Editado por: Abbas Mardari

Más datosHigh-risk companies have to deal with problems related to the environment, health, and safety (EHS) since the products of such companies create serious challenges to environmental safety. The presence of various similar and dissimilar risk factors in these companies complicates the known and unknown causal relationships whose interpretation and understanding are difficult. Therefore, EHS improvement has remained a great challenge to be solved by these companies. The design and implementation of ubiquitous systems are supported by the development of the Internet of Things (IoT) as well as their enabling technologies. IoT has been found capable of solving different problems of high-risk companies in regard to EHS-related challenges. A wide window for preference elicitation has been opened to decision experts (DEs) through the development of the q-rung orthopair fuzzy set (q-ROFS). The extensive research conducted into q-ROFS implies a great urge for a decision approach that can use accessible information appropriately to make decisions of the highest rationality. Using the q-ROFS advantages, the present study develops a novel approach with the “entropy-rank sum-weighting integrated approach (ERSWIA)” and “weighted aggregated sum product assessment (WASPAS)” model termed as “q-ROF-ERSWIA-WASPAS”. In this line, the q-ROF-ERSWIA is applied to compute the integrated weights of criteria, and the q-ROF-WASPAS is implemented to find the prioritization of organizations. A case study to assess the challenges of IoT-based applications in EHS industries in the era of Industry 4.0 is taken. Comparison and sensitivity studies are discussed to illustrate the usefulness of the presented approach.

Most industries report different rates of accident occurrence, which is a concerning issue that requires to be well addressed. Industries reflect the safety and health issues of their workers with mechanical maintenance protection and other management-related concerns (Rajmohan & Srinivasan, 2019). This situation has caused the “environment, health, and safety (EHS)” management to become progressively significant during the last decade, particularly when it comes to high-risk and high-reliability companies (Al Hashmi, 2017; Anuradha et al., 2020; Chen et al., 2020; Shavalieva et al., 2021). The top management of a company normally drives EHS, and despite many studies carried out on the topic of EHS leadership, the literature has failed to provide sufficient information regarding EHS governance and the company directors’ roles in organizational safety and EHS performance of their respective companies. EHS (or HSE) departments (Reason et al., 1998) in various industries have been found incapable of implementing effective and sufficient safety practices in the workplace to protect the managers and employees as well as contractors/sub-contractors and clients. Inefficiency in this regard adversely affects both the organization and the workforce. Such negative impacts may include production delays and compensation charges, tool and apparatus impairment, permitted costs, expenditures on options materials, and loss of commercial concerns and morale of employees (Aronsson, 1999). The hazards induced in this way may cause damage to employees, managers, supervisor subcontractors, third parties, and visitors.

Risk management policies and implementation are a means to reduce and/or eliminate fatal and non-fatal hazards in different environments (Wejie-Okachi et al., 2021). The clamor for zero number of “loss time injuries (LTI)”, fatalities, and financial loss required for companies to attract and retain small to large-scale contracts via enhanced Health, Safety, and Environment (HSE or EHS) procedures has now become more than ever before, a fundamental requirement to kick start any industrial small to large scale project and complete such. Due to the increasing accounts of preventable HSE fatalities across the globe, the need for the complete automation of monitoring facilities has become paramount (ILO, 2014). Industrial monitoring and control combine electronics, architecture, machinery, procedures, and people with algorithms and software to build a system to monitor and control the activities of industrial processes aimed at maximizing profits for an optimally safe working environment (Rajmohan & Srinivasan, 2019). Safety practices aim to eliminate the events that may cause wounds leading to death or chronic illness and keep the working environment free from pollution (Li et al., 2013). Xu (2011) examined the current form of data management for source chain value association. To do this, it revised the current investigation and development in data architecture to manage the source chain value.

The “Internet of Things (IoT)” technology provides opportunities for the convergence of heterogeneous processes, devices, and technologies. The term ‘things’ involves physical entities and non-physical entities such as devices, animal/ human bodies, and data generated from sensors (Walden & Noto La Diego, 2016). With automation enabled by IoT-engineered mechanisms and software systems, equipment failure, procedural flaws, and human errors are maximally reduced and eliminated from the entire operation (Chamola et al., 2020). Since 2001, there has been progressive use of GSM in Nigeria, which has given way to the growth of wireless networks and technologies in the country; thus, there are many opportunities for the implementation of IoT-based systems (Bakare & Alalibo, 2018). Such implemented systems have streamlined communication, effective industrial production, and proactive safety and control are achievable in many parts of the country. As a result, IoT-enabled applications are rapidly utilized in industries, transport, schools, health care, and other endeavors. Although there are standards and regulations for machines’ safe operation, some specific criteria could only be identified by specialists and managers in EHS.

Numerous technologies have been introduced to reveal the Industry 4.0 umbrella: “big data and analytics (BDA)” (Cai et al., 2019; Zhang et al., 2018), “autonomous robots, simulation (ARS)” (Buzys et al., 2018), IoT (Han et al., 2021), cybersecurity (Wu et al., 2013), “cloud computing (CC)” (T.S. Chen et al., 2016), additive manufacturing and augmented reality (Shi et al., 2016), “radio frequency identification (RFID)” (Li et al., 2018) and “real-time location system (RTLS)” (Yang et al., 2020). The IoT is a fundamental technology for Industry 4.0, bringing many benefits for automation and process control (Malik et al., 2021; Pivoto et al., 2021). Despite the increasing automation leading to a decrease in manual work, there is still a considerable presence of employees subject to accident risks. IoT connects many physical objects, e.g., home purposes, vehicles, medical devices, and RFID tags, within a network without any need for human intervention. Each of the things existing within this network could also be uniquely recognized at the item level (Zhou, 2009). Several innovative “information and communication systems (ICS)” such as the ubiquitous information system, have been developed owing to the extensive progress and increasing adoption of IoT-based technologies. More specifically, ubiquitous computing is aimed at creating interconnection in the physical world via networks, namely the Internet. In constructing such ICSs, IoT and Cloud Computing play the most important roles (Gubbi et al., 2013).

Meanwhile, adopting IoT for emergency management is considered to be promising from different perspectives (Al-Nabhan et al., 2019): 1) the existing heterogeneous and geographically distributed safety-related resources. These resources can be easily upgraded to IoT devices by incorporating sensing and communication capabilities. 2) IoT helps to easily gain access and interact with various objects, e.g., home appliances, monitoring sensors, vehicles, surveillance cameras, displays, and actuators. 3) IoT aids in developing several applications that employ massive and heterogeneous data created by interconnected devices, and this way, it provides novel services to individuals, firms, and public administrations. This includes a large number of domains, for instance, smart cities, smart buildings, smart grids, healthcare systems, transportation, and industrial automation. 4) population growth puts pressure on different aspects of people's lives and, on the other hand, augments the number and intensity of disastrous events. This raises the interest in emerging technology applicable to emergency situations and management in order to decrease the likelihood of grave human fatalities and property destruction. 5) Situational awareness and the failure of humans’ decision-making processes when a disastrous incident takes place. 6) Most incidents have rapidly changing characteristics during an emergency, which creates a challenge to the typically available systems that rely heavily on a static scene in the calculation of the safest routes for evacuation. 7) The recent development of emergency response information systems (ERISs) focuses on inter-organizational communication and collaboration in crisis management (Fantacci et al., 2014; Qiu et al., 2014). Generally, the objects that could be connected in an IoT-formed network required to have the following characteristics: 1) possessing unique identifiers, 2) being capable of gathering data from the environment, 3) being capable of operating and interacting with the real world through processing the data gathered, and 4) using the Internet standards for the communication and analysis of the data to provide it for further services (Thibaud et al., 2018). In the major part of the EHS industry, the working atmosphere is of high dynamicity regarding the processes, labor, and equipment management; as a result, IoT-based applications play key roles often through process mining and optimization techniques.

Due to several key industry applications, IoT has been extensively adopted in recent years. IoT is capable of gathering, sharing, and processing data; this way, it can provide industries with countless new opportunities; for instance, tracking and monitoring of products by means of IoT-based technologies can greatly improve the efficiency of production and distribution of products. IoT improves operations and provides numerous innovative solutions, for example, by forming new business models. For instance, the goods sale procedures could be enhanced using the IoT-collected data and real-time connectivity (Bughin et al., 2015). To evaluate the business value of the RFID (Bose et al., 2011; Bose & Yan, 2011) technology, Tzeng designed a model emphasizing the delivering business worth by refining the business procedures and increasing the business approach in a way to promote the RFID adoption (Tzeng et al., 2008).

