The digital transition is transforming society in general and industry in particular, so much so that the concept of Industry 4.0 is by now widespread and consolidated. However, there is the risk that too pronounced a focus on technology may lead to losing sight of the centrality of human resources. Among others, the European Commission has urged greater attention from research and industry on the human factor. There is a need for further theorizing concerning the role of humans in a digitalized industry. Understanding what is known in the literature on human resource management in an Industry 4.0 context is an important first step toward defining a roadmap for enhancing the human factor in a digitized industry. To achieve this goal, we conducted a systematic analysis of the literature. We used a text-mining approach implemented via the MySLR software platform, which uses latent Dirichlet allocation, to analyze 566 papers published in academic journals. In this way, we were able to identify the main trends in the literature, the most frequently analyzed topics, and the gaps and possible future developments. Our study provides a synthesis of the research in this domain, as well as a research framework based on three pillars related to the technological, human-centric, and organizational perspectives. The results provide researchers and managers with a clear and updated overview of research in the field of human resource management in the context of Industry 4.0, as well as future research directions.

The last decade has been characterized by changes, innovations, and technological developments that have radically transformed our life. At the same time, uncertain business conditions such as economic pressure, competition and globalization have substantially changed the competitive landscape (S. Bresciani et al., 2021; Bertello et al., 2021). In manufacturing, the interconnection between business process management and robotic process automation has enabled the digitalization of production processes, which has boosted internal efficiency (Ammirato, Sofo, Felicetti & Raso, 2019). The availability and widespread adoption of innovative technologies, such as artificial intelligence (AI), nanotechnology, augmented reality, and the Internet of things (IoT), is radically replacing any technological progress made since the 1960s to the point of upsetting and changing the business model of every sector (Müller, Buliga & Voigt, 2021). This shift in production paradigms, also known as the “4th Industrial Revolution,” “Industry 4.0,” or “I4.0″ (Maynard, 2015), has dramatically impacted working routines and employees’ habits (Fareri, Fantoni, Chiarello, Coli & Binda, 2020), making scholars aware of the importance of human resource management (HRM) in the transition towards the new technological paradigm (Jimeno-Morenilla, Azariadis, Molina-Carmona, Kyratzi & Moulianitis, 2021). Industry 4.0 is reshaping the way people work, learn, lead, manage, recruit, and interact with each other (da Silva et al., 2022), acting as a new strategic lever for competitiveness and a suitable set of technologies to overcome the productive crisis. Decentralization, empowerment of individuals, fewer formal rules, horizontal communication, and teamwork are recognized as relevant aspects characterizing the Industry 4.0 scenario (Schäfer et al., 2023).

Technological and digital competencies and the welfare of workers are assuming a central role over recent years (Bresciani, Dabić, & Bertello, 2022). In this regard, some scholars have introduced the concept of Human Resource Management 4.0 (HRM 4.0), sometimes referred to as Smart Human Resource 4.0, which concerns how to manage human resources in the Industry 4.0 context (Liboni, Cezarino, Jabbour, Oliveira & Stefanelli, 2019).

The adoption of the Industry 4.0 paradigm is becoming increasingly urgent in the current turbulent times, characterized by new and unprecedented challenges, such as the COVID-19 pandemic (Collings, McMackin, Nyberg & Wright, 2021) and international conflicts (Tosun and Eshraghi, 2022). Technological and organizational innovations and appropriate HRM practices can support companies in overcoming the dramatic effects of these crises, i.e. lockdowns, the lack of raw materials, service discontinuity, and falling supply prices (Chatterjee, Chaudhuri, Vrontis & Thrassou, 2022).

Ultimately, such crises are raising awareness of the need to reimagine our society, building a more inclusive, human-centric, and sustainable world that will be resilient in the face of future global challenges (Henderson, 2020). The adoption of this point of view also in industrial production motivates the need to go beyond the use of digitization and robotization in order to achieve efficiency and flexibility in production (Breque, De Nul & Petridis, 2021).

The Industry 4.0 paradigm is therefore shifting towards a sustainable, human-centric, and resilient approach that is known as “Industry 5.0″ or “I5.0″ (Breque, De Nul & Petridis, 2021). While the focus of Industry 4.0 is on improving the performance of mass-production processes, Industry 5.0 deals more with individuals and society, adding a human-centric, sustainable, and resilient focus to the industrial revolution (Adel, 2022). From a research perspective, Industry 5.0 is attracting the attention of scholars that would have not been interested in the technological perspective of Industry 4.0. According to Zizic et al. (2022) the focus of Industry 5.0 is twofold: “on the one side, Industry 5.0 is focused on the workers’ skills, knowledge, and abilities to cooperate with machines and robots, and on the other side, on flexibilities in production processes and environmental impact.”

Overall, the availability and widespread adoption of new technologies is driving deep change in organizations and HRM theories and practices. Companies of all types are implementing more HRM technology than ever; they are competing for business across cities and around the world, while also competing to attract and retain employees in an increasingly competitive labor market with widening skill gaps. The HR Federation survey revealed that global HR technology venture capital was worth over USD 3.1 billion in 2018, more than triple the amount invested in 2017 (McFarlane & LaRocque, 2019).

Of course, to get the most from investments in HRM technologies, companies must align digital transformation with corporate strategy. They must implement HR practices to encourage employee behaviors consistent with the organization's strategy. HR practices aligned with strategy enable companies to achieve the best digital transformation in order to achieve superior performance (Nicolás-Agustín et al., 2022).

Although, from a business perspective, the huge rise of HRM 4.0 demonstrates that companies are aware of the benefit of technology adoption, on the research side, the extent of changes due to the adoption of the HRM 4.0 paradigm and its impact on workers, the company, and society has not yet been fully addressed. Boundarouk and Brewster (2016) and Stone and Deadrick (2015) highlighted the need for further investigation into the relationship between HRM and technology. Marler and Boudreau (2017), which explored the current state of HR analytics and its potential consequences, stated that there is still much research needed to fully understand the implications of HRM4.0 on various stakeholders. Liao et al. (2017), in their review and future agenda study about HRM4.0, call for more studies to examine the impact of Industry 4.0 on various stakeholders in order to develop effective HRM strategies to address the challenges and opportunities posed by this new paradigm.

It seems that the literature lacks a clear and up-to-date picture of the current HRM 4.0 body of knowledge.

Bearing in mind this gap, the present work aims to answer the following questions:

- •

How is the HRM literature developing and being structured regarding Industry 4.0?

- •

What are the key topics addressed by prior research?

- •

What are the promising future HRM research directions for scholars?

The paper provides a synthetic and systematic description of the main topics of research in this field, as well as directions for future research, by summarizing unanswered questions and gaps in the existing literature to help future scholars advance the field further. To answer these questions, we conducted a systematic analysis of the academic literature (Kraus, Breier & Dasí-Rodríguez, 2020), collecting and analyzing scientific articles included in the Scopus, Web of Science, and PubMed databases. The main result is the identifcation and discussion of three main topics characterizing the investigated research domain, These topics are: 1. The technological perspective of I4.0, comprising study on how I4.0 technologies support HRM; 2. The human-centric perspective, which include studies dealing with the impact of I4.0 on HR and how technologies should be designed and implemented in a way that benefits society and enhances human well-being; 3. The organizational perspective, including papers entailing the organizational benefits of I4.0 technology adoption alongside HR processes. Based on this analysis, we provide an agenda for future research.

Literature reviews in the domain of human resource management (HRM) and industry 4.0The HRM literature has been extensively influenced by technological innovations. This has motivated some scholars to carry out systematic literature reviews (SLRs) to account for some aspects of the theoretical structure of HRM as a consequence of the technological and organizational changes in the working environment (van Harten et al., 2020). Although some studies have reviewed the current literature concerning HRM and technology innovation, very few have linked HRM with Industry 4.0.

Some SLRs have investigated the relationship of a single specific technology. For example, Marler and Fischer (2013) analyzed the relationship between HRM and Internet-based technology, reviewing the available research on e-HRM. This work aimed to provide evidence-based guidance to researchers and practitioners on the relationship between e-HRM and strategic HRM. Piccarozzi (2018) carried out a SLR to detect the topics and trends of “managerial” literature on Industry 4.0. The study identified a set of 10 research areas, one of which deals with HR. Arroyo and Osca (2019) reviewed the literature on big data and HRM, with a particular focus on the influences and effects of big data on HRM practices and systems. The results highlighted that big data is providing a new approach and methodology to manage data on employees and is offering opportunities for HRM. Ruparel et al. (2020) investigated the role of professional social media platforms in HRM (e.g. LinkedIn, Twitter, Meetup). They identified some broad themes related to the role of professional social media platforms in HRM processes, such as factors affecting the individual and organizational use of these platforms. These studies are focused on one-to-one relationships between a specific Industry 4.0 technology (e.g. big data, IoT, 3D manufacturing, etc.) and HRM.

To the best of our knowledge, the only SLR to investigate how Industry 4.0 affects the field of HRM was provided by Silva et al. (2022), who investigated HRM 4.0 with the aim of building a SLR. The authors analyzed 93 papers dating from 2017 to 2020. They found four main themes (HR digitalization, HR management, HR strategy, and HR competence) that represent the digital trends of Industry 4.0 impacting HRM. They used a broad set of keywords, treating “digital transformation” as synonymous with “Industry 4.0.” Notably, all these studies were carried out before the global COVID-19 pandemic, which has led to further HRM research.

MethodologyWe conducted a SLR to provide an overview of scientific research on synergies between Industry 4.0 and HRM. In line with the SLR principles provided by Tranfield, Denyer and Smart (2003), the research protocol we adopted consists of three main steps, namely paper location and selection, paper analysis, and results presentation/ analysis.

Paper location and selectionOur research is aimed at analyzing works at the intersection of Industry 4.0 and the HRM field of studies. In order to better define the boundaries of the phenomenon under investigation, we define below the search terms (Zahoor et al., 2020).

“Industry 4.0″ is an umbrella term referring to a new industrial paradigm embracing technologies such as cyber-physical systems (CPS), IoT, Internet of services (IoS), robotics, big data, cloud manufacturing, and augmented reality (Di Maria, De Marchi & Galeazzo, 2022; Pereira & Romero, 2017). According to Lichtblau et al. (2015), in addition to those already mentioned, other key elements of Industry 4.0 are machine learning, location detection technologies (GPS, Wi-Fi), augmented reality/ wearables, smart sensors, and 3D printing (Kong et al., 2019). In their SLR, Zheng et al. (2020) identified, among others, the following terms for Industry 4.0′s technologies: AI; blockchain; simulation and modeling; visualization technology; automation; industrial robots; and additive manufacturing. Industry 5.0 and related terms (I5.0, Fifth Industrial Revolution, 5th Industrial Revolution) were added to the research to complete the keywords set, although this is a quite new research field, referring more to a change in perspective in the adoption of Industry-4.0-related technologies than to a new industrial paradigm.

