Determination of tensile properties of metals or alloys is based on its type and shape which are found to be important aspects. Tensile specimen thickness, width, and rolling force direction affected the tensile properties of conventional metals such as copper sheet. Nevertheless, tensile specimen standards are still not specified yet, especially with regard to advanced materials such as thin wall ductile iron (TWDI). Following the recent findings of large deviations of tensile properties in TWDI plates, this paper describes a study of the effect of specimen width on the tensile properties of aluminium and steel sheets. The purpose of this study was to investigate whether the similar behaviour of tensile properties of TWDI would also occur in other metals. As-received commercial aluminium sheet grade and general structural hot-rolled steel were used for tensile specimen according to standard JIS Z2201 No. 13(b) and 5. The results showed that aluminium was more sensitive to tensile specimen width than compared steel.

Besides hardness number, tensile properties such as ultimate tensile strength (UTS), yield point and elongation are the properties that are most commonly used to determine the applicability of metals for various purposes. Tensile properties are also used for determining the grade classification of casting products. In the 1970s, both the American Society for Testing and Materials (ASTM) standards and British standards specifications permitted the use of standard as well as non-standard tensile specimens for rectangular cross-sections such as sheets and plates (ASTM Standards, 1979; British Standard [BS], 1970). However, Goh and Shang (1982) found that the geometry of tensile specimens affected the K and n values of the Holloman equation for copper sheet (H3101) distorting the stress-strain curve (Goh & Shang, 1982). The Holloman equation explains the relation of true strain and stress which can be expressed as follows:

