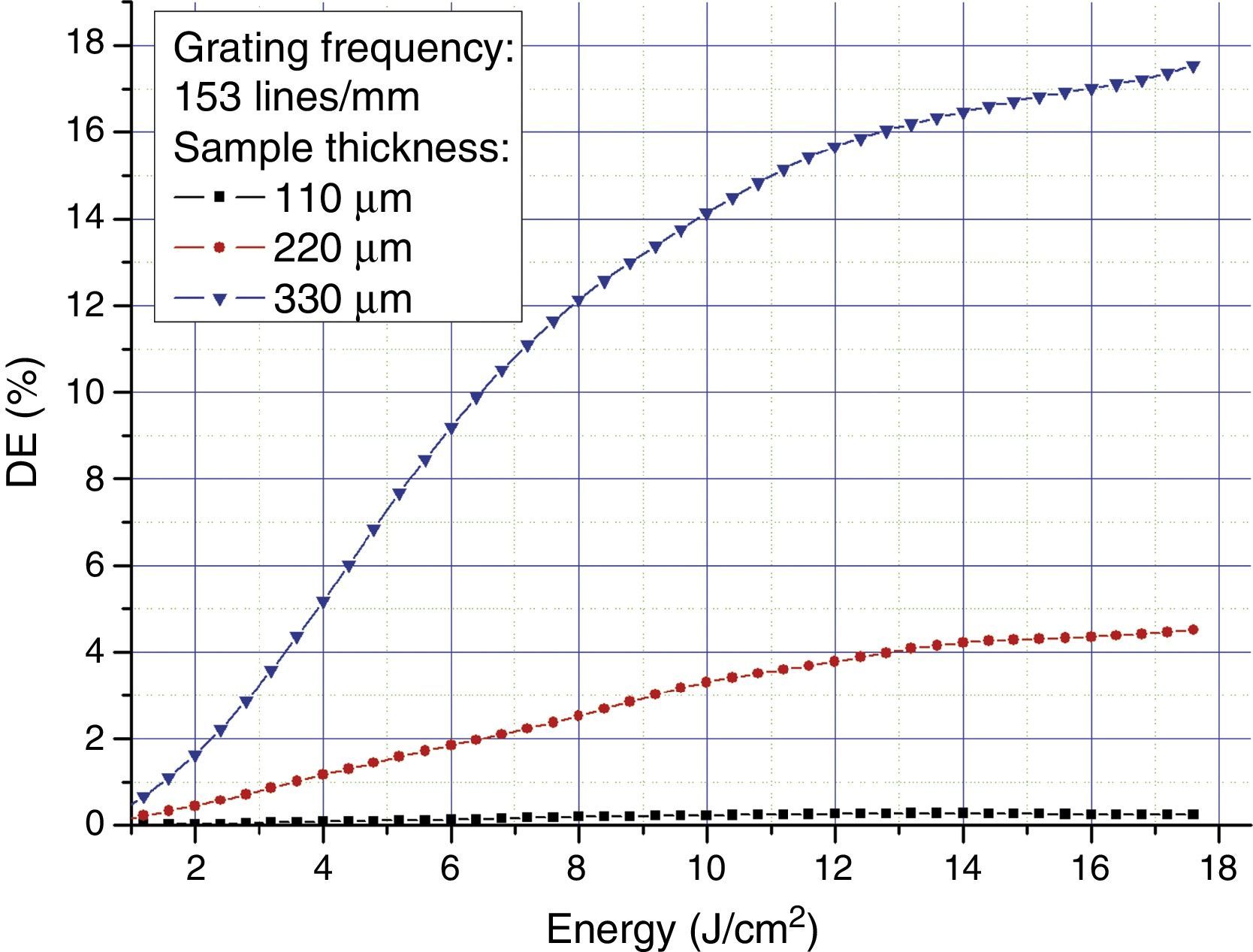

PHG was recorded in each of the cells at room temperature; the angle between beams was 2° so that the spatial frequency of the holographic gratings is 153lines/mm, and according to our measurements, the estimated frequency error is 3%. The DE was measured with an optical power meter Newport Model 2930C. Cell thickness was measured with a digital micrometer from Mitutoyo model IP65.