HRM is defined as the process of managing people in organizations in a structured and thorough manner (Beer, Spector, Lawrence, Quinn Mills & Walton, 1984) and includes all of the techniques employed to manage people and keep them up to date, qualified, and aligned according to the expectations of stakeholders (da Silva et al., 2022). It includes a set of processes, such as recruitment, selection, orientation, placement, training and development, performance appraisal, compensation, and benefits (Monks et al., 2013). Several SLRs on HRM have suggested relevant keywords in this research domain. Ruparel et al. (2020) adopted extremely specific search terms, such as “job,” “career,” “recruitment,” “selection,” “employability,” “human resource*,” and “HR*.” Other relevant terms, such as “talent management,” “workforce,” “work,” “work–life balance,” and “human capital” have also been highlighted (Markoulli, Lee, Byington & Felps, 2017). In their systematic review of HR systems, Boon, Den Hartog and Lepak (2019) adopted search terms such as “human resource management” (or human resource/ HR/ HRM) and “high performance/ involvement/ commitment work system” (or high performance/ involvement/ commitment HR/ HRM/ work practices).

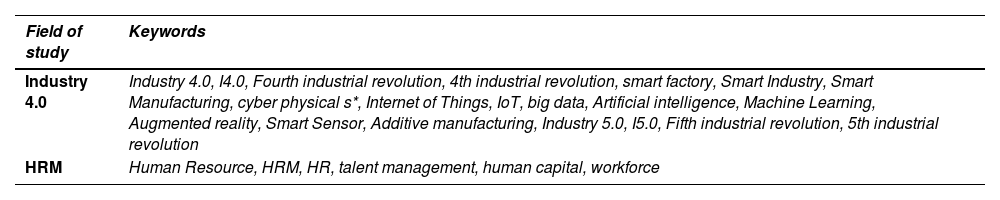

Starting from these literature sources, we were able to define the two sets of relevant keywords to be adopted in our database searches that are related to the research domains of Industry 4.0 and HRM, respectively (see Table 1).

sets of keywords for database research.

| Field of study | Keywords |

|---|---|

| Industry 4.0 | Industry 4.0, I4.0, Fourth industrial revolution, 4th industrial revolution, smart factory, Smart Industry, Smart Manufacturing, cyber physical s*, Internet of Things, IoT, big data, Artificial intelligence, Machine Learning, Augmented reality, Smart Sensor, Additive manufacturing, Industry 5.0, I5.0, Fifth industrial revolution, 5th industrial revolution |

| HRM | Human Resource, HRM, HR, talent management, human capital, workforce |

The search string was structured so that the results contained papers with at least one term from each set in the title, abstract, and keywords. We selected Elsevier's Scopus, Web of Science (WoS), and PubMed as scientific databases in which to perform our search. The first two sources are widely recognized as relevant and comprehensive scientific databases in the managerial field of study (Bhimani, Mention & Barlatier, 2019), while PubMed is the most relevant archive of biomedical and life sciences journal literature (Han et al., 2022).

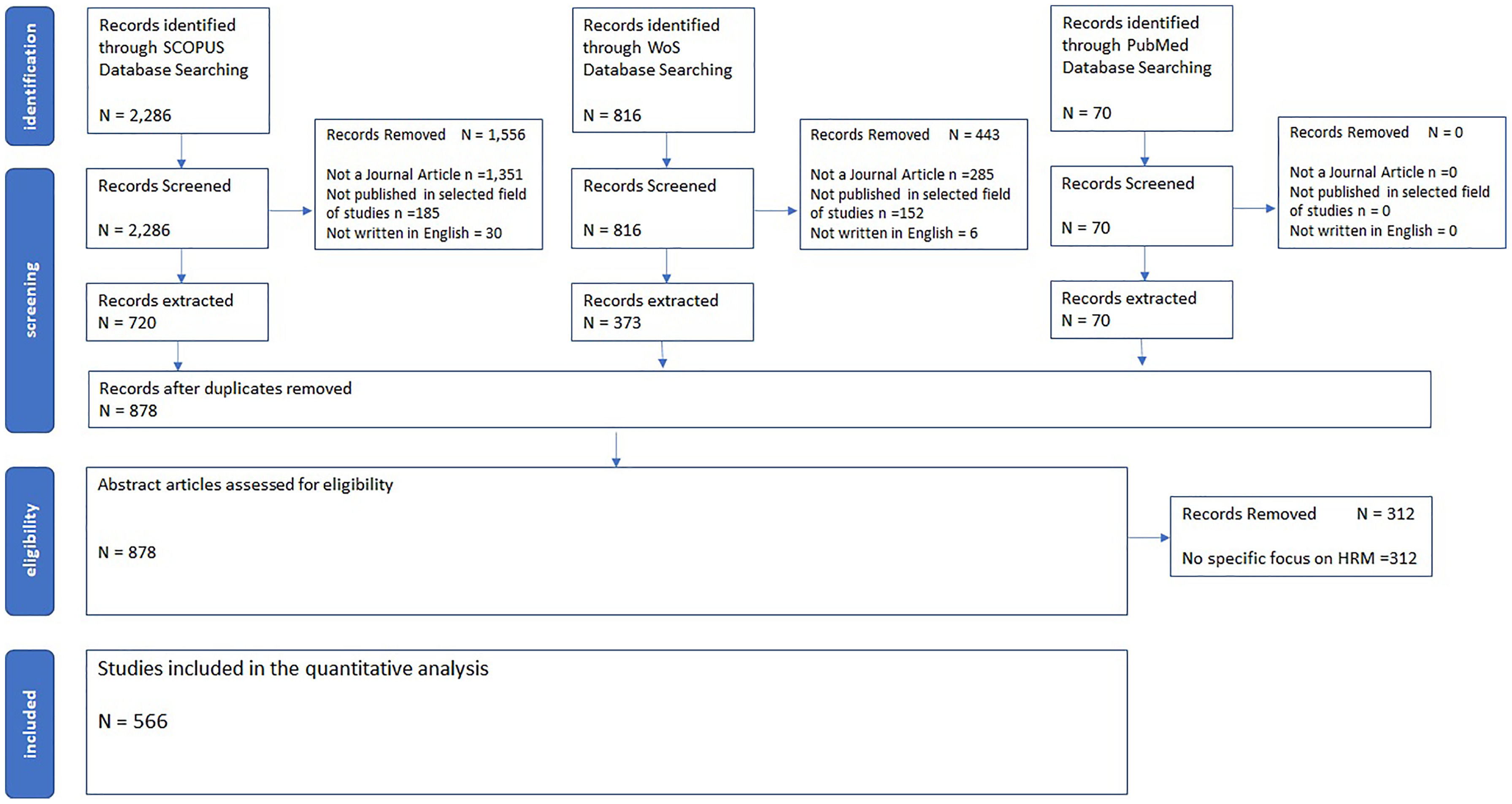

We performed the search at the beginning of October 2022, finding 2286 papers from Scopus, 816 papers from WoS, and 70 papers from PubMed. The following selection criteria were then introduced to ensure the quality and relevance of the papers to be analyzed:

- •

papers are written in English;

- •

papers are published in scientific journals;

- •

papers are indexed at least in one of the following subject areas: Business, Management and Accounting; Social Sciences; Engineering; Economics, Econometrics and Finance; and Decision Sciences.

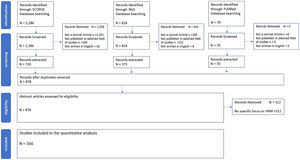

At the end of this step, we were left with 720 journal articles from Scopus, 373 articles from WoS, and 70 articles from PubMed. We then merged results from the three scientific databases, finding 878 unique papers. We manually analyzed the title and abstract of each paper to decide whether it matched the focus of our study (Christofi et al., 2021; Kraus et al., 2022). At the end of this process, a total of 566 papers to be analyzed has been found. The flow diagram in Fig. 1 graphically summarizes how the paper location and selection step was conducted.

Paper analysisWe performed a bibliometric analysis on our sample and examined the papers to evidence relationships and common points among them. The dataset was cleaned by removing stopwords and other terms (e.g. scholars’ affiliation, copyright statements, nationalities) that could be misleading with respect to our objectives. We utilized a text-mining approach based on latent Dirichlet allocation (LDA) to reveal the research topics in the context of HRM and Industry 4.0. The LDA technique gives as output k sets of relevant keywords (where each set represent a topic) and the document-term matrix, i.e. a matrix describing how much each paper is devoted to a specific topic (i.e. topic proportion).

To perform this activity, we utilized MySLR software (Ammirato, Felicetti, Rògano, Linzalone & Corvello, 2022), which is a semi-automated tool supporting researchers in performing SLRs.

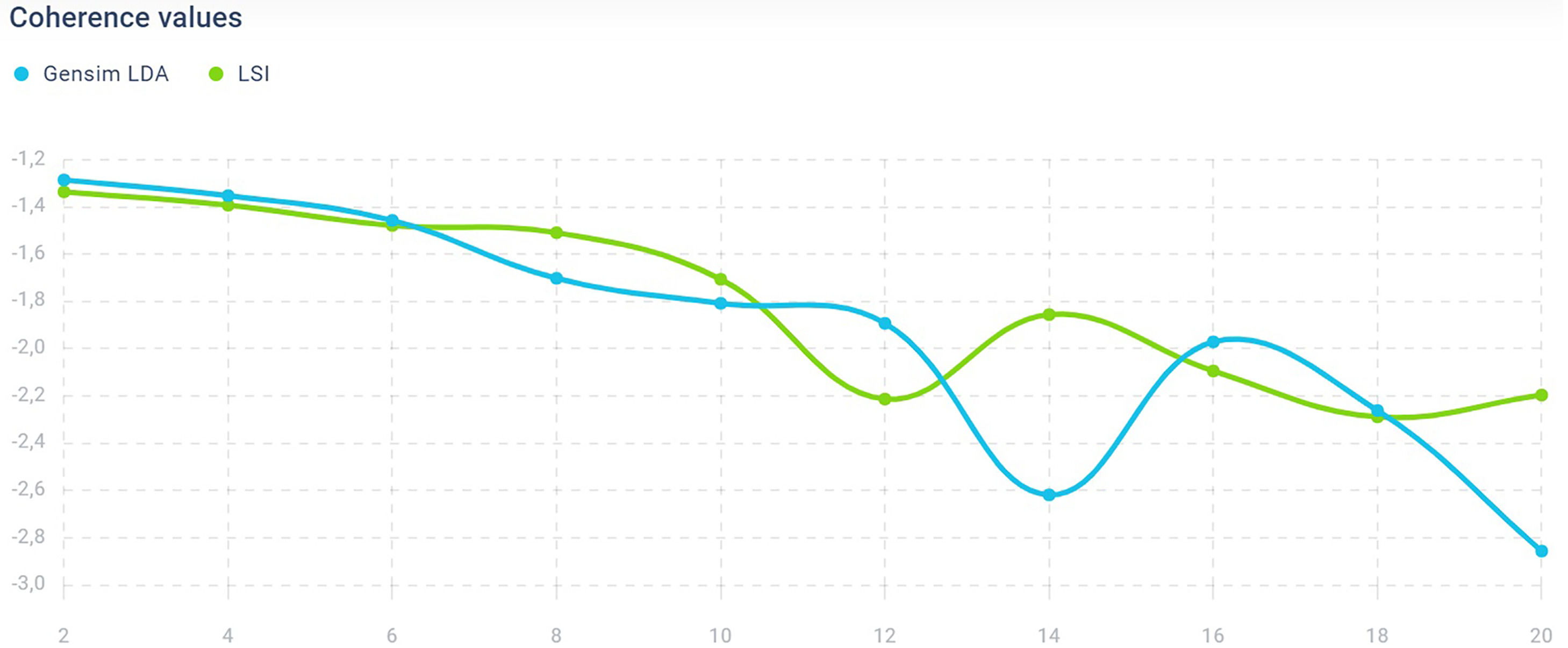

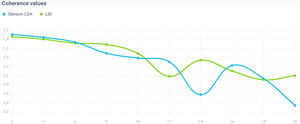

Following Blei (2012), we selected k, i.e. the number of topics to be extracted, by evaluating multiple LDA results with k ranging from 2 to 20. We chose k and the LDA algorithm to guarantee a sufficiently high value of topic coherence (Chen & Liu, 2014) and, at the same time, a simple interpretation of the results for a human reader. As shown in Fig. 2, the most meaningful set of topics was achieved with k = 3.