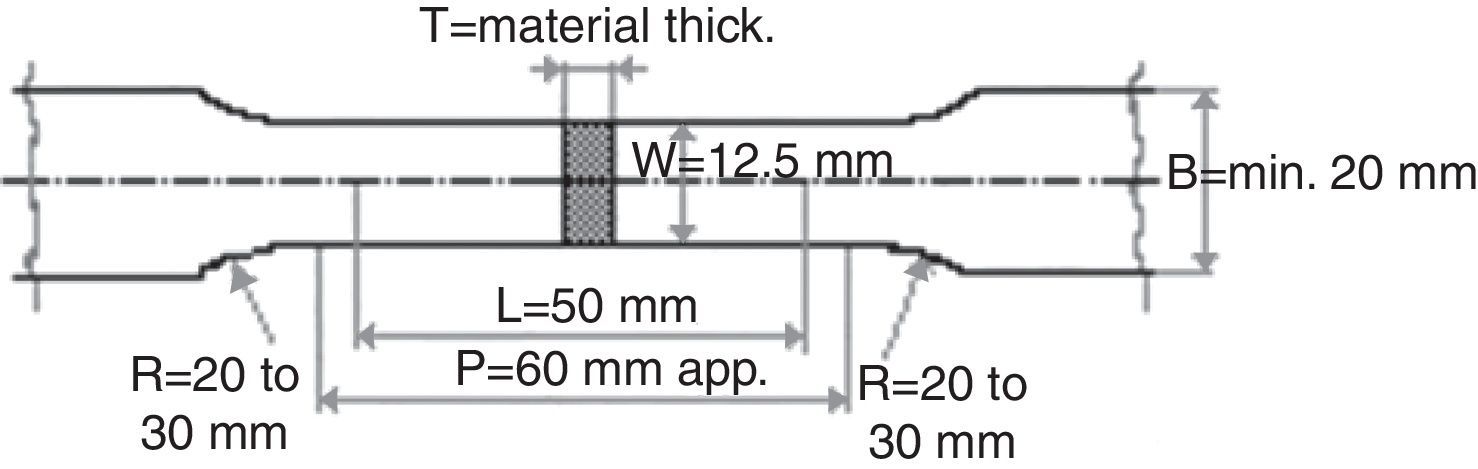

where σ is true stress, ¿ is true strain while K and n are constants. Since then, tensile specimens have been standardised. Despite this, sometimes type of specimen form may have more than one standard specimen, especially in the case of advanced materials. Zhao, Guo, Wei, Dangelewicz and Xu (2008) following Goh and Shang (1982) discovered that the elongation to failure, the post-necking elongation, and the strain-hardening rate of ultrafine-grained copper increased with increasing the sample thickness and decreasing the gauge length. Cao and Ma (2008) investigated the influence of sample shape on yield strength. Klünsner, Wurster, Supancic, Ebner and Jenko (2011) investigated the effect of specimen size on the tensile strength of WC–Co hard metal. Lopez, Verleysen, Baere and Degrieck (2011), examined tensile properties of thin-sheet T–6Al–4V after fatigue. Sun, Soulami, Choi, Guzman and Chen (2012) studied the effects of sample geometry on the strength and ductility of TRIP800 steel sheets. Yang and Lu (2013) found that tensile strength, ductility and work-hardening coefficient decreased with decreasing sample thickness when the sample thickness per average grain size was smaller than a critical value. Sulamet-Ariobimo, Soedarsono and Sukarnoto (2013) investigated thin-wall ductile iron (TWDI) plates (Suharno, Soedarsono, Soemardi & Sulamet-Ariobimo, 2011; Soedarsono & Sulamet-Ariobimo, 2012; Soedarsono, Suharno & Sulamet-Ariobimo, 2012a, 2012b; Sulamet-Ariobimo et al., 2013a, 2013b; Sulamet-Ariobimo, Soedarsono & Primananda, 2013; Sulamet-Ariobimo, Soedarsono & Suharno, 2015) according to the Japanese Industrial Standard (JIS) which provided several standard specimens for plate form. TWDI is as referred to a cast iron product with thickness below 5mm (Caldera, Chapetti, Massonen, & Sikora, 2007) 1000. Tension tests of TWDI are usually conducted which refer to ASTM E8, due to unavailability of an appropriate tension test machine; Sulamet-Ariobimo et al. could not use ASTM E8. Unlike the ASTM, the JIS has not adopted TWDI in its standard. Instead JIS Z2201 No. 13-B was chosen for this investigation. It is chosen due to the recommendation stated in JIS Z2201 that recommended test piece no. 5, 13A and 13B for sheet, plate, shape and strip including also the test piece recommendation for sheet less then 3mm. The results showed that all elongations of TWDI were below 10% the minimum standard for ductile cast iron (Ferrum Casting Ductile FCD) based on JIS G5502, although both the nodule counts and nodularity were high. Similar nodule counts and nodularity found in which were associated with high elongation found in other studies. Because of this contradiction, another type of standard specimen, JIS Z2201 No. 5, was used for the tensile properties testing. With this specimen type, the opposite results were obtained. The conclusion drawn from this research was that specimen width affected the elongation results. Goh and Shang (1982) also found that width as well as thickness and loading direction altered the tensile properties. The differences between the work of Goh and Shang and that of Sulamet-Ariobimo et al. appeared in the region of the strain-stress curve that was analysed. Goh and Shang considered the effects of specimen geometry on tensile properties in the plastic region whereas Sulamet-Ariobimo et al. considered these properties at failure. These findings of Goh and Shang and those of Sulamet-Ariobimo et al. have prompted further research into how their results on the relationship between specimen shape and tensile properties can be employed to other materials. The research reported here was conducted to examine the effects of tensile specimens presented according to JIS on tensile properties of aluminium and steel.2Experimental methodJIS specimens Z2201 No. 13(b) and 5 are used as can be shown in Figures 1 and 2. Both of these specimen types are used for aluminium and steel sheets as-received condition where the aluminium is a common commercial grade; the steel is general structural hot-rolled steel. The grade of each metal was determined based on its chemical composition analysis result.

Both tensile specimens were made from one sheet with spesific rolling force direction. The number of specimens are 5 pieces for each material and standard. Tensile test runs were conducted according to JIS Z2241. JIS Z2241 is a tension test standard method for metallic materials. It is state that the test piece shall be prepared in accordance with JIS Z2201 unless otherwise specified. The sampling and preperation of test piece shall be carried out in accordance with the product spesification of respective materials. Any process which could change the quality shall be avoided.

Determination of mechanical properties was based on JIS G3101 for steel and AA 1000 for aluminium. JIS G3101 is rolled steel for general structure standard. This standard included chemical composition and mechanical properties of general structure rolled steel grades that will be used to confirm the experimental data and to determine the grade of the steel. Like JIS G3101, AA 1000 is a standard for pure aluminium. AA1000 will also be used to confirm and determine the grade of the aluminium samples.

