The present paper looks into the situation of independent inventors in two South American countries. Little has been published on this topic in Brazil and other emerging economies. Despite the growing efforts of innovation-supporting institutions, public innovation policies have not always benefited inventors as intended. Based on the cases of three inventors (one Ecuadorian and two Brazilian), we identified the difficulties and challenges of elevating inventions to the category of innovation and tried to determine to what extent public policies and innovation-supporting institutions have contributed to this process. Our results show that independent inventors will continue contributing to innovation, most often by perfecting techniques and improving existing products, responding to adversity with determination and resilience and honing their creative skills. For many, acknowledgment is more important than profit. Inventors adhere to a vision, the belief that they can change realities and help others exercise their trades more efficiently, with quality of life.

Independent or individual inventors represent a minority in technical and scientific production in these times of progressive institutionalization of the invention process and the creation of alliances between the government, private firms and universities, a model referred to as the triple helix (Leite & Mota-Ribeiro, 2004; Salvador, 2008). However, independent production is still relevant in developing countries where technological development indices are low and little investment is made in research, development and innovation (INDECOPI, s.d.; INPI, 2016; GII, 2015).

In the countries sampled for this study, independent inventors have made a significant contribution to the increase in patent applications filed with the National Industrial Property Institute (INPI) and the National Institute for the Defense of Free Competition and the Protection of Intellectual Property (INDECOPI), organisms responsible for granting patents and issuing intellectual property licenses. However, the path from invention to innovation can be long and arduous for the inventor. Moreover, access to publication in the specialized literature and to debates on public research, development and innovation policies tends to be very limited.

Unsurprisingly, not much has been published on independent inventors (Barbieri, 1999; Chrisomalis, 1996; Conceição, 2003; Thiebaut, Rios, & Azevedo, 2016) and on the obstacles and challenges they face (de Fátima Morais, 2007; Gonçalves & Tomaél, 2013; Mendes, 2009; Pinheiro, 2001).

In order to review and expand the discussion on the situation of independent inventors, the following question was formulated: What challenges and opportunities do independent inventors encounter in the exercise of their trade? To answer this question, the following study objectives were established: i) analyze the challenges faced by independent inventors in their efforts to elevate inventions to the category of innovation, ii) analyze the adequacy of public policies and the contribution of innovation-supporting institutions to policy-making, considering the growing allocation of public funds to innovation-supporting programs, and iii) generate subsidies for the theorization on innovation and independent inventors.

The paper is laid out in five parts: an introduction, a section describing the theoretical framework, a section outlining the methods, a descriptive analysis of our findings, and a closing section with our main conclusions.

Theoretical frameworkHuman creativity can materialize in many different ways, resulting in inventions, whether tangible or intangible. However, much attention should be given to the question of intellectual property and its urgent need of legal protection.

Creativity and inventionAccording to Schumpeter (1982), economic development ultimately depends on technological innovation. Independent inventors, by combining the qualities of persistence and creativity, are highly valued on the current labor market. Perhaps the greatest advantage of independent inventors over corporate inventors is freedom of thought and action (Dahlin, Taylor, & Fichman, 2004).

Increasing attention is being given to creativity, invention and innovation due to their importance to economic dynamics. In the corporate world, organizations and professionals are encouraged to ensure environments are inventor-friendly in the hope of speeding up the process of invention and conversion to innovation (Hargadon & Sutton, 2000; Martins & Terblanche, 2003).

The creative process requires direct effort and insight on part of the inventor, not merely knowledge acquisition. The concepts of creation and invention are very close: as explained by Amorim and Frederico (2008, p. 17), creativity is immaterial, subjective and intangible. On the other hand, invention is the materialization of ideas generated by creativity (Tigre, 2006).

Leite and Mota-Ribeiro (2004) have shown that economic returns are not necessarily proportional to the effort invested in creative work, but this rarely demotivates inventors many of whom are driven by their ability to identify problems and find solutions. Creativity may be seen as fuelling the appearance of new ideas and, consequently, inventions capable of turning into innovations. Because creativity is so strongly tied up with the process of innovation—hence with economic growth—much is invested in fostering it.

