The objective of this study is to present an adapted technological capability metric for the offshore support vessel construction segment. Based on a literature review, a preliminary metric was developed and used to interview a group of researchers, professors, and managers from the naval industry. Through a qualitative approach, the collected empirical evidence was analyzed and organized in an analytical framework. A pilot test of the metric was then carried out at a shipyard in the city of Rio de Janeiro. The study's results indicate that the metric's application can offer firm managers and government policy-makers relevant information for the design and implementation of business and technological strategies for the supply vessel segment.

Pre-salt enables Brazil to promote a conscious effort to develop national firms of oil and gas production chains, including the offshore shipbuilding segment, the focus of this study. Offshore support vessels are high-technology small- and medium-sized ships, which offer permanent logistical support to operating units in maritime waters (Ruas & Lugli, 2009).

However, it is possible to observe an expressive technological gap in this sector when it is compared with countries that are leading the industry, especially South Korea and Norway. For shipbuilding firms to concurrently address the objectives of developing their international competitiveness and to meet pre-salt demands at a given time, it is necessary to tune their competitive strategies to the dynamics required for the development of technological capability (TC). Bolder and integrated public policies are also needed.

At an organizational level, TC is an ability that results from a knowledge stock related to engineering, a stock that is being driven by different learning mechanisms, which allows the realization of production activities and, on high levels of TC, innovate (Figueiredo, 2009). Since the pioneering studies of Katz in the 1970s and 1980s TC has been considered a key factor for the economic development of late-industrializing countries in Latin America.

In this article it is argued that, according to a view of strategic management based on technological innovation, measuring Brazilian naval construction firms’ TC levels in relation to their counterparts in developed countries constitutes a critical step in the diagnosis that guides the technological catch-up process; however, the development of metrics used in each segment has not been exploited in TC literature.

This research is therefore aligned with other studies based on the TC concept (Bell & Pavitt, 1995; Figueiredo, 2009; Lall, 1992) and is extended to focus on sectoral metrics (Moreira & Pitassi, 2013). The question that motivated the research is: At what level of technological capability are Brazilian shipbuilding firms of the offshore segment? The purpose of this article is to propose an adapted TC metric for the offshore support vessel construction segment.

This article contributes to theory by providing a metric for a sector that has not been contemplated in the TC literature. Regarding administrative practice, the metric can help managers of Brazilian shipyards in the development and implementation of technological catch-up business strategies. From the point of view of public policy (industrial, S&T&I, and commercial), the metric can assist in the development of projects such as the first Brazilian PSV, coordinated by Coppe/University Federal University of Rio de Janeiro (UFRJ), University of São Paulo (USP), and the Institute of Technological Research (IPT) in partnership with suppliers.

Theoretical frameworkTC in late-industrializing economiesTechnologies have a tacit nature involving multiple individual and collective organizational aspects of learning, which are embedded in organizational fabric and specific to the context in which they are developed (Bell & Pavitt, 1995). According to the Oslo Manual from the Organization of the Economic Cooperation and Development (2007), technological innovations include the introduction of technologically new products and processes and the achievement of significant technological improvements to them.

Research by Katz (1984) and Dahlman and Westphal (1982) generated numerous empirical studies on how firms of late-industrializing countries accumulate TC for the achievement of technological innovations. In the 1990s, a group of researchers based in England developed taxonomies and frameworks that gradually helped create a solid line of empirical research on the construction of TC in firms of developing countries (Bell & Pavitt, 1993, 1995; Lall, 1992).

Fig. 1 shows how TC accumulation begins with learning mechanisms, which interfere with the speed of TC accumulation. This is reflected in the performance indicators of firms, including innovation (Figueiredo, 2009).

Strategy and competitive factors in the naval industryAccording to the literature, the key features of the shipbuilding industry are: (i) building ships by commission, with average construction deadlines of 12 months; (ii) involving complex production processes, large-scale production, and intensive manual labor; (iii) provide high value-added goods with long lifecycles, whose demand has been greatly affected by global financial crisis; and (iv) requiring large, fixed capital investments (Cho & Porter, 1986; Coutinho, Sabbatini, & Ruas, 2006; Pasin, 2002; Ruas & Lugli, 2009; Silva & Martins, 2007; Souza, 2009; Won, 2010).

