Innovation practice contributes to economic development by fostering the development of new markets and the improvement of existing markets. This study aimed to identify the innovations in the flat knitting industry that occurred between 2008 and 2011. This applied nature study considers both qualitative and quantitative approaches with exploratory and descriptive purposes as its research method. A survey addressed to managers of 23 flat knitting industries was conducted. Data analysis was carried out in two stages: in the qualitative stage, content analysis of the interview was performed, while in the quantitative stage, a descriptive quantitative analysis through correlation statistics was used, in order to identify the level of relationship between the variables of the theoretical construct. The results of the qualitative stage showed that the flat knitting industry invests in innovation compatible with the market demands and fashion trends. The quantitative results identified relationships among the variables named annual turnover, number of employees and amount invested in marketing innovation. In addition, correlations were also observed among the variables skilled workforce and amount invested both in product and organizational innovation, and a relationship was identified between amount invested in product innovation and amount invested in marketing innovation.

Brazil is one of the few developing countries that has internalized all activities of the textile complex, in addition to manufacturing a wide range of products in such a manner that supplies all the market segments. The internalization occurred from the raw materials’ production (natural and chemical fibers) to clothing production. The segments that have become more modernized are those which manufacture textiles for domestic purposes and the knitting mills (Scherer & Campos, 1996).

Not only has the textile and clothing industry been studied nationally and internationally, but also by its sector, in pursuance of understanding the links within the textile and clothing chain, or the chain as a whole, as it happens for the flat knitting industry, which is part of the textile chain (Vogt, 2003).

According to the Industrial Marketing and Studies Institute (IEMI), the industrialization process in Brazil began with the textile industry. Its history and roots preceded the Portuguese arrival and colonization, since the natives inhabiting the country had already developed and had been using artisanal and primitive techniques, such as hand weaving plant fibers to produce coarse fabrics with the purpose of protecting their body (IEMI, 2014).

Such sector is relevant since it represents 5% of the manufacturing industry's gross domestic product and generates over 10% of jobs within this economic activity. One of the most significant contributions of the textile and clothing sector is the generation and distribution of income, therefore improving the living conditions of the Brazilian population while contributing to the following results: (a) it provides more than eight million direct and indirect jobs; (b) it creates first employment opportunities to inexperienced workers; (c) it is the main employer of women who are heads of household; (d) it engages all levels of the social and educational pyramid; and (e) it is a consistent alternative for income transfer programs (ABIT, 2011).

The diversity of prints, colors and patterns, the creative design, the manufacturing versatility, the sustainability and the knowledge of the links within the chain are some of the features which draw attention to Brazilian fashion overseas while helping to boost the country's image on the international market. The negotiations of Brazilian brands abroad from TEXBRASIL Program (Brazilian Fashion Industry Internationalization Program) go beyond US$ 330 million (IEMI, 2014). In this study, Caxias do Sul was chosen because it has one of the biggest National Knitting Centers, which mostly consists of flat knitting industries. Therefore, Caxias do Sul has been referred as the Knitting Capital of Brazil.

With regard to the relevance of the subject, authors such as Schumpeter (1912) state that innovation is the result of the establishment of inventions and knowledge made available to organizations which are driven by the pursuit of competitive advantages via an economic impact. In this context, innovation is understood as a new framework for the textile sector, because it can occur in any economic sector, including government services. However, the guidelines are geared toward the innovation of commercial companies, manufacturing industries, primary industries and the service sector (OECD, 2005).

The social and academic relevance was one of the criteria used for defining this research theme, given that the studied sector is socially relevant by generating jobs and is academically relevant since the innovation in this sector is directly involved with the academia, due to partnerships with the university in order to develop research projects for students’ engagement.

Considering that innovation is the driving force for economic development in a capitalist system, this study intended to approach this subject, while aiming to identify the variables that influence innovation in flat knitting industries seeking to achieve excellence as well as economic and social performance in the sector.

This study aims to address innovation in organizations belonging to the flat knitting sector of Caxias do Sul. Particularly, a set of variables were selected in order to identify the existence of relationships among them and innovation and to observe how innovation took place from 2008 to 2011.

Also, the study focused on discussing the four innovation dimensions (product, process, marketing and organizational) in companies belonging to the flat knitting sector of Caxias do Sul. The variables skilled workforce, number of employees and turnover were studied with the purpose of identifying their relationship with innovation during the studied period.

Given the context of the textile industry in Brazil, this study's guiding question was: Which innovations and dimensions of innovation were employed by the flat knitting sector of Caxias do Sul during the period from 2008 to 2011 and what is the relationship between innovation and the industry variables? The hypotheses postulated and tested in this research intended to verify the relationship among the variables skilled workforce, turnover and number of employees with the variables amount invested in product innovation, process innovation, marketing innovation and organizational innovation.

The objective of this research was to identify the innovations according to the four dimensions of the Oslo Manual (2005) and the relationship with the industry's variables on the industrial flat knitting sector of Caxias do Sul.

In order, to achieve the proposed objectives, the following stages were performed: (a) description of the flat knitting industrial sector of Caxias do Sul; (b) identification of innovations based on the Oslo Manual (2005); (c) classification of the innovation concept during the qualitative phase of the study via content analysis of interviews; (d) usage of correlation statistics in order to identify the relationships between innovation and industry variables in the quantitative phase.

The qualitative results indicated that the flat knitting sector of Caxias do Sul invests in innovation in a manner that is compatible with the market demands and fashion trends. The quantitative results identified correlations among the following variables: annual turnover with number of employees and amount invested in marketing innovation; number of employees with amount invested in marketing innovation; skilled workforce with amount invested both in product and organizational innovation; amount invested in product innovation with amount invested both in marketing and organizational innovation.

Next, the study brings an in-depth description of the theoretical constructs about product, process, marketing and organizational innovation, as well as about the Brazilian textile industry. The following section discusses the methodology employed for data collection and analysis. After that, the research results are presented along with their analysis. Finally, there is the conclusion section in which the study is completed considering the proposed objective and the limitations of the research and future research suggestions are indicated.

Literature reviewInnovationIn 1912, a development of the conceptual approach to innovation occurred, which was broadened due to Schumpeter's work. According to Schumpeter (1934), innovation is the action of innovating and creating processes which promote the disruption of the economic system while allowing the emergence of novelties.

In capitalist economies, economic development is driven by the impact of technological innovations, which occurs through a dynamic process of “creative destruction”. In this context, innovation is described as the creation of something novel by destructing what is becoming obsolete while challenging the idea of economic balance, as described in the neoclassical theory (Schumpeter, 1934).

With respect to the creative destruction process, the essential impulse needed for the process to occur is related to setting and keeping the capitalist engine in motion, which is derived from new consumer goods, novel manufacturing or transportation methods, new markets and modes of industrial organization created by the capitalist enterprise (Schumpeter, 1951).