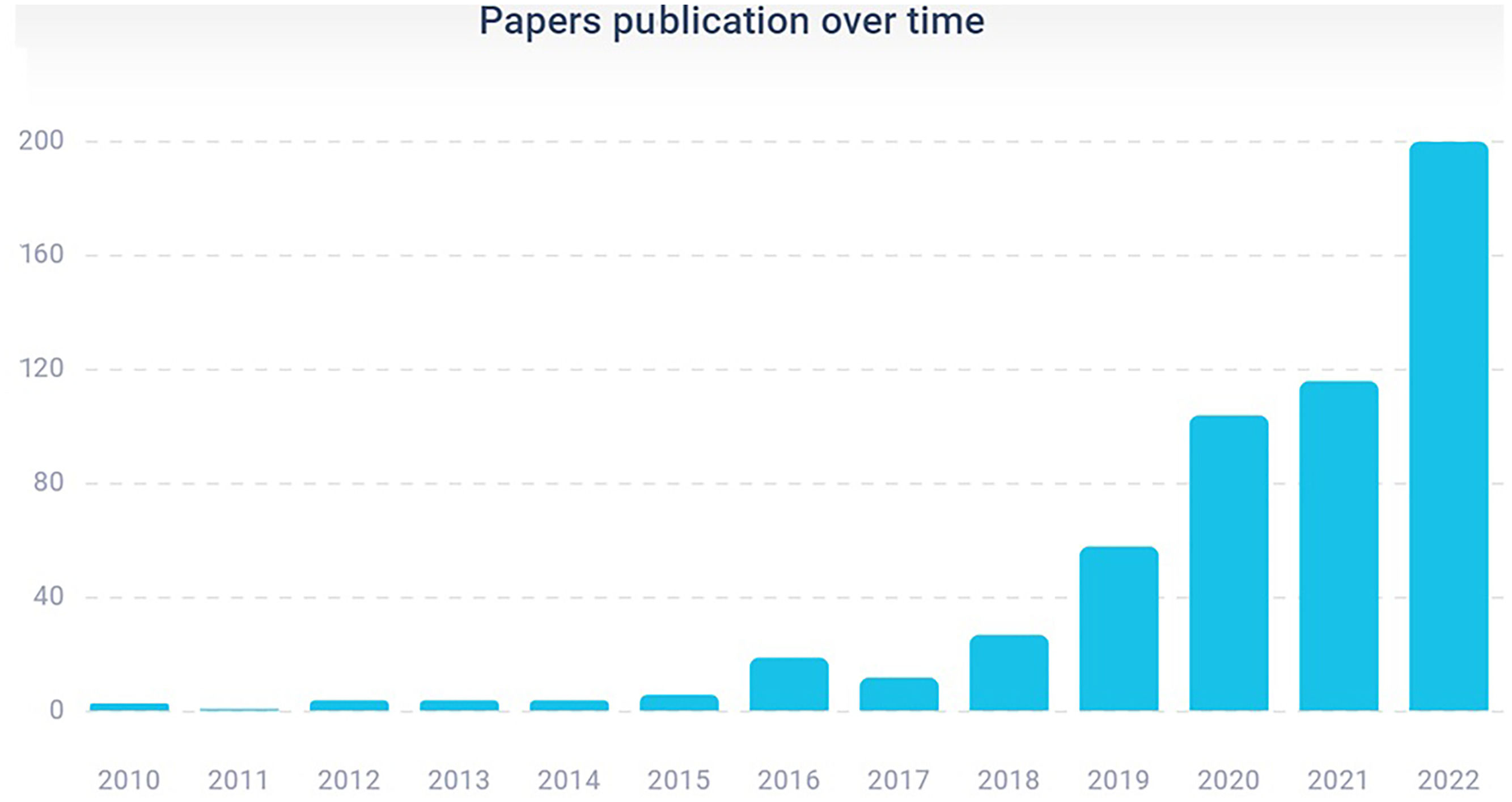

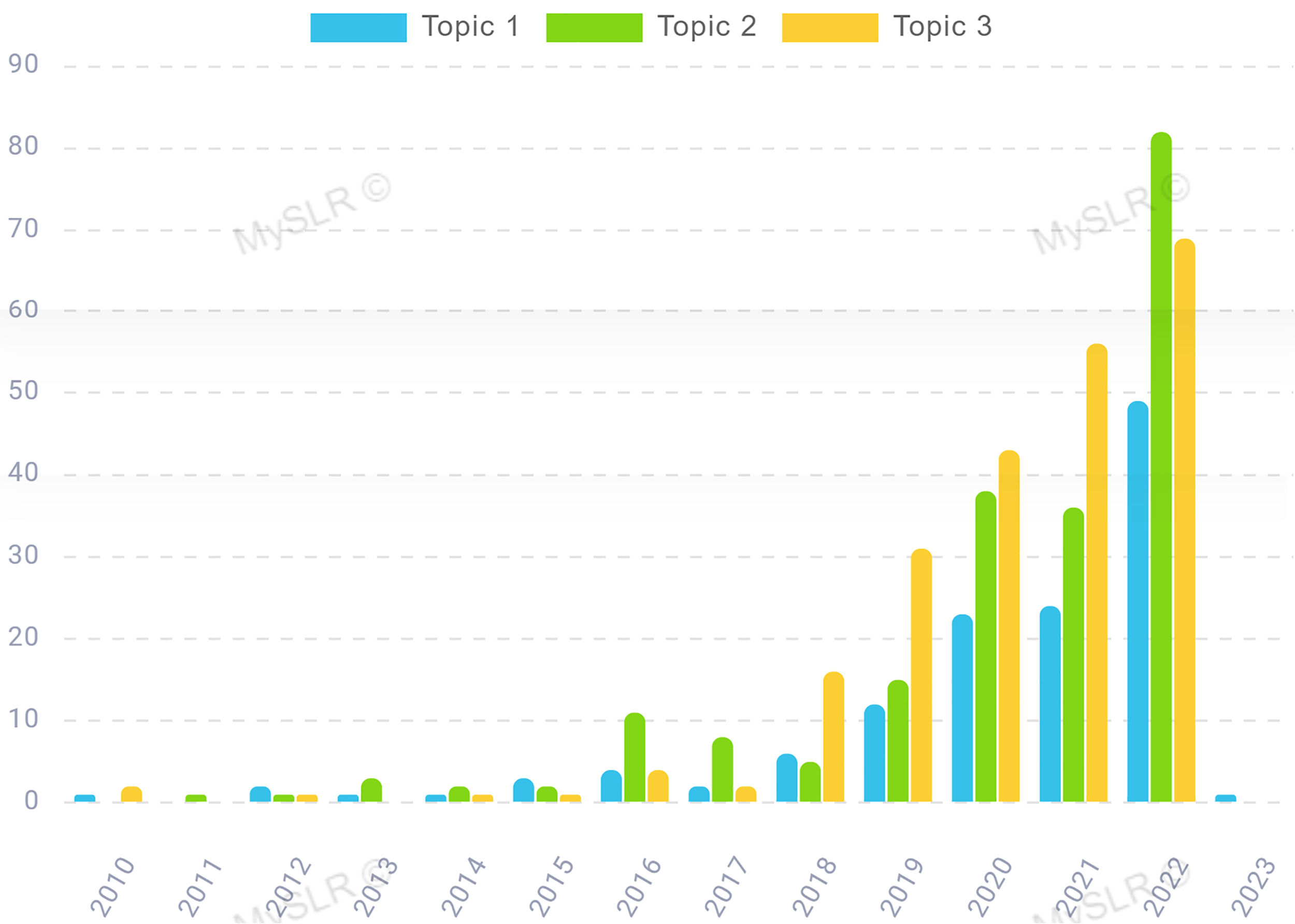

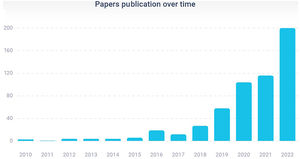

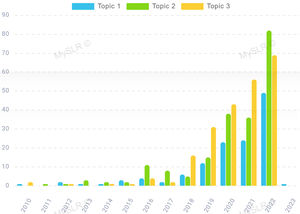

Results synthesisBibliometric analysisThe distribution of articles by year of publication shows that research at the intersection between Industry 4.0 and HRM has garnered increasing interest over recent years, as shown in Fig. 3.

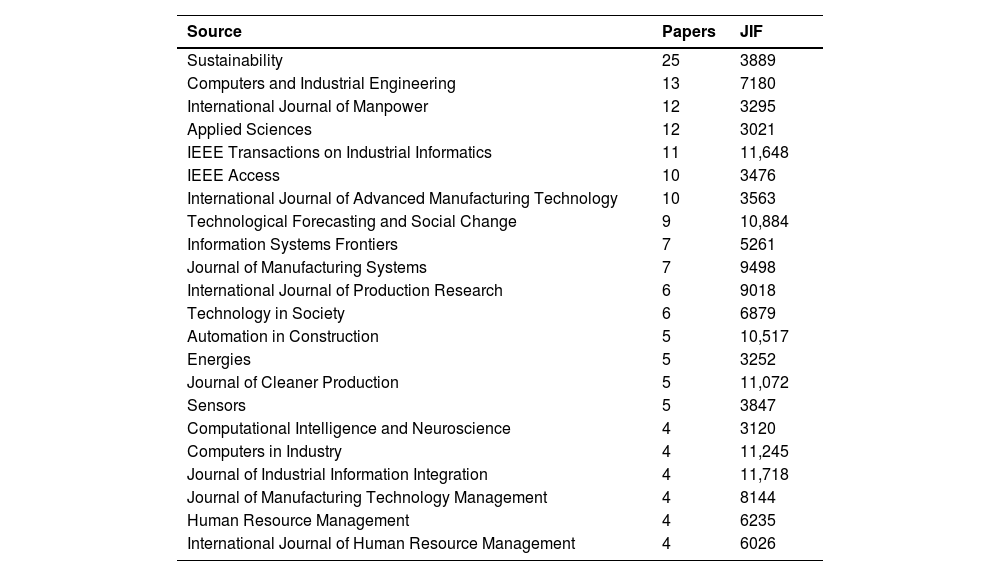

Most research was published in 2022 (n = 200), a year that experienced a growth of 84 research papers compared to the previous year (n = 116). In fact, 2022 saw an explosion of publications in this area of research, since in this year an amount of works equal to 35% of the total was published. Regarding the distribution of articles by publication outlet, the 566 papers in our sample were published on 311 journals, showing a high heterogeneity in terms of editorial collocation. Sustainability is the most prolific home for research on HRM and Industry 4.0 (n = 25 articles), followed by Computers and Industrial Engineering (n = 13), International Journal of Manpower (n = 12), and Applied Science (n = 12). As shown in Table 2, most publication outlets on this list are journals that are ranked with a journal impact factor greater than 3. This suggests that research on HRM and Industry 4.0 is welcomed in relevant journals.

