Intelligent manufacturing offers opportunities for green technology innovation at a low cost, helps eliminate outdated equipment, and improves pollution efficiency, which is essential for environmental protection. From the perspective of the industrial sector, based on the data of 269 Chinese cities, this study empirically examines the impacts of intelligent manufacturing on ecological environment using the fixed effect model and unconditional quantile model. The research results show that intelligent manufacturing can significantly reduce the concentration of PM2.5 in the air and environmental pollution by optimizing resource allocation during production and operation. The results of the external mechanism show that green technological innovation plays a positive mediating role in the impact mechanism of intelligent manufacturing to improve air quality. The marginal impact of intelligent manufacturing on environmental pollution is nonlinear, and the main trend is the M-type distribution trend of increasing first, then decreasing, and then rising. In particular, intelligent manufacturing has a greater welfare effect on the ecological environment at the lower quantiles. The results provide a viable path for the government to actively plan a strategic layout to improve the ecological environment and achieving the goal of high-quality economic development.

Since the reform and opening up, China's economic development has been driven by a strong comparative advantage and the full release of the “demographic,” “institutional,” and “structural” dividends. From 1978 to 2020, China's average economic growth rate reached 9.2%, making it the second-largest economy in the world (Data from China Statistical Yearbook 2021). However, for years, China's rapid economic growth relied primarily on the extensive economic development model of “high-energy consumption, low output, and high pollution.” In accordance with the promotion system for officials based on the GDP growth rate as the central assessment, local government officials tend to attract investments in projects with quick results and a significant increase in output. The primary driving force of economic growth is, thus, an industrial economy with high pollution and emissions. This crude economic development model has severely affected China's environment. Since 2012, most Chinese cities have suffered from frequent and severe haze pollution. The “Urban Outdoor Air Pollution Database 2018″ shows that in terms of the annual average PM2.5 concentration, 58 of the top 100 cities are in China. These cities have annual average PM2.5 concentrations greater than 62 μg/m3, far exceeding the WHO air quality guidelines (annual average PM2.5 concentration <10 μg/m3). The 2021 Bulletin on the State of China's Ecological Environment shows that of the 339 cities above the prefecture level in China in 2021, 218 (64.3%) met air quality standards; conversely, 121 (35.7%) cities exceeded ambient air quality standard (GB 3095–2012) formulated by Ministry of Ecology and Environment of the People's Republic of China, and a further 29.8% exceeded average PM2.5 concentrations. Regional heavy pollution weather processes continue to occur periodically, with an average PM2.5 concentration of 30 micrograms per cubic meter, still above the WHO-recommended air quality standards. Meanwhile, the concentrations of PM10, O3, SO2, NO2, and CO were 54 μg/m3, 137 μg/m3, 9 μg/m3, 23 μg/m3, and 1.1 μg/m3, respectively, which were still extremely severe.

Each country aims to develop good green economic policies to improve social welfare and achieve sustainable economic growth and development (Khan & Ozturk, 2020). The inefficient use of resources increases environmental pollution (EP) and severe haze problems, which are all negative results of rapid economic growth. The Rio+20 summit in 2012 laid the foundation for global green development, gaining widespread support from the international community and eventually becoming a mainstream economic development concept (Amato et al., 2017). Owing to the pressure of increasingly scarce resources and energy supply as well as the pressure of the carrying capacity of the ecological environment reaching its limit, the “green industrial revolution” is quietly taking place, and countries are choosing to shift from a “black development model” to a “green development model.”

Digital transformation is the starting point for the manufacturing industry to promote intelligent manufacturing (IM). Regarding the realization path of IM, most studies are based on the perspectives of the industrial Internet platform, cloud computing, big data applications, and artificial intelligence and examine new technology-enabled manufacturing or summarize the experience of IM as realized through a particular technology (Lyu et al., 2019). This study holds that technology-enabled manufacturing is based on the process of the collision and fusion between the new generation of information technology and modern manufacturing technology. The goal is to realize networked collaborative manufacturing, mass customization, and service-oriented transformation. IM emphasizes the value of the new generation of information technology and recognizes the deep integration and practical innovation of the new generation of digital intelligence and cross-field technologies such as manufacturing. IM takes digitalization as its core and data drive/data flow as a foundation and adopts intelligent means to address the bottlenecks in research and development (R&D), production, and management. Because the manufacturing workshop is at the center of manufacturing enterprises and the foundation of enterprise survival, the direction of development and the key technology of IM aim to realize the digital production of the workshop, that is, the digital workshop.

Since the 21st century, with the development of science and technology, IM, and digital workshops, the global manufacturing industry has been undergoing profound changes (Wang & Xu, 2022). Humans are experiencing the process of “digitalization” from traditional to digital social forms. Unlike the simple applications of general information and communication technologies (ICTs), digitalization includes all possibilities provided by general ICTs, from the use of essential technologies (the application of computers or the Internet) and modern technologies (the application of automation, cloud computing, and big data) to the gradual applications (adopting business models or production processes based on digital technology products and services). Innovation is the primary driver of green development, and technological progress is essential for weighing economic development against environmental quality improvement (Hou et al., 2021; Lee & Trimi, 2022). Environmental sustainability cannot be achieved without a substantial technological impetus. Given the further development of ICT, especially the modern Internet, digital technology is rapidly penetrating into all production processes and boundaries. The economy and society are undergoing a comprehensive transformation toward digitalization. Following rapid technological innovation, IM has emerged as the symbol and leading force of the fourth industrial revolution and set a direction for development and become an inevitable choice of the global manufacturing industry (Zhang & Ming, 2021).

IM clearly combines the advantages of advanced information and manufacturing technologies and is a new model that optimizes the manufacturing process, enhancing the design, production, management, and integration of the entire product life cycle (Wang et al., 2022). China is the world's largest developing country and the most populous, and its experience in environmental governance is generally representative. Data from World Robotics 2021 Industrial Robots, published by the International Federation of Robotics (IFR), suggest that nearly 168,000 new industrial robots will have been installed in China in 2020, accounting for 43.8% of the world's total, with increasing levels of automation and intelligence in the manufacturing sector. It is crucial to examine the effects of IM on EP from the IM perspective and identify the relevant mediating mechanisms and their heterogeneous effects in order to achieve environmental sustainability and address global climate change.

Literature reviewThere are global concerns about environmental sustainability, given the profound impact of environmental degradation on climate and the subsequent effects of climate warming. Although the existing literature has focused on the effects of technologies such as artificial intelligence for monitoring and environmental management, only a few studies have focused on the internal and external mechanisms and heterogeneity of IM to reduce EP. The literature related to the topic of this study can be grouped into three categories.

Relationship between IM and technological innovationAs a new factor of production, the wide application of digital technology offers more possibilities for enterprise innovation; in particular, the digital transformation of factories expands the technology application scenarios. Through intelligent transformation, industrial enterprises can link traditional innovation nodes (such as linking consumer market demand), significantly reduce enterprises’ market transaction costs, realize operations and technologies that are beyond the reach of traditional innovation models, and improve innovation R&D efficiency (Fadziso, 2018; Li et al., 2021; Shen et al., 2023). Sound infrastructure construction has laid a solid material foundation for the development of enterprises and for continuous breakthroughs and innovation (Fan et al., 2023). Existing studies have disagreed on the relationship between IM and technological innovation. Some scholars hold a positive attitude, believing that IM can promote the efficiency and quality of technological innovation through cost reduction and efficiency improvement as well as improvements in information transmission efficiency. Zhang and Xuan (2020) argued that IM will transform enterprise innovation behavior and encourage enterprises to change from intensive innovation to innovation that uses data science extensively. In intelligent transformation, factories will use automation technology to replace low-skilled labor as much as possible, helping enterprises reduce labor cost anxiety and thus enhancing their willingness to innovate. Xue et al. (2019) posited that IM offers a variety of channels for information exchange between workers in the same enterprise and different enterprises and even between cross-field technical employees, which helps break communication barriers and reduce enterprise management costs. However, with extensive research, some studies have shown that IM has inconsistent effects on technological innovation. Lach (2002) held that government support has a crowding-out effect on innovation and that incentives will be distorted even in the era of intellectual development. According to Li et al. (2023), the heterogeneous threshold effect of the level of government support limits the impact of IM on innovation quality. Limited government support has an inhibitory effect on the quality of the innovation driven by IM to a certain extent.