In line with the analytical framework adopted in this study, Lacerda (2003) emphasizes the importance of technology transfer from developed countries for the Brazilian shipbuilding industry to grow, as this learning mechanism streamlines and reduces involved risks. However, according to De Negri, Kubota, and Turchi (2009, p. 36): “the experiences of countries such as Korea and China have showed that becoming a competitive industry is important to create understanding and reduce dependence on technological packages from abroad.”

Bell and Pavitt (1995) demonstrate that there are industry standards for innovation that influence technological strategies of the firms present there. Given the competitive factors described in the section “TC in late-industrializing economies”, it is assumed in this study that the shipping industry can be classified as “scale intensive”. Therefore, a process of mastery of technology and products by firms is required. Innovations are incremental and derive from previous experiences in product design. In addition to engineering the actual shipyard, suppliers revert to an important source of innovation for process improvement and cost reduction.

Types of TC metricsAccording to Figueiredo (2009) there are two types of metrics to measure technological innovation levels: (i) conventional, widely used in developed economies, whose focus is expenditure on R&D and patents; and (ii) based on TC, whose theoretical development has been focused on emerging countries organizations. Given the differences between these approaches, it is important to first understand how they relate to each other.

It can be deduced from the section “TC in late-industrializing economies” that innovation is a journey of several steps, whose trajectory is not always linear and is influenced by different factors that act simultaneously at different levels (Freeman & Soete, 1997). Therefore, establishing metrics to evaluate it is a complex task, subject to many conceptual and methodological controversies, starting with the understanding of what innovation means at an organizational level (Manoochehri, 2010). The first dilemma is to clarify whether the goal is to measure technological innovations through R&D activities (Schwartz, Miller, Plummer, & Fusfeld, 2011) or more broadly, considering all the dimensions of the phenomenon, as recommended by the Oslo Manual (OECD, 2007).

Another challenge is to measure the innovation process considering three main stages: the directing inputs, the processes through which it is driven, and the financial and qualitative results obtained (Mankin, 2007). According to Huizingh (2011), the current economic environment requires the inclusion of non-conventional metrics that consider intermediate factors such as TC accumulation. Even though there is academic merit in this effort, it is recognized that the more comprehensive the metric, the more complex its preparation will be, making the measurement a near impossible task, or one that it is not recommended (Manoochehri, 2010).

For Figueiredo (2009), conventional innovation metrics do not consider transfer mechanisms or technological assimilation typical of emerging market firms. Contrarily, TC accumulation constitutes an intermediate stage of the technological innovation process (Huizingh, 2011), which is a necessary condition for firms of late-industrializing countries. In the view of this article, TC metrics initiate and accelerate the innovation journey (Bell & Pavitt, 1995).

A detailed analysis of the types of TC metrics found in the literature is beyond the scope of this study; however, some key differences are highlighted in order to clarify the option adopted in this article. First, we must emphasize that estimating the TC level of a firm is complex and also partly subjective because different managers within the same firm prioritize different capabilities, generating different results (De Mori, Batalha, & Alfranca, 2014).

In relation to emerging economies, empirical studies in the literature are found for TC metrics whose indicators are developed for specific sectoral and organizational contexts (Raghavendra & Subrahmanya, 2006; Romijn, 1999; Toyama, Kongmuamg, & Toyama, 2014). In general, these studies use statistical techniques and proxies with different levels of consolidation and complexity. Other studies start from statistics and official censuses in order to apply indicator construction techniques (Domínguez & Brown, 2004; Yan Aw & Batra, 1998).

Lall's (1992) taxonomy can be considered a milestone in the effort to quantify TC in firms belonging to developing countries. His focus was to classify TC in order to assimilate, adapt, and develop the technologies acquired from advanced countries. Bell and Pavitt (1995), seeking to improve and operationalize the analytical framework proposed by Lall (1992), featured a TC matrix that distinguishes the basic skills needed to operate from the most innovative CT.

The focus of this article is the operationalization of a TC evaluation model based on a technological competencies matrix, which allows a firm's capability accumulation over time to be analyzed according to its engineering capability and the innovation culture being developed (Dutrenit, 2007).

The TC metric comprises of technological functions arranged by levels of TC in columns and rows. In the quadrant resulting from technological function crossing with the TC level lies the common attributes described for firms that occupy the corresponding level (Figueiredo, 2005). That is, a TC metric lists the relevant technological functions of firm operations of a certain sector, the different TC levels of firms in the sector, and activities that firms must have to be classified at these levels.