Top contributing journals with 4 or more published articles.

| Source | Papers | JIF |

|---|---|---|

| Sustainability | 25 | 3889 |

| Computers and Industrial Engineering | 13 | 7180 |

| International Journal of Manpower | 12 | 3295 |

| Applied Sciences | 12 | 3021 |

| IEEE Transactions on Industrial Informatics | 11 | 11,648 |

| IEEE Access | 10 | 3476 |

| International Journal of Advanced Manufacturing Technology | 10 | 3563 |

| Technological Forecasting and Social Change | 9 | 10,884 |

| Information Systems Frontiers | 7 | 5261 |

| Journal of Manufacturing Systems | 7 | 9498 |

| International Journal of Production Research | 6 | 9018 |

| Technology in Society | 6 | 6879 |

| Automation in Construction | 5 | 10,517 |

| Energies | 5 | 3252 |

| Journal of Cleaner Production | 5 | 11,072 |

| Sensors | 5 | 3847 |

| Computational Intelligence and Neuroscience | 4 | 3120 |

| Computers in Industry | 4 | 11,245 |

| Journal of Industrial Information Integration | 4 | 11,718 |

| Journal of Manufacturing Technology Management | 4 | 8144 |

| Human Resource Management | 4 | 6235 |

| International Journal of Human Resource Management | 4 | 6026 |

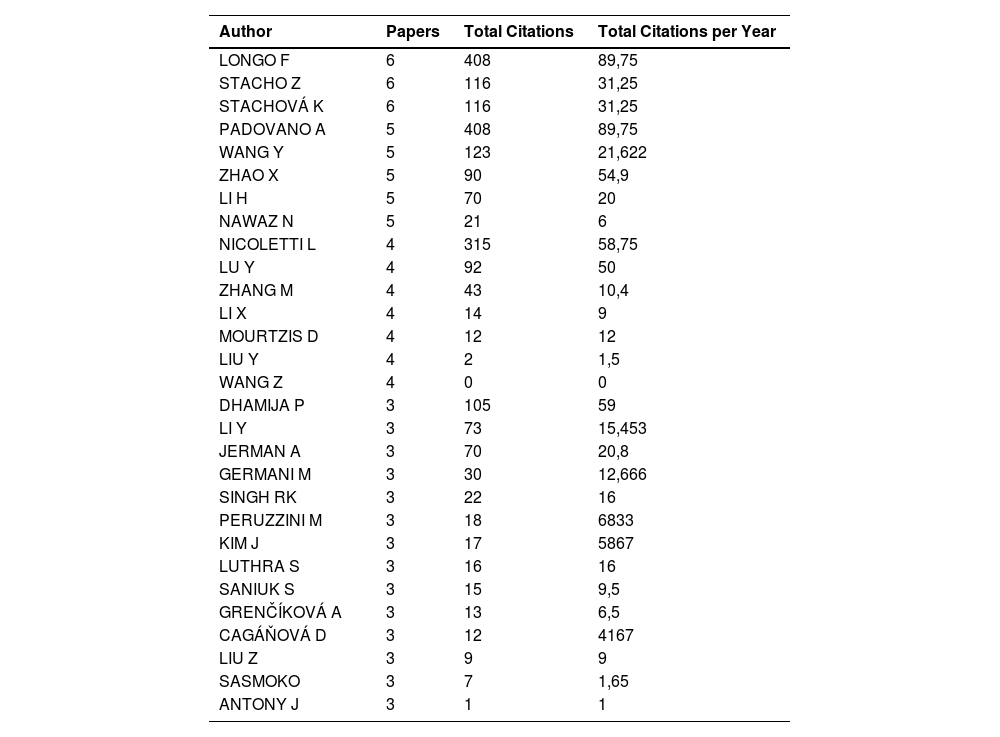

As shown in Table 3, the distribution of articles by authors indicates that Francesco Longo from the University of Calabria is the most prolific author working on HRM and Industry 4.0, since he has published the highest number of articles on the topic (n = 6 articles) and he has received the highest number of citations (n = 408 total citations). Out of the six articles that Longo has published, five articles were co-authored with Antonio Padovano and four were coauthored with Letizia Nicoletti from the same university. Notably, their seminal article (“Smart operators in industry 4.0: A human-centered approach to enhance operators’ capabilities and competencies within the new smart factory context;” Longo, Nicoletti & Padovano, 2017) is the most cited article (n = 285 citations) globally (see Table 3). The same article, together with another article by Longo et al. (2020), received the most local citations, i.e. citations from papers included in the analyzed collection (21 each). These works mainly deal with approaches to enhance smart operators’ competencies.

Top contributing authors with three or more published articles on HRM and Industry 4.0.

| Author | Papers | Total Citations | Total Citations per Year |

|---|---|---|---|

| LONGO F | 6 | 408 | 89,75 |

| STACHO Z | 6 | 116 | 31,25 |

| STACHOVÁ K | 6 | 116 | 31,25 |

| PADOVANO A | 5 | 408 | 89,75 |

| WANG Y | 5 | 123 | 21,622 |

| ZHAO X | 5 | 90 | 54,9 |

| LI H | 5 | 70 | 20 |

| NAWAZ N | 5 | 21 | 6 |

| NICOLETTI L | 4 | 315 | 58,75 |

| LU Y | 4 | 92 | 50 |

| ZHANG M | 4 | 43 | 10,4 |

| LI X | 4 | 14 | 9 |

| MOURTZIS D | 4 | 12 | 12 |

| LIU Y | 4 | 2 | 1,5 |

| WANG Z | 4 | 0 | 0 |

| DHAMIJA P | 3 | 105 | 59 |

| LI Y | 3 | 73 | 15,453 |

| JERMAN A | 3 | 70 | 20,8 |

| GERMANI M | 3 | 30 | 12,666 |

| SINGH RK | 3 | 22 | 16 |

| PERUZZINI M | 3 | 18 | 6833 |

| KIM J | 3 | 17 | 5867 |

| LUTHRA S | 3 | 16 | 16 |

| SANIUK S | 3 | 15 | 9,5 |

| GRENČÍKOVÁ A | 3 | 13 | 6,5 |

| CAGÁŇOVÁ D | 3 | 12 | 4167 |

| LIU Z | 3 | 9 | 9 |

| SASMOKO | 3 | 7 | 1,65 |

| ANTONY J | 3 | 1 | 1 |

Katarína Stachová and Zdenko Stacho from the School of Economics and Management in Public Administration in Bratislava contributed with six articles and 116 total citations. Their most cited paper (Stachová, Papula, Stacho & Kohnová, 2019) deals with the adoption of strategic approaches to employee education and development to face Industry 4.0 challenges and has five local citations. The most cited articles in the analyzed collection, with 30 or more total citations, are reported in Table 3.

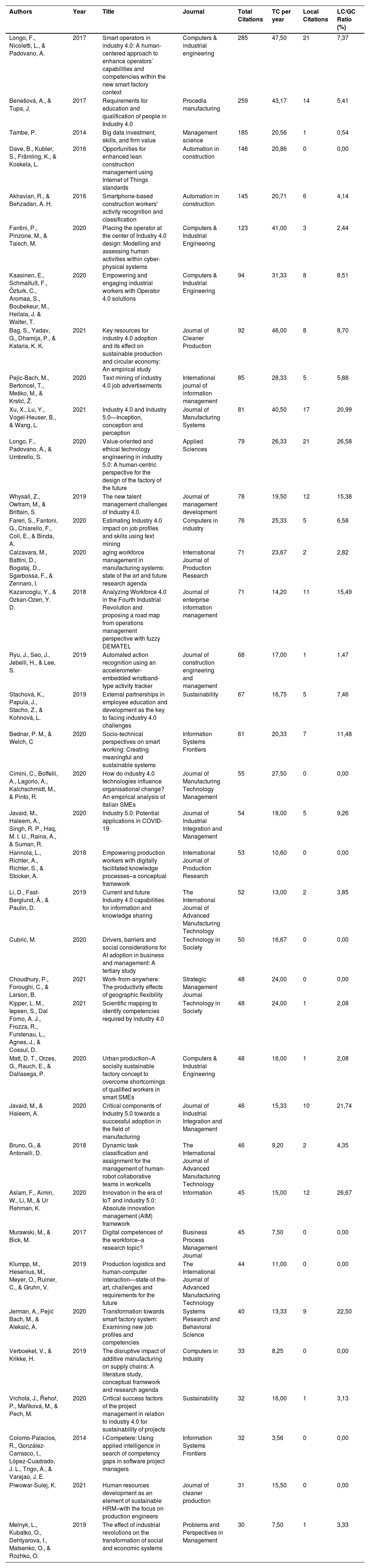

As reported in Table 4, If we look at the publication outlets of the most cited papers, Computers & Industrial Engineering (n = 4) is the journal with the largest number of publications on the topic investigated, with more than 30 citations, followed by The International Journal of Advanced Manufacturing Technology (n = 3) and Automation in Construction, Computers in Industry, Information Systems Frontiers, International Journal of Production Research, Journal of Cleaner Production, Journal of Industrial Integration and Management, Sustainability, and Technology in Society (n = 2).