Analysis of tensile specimens has found that the width of JIS Z2201 No. 5 is twice the width of No. 13(b). General structural hot-rolled steel was selected to represent the ferrous group and a common commercial grade of aluminium was selected to represent the nonferrous group.

Shimadzu universal testing machine with 20 tons of force load cell capacity and testing speed of 0.33mm/s for steel and 0.25mm/s for aluminium were used. All the test specimens are made with its as received plate condition. The test was performed on normal testing condition following the procedures in JIS Z2241.

The specimen is placed in the machine between the grips and an extensometer which can automatically record the change in gauge length during the test. The machine itself can record the change in length of the specimen which is held while applying an increasing load on specimen until rupture condition achieved. Throughout the tests the control system and its associated software record the load and extension of the specimen. The testing results obtained can be further analysed to determine the tensile properties of test specimens including: ultimate tensile strength, yield strength and elongation. The elastic modulus of the test specimens were not presented due to its elastic behaviour of metals beyond the scope of this work which focused on plastic behaviour.

As mentioned previously, chemical composition analysis and micro-structural examination were also performed to confirm the type and grade of the materials.

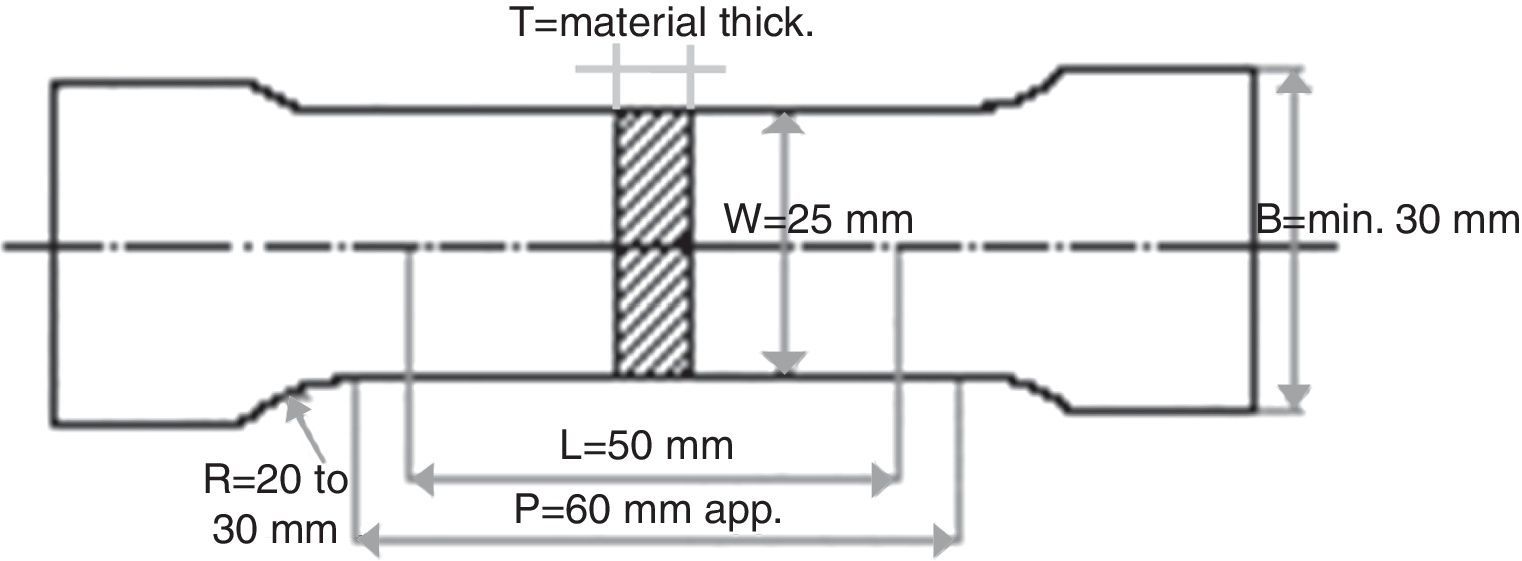

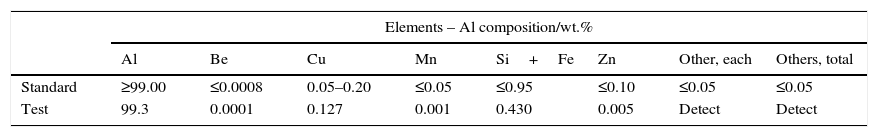

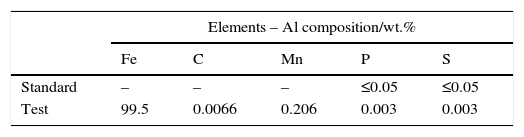

Tables 1 and 2 show the chemical composition of aluminium and steel specimen respectively, and on the basis of the results, the aluminium can be classified as AA 1100 and the steel as SS 400. All elements in the aluminium chemical composition are between the limit given by AA 1100. Beryllium, copper, manganese, silicon, iron and zinc are present because of their ability to improve strength. As with the aluminium, all the elements in the steel are within the range of SS 400 standard. Carbon and manganese are present because of their role in increasing strength.

Examination of the microstructure of the aluminium (Fig. 3a) shows an aluminium matrix with black spots. Since Fe is the alloying element present at the highest concentration, the black spots is assumed to be AlFe3. Micro-structural examination of steel shows the presence of ferrite and iron carbide or also known as cementite (Fig. 3b). These results are consistent with the standard microstructures of AA 1100 and SS 400.

