Editado por: Brij B. Gupta, Kwok Tai Chui

Última actualización: Julio 2022

Más datosSupply chain management (SCM) integrates all links and business processes involved in the supply chain through the information management system. Applying artificial intelligence algorithms to the SCM system can realize the visualization, automation, and intelligent management of all links in the supply chain. This can effectively help enterprises reduce operating costs and improve their ability to respond to market demands, thereby increasing overall operational efficiency. An effective member selection method is an important basis for smooth dynamic supply chain operation. To address the problem of high numbers of decision attributes and low numbers of data samples for decision analysis, this paper proposes a dynamic supply chain member selection algorithm based on conditional generative adversarial networks (CGANs). To ensure that classification performance will not be reduced, the member classification method on the chain can successfully reduce the data dimension and complexity in the classification process. Furthermore, machine learning is used for analyzing and predicting purchase and inventory links in the supply chain. For the vehicle scheduling module, the path is reasonably planned to improve the operation efficiency. The integrated implementation of the SCM system is finalized using the SSH framework.

Against the backdrop of economic globalization, the supply chain relationship is undergoing dramatic changes. Enterprises develop and grow effectively only when they constantly adjust their policies in accordance with market changes. Therefore, a smooth, efficient and cost-saving flow of information, money, logistics, and human resources is crucial to the operation of modern enterprises. This information must be mastered as accurately as possible to ensure economic success. Accordingly, open access to the “information island” existing in the enterprise supply chain has caused a breakthrough for enterprises to improve quality and increase production capacity. The supply chain is a complete process from order signing to product arrival in the hands of customers. Other constituent processes of the supply chain include raw material purchasing, warehousing, production, inventory, outbound, transportation and distribution (Rahmani et al., 2020; Hasani et al., 2021). An efficient and mature supply chain information management system necessitates the functions of on-demand traceability, process visualization, and management automation. Therefore, the accurate collection and reception of information in each link and the rapid and efficient implementation of manager decisions have become crucial to the supply chain (Guo et al., 2020). Artificial intelligence provides technical potential for the supply chain system to attain these requirements. It can also be used to price, adjust storage capacity, change transportation plans by predicting the weather, and timely adjusting business decisions using external data (Ghorashi et al., 2020; Gholizadeh et al., 2020). A neural network is an adaptive, nonlinear dynamic system that consists of hosts of interconnected neurons that enable it to perform complex logical operations. As a data processing system, a neural network imitates the structure and function of the human brain. These networks can carry out state responses to continuous or discontinuous input, and process the dynamic information in nonlinear relationships. A neural network is a manually established dynamic system that uses a directed graph as its topological structure. It processes data by making state responses to continuous or discrete inputs. The graph that serves as its topological structure represents processing units as nodes and weighted directed arcs (Alavidoost et al., 2021). Designed for handling search problems, the genetic algorithm is applicable to many types of general problems. This algorithm is founded on the parallel search of a chromosome group using three types of operations: selections, exchanges and mutations. This combination makes the genetic algorithm unique. Traditional algorithms are likely to fall into the local optimal solution, as they iterate from a single initial value. The genetic algorithm, however, is efficient for global optimization owing to its large coverage and basis on a string set. It is capable of processing many individuals in a population simultaneously. Because it can evaluate multiple solutions at the same time (Jamrus et al., 2020; Gaurav et al., 2022), the genetic algorithm does not risk falling into a local optimal solution. Furthermore, this algorithm is conductive to parallelization. To use the genetic algorithm, no knowledge of search space or availability of auxiliary information is required, except for the value of the fitness function, which is needed for individual evaluation. This fitness function is not restricted by continuous differentiability, and its definition domain can be set arbitrarily, thus significantly expanding the algorithm's application range. Furthermore, the genetic algorithm follows probabilistic, rather than deterministic, transition rules in its search process thanks to its properties of self-organization, self-adaption and self-study. When the algorithm executes a search using data derived from the evolutionary process, the individuals with high fitness exhibit higher survival probability and receive the optimal gene structure for the environment (Goodarzian et al., 2021; Brdesee et al., 2022). Based on these considerations, this study adopts conditional generative adversarial network (CGAN) to realize the dynamic partner selection method in the supply chain, while utilizing innovative machine learning for the analysis of purchasing and inventory links. The integrated implementation of the supply chain management (SCM) system was completed using the SSH framework.

Establishing strategic partnership is not only the focus of supply chain strategic management, but also the core of supply chain management. The key of supply chain management lies in the connection and cooperation among the node enterprises of the supply chain, as well as the good coordination among them in design, production, and competitive strategy and so on. In this paper, a CGAN method is proposed, based on the index data of the relevant factors of the partners, the alternative schemes used by the decision makers of the core enterprises in the supply chain to build the cooperative relationship are mined, which improves the accuracy and comprehensiveness of the decision-making. This method can cluster the existing candidate partners of enterprises, and find the types of enterprises to cooperate with, which is very useful for decision makers to make supply chain decisions and logistics planning. Because the judgment of many factors involved in partner selection is uncertain, this paper get more objective and scientific conclusions through reasonable quantitative analysis. This method not only effectively solves the problems of incompleteness, uncertainty and subjectivity of decision-making information, but also effectively solves the problem of dynamic selection of supply chain partners, providing a basis for decision-makers to make scientific decisions.

The rest of the paper is structured as follows. Section 2 discusses related studies, and Section 3 describes the design of the SCM system. Section 4 chiefly presents an integrated implementation of the system framework. The dynamic selection method of supply chain partners based on the CGAN is proposed in Section 5, and Section 6 serves as a conclusion, providing a summary and future directions of research.

Related WorkInventory management plays an important role in the supply chain. Through inventory management, enterprises can prevent stock shortages, maintain the continuity of the operation process, share ordering costs, and quickly meet users' ordering needs. However, because the prediction of future demand has significant uncertainty, inventory management is susceptible to issues such as goods hoarding, poor liquidity, capital backlogs, and high inventory management costs (Saputro et al., 2021). The prediction of demand is one of the most important bases for enterprise decision-making and planning, which is important to reduce risks and avoid blindness. This in turn transforms uncertain factors into macro controllable factors, and provides a scientific basis for SCM (Xu et al., 2021; Almomani et al., 2022). However, traditional inventory control theories and methods are difficult to adapt to new characteristics and requirements, and enterprises face great risks when adopting traditional management methods. In the past, inventory control was facilitated by the economic purchase quantity management method in microeconomics. When this method was applied to purchase goods, it was found that inventory quantity has always been in an unreasonable situation, and inventory redundancy and shortage has often occurred as a result (Carrera et al., 2020). BP neural networks have strong non-linear mapping ability, which is especially suitable for solving problems with complex internal mechanisms. Therefore, it is highly feasible and reasonable to exercise inventory control according to BP neural network prediction. Traditional prediction methods do not effectively solve the problem of accuracy due to the difficulties presented by complexity, dynamic nonlinearity, and uncertainty of the system. Small changes in the product demand of consumers at the front end of the supply chain will lead to progressively greater changes in the product demand of companies at the back end of the supply chain. During the overall period, inventory levels in the supply chain exhibit drastic fluctuations. From customers to retailers, distributors, and producers, the fluctuation range always increases, and the fluctuation of product demand has a more obvious impact on enterprises at the top of the supply chain. Thus, enterprises in different stages of the supply chain may diverge in market demand, resulting in the collapse of supply chain coordination. The influencing factors of the chain mainly include demand forecasting, batch ordering, product rationing, product pricing, and performance incentive. These factors combine and interact in various ways among different supply chains. Therefore, it is important to consider all factors to achieve coordination in the supply chain (Lu & Wang, 2020; Karimian et al., 2020). This study uses demand forecasting as an example to analyze the coordination of a supply chain.

SCM is one of the most important means for enterprises to obtain international competitive advantages. The use of information technology to reconstruct the business process, enable users to cooperate with suppliers, eliminate wasteful activities in the supply chain, simplify the business process, save time, improve quality, and reduce costs, is an effective means of enhancing global competitiveness of enterprises. Extensive academic efforts have been made to research inventory management. Du et al. (Du et al., 2020) developed a system model on the basis of the original management mode using a genetic algorithm and BP neural network to improve the efficiency of hospital drug inventory operations. Teerasoponpong (Teerasoponpong, 2022) proposed a decision support system (DSS) applicable to sourcing and inventory management with the goals of helping SMEs in data compilation and exploitation, and supporting their decisions under business ambiguities. Shen et al. (Shen et al., 2020) set up an integrated model to facilitate the inventory management of farmers’ fresh agricultural products at various links, including professional cooperatives, distribution centers, supermarkets, and other markets. Harifi et al. (Harifi et al., 2021) proposed several models of inventory control problems. These models were deterministic single-product, deterministic multi-product, and stochastic single-product. To solve the inventory routing problem (IRP), Dosdogru et al. (Dosdogru et al., 2021) proposed a new hybrid methodology that includes two phases that provide a generic framework for IRP. Wu et al. (Wu et al., 2021) tackled a multi-period location-inventory-routing problem with time windows and fuel consumption, which optimizes the routing, location, and inventory decisions for distribution centers and customers in supply chains of different levels. Badakhshan et al. (Badakhshan et al., 2020) incorporated cash flow modelling into the SD structure of the beer distribution game to develop the CFB function. Garg et al. (Garg et al., 2020) presented a multi-objective genetic algorithm optimization framework in the modeling of the bullwhip effect and NSGA for centralized and decentralized SCM. Potential improvements of inventory management in a stochastic environment have also attracted significant attention from the academic world. Liu et al. (Liu et al., 2020) focused on a coordinated location-inventory problem in a stochastic supply chain system which is disrupted by supply at random. Karimian et al. (Karimian et al., 2020) built a multi-item economic production quantity model with a shortage for a single-vendor, multi-retailer supply chain under vendor-managed inventory policy in an uncertain environment. Modern supply chains are prone to risks due to their complicated networks and wide geographical coverage. An integrated planning scheme may adjust the operation of supply chain networks effectively and minimize the impact of unknown changes and failures, thus reducing risk from both internal and external sources. Nezamoddini et al. (Nezamoddini et al., 2020) constructed a risk-based optimization framework for use in operational decisions. They proposed a model that handles uncertainties in connection with facility interruptions, lead times, and demands in supply, production, and distribution channels. Liu and Li (Liu & Li, 2021) developed a bi-level programming model for joint decision-making of order allocation and product configuration, where the coordination and protection mechanisms were used to coordinate between capacity-constrained suppliers and reduce the risks in supply chains. Han and Zhang (Han & Zhang, 2021) formulated a supply chain risk management model based on machine learning.