MethodologyThis article was based on a literature review and empirical evidence collected from interviews with researchers and professionals involved in the shipping industry. Examination of empirical evidence was followed by a systematic construction of analytical tables, as suggested by Miles and Huberman (1994).

According to Vergara's typology (2011), this study encompasses both bibliographical and field research: (i) bibliographical because the research was developed from a literature review in order to provide information for the preliminary construction of the TC metric for the shipbuilding industry; (ii) field research because, from the interviews, it was possible to organize and tabulate the empirical evidence collected in order to adapt the metric to the offshore naval sector. The research aims are methodological (Vergara, 2011), considering the construction of an instrument (model) to capture reality, which can be used in future research on technological innovation in Brazilian offshore naval firms. The organization of the research follows that of Moreira and Pitassi's research (2013), which presents four steps:

Step 1: Prepare the draft of the metric, taking as its starting point a literature review, particularly the work of Favarin, Pinto, Gattaz, and Taveira (2011), Souza (2009), and a study by Coppe (2007).

Step 2: With the metric derived from the literature, twelve semi-structured interviews were held with shipbuilding professionals and researchers. To identify experts, the technique of snowballing was used (Biernacki & Waldorf, 1981).

Step 3: The information obtained in the preliminary stages was supplemented, revised, and adjusted for suitability to the reality of the construction of offshore support vessels.

Step 4: Pilot tests. The appropriate metric (see Table 2) was applied to Alpha shipyard, where there were three interviews with key managers of this firm.

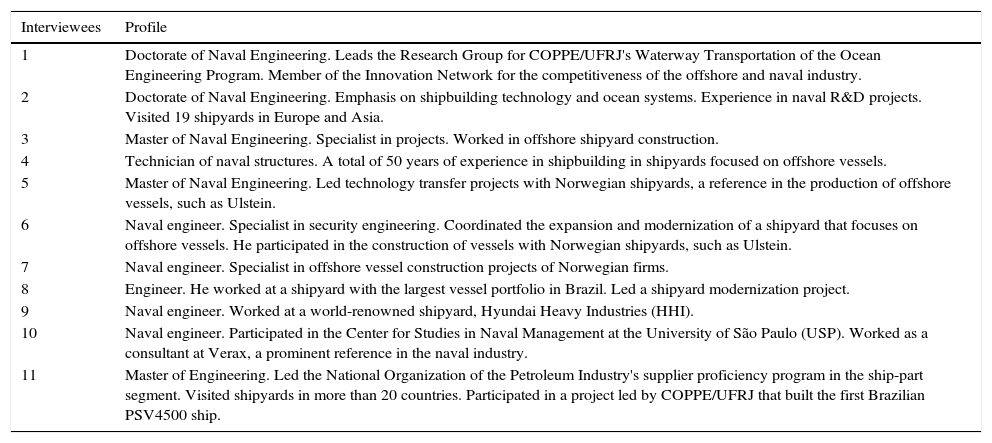

Table 1 shows the relationship of the professionals interviewed in the different phases:

List of interviewees.

| Interviewees | Profile |

|---|---|

| 1 | Doctorate of Naval Engineering. Leads the Research Group for COPPE/UFRJ's Waterway Transportation of the Ocean Engineering Program. Member of the Innovation Network for the competitiveness of the offshore and naval industry. |

| 2 | Doctorate of Naval Engineering. Emphasis on shipbuilding technology and ocean systems. Experience in naval R&D projects. Visited 19 shipyards in Europe and Asia. |

| 3 | Master of Naval Engineering. Specialist in projects. Worked in offshore shipyard construction. |

| 4 | Technician of naval structures. A total of 50 years of experience in shipbuilding in shipyards focused on offshore vessels. |

| 5 | Master of Naval Engineering. Led technology transfer projects with Norwegian shipyards, a reference in the production of offshore vessels, such as Ulstein. |

| 6 | Naval engineer. Specialist in security engineering. Coordinated the expansion and modernization of a shipyard that focuses on offshore vessels. He participated in the construction of vessels with Norwegian shipyards, such as Ulstein. |

| 7 | Naval engineer. Specialist in offshore vessel construction projects of Norwegian firms. |

| 8 | Engineer. He worked at a shipyard with the largest vessel portfolio in Brazil. Led a shipyard modernization project. |

| 9 | Naval engineer. Worked at a world-renowned shipyard, Hyundai Heavy Industries (HHI). |

| 10 | Naval engineer. Participated in the Center for Studies in Naval Management at the University of São Paulo (USP). Worked as a consultant at Verax, a prominent reference in the naval industry. |

| 11 | Master of Engineering. Led the National Organization of the Petroleum Industry's supplier proficiency program in the ship-part segment. Visited shipyards in more than 20 countries. Participated in a project led by COPPE/UFRJ that built the first Brazilian PSV4500 ship. |