Impact of intelligent technology on EPThe development of modern advanced information technologies, such as big data, artificial intelligence, the Internet of Things (IoT), and edge computing, has encouraged a transformation from traditional manufacturing to IM. With the continuous development of artificial intelligence technology, the emergence of a variety of new robots and biological classification technology has brought hope for environmental protection through science and technology (Cortés et al., 1999). IM is a type of technological innovation; however, its business model and development trajectory differ from general technological progress, and its impact on the economy and society is more profound than that of general technology.

Regarding the role of IM in the environmental field, studies have mainly investigated the impact of intelligent technology on environmental monitoring and governance. Zhang and Ji (2019) hypothesized that intelligent technology can accurately monitor and predict pollutants through data collection and analysis and establish the corresponding energy consumption model for control, which plays an essential role in addressing climate change and environmental deterioration. Chen et al. (2021) argued that the R&D demand derived from robot technology and the substitution of low-skill labor in China's manufacturing industry will help reduce industrial exhaust emissions and general industrial solid waste production. Sheng and Bu (2022) found that enterprises use robot technology to reduce pollution emissions mainly through artificial substitution, thereby increasing the use of clean energy, adding terminal treatment equipment, and enhancing sewage treatment capacity. Although the literature has examined how intelligent technologies affect the environment, previous research mainly focused on a specific intelligent technology or combinations thereof, such as digital twinning and robotics. However, few studies have directly discussed the impact of broader IM systems on the environment.

Technological innovation and EPTechnological innovation can promote industrial transformation and upgrading and reduce energy intensity to reduce the intensity of EP. First, innovation can increase a company's value by improving the quality and added value of its products and services (Kogan et al., 2017; Hombert & Matray, 2018). At the macro level, technological innovation is manifested in the optimization and upgrading of the industrial structure and the transformation of the economy into an intensive mode of production that has a high level of efficiency, high-tech content, and a low level of energy consumption, thus improving the ecological environment alongside economic development. Furthermore, innovation results in rapid technological development and increases total factor productivity and resource efficiency, thereby acting as a substitute for energy factors and reducing energy consumption under given output conditions. Furthermore, clean technologies, such as new-energy technologies, can contribute to the energy transition, shifting the energy mix from traditional to renewable energy sources and reducing the intensity of EP emissions (Cao & You, 2010; Tu & Xiao, 2010; Yang et al., 2019). There is already some evidence in the literature that technological innovation can reduce EP. For example, Mughal et al. (2022) claimed that technological innovation in individual countries, such as Bangladesh, has reduced CO2 and, thus, improved environmental quality. However, few studies have directly focused on the relationship between IM and EP. Most research has explored the logical relationship between ICT and carbon emissions. Some scholars believe that ICT not only helps residents form a green and low-carbon lifestyle but also promotes the green IM of enterprises, realizing the dual improvement of production efficiency and carbon efficiency and gradually becoming a non-negligible force for energy conservation and emission reduction (Lyu & Liu, 2021).

In summary, considerable research has focused on digitalization and EP, providing a valuable reference for this study to discuss the logical relationship between IM and smog pollution. However, only a few studies have analyzed how industrial intelligence has a multiplier effect on optimizing resource allocation. The contributions of this study are mainly as follows: first, from the perspective of reducing pollution control costs, improving resource use efficiency, and eliminating outdated machinery and equipment, this study focuses on how IM can reduce environmental pollutants and enrich the literature related to the intelligent transformation of industry. Second, combined with the panel data of the IFR and Chinese cities, the improvement effect of IM on air quality was verified from the perspective of industrial robots. Third, this study uses an unconditional quantile model to validate the nonlinear relationship between smart manufacturing and EP. Unlike other research (Santarius et al., 2020; Khan & Wu, 2022; Zhang et al., 2022; Zhao et al., 2022a; Bendig et al., 2023), when we evaluate the impact of IM on EP, we introduce the channel mechanism of green technology innovation and use the unconditional quantile regression model to test the nonlinear relationship between the two. Because using digital technologies such as the IoT, robotics, and cloud computing requires substantial electricity, the impact of smart manufacturing on EP is not linear (Jin & Xu, 2022). Therefore, examining the mechanism and nonlinear relationship of IM affecting EP may have more policy implications.

Theory and research hypothesesDirect effect of IM on reducing EPAssume that the representative firm produces only one good with output Y. Its production function is of the Cobb–Douglas form with constant returns to scale, and the factors of production contain three types of labor, capital, and energy. The form of the production function can be expressed as

where L(t), K(t), and E(t) denote the labor, capital, and energy inputs of the representative firm at time t, respectively. α,β, and ϕ denote the contribution of each input factor to output, and α+β+ϕ=1. A(t) denotes total factor productivity, which usually refers to technological progress, managerial innovation, and knowledge accumulation that increase the production efficiency. In general, the production of final products by companies is often accompanied by “bad” environmental output. It is assumed that each output unit ξ produces a unit of pollutant B. The Weak Disposability of Outputs Axiom shows that companies incur a cost to reduce their pollutant emissions. If a company reduces its pollutant emissions, it will have to spend a certain amount of money on production, resulting in a proportional reduction in the production of “good” output. Assume that the factor input used to treat the pollutant as a proportion of the total output is θ (θ∈[0,1]). The output Y(t) of Eq. (1) can then be considered a potential output, and the actual output function, net of pollution control costs, takes the following form:Assume that pollutant emissions B from representative firms are a function of output Y(t) and abatement intensity ρ (Stokey, 1998). Following Aghion et al. (2017), this study introduces an EP factor, the intensity of emission reduction, into the production function. Subsequently, the following functional expression exists:

Assume that the abatement intensity ρ is a function of ρ(θ)=A−1×(1−θ)1/ς, where ξ is the pollution control efficiency and ξ∈(0,1). The intensity of emission reductions is a decreasing function of technological progress and the intensity of pollution control inputs. The following expression can be obtained by combining Eqs. (2) and (3):

There are three main factors governing whether the production sector treats pollutants: the size of the enterprise, the cost of treating pollution, and the efficiency of treating pollution. Generally, regulators and producers focus on the first two factors while neglecting the most important factor of efficiency. The existing literature has recognized the positive role played by technological advances in improving the efficiency of EP control (Anderson, 2001; Acemoglu et al., 2012). The relationship between the digital transformation propensity of representative enterprises and the overall level of IM at the society level is assumed to be D=ϖDM, where ϖD>0 represents the digital propensity of representative enterprises and M is the overall level of development of intelligent industrial manufacturing. The intelligent transformation of industrial firms impacts the total factor productivity (TFP); thus, the form of Eq. (1) can be rewritten as follows:

In Eq. (5), A0(t) represents TFP before the digital transformation of representative enterprises; ϖA>0 represents the expansion factor of the digital transformation of representative enterprises to TFP. As seen from Eqs. (4) and (5), the stronger the enterprise is in digital transformation, the higher the pollution control efficiency will be. Given that digital transformation is also a function of IM, improving the intellectual level of industrial enterprises across society will help improve pollution control efficiency.