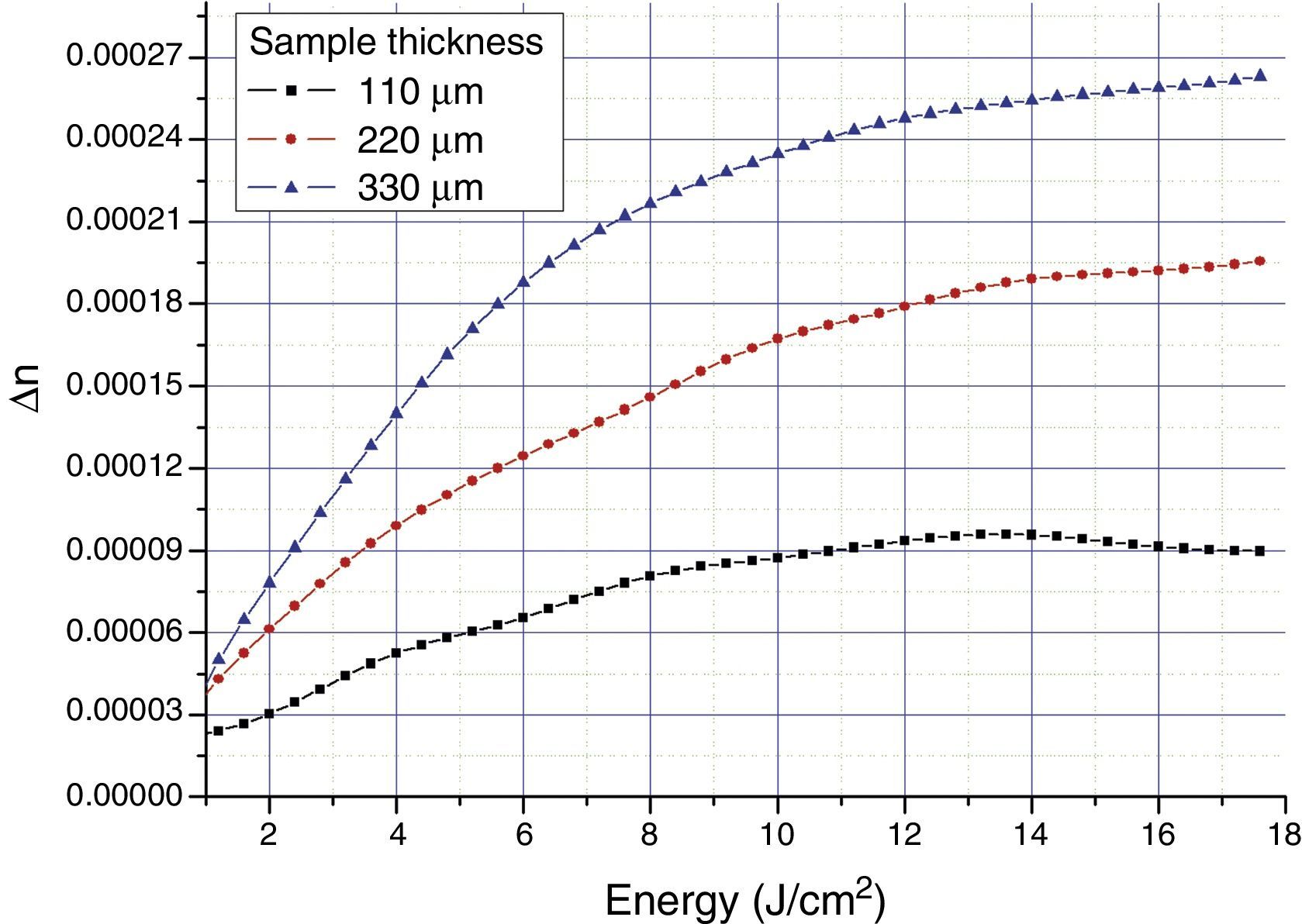

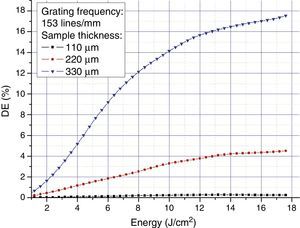

The DE of the recorded PHG is shown in Figure 4 and as is shown the values of DE are different for each PHG. The PHG recorded in the cell of 330μm has large DE and reaches 17.5% while the PHG recorded on the photosensitive cell with 220μm thickness has a maximum DE of 4.3%. Lower DE was obtained with the cell 110μm and is less than 1%.