Based on Schumpeter's theories, the Oslo Manual (2005) reports that radical innovations lead to intense changes, whereas incremental innovations provide continuous changes. Schumpeter proposes five assumptions in order for innovation to occur in a market: (a) the introduction of new products; (b) the introduction of new processes; (c) the opening of new markets; (d) the development of new sources supplying raw materials and other inputs; and (e) the creation of new market structures within an industry.

Innovation results from the implementation of inventions and the knowledge available to organizations driven by the search for competitive advantages which have an economic impact (Schumpeter, 1951). Ahmed (2001) denotes that innovation is a complex process. According to the author, even though it is something easily identified and quite important for organizational success, its management is complicated. Innovation can be defined as the inquiry, discovery, trial and implementation of new products, processes and organizational styles. The author defines its four fundamental properties as: (a) the uncertainty generated by the existence of technical and economic problems with unknown solution procedures; (b) the reliance on new technological opportunities in the scientific knowledge; (c) the increasing of formal research, development and execution activities within integrated manufacturing firms; and (d) the learning process due to informal problem solving activities and to the efforts made to meet customers’ requirements (Dosi, 1982).

Innovation dimensionsInnovation is classified by dimensions and therefore, it is seen as an evolving process in which new or significantly improved products or processes replace the existing ones. These theoretical approaches classify innovation in four categories (Tidd, Bessant, & Pavitt, 2005). First, product and/or service innovation, which implies changes in a product or service provided by the organization by using new or existing technologies. It refers to the development and marketing of new products and services, related to customer satisfaction. Second, process innovation, which includes changes in the way in which new or significantly improved products or services are created and delivered. It is the development of different ways of manufacturing and providing services. Third, marketing innovation (competitive position), which refers to changes in the context in which goods or services are introduced to the market by focusing on the consumers’ needs. It is the development of new power and leadership structures. Lastly, organizational innovation (management or mental process), which is comprised by changes in the underlying mental models which shape what the organization does, therefore, it is the result of strategic decisions taken by the company through a newly developed business in order to provide a sustainable competitive advantage.

The innovation dimensions studied in the flat knitting industries of Caxias do Sul are referenced by authors who emphasize the innovation concepts from the four innovation dimensions, according to the Oslo Manual (2005).

Oslo Manual (2005) states that product innovation is the introduction of new or significantly improved goods or services. With respect to the characteristics of goods or services, it involves improvements on technical specifications, components and materials, ease of use and the incorporation of software and other functional characteristics. According to Jonash and Sommerlatte (1999), the product or service innovation addresses the source of change, which enables a competitive advantage; however, in services, innovation includes the provision of a new service. Tidd et al. (2005) report that product/service innovation is related to changes in the products or services provided by an organization.

Process innovation is centered on improving the efficiency and effectiveness of the production process (Higgins, 1995). It involves changes in the way products and services are created and delivered to customers (Tidd et al., 2005).

Oslo Manual (2005) describes process innovation as the implementation of a new or significantly improved method of production or delivery. Significant changes in techniques and equipment are part of process innovation, which intends to reduce production or distribution costs in order to improve the quality and distribution of products (OECD, 2005).

Marketing innovation is the one which generates significant improvements in some of the marketing elements, such as product, price, promotion, distribution and market. It may be based on product differentiation, promotion, distribution, market or costs, in this case, the price (Higgins, 1995). They are considered changes in the context in which products and services are introduced to the market (Tidd et al., 2005).

Thus, marketing innovation addresses the implementation of new methods, with significant changes in product development, packaging, promotion, positioning, and even in pricing. Therefore, marketing innovation seeks to address the consumers’ needs, by the way new markets are opening, the product repositioning of a company within the market, aiming to increase sales (OECD, 2005).

Organizational innovation is essential for companies that intend to follow strategic challenges, since they result in improvements in the organization's management (Higgins, 1995). Thus, organizational innovation means the implementation of a new organizational method in a company's business attitudes, such as the arrangement of the workplace and also external relationships. New methods aid in the organization's routines and procedures, in addition to driving the work and practices which facilitate learning and knowledge sharing within the company (OECD, 2005).

Product innovation is conceived as an improvement of quality, while process innovation enhances product innovation for a low quality company (Bacchiega, Lambertini, & Mantovaini, 2011), and it is strengthened by the recruitment of new skills and staff in training (Bocquet, 2011).

One of the product innovation trends is the full integration of environmental concerns since the beginning of the product creation phase. Such trend is known as the “eco-innovation project” which applies simultaneous engineering principles based on definition, as well as the corresponding Information and Communication Technology (ICT) tools of innovation processes, thus improving communication and decision-making among geographically distributed groups (Sorli & Stokic, 2011).

Quality innovation offers the company the opportunity to grow faster, better and with more satiety than its competitors do. Consequently, the company can dictate the paths of its industry (Davila, Epstein, & Shelton, 2012).

Product innovation is the input process adopted to improve the production of a standardized product (Abernathy & Utterback, 1978) and it is defined as the one used in different sectors (Pavitt, 1984). Despite the fact that innovation importance is recognized, not all organizations are capable to develop or apply it considering that the average percentage of companies that have implemented any innovation from 2008 to 2010 was 53% (European Union, 2013).

The best performance of the company tends to focus on product and process innovation, and there is no simple winning strategy regarding the complementarity among different forms of innovation (Ballot, Fakhfakha, Galia, & Salter, 2015).

Brazilian textile sectorIn Brazil, there has been a fast industrial growth, and the textile industry contributed to it, since it had reached, before 1930, self-sufficiency in the production of fabrics for the domestic market and had all the necessary requirements for the development of other dependent areas. In this context, Brazil emerged as a producer of demanded raw materials, such as cotton and wool (Reichel and Moreira, 1978).

The textile industry was the first industrial sector to be developed in Brazil, with few requirements for its implementation and a stable and safe market. Therefore, this sector was a pioneer due to the ease of the initial manufacturing process, while also expanding within the capitalist characteristics (Herédia, 1995, 2003).

Brazil is on the list of the top 10 world markets of textile industry, apart from being the second worldwide leading indigo supplier and the third biggest knitwear supplier. Moreover, Brazil is among the six leading countries of the clothing sector and is among the eight biggest yarn, thread and fabric markets (ABIT, 2011).

The textile industry is one of the most important sectors of the Brazilian economy, representing 5.2% of the manufacturing industry, which is composed of a total of 30,000 companies that represent 17.3% of the jobs within the industry, while generating an average of 1.65 million direct jobs. During the past 15 years, the activity in the global has had a 125% increase, with a 5.6% average growth rate per year (IEMI, 2014).

In Rio Grande do Sul state, the emergence of the textile sector occurred in the late nineteenth century when new industries settled within the region, among them, the textile industry. In this context, it is important to address the origins of the textile industry in this state, which due to its latitude has a transitional climate between the tropical and temperate zone creating unique weather conditions, which are quite different from other parts of Brazil. In some regions, for example, frost and snow are commonly observed during the winter season. By colonizing and establishing in this region, the European immigrants were able to stimulate the industrialization of the state (Vogt, 2003).