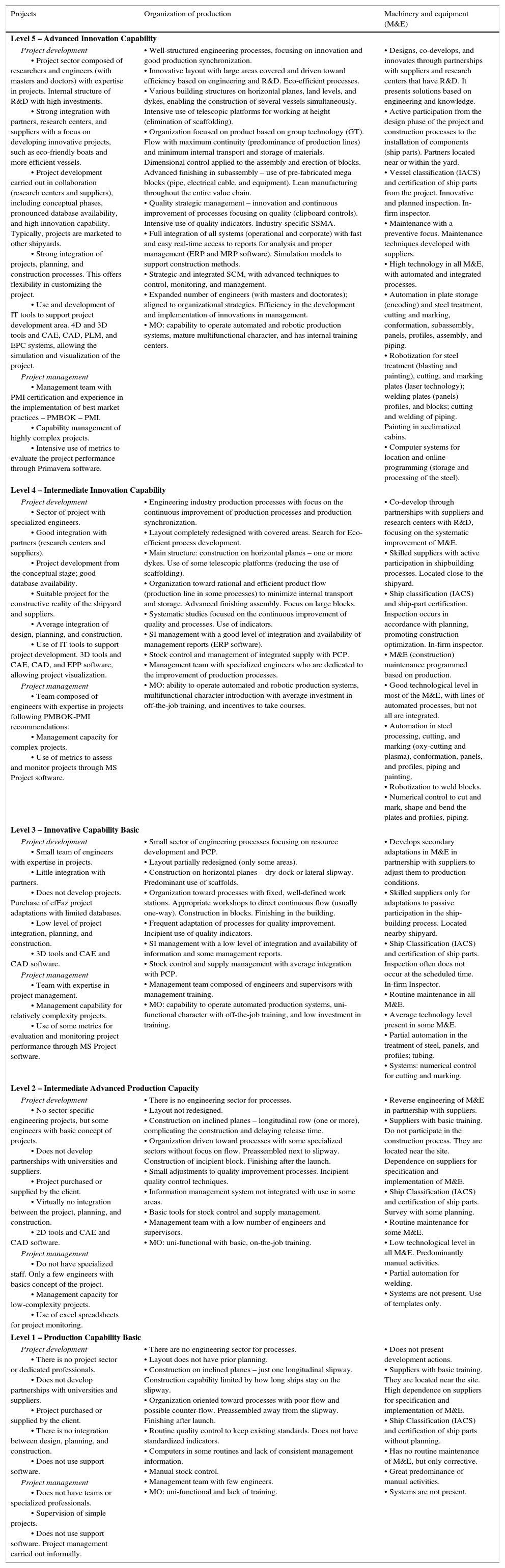

The results of the research, namely, the proposed TC metric adapted for the offshore naval industry, can be seen in Table 2.

Analytical framework adapted to the naval industry, offshore support vessels.

