To analyze the accelerator concentration on alginate impression material setting time made of brown algae Sargassum sp.

MethodThis study was an experimental laboratory using samples of impression material made of brown algae Sargassum sp. Measurement of setting time using stopwatch and morphological surface analysis using Scanning Electron Magnetic (SEM).

ResultThe average setting time for the fastest calcium sulfate accelerator is 3.11min (17g) and the longest is 6.13min (15g). As for the fastest potassium titanium fluoride accelerator material the timeline setting is 3.81min (4g) and the longest is 5.73min (2g). SEM analysis showed that alginate printing impression materials with accelerator materials of calcium sulfate 17g and potassium titanium fluoride 4g showed the smaller, finer denser and more homogenous surface morphology.

ConclusionImpression material made of Sargassum sp. with accelerator calcium sulfate 17g and potassium titanium fluoride 4g has a better setting time and surface morphology.

Alginate is used as a preliminary impression to make an individual tray, study models that help in the making of treatment plans, removable partial denture impression, orthodontic models, and restoration treatment plans.1–8 Alginate impression materials are available in powder form containing several components, one of the main components of which is potassium alginate which is soluble in water.9,10

Potassium alginate can be obtained from the extraction of brown algae (Phaeophyceae). There are several brown algae that can produce alginate, one of which is Sargassum sp.11 Brown algae grow wild and their potential has not been utilized in industrial fields, especially in the manufacture of impression materials in the field of dentistry.12 Other compositions are diatomaceous earth and zinc oxide, accelerator material in the form of calcium sulfate and potassium titanium fluoride and retarder material in the form of trisodium phosphate.

The addition of accelerator materials is important because it can regulate the time needed for material manipulation, applications in the oral cavity until the material becomes stiff or reaches a certain elasticity known as setting time. The setting time is related to the time used till material reaches the final thickening or hardening status. One of the tools for calculating the setting time by using a stopwatch.10 Clinically, the normal time setting required by hydrocolloid irreversible impression materials is 3–4.5min.9,10 It is important to pay attention on how much accelerator material is added to alginate impression material because it can affect the morphological quality of impression surface.

Accurate dental impression is strongly influenced by the setting time and surface smoothness of impression using irreversible hydrocolloid alginate impression material. The objective of this study was to analyze how much the concentration of accelerator material addition on alginate impression material made of brown algae Sargassum species, to produce the right setting time and good morphological surface to obtain high-accuracy impression.

Material and methodThis study was an experimental laboratory using brown algae Sargassum sp., 5% HCl, 4% Na2CO3, 12% NaOCl, 10% Ca2CO3, isopropanol (IPA), calcium sulfate, trisodium sulfate, diatomaceous earth, potassium titanium fluoride, zinc oxide, aquades, and waterone.

Extraction of potassium alginate Sargassum sp.Brown algae Sargassum sp. obtained from the coastal waters of Putondo-Punaga, Takalar District, South Sulawesi Province, Indonesia was extracted to produce potassium alginate.

Five kg dried brown algae was soaked in HCl 1% solution for 1h, then cleaned with distilled water, mixed with 4% Na2CO3 solution afterward then heated at 60°C for 2h, then diluted with distilled water and blended, then filtered. The filter is filtered with 12% NaOCl solution, 5% HCl was added (pH 2–3) to form a lump of alginate acid foam, then filtered again, washed and added with 10% Ca2CO3 to reach pH 7. 95% isopropanol was added on alginate acid with a ratio of 1:2 to be converted to potassium alginate and then frozen for up to 12h. Then dried into the freezer dryer, blended and sifted with 200 mess to become potassium alginate powder.

Preparation of impression material made of brown algae Sargassum sp.Dental impression materials was made by mixing all prepared ingredients (potassium alginate extracted from Sargassum sp. Brown algae, diatomaceous earth, zinc oxide calcium sulfate, trisodium phosphate and potassium titanium fluoride) at a certain percentage using mortar and pestle. After all components of the material were mixed evenly followed by sifting using a 200 mesh, a total of 45 samples were prepared with a 15 sample calcium sulfate accelerator formulation, 15 samples of titanium fluoride potassium and 15 control samples (Hygedent), then each formula was divided into 3 groups with 5 times repeated measurements. Formula samples can be seen in the following table:

Setting time measurementA total of 4g of impression material for each formula were mixed with distilled water for 30seconds at 23°C, then poured in cylindrical molded containers with a diameter of 30mm and height of 16mm. The setting time is measured/recorded using a stopwatch, starting at the time of mixing the material until the impression material was no longer attached to the indicator tool.