Flat knitting sectorWithin the textile activity, the knitting segment is the oldest, originating from the hand knitting process. Knitting appeared among Arabs and nomadic tribes, who weaved their herds’ wool employing curved needles, and subsequently spreading the technique from Tibet to the Iberian Peninsula. From Spain, the technique was disseminated to the Shetland Islands. During the seventeenth century, silk knits were devised and knitting needles became straight with sharp tips (Rech, 2001).

Flat knitting relies on machinery that transforms yarn into knitwear. The knitting equipment is known as loom or flat knitting machine, weaving frames, panels or individual parts. The yarn used is a finished material that remains intact during the knitting process. Moreover, the combination of needle styles used on the knitting machines along with the yarns available on the market result in fabrics with several texture types, ranging from delicate to rustic. The flat knitted fabric is flexible and adapts to the human body, allowing the elaboration of diversified apparels (Roos, 2001). Design and fashion have greatly influenced the technology development of flat knitting (Matković, 2010).

Known in Europe since the fifteenth century, the knitting industry experienced the fastest technical improvement among the textile sector, where the needle was established as the main tool of all knitting looms, thus enhancing the capability to manage thicker materials which impact the thickness of the knitwear being produced (Araújo, 2005).

According to Rech (2001), the knitting industry’ task is to manufacture knitted fabrics from different yarn types. This industry category is not only restricted to the production of clothes, but also it is best known for that. Five factors are responsible for the proliferation of this area: (a) no need for large capital investment; (b) lower manufacturing costs when compared to the flat weave fabric industry; (c) introduction of new technologies; (d) investments in research and development of raw materials appropriate for the climate; and (e) popularization of knitted fabrics depending on fashion trends.

Turnover, skilled workforce, number of employeesConsidering the Brazilian scenario, the survey found that the turnover of the interviewed knitting industries of Caxias do Sul has declined in the past two years going in accordance to the findings reported by the National Confederation of Industry of Brazil. In 2012, the cumulative performance until October yielded a 2.6% total turnover, while November and December exhibited no variation. Despite the positive indication given by the turnover numbers, the industry continues to function with a high idleness degree. The Installed Capacity Utilization Level was 81% in October and, according to the manager, there has been a slow recovery, however there is idleness in the industry (Aliski, 2012).

The scarcity of highly-skilled workforce, the lack of legal frameworks to regulate some economic sectors and the difficulty of ensuring intellectual property rights for innovations developed in the country are some of the main aspects limiting the advancement of Brazilian innovations in the short term (Valor Econômico, 2012). As for the relevance of having a skilled workforce, the entrepreneurs of the knitwear industries confirmed the importance of having skilled professionals for conducting the required tasks.

Even though the research did not seek to evaluate people management practices, the employee numbers were considered in order to measure and compare the quantity of employees in the quantitative analysis. The Brazilian Micro and Small Business Support Service (SEBRAE) adopts the criterion of the Brazilian Institute of Geography and Statistics (IBGE) to identify company size as: micro enterprise (up to 19 employees), small enterprise (20–99 employees), medium enterprise (100–499 employees) and large enterprise (more than 500 employees) (SEBRAE, 2012).

Methodological proceduresIn order to identify innovation in the industrial sector of flat knitting in Caxias do Sul, this study has an applied nature, with a qualitative and a quantitative approach. It integrates exploratory and descriptive research with multiple data collection method and an in-depth literature review on innovation, the textile sector in Brazil and Rio Grande do Sul, and the flat knitting sector, with the purpose of clearly defining the general concepts.

The research encompasses two patterns, because it is characterized with exploratory and descriptive objectives to breakdown the subject of innovation in the four dimensions suggested by the Oslo Manual (2005), in the flat knitting industry, based on its characterization and analysis. By the second pattern, it is considered a field research, since it investigates the existing innovation within companies by interviewing a representative from each company, with the theoretical framework pre-established and applied on the research.

In the study, the exploratory phase began by inquiring on the history of the flat knitting industry of Caxias do Sul, by visiting and interviewing the president of FITEMASUL (2011) (Labor Union of the Hosiery, Weaving and Knitting Industries of the Northeast Region of Rio Grande do Sul), situated in Caxias do Sul. Furthermore, master's theses, scientific articles and public research agencies were also analyzed. As for the methodology employed, the literature review was used to provide a supportive framework for the study, which analyzed an individual or a group in order to better understand them.

The population targeted in this research were the flat knitting industries that are members of FITEMASUL (2011), which is composed of 31 companies of the textile sector. In the first screening, five members were excluded from the population, as they did not fit into the category of activity, named flat knitting, in which the member companies of the population produced flat knitting. In addition, after the interviews during the second screening, three other companies were excluded from the population because they fell outside the knitting industry's profile since they acted as subcontractors of other companies and/or did not produce knitted garments.

As a result, the population interviewed and analyzed in this study was composed of 23 companies associated to FITEMASUL (2011), falling within the classification parameter as exclusive producers of flat knitted fabric.

For the qualitative research phase, the individual interview technique was employed. Thus, the basic list of questions served as a guide within the research and, after the pilot interviews, it was modified in order to improve the questions to better comprehend the interviewees. This was helpful for the research in the organization.

At this phase of the research, the observations occurred during the interviews at the organizations allowing the identification of the similarities in the way organizations think and operate. Consequently, an investigation was performed considering the variables driving innovation through certain variables identified during the quantitative phase of the research.

During the interview analysis, the recordings and subsequent transcriptions were used to analyze the interviewees’ responses. Therefore, at this moment the data gathered were used and transformed into applied knowledge (Wolcott, 1994).

For data analysis, content analysis was applied, where data is examined through observation and analysis of content or written text messages, such as reports, letters, advertisements, open questions surveys and similar content. In other words, the researcher scrutinizes the frequency of words and main topics, then identifies the content and specific information within the text, which can later be used to quantify the qualitative data (Hair et al., 2005).

Content analysis was performed according to Bardin (2011), consisting of three stages: (a) pre-analysis: an idea organization phase which starts and ends through theoretical research on the subject of innovation; (b) material exploration: coding and enumeration operations; (c) processing of results and interpretation: at this stage the classification of elements is performed, in accordance to the similarities and differences, with future regrouping based on common characteristics (Bardin, 2011).

The content analyzed through interviews and questionnaires was tallied in order to arrange the answers by their repetition rate, thereby enhancing the emphasis on the innovations implemented in the flat knitting industries of Caxias do Sul. By interviewing managers, the main goal was to collect information related to the research objectives. The software Atlas TI was used to observe the frequency of the terms mentioned by the interviewees in the qualitative stage.