Generally, as neutral technological progress, IM technology can naturally take on the characteristics of permeability, coordination, and substitution of digital technology and penetrate various fields of social life. On the one hand, according to Moore's Law, chip-based, digital, and information-based products will be continuously updated, and the prices of related products will drop rapidly with the change in and popularity of technology. Intelligent technology will help manufacturers phase out high-energy and low-efficiency production equipment, thus reducing energy consumption and pollutant emissions. With the expansion of users’ scale, the cost of hardware input in intelligent infrastructure construction will decrease marginal cost and increase marginal income, producing apparent economies of scale and thus improving TFP. On the other hand, the use of IM technology to develop green technologies, such as energy conservation and emission reduction, flexible manufacturing, and bio-manufacturing, and the transformation of production technologies, processes, and circulation processes with high-energy consumption and high pollution can effectively shorten the development cycle of technologies and products; promote the coordinated development of industries in a more flexible, economical, and effective manner; enhance the market consistency of new technologies or products; reduce the energy consumption ratio of resources in each link of the industrial chain; and achieve pollution reduction. Data and digital solutions that carry out IM using its underlying logic can play an essential role in supporting the creation of a circular economy. Intelligent technology helps improve product design, shorten the design and manufacturing period, promote product reuse, and realize waste management. IM is likely to overturn the current linear acquisition, manufacturing, and processing model; reduce resource consumption; and even support the dematerialization of the entire economy. These possibilities can be demonstrated by the role of industrial intelligence in improving information sharing and business models (Hedberg &, Šipka,2021). Therefore, this study proposes two research hypotheses.

Hypothesis 1 (H1): Industrial IM can promote the digital transformation of enterprises, limit their pollution discharge behavior, improve pollution control efficiency, and reduce EP.

Hypothesis 2 (H2): IM reduces EP by improving TFP.

Heterogeneity effect of IM on reducing EPThe conclusion drawn from the numerical model indicates that the rate of popularization of artificial intelligence technology in China is still relatively low at this stage, and the improvement effect of intelligent technology on EP will not be fully apparent until 2035. According to Feng et al. (2018), enterprises only need methods to improve production efficiency and scale through intelligence. However, overall, the impact of a low level of intelligence on green development is negligible. With the continuous progress of automation technology, the social installation of artificial intelligence applications has accumulated a certain amount of inventory. The related infrastructure, high-skilled labor, and complementary technology are also gaining perfection. Therefore, Zhao et al. (2022b) claimed that intelligent technology cannot only realize revolutionary green technology innovation (GTI) but also change the energy consumption structure of fossil fuels, expand the use of clean energy, establish new products and technological systems, and reset the technological trajectory of the entire industry. From the perspective of time evolution, the impact of artificial intelligence technology, including IM systems, on the environment is nonlinear. In the past few decades, Internet information technology, including IoT and the cloud network of marginal computing, has also faced the dilemma of marginal diminishing effect. Therefore, this study posits that the impact of industrial IM on EP is affected by the popularity of automation and the diminishing marginal effect of technology. Hence, the role of Im in mitigating EP is not monotonous and linear.. Therefore, the following hypothesis is obtained.

Hypothesis 3 (H3): The effect of industrial IM on reducing EP is nonlinear.

Intermediary mechanism of GTIChina's natural resource reserves have been described as “being rich in coal, poor in oil, and less in gas,” with the pollution from coal combustion being the most serious of all resources. Therefore, to improve China's environmental quality, we must improve the efficiency of factor utilization and R&D of environmentally friendly technologies. Green technologies can facilitate the development of new manufacturing processes and products that are less harmful to ecosystems and the natural environment (Khan et al., 2021). Green technology aims to absorb all kinds of advanced and novel technologies and improve existing technologies and products to reduce energy consumption, prevent pollution, and save natural resources. Green technology also includes the adoption/reorganization of the management strategies of enterprises, namely, in terms of the environment, energy, quality management, green supply chains, and green marketing, to minimize harmful impacts on the environment (Xie et al., 2022). IM is a kind of internal technological innovation. Simultaneously, digital and digital knowledge and information are critical factors in the production of new industrial modes. This implies that IM and technological innovation do not have a simple one-way inclusion relationship but the mutual influence and promotion of a two-way interactive relationship (Li & Zhou, 2021).

In constructing an enterprise's green production mode, asset specialization reduces the possibility that fixed assets can be used for other purposes without losing production value. Traditional industries find it difficult to obtain funds for green production technology and innovation; consequently, EP can be severe (Vita et al., 2011). The integration of new-generation information technology and advanced manufacturing technology accelerates the process of networking, digitization, and intelligence in the manufacturing industry and offers possible solutions for the real manufacturing economy to reduce operating costs and improve GTI. Intelligent knowledge makes information and technology more modular and mobile, reducing asset specificity in traditional business activities, promoting the value arrangement of green creation, and reducing smog pollution (Murphree & Anderson, 2018; Banalieva & Dhanaraj, 2019). On the one hand, by adopting a “machine substitution human” strategy, enterprises can replace human labor with automated and intelligent production methods and increase the numerical control rate of key production processes, reducing the rate of defective products and the risk of human errors. In addition, IM systems enabled by big data and artificial intelligence technologies can independently optimize production processes and reduce energy consumption in the production process. Concurrently, enterprise production can rely on an advanced information management system. During production, intelligent technology first collects and analyzes information obtained from a large amount of production process data and then provides the optimal decision solution. This process reduces the costs of material management and collaboration between departments. At the individual enterprise level, with the support of the essential attributes of dematerialization and virtualization, industrial intelligence technology can realize the effective allocation of energy across society by reducing information asymmetry and can integrate deeply with production and energy utilization technologies, effectively promoting intelligent changes in enterprise production processes and realizing the “lightness” of enterprise production methods (Lange et al., 2020). On the other hand, driven by the new generation of information technology, IM systems can break the “data silo effect” between enterprises and coordinate R&D activities up and down the enterprise industry chain. By improving technology spillover and knowledge diffusion through open innovation activities, enterprises can reduce the cost and cycle time required to develop green technologies (Peng & Tao, 2020; Ning et al., 2023).

Finally, introducing digital technologies, such as blockchain and big data analytics, can enhance the government's ability to monitor corporate pollution emissions. Digital technologies and e-government systems provide advanced resources and tools for government regulation through improved efficiency and transparency, limiting companies’ responsive, strategic, and low-quality innovations while increasing the disclosure of corporate social responsibility information. A typical example is an IM system that advances the construction of smart cities by applying innovative factors such as various sensors, intelligent remote-control devices, and monitoring equipment to manage urban production. Industrial intelligence technology entails the intelligent transformation of enterprise pollution management modes and technical means and a real-time dynamic collection of closely related air, water, soil, and other environmental information regarding enterprise pollution. Given the pressure of environmental protection, green innovation is essential for enterprises to gain a competitive advantage (Song & Yu, 2018). As the public gains environmental awareness and information become increasingly transparent, industry standards and customer demands will increase in line with changing consumer needs, forcing companies to increase their demand for efficient, clean, and high-quality technologies. Therefore, developing green technologies using IM systems to improve energy efficiency and reduce EP is imperative for the green transformation of companies. Therefore, the following hypothesis is proposed.

Hypothesis 4 (H4): IM can promote the development of green technology in enterprises, which changes the original technology mix and, in turn, improves the efficiency of pollution control and reduces EP.

Research design and data sourcesVariables and definitionEnvironmental pollution. Compared with other haze pollutant components, PM2.5 is more typical because it covers a wide area, is not easily dispersed, is highly reactive, and carries toxic and harmful substances (Agarwal et al., 2019). Research has shown that air pollution has become a significant trigger for diabetes, with about one-fifth of the global burden of type 2 diabetes being attributable to PM2.5 pollution, and that the burden of diabetes attributable to PM2.5 is exceptionally high in Africa, South Asia, and East Asia (Burkart et al., 2022). Long-term exposure to severe PM2.5 will have severe adverse effects on the nervous system, cognitive function, and mental health of humans, particularly exacerbating the incidence of neurodegenerative diseases and depression (Fonken et al., 2011; Wei et al., 2017; Ventriglio et al., 2020). From 2013, particulate matter with a diameter of less than 2.5 μm, the main constituent of haze, has been the primary air pollutant in China (Zeng et al., 2019; Lin et al., 2022). Therefore, this study select PM2.5 as an index to measure air pollution.