It is difficult to prevent workplace accidents and illnesses in hazardous work settings such as underground mines. Despite the existence of IoT solutions for health and safety in such places, every workplace has different characteristics, and generally, human beings sitting in control rooms have to perform monitoring tasks. When an emergency occurs, some conflicts might arise among prohibitions and obligations, and humans may have to decide without assistance since they have no complete control over the condition. Nevertheless, the implementation of IoT in large industrial applications has encountered numerous challenges, including energy efficiency, scalability (network size, interoperability), communication and data-based concerns (connectivity, throughput, latency, standardization), and safety and security (privacy, reliability, and protection). Various IoT-enabled components share some of these challenges; these components include sensor devices to “back-end system (BES)” and “service-oriented architecture (SOA)” design (Li & Madnick, 2015). The literature shows that some industries, e.g., food supply chain, healthcare services, and infrastructure monitoring, have already adopted IoT applications in a successful way (Gubbi et al., 2013; Kim & Kim, 2016; Xu et al., 2014). The above-noted industries have at least one characteristic in common: lives are at stake in the work setting or in the final product/service delivered. Thus, they could be recognized as high-risk EHS industries. These industries involve practical aspects of safety and environmental protection. Companies in these domains have to ensure that their activities cause no damage to anyone. These industries extensively make use of IoT-based applications. Liu et al. (2017) identified and classified the current research themes that are relevant to data completeness in healthcare. In addition, Haase et al. (2016) suggested several solutions to assure uncongested pilgrim flows with broad real-time reporting.

The implementation of IoT in high-risk EHS industries in large industrial applications has faced various challenges. To assess the challenges, the “multi-criteria decision-making (MCDM)” models play a significant part. Sometimes, “decision makers (DMs)” fail to give accurate results in real MCDM problems, which is because of time complexity, the deficiency of information, and the unpredictability of human beings’ thoughts. To address this concern, the “intuitionistic fuzzy sets (IFSs)” (Atanassov, 1986) are defined in terms of the “belongingness degree (BD)” and “non-belongingness degree (ND)”. Roughly three decades later, to eliminate the weaknesses of IFS, “Pythagorean fuzzy sets (PFSs)” (Yager, 2014) have been described with the BD and ND, and satisfy the squares addition of BD and ND is ≤1. Today, PFS is used as a tool more influential than IFS, which can handle the problem of uncertainty that may arise in real-world MCDM problems (Rani et al., 2019). Next, R.R. Yager (2017) pioneered the “q-rung orthopair fuzzy sets (q-ROFSs)” that are depicted by BD and ND. The q-ROFSs theory fulfills a constraint where the sum of the qth powers of BD and ND is ≤1, where q ≥ 1. In q-ROFSs, the information space is broader than PFSs and IFSs, analogous to the parameter q (q ≥ 1). Thus, the IFSs and PFSs are two particular forms of q-ROFSs. Hence, q-ROFS can more flexibly handle higher levels of information uncertainty. For instance, the fundamental postulates of q-ROFSs were investigated by Yager and Alajlan (2017); they applied this concept to information representation. Different arithmetic and geometric operators were examined in the study of Liu and Wang (2018) in regard to q-ROFSs. Pinar and Boran (2019) gave a distance measure-based model applicable to q-ROFSs to be used when selecting the best supplier. In the study of Tang et al. (2020), an innovative q-ROFS-based model was designed to deal with the three-way decision problems more effectively. An extended WASPAS method was examined by Rani and Mishra (2020) in terms of evaluating fuel technologies with q-ROFSs.

Additionally, a number of MCDM models have been presented under diverse uncertain settings. For instance, the “weighted aggregated sum product assessment (WASPAS)” (Zavadskas et al., 2012) has been widely used in various real-world problems. Indeed, WASPAS integrates the utility of the following tools, namely the “weighted sum model (WSM)” and “weighted product model (WPM)”, and it offers a higher precision rating. Moreover, WASPAS has been extended to different fuzzy environments addressing information uncertainty in MCDM problems (Mishra & Rani, 2018). For example, Mardani et al. (2017) comprehensively examined SWARA and WASPAS under various uncertain conditions. In another study, Mishra et al. (2019) introduced WASPAS for evaluating the “green supplier selection (GSS)” problem on “hesitant fuzzy sets (HFSs)”. An integrated structure was developed by Mardani et al. (2020) using SWARA, WASPAS, and the Strengths, Weaknesses, Opportunities, and Threats (SWOT) model under HFSs in order to evaluate the “digital technologies intervention (DTIs)” for the control of the COVID-19 outbreak. Alrasheedi et al. (2022) used SWARA and WASPAS models on Pythagorean fuzzy sets (PFSs) to propose an integrated decision-making model that could be applied to the problem of selecting the most sustainable supplier for manufacturing firms.

Consequently, to consider the utility and benefits of q-RFOSs, a WASPAS tool for treating the MCDM problem has been presented. Also, a new weighting technique named as q-ROF-“entropy-rank sum-weighting integrated approach (ERSWIA)” is discussed to compute the criteria weights. Then, q-ROF-WASPAS is used to rank the options in the MCDM problems. Thus, in this study, an integrated q-ROF-ERSWIA-WASPAS is implemented to identify the challenges of IoT-based applications in high-risk EHS industries in the era of Industry 4.0. Also, we identify the related challenges of IoT-based applications in high-risk EHS industries in the era of Industry 4.0 using a survey approach based on the review of the current literature as well as an interview of experts in industry and university domains. Thus, the main contributions of the paper are presented as

- -

Conduct the survey method using DMEs’ discussions and the literature review to recognize the challenges of IoT-based applications in high-risk EHS industries in the era of Industry 4.0.

- -

Develop a comprehensive approach to analyze the challenges of IoT-based applications in the era of Industry 4.0 using the q-ROFSs.

- -

This paper proposes an integrated approach using the q-ROF-ERSWIA and WASPAS models under q-ROFSs to rank the industries and analyze and assess the challenges of IoT-based applications in the era of Industry 4.0.

- -

The q-ROF-ERSWIA is utilized to assess and prioritize the challenges of IoT-based applications in high-risk EHS industries in the era of Industry 4.0.

- -

Present sensitivity and comparison analyses to certify the integrated q-ROF-ERSWIA-WASPAS approach.

The remaining paper is organized in the following sections. Section 2 discussed the main challenges of IoT-based applications in the era of Industry 4.0. Section 3 provides the introduced q-ROF-ERSWIA-WASPAS method. Section 4 presents the results of the study, the case study, the sensitivity analysis, and the comparison. Finally, section 5 discusses the conclusion of the study.

Related workIoT has shown much potential to be applied to the EHS objectives in high-risk companies. IoT in such companies can assure reliable, protected, efficient arrangements since the applications working based on this new technology can operate at a fine granular level and give rich low-level data (Rath & Pattanayak, 2019). Nowadays, IoT possesses an important position among the most robust communication ideal models proposed during the first two decades of the current century (Rajmohan & Srinivasan, 2019). In such context, all articles in people's routine lives are indeed a piece of the web due to their communication and figuring capacities (Fan et al., 2014). IoT expands the use of the Internet and causes it to be an inescapable phenomenon. It provides reliable connections amongst a variety of gadgets, e.g., checking cameras, environmental sensors, and medical devices/applications. Accordingly, IoT is presently offering many benefits to many domains, such as “environmental pollution monitoring (EPM)” and “aqua quality management (AQM)”. IoT involves many sorts of modest sensors by which people can monitor and report the quality of administrations at any place and any time. These facilitations provided by IoT could cause individuals to feel more personal satisfaction (He et al., 2014). The IoT has been considered to have critical prospective in the high-chance EHS enterprises.