To research SCM system software, industries can integrate MRP Ⅱ and ERP software interfaces or other specific functional modules, including customer demand forecasting, operation planning and decision analysis ability, enterprise production scheduling, inventory management plan, cooperative enterprise logistics management and service, quotation and negotiation decision-making model, transportation decision, transportation route planning, and other functions. The prediction model, decision-making scheme model, path planning scheme, and scheduling algorithm are integrated through the network, database, and front-end technology to provide interactive and intuitive options for decision-making at all levels. This approach enables users to obtain static data and ensure real-time tracking of dynamic data, which greatly improves the response of enterprises to market changes. The development planning of the enterprise should proceed from a general perspective to avoid the disadvantages caused by the pursuit of local optimization. The integration of production planning and distribution as the two main functions in supply chain (SC) management is a major current problem. Cai et al. (Cai et al., 2021) suggested green computing energy management, promoted a collaborative distribution optimization framework and algorithm for an intelligent SCM, and constructed a joint optimization model of VRP & VFP for logistics distribution. Gharaei and Jolai (Gharaei and Jolai, 2021) solved the production scheduling and distribution problem in a multisite supply chain from the three-agent perspective of the manufacturer, distributor, and customer. Mousavi et al. (Mousavi et al., 2020) investigated the production and air transportation scheduling problem with time windows for the due date. Deng et al. (Deng et al., 2021) studied the carbon emission costs during transportation and cold storage, the effect of temperature changes on the decay rate of fresh products during unloading, and the traffic along the actual distribution route. Khan et al. (Khan et al., 2020) presented a hybrid prediction model based on recurrent neural networks, long short-term memory, gated recurrent units, and a genetic algorithm to further optimize the parameters of the hybrid prediction model. Huang and Yang (Huang & Yang, 2020) constructed a multi-item joint ordering framework under the global cruise ship supply chain, including integrated operation of purchases, different order cycles, delivery, and inventory based on a cruise distribution center. Shen et al. (Shen et al., 2021) combined big data and intelligent computing to study the agricultural product intelligent SC system, and used the network equilibrium method to build an SC model that considers the effort level of multiple producers and retailers. Ali et al. (Ali et al., 2021) presented a novel algorithm that demonstrates how an SC can be designed to solve multi-product, multi-objective, and multi-stage supply chain problems based on real-time data. Because the development of green supply chains has become a trend, Hu et al. (Hu et al., 2020) proposed an effective Tabu search algorithm by increasing the sensitivity of governments to environmental issues. This study analyzed the performance of data classification and balance levels of CGAN, and applied it to partner selection in a dynamic supply chain, meanwhile, this study completes the integration and implementation of the SCM system framework, so that the system has scalability and portability. Table 1 is the summarize existing work key feature and its limitation.

Existing Work Key Feature and Limitation.

| Existing work key feature | Existing work limitation | |

|---|---|---|

| Supply chain design | The traditional supply chain design problem is to analyze the normal operation environment. It is usually assumed that the supply chain will operate according to the plan once it is designed. However, in reality, due to the impact of unexpected events, the nodes and their connections of the supply chain may fail to operate according to the original plan. | The design of supply chain needs to consider the factors of unexpected events into the design of supply chain. Taking emergencies into account, the traditional supply chain design problems usually change. The objective function of some problems will change. |

| Supplier selection strategy and procurement strategy | The main problem of supplier selection and purchase strategy is the decision of supplier combination and order allocation among suppliers. In the event of an emergency, we can try our best to ensure that the supply of products will not be affected by reasonable selection of suppliers and allocation of orders. | The first is supplier selection, and the second is emergency procurement and backup suppliers. Supplier selection refers to the selection of the main supplier. The backup supplier is the supplier that is activated when the main supplier is interrupted. Purchasing from the backup supplier is backup procurement or emergency procurement. |

| Inventory and ordering strategy | Using inventory and ordering strategies to deal with supply chain disruption risk, especially supply disruption risk, is the focus of many studies. The traditional inventory and order model does not consider the possibility of interruption risk. When the interruption risk is considered, the traditional inventory and order model needs to be re studied. | Considering the interruption risk into the traditional inventory and order models, many models are difficult to obtain analytical solutions, but are solved by numerical analysis and simulation. |

| Supply chain coordination strategy | In the case of decentralized decision-making in the supply chain, due to the existence of double marginal effect, the overall optimal profit of the supply chain is often difficult to achieve. In order to mediate conflicts and make better cooperation among supply chain members, it is necessary to design a supply chain coordination mechanism. | Consider supply side risk, demand side risk, transportation risk and other costsIn the case of risk, analyze the behavior and equilibrium conditions of each node. |

| Demand management strategy | Demand management strategies include demand transfer, late delivery order and compensation strategy. | Considering the sensitivity of demand time, how to influence customers' demand preference, so as to respond to random supply. |

The essence of supply chain network connection collaboration is to realize five connections, namely, connecting customers, connecting suppliers, connecting products, connecting production equipment and connecting managers. After the intelligent transformation of the enterprise's supply chain, these five connections will be connected and become a supply chain node. A small cycle of connections will be generated between customers, suppliers, production equipment, products and management. It can also be connected with other business systems to form a high degree of supply chain network collaboration sharing information.

In terms of the integration and transformation of logistics data in the supply chain, the two emerging technologies, machine learning and big data, can be used to realize the real-time transformation of logistics data processing and the integration of supply chain data using mobile handheld terminal devices. With the continuous development of the new generation of information technology, the traditional supply chain management mode has been transformed. The collaboration of network connection has also brought a new revolution to the industry and realized a wider range of connection and collaboration.

Supply chain management is a very important link in the company's business operation. At the same time, in the operation link, the optimization of operation is the core and key to meet the maximum demand of customers with the minimum cost. The goal of supply chain management is to shorten the company's capital turnover period, reduce the risks faced by the enterprise, achieve the profit growth of the company's performance, and provide predictable income to the managers.

The traditional supply chain is a logistics network system composed of supply chain, manufacturers, warehouses, logistics centers and channel providers. Different enterprises have different business nodes, and the supply chain networks formed are different. However, the core of the supply chain is to manage the company's logistics, capital flow and information flow around the enterprise. The process from the production of products or the purchase of raw materials to the final delivery of goods to customers through the company's sales logistics network.

For modern enterprises, better control of enterprise information flow, better use of artificial intelligence and big data to achieve resource sharing, and on this basis, improve the service quality of enterprises, shorten logistics costs and time, so as to ultimately achieve a win-win situation between customers and enterprises. It can be seen that supply chain management is a very important link in enterprise operation management. Supply chain management includes all management activities from enterprise strategy to tactics formulation and operation management.

The integration of artificial intelligence and supply chain management system can bring synchronization in technical standards to enterprises, without the need to develop other application systems. It can not only achieve internal management of enterprises, but also bring improvement to enterprise supply chain management. In order to adapt to the changing enterprise management environment, the coordination of the supply chain management system can comprehensively grasp various management methods required by the enterprise operation. Dynamic management can implement flexible organization and strengthen internal processes to adapt to external changes. Strengthen planning and organization, and adopt flexible countermeasures to cope with changes. The coordination of supply chain system can promote the efficiency of production, logistics, organization and finance.

Establish an Intelligent Supply Chain Management ModeThe goal of the intelligent supply chain management information system is that the resources between the business departments of the company can be interconnected. First, the middle layer management platform, machine learning algorithm and internal processing flow are introduced to realize the integration. The second step is to standardize the data information format, establish a complete information platform, and release the data of various departments in a hierarchical and standardized manner. The third part is to share the data resources among various departments by using the set permission specifications, so that the internal personnel can see the relevant information in a timely, complete and accurate manner, and the data flow between the platforms can also flow smoothly.

This new mode is one of the ways to realize the transformation of the supply chain, and the ultimate goal is to realize the information sharing among various departments and customers within the company. The intelligent management mode can also provide electronic and customized management of supply chain orders, better guide customers to place orders in an electronic way, and internally manage these orders in a networked and electronic manner, making information sharing more convenient and efficient. At the same time, it can also establish a client-side order query mode to facilitate customers to timely understand the logistics and inventory situation.

Main Characteristics of Supply Chain IntelligenceThe main features of supply chain intelligence are as follows:

- (1)

Customer Order Pull

In the supply chain system, the orders issued by customers drive the production of enterprises, and the flow of the entire supply chain value flow needs to be pulled by customers' orders. When no customer order is generated, the upstream enterprises of the supply chain do not provide any service. After receiving the customer order, the whole supply chain responds quickly and provides services.

- (2)

Punctual and Accurate

Punctuality is a prerequisite for the supply chain system to achieve internal smoothness and a certain degree of rhythm relaxation. All node enterprises in the supply chain must deliver on time according to the plan; Accuracy is a necessary condition for the lean supply chain, including accurate customer demand, accurate inventory, accurate delivery time, etc., which puts forward new requirements for the reasonable layout of suppliers.

- (3)

High Quality and Low Cost

In the supply chain system, each node enterprise greatly reduces the production cost and eliminates the waste of equipment, personnel and process through reasonable resource allocation and efficient information exchange. Thus, the main energy is put on quality control, which ensures the high quality of supply chain services.