As shown by Parolin (2001, p. 34), the literature on creativity and corporate innovation covers three main perspectives: i) the characteristics of highly creative and innovative individuals, ii) the characteristics of environments favoring or inhibiting creativity and innovation, and iii) the cognitive skills required by creative and innovative thinking. Likewise, Alencar (2010) believes creativity is inherent to the individual and that cognitive skills are susceptible to stimulation and development through training; therefore, organizations should make the work environment creativity-friendly and even offer incentives beyond professional remuneration.

Independent inventorsThe World Intellectual Property Organization (WIPO) defines ‘inventor’ as a natural or legal person authoring an invention. Inventors are entitled to legal protection of their intellectual property through the filing of a patent application. A patent is a right to exclusive commercial exploitation granted, upon application, by a government agency (or equivalent) to an inventor in exchange for detailed public disclosure. Industrial patents may be for inventions (if the criteria for novelty and usefulness are known), inventive activities, industrial applications and utility models (minor improvements of existing products or processes) (WIPO, 2015).

Barbieri (1999, pp. 39–40) classifies inventors into three types: i) inventors employed by R&D centers, ii) inventor-entrepreneurs who, though independent, do not fit the artisanal/workshop model, but start their own business to exploit their inventions, iii) independent inventors of the classic artisanal type who invent at home or on the job, such as when a motorcycle mechanic converts a motorcycle into a mini tractor.

Independent inventors develop their inventive skills on the margin of the larger corporate world (Pinheiro, 2001, p. 2). Despite social discrimination (many relate being stigmatized as “Gyro Gearloose” types) and the lack of public policies to support the development of their inventions (few inventions are ever operationalized), independent inventors are often remarkably resilient (Mendes, 2009). As put by Leite and Mota-Ribeiro (2004, p. 2), the predominant image of the independent inventor is not one of economic success, social projection and prestige.

In Brazil, data collected by the INPI show that, despite the decline in the proportion of patent applications filed by independent inventors, reaching 54% in 2014, most applications still come from this segment. Peru has no tradition of registering or patenting inventions, but the number of applications has grown by 260% since the introduction of government incentives in 2006 (Banco-Mundial, 2015).

One of the consequences of strengthening the national system of innovation is the establishment of associations of inventors, which often serve as intermediaries and catalysts helping inventors obtain patents and, if successful, starting their own small or mid-sized technology-based firms to manufacture and market their inventions (WIPO, 2015).

To deal with problems such as limited access to funding, R&D laboratories and patent offices, Brazilian independent inventors are now supported by the Brazilian Association of Inventors and Industrial Property (ABRIPI), which defends their interests at the level of the federal government (ABRIPI, 2013). In Peru, the government agency INDECOPI plays an important role organizing activities, encouraging inventors to register their inventions and facilitating contact between local economic actors and potential investors (INDECOPI, s.d.).

Intellectual property protection policies and incentives to innovation in Brazil and PeruAccording to the WIPO, intellectual property may be either industrial property (patents of inventions, trademarks, industrial designs, geographical indications) or copyrights (literary, artistic and scientific creations, performances by singers and other artists, recordings and radio broadcasts (WIPO, 2015).

The Brazilian Constitution of 1988 protects intellectual property, whether it be industrial property or copyrights, and provides incentives for innovation. However, to ensure exclusive rights to the exploitation of industrial property, the inventor must obtain a patent (inventions and utility models) or a certificate of registry (trademarks and industrial designs) (Santos & Soares, 2011).

As pointed out by Silva and Dantas (2013), once established, laws have to be regulated. Passed in 2004, the so-called ‘Law of Technological Innovation’ (LTI) (Law #10.973) was regulated on 11 October 2005 by directive #5563 to help foster innovation in the academic and corporate environment. The purpose of the LTI is three-fold: i) create an environment favoring the development of partnerships between universities, technology institutes and firms, ii) encourage the participation of S&T institutes in the innovation process, and iii) stimulate corporate innovation.