The act of reporting has become more feasible by the recent progress that occurred in IoT and its use in industrial safety measurement applications. In recent years, the literature has introduced a number of wireless sensor networks that can help users to constantly check industrial safety in various areas such as healthcare and environment control. This section discusses some of the customary research extensions that have occurred by means of industrial safety estimation frameworks using IoT-based sensor networks (Li et al., 2012). Alarm networks have raised some infringement secrecy states, for instance, the susceptibility of these networks to antagonistic privacy assaults that are exclusively planned for individuals’ well-being in the working place (Lazarescu, 2013). The arrangement of remote device systems and web innovation of farmlands has programmed industrial system administration strategies. Investigating the scheme on the Internet has strengthened the approach of coordinating the horticultural plants of farmland with industrial policy frameworks (He et al., 2014). In cases where industrial safety is scarce, the data are sent to the credit center and administration's portable with the same procedure at a corresponding time. This helps to find a way to obtain related measures conveniently and become capable of finding a certain period using core-domain IoT ontology networks (Chandu et al., 2018).

Recent decades have witnessed a tremendous interest in producing and storing massive amounts of information. T.S. Chen et al. (2016) introduced smart clothing integrated with “blood oxygen saturation (BOS)”, and temperature sensors. In another study, an IoT-based “health monitoring system (HMS)” was proposed by Mdhaffar et al. (2017) using LoRaWAN. By means of the LoRaWAN network, different physiological data (e.g., blood glucose, blood pressure, and body temperature) of rural people could be transmitted to a distant LoRa server. The outdoor LoRa gateway is capable of covering approximately 33 km2; as a result, this could be of great help in regions without any cellular networks. LoRa has been exposed to different experimental studies; the results have confirmed its ability to monitor rural people's health conditions. In addition, its wireless system consumes less power than conventional cellular networks. Yang et al. (2016) introduced a wearable ECG monitoring procedure that could be directly connected to the IoT-cloud via Wi-Fi. The way they suggested the use of the system allows for real-time ECG data collection in addition to visualizing and storing the data. This is helpful when diagnosing cardiovascular diseases in their early stages. A methodical review of the “wearable sensor systems (WSSs)” was designed by Zhu et al. (2015) to monitor the health status of infants. They also discussed various models and applications proposed to measure the vital signs of infants regarding their monitoring methods, power supply, wireless techniques, and biomedical parameters.

As noted earlier, the majority of the studies conducted in this domain have been based on either environmental or physiological parameters. The literature, on the other hand, lacks research focused simultaneously on both aspects. For instance, the authors (Catarinucci et al., 2015) proposed a smart IoT architecture system applicable to monitoring environmental and health conditions. Their proposed system employed an ultra-low power hybrid network comprising two wireless technologies: the RFID (which is used to track the purposes) and 6LowPAN (which is applied to “wireless sensor networks (WSNs)”). The sensor nodes are equipped with a multi-sensor board capable of gathering both physiological parameters (e.g., acceleration and ECG signals) and environmental data (e.g., barometric pressure and temperature) in real-time. A customized REST web service makes the collected data accessible to both remote and local users. In another study, a demonstration platform was developed by Catarinucci et al. (2015) to monitor the physiological and environmental conditions continuously. It uses some new flexible materials conforming to human beings’ bodies; they can measure a variety of parameters, for instance, pressure, PPG, ECG, hydration, and “volatile organic compounds (VOCs)”. Wu et al. (2018) proposed a self-powered wearable safety monitoring application that worked with the LoRa. The sensor nodes in this application are proficient in observing safety-related environmental parameters, e.g., carbon dioxide (CO2), ultraviolet (UV) index, temperature, and relative humidity. It uses LoRa for the transmission of the collected data from the wearable nodes to the IoT gateway through which the data are uploaded to the cloud server to be used in data analysis processes.

Wilhelm et al. (2016) designed a wearable environmental monitoring system in an urban area in Singapore. To achieve outdoor localization, their proposed system uses Wi-Fi instead of GPS. This was chosen due to two negative characteristics of GPA, i.e., its high power consumption and large size. Nevertheless, the system is able to assess various environmental circumstances, namely humidity, ambient pressure, light, temperature, sound pressure, and acceleration. The power of the sensor nodes in this system is provided by a rechargeable lithium battery, which can last up to 7 days. Lee and Shim (2007) discussed the three key determinants of RFID adoption in companies and the relations among them. Therefore, training and awareness campaigns play significant roles in spreading RFID adoption (Yee-Loong Chong et al., 2015). As suggested by Kim and Kim (2016), it is necessary to take a piecemeal model to adopt IoT in healthcare applications in a way to evade the resilience of this certain conservative industry. The authors (Wu et al., 2011) believe that personal innovativeness in IT (PIIT) and perceived service availability (PSA) could play the role of key drivers in TAM and TPB. Generally, both current and future implementers believe that RFID has more benefits than barriers compared to those that do not implement it at all (Reyes et al., 2012).

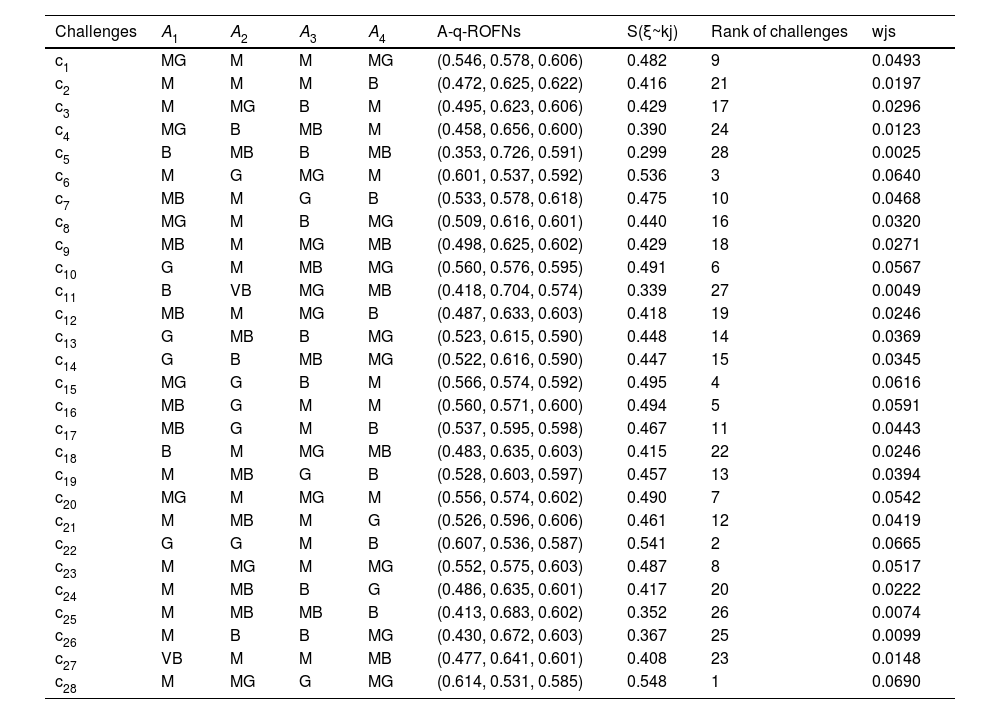

A novel model was designed by Khalifa and Zabani (2016) to streamline the virtual machines option choice in the cloud-IoT health management to treat key aspects of information unified in Industry 4.0 effectively. However, in this study, to recognize the main challenges of IoT-based applications in high-risk EHS industries in the era of Industry 4.0 had performed a survey method with the recent literature review, in total, we have identified 28 important challenges including energy efficiency (c1), communication (c2), connectivity (c3), latency (c4), throughput (c5), standardization (c6), network size (c7), interoperability (c8), reliability (c9), privacy protection (c10), business model (c11), standardization (c12), compliance with regulatory (c13), industry standards (c14), commitment and comprehension from the different stakeholders (c15), support of communities (c16), staff training (c17), credibility among stakeholders (c18), consumers credibility (c19), social acceptance (c20), trust (c21), affordability (c22), high cost of implementation (c23), absence of global or national standards (c24), regulation (c25), time-to-market (c26), responsibility (c27) and consensus between stakeholders (c28) for IoT-based applications in high-risk EHS industries in the era of Industry 4.0.

A new integrated decision-making methodologyBasic conceptsSome idea about the q-ROFSs is presented.