Because China has been late in monitoring haze pollution, with monitoring data for PM2.5 in some key cities not available until late 2012. Given, and given the relatively small amount of statistical data available, this study uses data published by the Atmospheric Composition Analysis Group at Dalhousie University. These data combine NASA's satellite-derived aerosol optical depth with chemical transport models and actual ground-based detection stations to obtain interannual mean PM2.5 data with an accuracy of 0.01° × 0.01°for Europe, North America, and China. This study used Arcgis 10.6 software to combine the raw data with vector layers of Chinese prefecture-level cities to obtain the annual average PM2.5 values for each city in China from 2006 to 2020. Surface source data from satellites have a more comprehensive coverage and higher spatial resolution and better reflect the overall state of air pollution than point source data.

Intelligent manufacturing. At this stage, technological progress is no longer focused mainly on enhancing the effects of human labor but presents itself as a substitute for human labor. This study uses the density of industrial robot installations to measure the level of IM. Since 2006, the IFR has provided more detailed figures on the number of industrial robots installed by industry, but it continues to publish data at the national level. Acemoglu and Restrepo (2017) used a general equilibrium model to examine the impact of robotics on regional labor markets in the United States and constructed a measure of “robot penetration” at the regional level based on the model's findings, similar to the “Batiuk instrument” (Bartik, 1991; Goldsmith-Pinkham et al., 2020). The 14 major categories of the IFR dataset and the manufacturing sub-sectors in China were matched to determine the total number of robots installed at the national level. Subsequently, using 2006 as the base year, the ratio of employment in manufacturing sub-sectors in each city to the national total was used to construct the robot installation density at the “industry–city” level. Finally, the robot installation densities for each industry were aggregated to obtain city data (Yang & Shen, 2023). The mathematical expression for calculating the installed density of an industrial robot is

where IMit is the density of robot installations in city i in period t. The variable employsit denotes the number of persons employed in s industry in city i at period t. Robst denotes the number of robots held in industry s in period t. employst=2006 is the number of people employed in industry s in 2006, and Robst/empilyst=2006 represents the industry-level robot installation density indicator for each year. Using 2005 as a benchmark, robot installation density in the US manufacturing sector was introduced as an instrumental variable to mitigate the endogenous effect of China's industrial distribution on robot installation density inasmuch as possible (Wang & Dong, 2020). In Eq. (6), MRobst/employst=2005 is the annual industry-level robot installation density in the United States.Total factor productivity (TFP). To avoid statistical errors caused by traditional measurement methods and obtain the maximum expected output with minimum resource consumption and EP under certain factor input combination conditions, this study uses the SBM direction distance function and GML index method (SBM-GML) to measure TFP. The Cobb–Douglas (C–D) production function is still used in the evaluation system of TFP, selecting labor (employment at the end of the year), capital (capital stock), land (urban built-up area), and energy consumption (10,000 standard tons of coal) as the input vectors. The expected output selects each city based on the actual GDP in 2006 as the proxy variable. The undesired output uses SO2, industrial wastewater, and dust as output variables.

Green technological innovation (GTI). There are many measures of GTI, of which R&D expenditure and the number of patents in environmental technology are widely used. Generally, the former is regarded as the input to innovation activities, while the latter is viewed as the output. The disadvantages and advantages of these indicators have been discussed (Popp, 2012). In 2010, the IPC of green inventory was launched by the World Intellectual Property Organization and the OECD indicator of environmental technology to match the number of green patents applied and authorized each year at the city level (Ghisetti &.Quatraro, 2017; Du et al., 2019). The International Patent Green Classification List (green list) divides green patents into seven categories, including alternative energy production, waste management, agriculture or forestry, energy conservation, and transportation, following the United Nations Framework Convention on Climate Change. Furthermore, this article identifies green patents not mentioned in the green list using the keywords related to green technologies provided by Wagner (2007). Considering the time required to develop technologies to patent grants, these technologies will likely impact a company's production performance while still in the application process. Therefore, the number of patent applications is more reliable and time-sensitive than the number of patents granted.

Control variables. This study controls for the macroeconomic characteristics of cities to eliminate these variables’ potential impact on EP. The industrial structure of an economy significantly influences the efficiency of resource use and the degree of environmental friendliness in economic development. The optimization and upgrading of the industrial structure affect the regional division of labor, the industrial layout, and the prospects for low-carbon sustainable development of a region (Dong et al., 2021). From the perspective of the proportional structure of industrial sectors, this study uses the share of value added of the tertiary sector in GDP to measure the industrial structure. A well-developed financial structure encourages firms in the energy sector to adopt modern technologies, thereby reducing emissions of energy pollutants. A stable financial system can create a stable supply of credit for businesses to increase investment in environmental technologies, which can help improve environmental quality (Kumbaroglu et al., 2008; Nasreen et al., 2017). This study uses the ratio of loan balances of financial institutions to the administrative area to measure the financial structure. The environmental Kuznets curve hypothesis suggests that environmental degradation gradually increases with economic growth but reaches a specific critical value when EP gradually declines with economic growth. This nonlinear relationship between economic growth and EP is seen in less developed economies (Aung et al., 2017; Hao et al., 2021). This study uses GDP per capita to measure economic growth. The concentration of the population in the central city shortens the commuting distance for all types of activities. The high-density distribution of the population and the specialized layout of the city's functional areas have led to a relatively robust transport network and infrastructure, which not only reduces residents’ reliance on small cars for travel but also promotes the development of green public transport, such as buses, shared bikes, and railways, which can reduce tailpipe emissions and energy consumption (Yi et al., 2022). This study uses the number of people per square kilometer and the natural population growth rate to measure population agglomeration. Theoretical research on environmental economics has shown that foreign direct investment has a complex “double” impact on the host country's EP. The pollution haven hypothesis holds that to avoid the high cost of environmental regulation in their home countries, foreign-invested enterprises will transfer their polluting production activities to developing countries with relatively lenient environmental regulations and standards and eventually cause the developing countries to bear the consequences of EP (Nejati & Taleghani, 2022). The pollution halo hypothesis holds the opposite view, that is, foreign direct investment enterprises have developed a set of mature environmental management concepts and green environmental protection technologies owing to strict environmental supervision in their home countries. Through technology spillovers and knowledge diffusion, foreign direct investment positively impacts the host countries’ environmental protection (Birdsall & Wheeler, 1993). This study uses the utilization of foreign direct investment in various cities to measure foreign direct investment. With the continuous evolution of the public administration paradigm, the focus of environmental governance has gradually shifted from government investment to government expenditure and from government administrative efficiency to the supply of environmental public goods. This study chooses the proportion of government general budget expenditure to GDP as a measure of government macro-control.

Linear regression modelsBased on the new economic growth theory, the following econometric model has been constructed to verify the impact of intelligent industrial manufacturing on EP, combining H1 and existing research (Zhu et al., 2023):

where a1 and ak denote the parameters to be estimated and a0 denotes the constant error term. Control represents a set of information that contains all the control variables. λi is an individual fixed effect. νt is time-fixed effect. εit is a random perturbation term that obeys a white noise process. k represents the order of the control variables. In the actual estimation process, to prevent outliers from influencing the model estimation results, the continuous-type explanatory variables are adjusted by winsor2 at the 1st and 99th percentile of their distribution.Mechanism test modelThe theoretical analysis shows that IM improves resource utilization efficiency and increases industrial enterprises’ demand for green technology R&D. Green technologies can improve environmental management efficiency and reduce pollutant emissions. Smart manufacturing can thus reduce pollution by promoting green innovation. Owing to the endogeneity of the three-stage mediating effect model, the mechanism test in this study only evaluates the influence of IM on the mechanism variables to overcome endogeneity issues (Jiang, 2022). Thus, the following two equations can be obtained:

According to the new mediation effect test method, part of the mechanism test only needs to pay attention to whether the regression coefficient of the core explanatory variable to the mediation variable is significant and meets the expectation.