The passing of the LTI has benefited independent inventors in the form of more systematic incentives. For example, the law makes it possible for public universities to support independent inventors through technological innovation centers, as long as a patent application has been filed with the INPI. In addition, an analysis of the sales strategy and the market potential is required by the center before initiating development or incubating the manufacturer.

However, patenting can be a slow and complex process. According to Federman (2010, p. 50), patents are a ‘taboo’ for many independent inventors who claim lack of time and funds to deal with the paperwork, complexity, delays and costs involved.

On the other hand, the LTI has been criticized by some inventors and by the ABRIPI due to its economic criteria for partnerships with S&T institutes, since inventors are required to share the profits they obtain from the sales of their inventions. As explained by Mendes (2009, p. 46), the law disposes that S&T institutes can create regulations for cooperation with inventors but does not determine the adoption of the criteria of economic feasibility and socioeconomic impact for approving inventions of public interest. In the opinion of Christensen and Kaufman (2008), the traditional evaluation criteria can delay (or even obstruct) the development of new technologies because they fail to take into account intangible aspects inherent to the process of innovation.

Inventors overcoming these initial hurdles may become innovative entrepreneurs but will face other challenges typical of small and mid-sized businesses, including limited access to credit (working capital or investment), small production scale, and poor brand awareness and market tradition. Moreover, the transition from the stage of informal development to the stage of formal economic activity often entails prohibitive costs. On the other hand, small businesses tend to be more flexible than large corporations, with faster decision making, less bureaucracy and a working atmosphere marked by enthusiasm (Pinheiro, 2001; Thiebaut et al., 2016).

In 1995, the government of Peru created the INDECOPI through legislative directive #807. The country is signatory of the Andean Community (CAN) trade agreement, to which multinational regulations are applicable. The most important of these is decision #486-2000 which establishes analogical property rights for citizens of member countries and the extension of patents to the entire community (INDECOPI, s.d.).

A hallmark in the development of the regulations and treaties of the INDECOPI is the establishment in 2006 of an ST&I funding program named FINCYT. The program started out with funds from the World Bank and the mission of generating new S&T know-how, promoting corporate innovation and strengthening the national innovation system (INDECOPI, s.d.; FINCYT, s.d.).

The original regulations of the FINCYT offered no incentives to individual inventors, but following budgetary changes in 2013 a project was created for the inclusion of individual inventors, fostering the emergence of new businesses and upstarting incubators. The funds are supplied by the Marco Fund for ST&I (FOMITEC) and investment is non-refundable. Depending on technical criteria, the amount invested in a project ranges from PEN 50,000 to 170,000 (FINCYT, s.d.).

Although the program is considered an advance in a country which only recently implemented a national innovation system, individual inventors are still not entirely supported since submitting an application to the FOMITEC requires having operated a company for at least one year and being certified by the national inspection agency, or (in the case of the program ‘Startup’) associating with up to four other independent inventors co-responsible for keeping project deadlines on pains of having to return funds to the public coffers (FINCYT, s.d.).

MethodologyA qualitative approach was adopted in the present study (Dyer & Wilkins, 1991). According to Stake (1998), the qualitative method does not generalize a priori; rather, it attempts to capture the complexity of the investigated realities and phenomena.

The choice of multiple case study was based on Godoy, Bandeira-de-Melo and Silva (2010, p. 121), according to whom the method is adequate for focusing on practical problems derived from intricate individual and social situations present in everyday activities, procedures and interactions.

Information was collected through semistructured interviews and simple observations made during field work using notepads (Gil, 2010). In addition, information on the institutional environment of the inventors was retrieved from the websites of INPI, INDECOPI and ABRIPI.

Conducted in the home setting, the interviews were narrative. According to Jovchelovitch and Bauer (2004), narrative interviews are in-depth interviews with specific features, using as point of departure a self-generating schema (‘once upon a time’), based on what is experienced by the story-teller.

The interviews were recorded, transcribed and imported as audios and documents into a project of the software Atlas T.I v. 7.5.10. Oliveira, Martins, and Vasconcelos (2012) recommend the use of in-depth interviews when analyzing social realities from the perspective of the social agents.