Thickness is an important parameter in this adhesive as shown in Figure 4. The material has a nonlinear behavior with respect to energy exposure. The energy required for these results is very high because the material was exposed to the wavelength of 457nm and the peak absorbance nearest is at 420nm and is of the order of 1%.

After the polymer has been exposed and the PHG is recorded, changes its phase from liquid to solid and remains in this state without returning to its liquid phase.

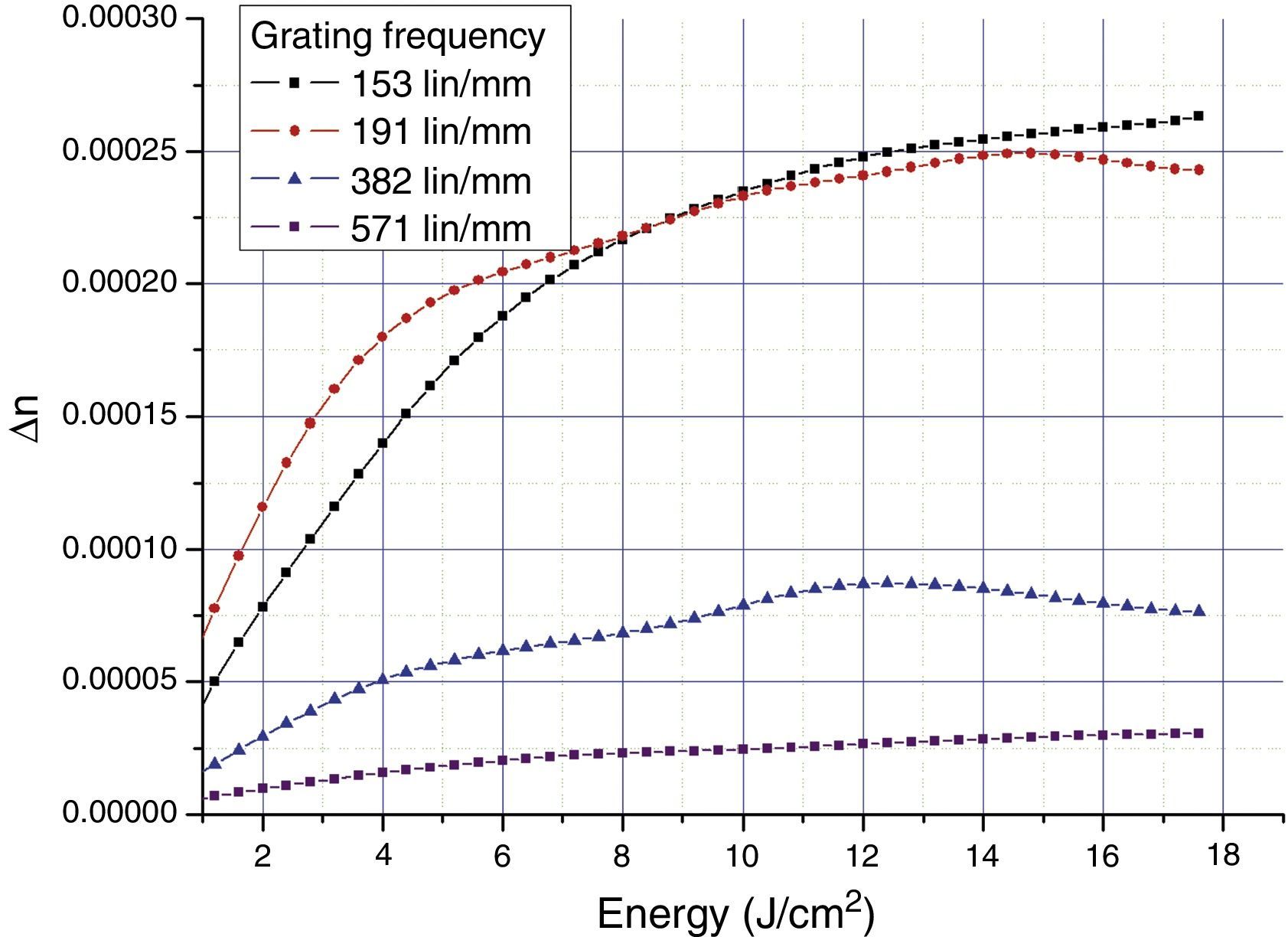

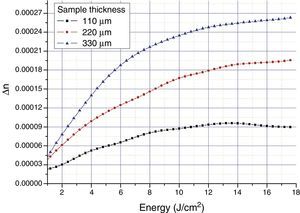

Using the results of the diffraction efficiency shown in Figure 4 the refractive index modulation according to Kogelnik theory is calculated. The refractive index modulation for holographic gratings recorded in the different cells is shown in Figure 5.

PHG is recorded by modulation of the refractive index so that material shows phase modulation. Figure 5 shows that the photosensitive cells with different thickness which were exposed to the same energy have different modulation. Cells with higher volume have more free radicals that interact in the cross-linking process producing higher modulation of the refractive index.

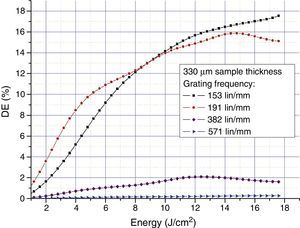

Another important parameter for holographic gratings is the spatial frequency that can be modified if the interference angle is changed. This change can generate PHG of different frequency. The angle between the beams is changed so that the interference patterns generated have different spatial frequency. In the experimental arrangement shown in Figure 1 the angle was changed to produce holographic gratings with spatial frequency of 153, 191, 382 and 570lines/mm.