Unconditional quantile regression modelCompared with the traditional linear measurement model, the quantile regression model has two advantages. First, the general linear regression model focuses on the influence of independent variables on dependent variable conditional expectation E(l|x), and the average estimation effect obtained can only reflect the concentration trend of the parameter distribution in l|x. The quantile regression model can estimate the conditional quantiles of conditional distribution at different intervals and can better reflect the correlation between variables. Second, using the weighted average of the absolute values of the residuals as the minimization objective function can reduce the influence of outliers on the estimation results. The quantile regression model can be divided into a conditional quantile regression (CQR) model and an unconditional quantile regression (UQR) model. Because the conditional cumulative distribution function Fl|x(·) of CQR depends on the independent variable x and the estimation results of this method consider too many or even unnecessary individual characteristics, it is also vulnerable to changes in covariate deletion. UQR overcomes these defects, and the estimated result is unconditional (Firpo et al., 2007). The basic approach of this model is to estimate the unconditional quantile bias effect using the recentering influence function (RIF) defined by the influence function in robust estimation. In this study, let qτ be the unconditional quantile of EP (to simplify the formula, replace EP with Y); the recentering response function of the unconditional quantile model can be expressed as

where RIF(qτ,y,Fy) is the recentering response function corresponding to FY in quantile τ−. qτ is the unconditional quantile of Y, subject to Fy(qτ)=τ, f(·) is a density function of Y. Using the iterative law of conditional expectation (the expectation of the conditional mean is equal to the unconditional mean) to calculate the conditional expectation of Eq. (10) can obtainTherefore, the UQR model is as follows:

To solve the influence of marginal change inFXRIF(EP,qτ) in Eq. (12), differential processing is performed to obtain the unconditional quantile bias effect (UQPE) of the unit translation transformation of independent variables on the quantiles of the dependent variables:

Because panel data are used in this study, unobservable factors that do not change with time but affect IM must be controlled. The fixed effect UQR model was proposed by Borgen (2016). The estimation of UQPE is divided into two steps: first, RIF is estimated; second, RIF is considered an explained variable, and regression is performed based on core explanatory variables and related control variables. The model is as follows:

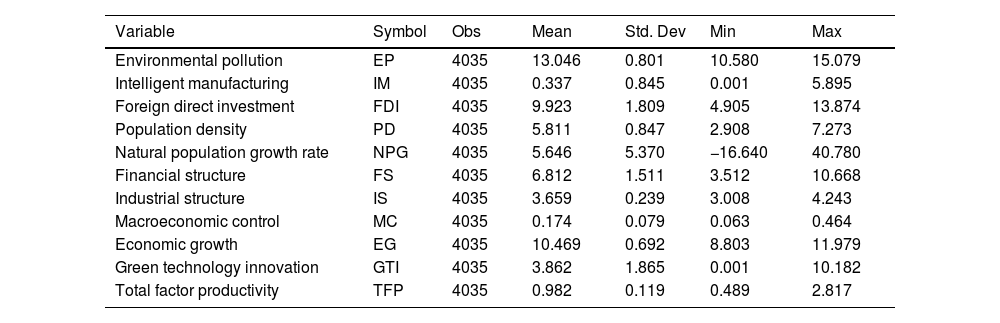

Data sources and descriptive statistical analysisBased on data availability, this study considers the panel data of 269 prefecture-level and above cities in China from 2006 to 2020 as statistical samples to empirically test the impact of IM on EP. The concentration data of PM2.5 are taken from the Atmospheric Composition Analysis Group of Dalhousie University. The raw data on IM are from the International Robot Alliance and China City Statistical Yearbook. The original GTI data are from the State Intellectual Property Office of China and Research Data Service Platform of China (CNRDS). The original data of the control variables are obtained from the China National Bureau of Statistics, China Urban Statistical Yearbook, China Urban and Rural Construction Statistical Yearbook, EPS database, and CSMAR database. Descriptive statistics for each variable are shown in Table 1.

Variable definitions and descriptive statistics.

| Variable | Symbol | Obs | Mean | Std. Dev | Min | Max |

|---|---|---|---|---|---|---|

| Environmental pollution | EP | 4035 | 13.046 | 0.801 | 10.580 | 15.079 |

| Intelligent manufacturing | IM | 4035 | 0.337 | 0.845 | 0.001 | 5.895 |

| Foreign direct investment | FDI | 4035 | 9.923 | 1.809 | 4.905 | 13.874 |

| Population density | PD | 4035 | 5.811 | 0.847 | 2.908 | 7.273 |

| Natural population growth rate | NPG | 4035 | 5.646 | 5.370 | −16.640 | 40.780 |

| Financial structure | FS | 4035 | 6.812 | 1.511 | 3.512 | 10.668 |

| Industrial structure | IS | 4035 | 3.659 | 0.239 | 3.008 | 4.243 |

| Macroeconomic control | MC | 4035 | 0.174 | 0.079 | 0.063 | 0.464 |

| Economic growth | EG | 4035 | 10.469 | 0.692 | 8.803 | 11.979 |

| Green technology innovation | GTI | 4035 | 3.862 | 1.865 | 0.001 | 10.182 |

| Total factor productivity | TFP | 4035 | 0.982 | 0.119 | 0.489 | 2.817 |

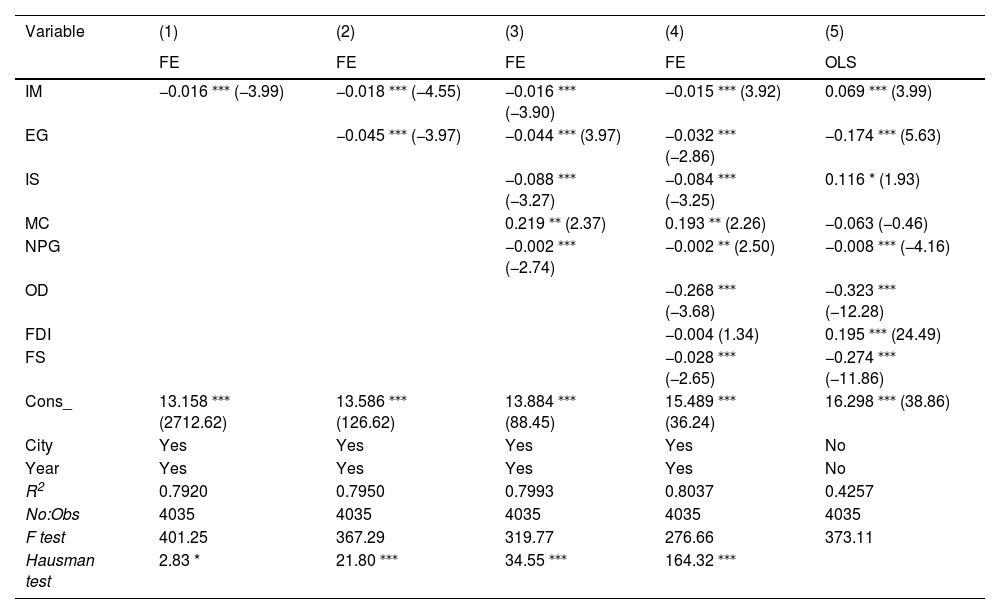

In accordance with the research hypotheses and topic, this section focuses on whether IM can significantly reduce EP. The commonly used fitting models for a given panel data include the ordinary least square (OLS), random effect (RE), and fixed effect (FE) models. In general, the OLS model can be used as a baseline because of its simplicity; however, it does not include individual effects. The advantage of the FE and RE models is that these models incorporate individual effects. The FE model should be used when the individual effects are related to the independent variables because the coefficient estimates of the RE model are inconsistent. The RE model should be used when the individual effect is unrelated to the independent variable because of its efficiency. In the actual fitting process, the Hausman and F tests are used to judge the suitability of a model for sample data. In fact, in the linear panel model, FEs are used by default because it is difficult for individual effects to be truly independent of the independent variables and because as the amount of data increases, the problem of validity becomes decreasingly critical. Most focus on the problem of consistency. The Hausman test and F tests results show that the sample data in this study are more suited to the FE model; therefore, this study uses the FE model as the benchmark regression model. To obtain more robust parameter estimation results, this study uses stepwise regression to substitute the control variables in the measurement model. Table 2 reports the calculation results of the FE model and mixed least squares method. Specifically, columns (1)–(4) report the results of the FE model, column (5) reports the results of the OLS method.