| Projects | Organization of production | Machinery and equipment (M&E) |

|---|---|---|

| Level 5 – Advanced Innovation Capability | ||

| Project development • Project sector composed of researchers and engineers (with masters and doctors) with expertise in projects. Internal structure of R&D with high investments. • Strong integration with partners, research centers, and suppliers with a focus on developing innovative projects, such as eco-friendly boats and more efficient vessels. • Project development carried out in collaboration (research centers and suppliers), including conceptual phases, pronounced database availability, and high innovation capability. Typically, projects are marketed to other shipyards. • Strong integration of projects, planning, and construction processes. This offers flexibility in customizing the project. • Use and development of IT tools to support project development area. 4D and 3D tools and CAE, CAD, PLM, and EPC systems, allowing the simulation and visualization of the project. | • Well-structured engineering processes, focusing on innovation and good production synchronization. • Innovative layout with large areas covered and driven toward efficiency based on engineering and R&D. Eco-efficient processes. • Various building structures on horizontal planes, land levels, and dykes, enabling the construction of several vessels simultaneously. Intensive use of telescopic platforms for working at height (elimination of scaffolding). • Organization focused on product based on group technology (GT). Flow with maximum continuity (predominance of production lines) and minimum internal transport and storage of materials. Dimensional control applied to the assembly and erection of blocks. Advanced finishing in subassembly – use of pre-fabricated mega blocks (pipe, electrical cable, and equipment). Lean manufacturing throughout the entire value chain. • Quality strategic management – innovation and continuous improvement of processes focusing on quality (clipboard controls). Intensive use of quality indicators. Industry-specific SSMA. • Full integration of all systems (operational and corporate) with fast and easy real-time access to reports for analysis and proper management (ERP and MRP software). Simulation models to support construction methods. • Strategic and integrated SCM, with advanced techniques to control, monitoring, and management. • Expanded number of engineers (with masters and doctorates); aligned to organizational strategies. Efficiency in the development and implementation of innovations in management. • MO: capability to operate automated and robotic production systems, mature multifunctional character, and has internal training centers. | • Designs, co-develops, and innovates through partnerships with suppliers and research centers that have R&D. It presents solutions based on engineering and knowledge. • Active participation from the design phase of the project and construction processes to the installation of components (ship parts). Partners located near or within the yard. • Vessel classification (IACS) and certification of ship parts from the project. Innovative and planned inspection. In-firm inspector. • Maintenance with a preventive focus. Maintenance techniques developed with suppliers. • High technology in all M&E, with automated and integrated processes. • Automation in plate storage (encoding) and steel treatment, cutting and marking, conformation, subassembly, panels, profiles, assembly, and piping. • Robotization for steel treatment (blasting and painting), cutting, and marking plates (laser technology); welding plates (panels) profiles, and blocks; cutting and welding of piping. Painting in acclimatized cabins. • Computer systems for location and online programming (storage and processing of the steel). |

| Project management • Management team with PMI certification and experience in the implementation of best market practices – PMBOK – PMI. • Capability management of highly complex projects. • Intensive use of metrics to evaluate the project performance through Primavera software. | ||

| Level 4 – Intermediate Innovation Capability | ||

| Project development • Sector of project with specialized engineers. • Good integration with partners (research centers and suppliers). • Project development from the conceptual stage; good database availability. • Suitable project for the constructive reality of the shipyard and suppliers. • Average integration of design, planning, and construction. • Use of IT tools to support project development. 3D tools and CAE, CAD, and EPP software, allowing project visualization. | • Engineering industry production processes with focus on the continuous improvement of production processes and production synchronization. • Layout completely redesigned with covered areas. Search for Eco-efficient process development. • Main structure: construction on horizontal planes – one or more dykes. Use of some telescopic platforms (reducing the use of scaffolding). • Organization toward rational and efficient product flow (production line in some processes) to minimize internal transport and storage. Advanced finishing assembly. Focus on large blocks. • Systematic studies focused on the continuous improvement of quality and processes. Use of indicators. • SI management with a good level of integration and availability of management reports (ERP software). • Stock control and management of integrated supply with PCP. • Management team with specialized engineers who are dedicated to the improvement of production processes. • MO: ability to operate automated and robotic production systems, multifunctional character introduction with average investment in off-the-job training, and incentives to take courses. | • Co-develop through partnerships with suppliers and research centers with R&D, focusing on the systematic improvement of M&E. • Skilled suppliers with active participation in shipbuilding processes. Located close to the shipyard. • Ship classification (IACS) and ship-part certification. Inspection occurs in accordance with planning, promoting construction optimization. In-firm inspector. • M&E (construction) maintenance programmed based on production. • Good technological level in most of the M&E, with lines of automated processes, but not all are integrated. • Automation in steel processing, cutting, and marking (oxy-cutting and plasma), conformation, panels, and profiles, piping and painting. • Robotization to weld blocks. • Numerical control to cut and mark, shape and bend the plates and profiles, piping. |

| Project management • Team composed of engineers with expertise in projects following PMBOK-PMI recommendations. • Management capacity for complex projects. • Use of metrics to assess and monitor projects through MS Project software. | ||