- (4)

Emphasis on Coordination

The supply chain system is an organism composed of various enterprises and various production processes. If all parts can't maintain coordination and cooperation, the operation of the supply chain system will face serious problems. The coordination of the supply chain includes two levels. One is the internal process coordination, which emphasizes the information exchange between various links within the production to make each process perfectly connected. The second is external communication, which emphasizes the strengthening of communication and cooperation among the enterprises at each node of the supply chain and the establishment of a perfect information exchange channel.

- (5)

Information Networking

A smooth operation of the supply chain system can't be separated from the information exchange between the node enterprises. However, to make the exchange smooth, we must rely on the powerful Internet system and big data. Only through the Internet platform can enterprises in the upstream and downstream of the supply chain come together to negotiate and deal with the difficulties and problems encountered in the operation of the supply chain.

- (6)

Continuous Improvement

Compared with other supply chain management, the biggest characteristic of intelligent supply chain management is that the improvement activities of intelligent supply chain occur at various nodes and time periods in the operation process of the supply chain. It is a dynamic and continuous process. Through the virtuous cycle from finding problems to improving problems and then to finding problems, the overall performance of the supply chain is constantly optimized and improved. Therefore, the first step of implementing the intelligent supply chain is from improvement.

Integrated Supply Chain Collaborative Management PlatformMachine learning is an artificial intelligence technology that discovers and extracts the hidden information from the data warehouse. It can automatically analyze the data, conduct inductive reasoning and association on them, find some internal relationships between the data, and find out potential patterns that play a very important role in information prediction and decision-making behavior, so as to establish new business models to help decision makers make correct market strategies. The main inputs in the supply chain system are the data from the data warehouse, the converted data of each subordinate department, and the knowledge and experience stored in the knowledge base of the data mining system. The data selected from the data warehouse is processed in the knowledge base discovery engine, which provides a large number of data extraction algorithms to generate auxiliary patterns and relationships. Some discoveries need to be added to the knowledge base so that subsequent discoveries can be extracted and evaluated. The new knowledge obtained by mining will be saved in the mining knowledge base again.

The small sample machine learning data classification based on the condition generation countermeasure network designed in this study has good effect, the data balance processing effect is successful, and the overall generalization is better than the traditional data processing algorithm.

Through the integration of the unified collaboration platform and various decentralized professional tools, this paper summarizes the originally scattered data generated in each stage of the whole process management of the supply chain into the data pool for unified management, forming a single data source management, ensuring that the business data can flow smoothly and have traceability at all stages of the management, and ensuring that customers and managers can obtain correct and reliable data at any time. At the same time, the integrated collaborative management platform can be integrated through a variety of enterprise information systems to open up the flow of multi professional data in the enterprise. Through the integrated collaborative management platform, a multi-disciplinary and unified product multi-stage can be formed. Through configuration management, the product's multi-disciplinary data can be set with uniform parameters and relationships, and the product can be managed with uniform configuration. In addition, this paper uses CGAN to realize the dynamic selection method of supply chain partners. Firstly, the sample data is mapped to Hilbert space, and then the feature extraction problem is transformed into a linear solution problem to obtain the feature matrix of the sample data. At the same time, the information entropy and mutual information of each sample data feature matrix are calculated, and the relative entropy of the target is adjusted according to the calculation results. The experimental results show that the CGAN data classification is accurate, the data balance level is high, and the overall generalization is improved. Therefore, CGAN is suitable for partner selection in dynamic supply chain.

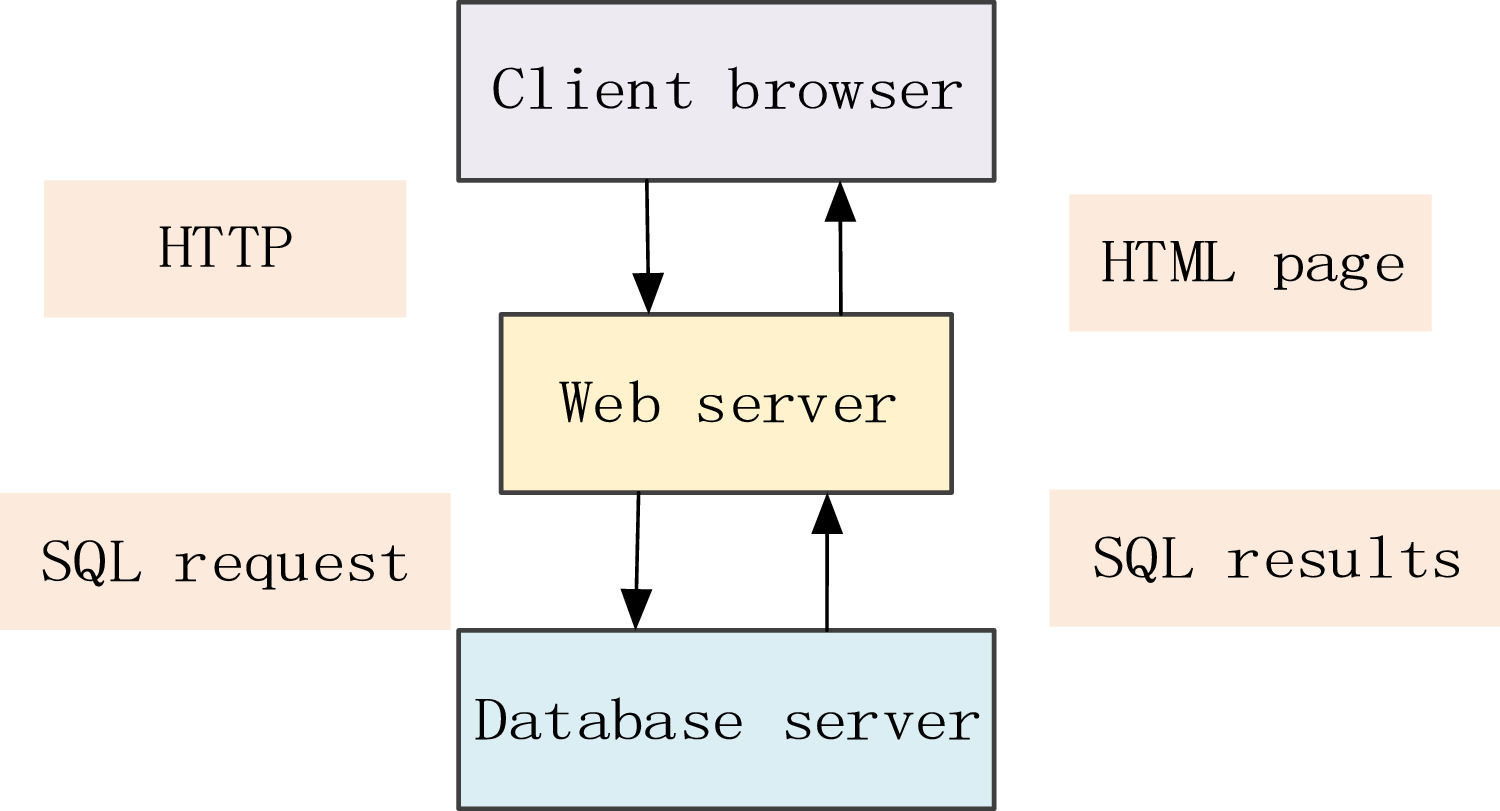

Design of SCM SystemFunction Design of SCM SystemManagement information system platform modes can be roughly categorized into four types: host terminal mode, file server mode, client/server (C/S) mode, and browser/server (B/S) mode. The first two modes cannot fully meet the needs of Internet users due to hardware limitations and the increased number of users and data. Therefore, modern enterprise management information systems generally implement B/S or C/S mode. Our system adopts the current leading B/S mode, which is an expansion of the C/S mode. The pre-display function of the original client's application module is helpful for maintenance and upgrading. It is usually composed of presentation, function and data layers. The architecture of the pattern is shown in Fig. 1.