The discourses extracted from the interviews were submitted to open content analysis in order to identify the structure and the elements of the content and clarify their specificities, followed by descriptive analysis (Bardin, 2011; Laville & Dionne, 1999).

Finally, the topics were categorized as suggested by Bardin (2011) in the following steps: i) in-depth reading of transcriptions; ii) reading of selected passages; iii) identification of clusters of meaning; and iv) topicalization.

The interviews were conducted between July and December 2015. The interviewees included two Brazilian independent inventors, an Ecuadorian independent inventor (currently a Peruvian subject), the manager of a business incubator, the Deputy Head of the Ceará State Department of Agriculture, and a former president of the ABRIPI.

The selected cases were successful inventions acknowledged and/or awarded innovation prizes in their respective areas. The socioeconomic impact of the inventions (greater productivity, income and quality of life for consumers) was also taken into account.

During the interviews with the three inventors (whom we shall refer to as Alpha, Beta and Omega throughout the study) we looked into how the inventions came into being, from concept to marketing, along with the main challenges and opportunities encountered.

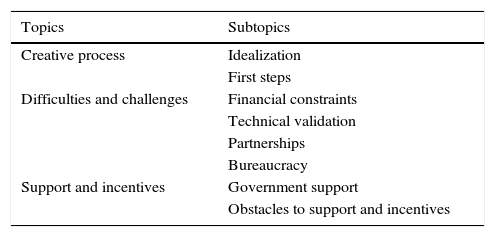

Results and discussionThe following subtopics were extracted from the interviews: idealization, first steps, financial constraints, technical validation, partnerships, bureaucracy, government support, and obstacles to support and incentives (Table 1).

Topics and subtopics of content analysis.

| Topics | Subtopics |

|---|---|

| Creative process | Idealization |

| First steps | |

| Difficulties and challenges | Financial constraints |

| Technical validation | |

| Partnerships | |

| Bureaucracy | |

| Support and incentives | Government support |

| Obstacles to support and incentives |

Source: The authors.

The cases selected for the study have had socioeconomic impacts in different areas, associated with improvements in family farming productivity, safety, quality of life and sustainability.

Mini tractor for use in family farmingAlpha's patent application describes the minitractor as follows: agricultural quadricycle composed of a horizontal chassis, a differential, a gearbox with 4 speeds and 1 reverse, a 1-cylinder diesel engine with 9 cv, measuring 165cm in length and 80cm in width, designed to pull agricultural implements, with a bar for mounting tools for tillage, seeding and cultivation (retrieved from the national depository of patent applications, Brasil Patente #PI 0905463-4 A2, 2009).

The mini tractor is produced in artisanal fashion at Alpha's workshop and still requires adjustments to technical norms and other certifications. Nevertheless, farmers and cooperatives have shown much interest in purchasing the product. Alpha has been manufacturing on demand, with over 30 units sold at the time of writing. However, due to lack of funds, working capital and modern machine tools, Alpha is unable to shorten manufacturing time and increase the scale of production.

Buyers have to pay in advance and wait over two months for delivery. Using incentives granted by the state government, Alpha has attended fairs (some of which abroad) to display his invention. His stand has attracted numerous visitors and received positive reviews.

Safety vest for motorcyclistsIn the national depository of patent applications (Brasil Patente #PI 0704794-0 A2, 2007), Beta describes his invention as a safety vest for motorcyclists with several functions, including i) protect the body in the case of an accident, ii) serve as a sling for the removal of the injured motorcyclist, iii) provide a surface for advertising display, and iv) protect the cervical region. The vest was designed specifically for motorcyclists, with focus on injury prevention.

Use of banana palm fiber in shoemakingOmega is an inventor-entrepreneur according to the classification of Barbieri (1999). The combination of manual skill and banana farming (a family business in Ecuador) inspired the inventor to extract the fiber of palm leaves. After many experiments, a fiber was developed which is resistant and malleable enough to serve as raw material for bags, wallets and footwear.