The data collection tool was prepared in a structured manner, containing both open and closed questions divided into three parts. Part I refers to the Interviewee Profile and the Organization Profile. In Part II, the questions aimed to identify the relationship among industry variables (turnover, number of employees and skilled workforce) and innovation variables (amount invested in product, process, marketing and organizational innovation). In Part III, questions were elaborated to identify how, where and in which ways innovations occur in the knitting industries of Caxias do Sul, addressing the four dimensions of the Oslo Manual (2005). The collection tool was based on the works by Nodari (2010).

Upon completion of the data collection, the next step was data preparation, analysis and interpretation. Since the questionnaire was structured with only one open question, the results were tallied using the software Sphinx Léxica 4.5. However, some questions needed to be adapted for tallying so that the amount of companies that had implemented innovations could be measured.

Data collected were subjected to descriptive statistical analysis followed by multivariate analysis. Since the population was considered in the study, the variables did not have to be nominated as dependent or independent. In this case, the correlation among the variables of innovation was analyzed through bivariate partial correlation, since this technique encompasses the sample data analysis in order to know the relationship among two or more variables in a population (Hair et al., 1995, 1998a; Hair, Anderson, Tatham, & Black, 1998b).

The chosen variables are considered classic for the industry, since they may determine in this research the level of innovation of an organization. The variables of the studied industry are: annual turnover, number of employees and skilled workforce. The innovation variables, according to Oslo Manual (2005), are: amount invested in product innovation, process innovation, marketing innovation and organizational innovation.

The variables annual turnover and number of employees were analyzed in order to identify if such variables allow or are related to the development of innovation in the organization. The variable skilled workforce was analyzed in order to identify whether the employees are formally trained in the technical area of knitting manufacturing, consequently allowing the researcher to verify whether the employees’ skills impact the development of innovation.

As for the selected dimensions, the relationship among the investment in product, process, marketing and organizational innovation was evaluated, according to the classification given on Oslo Manual (2005). This allowed the data analysis on the relationships among variables, confirming the structure of the dimensions to meet the relationships among them.

In order to achieve the general and specific objectives of this research, primary and secondary data were collected. Primary data resulted from the individual interviews using a semi-structured questionnaire, carried out in the companies along with the owners and/or managers of the 23 participant knitting industries given the respondents’ profile and time availability. In order to obtain benefits and consistency from the data verbalized by respondents, the duration of the interviews was controlled not to exceed one hour, which is the appropriate time suggested by Wolcott (1994).

On the other hand, secondary data were derived from the literature review, databases and other information in journals, articles, theses and studies on the researched subject and on the flat knitting sector. These data provided a conceptual basis to consolidate the theoretical framework. Experts from the innovation area performed the interview script validation. This validation was recorded in notes on the script itself by one of the experts and via e-mail by another expert, thus allowing adjustments in some questions’ format and order.

After the preparation and validation of the data collection instrument, the companies were contacted. Two companies per day were interviewed, with properly set appointments, totaling an average of 6 companies a week, considering that this number varied based on the respondents’ availability. In order to organize the scheduled times and dates for the interviews, an interview spreadsheet was prepared in Microsoft Word text editor, thus arranging the visits and making the researcher's work easier. Such list depicted the week and the month in which the interviews would take place, the name of each company, the name of the respondent, the address, the time of the scheduled interview and the company's contact, in case a confirmation was needed.

The additional procedures, which were collecting the records of the interviews at the companies, took place during the next stage. Recordings were made using a smartphone. The equipment was chosen because of the feasibility of recording in high definition, in order to facilitate the transcription process after the interviews.

The first interview conducted was with the president of FITEMASUL (2011), who described his vision about the flat knitting industry in Caxias do Sul.

Analysis and results discussionIn the proposed study, which aimed to research and identify the innovations in the flat knitting industry, it was found that companies innovate via new products and processes as well as based on fashion trends in other countries. Moreover, some companies hire designers in order to create unique models with distinctive raw material. “Every year we must have innovation, we have to change, even the raw material usage, how it is used in the product […]” (Interview with a business owner). “There are always new products here, inside the knitting industry, because it is a company dealing with fashion, and fashion is in constant need to innovate […]” (Interview with a business owner).

The accounts brought up by the interviewees emphasize that new products are essential for the company to remain relevant in the market. Design and fashion require constant exposure and evolution of the businessperson in the release of collections.

The respondents were asked about the process innovation to possibly identify the changes occurring within the organizations during their product development process, including technologies and equipment used in manufacturing. “[…] when a product is developed, we have to plan its manufacturing process, with each new product, you also have to devise a new process […]” (Interview with a business owner). “Changes on ironing, washing, and dyeing are processes that need to be incorporated, adapted and amended based on what we had been doing” (Interview with a business owner).

When analyzing the interviewees’ responses regarding process innovation, it is evident that companies invest in information technology and in new fabrication techniques for product preparation and production. The respondents were also questioned about marketing innovation, in order to investigate and identify the existence of transitory practices employed in their product design, sales method, and brand and publicity. “Products with emphasis on design, having a catalog, by the way we had never had a catalog, but we have incorporated one since 2010. We have integrated a box with the company's brand. The tape of the box has the company's brand. We started to rely on more criteria when choosing a carrier […]” (Interview with a business owner). “I implemented computerized aspects of brand display, brand concept, by creating Facebook, blogs, packaging, buttons, bows, folders, tags which go in accordance with the same Facebook cover, same folder cover, labels, which are all telling the same story in order to be memorable to the people […]” (Interview with a business owner).

According to the survey, marketing innovation occurs on investment in retail, through promotional material for the customer at the time of purchase and advertising on social networks. Companies also invest in stamping their brands on their products by incorporating notions, such as buttons and metal plates. Lastly, companies establish promotions and partnerships with clothing sector entities, such as Serra Gaúcha Association of Shopping Centers (ACECORS).

Furthermore, the participants were interrogated about organizational innovation with the objective to determine and identify whether companies innovate through organizational management, by altering their physical space and reassessing the internal and external working environment. “By partnering with advertising agencies, by opening a store both for retail and wholesale, by expanding the store space and by having electronic invoices” (Interview with a business owner). “Our organizational innovation was a shift in both our and their mindsets. We also organized ourselves to increase the production, enabling us to meet their demand, which is quite high. Outsourcing, by having three external suppliers, has facilitated our capability to meet the manufacturing demand” (Interview with a business co-owner).

Some companies mentioned changing routine management practices, which provided an improvement on their negotiation and sales.

According to Hirsch-Kreinsen (2008), low and medium technology (LMT) companies, such as those of the textile industry, are required to have a wide variety of targeted and non-targeted strategical options regarding technology since their markets are established and competitive. The author states that the most frequent innovations in low and medium technology sectors are incrementally improving the products by upgrading the individual components without making significant changes to the project as a whole.