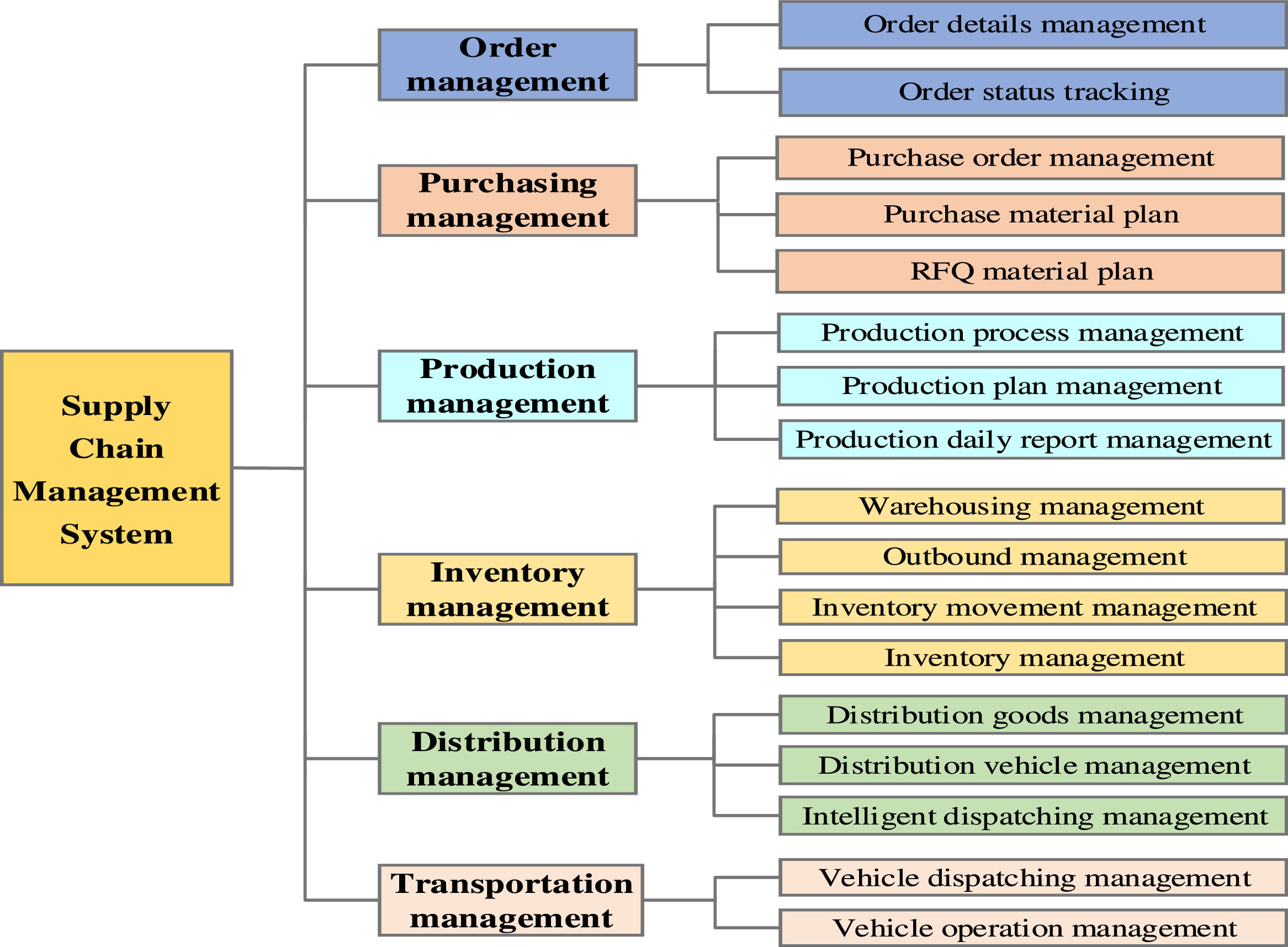

After the theoretical model and algorithm are established, a practical application system is needed to verify actual performance to optimize the operation mode and increase management efficiency. The specific system function design is shown in Fig. 2.

As shown in Fig. 2, the SCM system designed in this study is composed of order, purchasing, production, inventory, distribution, and transportation modules. Each module includes corresponding business. Other interface is possible to work in our model, the innovation of this model lies in:

- (a)

First, define the WebService interface. After defining the interface, both parties define the transmission rules, transmission fields and necessary contents. JSCON transmission is used to support multi header and table body data and multi table body data.

- (b)

The interface is divided into two categories: down and up (upload and download). It is determined by the information in the header. When the interface information receives the content, it will view the information fixed in the header, such as supplier code, whether the date is upload or download, and whether the content in the data table body is empty (this is the pre check content). If it is unqualified, it will directly return the information to the client to upload again.

- (c)

If the information passes the pre check, the infrastructure will be used to allocate tasks, generate task codes, store them in the database in the temporary table, and wait for the platform system to start the automatic import task.

- (d)

Register the task type, task type code, name, source data table, target table, type, level, time, deletion flag and other information in the database.

- (e)

When each task is started, it first finds the corresponding task through the transmission information, obtains the storage table corresponding to the task through the task, and starts through the stored procedures in the table. The startup of each stored procedure will generate a unique task number.

- (f)

There are three processes in the start-up storage process (including preparing data, verifying data and synchronizing data). These three processes are associated with a unified number. If the data is unqualified in the data storage process, the data will be recorded in the error table.

- (g)

When the data is synchronized between tables, the number of synchronization items and the number of errors are returned after synchronization so that the foreground personnel can query.

- (h)

Support simultaneous multitasking.

The SCM system designed in this paper standardizes and automates the operation and maintenance process, simplifies the operation and maintenance, greatly improves the efficiency of operation and maintenance, and reduces the maintenance cost. It is a very stable and well functional SCM management system. In addition, the system also combines the CGAN algorithm to analyze the index data. On the basis of establishing the relevant factors of the partners, it mines the alternative schemes that the decision makers of the core enterprises in the supply chain use to build the cooperative relationship, so as to improve the accuracy and comprehensiveness of the decision-making. It can provide data support for formulating task plans and allocating operation and maintenance forces.

- (1)

Reliability requirements:

- (a)

Solve the problem of overlapping calls of synchronization tasks, synchronization tasks are called regularly by scheduled tasks. A scheme needs to be designed to prevent the same task from overlapping, that is, to prevent the previous task from running and the next task from starting again (to prevent data inconsistency, deadlock, etc.).

- (b)

Solve the problem of data consistency, the data synchronized from the interface table to the platform table or from the platform table to the interface table must be consistent. It is necessary to avoid transferring inconsistent interface table data to the platform or transferring inconsistent platform data to the interface table.

- (a)

- (2)

Maintainability requirements:

- (a)

Data traceability, data written to or read from the interface table can be traced. Who, when, and what data can be written or read by viewing the log? Success or failure? Logging can be performed according to different

- (a)

Synchronize data to set the log level and log switch.

- (b)

Data maintenance, in order to maintain the high performance of the system, data (including business data and log data) needs to be archived regularly.

- (c)

Abnormal pre-warning, in the process of data transmission, it is necessary to give early warning to relevant personnel for abnormal conditions, so as to manually intervene and handle problems.

- (b)

This module mainly manages, tracks, and responds to information requested by customers. Through order management, it commands the production rhythm and adjusts inventory quantity, thereby improving production efficiency and boosting the supply cycle. Links are adjusted in the supply chain according to the order situation, thus ensuring rapid response to the market. Once order is signed, the system automatically generates a unique order number, which can be used to track the flow of orders in all links of the enterprise's supply chain in real time, and master the overall process of order production, packaging, and distribution (Yuan et al., 2020). Furthermore, the order number is directly scanned and identified from the sensing layer through an RFID (Radio Frequency Identification Technology) electronic tag, which avoids manual errors. The order business process is shown in Fig. 3

In the order management, the company shall specify the scope of abnormal purchase and the approval procedures for abnormal purchase. The system will automatically calculate the quantity and period of purchase for over quantity purchase and near validity drug purchase. When creating a purchase order, the over quantity or near validity purchase will automatically trigger the approval of abnormal purchase. The purchase order can be successfully created only after the approval is passed. The company shall formulate a single procurement contract template to clarify the responsibilities and rights of both parties. The procurement business department shall initiate contract approval in accordance with the relevant provisions of contract management and sign the contract after the approval of the authorized person, so as to ensure that the terms such as procurement price and quantity are consistent with the approved supplier selection results and procurement requirements documents, and ensure that the contract terms are approved. The procurement business department shall communicate with the supplier to confirm the purchase quantity according to the sales and inventory conditions, in combination with the factors such as order cycle, in transit period, minimum order quantity, service level, etc. the procurement personnel shall create purchase orders in the system according to the purchase contract, which shall be implemented after being reviewed by the procurement manager. Warehouse transfer orders and tax paid transfer orders can be created only after they are created and approved.

Purchasing Business Process DesignAccording to the order, it is necessary to purchase the detailed list of materials required for the production of products, put forward the purchase information to the supplier in the form of purchase order, and track the purchase process to make sure that the materials reach the enterprise in the shortest time possible and ensure the normal production operation. According to the order number, the system receives detailed information including material price, performance, and model from the supplier through electronic data interchange (EDI), selects the intended company, and signs the purchase order contract. After signing the contract, the supplier's logistics information is accessible through the order number until the purchase is completed (Al-Farsi et al., 2021).

Production Business Process DesignThe production module is largely responsible for the management and control of production links. Through this module, we can prevent excessive or insufficient production quantity, accurately understand the status of production activities, and improve product quality. The installation equipment can display production information such as process flow, material information, production quantity, and yield, and paste the electronic label. Personnel can then manufacture products according to the equipment prompt. After the operation, the reader can scan the electronic label and feed back the completion information to the SCM system. Finally, managers can understand the station production through the system, monitor and adjust the production process to improve the yield, make production activities more refined and flexible, and visualize the production process (Vegter et al., 2021).

Inventory Business Process DesignInventory business, also known as warehouse management, is largely used to store qualified products temporarily in advance of orders or according to market forecasts. A temporary transfer station is used for production, supply, and sales. As the integration of logistics and information flow, inventory business is important in improving product delivery speed, market response ability, and production efficiency. It is generally composed of receipt, issue, warehouse transfer, and inventory counting businesses (Asamoah et al., 2021).

- (1)

Warehousing business process design: Paste the electronic tag on the storage shelf and mark the storage location information. When items with an RFID tag pass through the access control, the reader will automatically collect and match with the system order, send the information back to the supply chain system, and simultaneously write it into the database.

- (2)

Issue business process design: The system first writes the material information to be delivered out into the RFID electronic tag of the transport vehicle. When the material passes through the access control system, the reader displays the material information to be delivered out in the system. Finally, the system terminal triggers the delivery business process to complete the delivery of materials.

- (3)

Business process design of database transfer: The stock transfer business of inventory goods refers to the transfer of materials between warehouses or storage locations. The process of warehouse transfer can accurately identify storage location information through an electronic label to ensure the real-time tracking of goods.

- (4)

Inventory business process design: The management personnel read the information on the electronic tag through the reader, automatically obtain the details, transmit the information to the SCM system through the Internet, compare it with the material database, and update the database after confirmation to improve the automation level of inventory counting.

Distribution business is an important link in the supply chain and serves as the embodiment of the relationship between information flow and logistics. In the distribution business, the following aspects need to be considered: (a) goods must be delivered on time, which requires the planning and management of vehicle transportation paths. (b) Products must be delivered completely and within the agreed time. (c) To reduce the burden of enterprises, delivery costs must be minimized. The design process of a distribution business is as follows: first, classify and package the products to be transported, and write the information into the RFID electronic tag of the product packaging box with the terminal. Then, optimize the distribution route according to the customer location and vehicle conditions (Tang and Liu, 2020).

Transportation Business Process DesignIn the design of a transportation business process, the goods, containers, and vehicles are labeled electronically, and the geographical location is updated through the readers on the delivery point, transfer station, and target warehouse. This ensures identification, anti-counterfeiting, positioning, and user tracking. Through the electronic tag and vehicle GIS system, the article and vehicle location information can be uploaded to the Internet, thereby allowing for the accurate prediction of arrival time and real-time monitoring of the transportation process (Srinivasan et al., 2021).