The creative processAccording to Pinheiro (2001), the creative process of independent inventors usually takes place on the margin of larger business structures and tends to be related to the inventor's personal life experience. Barbieri (1999) observed that most inventions of inventor-entrepreneurs are made in response to needs in the workplace or household. This view is supported by the discourse of the inventors interviewed for this study when describing the genesis of their inventions.

IdealizationAlpha conceived the idea of building a mini tractor as a child: “When I was seven years old I saw a bulldozer making a road through a field and I thought to myself: a tiny tractor is just what is needed to remove the soil between the rows. I never stopped thinking about it”. Three decades later the idea had become a prototype. Alpha is near-illiterate and makes a living from motorcycle repair and subsistence farming.

During recovery at the hospital after a serious motorcycle accident, Beta observed the arrival of several victims of accidents and noticed that the most severe cases were often motorcyclists. He figured that “if some kind of protection existed, I wouldn’t be so badly injured and half the motorcyclists admitted today would be at home with their families”. This confirms the claim by Barbieri (1999) that independent inventors most often improve already existing products and processes, especially those related to their work routine. The inventor Beta adds that many injuries could be avoided if the safety vest was made mandatory by the traffic code. It is Beta's dream to see the safety vest enjoy the same status as mandatory equipment for motorcyclists as the helmet does today.

Omega falls in the category of inventor-entrepreneurs (Barbieri, 1999). She is from a family of banana farmers in Ecuador, but unlike her siblings she never been interested in agriculture or food processing. Being a fashion lover, she moved to Lima (Peru) to study shoe design. During the course, it struck her that banana palm fiber might be useful in shoemaking: “banana leaves are treated as refuse, but why not use them to make sustainable fashion footwear?” After much trial and error, the fiber was resistant and malleable enough for the purpose.

First stepsThe first prototype of the mini tractor was a three-wheeler. It took almost a year to build and test in routine farm operations on Alpha's own land. During a visit of the Deputy Head of the State Department of Agriculture to the municipality, Alpha's prototype was demonstrated in action. The delegation was impressed and acknowledged the relevance of the tractor to family farming. Alpha said: “I told him I could make a better model, even one with a diesel engine, so I was invited to come to the capital the following Monday and bring the material. The system used to lift farming implements was manual at the time so I built a hydraulic one in my workshop”.

Since the day of that visit, many incremental innovations have been incorporated into the design of the mini tractor. The most recent was the addition of a canopy: The Alpha inventor said that now the farmer can work in the shade. More improvements are on the way: “I am working on this one here [points to unfinished prototype]... the hydraulic system will be more modern” (Alpha, 2015).

When Beta had recovered from his accident, he started working on a prototype for which he was later awarded first place in a national competition for inventors. Once the initial tests and adjustments had been made, Beta received an order for 400 units from the mayor's office of a small town in Northeastern Brazil. However, due to budgetary regulations, municipal governments are not allowed to make advance payments. As a result, Beta was unable to deliver the order for lack of funds to set up the necessary manufacturing structure.

Unlike the other two inventors, Omega had access to funding and the support of the family business: “I knew I wasn’t cut for jam factory manager so I told my father I wanted to be a fashion designer. Some weeks later I was enrolled in a course [...]. When I got the idea of using banana palm fiber as raw material for fashion products, we hired some women living near the farm to process the fiber. During the next months, we made adjustments in texture until the fiber was ready for manufacture”. Omega is both an independent inventor and an entrepreneur. She started up a business to produce and distribute her product and render services based on intellectual property (Bittencourt, 2010). From the get-go, she made plans for commercial exploitation, looked into the requirements and advantages of patent registration, and prepared to export to the US and Germany, countries in which the family business maintains sales offices.

Difficulties and challengesAs shown by Pinheiro (2001), even when the initial difficulties are overcome and the inventor has become an entrepreneur, other significant obstacles present themselves: limited access to credit (working capital or investment), small production scale (high manufacturing cost per unit) and lack of an established trademark and market tradition.

Financial constraintsAlmost all independent inventors face substantial financial constraints. The lack of resources may prevent inventions from being converted into innovations. As we have seen, without money to operationalize production, Alpha needs advance payment and two months to deliver a single unit. Such constraints compromise sales and the economic feasibility of the business.