Most cited articles in the analyzed collection (30 or more total citations).

| Authors | Year | Title | Journal | Total Citations | TC per year | Local Citations | LC/GC Ratio (%) |

|---|---|---|---|---|---|---|---|

| Longo, F., Nicoletti, L., & Padovano, A. | 2017 | Smart operators in industry 4.0: A human-centered approach to enhance operators’ capabilities and competencies within the new smart factory context | Computers & industrial engineering | 285 | 47,50 | 21 | 7,37 |

| Benešová, A., & Tupa, J. | 2017 | Requirements for education and qualification of people in Industry 4.0 | Procedia manufacturing | 259 | 43,17 | 14 | 5,41 |

| Tambe, P. | 2014 | Big data investment, skills, and firm value | Management science | 185 | 20,56 | 1 | 0,54 |

| Dave, B., Kubler, S., Främling, K., & Koskela, L. | 2016 | Opportunities for enhanced lean construction management using Internet of Things standards | Automation in construction | 146 | 20,86 | 0 | 0,00 |

| Akhavian, R., & Behzadan, A. H. | 2016 | Smartphone-based construction workers' activity recognition and classification | Automation in construction | 145 | 20,71 | 6 | 4,14 |

| Fantini, P., Pinzone, M., & Taisch, M. | 2020 | Placing the operator at the center of Industry 4.0 design: Modelling and assessing human activities within cyber-physical systems | Computers & Industrial Engineering | 123 | 41,00 | 3 | 2,44 |

| Kaasinen, E., Schmalfuß, F., Özturk, C., Aromaa, S., Boubekeur, M., Heilala, J. & Walter, T. | 2020 | Empowering and engaging industrial workers with Operator 4.0 solutions | Computers & Industrial Engineering | 94 | 31,33 | 8 | 8,51 |

| Bag, S., Yadav, G., Dhamija, P., & Kataria, K. K. | 2021 | Key resources for industry 4.0 adoption and its effect on sustainable production and circular economy: An empirical study | Journal of Cleaner Production | 92 | 46,00 | 8 | 8,70 |

| Pejic-Bach, M., Bertoncel, T., Meško, M., & Krstić, Ž. | 2020 | Text mining of industry 4.0 job advertisements | International journal of information management | 85 | 28,33 | 5 | 5,88 |

| Xu, X., Lu, Y., Vogel-Heuser, B., & Wang, L. | 2021 | Industry 4.0 and Industry 5.0—Inception, conception and perception | Journal of Manufacturing Systems | 81 | 40,50 | 17 | 20,99 |

| Longo, F., Padovano, A., & Umbrello, S. | 2020 | Value-oriented and ethical technology engineering in industry 5.0: A human-centric perspective for the design of the factory of the future | Applied Sciences | 79 | 26,33 | 21 | 26,58 |

| Whysall, Z., Owtram, M., & Brittain, S. | 2019 | The new talent management challenges of Industry 4.0. | Journal of management development | 78 | 19,50 | 12 | 15,38 |

| Fareri, S., Fantoni, G., Chiarello, F., Coli, E., & Binda, A. | 2020 | Estimating Industry 4.0 impact on job profiles and skills using text mining | Computers in industry | 76 | 25,33 | 5 | 6,58 |

| Calzavara, M., Battini, D., Bogataj, D., Sgarbossa, F., & Zennaro, I. | 2020 | aging workforce management in manufacturing systems: state of the art and future research agenda | International Journal of Production Research | 71 | 23,67 | 2 | 2,82 |

| Kazancoglu, Y., & Ozkan-Ozen, Y. D. | 2018 | Analyzing Workforce 4.0 in the Fourth Industrial Revolution and proposing a road map from operations management perspective with fuzzy DEMATEL | Journal of enterprise information management | 71 | 14,20 | 11 | 15,49 |

| Ryu, J., Seo, J., Jebelli, H., & Lee, S. | 2019 | Automated action recognition using an accelerometer-embedded wristband-type activity tracker | Journal of construction engineering and management | 68 | 17,00 | 1 | 1,47 |

| Stachová, K., Papula, J., Stacho, Z., & Kohnová, L. | 2019 | External partnerships in employee education and development as the key to facing industry 4.0 challenges | Sustainability | 67 | 16,75 | 5 | 7,46 |

| Bednar, P. M., & Welch, C | 2020 | Socio-technical perspectives on smart working: Creating meaningful and sustainable systems | Information Systems Frontiers | 61 | 20,33 | 7 | 11,48 |

| Cimini, C., Boffelli, A., Lagorio, A., Kalchschmidt, M., & Pinto, R. | 2020 | How do industry 4.0 technologies influence organisational change? An empirical analysis of Italian SMEs | Journal of Manufacturing Technology Management | 55 | 27,50 | 0 | 0,00 |

| Javaid, M., Haleem, A., Singh, R. P., Haq, M. I. U., Raina, A., & Suman, R. | 2020 | Industry 5.0: Potential applications in COVID-19 | Journal of Industrial Integration and Management | 54 | 18,00 | 5 | 9,26 |

| Hannola, L., Richter, A., Richter, S., & Stocker, A. | 2018 | Empowering production workers with digitally facilitated knowledge processes–a conceptual framework | International Journal of Production Research | 53 | 10,60 | 0 | 0,00 |

| Li, D., Fast-Berglund, Å., & Paulin, D. | 2019 | Current and future Industry 4.0 capabilities for information and knowledge sharing | The International Journal of Advanced Manufacturing Technology | 52 | 13,00 | 2 | 3,85 |

| Cubric, M. | 2020 | Drivers, barriers and social considerations for AI adoption in business and management: A tertiary study | Technology in Society | 50 | 16,67 | 0 | 0,00 |

| Choudhury, P., Foroughi, C., & Larson, B. | 2021 | Work‐from‐anywhere: The productivity effects of geographic flexibility | Strategic Management Journal | 48 | 24,00 | 0 | 0,00 |

| Kipper, L. M., Iepsen, S., Dal Forno, A. J., Frozza, R., Furstenau, L., Agnes, J., & Cossul, D. | 2021 | Scientific mapping to identify competencies required by industry 4.0 | Technology in Society | 48 | 24,00 | 1 | 2,08 |

| Matt, D. T., Orzes, G., Rauch, E., & Dallasega, P. | 2020 | Urban production–A socially sustainable factory concept to overcome shortcomings of qualified workers in smart SMEs | Computers & Industrial Engineering | 48 | 16,00 | 1 | 2,08 |

| Javaid, M., & Haleem, A. | 2020 | Critical components of Industry 5.0 towards a successful adoption in the field of manufacturing | Journal of Industrial Integration and Management | 46 | 15,33 | 10 | 21,74 |

| Bruno, G., & Antonelli, D. | 2018 | Dynamic task classification and assignment for the management of human-robot collaborative teams in workcells | The International Journal of Advanced Manufacturing Technology | 46 | 9,20 | 2 | 4,35 |

| Aslam, F., Aimin, W., Li, M., & Ur Rehman, K. | 2020 | Innovation in the era of IoT and industry 5.0: Absolute innovation management (AIM) framework | Information | 45 | 15,00 | 12 | 26,67 |

| Murawski, M., & Bick, M. | 2017 | Digital competences of the workforce–a research topic? | Business Process Management Journal | 45 | 7,50 | 0 | 0,00 |

| Klumpp, M., Hesenius, M., Meyer, O., Ruiner, C., & Gruhn, V. | 2019 | Production logistics and human-computer interaction—state-of-the-art, challenges and requirements for the future | The International Journal of Advanced Manufacturing Technology | 44 | 11,00 | 0 | 0,00 |

| Jerman, A., Pejić Bach, M., & Aleksić, A. | 2020 | Transformation towards smart factory system: Examining new job profiles and competencies | Systems Research and Behavioral Science | 40 | 13,33 | 9 | 22,50 |

| Verboeket, V., & Krikke, H. | 2019 | The disruptive impact of additive manufacturing on supply chains: A literature study, conceptual framework and research agenda | Computers in Industry | 33 | 8,25 | 0 | 0,00 |

| Vrchota, J., Řehoř, P., Maříková, M., & Pech, M. | 2020 | Critical success factors of the project management in relation to industry 4.0 for sustainability of projects | Sustainability | 32 | 16,00 | 1 | 3,13 |

| Colomo-Palacios, R., González-Carrasco, I., López-Cuadrado, J. L., Trigo, A., & Varajao, J. E. | 2014 | I-Competere: Using applied intelligence in search of competency gaps in software project managers | Information Systems Frontiers | 32 | 3,56 | 0 | 0,00 |

| Piwowar-Sulej, K. | 2021 | Human resources development as an element of sustainable HRM–with the focus on production engineers | Journal of cleaner production | 31 | 15,50 | 0 | 0,00 |

| Melnyk, L., Kubatko, O., Dehtyarova, I., Matsenko, O., & Rozhko, O. | 2019 | The effect of industrial revolutions on the transformation of social and economic systems | Problems and Perspectives in Management | 30 | 7,50 | 1 | 3,33 |

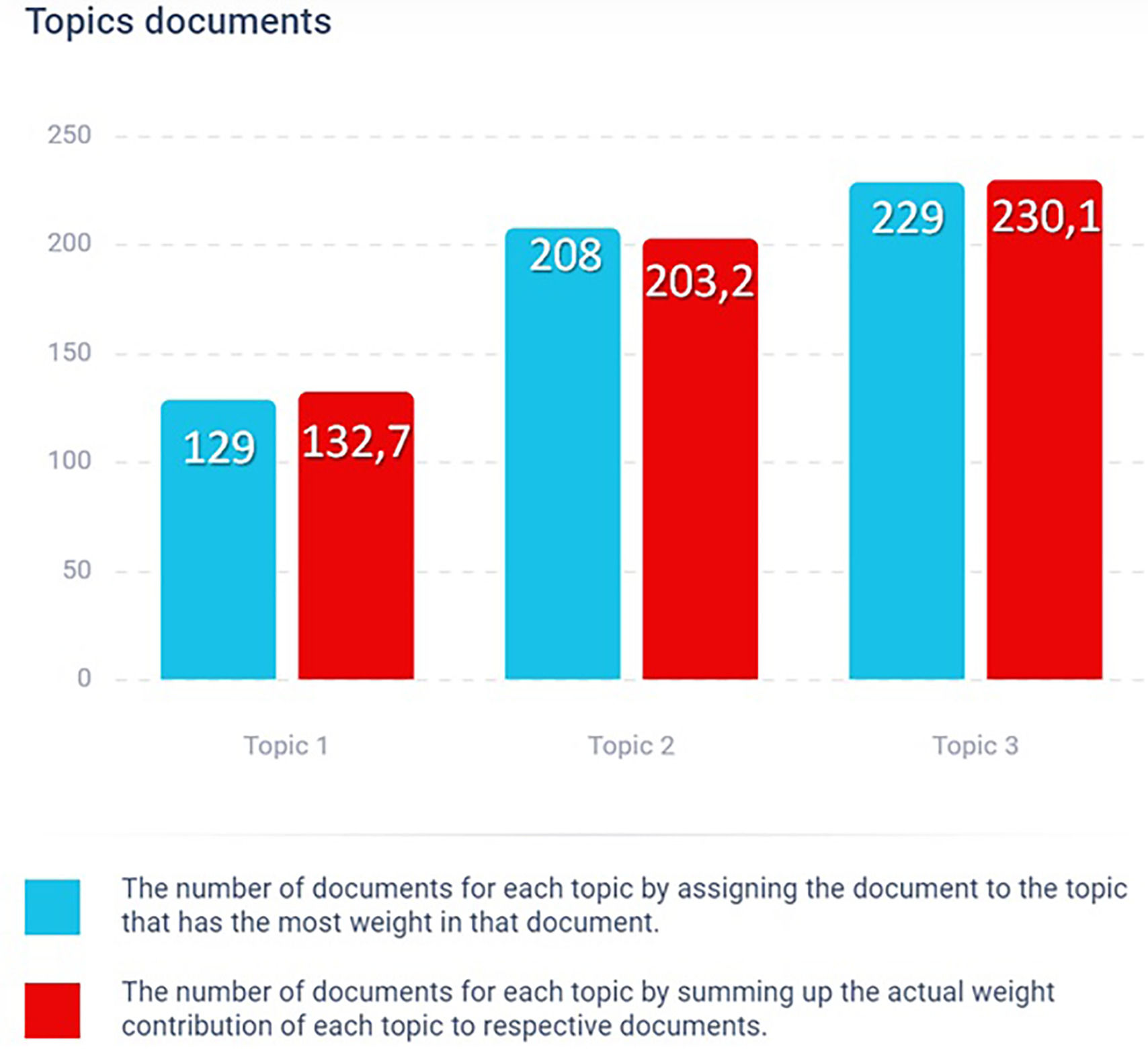

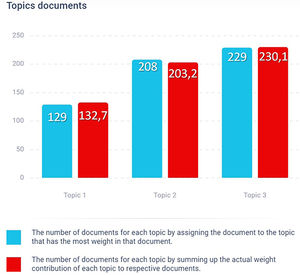

Three topics were identified through the LDA procedure, each of which is related to a different perspective: technological for topic 1; human-centric for topic 2; and organizational for topic 3.