| Level 3 – Innovative Capability Basic | ||

| Project development • Small team of engineers with expertise in projects. • Little integration with partners. • Does not develop projects. Purchase of efFaz project adaptations with limited databases. • Low level of project integration, planning, and construction. • 3D tools and CAE and CAD software. | • Small sector of engineering processes focusing on resource development and PCP. • Layout partially redesigned (only some areas). • Construction on horizontal planes – dry-dock or lateral slipway. Predominant use of scaffolds. • Organization toward processes with fixed, well-defined work stations. Appropriate workshops to direct continuous flow (usually one-way). Construction in blocks. Finishing in the building. • Frequent adaptation of processes for quality improvement. Incipient use of quality indicators. • SI management with a low level of integration and availability of information and some management reports. • Stock control and supply management with average integration with PCP. • Management team composed of engineers and supervisors with management training. • MO: capability to operate automated production systems, uni-functional character with off-the-job training, and low investment in training. | • Develops secondary adaptations in M&E in partnership with suppliers to adjust them to production conditions. • Skilled suppliers only for adaptations to passive participation in the ship-building process. Located nearby shipyard. • Ship Classification (IACS) and certification of ship parts. Inspection often does not occur at the scheduled time. In-firm Inspector. • Routine maintenance in all M&E. • Average technology level present in some M&E. • Partial automation in the treatment of steel, panels, and profiles; tubing. • Systems: numerical control for cutting and marking. |

| Project management • Team with expertise in project management. • Management capability for relatively complexity projects. • Use of some metrics for evaluation and monitoring project performance through MS Project software. | ||

| Level 2 – Intermediate Advanced Production Capacity | ||

| Project development • No sector-specific engineering projects, but some engineers with basic concept of projects. • Does not develop partnerships with universities and suppliers. • Project purchased or supplied by the client. • Virtually no integration between the project, planning, and construction. • 2D tools and CAE and CAD software. | • There is no engineering sector for processes. • Layout not redesigned. • Construction on inclined planes – longitudinal row (one or more), complicating the construction and delaying release time. • Organization driven toward processes with some specialized sectors without focus on flow. Preassembled next to slipway. Construction of incipient block. Finishing after the launch. • Small adjustments to quality improvement processes. Incipient quality control techniques. • Information management system not integrated with use in some areas. • Basic tools for stock control and supply management. • Management team with a low number of engineers and supervisors. • MO: uni-functional with basic, on-the-job training. | • Reverse engineering of M&E in partnership with suppliers. • Suppliers with basic training. Do not participate in the construction process. They are located near the site. Dependence on suppliers for specification and implementation of M&E. • Ship Classification (IACS) and certification of ship parts. Survey with some planning. • Routine maintenance for some M&E. • Low technological level in all M&E. Predominantly manual activities. • Partial automation for welding. • Systems are not present. Use of templates only. |

| Project management • Do not have specialized staff. Only a few engineers with basics concept of the project. • Management capacity for low-complexity projects. • Use of excel spreadsheets for project monitoring. | ||

| Level 1 – Production Capability Basic | ||

| Project development • There is no project sector or dedicated professionals. • Does not develop partnerships with universities and suppliers. • Project purchased or supplied by the client. • There is no integration between design, planning, and construction. • Does not use support software. | • There are no engineering sector for processes. • Layout does not have prior planning. • Construction on inclined planes – just one longitudinal slipway. Construction capability limited by how long ships stay on the slipway. • Organization oriented toward processes with poor flow and possible counter-flow. Preassembled away from the slipway. Finishing after launch. • Routine quality control to keep existing standards. Does not have standardized indicators. • Computers in some routines and lack of consistent management information. • Manual stock control. • Management team with few engineers. • MO: uni-functional and lack of training. | • Does not present development actions. • Suppliers with basic training. They are located near the site. High dependence on suppliers for specification and implementation of M&E. • Ship Classification (IACS) and certification of ship parts without planning. • Has no routine maintenance of M&E, but only corrective. • Great predominance of manual activities. • Systems are not present. |

| Project management • Does not have teams or specialized professionals. • Supervision of simple projects. • Does not use support software. Project management carried out informally. | ||