Database Design of SCM SystemDatabase Design PrinciplesDatabase design is intended to construct the optimal database mode for a given application environment, establish the database and its related applications, and effectively store data to satisfy users’ application needs. Database technology is the basis of information systems. The use of information systems is the process of information processing, storage, and flow, and the success or failure of an information system is directly related to the rationality of database design. The purpose of system database modeling is to enable enterprise leaders, managers, and information technicians to have a unified, general, and complete understanding of the planned information system, so as to formulate the overall scheme scientifically. Whether the database design is reasonable directly affects the difficulty of later system maintenance, and serves as the basis of system operation stability and robustness. Database structure design should also take into account the design mode of the existing enterprise database to ensure smooth integration between different system platforms when implementing the information engineering construction.

Database E-R Diagram and Data Table DesignThe management system of the supply chain is characterized by a complex process that handles immense data shared by multiple modules. Consequently, it is of vital importance to successfully perform data query and management and design a database system that is rationally structured, convenient to use, and highly efficient. The data table relationship is shown in Fig. 4.

Database Features of SCM SystemSCM in this paper is an open system database server (DB2, Informix, SQL server, SQL server, etc.) that integrates multiple platforms; it extends the content management that provides integrated access channels for various data types of information; Help customers analyze and extract valuable business information from various data; Integrate distributed information integration in heterogeneous environments.

SCM in this paper can be transferred to federated systems of distributed servers. More information about data system used in our research is as follows:

- (1)

Incremental synchronization: because there are many enterprise customers and a large amount of data, the system must support incremental modification, and only the modified data is synchronized each time.

- (2)

Support the following data processing: add data / modify data / seal data / delete data.

- (3)

Support setting life cycle: initial account creation / activation / offline / offline activation / refresh.

- (4)

Inbound data integration scenario: before entering the platform table from the interface table, the data should be checked for validity. The system should identify and alert the records that failed the check. Only the data that successfully passed the check can enter the distribution platform.

- (5)

Outbound data integration scenario: outbound data has three integration methods:

- (a)

The first type is outbound. The data in the interface table is accessed by the target system only once.

- (b)

The second is that the data exported to the interface table is accessed by the target system only twice.

- (c)

The third type is outbound. The data in the interface table may be accessed by multiple (unknown) target systems.

- (a)

In SCM, enterprises can choose to build a cloud computing platform or rent cloud services from cloud based resource service companies. By renting basic services, enterprises do not need to spend too much hardware cost, and the cost of information sharing will be reduced accordingly. In the case of enterprises' own construction, the initial investment is relatively large, but in the long run, the characteristics of cloud computing in low management cost and energy consumption can make up for the later cost consumption. At the same time, cloud computing has brought about the development of flat, fuzzy and dynamic collaborative organization results, and collaborative resources are also intelligently configured. The flattening of enterprises can reduce the number of managers and the cost of manpower; The fuzziness of enterprise boundary can reduce the communication cost; Enterprise dynamic can increase the technological advantages of enterprises; Automatic allocation of resources can reduce unnecessary investment and make full use of existing resources. Based on the change of organizational structure, the cost of manpower, communication and resources can be reduced, and the cost of enterprise collaboration can be greatly reduced.

- (1)

Supplier cloud: the supplier's agent in the supply chain platform, the list of collaborative activities mainly includes warehouse management, production management, transportation management, plan management, etc.

- (2)

Manufacturer cloud: the manufacturer's agent in the supply chain platform. The list of collaborative activities mainly includes: demand management, procurement management, transportation management, production management, customer relationship management, plan management, etc.

- (3)

Distributor cloud: The distributor's agent in the supply chain platform mainly includes the following list of collaborative activities: sales management, purchase management, warehouse management, transportation management, customer relationship management, etc.

- (4)

Retailer cloud: the agent of the retailer in the supply chain platform, which mainly includes the following collaborative activities: Sales management, procurement management, transportation management, warehouse management, etc.

- (5)

Customer cloud: the customer's agent in the supply chain platform.

The vehicle routing problem (VRP) is the key to optimize distribution and transportation routes, reduce transportation costs, and ensure scientific, intelligent, and automatic transportation scheduling. It can also save considerable operational costs for businesses, and is advantageous in SCM and portfolio optimization. Because the VRP relates to delivery time, the VRP with time window (VRPTW) adds the constraint of delivery time to the basis of VRP. In this type of problem, the earliest and latest arrival times are denoted by Te and Tl, respectively. When vehicles distribute materials from one or more distribution centers to multiple destinations under time constraints, the vehicle scheduling scheme with the lowest cost is obtained.

- (1)

Algorithm principle

VRPTW is controlled by adding time window T based upon VRP. The acceptable receiving time limit for customers T is determined by the earliest receiving time T0, and the latest receiving time T1. If the delivery exceeds the time limit, customers cannot accept it.

- (2)

Algorithm description

Set customer i(i∈v) and transport vehicle k,xijk={1,iε(i,j)1,i∉(i,j).

Define the vehicle load capacity as D and the customer demand as BBB. The customer di service starts at tbi and ends at toi. When xijk=1, the transport vehicle k is from customer i to customer j, and yki is the vehicle k serving i. The service time required for i to customers is tsi; i.e., tsi=tbi−toi. The driving time from i to j is tij. The waiting time before starting the service is twi.

- (3)

Constraints

∑idiyki≤Di∀ki means the total demand of customers ≤ load;

∑kyki=1,i∈V, means that each vehicle only serves customers once.

Compulsory transportation vehicles form a closed loop from company → customer → company, where s is the number of customers visited.

toi+tij≤tbj,toi≤tbj indicates that there is a better transportation path.

tei≤tbi≤tli,i∈V, the only number of customer service and the only number of vehicle service customers.

- (4)

Algorithm optimization

According to the optimization objective of VRPTW, i.e. the minimization of the number of vehicles and total route length, all tasks are completed, and the following equation is obtained:

∑i∑j∑ktijxijk is the total time spent on the planned route carrying goods.

The vehicle speed is constant, and tij is directly proportional to the route length. Therefore, the calculated values of the minimum time and total distance are consistent.

∑j∑kxojk traverses the minimum number of customers.

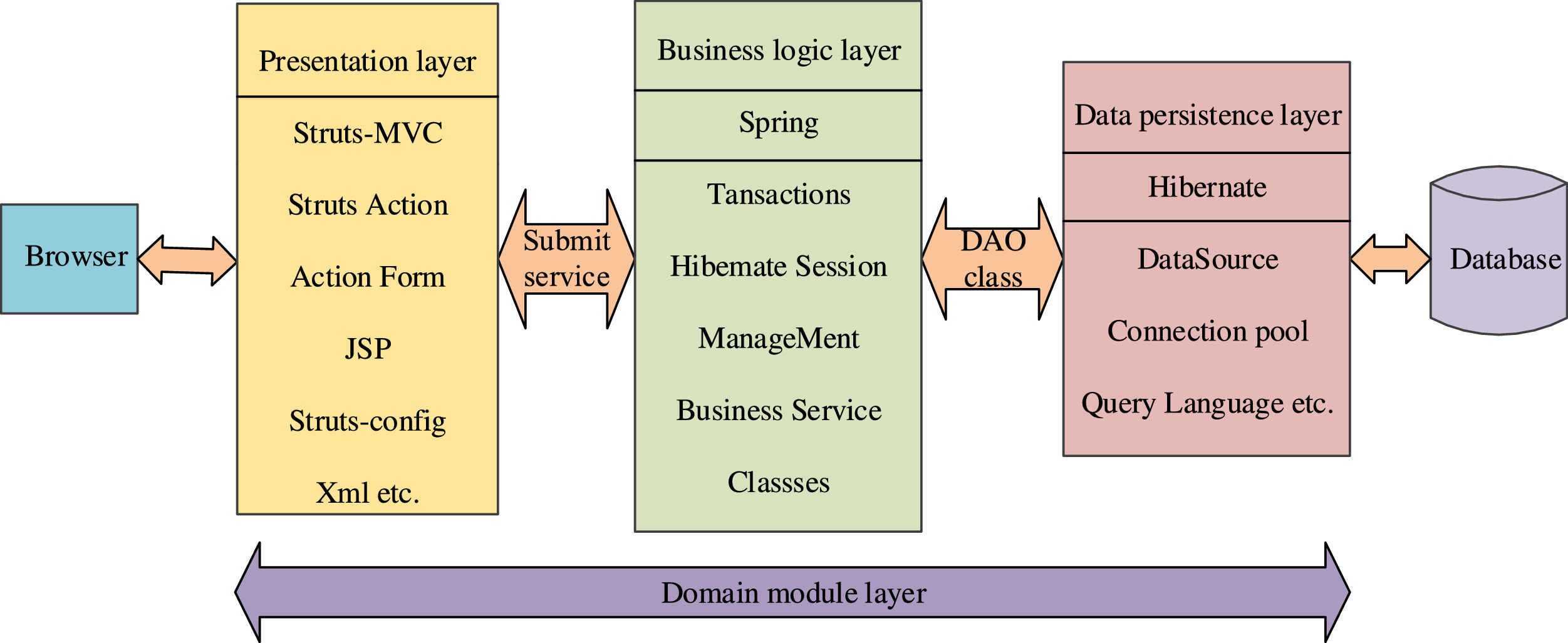

Integrated SSH FrameworkWhen developing a SCM system, enterprises should account for existing system assets and focus on the application of open-source tools and software to make the system scalable and portable. The SSH framework is a new technology that inherits the layered architecture mode of the J2EE framework. The difference between the frameworks is the implementation method between layers. When J2EE and SSH frameworks complete the same computing tasks, SSH consumes less resources. At the same time, SSH has no special requirements on the platform specificity of business objects. In SSH, the implementation of business logic can be completed through ordinary Java objects.