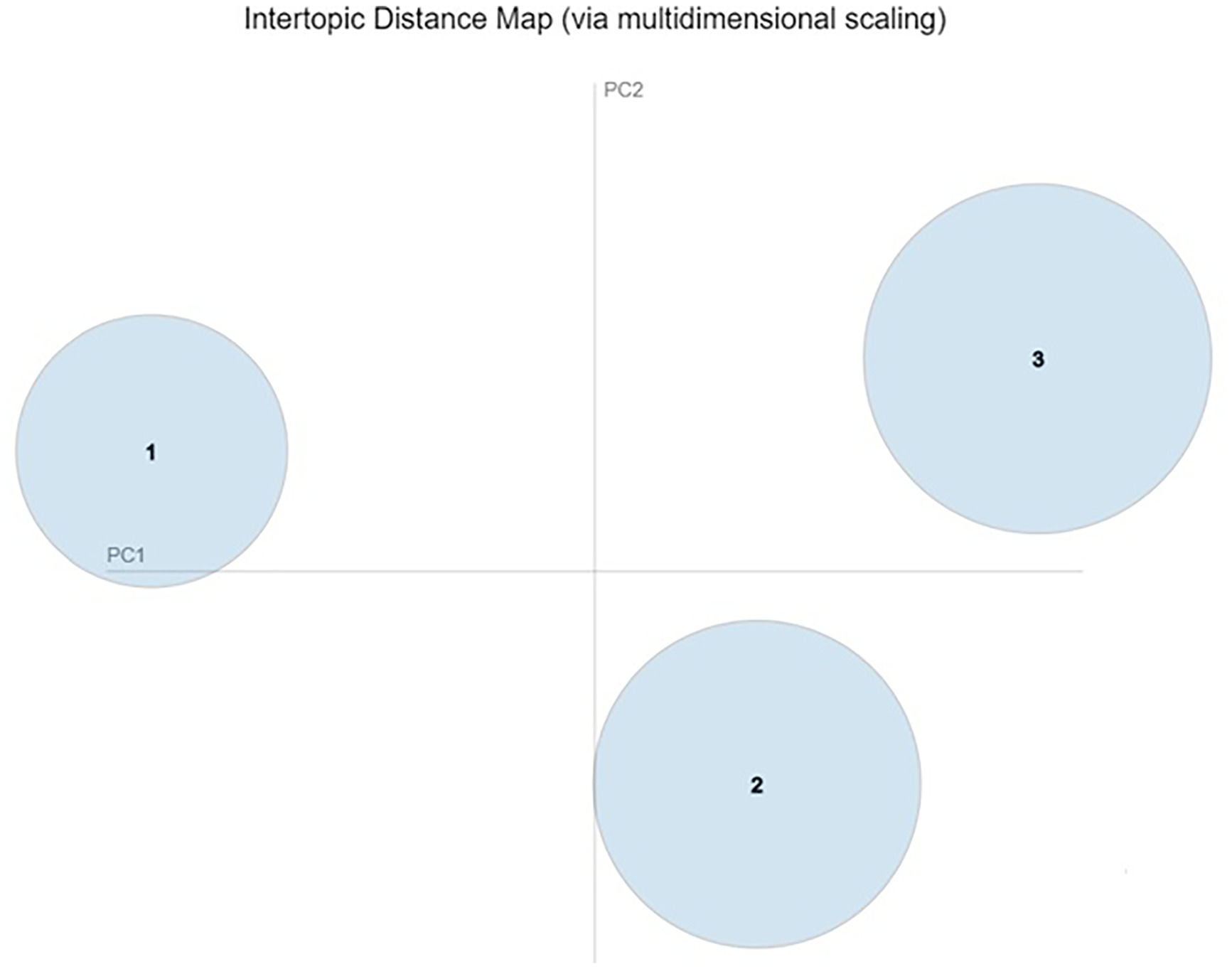

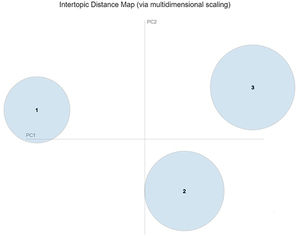

As shown in Fig. 4, the LDA procedure assigned 129 papers to topic 1, 208 papers to topic 2, and 229 papers to topic 3. The blue column shows the number of documents for each topic by assigning the paper to the topic with the highest weight in the document-term matrix obtained as the output of the LDA procedure, while the red column represents the sum of the actual weight contribution of each topic given by the respective documents. This would seem to suggest a strong polarization of the documents on the individual topics; in other words, the papers that are assigned to a topic have little to do with the other topics. This insight is confirmed by the intertopic distance map, a visualization of the topics in a two-dimensional space, where the area of these topic circles is proportional to the number of words that belong to each topic across the dictionary (see Fig. 5). Furthermore, the more these areas are distant, the fewer keywords the topics have in common.

Some interesting considerations emerge when analyzing the evolution of the publications within topics over time (see Fig. 6):

- •

The number of papers is rapidly increasing, both overall and in each topic; therefore, all the topics represent both present and future research areas.

- •

A deep examination of the data up to 2021 (excluding the ongoing publication year of 2022) highlights that topic 3 had the highest growth rate in terms of papers, while topics 1 and 3 appeared to slow down in the last year. Considering the characteristics of topic 3, this could be interpreted as a more traditional look at Industry 4.0 technologies as a support for HRM performance optimization. According to Liboni et al. (2019), we could refer to this topic also as HRM 4.0.

- •

In 2022, a renewed interest in Industry 4.0 and HRM is clear in each topic. Notably, there is a high growth rate in topic 2. This may be owing to scholars’ desire to support society to overcome the effects of unexpected crises, on the one hand, and the pathway that policymakers aim to follow to face such situations (EU Commission, 2022), on the other hand, thus boosting the scientific production in this research field. It seems that scholars are looking at Industry 4.0 technologies as leverage for a new dimension of HRM. Extending the concepts in Xu et al. (2021) to HRM, we could refer to this topic as HRM 5.0

In the following, the three topics identified through the LDA procedure are presented and discussed.

Topic 1. The technological perspective: Industry 4.0 technologies for HRM. This concerns the exploitation of Industry 4.0 technologies, applied to the workforce or to work, to support HR managers in the execution and/ or innovation of HR activities, encompassing workforce distribution, workload allocation, planning/ control of production activities (Akhavian et al., 2016), and human–technology integration (Bruno & Antonelli, 2018; Fantini et al., 2020; Longo et al., 2020).

An important aspect deals with the design of Industry 4.0 technologies for the automation of human activities. Technologies may automate repetitive and time-consuming tasks and let people focus on more strategic and value-adding activities (Stadnika & Antonelli, 2019). Robots and other forms of automation allow operational planning and control of activities (Akhavian & Behzadan, 2016), as well as the optimization of the use of space, resources, and equipment.

Some works have addressed the use of Industry 4.0 technologies for workers’ activity tracking. Akhavian and Behzadan (2016) proposed a solution based on embedded smartphone sensors to track workers’ movements and actions, while Riu et al. (2019) described a system for recognizing actions using an accelerometer-embedded wristband-type activity tracker. In both cases, machine learning algorithms were used to classify and identify the specific tasks being performed.

Another key aspect of Industry 4.0 technology in HRM is the use of big data and analytics to improve decision-making (S. Bresciani et al., 2021; Sahoo et al., 2019; Yi & Liu, 2020). For example, data from IoT sensors and other sources can be used to track employee performance, attendance, and productivity, allowing HR managers to identify areas for improvement and make more informed decisions about staffing and training (Hamilton & Sodeman, 2020). Additionally, AI-powered chatbots and virtual assistants can help with recruitment, onboarding, and employee engagement (Albert, 2019).

Augmented reality and virtual reality represent relevant applications in the field of Industry 4.0 technologies with a significant impact on HRM. Various applications of augmented reality in the manufacturing sector have been found in the literature, with particular attention paid to repair and maintenance work (Koteleva et al., 2022; Palmarini et al., 2018). Khandelwal and Upadhyay (2021) critically reviewed applications of virtual reality in the area of human resource development. Some works have evidenced how virtual reality allows remote interactions among workers (Sivathanu & Pillai, 2018). Virtual reality allows us to overcome the challenges of time and distance, thus making learning and development current, efficient, and effective (Schmid Mast et al., 2018).

The deployment of so-called “cobots” (collaborative robots) has changed the game in the Industry 4.0 context (Bruno & Antonelli, 2018). Cobots work side by side with human operators on joint tasks (Paliga, 2022), allowing them to merge the productivity of automated systems with the flexibility and dexterity of human operators (Faccio et al., 2023). Faccio et al. (2023) carried out a literature review on cobots, considering three main dimensions: robot features; modern production systems’ characteristics; and human factors. El Zaatari et al. (2019) provided an overview of collaborative industrial scenarios and programming requirements for cobot applications. Cobot technologies have been featured in three categories, namely communication, optimization, and learning features.

Other research has investigated machine learning methodologies and software (e.g. radial basis function, multilayer perceptron neural networks, etc.; Oliveira et al., 2010) and neural networks (Colomo-Palacios et al., 2016) for HRM.

However, vulnerability and HR security-related issues may occur where “everything is connected with everything else” (i.e. smart factories) without other forms of governance (Ozdemir, 2018). On the one hand, these highly integrated systems exploit the opportunities of Industry 4.0 but, on the other hand, they make the factory vulnerable to systemic risks, such as total network collapse from hacking or Internet viruses.

Studies on this topic tend to provide methodologies to support the design of different work configurations based either on a more human or more technological framework (Longo et al., 2020).

Within this topic, many studies are contextualized to modeling (projects, manufacturing lines) or specific sectors, e.g. construction (Akhavian et al., 2016; Ryu et al., 2019), software projects (Colomo-Palacios et al., 2014; Oliveira et al., 2010; Ryu et al., 2019), and manufacturing in smart factories (Bruno & Antonelli, 2018; Suto et al., 2015).