Definition 3.1 (R.R. Yager, 2017). Let ξ={z1,z2,...,zn} be a fixed set. Then, M={(zi,μM(zi),νM(zi))|zi∈ξ} is a q-ROFS, where μM(zi)∈[0,1] and νM(zi)∈[0,1] are the BD and ND of zi∈ξ, respectively, with 0≤(μM(zi))q+(νM(zi))q≤1 and q≥1. The “indeterminacy degree” is given as πM(zi)=1−(μM(zi))q−(νM(zi))qq,∀zi∈ξ.. The pair (μM(zi),νM(zi)) is referred as the “q-rung orthopair fuzzy number (q-ROFN)”, symbolized by φ=(μφ,νφ).

Definition 3.2 (Liu & Wang, 2018). Let φ=(μφ,νφ).φ1=(μφ1,νφ1) and φ2=(μφ2,νφ2)∈q−ROFNs(ξ). Some operations can be defined by

Definition 3.3 (Liu & Wang, 2018). Let φ=(μφ,νφ)∈q−ROFN(ξ). The score and accuracy functions are defined as S(φ)=0.5((μφq−νφq)+1) and h(φ)=μφq+νφq, respectively.

Definition 3.4 (Liu et al., 2019). Let φ1=(μφ1,νφ1) and φ2=(μφ2,νφ2)∈q−ROFNs(ξ). The distance measure for φ1 and φ2 is presented as

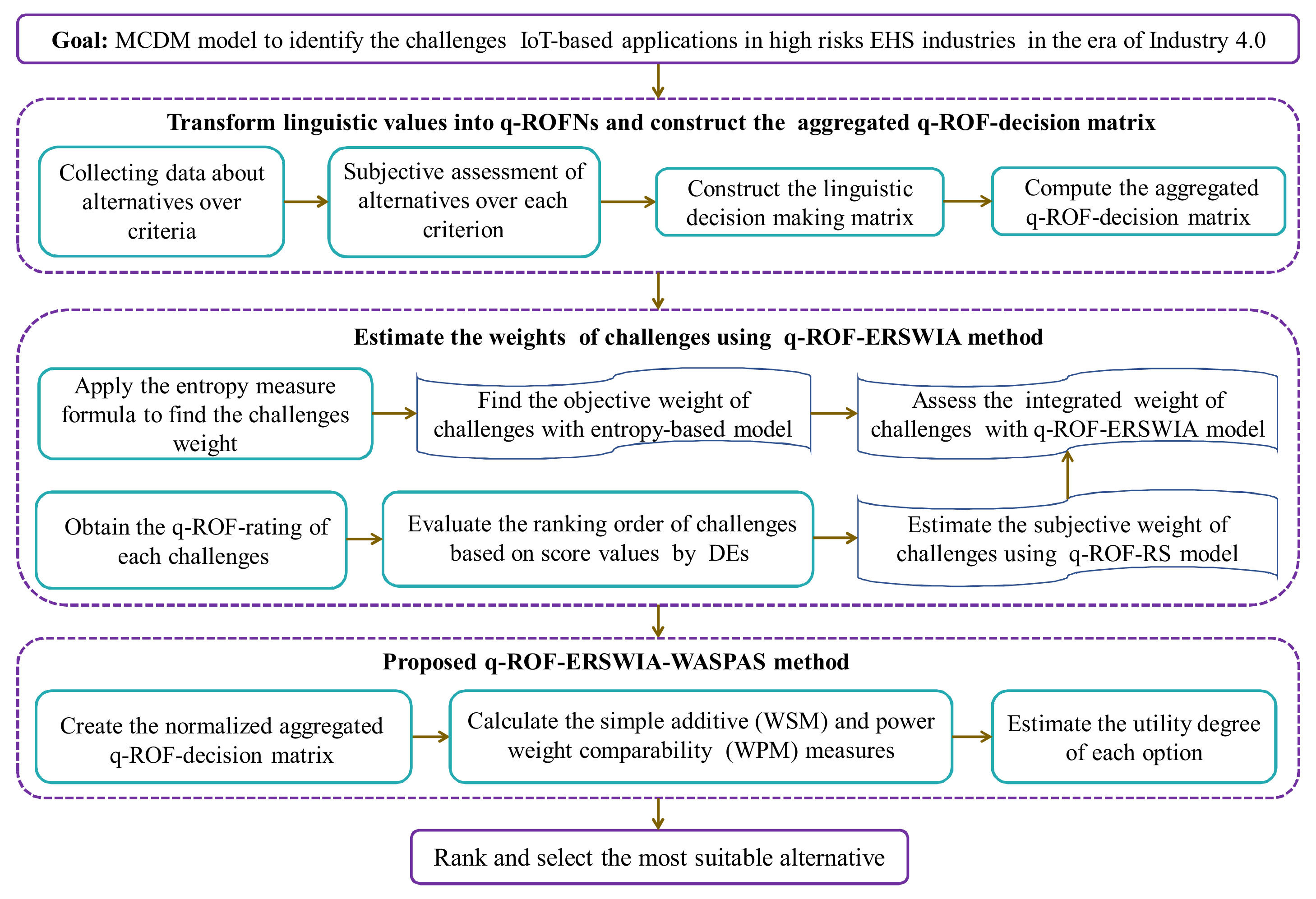

Here, we present an integrated WASPAS method with the rank-sum tool for handling the MCDM problems on q-ROFSs and named it the q-ROF-ERSWIA-WASPAS approach. The process of the presented method (see Fig. 1) is given by

Step 1: Generate a “linguistic decision matrix (LDM)”.

A set of l DMEs A={A1,A2,...,Al} define m options I={I1,I2,…,Im} and n criteria C={C1,C2,…,Cn}, respectively. Considering the imprecision of human thinking, deficiency of data, and indefinite information about the choices, the DMEs assign q-ROFNs to appraise his/her rating on option Ii concerning a criterion Cj. Let Z(k)=(ξij(k))m×n,i=1,2,...,m,j=1,2,...,n be the LDM by DMEs, where ξij(k)-states the “linguistic values (LVs)” to an option Ii with respect to criterion Cj given by kth DME.

Step 2: Find the of DME's weight

To find the DMEs’ weights, the significance rating of each DME is determined as the LVs and then considered by q-ROFNs. Let Ak=(μk,νk) be a q-ROFN. Then, the DME's weight is estimated as

Here, ϖk≥0,ϖk∈[0,1] and ∑k=1lϖk=1.

Step 3: Achieve the “aggregated q-ROF-decision matrix (A-q-ROF-DM)”.

To find the A-q-ROF-DM, the “q-ROF weighted averaging (q-ROFWA)” operator is utilized by merging all the LDMs and created the A-q-ROF-DM Z=(zij)m×n, where

Step 4: Computation of criteria weight by q-ROF-ERSWIA

Suppose w=(w1,w2,...,wn)T is the weight of the criterion set with wj≥0,∑j=1nwj=1 and wj∈[0,1]. The process for determining the integrated weight is presented as follows:

Case I: Determination of objective weights with the entropy-based tool.

Here, we consider the entropy-based procedure to find the weight of criteria under the q-ROFS environment as

where, E¯nt(zij)=Ent(zij)/maxjEnt(zij),j=1,2,...,m andEnt(zij)=1n(1−exp(−1/2))∑i=1n[{1−exp(−(νijq+1−μijq2))}I[μijq≥νijq]+{1−exp(−(μijq+1−νijq2))}I[μijq<νijq]] denotes q-ROF-entropy of zij (Mishra & Rani, 2021).

Case II: Estimation of subjective weight by RS method

In the MCDM process, the DMs’ views of each option with dependent attributes are very significant when choosing an appropriate choice for the MCDM problem. In this critical issue, the DME offers its significance ratings (Stillwell et al., 1981; Hezam et al., 2022). Now, the process of the q-ROF-RS method assists the DMEs to find the priority order of considered attributes. Then, the following is utilized to achieve the weight (wjs)-value as

where rj symbolizes the priority of each attribute, j = 1,2,3,…, n.Case III: Estimate the weights with the use of the q-ROF-ERSWIA

We apply the combination of the q-ROF-entropy and q-ROF-RS tools. In other words, we integrate the subjectivity and the objectivity of weight values of attributes to achieve the integrated weight of attributes as follows:

where τ defines the strategic precision coefficient and τ∈[0,1].Step 5: Computation of the “weighted sum model (WSM)” Ci(1) and “weighted product model (WPM)” Ci(2) values for each option as follows:

Step 6: Find the “utility degree (UD)” of each option.