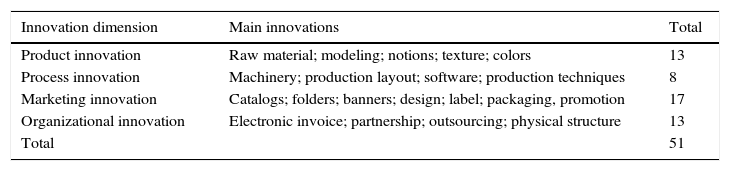

Business people often use strategies to remain competitive in the market. In order to classify the strategies used by those working in Caxias do Sul, the ones the author Hirsch-Kreinsen (2008) attributes to low and medium technology companies were used in the analysis. Such strategies include: (a) the step-by-step strategy is based on the additional continuous development of already known products; (b) the customer-oriented strategy looks for innovations that pursue to ensure and improve the company's market position; (c) the process specialization strategy, in which innovation efforts are directed to the structure of organizational and technical processes. Chart 1 describes the innovations most commonly mentioned by the respondents.

Innovations most commonly mentioned on the interviews.

| Innovation dimension | Main innovations | Total |

|---|---|---|

| Product innovation | Raw material; modeling; notions; texture; colors | 13 |

| Process innovation | Machinery; production layout; software; production techniques | 8 |

| Marketing innovation | Catalogs; folders; banners; design; label; packaging, promotion | 17 |

| Organizational innovation | Electronic invoice; partnership; outsourcing; physical structure | 13 |

| Total | 51 |

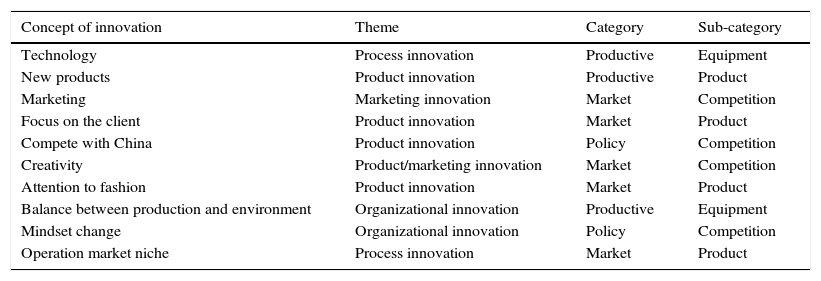

Chart 2 introduces the concepts most often mentioned by the interviewees, being classified as categories and subcategories of content analysis.

Concepts of innovation classified in categories and subcategories.

| Concept of innovation | Theme | Category | Sub-category |

|---|---|---|---|

| Technology | Process innovation | Productive | Equipment |

| New products | Product innovation | Productive | Product |

| Marketing | Marketing innovation | Market | Competition |

| Focus on the client | Product innovation | Market | Product |

| Compete with China | Product innovation | Policy | Competition |

| Creativity | Product/marketing innovation | Market | Competition |

| Attention to fashion | Product innovation | Market | Product |

| Balance between production and environment | Organizational innovation | Productive | Equipment |

| Mindset change | Organizational innovation | Policy | Competition |

| Operation market niche | Process innovation | Market | Product |

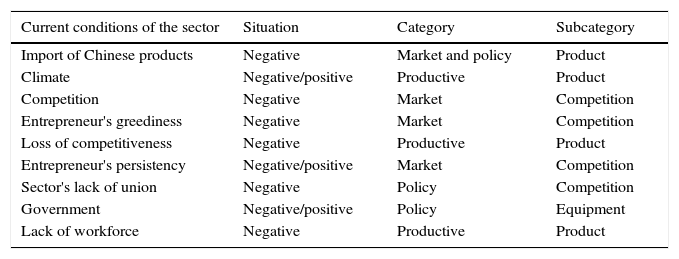

In reference to the respondents’ perception and voluntary explanation about the sector, the conclusions obtained by the researcher are exposed. One of the categories assigned by the author to the respondents’ answers was “import of Chinese products”, which was mentioned several times as a threat to the knitting industry of Caxias do Sul and other municipalities of Serra Gaúcha, as well as the “climate”.

Another category assigned as common within the sector was “competition”. Though, it becomes threatening when business owners stop producing and start buying ready-made products from other countries and later sell them at unbeatable prices directly to the consumers. This conduct leads to the category “entrepreneur's greediness”, which leads to “loss of competitiveness” for local products and companies. On the other hand, “entrepreneur's persistency” is present due to the behavior of business people who prefer to maintain their production and sales practices compatible with the national products, with their own features. In this case, the “sector's lack of union” corresponds to the desire of many entrepreneurs for strengthening the national products manufactured in Serra Gaúcha, with the idea of being part of an organized system which favors entrepreneurs who participate of a productive knitwear center.

Moreover, “government” was a category assigned based on the entrepreneurs’ opinions claiming the importance of the establishment of subsidies for the sector by the public authorities, as quoted, in the tax barriers for imported apparel products. In this scenario, the “lack of workforce” is another aspect mentioned by the respondents, who acknowledge the existence of a scarce workforce. Chart 3 describes the most commonly mentioned categories that were identified in the content analysis encompassing the current and future situation of the knitting industry in the city of Caxias do Sul.

Categories most commonly mentioned in the identification of content analysis.

| Current conditions of the sector | Situation | Category | Subcategory |

|---|---|---|---|

| Import of Chinese products | Negative | Market and policy | Product |

| Climate | Negative/positive | Productive | Product |

| Competition | Negative | Market | Competition |

| Entrepreneur's greediness | Negative | Market | Competition |

| Loss of competitiveness | Negative | Productive | Product |

| Entrepreneur's persistency | Negative/positive | Market | Competition |

| Sector's lack of union | Negative | Policy | Competition |

| Government | Negative/positive | Policy | Equipment |

| Lack of workforce | Negative | Productive | Product |

After the qualitative stage, the data underwent statistical analysis, in which descriptive statistics and multivariate analysis were conducted. In the context of operationalization, the questionnaires were answered during the interviews conducted from September to October 2012, with an approximate duration of 1h10min per interview.

The variables selected for the analysis of the flat knitting industries of Caxias do Sul (n=23) were skilled workforce, number of employees and annual turnover. These items were correlated with the variables of the four dimensions of innovation, which include investment in product innovation, process innovation, marketing innovation and organizational innovation. In order to analyze these variables, a non-parametric Spearman's Rho correlation coefficient was used, as it accepts variables of free distribution and measures on a minimum ordinal scale.