For example, while participation in invention fairs is usually viewed as a valuable opportunity for nascent businesses, it has become a source of frustration for Alpha: “what does attending these fairs benefit me if I can’t produce the mini tractor fast enough to deliver?”

Technical validationThe most frequent complaint among Brazilian independent inventors is limited access to credit. Inventors are often asked by banks to provide collateral or meet other requirements, such as owning a patent or having performed all the necessary tests. A relative of Alpha's observed that “when you go to the bank, they ask for the registry, the patent, the tests [...] but since we haven’t performed the tests the entire process stops, and no funding is granted”. Beta had a similar experience when he requested a start-up loan of BRL 300,000 to set up a safety vest production line. However, without funding and working capital, production was halted and important sales opportunities were missed.

In addition, access to accredited institutions capable of performing validation tests and making inventions comply with technical safety regulations is not always a simple matter. According to the Deputy Head of the Ceará State Department of Agriculture (a supporter of the mini tractor project), “the University is equipped to perform strength tests but nothing has been done yet [...] we tried through the CENTEC, then through the University, but have made no progress”. The laboratory which, according to Beta, is equipped to perform the necessary testing of his invention is located in São Paulo. Thus, in addition to the prohibitive cost of the laboratory tests, inventors in this part of the country are hindered by geographical barriers.

Funding partnersFinding credit is not the only challenge independent inventors face. For example, Omega had access to funding but her shoemaking business did not produce the expected results for several months due to the lack of manpower trained in the use of the new raw material. She said: “My father and I visited a large number of shoe factories in an attempt to outsource the manufacturing part. Factories willing to partner did not meet our criteria for structure and quality, and the more well-established firms would not talk to us”. The solution was to take the risk and hire independent craftspeople from Ecuador to produce the first collection of shoes. The two Brazilian inventors also reported difficulties in finding affordable qualified assistants. The Deputy Head of the Ceará State Department of Agriculture (a supporter of the mini tractor project) said: Alpha can’t afford hiring a qualified manager or technician [...] especially in this area of engineering”.

Another obstacle is the discouraging lack of belief in the potential of the invention. The Deputy Head of the Ceará State Department of Agriculture recalled prospecting for potential investors for the mini tractor project: “I asked company owners if they would help Alpha by becoming funding partners, but they don’t believe in small-sized farming machinery”. The coordinator of the CENTEC identifies this attitude as a major obstacle to the development of inventions: “Alpha needs an investor but has found none so far”. Likewise, Beta reported having many doors closed on him: “they think I am crazy”.

BureaucracyThe red tape involved in registering a patent is another deterrent for independent inventors (Barbieri, 1999), especially due to lack of knowledge of the application process. Following her father's suggestion, Omega decided not to file for a patent on her invention. She figured that “banana palms grow everywhere, so if I disclose the secret of producing fiber of that texture, the next day the entire world will be making it”. This statement points to one of the reasons why so few patent applications are filed in Peru (up to a hundred a year), although the number is growing.

Many independent inventors fear that filing for a patent will expose their invention to piracy before they have had time to negotiate with potential investors. The justice system in countries like Brazil and Peru is slow and inefficient, making it nearly impossible to recover financial losses from copyright infringement (Omega). This is supported by Mendes (2009) who adds that, even when the invention is successfully registered, the right to exclusive commercial exploitation is limited to 15 or 20 years (utility models and patents, respectively). In other words, independent inventors have to operationalize their inventions as quickly as possible, before they become freely available to all.

The former president of the APRIDI believes that no country in the world offers inventors worse conditions than Brazil, adding that Brazil was last in the ranking of the World Economic Forum (WEF) with regard to innovation. The WEF considers the LTI a punitive instrument because it obliges independent inventors to transfer one third of their profits to the partnering S&T institute. On the other hand, the interviewee pointed out that the few Brazilian inventions which have become massively successful innovations (e.g., the BINA caller identification system and captopril) have grossed billions of reais.

Support and incentivesThe increase in the number of patents granted independent inventors may to some extent be explained by the support provided by S&T-fostering organizations.