Topic 2. The human-centric perspective: beyond Industry 4.0 towards Industry 5.0. The human-centric perspective emphasizes the importance of considering the impact of Industry 4.0 technologies on workers and society as a whole (Longo et al., 2020). This perspective is based on the idea that technology should be designed and implemented in a way that benefits society and enhances human well-being (Nahavandi, 2019).

Although studies have shown that Industry 4.0 technologies have the potential to create new jobs and opportunities, particularly in the areas of data analysis and robotics (Ali & Aboelmaged, 2022), one of the key concerns deals with potential negative impacts on workers’ well-being, such as mental and moral/ ethical constraints (Longo et al., 2020), stressful working situations (Cirulis & Ginters, 2013), and job displacement as a result of automation and the increased use of robots and other advanced technologies in the manufacturing process (Leesakul et al., 2022).

Extreme connectivity creates new social and political power structures that, if left unchecked, might lead to authoritarian governance by one person in total control of network power. Safety solutions have been proposed, including symmetrical innovation (innovations designed with built-in safe exit strategies), emphasis both on the acceleration and deceleration of innovation in case of negative effects, and next-generation research on social sciences and humanities for the global governance of Industry 5.0 technologies (Dezi et al., 2018; Ozdemir, 2018).

This topic combines an exploration of the potential applications of Industry 5.0 with potential Industry 4.0 concerns regarding societal issues (Bednar & Welch, 2020; Calzevara et al., 2020), environmental issues (Del Giudice et al., 2021; Song et al., 2017), global health (Javaid et al., 2020), and human sustainability and preferences (Dave et al., 2016).

Industry 5.0 is considered an evolution of Industry 4.0 aimed at merging the creativity of human experts in collaboration with efficient, intelligent, and accurate machines to obtain resource-efficient and user-preferred working solutions (Bednar & Welch, 2020; Calzavara et al., 2020; Javaid et al., 2020; Maddikunta et al., 2022). Industry 5.0 includes the integration of technologies such as quantum computing, 5 G, and blockchain, focusing on creating a better balance between technology and human needs. Industry 5.0 aims to create a more sustainable and equitable future for workers and society as a whole (Maddikunta et al., 2022).

According to Bag et al. (2021), human resources represent a key resource for Industry 4.0 adoption, with a positive impact on sustainable production and, in turn, a positive relationship with circular economy capabilities (Bag et al., 2021). Del Giudice et al. (2020) focused on the role of big data in circular supply chains, showing that HRM practices enhance firms’ circular economy performance.

Some works have addressed the relationship between societal trends and Industry 4.0 technologies (Bednar & Welch, 2020; Calzavara et al., 2020; Javaid & Haleem, 2020), workforce demographics, smart working, and Industry 4.0 technologies, which are relevant keywords for this sub-topic (Calzavara et al., 2020). The demographics of the workforce are changing (e.g. a general aging of the population and a higher average retirement age of the workforce has been reported worldwide) and the relocation and distribution of work are also changing (remote working and smart working). Scholars have investigated how Industry 4.0 technologies can help to face these societal and organizational changes that are both affecting the workforce and supporting the economic system's performance. In this context, a socio-technical systems approach to organizational analysis emerges as a viable solution (Bednar & Welch, 2020).

Industry 4.0 technologies pave the way for emerging HRM systems to support workers’ self-development (Chen et al., 2019; Hannola et al., 2018; Shamim et al., 2017). Management practices in the context of Industry 4.0 are drivers for the organization to enable workers to develop dynamic capabilities, which are needed for an organization to make use of Industry 4.0 in service production, such as banking systems (e.g. in response to the impact of the FinTech) (Chen et al., 2019), and in personal services, such as hospitality (Shamim et al., 2017).

Topic 3. The organizational perspective: improving performance with HRM and Industry 4.0. This topic focuses on the skills of human resources, particularly those related to the use of digital technologies, to assess the potential exploitation, or improvement, entailed by the use of Industry 4.0 technology in the organization. The topic explores and analyzes the characteristics of the different phases of the HR lifecycle in order to highlight the benefits of digital technology adoption alongside HR processes (from recruitment to talent management, from skills management to education, training, and the development of the human capital). The topic, in essence, points out the problems and challenges of Industry 4.0 technologies from an HR perspective (Kraus et al., 2018; Ozdemir, 2018; Popovic, 2018; Tambe, 2014). The topic also addresses some digital technologies, such as social media, and their connection with the labor market, employment, and workers’ skills (Tambe, 2014).

The changes brought about by Industry 4.0 technologies have had a substantial impact throughout the HRM lifecycle. On the one hand, there is the availability of new tools for HR managers (Rana & Sharma, 2019). Digital tools based on AI and big data analysis may assist organizations in increasing performance during the selection and assessment of the workforce (Nankervis et al., 2019), training (Sartal et al., 2022), and reward-system management (Abd Razak & Ismail, 2018).

On the other hand, the technologies introduced in company production processes require human resources’ specific aptitudes and skills. Some research has analyzed the critical skills characterizing Industry 4.0 with respect to traditional workers. Beyond the possession of competencies in the field of digitization, AI, robotics, and big data (Sima et al., 2020), the possession of soft skills (Pejic-Bach et al., 2020), disposition towards continuous training (Flores et al., 2020), and flexibility and a collaborative attitude (Matt et al., 2020) represent distinctive features sought after in Industry 4.0 workers.

Other works have emphasized how the introduction of Industry 4.0′s systems and technologies entails opportunities and pitfalls for organizations (Benesova & Tupa, 2017; Nahavandi, 2019; Xu et al., 2021), as would any transition to a new production paradigm. This topic focuses on the challenges, drivers, risks, and opportunities of the transition, covering the following key dimensions: employees’ education and qualifications (Benesova et al., 2017); and human–machine interaction, i.e. the coupling of workers’ (human) mind with robots’ (artificial) intelligence to increase collaboration and reduce competition (Industry 5.0) (Nahavandi, 2019; Xu et al., 2021).

Industry 4.0 technologies have a positive impact on HR capabilities and the empowerment of employees (both at production and management levels) (Popovic et al., 2018). Romero et al. (2020) emphasized the role of technologies in augmenting the capacities and capabilities of operators in cyber-physical systems. They defined the “Operator 4.0″ as “a smart, skilled operator who performs not only cooperative work with robots but also aided work by machines as and if needed by means of human cyber-physical systems, advanced human-machine interaction technologies and adaptive automation towards achieving human-automation symbiosis work systems" (Romero et al., 2020, p.1). The Operator 4.0 appears to be more engaged, having greater autonomy and opportunities for self-development (Kaasinen et al., 2020). Accordingly, smart factories obtain benefits from workers with different skills, capabilities, and preferences. Cagliano et al. (2019) shed light on the interplay between Industry 4.0 technologies and work organization both at a micro and a macro level. They identified four types of socio-technical configurations, showing how the greater the technological complexity, the more the operators are empowered in terms of job breadth and autonomy.

Other works have addressed the challenges of the (rapid) changes needed in employees’ competencies because of Industry 4.0 (TM et al., 2021). The gap between employees’ current capabilities and the evolving requirements of their roles is a challenge for HR managers across the stages of the entire talent pipeline (attraction and recruitment, training and development, career development, talent mobility, and succession planning) (Pejic-Bach et al., 2020; Whysall et al., 2019).

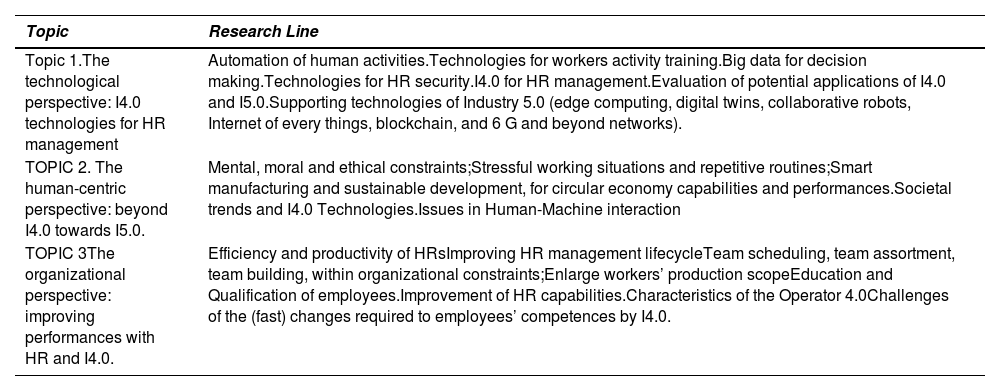

For each of the three topics, we summarize the main lines of research described above in Table 5.

Summary of the research lines rising from the study.

| Topic | Research Line |

|---|---|

| Topic 1.The technological perspective: I4.0 technologies for HR management | Automation of human activities.Technologies for workers activity training.Big data for decision making.Technologies for HR security.I4.0 for HR management.Evaluation of potential applications of I4.0 and I5.0.Supporting technologies of Industry 5.0 (edge computing, digital twins, collaborative robots, Internet of every things, blockchain, and 6 G and beyond networks). |

| TOPIC 2. The human-centric perspective: beyond I4.0 towards I5.0. | Mental, moral and ethical constraints;Stressful working situations and repetitive routines;Smart manufacturing and sustainable development, for circular economy capabilities and performances.Societal trends and I4.0 Technologies.Issues in Human-Machine interaction |

| TOPIC 3The organizational perspective: improving performances with HR and I4.0. | Efficiency and productivity of HRsImproving HR management lifecycleTeam scheduling, team assortment, team building, within organizational constraints;Enlarge workers’ production scopeEducation and Qualification of employees.Improvement of HR capabilities.Characteristics of the Operator 4.0Challenges of the (fast) changes required to employees’ competences by I4.0. |

Overall, the results show that the study of HRM in light of the Industry 4.0 paradigm, although quite new, is a consolidated research field with two reference perspectives, namely the technological one (as in topic 1) and the organizational/ managerial one (as in topic 3), which are highly consolidated that may represent “safe” directions for present and prospective scholars. In contrast, topic 2, which is neither well-structured nor consolidated yet, seems to represent the most promising future direction for research in this field.

Discussion and a future research agendaThe impact of Industry 4.0 on HRM is a complex and multifaceted issue. The three research topics are interconnected and, in a way, complementary, so it is important for researchers to take a holistic, interdisciplinary approach that considers the various technological, organizational, and societal dimensions of the evolution of HRM in the context of Industry 4.0.

Based on the results of our SLR, we propose a research agenda highlighting possible developments of the three research topics and, for each of them, opportunities and challenges, suggesting a number of specific areas that are currently underexplored.