Results of the linear regression.

| Variable | (1) | (2) | (3) | (4) | (5) |

|---|---|---|---|---|---|

| FE | FE | FE | FE | OLS | |

| IM | −0.016 ⁎⁎⁎ (−3.99) | −0.018 ⁎⁎⁎ (−4.55) | −0.016 ⁎⁎⁎ (−3.90) | −0.015 ⁎⁎⁎ (3.92) | 0.069 ⁎⁎⁎ (3.99) |

| EG | −0.045 ⁎⁎⁎ (−3.97) | −0.044 ⁎⁎⁎ (3.97) | −0.032 ⁎⁎⁎ (−2.86) | −0.174 ⁎⁎⁎ (5.63) | |

| IS | −0.088 ⁎⁎⁎ (−3.27) | −0.084 ⁎⁎⁎ (−3.25) | 0.116 * (1.93) | ||

| MC | 0.219 ⁎⁎ (2.37) | 0.193 ⁎⁎ (2.26) | −0.063 (−0.46) | ||

| NPG | −0.002 ⁎⁎⁎ (−2.74) | −0.002 ⁎⁎ (2.50) | −0.008 ⁎⁎⁎ (−4.16) | ||

| OD | −0.268 ⁎⁎⁎ (−3.68) | −0.323 ⁎⁎⁎ (−12.28) | |||

| FDI | −0.004 (1.34) | 0.195 ⁎⁎⁎ (24.49) | |||

| FS | −0.028 ⁎⁎⁎ (−2.65) | −0.274 ⁎⁎⁎ (−11.86) | |||

| Cons_ | 13.158 ⁎⁎⁎ (2712.62) | 13.586 ⁎⁎⁎ (126.62) | 13.884 ⁎⁎⁎ (88.45) | 15.489 ⁎⁎⁎ (36.24) | 16.298 ⁎⁎⁎ (38.86) |

| City | Yes | Yes | Yes | Yes | No |

| Year | Yes | Yes | Yes | Yes | No |

| R2 | 0.7920 | 0.7950 | 0.7993 | 0.8037 | 0.4257 |

| No:Obs | 4035 | 4035 | 4035 | 4035 | 4035 |

| F test | 401.25 | 367.29 | 319.77 | 276.66 | 373.11 |

| Hausman test | 2.83 * | 21.80 ⁎⁎⁎ | 34.55 ⁎⁎⁎ | 164.32 ⁎⁎⁎ |

As shown in Table 2, the four results of the FE model are highly consistent; only the coefficients of the fitting parameters vary, indicating that the results of Eq. (7) are robust. The first column of Table 2 shows the FE estimates results without including any control variables and indicates that the average effect of IM on EP is −0.016, which is statistically significant at the 1% level. The FE estimation results, with all the control variables added in the fourth column, show that the average effect of IM on EP is −0.015 and is statistically significant at the 1% level. Overall, the FE estimates suggest that IM can reduce PM2.5 emissions and improve ecological quality, thus validating H1. There are many causes of pollution; however, in the case of pollutants emitted from industrial production, poor technology and manual handling are the leading causes, which are humanly controllable. Poor technology reduces the efficiency of energy use and the ability to use clean energy, while manual handling often causes additional pollution. Modern information technologies, such as artificial intelligence, cloud computing, and blockchain, have accelerated the integration of data elements with traditional manufacturing industries; promoted the transformation and upgrading of traditional industries through industrial linkages, technology diffusion, and knowledge spillovers; and generated strategic emerging industries that are more environmentally friendly. Second, as an essential part of pollution management, enterprises can use the virtual reality, database, and IoT technologies of the IM system to effectively integrate various information resources in production decision-making and analyze product, process, and resource data for decision-making and planning reorganization (Magazzino et al., 2021). Digital technology provides an opportunity for better observability, the improved forecasting of resource needs, and the consistent optimization of energy savings. By improving resource utilization efficiency, the production process can be advanced efficiently, thus reducing pollutant emissions. In addition, smart terminal equipment plays a key role in measuring and optimizing the energy consumption of enterprises and households. Bastida et al. (2019) showed how the digital transformation of the energy sector affects users’ perception of energy consumption. Finally, the introduction of installed industrial robots is a vital substitute for human labor and increases the organic composition of a company's capital. IM has advantages over human labor in terms of technical standards, processes, and production precision, which can improve the purification and energy use efficiency and reduce EP.

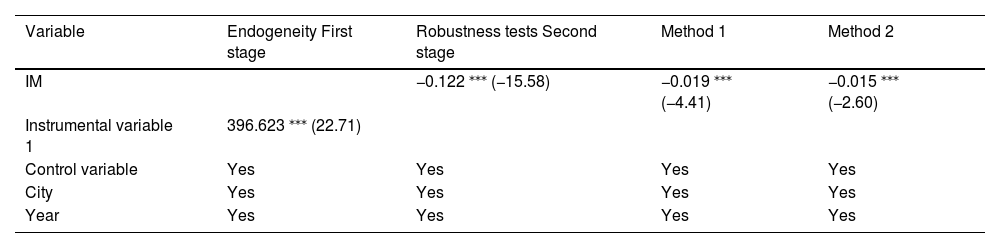

Endogenous testBecause many factors can reduce EP, this study selects several control variables to mitigate the endogeneity problems arising from the omission of essential variables. However, the causal endogeneity between IM and EP is still worth caution. For example, places with less EP may have better network infrastructure and may promote the rapid development of IM. Urban environmental quality may have a specific reverse effect on the development of IM. Because machines and equipment must maintain a suitable temperature for regular operation, market players may prioritize cities with good air quality and suitable temperatures for the layout of digital industries. Finally, the industrial structure mainly manifests in the resource-dependent extensive economic development mode in areas with severe EP. Thus, IM with high-tech characteristics will be ignored because of the significant investment capital. However, enterprises face more stringent policy constraints in areas with high-quality environments. The self-emission control and emission reduction of the manufacturing sector with a high level of pollution should be based on the R&D of clean technology. The information and technical demands of technological R&D will undoubtedly force enterprises to undertake intelligent transformation and deepen the application of artificial intelligence technology in the management business and production process. The reverse causality between smart manufacturing and EP may challenge the reliability of the estimated results of the FE model herein. This study uses an instrumental variable approach to eliminate the endogeneity problem.

Following the principle of exclusivity and correlation, this study mainly selects topographic relief as the instrumental variable. Geographical conditions of mountainous and hilly areas is difficult to improve the facilities that support the related transport infrastructure and industry chains, thus limiting intellectual manufacturing development. Topographic relief naturally affects air circulation rates and local climate and has no direct correlation to pollutant emissions. Regarding data characteristics, topographic relief comprises cross-sectional data that do not change over time, and its effect on IM may vary from year to year. The intersecting multiplier term of topographic relief and annual dummy variables were used as the instrumental variables (Cao et al., 2021).

The results of the two-stage least squares first-stage estimation in Table 3 show that the two instrumental variables significantly impact IM. The instrumental variable validity test results showed that the C–D Wald F statistic of 515.94 was more significant than the 10% critical value of 16.38, indicating that there was no weak instrumental variable problem with the instrumental variables. The p-value of the LM statistic was less than 0.001, strongly rejecting the original hypothesis that the instrumental variables were unidentifiable. From the results of the second-stage estimation, the regression coefficient of IM on EP is −0.122 and is statistically significant at the 1% level. This result is similar to the FE estimation that IM can reduce EP.

Endogeneity and robustness tests.