Government supportThe government support received by Alpha through the State Department of Agriculture resulted in an immediate order for ten units from the Farming Cooperative of Tauá (a town in the rural zone of Ceará). Subsequently, Alpha was offered training at a vocational technology school, after which he was eligible for inclusion in a government business incubator program (CENTEC, INTECE). The coordinator of the INTECE explained that the institution “provided full support, from the making of the business plan to the development of the prototype and patenting”. Admission to the business incubator program made it possible for Alpha to attend invention fairs in Brazil and abroad. However, as we have seen, the publicity generated was wasted due to lack of start-up capital and manufacturing capabilities, leading to frustration. Alpha's dream is to contribute to family and subsistence farming everywhere by increasing productivity and reducing work load.

Beta's project was also incubated by the INTECE, with the possibility of training and attendance of fairs and expositions. Beta received assistance with the submission of proposals for public bids, and was awarded first place in a national TV program for new inventions. Along with the INTECE, the REDENIT-CE (an institution supporting ST&I centers in Ceará) helped register Beta's invention with the patent office. The SEBRAE (an institution supporting small and mid-sized businesses in Ceará) contributed with the development of a commercial design, a process which took six months. Beta believes the time spent on the development of the model and the absence of advertising during this period cooled off demand. When he contacted investors who had previously expressed interest, he couldn’t even get an appointment.

Obstacles to support and incentivesOmega did not request government support because the rules of cooperation require filing for a patent, an idea she rejects. According to her, replicating her invention would be easy for any established manufacturer due to the abundance of cheap raw material. She added: “it is difficult for small producers to gain a foothold on the market, even with an ecological product; imagine what would happen if well-established firms learn how to use this material... I’d be out of business.”

Final considerationsBrazil has made progress in the area of innovation over the past years, but not enough to remain competitive against more developed nations on the domestic and international market. Challenges are manifold: difficulties with the registration of patents (red tape and delays), limited access to credit (banks do not accept intangible assets as collateral), misalignment between the interests of independent inventors and universities/S&T institutes, lack of legal and technical assistance, limited access to information, etc.

The current instruments of incentive are inadequate. The results of our study show that in Brazil the strategy of investment as incentive to innovation is not cost-effective and should be revised. Rather than focusing on how much to invest, more attention should be given to how resources are employed. By supporting independent inventors all the way from incubation to marketing, recently introduced Peruvian public innovation policies have turned out to be more efficient than the strategies adopted by Brazilian agencies.

Brazilian agencies should identify ways to make the institutional environment more innovation-friendly for independent inventors, strengthening the interaction between the parties. As shown by Salerno and Kubota (2008, p. 35), while most innovation takes place in the corporate setting, the government has the power to influence corporate behavior, strategies and decisions regarding innovation.

The obstacles to innovation identified in the present study should be looked into further and addressed by public innovation policies. Innovation laws appear to be more flexible in Peru than in Brazil, but the difficulties described by our Peruvian and Brazilian interviewees were somewhat similar, especially with regard to the operational aspects (manufacturing and marketing).

Despite all the difficulties, independent inventors will continue to contribute to innovation, most often by perfecting techniques and improving existing products in close connection with manufacturing, marketing of goods and services and the exercise of their own daily occupations. Sometimes creative genius seems to be spurred by adversity, to which independent inventors respond with much determination and resilience. For many, acknowledgment is more important than profit. Inventors adhere to a vision, the belief that they can change realities and make it possible for others to exercise their trades more efficiently, with quality of life.

It is hoped that our results will serve as subsidy for the making of public innovation policies supporting the efforts of independent inventors by expanding the mechanisms of access to public funding in this segment.

Future studies might look into the situation of independent inventors in other Brazilian states where innovation-supporting institutions have been more efficient, and compare Brazilian public innovation policies with those of countries higher up on the Global Innovation Index.

Conflicts of interestThe authors declare no conflicts of interest.

Peer Review under the responsibility of Departamento de Administração, Faculdade de Economia, Administração e Contabilidade da Universidade de São Paulo – FEA/USP.