Data were obtained, collected and processed with ANOVA test to determine setting time differences in each group of alginate impression material formulations made of brown algae Sargassum sp. LSD Post-Hoc test were performed to determine the difference in the setting time value between each group, compared to the control impression material. Chi square test was used in observing surface morphology. The confidence level was 95% or the value of p=0.05.

Impression surface morphologyThe SEM tool used in this study was “Inspect S50”. Data were obtained, collected and processed with ANOVA test to determine setting time differences in each group of alginate impression material formulations made of brown algae Sargassum sp. LSD Post-Hoc test was performed to determine the difference in the setting time value between each group, compared to the control impression material. Chi-square test was used in observing surface morphology. The confidence level was 95% or the value of p=0.05.

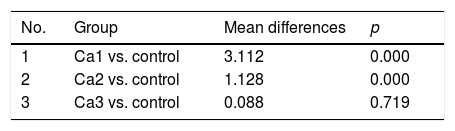

ResultSetting timeThe average setting time on each impression material and comparing it with the control impression material can be seen on the following table.

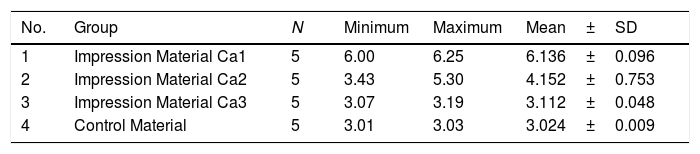

Table 1 showed that the impression material with the fastest setting time is the Ca3 formula which is 3.112min then followed by the C2 formula 4.152min and the longest setting time is the formula Ca1 with 6.136min. The control impression material has an average setting time of 3.024min.

Average setting time (min) of several calcium sulfate formulation in alginate impression materials made of brown algae Sargassum sp. and standard alginate as control materials.

| No. | Group | N | Minimum | Maximum | Mean±SD |

|---|---|---|---|---|---|

| 1 | Impression Material Ca1 | 5 | 6.00 | 6.25 | 6.136±0.096 |

| 2 | Impression Material Ca2 | 5 | 3.43 | 5.30 | 4.152±0.753 |

| 3 | Impression Material Ca3 | 5 | 3.07 | 3.19 | 3.112±0.048 |

| 4 | Control Material | 5 | 3.01 | 3.03 | 3.024±0.009 |

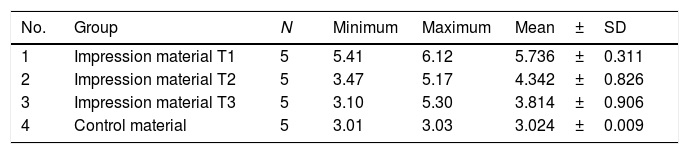

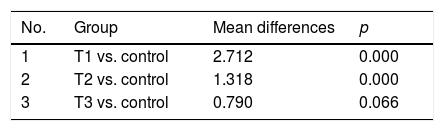

Table 2 showed that the impression material with the fastest setting time is T3 formulation with 3.814min, followed by a T2 formulation 4.342min, and the longest one is a T1 formula with 5.736min. The control material has an average setting time of 3.024min.

Average setting time (min) of several potassium titanium fluoride formulations in alginate impression materials made of brown algae Sargassum sp. and standard alginate as control materials.

| No. | Group | N | Minimum | Maximum | Mean±SD |

|---|---|---|---|---|---|

| 1 | Impression material T1 | 5 | 5.41 | 6.12 | 5.736±0.311 |

| 2 | Impression material T2 | 5 | 3.47 | 5.17 | 4.342±0.826 |

| 3 | Impression material T3 | 5 | 3.10 | 5.30 | 3.814±0.906 |

| 4 | Control material | 5 | 3.01 | 3.03 | 3.024±0.009 |

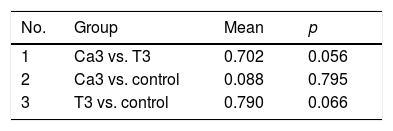

The average setting time of Ca3 formula almost has the same time with the control material, 3.112: 3.024min and statistical tests also showed differences though are not significant, while for the formula Ca1 and Ca2 showed significant differences (Table 3).

The average setting time of T3 formula has the same time with control material. This result was also reinforced by the results of statistical tests that show no significant difference, while for formulas T2 and T1 the results showed significant setting time differences (Table 4).

A very small difference between C3, T3 and control material formulas, thus no significant difference with those two formulas and control (Table 5).