To more rigorously examine the robustness of the findings that smart manufacturing reduces EP, this study uses the following two methods for robustness testing. First, it replaces the core explanatory variables. Artificial intelligence technology was proposed as a new general-purpose technology in the 1950s. However, owing to the limitations of computer data processing, it spent more than 40 years in the recognition stage until the computer improved in pattern recognition and prediction, at which point it entered the rapid development stage again. The identification and introduction phase of intelligent industrial technology will prompt the transfer of many resources from the production sector to complementary investment. The new technology will subsequently spread through the core industry to the surrounding industries until it can be used in various industries. These industries will need a long time to adapt and operate. Therefore, IM takes a long time to improve EP. In addition, an enterprise adopting an intelligent transformation requires a period of practice and exploration to adapt and optimize the corresponding process technology and production process. Therefore, the positive effect of IM on the improvement of pollution control efficiency may have a time lag effect. A one-period lag of IM was used as the core explanatory variable to test for time lag effects.

Second, regarding the replacement of econometric models, in traditional panel FE models, both individual and time FEs are substituted additively, thus controlling for individual differences that do not vary over time and time differences that do not vary over individuals in the sample. Bai (2009) introduced individual and time interaction effects in a linear panel model to capture differences in the effects of common factors across individuals. The interactive FE model fully considers the multidimensional shocks existing in the real economy and the asymmetry of different individuals’ responses to these shocks. Thus, Eq. (7) can be rewritten as follows:

where Ft is the common factor, λ′i is the factor load, and λ′iFt is the interaction fixing effect.Table 3 shows that in the results of both robustness tests, there is a negative relationship between IM and EP. Their estimated coefficients were −0.019 and −0.015, respectively, and both were significant at the 1% significance level. The sign and significance of the estimated coefficients of the two model parameters are consistent with the results of the FE estimation. Therefore, the result that IM can reduce EP is robust.

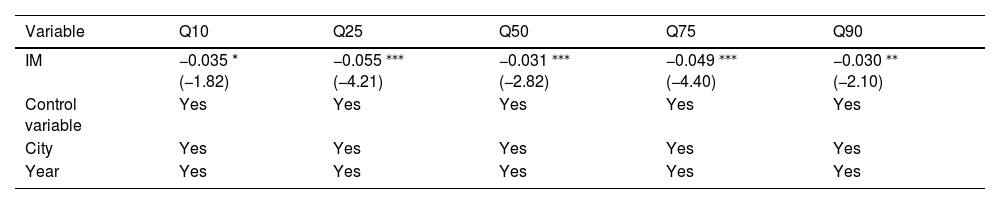

Nonlinear analysisFor the UQR model, five representative quartiles of 10%, 25%, 50%, 75%, and 90% were selected to estimate Eq. (12) as per the empirical tests available in the literature (Ma et al., 2019; Tran & Vu, 2020). As seen from Table 4, the marginal impact effect of IM on EP is negative at different sub-points, indicating the validity of the conclusion that IM reduces EP during the study period. The trend in the variation of the parameter estimates of IM at different points of division is apparent, indicating that its impact on EP is nonlinear, thus verifying H3.

Specifically, the direction and significance of the impact of IM on EP were similar to the mean regressions in Table 2 for the five sub-locations selected. The absolute value of the parameter estimates for the five quartiles in the UQR is significantly higher than that in the mean regression at −0.015, possibly because the quartiles tolerate some outliers and the estimated coefficients increase without changing the direction of influence or significance. As the quantile shifts from 10% to 90%, the impact of smart manufacturing on EP decreases, with the regression coefficient falling from −0.035 to −0.030. The impact of IM on EP reaches an inflection point at the 50% quantile, with regression coefficients at both ends being more remarkable than that at the inflection point. The effect of IM on reducing EP is an “M-shaped” trend: up, then down, then up again, and finally down. The role of IM in reducing EP is greater in the 25% quantile, followed by the 75% quantile, and then the 10% quantile. The sum of the coefficient values for the 10% and 25% quartiles is more significant than that for the 75% and 90% quartiles. This result indicates that the protective effect of IM on the ecological environment is more significant at lower PM2.5 concentrations. According to the regional distribution of PM2.5 concentration in the air in China, the stations with higher PM2.5 concentrations are located in north China, central China, and northern east China, while the stations with lower PM2.5 concentrations are located in the Qinghai–Tibet Plateau and southwest China (He & Zhang, 2020; Liu et al., 2023). Owing to the diminishing marginal effect of information technology, IM is crucial for environmental protection in economically underdeveloped areas. By contrast, the eastern coastal areas have a relatively excellent digital infrastructure, high population density, and high economic density, leading to more complex impacts of IM on the environment. In addition, with the rapid development of information technology and the constant change in market demand, the complexity of intelligent technology at the production frontier is continuously increasing, and the emerging digital product field is constantly emerging; therefore, the manufacturing industry must invest heavily to promote technological and manufacturing equipment upgrading. Areas and industries at the forefront of technology urgently need to explore application scenarios and business models in relation to advanced information technology. Moreover, in technology and equipment upgrading, manufacturing personnel must be able to absorb and transform new technologies, transform traditional production concepts, and reallocate resources for production. This increases the requirements for the organizational structure, resource identification, and integration ability of the manufacturing industry and, finally, means that IM has a weak impact on EP. Therefore, smart manufacturing presents better mitigation in western regions where PM2.5 concentration is low.

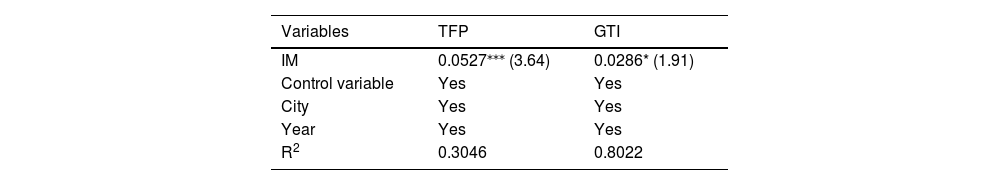

Channel testThe aforementioned benchmark regression results support the inhibitory effect of IM on EP; however, there is an indirect physical mechanism for this effect. To evaluate whether IM can reduce EP by optimizing resource allocation to improve TFP in the production process, as well as examine the mediating role of GTI, this study used the mediation effect model to verify H2 and H4.

The results in Table 5 show that the regression coefficients of IM in terms of TFP and GTI are 0.0527 and 0.0286, respectively, which pass the significance test of 1% and 10%, respectively. These results show that the production mode of IM not only improves the resource allocation ability within the city but also promotes the willingness of enterprises to undertake GTI. Therefore, H2 and H4 are verified. Intelligent technology has the characteristics of data, networks, and intelligence, and its integration with the manufacturing industry is increasing. This industry has realized the unprecedented changes in the manufacturing paradigm. IM reduces the cost of information dissemination, improves the efficiency of market transactions, accelerates the diffusion of new knowledge and technology, and helps manufacturing researchers broaden channels for acquiring new knowledge, thus improving the level of independent innovation (Erik et al., 2019). In accordance with the equation of the new mediation effect test, this section focuses on the influence path of IM on the mechanism variables. The application of digital technologies such as artificial intelligence and big data has improved the ability of self-renewal and knowledge production of the manufacturing system. Intelligent technology, combined with the rolling task, can optimize the production process of the manufacturing workshop, solve the complex problem of production factor scheduling and distribution, address the dynamic changes in actual production demand, and improve TFP (Nordhaus, 2021). IM has a network effect and acts as a platform through digital infrastructure, which reduces the mobility barriers of production factors in the manufacturing industry. The manufacturing industry can make timely adjustments to the factor input in the production process, avoid the problem of redundant or insufficient factor input, and optimize its factor allocation efficiency.