By combining the assessment values with the use of Eqs. (7) and (8), we find the UD of each option as

where ‘λ∈[0,1]’ indicates the decision precision parameter. When λ=0 and λ=1, WASPAS is changed into the WPM and WSM, respectively).Step 7: Prioritize the option based on the score values of Ci,i=1,2,...,m.

Step 8: End.

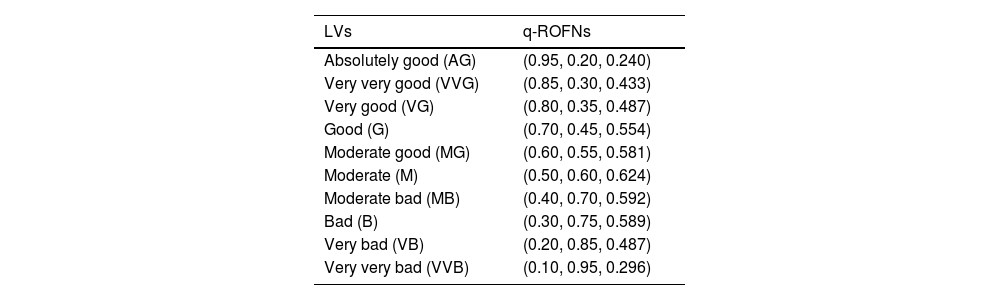

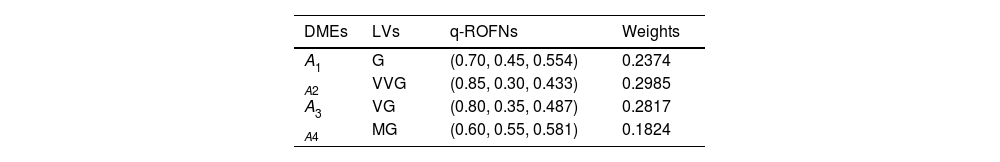

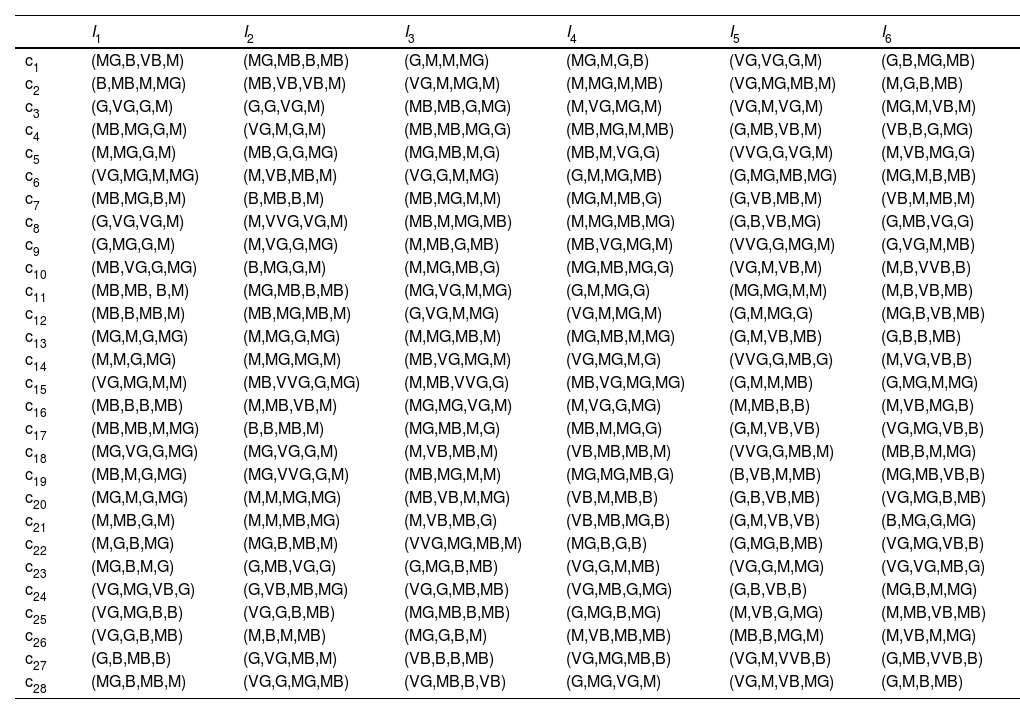

The current research conducted a survey by reviewing the existing literature and holding interviews with relevant experts to determine the key challenges that may arise with IoT-based applications in high-risk EHS industries within the Industry 4.0 age. To do so, several experts from academia and industry have been invited to participate in this survey. In this first step, the comprehensive list of the challenges related to general IoT has been extracted from the literature and sent to the experts as a questionnaire. In the next step, we asked the experts to select the most important challenges related to IoT in high-risk EHS industries; although most of the challenges in general IoT were included in the experts’ selection for all industries, however, there are some specific challenges for high-risk EHS industries were selected by experts, therefore, in total, 28 challenges have been selected the evaluate the IoT-based applications in high-risk EHS industries in the era of Industry 4.0. After the research framework was constructed, seven experts with IoT experiences were chosen to participate in the study to evaluate these challenges. These seven experts were selected from software, hardware, and manufacturing industries located in the industrial park. All the selected industries have >200 employees, and the 26 experts have >10 years of experience making decisions on IoT development and applications. Among the answers, five questionnaires were found with inconsistent answers, which would be sent back to the respondents to answer again. One of the experts declined to revise because of a time shortage. As a result, the answer corresponding to this expert was discarded from the analysis process. Thus, the results presented here are based on the responses received from only four experts. A novel q-ROF-ERSWIA-WASPAS is developed. In this way, the q-ROF-ERSWIA is applied to compute the integrated weights of challenges, and the q-ROF-WASPAS is implemented and used to find the ranking of industries in the era of Industry 4.0. Table 1 presents the ratings of DMEs and challenges in terms of LVs and then changed into q-ROFNs. Table 2 gives the DEs’ weights on the basis of Table 1 and Eq. (2). Table 3 designates the LDM for each DME for the evaluation of the industry over the considered challenges.

Ratings of criteria and DMEs regarding the LVs.

The LDM for challenges of IoT-based applications in the era of Industry 4.0.