In addition, the SSH composite framework has the following four technical advantages: (a) It separates Java and HTML code, reducing the requirements for development complexity. (b) The work between the layers of the system is relatively independent, and the code coupling degree is low. (c) Even if it is separated from the AOP mechanism of spring environment, SSH will not hinder AOP from realizing business functions. (d) Hibernate and other cross platform technologies used with SSH are highly open-source, which has promoted the framework's rapid development.

Due to its technical advantages, SSH enables a system developed under its framework to retain strong expansibility and portability. Furthermore, the open source model greatly simplifies system development, thus significantly reducing development time. This study adopts the SSH integration framework to realize the SCM system. The framework is illustrated in Fig. 5.

Implementation of Each Layer of SSH Integration FrameworkThe system that integrates the SSH framework contains four layers, each having different responsibilities. They are presentation layer, business logic layer, data persistence layer, and domain module layer. This layout enables developers to quickly develop web applications with clear structure, good reusability, and convenient maintenance. The system's overall infrastructure depends on Struts, which are responsible for separating MVC. The model part of the Struts framework controls business jumps and uses the Hibernate framework to support the persistence layer. Struts and Hibernate are managed by Spring.

- (1)

Implementation of SSH Presentation layer

The development of SCM systems on the basis of the Internet of Things adopts J2EE architecture, provides services in the view layer of the MVC mode, and realizes the system display layer through JSP. The display layer serves as the interface between the system and user, as it responds to the user's requests and displays the results returned by the system. Therefore, JSP is used for code development to realize system response to user requests. The response data is displayed in real time through HTML-XML and other markup languages. The following problems should be paid attention to in the specific development and implementation.

- (a)

Data verification problem. Because the display layer directly interacts with the user, it is necessary to verify whether user input data conforms to the format defined by the data layer.

- (b)

Personalized label display needs. Because users may have personalized or customized display needs, the system can define personalized labels through the data layer to realize them.

- (c)

User operation problems. The display layer serves as the window for users to interact with the system. This interaction is often carried out through the page. Therefore, the order of page user input, as well as the realization of list page, paging, and other displays, are convenient for use.

- (a)

To fulfill most enterprises’ needs for system application, the SCM system should include core business processing, enterprise daily application, collaborative office management, personalized requirements, and expandable functional requirements. JSP technology combined with the MVC mode can be used to complete the implementation of the display layer. Due to the powerful function and flexible use of MVC, the interactive interface of the display layer developed through JSP technology features personalized characteristics. It is easy to realize the interface display and the transmission and application of data through the association with the system business through the view layer.

- (2)

Implementation of SSH business logic layer

The business logic layer, which is implemented based on command calls, integrates a large number of command interfaces. Different functions of the system can call different interactive operations through the call interface. These include data display, abnormal page processing, misoperation prompt, and others. Furthermore, this layer provides process organization and management services for priority management with concurrent users, so as to improve the value of the system interaction experience and business logic.

- (3)

Implementation of SSH domain module layer

The domain module layer is largely responsible for controlling the business objects, rules, and logic. It provides access to an interface for the business logic layer and calls the data persistence layer to complete processing in the database. Therefore, it is a very central layer that directly determines the correctness, availability, stability, and fluency of the supply chain system implementation. Furthermore, it provides flexibility, maintainability, and expansibility support for the realization of business.

- (4)

Implementation of SSH data persistence layer

This layer mainly manages the operation of the database, facilitates interactive operations with data through the interface, and provides the method of data operation call to the domain module layer. The data persistence layer provides the implementation method for all business data processing in the system, as well as the interface for calling operations. Generally, SQL is used to write specified methods and data operations such as addition, deletion, modification, and query. The layer also enables the combination of these operations. Therefore, when other layers use the method of the data persistence layer, they do not need to understand the mechanism of content operation. Instead, they only need to provide the data type returned by the method to ensure the processing of corresponding business logic.

Dynamic Selection Method of Supply Chain Partners Based on CGANIn machine learning, traditional algorithms can easily produce unbalanced data, resulting in poor generalizability. To solve this problem, we propose a dynamic selection method of supply chain partners based on the CGAN of machine learning.

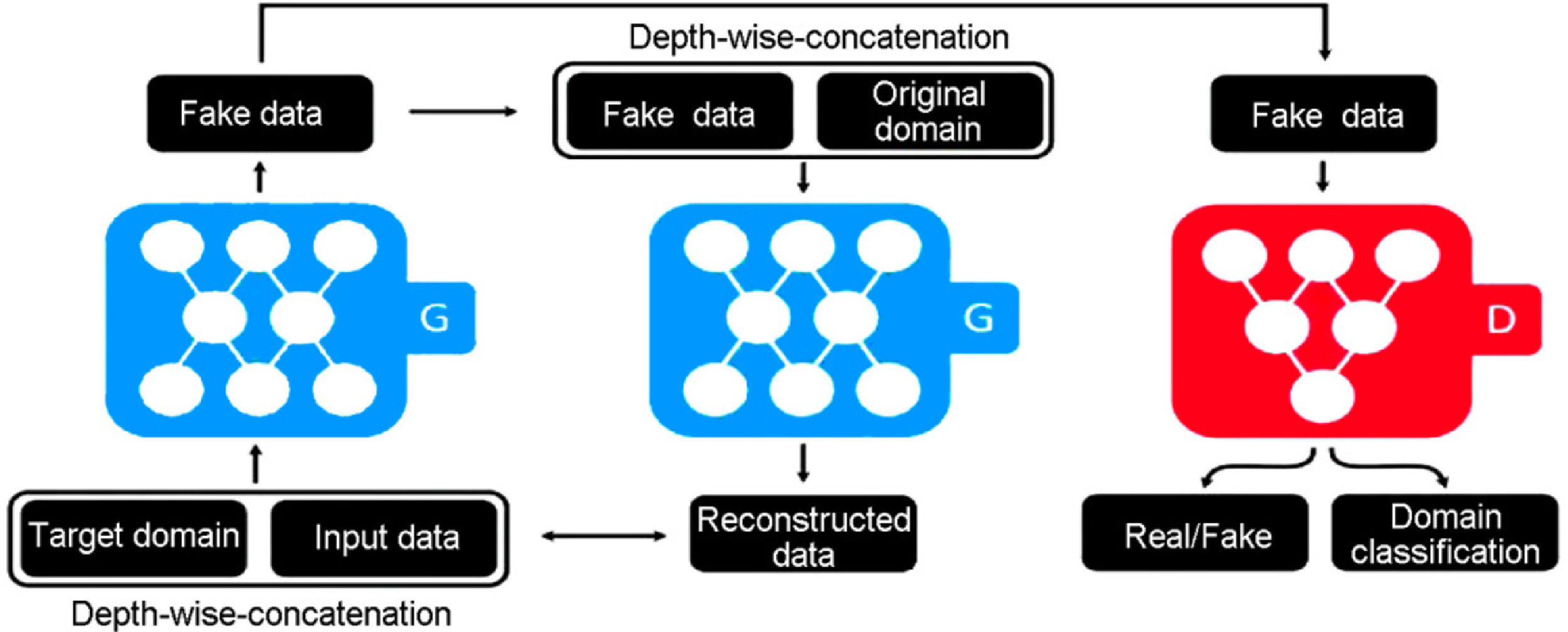

Small Sample Data Processing Based on CGANCGAN is composed of generator and discriminator. The generator receives a random noise signal (which can be uniformly or Gaussian distributed), and generates the corresponding sample. The discriminator then receives the real and generated samples. The function of the discriminator is mainly to judge the generated sample's authenticity using a probability value. The generator continuously strengthens its ability to improve the generated samples, until the discriminator is unable to distinguish between the real and generated samples. The structural framework of CGAN is shown in Fig. 6.

Below is the CGAN training strategy: randomly initialize generator G and discriminator D, and alternatively train G and D until convergence.

In the training of discriminator,

- (1)

Sample the authentic samples {x1,x2,…,xm} of m in the dataset;

- (2)

Sample m vectors {z1,z2,…,zm} from a distribution (even, normal);

- (3)

Obtain m synthesized data: {x̲1,x̲2,…,x̲m}, x̲i=G(zi) through G;

- (4)

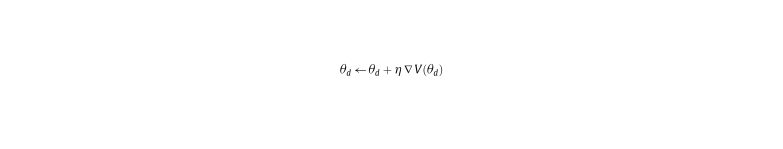

Update the discrimination parameter θd and maximize the objective function:

In the training of generator,

- (1)

Sample m vectors {z1,z2,…,zm} from a distribution (even, normal);

- (2)

Update the generator G’s parameter θg and maximize the objective function;

The discriminator of CGAN inputs samples (which can be real or generated) and outputs corresponding scalars (i.e. probability values belonging to the real samples). At first, because the generator is relatively weak, the generated samples are easily distinguished; however, with continuous strengthening of the generator, the discriminator is eventually unable to distinguish the two, and finally can only output a probability of 0.5 (indicating that the real probability is equal to the generated probability). This process is equivalent to a maximum and minimum game process. The discriminator continues to maximize the discrimination into samples, and the generator also continues to improve its ability to generate samples, eventually reaching a Nash equilibrium. Fig. 7 shows the generator of CGAN.

In CGAN, two neural networks confront each other in a zero sum game. The task of the first network, the generator, is to deceive the second network, the discriminator. The generator creates "fake" data, in which case the two networks can be improved iteratively. These networks can be considered as black boxes, representing arbitrarily complex functions, applied to noise or real data. The input of the generator is some random noise that produces a pseudo image. The input of the discriminator includes a pseudo sample and a sample from the real set. The training of the two networks requires a loss function, and the loss function of each network depends on the other network. To train the network, back propagation is carried out, and the neuron weights of other networks are simultaneously frozen. Generally, the discriminator and generator networks can take the form of any mapping function.