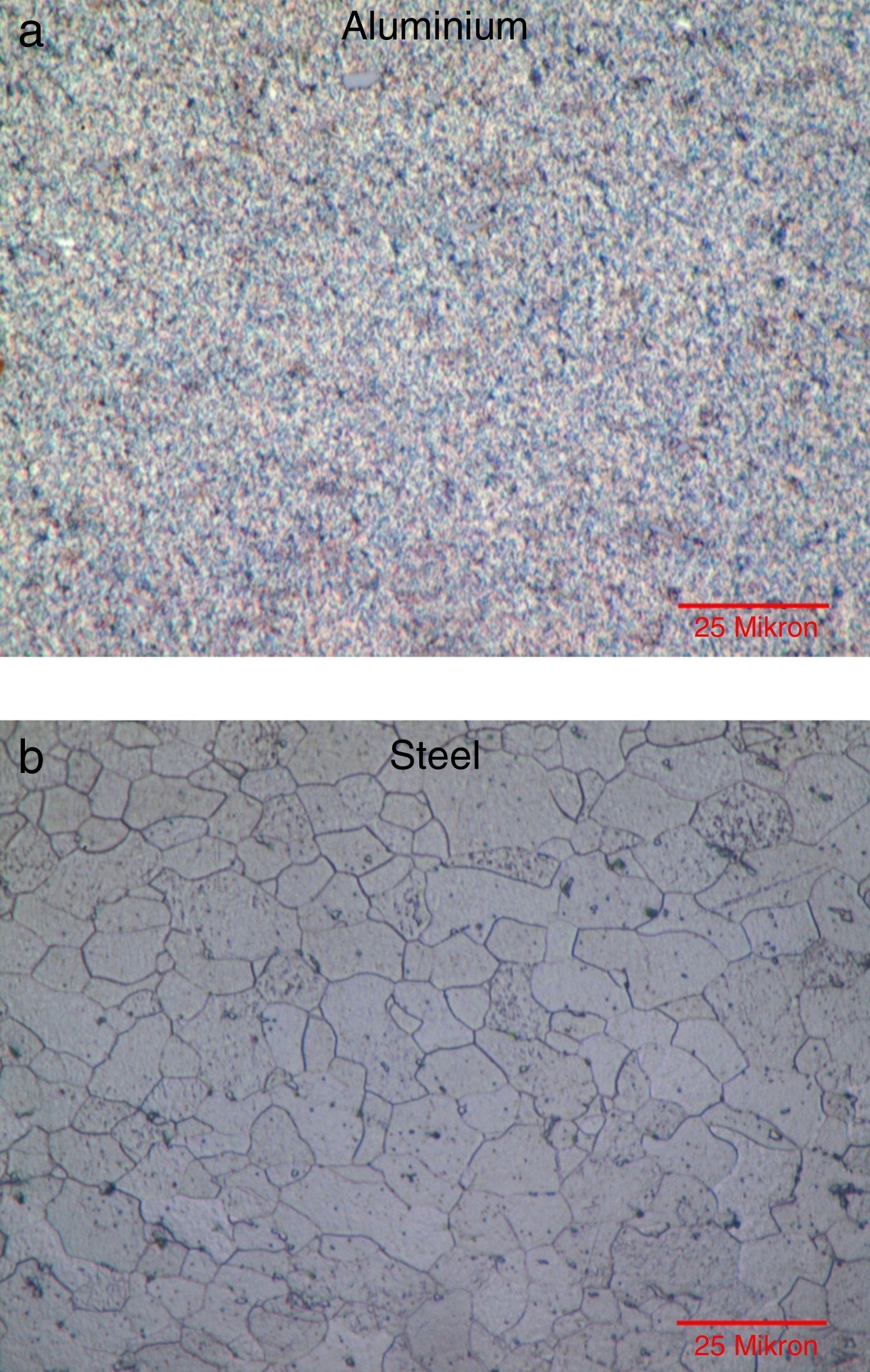

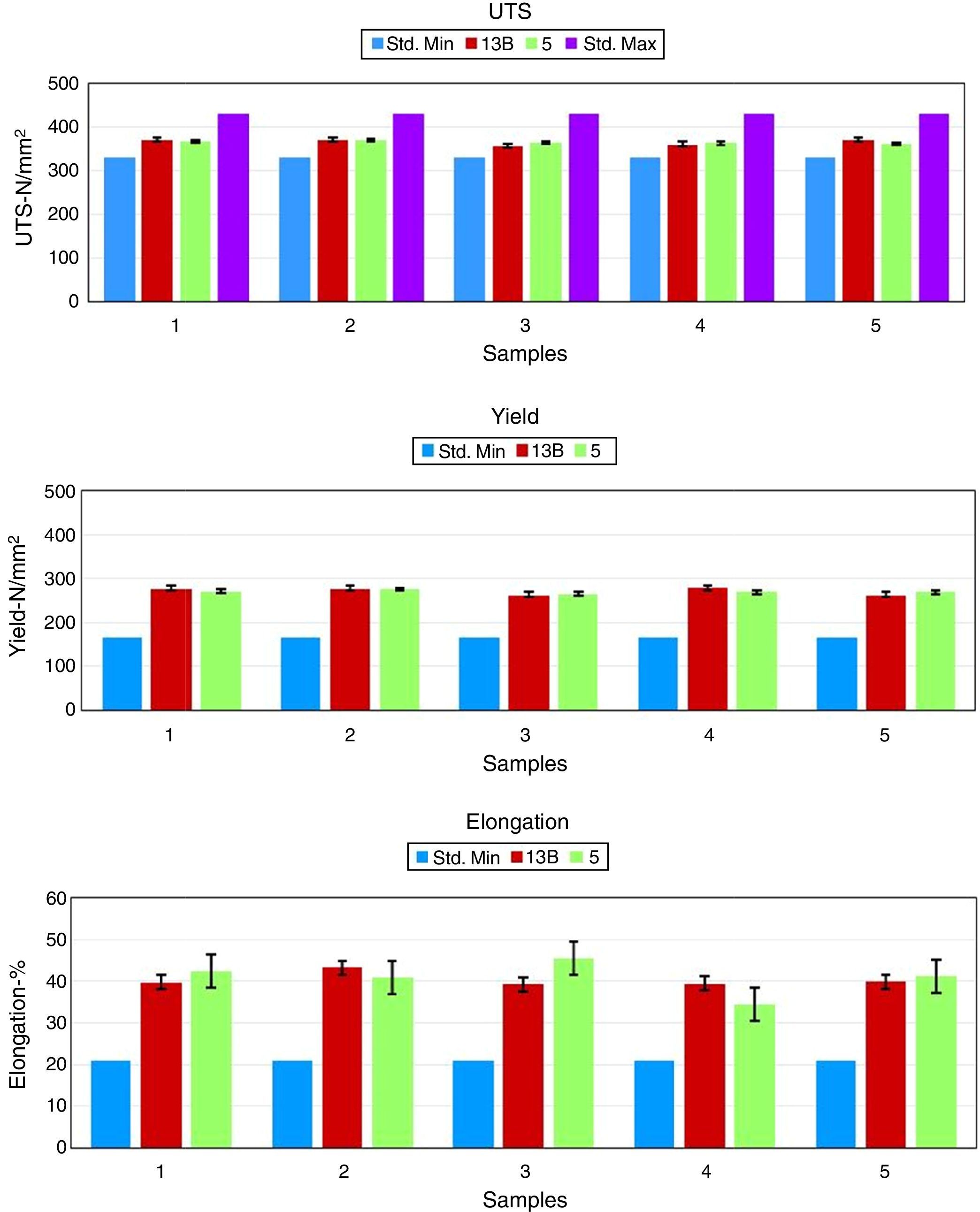

3Results and discussionTensile properties of aluminium and steel resulted from the experimental testing can be shown in Figures 4 and 5.