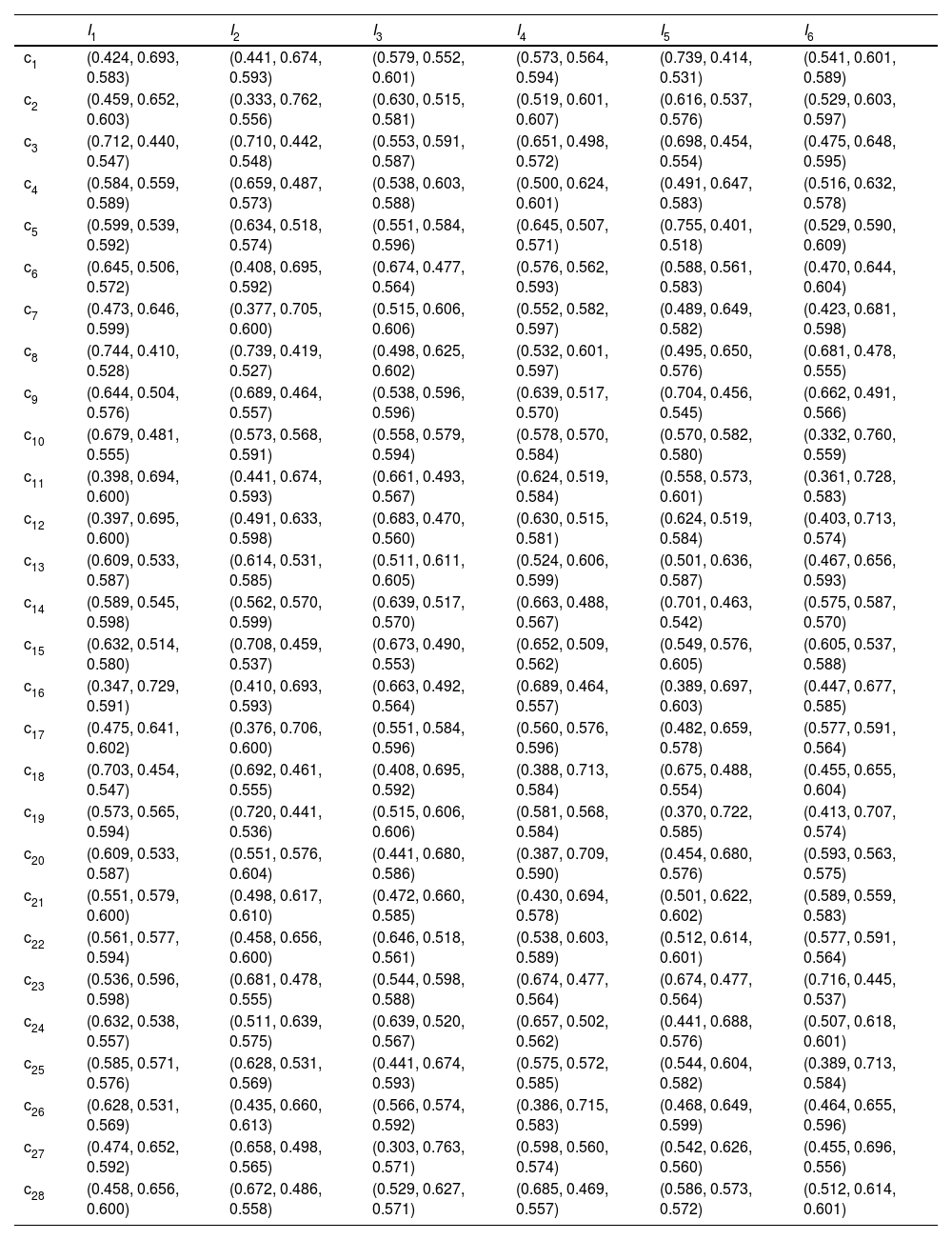

From Table 3 and Eq. (3), we create the A-q-ROF-DM Z=(zij)m×n and present it in Table 4 to prioritize the industries for the challenge of IoT-based applications in high-risk EHS industries in the era of Industry 4.0.

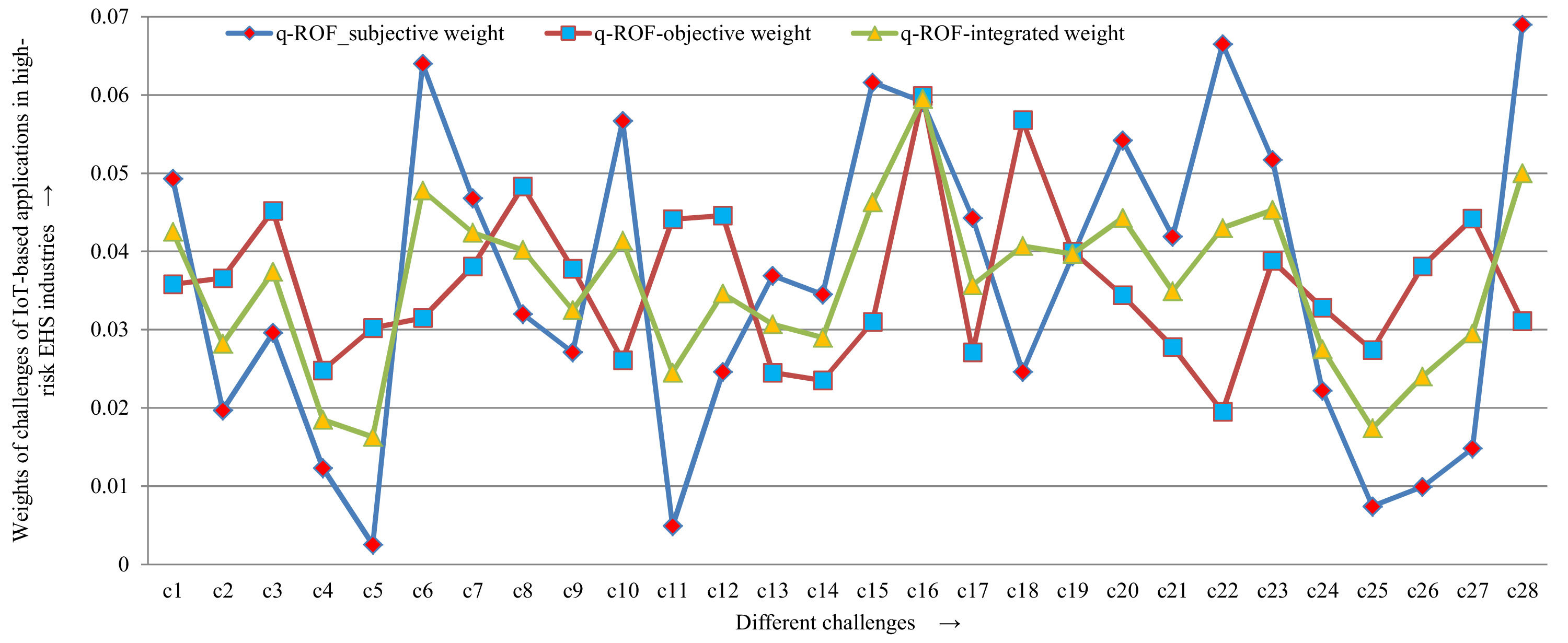

Step 4. Applying Eq. (4), the objective weight (wjo) of each challenge is computed and shown in Fig. 2.

The A-q-ROF-DM for challenges of IoT-based applications in the era of Industry 4.0.

wjo= (0.0358, 0.0366, 0.0452, 0.0248, 0.0302, 0.0315, 0.0381, 0.0483, 0.0378, 0.0261, 0.0441, 0.0446, 0.0245, 0.0235, 0.0310, 0.0599, 0.0271, 0.0568, 0.0400, 0.0344, 0.0278, 0.0195, 0.0388, 0.0328, 0.0274, 0.0381, 0.0442, 0.0311).

Using Eq. (5), the subjective weight (wjs) of each challenge is obtained in Table 5 and mentioned in Fig. 2.

Weights of the challenge of IoT-based applications in the era of Industry 4.0 using the RS method.

Next, we have applied the q-ROF-ERSWIA with the use of Eq. (6) to determine the weight of each challenge for τ=0.5 is depicted in Fig. 1 and given by

wj = (0.0425, 0.0282, 0.0374, 0.0185, 0.0163, 0.0478, 0.0424, 0.0402, 0.0325, 0.0414, 0.0245, 0.0346, 0.0307, 0.0290, 0.0463, 0.0595, 0.0357, 0.0407, 0.0397, 0.0443, 0.0349, 0.0430, 0.0453, 0.0275, 0.0174, 0.0240, 0.0295, 0.0500).

From Fig. 2, the weights of different challenges of IoT-based applications in high-risk EHS industries in the era of Industry 4.0 are depicted. We observe that the challenge support of communities (c16) with weight 0.0595 is the essential challenge of IoT-based applications in the era of Industry 4.0, followed by the consensus between stakeholders (c28) with weight 0.0500, standardization (c6) with weight 0.0478, commitment and comprehension from the different stakeholders (c15) with weight 0.0463 and high cost of implementation (c23) with weight 0.0453 other vital challenges of IoT-based applications in the era of Industry 4.0, while others are considered crucial the challenges of IoT implementation in high-risk EHS industries in the era of Industry 4.0.

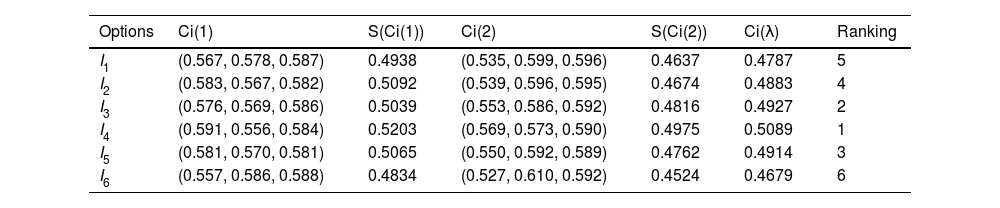

Steps 5–7. Using Table 4 and Eqs. (7)-(8), the WSM and WPM values are obtained. From Eq. (10), the UD (at λ=0.5) of each industry is computed and given in Table 6. From Table 6, the prioritization of different industries over various challenges of IoT-based applications in the era of Industry 4.0 is I4≻I3≻I5≻I2≻I1≻I6 and industry-IV (I4) is the most desirable industry with different challenges of IoT implementation in high-risk EHS industries in the era of Industry 4.0.