Below is the procedure of CGAN algorithm: train the discriminator first, and then train the generator in every iteration, in the discriminator part,

- (1)

Sample m positive examples{(c1,x1),(c2,x2)…(cm,xm)} from the dataset;

- (2)

Samplem noise points{z1,z2,…,zm} from a distribution;

- (3)

Generate data {x∨1,x∨2…x∨m} through x∨i=G(ci,zi);

- (4)

Sample m sample points {x^1,x^2…x^m} from the dataset;

- (5)

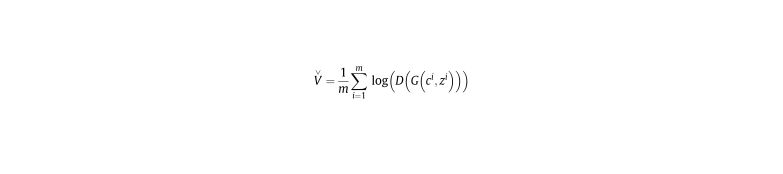

Update the discriminator parameter θd and maximize V∨;

The difference between this optimization process and the conventional GAN solving process lies in the addition of 1m∑i=1mlog(1−D(ci,x^i)).

In the generator part:

- (6)

Sample m noise points {z1,z2…zm} from a distribution;

- (7)

Sample m conditions {c1,c2…cm} from the dataset;

- (8)

Maximize by updating generator parameter θg:

The solution requires not only to train the discriminator in advance or reduce its learning rate compared with the generator, but also change the number of updates of the generator/discriminator at each iteration. It is easy to see when CGAN will merge, because the stability of the two networks will occur somewhere in the middle.

Under the condition of conditional generation countermeasure network, the specific steps of small sample machine learning data processing algorithm are as follows

Step 1: map the small sample machine learning data into the Hibert space;

Step 2: transform the data feature extraction problem into a linear solution problem, calculate the linear marking of each projection direction of the data in the space, obtain the corresponding sample eigenvalues, and form the eigenmatrix from the corresponding eigenvectors to obtain the sample data eigenmatrix;

Step 3: in the unbalanced state, adjust the information entropy appropriately until the relative entropy reaches the set balance target, calculate the information entropy and mutual information of each sample data characteristic matrix, and adjust the relative entropy of the target according to the mutual information calculation results to make the data reach balance;

Step 4: input the processed data into the condition generation countermeasure network, take the data processing target as the objective function, the discriminator reaches the optimal result, output the optimal result under the condition of given the network optimal discriminator, and complete the small sample machine learning data processing

The generator of CGAN takes noise and labels as inputs, and the discriminator will generate objects, and the original objects and labels as inputs. At the same time, CGAN optimizes the judgment criteria of the discriminator, which judges false data + arbitrary labels and true data + wrong labels as false, and judges’ true data + correct labels as true. In this way, the user-defined label can output the desired data.

CGAN (Conditional GAN) uses tags to train generators and discriminators. The generator learns to generate realistic samples for each tag in the training dataset, while the discriminator learns to distinguish between true sample tag pairs and false sample tag pairs.

The generator of CGAN synthesizes a pseudo sample using the noise vector and the label. The purpose of this pseudo sample is to make the discriminator think that it is the real sample of a given tag as much as possible. The discriminator of the CGAN accepts the labeled real sample or the labeled pseudo sample. The discriminator learns how to identify real data and match pairs, and also learns to identify false sample tag pairs and distinguish them from real sample tag pairs.

CGAN training process:

- (1)

Training a discriminator to randomly take a small batch of labeled real samples and their labels (x, y); Calculate d ((x, y)) of a given small batch and back propagate the binary loss update to minimize the loss; Randomly take a small batch of random noise vectors and class labels, and generate a small batch of pseudo samples; Calculate small batch and back propagate binary loss updates to minimize losses.

- (2)

A training generator that randomly takes a small batch of random noise and category labels to generate a small batch of pseudo samples; Calculate and back propagate the binary loss update for a given small batch to maximize the losses.

In the experimental study of small sample machine learning data processing, the car evaluation data set was selected from the public data set UCI, with the number of samples being 96. To illustrate the global optimality of CGAN, we compared it with the BP neural network (BPNN) and particle swarm optimization (PSO), and analyzed the generalizability of each data processing algorithm through an AUC curve.

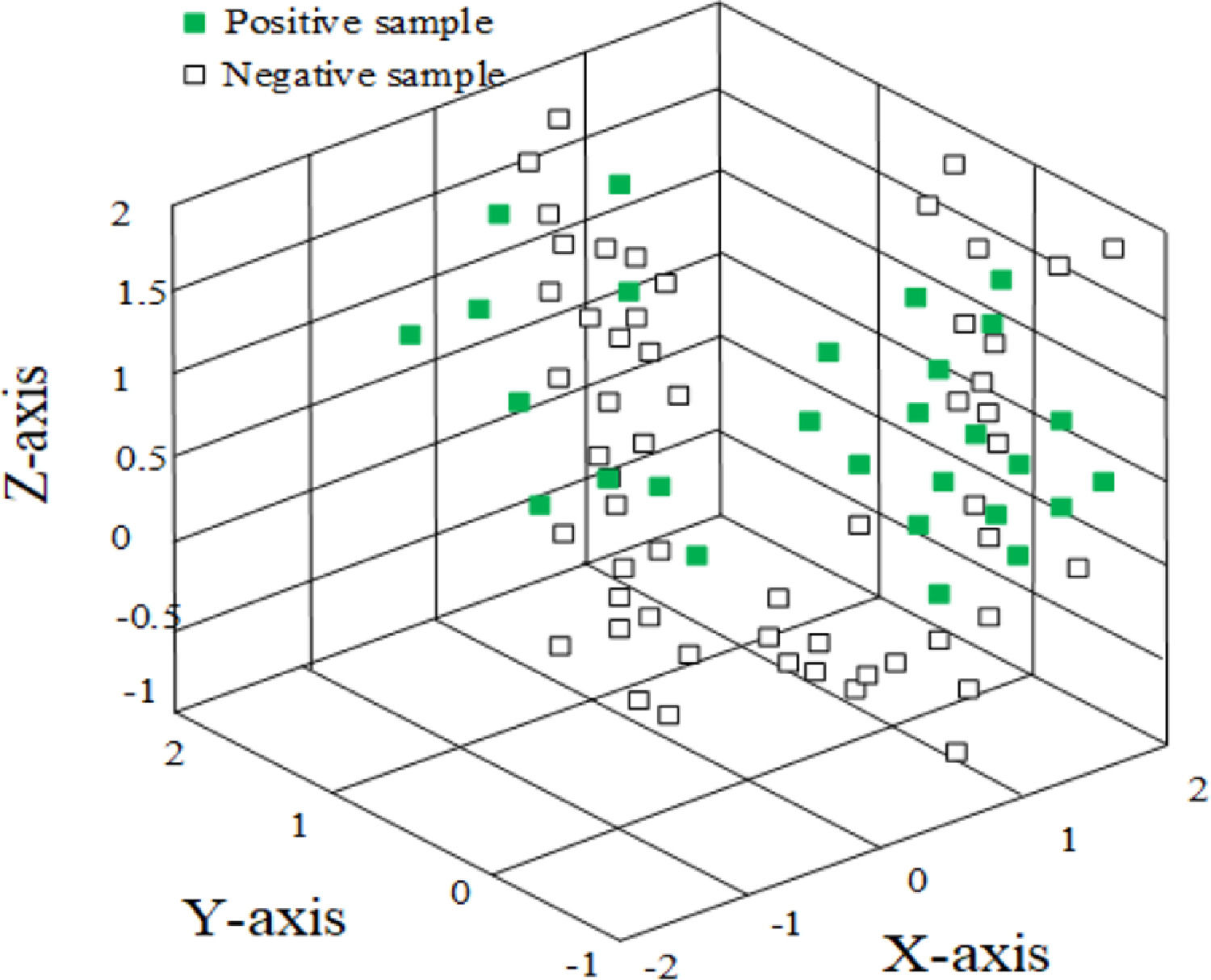

In the experiment, a two-dimensional Gaussian model was used to process experimental data into unbalanced data. All positive samples were sampled at M([67],[3224]), and all negative samples were sampled at M([54],[4223]). The proportion of positive and negative samples of the generated experimental data was 1:10, with the entire sample set divided into training and testing sets. We used a Gaussian distribution under non-degenerate linear transformation to ensure the unity of data. Beginning with the two-dimensional standard normal distribution M([11],[1001]), any two-dimensional Gaussian distribution was obtained through linear affine transformations, and the two-dimensional standard Gaussian distribution data, namely x∼M(0,1), y∼M(0,1), were obtained through a one-dimensional standard normal distribution. The data pairs used in the experiment meet the two-dimensional standard Gaussian distribution, and the distribution of the obtained data on the two-dimensional plane is shown in Fig. 8.

It can be seen in Fig. 8 that the imbalance between the positive and negative sample data in the artificial unbalanced data set is obvious, and the distribution of the data in the two-dimensional space appears to be oval, indicating that the experimental data set was transformed from the standard Gaussian distribution. In prior studies, the unbalanced data had a negative impact on the data processing algorithm, thus deteriorating the processing effect. In this experiment, the proportion of positive and negative samples was controlled, the generated data set was studied, and the ROC curve comparison results were obtained using CGAN, BPNN, and PSO, as shown in Fig. 9.

The abscissa FP-rate and ordinate TP-rate shown in Fig. 9 respectively represent the proportion of negative and positive samples, with classification errors in the total samples. By observing the ROC curve, it can be seen that among the three groups of experimental results, the area enclosed by the CGAN and FP rate axes is the largest, and the area enclosed by the BP neural network and FP rate axes is the smallest. After calculation, the AUC value of PSO is 0.9152, that of the BP neural network is 0.8533, and that of CGAN is 0.9627. In data classification, a higher AUC value denotes a better classification effect.