In the case of aluminium, for both types of specimen, the UTS values (denoted by Rm in JIS) lie within the maximum and minimum limits specified by the standard (Fig. 4). The yield strengths (denoted by Ry in JIS) for both types coincide with the minimum limit of the standard, which is why there is only one line in the graph in Figure 4b. The elongations lie within the limits, but in contrast to UTS and yield strength, there are differences between the specimen types, the differences in elongation values reach 32%. Therefore, in aluminium, the most sensitive property is elongation.

In the case of steel (Fig. 5), the values of UTS, yield, and elongation all lie within the maximum and minimum limits specified by the standard. Again, there is no variation in UTS and yield point between the specimen types, but there is a difference in the value of the elongation. However, the difference in elongation is relatively small, which is at 1%, so it can be considered to be similar for the two specimen types.

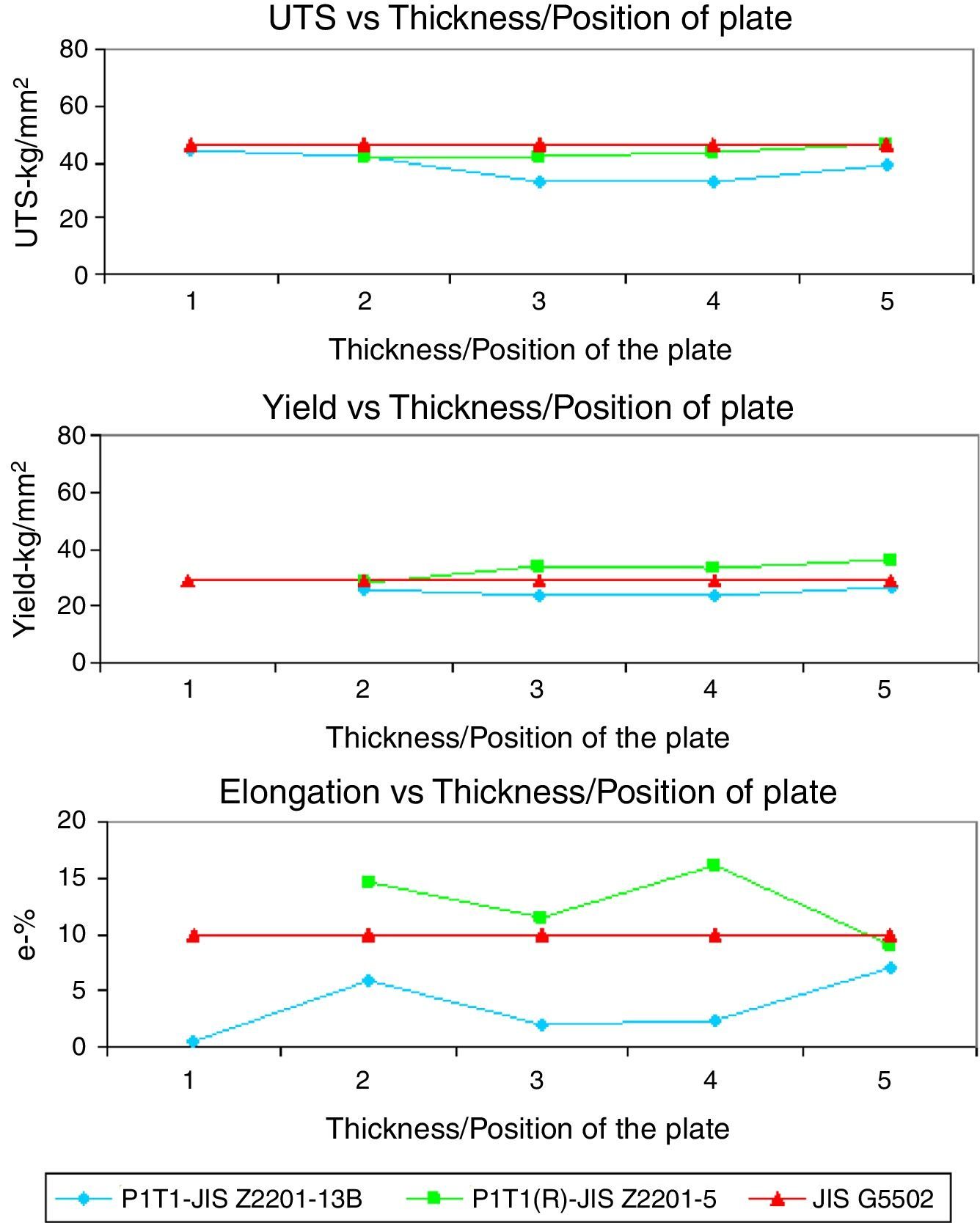

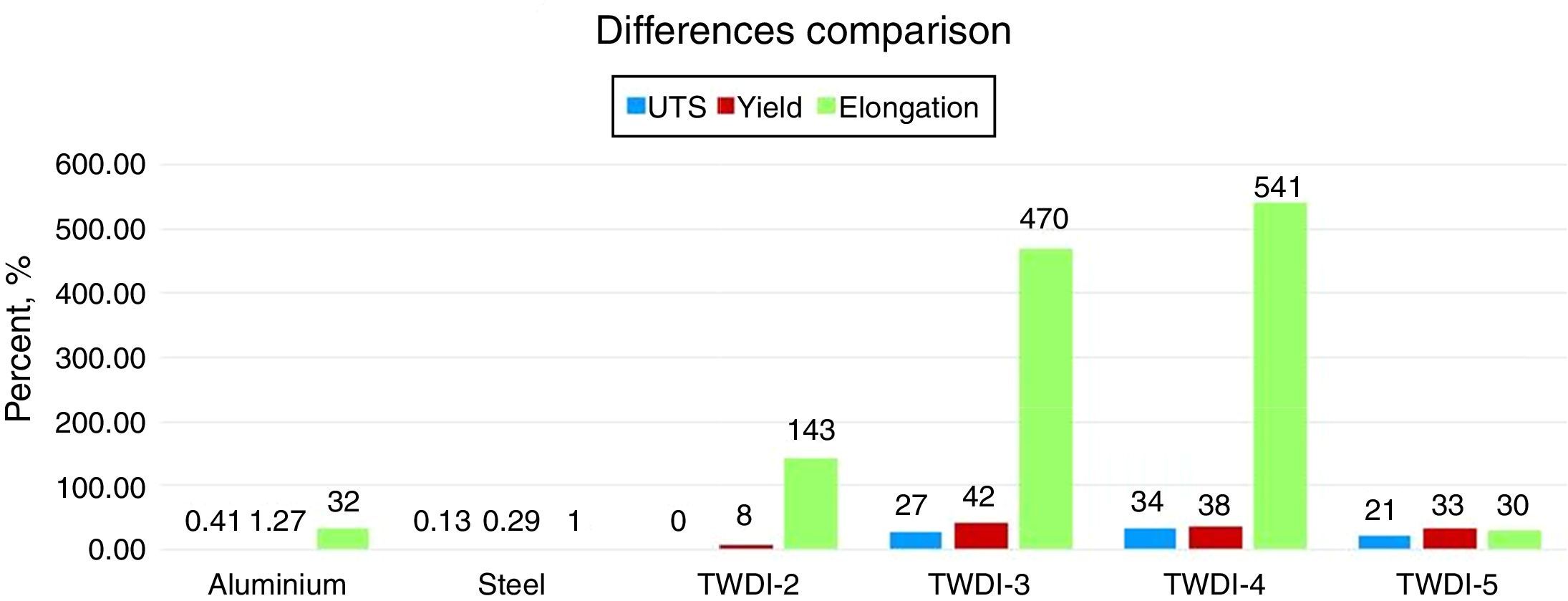

Considering the corresponding results for TWDI (Soedarsono & Sulamet-Ariobimo, 2012; Sulamet-Ariobimo et al., 2013a, 2013b; Sulamet-Ariobimo, Soedarsono & Primananda, 2013) it can be seen (Fig. 6) that the tensile properties of TWDI are sensitive to specimen width. This sensitivity is found not only in elongation as with aluminium, but also in UTS and yield strength. Also, in contrast to aluminium and steel, where despite differences between specimens, the values of the entire properties lie within the maximum and minimum limits; this is not the case for TWDI. Both type of specimens give similar tensile properties trends, but the specimen of JIS Z2201-5 give higher values. The manufacturing process is suspected to be the cause of this behaviour.