ConclusionIn recent years, modern digital technologies, represented by artificial intelligence, smart manufacturing, and big data analysis, have developed rapidly and penetrated deeply into all areas of society, including government governance, enterprise production, and individual lives, with a significant impact on energy conservation and emission reduction. A series of new technologies, products, and models spawned by IM are used in EP control. The role of modern information technology is particularly notable in environmental monitoring and the low-cost acquisition of GTI knowledge, which will help reduce EP. This study uses the panel data of 269 cities in China from 2006 to 2020 to investigate the impact of IM on EP and the intermediary role of GTI. The empirical evidence shows that IM can significantly reduce the concentration of PM2.5 in the air and protect the environment. In addition, the instrumental variable method, replacement of explanatory variables and measurement models, and self-help robust standard errors for multiple tests are used to ensure the robustness of the benchmark results. The internal mechanism test results show that IM can reduce EP by promoting TFP. Consistent with the conclusions of previous research, we found that IM with digitalization at its core plays a vital role in environmental sustainability (Pigola et al., 2021; Xu et al., 2023). However, further research found something different. The effect of IM on EP is nonlinear. Smart manufacturing reduces EP the most at the 25% quantile, followed by the 75% quantile and the 10% quantile. It can be argued that the positive effects of IM are more significant in the lower quartile. IM has a more significant effect on ecological improvement in areas with better environmental quality. Finally, IM can indirectly improve air quality through mechanisms that promote the development of green technologies in companies. Similar to previous investigations, we found that IM promotes the spillover and use of knowledge (Bouncken & Barwinski, 2021; Vuori et al., 2019), resulting in increased green TFP (Ribeiro-Navarrete et al., 2021). Simultaneously, to promote digitalized IM-related work, IM is an essential method of pollution control and sustainable development for enterprises (Bolton & Hannon, 2016; Sarkodie et al., 2019;Alam & Murad, 2020).

Policy enlightenmentAs the largest developing country in the world, China should accept responsibility and adopt a mission to promote collaborative governance in terms of pollution and carbon reduction. Digitization and intelligentization are the themes of modern-day industrial development. The industry is the primary source of carbon dioxide and EP. The Chinese government's experience in the intelligent transformation of the manufacturing industry and the reduction of EP through IM has contributed to China's solutions and wisdom for global environmental governance and helped other countries learn from these experiences to protect the environment in accordance with local conditions. The results of this study show that the Chinese government should accelerate the intelligent transformation of industrial enterprises, use various methods to promote the strategy of Made in China 2025, and accelerate the overall level of IM. Accordingly, this study proposes the following policy implications.

First, relevant departments should actively promote the development of IM and encourage enterprises to accelerate the process of digital transformation. The results herein show that IM can improve the efficiency of pollution control, reduce the pollution control costs for representative enterprises, and ultimately reduce pollutant emissions. Therefore, a focus on developing IM to promote the digital transformation of enterprises is imperative. For the rapid development of industrial intelligence, functional departments must make overall plans for IM production, equipment, technology, and management from an industrial integration perspective and constantly improve the IM policy system and coverage areas. Given major industrial and technical problems, we should concentrate elite resources, using “the open competition mechanism to select the best candidates” to quickly address the scientific and technological problems of “bottleneck project” Industrial policies should fully use the market's decisive role in allocating IM resources. Government departments should maintain a smooth flow of production factors, such as talent, capital, and technology, among high-tech industries to promote the rapid development of the IM industry. Furthermore, administrative departments should carry out trials and demonstrations of IM in key industries and strengthen the role of leading enterprises in innovation. Social forces must be actively guided to participate in the investment and distribution of basic research so that enterprises become the leading force in integrating innovation elements. Enterprises in China should leverage intelligent technology, optimize resource allocation, strengthen the R&D of intelligent technology, cultivate technological independence, eliminate pollution-related technologies, and reduce pollution emissions. Moreover, deep integration applications and innovative digital and manufacturing technology development in various industries must be encouraged. A group of representative enterprises in specific industries can be selected to demonstrate the overall digital transformation, and a comprehensive and multidimensional transformation model for similar enterprises should be provided.

Second, enterprises must actively participate in the top-level design of national standards; develop standards in terms of IM architecture, technical realization, and application structure; and improve the openness and compatibility of existing standards. Enterprises must strengthen the research on the standards of important new technologies and products and comprehensively cover the common and key technical standards such as basic generality, technology, management, testing, and evaluation. Moreover, enterprises should actively adopt advanced standards, encourage changes to adopt international standards, and gradually build a progressive, open, and coordinated IM standard system. Related market subjects will continue to improve the construction of IM inspection and certification systems and service platforms in the fields of complete set, safety, process, and machine performance as well as key components. The administrative department should examine and formulate a policy of intelligent certification and acceptance, support the priority use of certified products in major projects, encourage local governments to establish corresponding acceptance mechanisms, and promote the healthy development of industry norms.

Third, government departments should comprehensively consider resource endowments within their respective jurisdictions and formulate incentive policies accordingly. In order to maximize the benefits of IM technology to the growth of the green economy, relevant entities should develop intelligent incentive policies based on regional resource endowments, expand the scope of intelligent applications, and gradually establish an intelligent high-tech industrial system. For example, the government should establish a credit fund for IM to address the issues of financing for the development of enterprises. Banks and other financial institutions should be encouraged to use funds, interest discounts, and guarantees to provide exclusive financial services for intelligent upgrading for manufacturing enterprises. The government should strengthen fiscal policy support, expand the proportion of government research projects on IM, improve tax policies on technological innovation in IM, identify costs incurred for enterprise and technology R&D, coordinate various fiscal and tax policies to support IM technology innovation, and enhance the policy synergy effect.

Finally, the government should encourage enterprises to increase investment in R&D and emission reduction technologies. GTI comprises management and technology innovation, including environmental protection as the goal; it is closely related to ecological, sustainable, and environmental innovation. Studies have shown that IM can reduce the cost and shorten the cycle of green technology R&D, thus promoting the technological progress of emission reduction and reducing EP. However, the R&D of green technologies and the digital transformation of enterprises depend on the availability of sufficient funds. Therefore, financial and policy support must be strengthened for the technological innovation of enterprises, with special assistance for the R&D of enterprises concerning environment-friendly technologies and policy support for technological R&D and environmental protection of small and weak microenterprises, such as significant tax reductions and exemption policies. Market entities and credit management departments should collaborate to improve the corporate governance environment, establish an evaluation mechanism for corporate green development, and constantly expand the scope of environmental information disclosure by enterprises. The external role of green finance governance should be fully utilized. Focusing on the transformation and upgrading of traditional industries, we should implement several demonstration projects for the application of green technologies and projects to upgrade green technologies and accelerate the transformation of traditional industries. Specifically, we should focus on emerging electronic information industries, high-end equipment manufacturing, digital, new materials, and new-energy vehicles with comparative advantages and development potential; tackle critical technologies; and enhance our capacity for GTI.

LimitationsTo strengthen the existing qualitative and quantitative information, the research gap can be highlighted in light of the following caveats and limitations. First, the present study focuses on the relationship between IM, GTI, and EP; therefore, it would be more robust and interesting if future researchers inspect the relationship between IM and EP at a micro or macro level (firms or industrial level), specifically by analyzing the relationship between IM and environmental sustainability in different firms and industries in China. Second, we have focused on the impact of smart manufacturing on EP but found measurement to be a challenge. China's ecology department published PM2.5 concentration data for each city consecutively in 2012; therefore, China's monitoring data cannot satisfy the required number of statistical samples. Thus, considering only airborne PM2.5 concentrations to measure air quality may be a compromise. Future studies must consider air pollutants. In addition, measuring the development of IM at the city level is also a challenging task. This study uses the installation density of industrial robots and the number of automation equipment used in factories as the proxy variable of digital technology. Because industrial robots can only partially reflect the intelligent transformation of industry and the adoption of digital technology, this index may not be accurate for measuring digital technology. Third, there is a need to construct a theoretical link between IM usage and the energy environment from multiple perspectives and acquire a more in-depth understanding of the drivers of energy saving and emission reduction driven by robot usage. Finally, this study uses a poor cause-and-effect identification method when analyzing the causal relationships between variables. An excellent instrumental variable is often challenging to obtain; therefore, the conclusions of the 2SLS model may still need to be questioned. In future studies, using the policy evaluation method to test the influence mechanism and causality among variables in accordance with the policies related to IM or smart cities promulgated by China will be of great significance.

Disclosure statementThe authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.