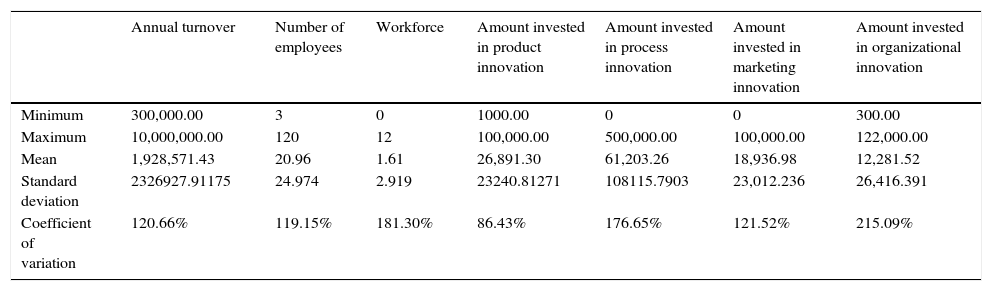

The values assigned by the software IBM SPSS Statistics 20 revealed the minimum and maximum values for each analyzed variable. The mean, standard deviation and variance were also calculated (Table 1). The maximum amount found in the descriptive analysis of the variables was R$ 10,000,000.00 for the turnover, while the maximum value for the number of employees was 120 with just a single company having this amount. The maximum number of people with skilled workforce in a company was 12.

Mean, standard deviation and variance of the variables.

| Annual turnover | Number of employees | Workforce | Amount invested in product innovation | Amount invested in process innovation | Amount invested in marketing innovation | Amount invested in organizational innovation | |

|---|---|---|---|---|---|---|---|

| Minimum | 300,000.00 | 3 | 0 | 1000.00 | 0 | 0 | 300.00 |

| Maximum | 10,000,000.00 | 120 | 12 | 100,000.00 | 500,000.00 | 100,000.00 | 122,000.00 |

| Mean | 1,928,571.43 | 20.96 | 1.61 | 26,891.30 | 61,203.26 | 18,936.98 | 12,281.52 |

| Standard deviation | 2326927.91175 | 24.974 | 2.919 | 23240.81271 | 108115.7903 | 23,012.236 | 26,416.391 |

| Coefficient of variation | 120.66% | 119.15% | 181.30% | 86.43% | 176.65% | 121.52% | 215.09% |

The maximum amount invested annually in product innovation was R$ 100,000.00, and the minimum was R$ 1000.00. As for process innovation, the maximum amount invested annually was R$ 500,000.00. On the other hand, the maximum amount invested in marketing innovation was R$ 100,000.00. The minimum amount invested annually in organizational innovation was R$ 300.00, while the maximum amount was R$ 122,000.00.

Correlation is a type of study that aims to measure the degree of interdependence among two or more variables (Sampieri, Collado, & Lucio, 2001). The correlation coefficient (r) indicates the strength of the relationship between the variables evaluated, and the sign (+ or −) indicates the direction of the relationship. The value can range from −1 to +1, in which +1 indicates a perfect positive relationship, 0 indicates no relationship and −1 indicates a perfect negative relationship (Hair et al., 1998a, 1998b).

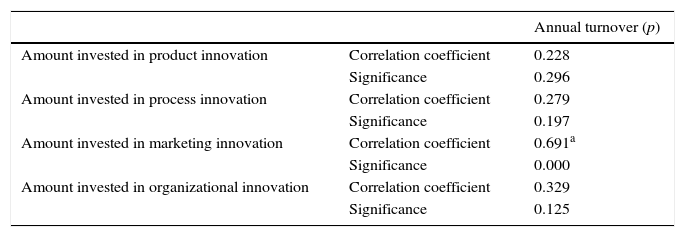

In the correlation between the variable turnover and the innovation variables, two out of the 23 companies were excluded from the analysis because data on annual turnover were not provided. The correlation among variables was performed with the software SPSS Statistics 20, according to Table 2. The variable annual turnover correlation with the variables of amount invested in the four dimensions of innovation resulted in a moderate positive correlation (0.5≤p<0.8), according to Santos (2007), between annual turnover and amount invested in marketing innovation.

Correlation between turnover and investment in innovations.

| Annual turnover (p) | ||

|---|---|---|

| Amount invested in product innovation | Correlation coefficient | 0.228 |

| Significance | 0.296 | |

| Amount invested in process innovation | Correlation coefficient | 0.279 |

| Significance | 0.197 | |

| Amount invested in marketing innovation | Correlation coefficient | 0.691a |

| Significance | 0.000 | |

| Amount invested in organizational innovation | Correlation coefficient | 0.329 |

| Significance | 0.125 |

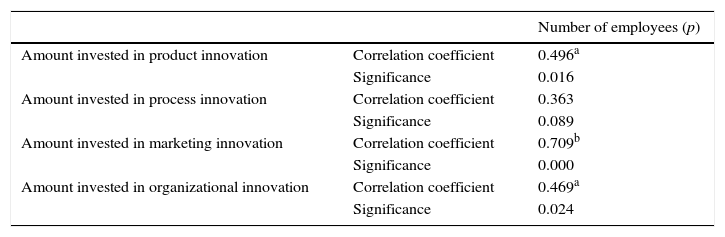

In Table 3, the variable number of employees was correlated with the company's investment variables in the four dimensions of innovation. A moderate positive correlation (0.5≤p<0.8) between the number of employees and the amount invested in marketing innovation can be observed. In addition, there are weak positive correlations (0.1≤p<0.5) between the number of employees and the amount invested in product and organizational innovation.

Correlation between number of employees and investment in innovations.

| Number of employees (p) | ||

|---|---|---|

| Amount invested in product innovation | Correlation coefficient | 0.496a |

| Significance | 0.016 | |

| Amount invested in process innovation | Correlation coefficient | 0.363 |

| Significance | 0.089 | |

| Amount invested in marketing innovation | Correlation coefficient | 0.709b |

| Significance | 0.000 | |

| Amount invested in organizational innovation | Correlation coefficient | 0.469a |

| Significance | 0.024 |

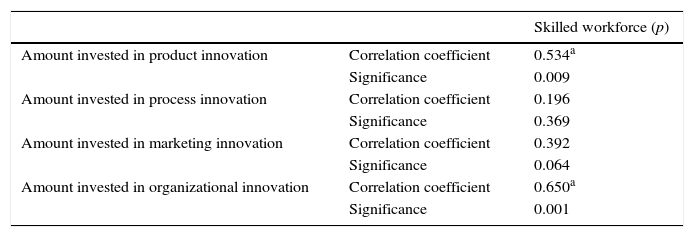

According to Table 4, the correlation between skilled workforce and amount invested in innovation in the four dimensions of innovation was measured yielding to a moderate positive correlation (0.5≤p<0.8) between skilled workforce and amount invested in product and organizational innovation.