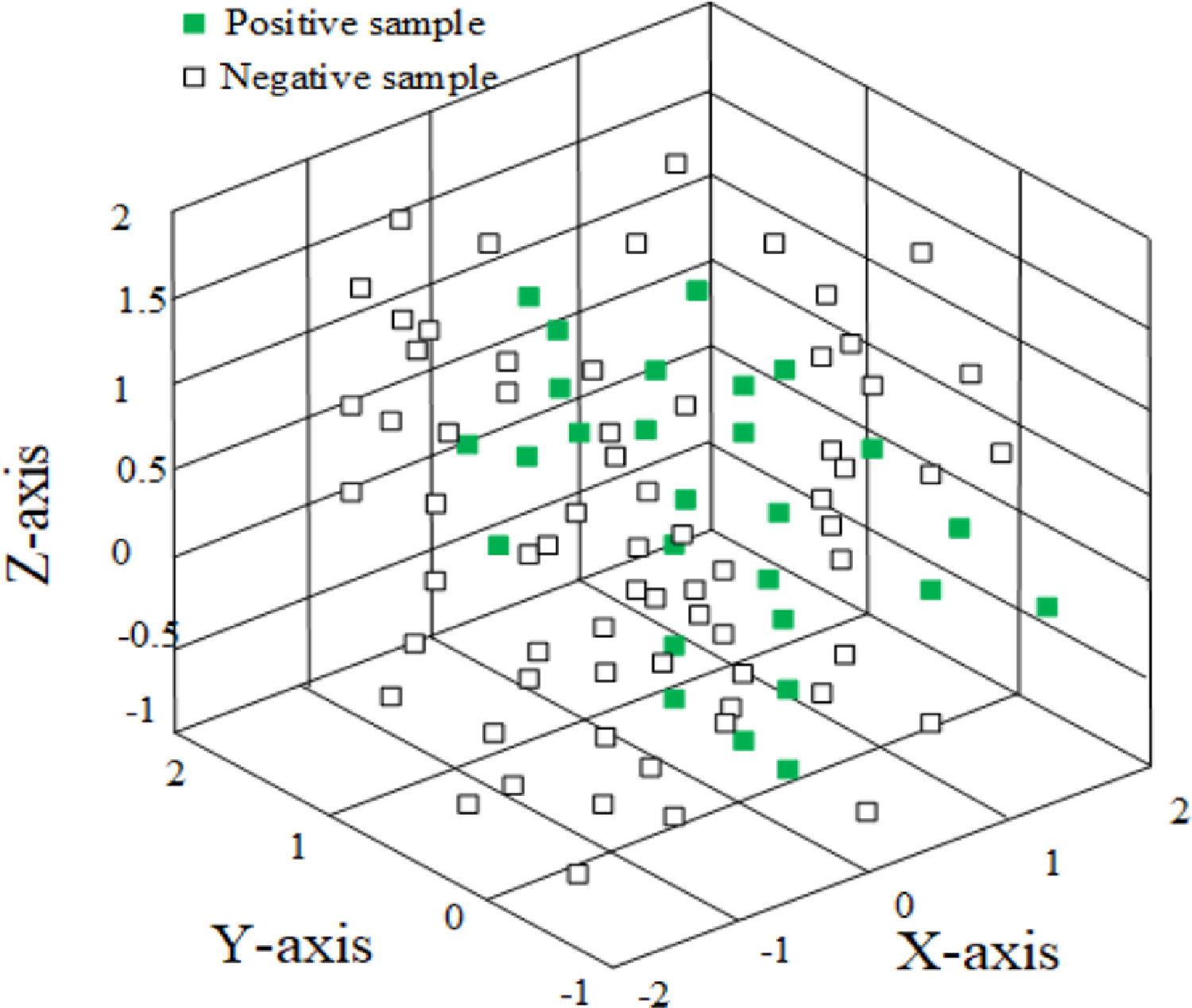

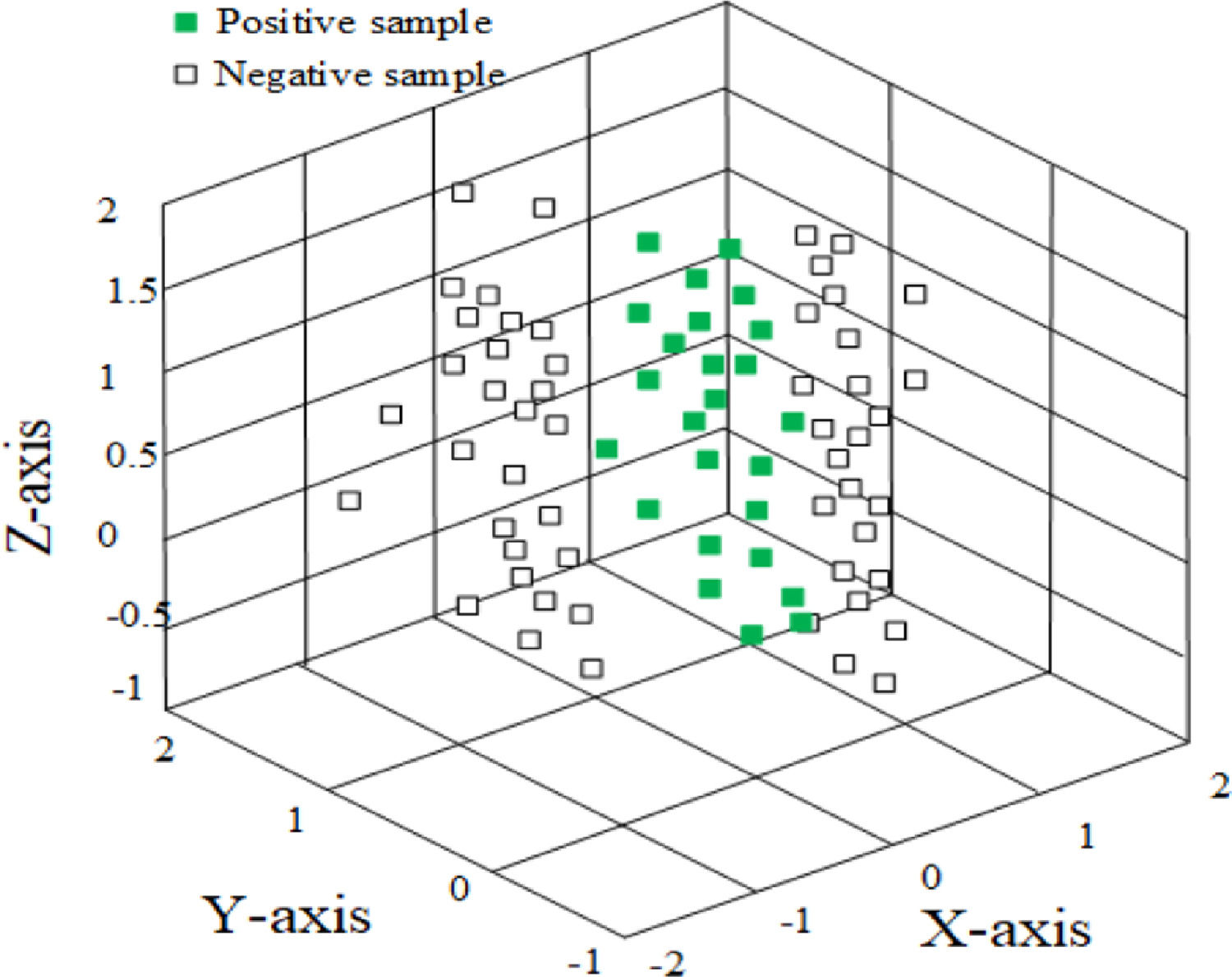

It can be seen from the results that CGAN exhibits a better classification and processing effect for small sample unbalanced data. Based on this information, the data processed by the algorithm is displayed through visualization technology. The comparison results of the data balance experiment are shown in Figs. 10-12.

As can be seen in the figures, although the negative sample segmentation in Fig. 10 is obvious, the positive sample data is distributed around the negative sample, and the data are cross-fused together and obviously unbalanced. The experimental results in Fig. 11 show that negative and positive sample data are mixed together, there is no obvious boundary, and the data balance is poor. The experimental results in Fig. 12 show that positive and negative samples exhibit obvious segmentation, obvious cluster form, and good data balance. Overall, the small sample machine learning data classification effect based on conditional generation countermeasure network designed in this study is good, the data balance processing effect is successful, and the overall generalizability is better than that of the traditional data processing algorithm.

In this study, CGAN was used to realize the dynamic selection method of supply chain partners. First, the sample data was mapped in Hilbert space, and then the data feature extraction problem was transformed into a linear solution problem to obtain the sample data feature matrix. At the same time, the information entropy and mutual information of each sample data feature matrix were calculated, and the relative entropy of the target was adjusted according to the calculation results. The experimental results show that the data classification of CGAN is accurate, the data balance level is high, and overall generalizability is improved. Therefore, CGAN is suitable for partner selection in dynamic supply chains.

Conclusion and Future WorkThis study developed an overall design of the SCM system, including six modules: order management, purchasing management, production management, inventory management, distribution management, and transportation management. Then we expounded these six modules in detail, designed the system database, and constructed an entity ER diagram. To solve the problem of more decision attributes and less data samples for decision analysis, we proposed a dynamic supply chain member selection algorithm based on CGAN. Furthermore, we used innovative machine learning to solve the problems of procurement, inventory, and route planning in the supply chain. We also employed SSH to integrate the system framework in the presentation, business layer, data persistence, and domain module layers. The focus of future research is further optimization and improvement of certain modules involved in this study. We also aim to determine how the system can process massive data effectively, mine more effective resources from existing data, and apply these resources to the SCM system.

This work was supported by Key Research and Development plan of Jiangsu Province (Grant No.BE2021716), The National Natural Science Foundation of China (32101535), Jiangsu Modern Agricultural machinery equipment and technology demonstration and promotion project (NJ2021-19) and Jiangsu Postdoctoral Research Foundation (2021K112B).