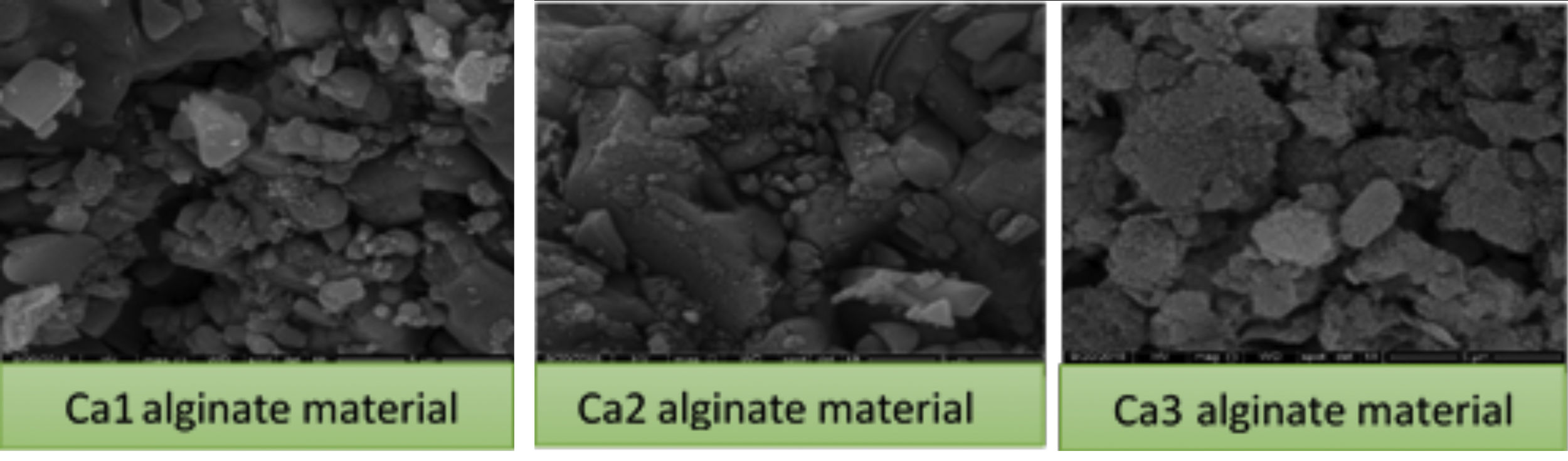

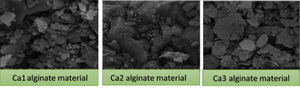

Surface morphology of alginate impression materialFig. 1 showed the results of surface morphology by SEM analysis at 20,000 magnification. Ca1 alginate material showed larger and sharper particles, while the surface on Ca3 formula showed the smoothest surface, the smallest particle size, density and homogenous. This mixture profile is a good profile for impression material because it will easily follow the contours of the teeth and tissues contained in the oral cavity.