The UD of industries in the era of Industry 4.0.

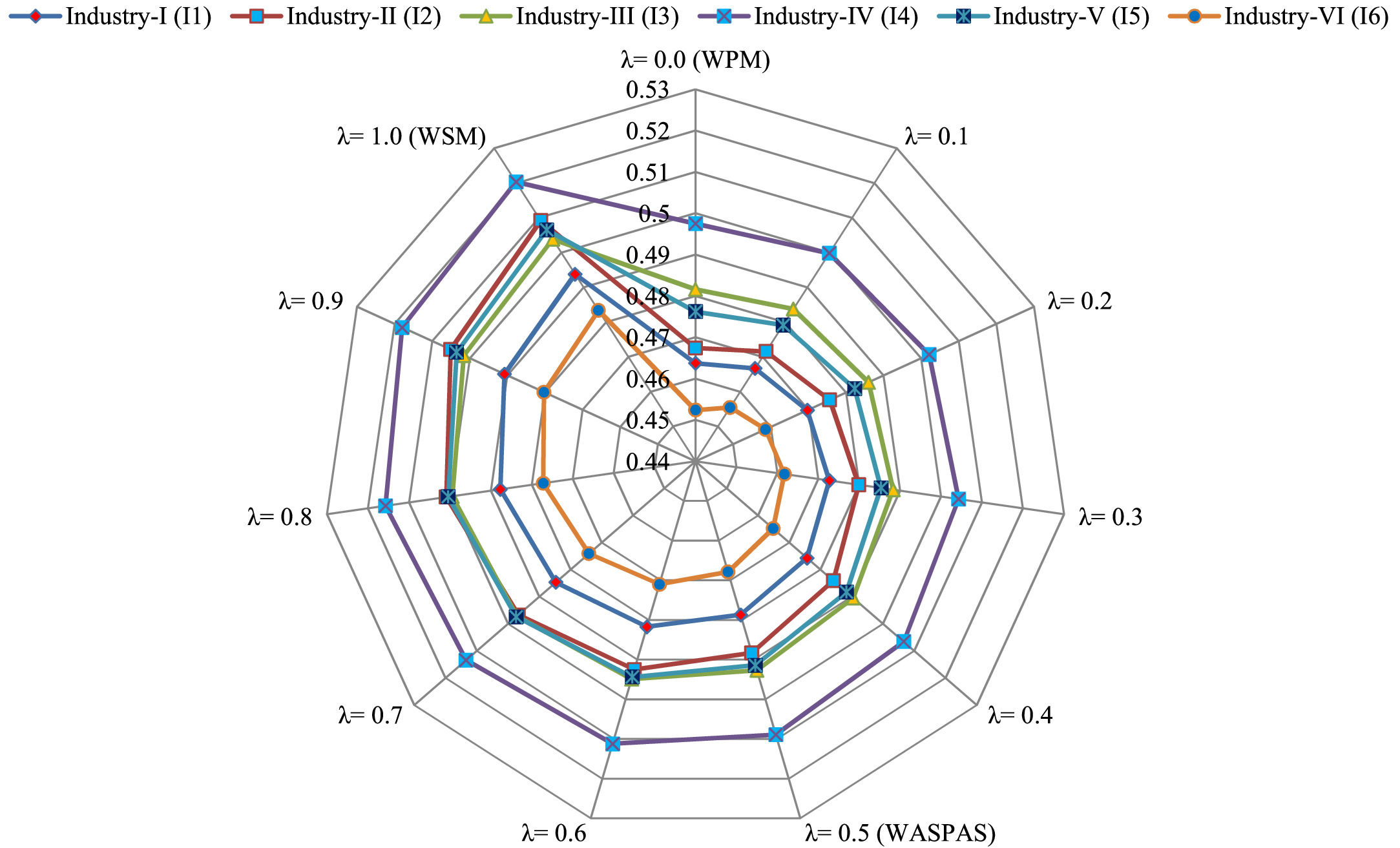

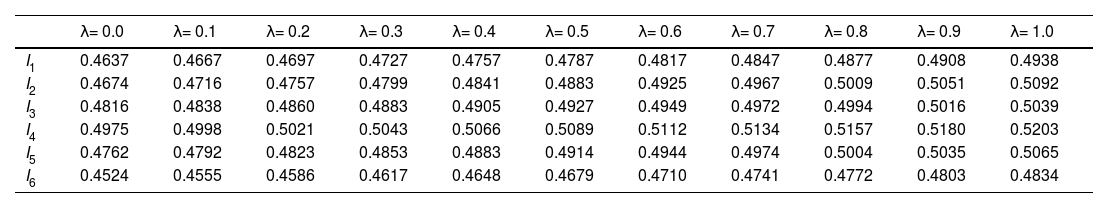

From different λ∈[0,1] values, the weights of different challenges were analyzed for the purpose of exploring the developed method's behavior. To change the λ values helps estimate the presented framework sensitivity when varying from WSM to WPM. Table 7 and Fig. 3 demonstrate the rank of the blockchain models considering the variations of challenges weight values from various values of the parameter λ∈[0,1]. Therefore, it could be said that a desirable industry for the diverse challenges related to the high-risk EHS industries in the Industry 4.0 age depends on and has the sensitivity to considered challenges’ weights. As a result, the presented framework was found to sufficient stability over different challenges’ weights and various parameters. Based on these figures, within all of the sets, industry (I4) achieved the first rank form λ=0.0 to λ=1.0, whereas industry (I6) achieved the worst rank form λ=0.0 to λ=1.0. Accordingly, it was explored that through the use of various parameter values, the stability of the q-ROF-ERSWIA-WASPAS method could be enhanced.

The UD of options with different challenges’ weights.