Correlation between skilled workforce and investment in innovations.

| Skilled workforce (p) | ||

|---|---|---|

| Amount invested in product innovation | Correlation coefficient | 0.534a |

| Significance | 0.009 | |

| Amount invested in process innovation | Correlation coefficient | 0.196 |

| Significance | 0.369 | |

| Amount invested in marketing innovation | Correlation coefficient | 0.392 |

| Significance | 0.064 | |

| Amount invested in organizational innovation | Correlation coefficient | 0.650a |

| Significance | 0.001 |

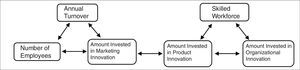

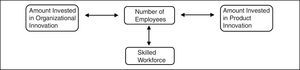

Based on all the correlation analysis performed, two kinds of correlations could be recognized. First, with a significance level of 0.01% (moderate positive correlation 0.5≤p<0.8), a moderate positive correlation of the following variables was observed: (a) annual turnover with number of employees and amount invested in marketing innovation; (b) number of employees with amount invested in marketing innovation; (c) skilled workforce with amount invested in product and organizational innovation; and (d) amount invested in product innovation with amount invested in marketing and organizational innovation. Second, with a significance level of 0.05% (weak positive correlation 0.1≤p<0.5), a weak positive correlation of the following variables could be identified: (a) number of employees with skilled workforce and (b) amount invested in product innovation with amount invested in organizational innovation.

In accordance to the highlighted coefficients, moderate positive correlations are indicated with two asterisks, while weak positive correlations are identified with one asterisk. It can be concluded that entrepreneurs who invest in new products or in the improvement of existing products tend to innovate in marketing and, consequently, in the company's management.

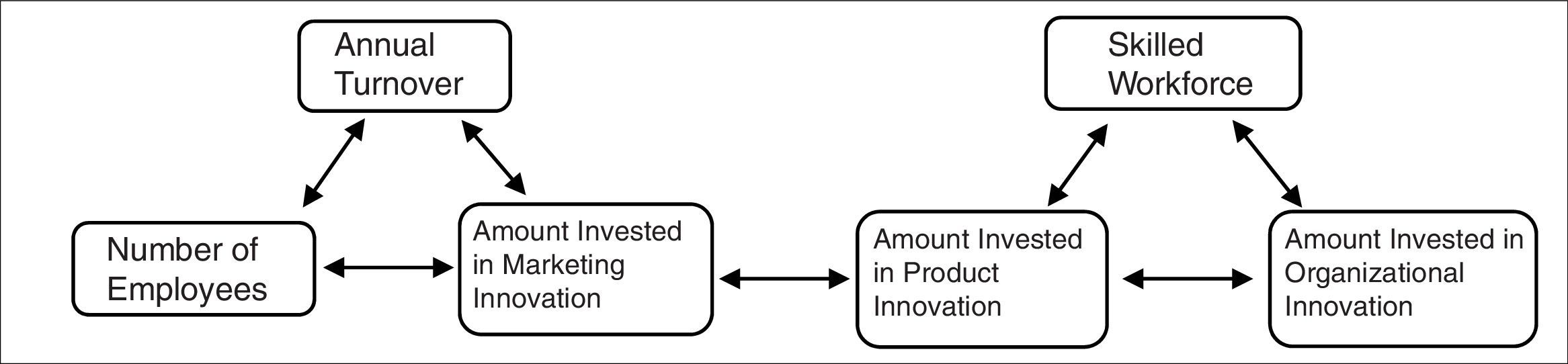

In the correlation analysis with a significance level of 0.01%, a moderate positive correlation was verified, according to Santos (2007), which indicates the correlation between 0.5≤p<8 of: (a) annual turnover with number of employees; (b) annual turnover with amount invested in marketing innovation; (c) number of employees with amount invested in marketing innovation; (d) skilled workforce with amount invested in product innovation; (e) skilled workforce with amount invested in organizational innovation; (f) amount invested in product innovation with amount invested in marketing innovation; and (g) amount invested in product innovation with amount invested in organizational innovation. Fig. 1 illustrates the moderate positive correlations observed in the analysis.

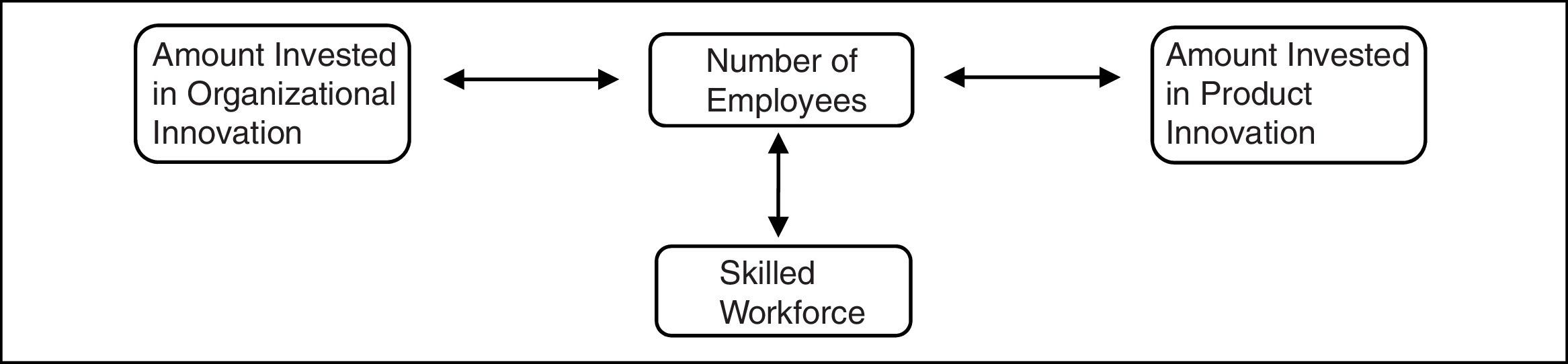

In a correlation analysis with a significance level of 0.05%, a weak positive correlation was identified, according to Santos (2007), indicating a correlation between 0.1≤p<0.5, of: (a) number of employees with amount invested in product innovation; (b) number of employees with amount invested in organizational innovation; and (c) number of employees with skilled workforce. Fig. 2 shows the weak positive correlations between the variables.

Based on the results, some hypotheses could be explained after the qualitative stage due to its findings and also as a motivational factor for performing the quantitative stage. It was already accepted, for example, that the variable annual turnover was also related to amount invested in product and process innovation; however, the correlation findings between the annual turnover and the amount invested in marketing innovation were surprising. Regarding the number of employees, it was hypothesized that it would only be related to the amount invested in process innovation, nonetheless it also exhibited correlations with amount invested in product, marketing and organizational innovation. Even though the variable skilled workforce was expected to be related to amount invested in process innovation, it was remarkable to find a relationship with the amount invested in organizational innovation.

Final considerationsBased on the proposed objective, the study results demonstrated that the flat knitting industry features innovation as a guiding principle facilitating the progress of organizations, in this case, the knitting sector, where high quality and modernity, among other requirements, are demanded by the market.

In this study, 51 incremental innovations were implemented during the course of the study. The innovations mentioned by respondents include incremental changes in the procedures, techniques, materials and marketing components, which are related to the four dimensions of innovation. It can be concluded that the flat knitting sector innovates in a manner that allows the characterization of a changing environment, which constantly searches for further improvements and qualifications of the products and services offered to customers.