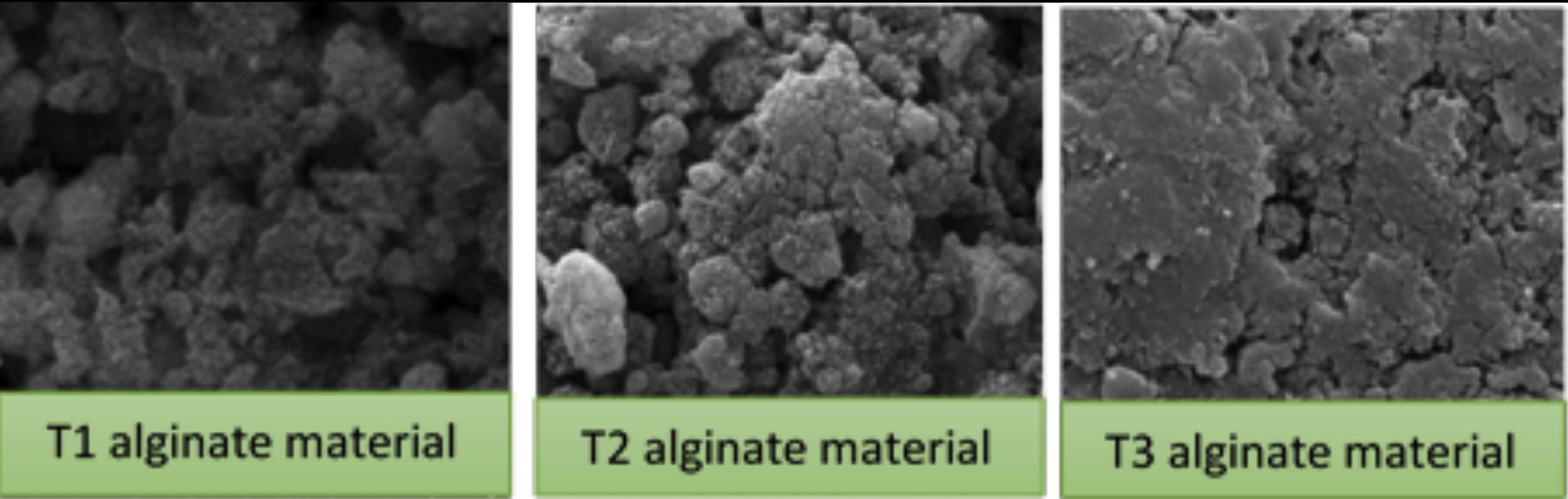

Fig. 2 showed the results of surface morphology examination by SEM analysis at 20,000 times magnification. T1 alginate impression material showed a profile that resembles a honeycomb which is a characteristic of alginate-based impression material. Characteristics of hollow materials like this are not good for an impression because it showed that the material was not mixed and blends well. T3 impression material showed a continuous and tight profile compared to T1 and T2 materials.

DiscussionSeveral studies has been carried out regarding brown algae from Indonesian Makassar waters, the results showed several physical properties that resemble standard alginate impression materials.13 Setting time is the time used to manipulate the material into certain elasticity. The material usually used to adjust the setting time is an accelerator in the form of calcium sulfate and potassium titanium fluoride, while the retarder can be in the form of trisodium phosphate.9,10

The results of setting time examination showed that the increased percentage of calcium sulfate and potassium titanium fluoride accelerators led to a faster setting time of alginate impression materials. This showed that the higher the percentage of the accelerator, the faster the formation of alginate gel occurs. The impression material with formulation of calcium sulfate 17g (C3) accelerator has the fastest setting time of 3.112min, while the 4g (T3) titanium fluoride potassium accelerator has the fastest setting time with 3.814min, while the control setting is 3.024min. Based on the recommendations of the American Dental Association (ADA) no. 18 and ISO 1563 there are 2 types of setting time for alginate, namely fast set with a setting time of 1–2min and normal set with a setting time of around 3–4.5min. Thus, the results of this study fall into the category of alginate with a normal set or regular set.14–16

The setting time must be sufficient to give practitioners time when mixing ingredients, placing the material into the tray, and into the patient's mouth, giving comfort to patients not to open their mouths for too long. The setting time can also be influenced by several factors including water powder ratio, water temperature used, room temperature, stirring technique, mixing time and composition of alginate.17,18

The results of one-way ANOVA LSD post-hoc test showed that the comparison between alginate impression material Sargassum sp. C3 formula and T3 formula with control material showed no significant differences (p>0.05) which means that the setting time of the formula corresponds to the standard impression material that circulates in the market.

In mixing powder and water, soles and alginates are formed, salt, calcium, and phosphate begin to dissolve. The gel formation is blocked by trisodium phosphate which reacts with calcium sulfate to produce calcium phosphate deposits. Calcium phosphate is formed earlier than calcium alginate, this is due to lower levels of calcium phosphate solubility compared to calcium alginate. Trisodium phosphate found in alginate, as a retarder will affect the working time when mixing water with alginate material. After the phosphate ion has reacted, the calcium ion will react with soluble alginate (water-soluble alginate) to form calcium alginate. The replacement of the monovalent sodium group with divalent calcium produces cross bonds in the alginate chains and the conversion of material from the sol form to the gel. When a setting reaction occurs, and the degree of crosslinking increases, the gel gives off elastic properties.9,10

By comparing the alginate impression formula Ca3 and T3, it can be concluded that the brown algae impression material with calcium sulfate 17g (Ca3) accelerator has the setting time that is closest to the control impression material time setting, namely 3.112: 3.024min and Ca3 impression formula has the best morphological surface because it has smaller particle size, less porous and homogeneous so that it shortens the setting time of impression material compared to T3 formula material. Impression materials with smaller size particle and smaller porous are very recommended to be used as teeth and tissue impression in oral cavity, because they can replicate dental tissue and its surrounding areas with a high degree of accuracy.

ConclusionSargassum sp. brown algae impression material with accelerator composition of calcium sulfate 17g and potassium titanium fluoride 4g has a better setting time and surface morphology compared to impression materials with other formulas.

Conflict of interestThe authors declare no conflict of interest.

Peer-review under responsibility of the scientific committee of the International Conference on Women and Societal Perspective on Quality of Life (WOSQUAL-2019). Full-text and the content of it is under responsibility of authors of the article.