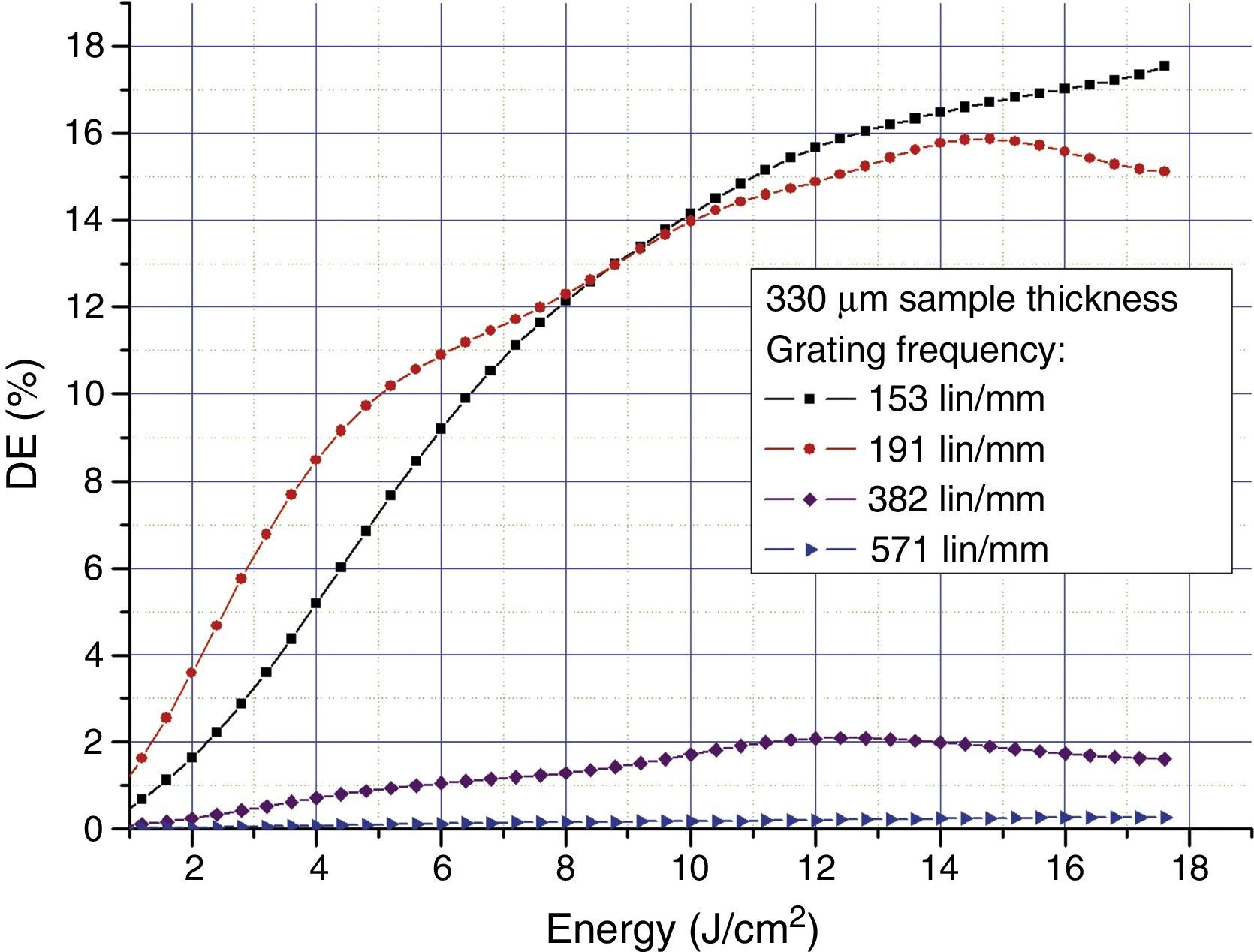

According to the results of the diffraction efficiency of the holographic grating recorded in the cell of 330μm, one can observe that it is the best cell for holographic recording. In this sense, this cell is used to record the holographic gratings with different spatial frequency and the results are shown in Figure 6. The highest diffraction efficiency is obtained for the holographic grating of 153lines/mm and, as already mentioned, has a value of 17.5%. For the gratings with spatial frequency of 191, 382, and 571lines/mm DE is very low. These results indicate that the material has a low resolution.

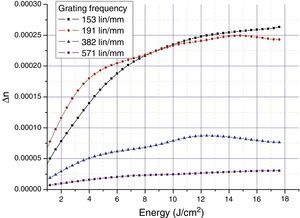

Considering the results of the diffraction efficiency shown in Figure 6, in Figure 7 the refractive index modulation is shown.

The refraction index variation (Δn) by Kogelnik's theory were obtained by the data of Figures 5 and 7, as a function of energy, which is implicitly related to diffraction efficiencies and the optimum specific thicknesses from cell emulsions formed with NOA 72®.

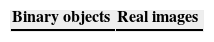

For recording the Fourier hologram, arrangement shown in Figure 2 was used. The angle of 2° and the photosensitive cell with thickness of 330μm was used because these conditions were the best results obtained. Once Fourier holograms are recorded, the arrangement shown in Figure 3 was used to reconstruct the images with a He–Ne laser. The images were captured with a CCD camera and are shown in Table 1.

In the left column of Table 1 pictures of some of the binary objects used to make its Fourier hologram are shown. Right column of Table 1 shows the photograph of the real image obtained in the reconstruction of the Fourier hologram from one of the diffracted orders of the conjugate pair.

5ConclusionsThe polymer adhesive NOA 72® is a good photosensitive material suitable for recording holographic phase gratings. Gratings recording are performed by modulation of the refractive index and reach maximum diffraction efficiency of 17.5% with a cell thickness of 330μm.

The phase holographic grating that is recorded in this material has low resolution with 153lines/mm. The wavelength used is λ=457nm from an Ar laser. To measure the diffraction efficiency a light beam of λ=632.8nm from a He–Ne laser was used. Before registration process the polymer is in its liquid phase and at the end of the registration process becomes solid.

Besides the recorded holographic gratings is also possible to record Fourier holograms of binary objects. Not require complex procedures for preparation of samples and requires no development processes.

Conflict of interestThe authors have no conflicts of interest to declare.

Peer Review under the responsibility of Universidad Nacional Autónoma de México.