In order to achieve the goals of this study, four specific objectives were listed. The first specific objective pursued to characterize the flat knitting industrial sector in Caxias do Sul. This goal was achieved through the literature review, access to files, observation, document analysis, and quantitative tallying. First, the context of the flat knitting industry in Caxias do Sul was explained, followed by constructing a report on the innovation context within the sector itself based on the data collected during the interviews. At this stage, it was noticed that the companies belonging to the flat knitting sector are classified as micro and small-sized companies, which are constantly organizing and adjusting their processes and seeking to remain updated on the latest European trends, with trips abroad, in order to later launch the winter collection in Brazil.

The second specific objective sought to examine and describe the innovations in the flat knitting industries of Caxias do Sul, based on Oslo Manual (2005), which are: (a) product innovation (goods or services); (b) process innovation; (c) marketing innovation; and (d) organizational innovation. This aim was accomplished through the interviews conducted with the people in charge of the studied companies. In this study, 13 product innovations, 8 process innovations, 17 marketing innovations and 13 organizational innovations were identified. The main product innovations are based on the introduction of new raw materials, modeling, adding notions to knitwear, introducing trends in the collection and changing the texture and colors of the products.

When dealing with process innovation, the highlighted components were significant amends in the machinery, production layout, software for controlling production and programming and production techniques. Marketing innovations were the most common, showing that an increasing number of companies are willing to market their products by making and designing catalogs, brochures, banners, product parts, labels, packaging and promotions. It is a type of advertising direct to customers. On the other hand, having a website and social media platforms facilitates the promotion of the company and its products globally. Finally, the most mentioned organizational innovations were the establishment of an electronic invoice and partnering with other sector entities, in order to make sales easier. Outsourcing of labor was another practice adopted by the management of knitting industries with the purpose of reducing costs of labor and increasing the production.

The third objective pursued to classify the innovation concept in the qualitative phase of the study. The concept of innovation was questioned with the intention to investigate the perception and knowledge of the respondents on the subject. The categories designated were based on excerpts taken from the interviews, which referred to these concepts and classified the respondent's opinions in those expressions that denominated innovation.

“Process technology/innovation” was mentioned as process innovation; however, “product innovation” was listed as innovation when creating new collections and applying new materials. “Marketing innovation” was classified as such because it is defined by the changes in the publicity process, visual enhancement of the companies’ products and brands. “Organizational innovation” was categorized by the author in order to classify the concept of respondents, in which innovation is a set of changes in the organization that involves reforming the structure and business practices.

Respondents cited that the main tool, no matter the type of business, is to be customer focused, based on some excerpts from the interviews that mentioned contact and attention to the customer as “focus on the client”. Another category addressed by the author was “compete with China”, because some respondents mentioned that innovation was being able to compete with the Chinese products. “Raw material innovation” was another category defined by the author to highlight that some respondents believe that innovation is associated with the usage of unique raw materials in their products and processes.

Among other definitions, respondents stated that innovation relies on “creativity”, by offering well-designed and sophisticated products. Others mentioned that innovation is characterized by “attention to fashion”, another category used to classify interview remarks that conceptualize fashion as an innovation.

Some respondents affirmed that innovation means a “balance between the production and the environment”, which is the category chosen whenever innovation and the environment demonstrations were mentioned. Also related to this category is “mindset change”, which involves the implementation of new ways of working, both in business and in the company's relationship with society. Finally, the “operation market niche”, a category classifying innovation as a change on the type of work and, consequently, a change of clients.

The fourth and final specific objective proposed to quantitatively analyze the correlation relationships among the variables. The company's average investment in innovation when compared to their annual turnover was 2.79% in product innovation, 4.18% in process innovation, 1.08% in marketing innovation and 0.90% in organizational innovation.

Correlations among the studied variables led to the following results: (a) the annual turnover exhibited only a moderate positive correlation with the amount invested in marketing innovation; (b) the number of employees was compared to the amount invested in innovation, resulting in two weak positive correlations, with the amount invested in product innovation and with the amount invested in organizational innovation. The correlation analysis of this variable also resulted in a moderate positive correlation with the amount invested in marketing innovation. The variable skilled workforce was tested with the variables of amount invested in innovation and there were two moderate positive correlations, which were with the amount invested in product innovation and with the amount invested in organizational innovation.

When dealing with the correlations among all variables, 10 correlations can be observed, 7 of them can be classified as moderate positive correlations and 3 as weak positive correlations, according to Hair et al. (1998a, 1998b).

Regarding the knitting companies’ characteristics, all are located in Caxias do Sul and possess their own headquarters. Based on this study, the profile of the flat knitting industry of Caxias do Sul can be described as a sector that invests part of its turnover in innovation and in exchange, these innovations generate more turnover. To sum up, 100% of respondents said they innovated in products, 87% responded they innovated in processes, 100% reported they innovated in marketing and 100% acknowledged they innovated in the organizational dimension during the period from 2008 to 2011.

It is noteworthy that even with a turnover decrease, a scarce skilled workforce and sometimes an unfavorable regional climate for knitting industries, companies kept investing in new products and improving the existing ones. The companies have also been investing in their processes, marketing and company management in the pursuit of implementing innovations that, despite the environmental adversity, keep the economic returns of the sector.

The following aspects can be highlighted as limitations for the study: the studied population of 23 companies may not represent the total number of companies located in the city of Caxias do Sul; the choice of words for categorization may not fully represent the expressions used by the interviewees thus possibly inducing error; the neutrality, since there was a semi-structures research script, which allowed interviewees to express private data, but may not represent the reality, inducing the researcher to error; and, finally, the quantitative analysis may be compromised since only four innovation variables were measured compared to three industry variables in the correlations among the variables.

This research opens possibilities for future reflection. Future studies may aim to broaden the study going beyond the population surveyed in Caxias do Sul; expand the study covering other cities from Serra Gaúcha, where flat knitting industries are a representative sector for the economy; address issues such as the analysis of production the system and the market, which may or may not be related to innovation; test existing innovation models in the researched companies; increase the number of correlation analyses of the research data; cross-check the variables from the research instrument and adopt a purely quantitative research approach.

Compliance with ethical standardsInformed consentIn order to carry out this research, the authors conducted interviews with managers of the researched companies, who were previously contacted and informed about the research. Therefore, informed consent was obtained from all individual participants included in the study.

Ethical approvalAll procedures performed in studies involving human participants were in accordance with the consent of FITEMASUL (Labor Union of the Hosiery, Weaving and Knitting Industries of the Northeast Region of Rio Grande do Sul).

Conflicts of interestThe authors declare no conflicts of interest.

Coordination for Improvement of Higher Education Personnel (Coordenação de Aperfeiçoamento de Pessoal de Nível Superior – CAPES, Brasil).

Holds a fellowship of research productivity granted CNPq – Brazil.

Peer Review under the responsibility of Departamento de Administração, Faculdade de Economia, Administração e Contabilidade da Universidade de São Paulo – FEA/USP.