Topic 1. technological perspective: industry 4.0 technologies for HRM and innovationScholars dealing with this topic tend to have an “inward-looking” perspective (Dumas et al., 2018). They have analyzed how digital technologies support the various phases of the HRM lifecycle in order to improve process performance and the well-being of workers and operators. Digital technologies are generally the focus of these studies, while HRM is the application field. Scholars have experimented with tools, models, methods, and infrastructures, their application to the workforce, and organizational and managerial consequences. The challenges are various. First, the transformative impact of the innovative technologies proposed (AI, augmented and virtual reality, robotics, etc.) on operators and work environments should be better evaluated, including in the long run. Second, as a secondary effect of the recent crisis, the virtualization of work has had a strong impact on working routines and workspaces, the extent of which at the organizational and personal levels remains an unaddressed topic.

We suggest that the following sub-topics require a deeper understanding:

- 1.

Human–machine collaboration: As machines and technologies become more integrated into the workplace, there will be a growing need for employees to collaborate with machines and technology. Future research in this area should investigate the best practices for human–machine collaboration, including how to design and implement processes that maximize the benefits and minimize the risks of such collaboration.

- 2.

Data governance and security: As Industry 4.0 technologies are generating increasing amounts of data, it is becoming crucial for HR departments to ensure that data are collected, processed, and stored securely, while also ensuring that data governance policies are aligned with the company's ethical and legal compliance requirements. Research should investigate the impact of Industry 4.0 on employee privacy and data security, including identifying best practices for protecting employee data in an automated workplace.

- 3.

New forms of employee representation and participation: Industry 4.0 and the rise of digital technologies may open up new ways for employees to participate in decision-making and representation, such as digital employee representation platforms, virtual works councils, and employee-driven innovation portals. An opportunity for research in this area is to explore the implications of these new forms of employee representation and participation for companies, employees, and labor relations.

Scholars approaching this topic tend to have an “outward-looking” perspective (Dumas et al., 2018). Performance optimization is no longer the main aim of adopting Industry 4.0 technologies. On the contrary, scholars are interested in how to support sustainability and resilience at the organization, industry, and societal level. The organization is generally considered as part of a more general context. Opportunities arise for scholars, both at the theoretical and application level, to study models and methods to guide the technology adoption in these early stages of the Industry 5.0 paradigm. However, more research is needed to clarify how digital technologies can become engines for achieving socially oriented goals. Challenges are related to the novelty of the field, characterized by research approaches that are not yet consolidated, with scientific results needing to be evaluated in the long run.

Possible sub-topics that require a deeper understanding include:

- 1.

Employee engagement and retention in the digital workplace: Industry 4.0 technologies can make it easier to work remotely and collaborate with colleagues across different locations and time zones. However, these technologies can also lead to increased feelings of isolation and disconnection. Research in this area should explore how HR departments can support employee engagement and retention in the digital workplace, as well as how to mitigate the negative effects of remote working. Moreover, it is important to deepen understanding of the implications of this trend for HRM, such as how organizations can manage and support remote workers, as well as ways to ensure that they feel connected to the organization.

- 2.

Ethics and fairness in the digital workplace: Industry 4.0 technologies raise a number of ethical and fairness concerns, such as issues of data privacy, bias, and accountability. Research in this area should explore how organizations can address these concerns and ensure that the use of Industry 4.0 technologies is consistent with ethical standards. As automation and AI technology continue to change the nature of work and the way companies manage their employees, researchers may examine the effect on workplace diversity, worker replacement and upskilling, and workers’ rights, among other topics.

- 3.

Impact on employee well-being: Industry 4.0 technologies can have a significant impact on the way that employees work. Research should investigate the extent to which these technologies are likely to lead to improved employee well-being, as well as whether they are more likely to have negative impacts, such as increased stress.

- 4.

The role of human resources in digital transformation: Industry 4.0 is not only a technical transformation but also a cultural one. Research should investigate the role of HR departments in helping organizations to make the cultural changes necessary to successfully adopt and integrate new technologies, as well as how they can support the development of a digital-ready workforce.

Scholars are interested in the organizational aspects of HRM and, more generally, in how Industry 4.0 technologies impact the organizational performance of the HRM process. Scholars have the opportunity to deepen their understanding of the success- and failure-related aspects of HRM in various phases of workers’ life during human–machine interaction, including education, employment, job profile, qualifications, competence mapping, and capability enhancement. Particular attention should be devoted to daily routines' safety and security aspects. The challenges are mainly due to the necessity to understand how to innovate the theory and practice of HRM to face the rapid pace of technological progress.

Possible sub-topics that require a deeper understanding include:

- 1.

Impact on roles and skills: This concerns the impact of automation and AI on job roles and the skills required. As Industry 4.0 technologies, such as automation and AI, become prevalent in the workplace, they may change the nature of many jobs, making some tasks obsolete while creating new ones. Research in this area is expected to explore how these changes will affect the skills and qualifications required for different roles, as well as how HR departments can plan and prepare for these changes. Moreover, researchers could examine how organizations can effectively manage and train their workforce in the face of these changes, as well as how they can adapt their HR policies and practices to support the adoption of Industry 4.0 technologies.

- 2.

Impact on recruitment and talent acquisition: With Industry 4.0, the nature of job roles and skills requirements will change, and this may affect the recruitment process and the means of acquiring the talents that organizations need. Research in this area should explore how best to adapt recruitment and talent-acquisition strategies to the changing job market, including how to identify and attract candidates with the skills needed for the digital workplace.

- 3.

Monitoring employees’ performance: Advanced technologies, such as AI and IoT, can provide organizations with new ways to monitor and measure employee performance, and they may also enable new forms of collaboration and communication among employees. Research in this area should explore the ways in which Industry 4.0 technologies can be used to improve employee engagement and performance, as well as the potential downsides of such technologies, such as the impact on employee privacy or the potential for increased surveillance.

Industry 4.0′s new technologies have led to a dramatic transformation of the manufacturing industry (Sarbu, 2022). These technologies have not only had a substantial impact on the financial and operational performance of companies but are increasingly changing the way in which human capital is conceived and managed within factories (Flores, Xu & Lu, 2020).

The present study aimed to understand the structure of the existing literature on Industry 4.0 and HRM in terms of the major research topics. For this reason, an SLR based on LDA was employed. By analyzing 566 papers, we found three main broad topics that the literature has been focusing on, which also represent areas for future research:

- 1.

Digitalization perspective: Industry 4.0 technologies for HRM and innovation. Concerns how Industry 4.0 technologies support HR managers to design and monitor the tasks, working conditions, and activities of the workforce.

- 2.

HRM 4.0 – management and organization perspective: improving performance with Industry 4.0 technologies. Concerns the potential of Industry 4.0 technologies to improve workforce and HRM performance throughout the different phases of the HR lifecycle.

- 3.

HRM 5.0 – Criticisms of Industry 4.0 and discussions regarding Industry 5.0 considering sustainability challenges. Concerns the strategic implications of implementing Industry 4.0 technologies from a human-centric and sustainability perspective.

This paper has important implications for scholars. First, to the best of our knowledge, this study is the first to provide a systematic overview evaluation of extant literature on HRM and Industry 4.0 from a business and management perspective. Specifically, this review study analyzes extant research from the defined perspective, structuring the various sub-areas identified within this research field and both providing original and general insights, enabling a deep and unifying picture of the topic to emerge. Second, the use of a digital tool based on a machine learning approach, namely MySLR, made possible the application of the research protocol in a rigorous way that reduced considerably the biases of a manual and subjective protocol application. This review indicates that research on the intersection between HRM and Industry 4.0 is rapidly emerging but that several research gaps are still present. In order to overcome these gaps, our review provides an important contribution to the literature and new insights to guide future research in this area.

From a theoretical perspective, sociomaterialism seems a promising theoretical framework to interpret the phenomenon under investigation (Orlikowski, 2007) Sociomaterialism posits that human and material agencies are inseparable, and their interactions shape organizational practices and outcomes (Orlikowski & Scott, 2008). This perspective may help disentangling the weave of social and material aspects in the workplace, particularly as organizations adopt advanced technologies such as big data, automation, and cyber-physical systems (Myllymäki, 2021). As suggested by Hecklau et al. (2016), HRM must focus on fostering a holistic approach to employee development, encompassing technical, social, and emotional skills. This requires a significant investment in organizational learning, shaping the sociomaterial conditions suitable for nurturing these competencies. Integrating a sociomaterial perspective can help to address current limitations in our understanding of how technology and human actors interact to produce emergent outcomes, by highlighting the importance of considering the materiality of technology, wider groups of actors and their agency, and emergent practices around technology.

The shift toward HRM 4.0 is not easy, requiring a reassessment of the HRM processes themselves, entailing several competencies and sensibilities for HR managers. First, HR managers should acquire competencies in Industry 4.0′s technologies (both to acquire information from workers and to make this information insightful and valuable for HRM). Second, HR managers are becoming the guardians of workers’ well-being since they preside over the balance between “digital technology” and “human” components of the work. The measurement and monitoring of human well-being is becoming crucial for HR managers in the context of the digitalization (Industry 4.0) of the company, in terms both of intensity and timing. HR managers should adopt performance measurements and management models, enabling the reframing of new concepts and indicators both at individual and organizational levels.

At a higher level, vulnerability and HR security-related issues emerge as critical for top managers, owing to the ever-increasing intra- and inter-connection of workers. Managers should therefore focus on systemic risks and alternative forms of governance wherever networks and technology may collapse. The design of alternative work configurations, mitigating the associated risks and dependence on the technological framework, is critical for company management (Longo et al., 2020). This study also addresses the new skills and aptitudes that both workers and HR managers should acquire to cope with the Industry 4.0 working environment (Rana & Sharma, 2019).

The results of the study provide insights for policymakers, mainly with regard to the threats of Industry 4.0 and the need to embrace Industry 5.0, in terms of benefitting society and enhancing human well-being. Policymakers should plan and monitor mental, moral, and ethical objectives throughout the HR digital transition (Longo et al., 2020). Political support for such a transition should also consider, and try to avoid, new social and political power structures, stemming from extreme connectivity, that risk establishing authoritarian governance by a core of a few groups in total control of network power (Ozdemir, 2018). The results of the study address Industry 5.0 as a viable pathway for policymakers to merge humans and intelligent working solutions (Bednar & Welch, 2020; Calzavara et al., 2020; Javaid et al., 2020; Maddikunta et al., 2022). Industry 5.0 can also be a valuable tool when facing the current changes in demographics and work habits (i.e. the relocation and distribution of work), enabling policymakers to create a more sustainable work–life balance (Maddikunta et al., 2022) while also supporting the economic system's performance.

Limitations of the studyThe study's main limitations are contextual and derive from applying the research protocol. First, considering the adopted managerial perspective, we limited the search to papers indexed in business and management subject areas within the three databases (Scopus, WoS, and PubMed). Although they are the most documented and, together, embody the most complete scientific sources, they may not include all studies relevant to our topic. Second, only papers written in English and published in scientific journals were considered. Therefore, other studies that could be relevant, such as conference proceedings, theses, doctoral dissertations, and book chapters, were excluded. Third, the findings are influenced by the definition of the initial set of keywords and the adopted search formula (Nofal et al., 2018). We tried to overcome this limitation by adopting a recursive approach that allowed extending the sets of keywords by considering the keywords used in the papers found in our review.