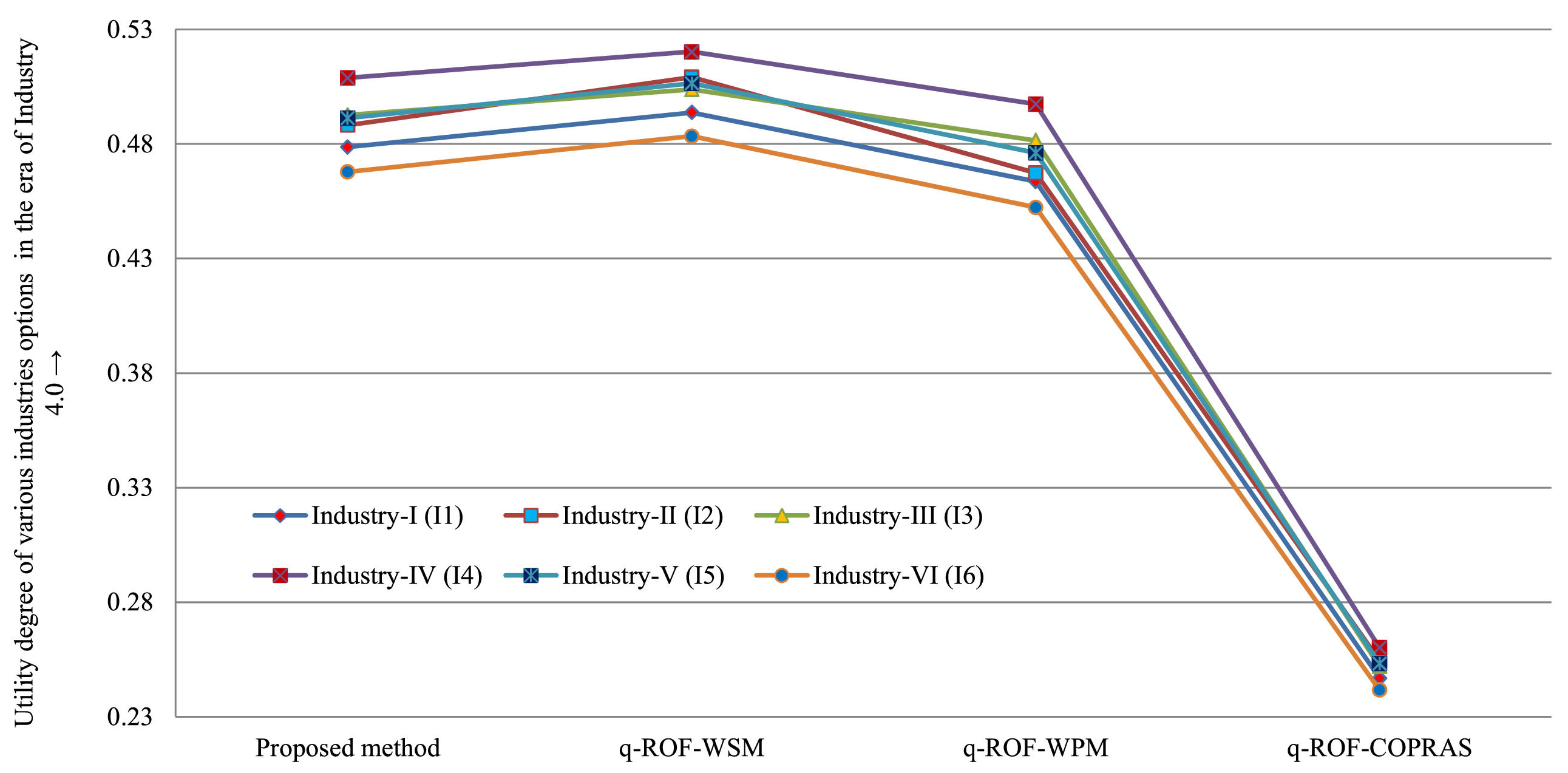

Here, the proposed framework is compared to other existing methods considering both theoretical and numerical factors for q-ROFSs. We consider the following method to compare the developed methodology as q-ROF-COPRAS (Krishankumar et al., 2019), q-ROF-WSM, and q-ROF-WSM (Rani & Mishra, 2020).

The procedure of q-ROF-COPRAS is given as follows:

Steps 1–4: Same as the presented approach

Step 5: As all the attributes are of the benefit-type, the assessment rating is analyzed of each industry as βi=⊕j=1nwjzij,i=1(1)m. The “relative degree (RD)” of each option is obtained: RD1 = 0.2469, RD2 = 0.2546, RD3 = 0.2520, RD4 = 0.2602, RD5 = 0.2533 and RD6 = 0.2417.

Step 6: Compare the RD of the six industries according to the RDs and get the priority of these industries as RD4≻RD2≻RD5≻RD3≻RD1≻RD6 and the industry-IV (I4) is the optimal one among the industries options.

Step 7: Assess the UD ℏi=RDiRDmax×100%, of each option as ℏ1=94.88%,ℏ2=97.84%,ℏ3=96.84%,ℏ4=100.00%,ℏ5=97.34% and ℏ6=92.89%.

Here, a comparison is discussed with the presented and some extant models, comprising the q-ROF-WSM and q-ROF-COPRAS and is depicted in Fig. 4. By comparing with the q-ROF-COPRAS method, the final ranking of the industries is I4≻I2≻I5≻I3≻I1≻I6. and the most industry is I4 for the challenges of IoT-based applications in the era of Industry 4.0. Hence, we observe that the optimal industry is the same with all the proposed q-ROF-COPRAS, q-ROF-WPM, and q-ROF-WSM approaches, while the prioritization of options slightly varies with diverse extant models. In general, the advantages of the “q-ROF-ERSWIA-WASPAS” approach over the existing methods are presented as follows:

- •

The weights of challenges in the presented method were assessed by the q-ROF-ERSWIA method as q-ROFNs by DMEs, whereas in Krishankumar et al. (2019), the criteria weights were calculated by linear programming model.

- •

The q-ROF-ERSWIA-WASPAS is a robust utility-based tool, which is an integration of WPM and WSM. The accuracy of the presented approach is strength than q-ROF-WPM and q-ROF-WSM. The q-ROF-ERSWIA-WASPAS is enabled to reach the peak precision of assessment using the presented approach for optimizing weighted aggregated operators and a new weighting-finding approach.

- •

The q-ROF-ERSWIA is applied to find the subjective and objective weights of the challenges in the era of Industry 4.0, which makes the presented “q-ROF-ERSWIA-WASPAS” tool more practical, flexible, and proficient.

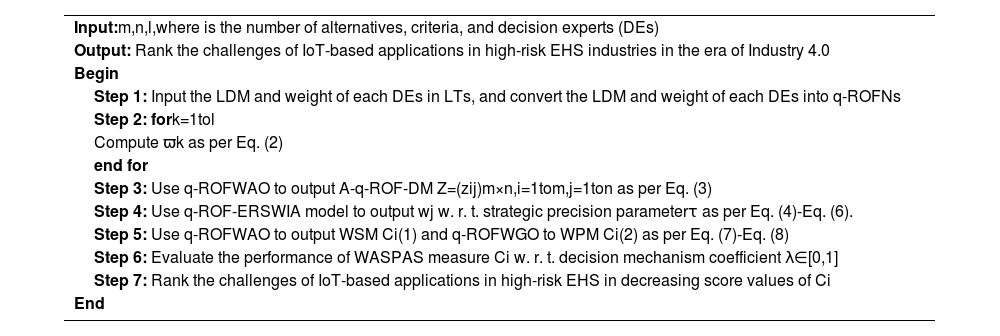

Many researchers have focused on high-risk EHS industries and their technological upgradation during the past decade. More specifically, the IoT has been used in this context to connect different medical devices, sensors, and healthcare providers, which has led to the provision of high-quality remote medical services. Such developments have enhanced patients’ safety, alleviated the risks associated with EHS industries, improved the availability of healthcare services, and also enhanced the operational efficiency of the healthcare industry. On the other hand, various challenges have arisen in the process of implementing IoT in high-risk EHS industries in the Industry 4.0 age. As a result, for the analysis, ranking, and evaluation of these challenges, the current research proposed an innovative decision-making approach, called q-ROF-ERSWIA-WASPAS, by means of q-ROF-ERSWIA and q-ROF-WASPAS methods for the evaluation of the research framework. In this approach, q-ROF-ERSWIM was employed to rank the challenges of IoT-based applications in high-risk EHS industries, and WASPAS was utilized for the computation of the preference order of various industries in the era of Industry 4.0. To validate the outcomes found by the presented approach, the results were compared with those of the q-ROF-WSM, q-ROF-COPRAS, and q-ROF-WPM methods. For computing the weight of each challenger-related IoT-based application in the era of Industry 4.0 using q-ROF-ERSWIM, the experts played highly important roles in evaluating and calculating the weights. The present study investigated the key challenges that may arise when applying IoT to high-risk EHS industries in the Industry 4.0 age. This study reviewed the work already done in this regard and the work that is required to be done in future research. Recent progress has made IoT implementation possible; nonetheless, this progress has not effectively addressed the versatility and prerequisites IoT will face. The authors of the present paper believe that, in the coming years, due to the huge interest shown by industries in implementing IoT, handling these concerns will be a powerful driving aspect for networking and communication research from both academic and industrial perspectives. The current study attempted to review the most important challenges associated with the use of IoT in high-risk EHS industries. In this regard, several challenges were identified, which could be focused upon to develop IoT implementation in such industries in the future.Algorithm 1

Pseudo code representation of q-ROF-ERSWIA-WASPAS for MCDM problems.

| Input:m,n,l,where is the number of alternatives, criteria, and decision experts (DEs) |

| Output: Rank the challenges of IoT-based applications in high-risk EHS industries in the era of Industry 4.0 |

| Begin |

| Step 1: Input the LDM and weight of each DEs in LTs, and convert the LDM and weight of each DEs into q-ROFNs |

| Step 2: fork=1tol |

| Compute ϖk as per Eq. (2) |

| end for |

| Step 3: Use q-ROFWAO to output A-q-ROF-DM Z=(zij)m×n,i=1tom,j=1ton as per Eq. (3) |

| Step 4: Use q-ROF-ERSWIA model to output wj w. r. t. strategic precision parameterτ as per Eq. (4)-Eq. (6). |

| Step 5: Use q-ROFWAO to output WSM Ci(1) and q-ROFWGO to WPM Ci(2) as per Eq. (7)-Eq. (8) |

| Step 6: Evaluate the performance of WASPAS measure Ci w. r. t. decision mechanism coefficient λ∈[0,1] |

| Step 7: Rank the challenges of IoT-based applications in high-risk EHS in decreasing score values of Ci |

| End |