Comparison of tensile properties for aluminium, steel and TWDI are presented in Figure 7. It shows that elongation is sensitive to the width of specimen even for steel. Elongation differences in steel is 1% while UTS and yield are both 0.13 and 0.29%. Elongation differences in aluminium is 32% while UTS is 0.41% and yield is 1.27%. As for TWDI (Soedarsono & Sulamet-Ariobimo, 2012; Sulamet-Ariobimo et al., 2013a, 2013b; Sulamet-Ariobimo, Soedarsono & Primananda, 2013), elongation differences lie between 30 to 541%, while UTS and yield lie between 0 to 34% and 8 to 42%.

Goh and Shang concluded that specimen thickness, width, and force direction affected tensile properties with thickness having the strongest effect and width the weakest. Although Goh and Shang's data were collected from plastic region on strain–stress curve, their findings still supported the conclusions of the present research.

The width of the specimens differ twice from one to another. Based on this fact, crack propagation velocity is suspected to be the primer caused of the different manners exhibited by TWDI, steel and aluminium. Analysis for the crack propogation velocity was based on several parameters which were: production history, crystal lattice, and nucleation process.

Based on production history, both steel and aluminium were manufactured by rolling process whereas TWDI formed by casting process. In rolling process, metals will experience annealing as the finishing process, which aims are to release internal stress and recover the microstructure condition. This is not happening in casting. So the velocity of crack propagation in steel and aluminium will run slower than TWDI. It will provide more time for tensile curve to capture this process accurately. Hence the width of specimen did not affect the steel and there was a slightly effect on the aluminium.

Regarding crystal lattice, steel and TWDI as ferrous metals have body centred cubic (BCC) lattice whereas aluminium has face centred cubic (FCC). BCC has lower density (68%) compared to FCC (74%). This will detain crack propagation. So the crack propagation velocity in BCC will be slower than in FCC. This explained why differences in the elongation of aluminium reached 53% whereas its UTS and yield are below 10%. Furthermore aluminium tends to have poor nucleation rate compare to steel. This will increase the grain size which will further improve crack propagation velocity.

The presence of alloying elements might affect the tensile properties behaviour. Beryllium, copper, manganese, silicon, iron and zinc were present in the aluminium only carbon and manganese in steel. Both of these alloyed are associated with alloy whereas the steel which primary carbon and manganese contained as alloying elements which contribute to improve strength.

4ConclusionThe main differences of the tensile specimens used in this research laid in the width. The width of JIS Z2201 No. 5 is twice the width of JIS Z2201 No. 13(b). This condition will affect the accuracy of data recording during tensile testing which was based on crack propagation velocity. Wider width will give more accurate data for high crack propagation velocity. Aluminium, steel, and TWDI have different crack propogation velocity due to their lattice conditions.

Both aluminium and steel, gave different results which compare to TWDI. The properties of aluminium and steel were found within the maximum and minimum limits of the standard for both specimens types. This was not the case of TWDI. The greatest differences found in aluminium and steel were 32% whereas in TWDI would reach 541%. Elongation was the most sensitive of tensile properties to the width of specimen due to the lack of alloying elements that could improve it.

Aluminium tended to be more sensitive to specimen width than steel due to its crystal lattice condition, nucleation rate, and alloying effect. Further research should be carried out to ascertain the causes of this behaviour.

Conflict of interestThe authors have no conflicts of interest to declare.

The authors would like to express their gratitude to the Ministry of National Education, Republic of Indonesia for the Hibah Bersaing research grant no. 180/K3/KM/2014.

Peer Review under the responsibility of Universidad Nacional Autónoma de México.

![Tensile properties of TWDI [10,12]. Tensile properties of TWDI [10,12].](https://static.elsevier.es/multimedia/16656423/0000001400000002/v3_201703180233/S1665642316300141/v3_201703180233/en/main.assets/thumbnail/gr6.jpeg?xkr=ue/ImdikoIMrsJoerZ+w96p5LBcBpyJTqfwgorxm+Ow=)