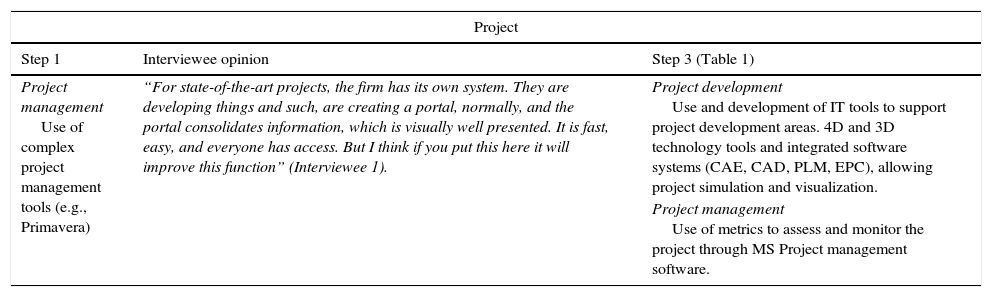

Table 3 presents evidence of how the interviews with experts helped to develop the metric consolidated in Table 2. Given space limitations, this article only selected the “projects” function. For the same reason, discussion will focus on level 5, which relates to the frontier of knowledge. The TC description corresponding to lower levels was done by the authors of this study based on the discussions with the experts.

The role of experts in metric adaption.

| Project | ||

|---|---|---|

| Step 1 | Interviewee opinion | Step 3 (Table 1) |

| Project management Use of complex project management tools (e.g., Primavera) | “For state-of-the-art projects, the firm has its own system. They are developing things and such, are creating a portal, normally, and the portal consolidates information, which is visually well presented. It is fast, easy, and everyone has access. But I think if you put this here it will improve this function” (Interviewee 1). | Project development Use and development of IT tools to support project development areas. 4D and 3D technology tools and integrated software systems (CAE, CAD, PLM, EPC), allowing project simulation and visualization. |

| Project management Use of metrics to assess and monitor the project through MS Project management software. | ||

As can be seen above, the opinion of the interviewee on the use of computer tools in the technological “projects” function enabled the authors of this article to specify a number of applications as well as split their use to support either project development or management projects.

Empirical research confirmed the relevance of factors highlighted in the theoretical framework. Corroborating the Figueiredo's argument (2009), interviews with experts showed that the metric can help in the understanding of strategy and corresponding business models: I think what you have to add here is that the shipyards of this level have an engineering department that works internally, which is very strong. It is strategic because engineering does not give money directly, but has other outcomes. You have to understand that. But they also sell these projects to others. (Interviewee 1)

Technology transfer is widely used as a learning strategy, which is validated by Favarin, Pinto, Gattaz, and Taveira's argument (2010). The statements obtained also left a clear need, as pointed out De Negri et al. (2009), to deepen learning of imported technologies to break technological dependence at some point in the trajectory of TC accumulation: So the guy has to learn to read the information … and we try to encourage him to use it more. You eliminate the amount of design… I would say you have to exploit what our labor force is able to do, always pushing the guy to learn more. You have to invest in him to raise the level. (Interviewee 5)

The metric construction and application raised discussions that show a change in work organization and the possibility of adopting different business models in the naval industry, even when considering level 5 of Souza's taxonomy (2009). The statements made regarding the relevance of the development of national ship-part suppliers and incremental innovations in design and production processes corroborate the pattern of “intensive scale” sectoral innovation proposed by Bell and Pavitt (1995).

Evidence collected in the literature suggests that, for the highest levels of TC, shipyards still internally maintain all TC functions. However the analytical framework of TC used in this article (Figueiredo, 2009) does not explore in depth the interrelationship between the development of technologies and changes in business models. Evidence collected indicates that the current state of division in the production and dissemination of knowledge enables a further decoupling of technological functions of project, production organization, and machinery and equipment: The yards are not required to have the ability to develop projects, they do not need to do projects, because they work with standard products, such as platforms and oil rigs, which are very complex units and engineering is normally done by specialist firms (interviewee 2).

A pilot test was performed on Alpha shipyard, which was acquired in 2004 by a group that already had a maritime support firm for oil platforms. At the time this survey was conducted Alpha shipyard had a fleet of 21 vessels, of which 15 were built by the shipyard. Besides the construction of offshore support vessels the shipyard was also active in ship repairs.

Although the basic objective of the pilot test was to validate the metric in the field, interviews with firm executives also contributed to the refinement of the instrument, as can be seen in relation to basic innovation capability and the corresponding competencies of the project team: I had also marked here on the projects, project engineering, which is the basic innovation capability… Because if you do not have a guy with some project specialization, the guy will not be able to develop the project. (Interviewee 13)

The completion of the pilot test also identified interpretation problems, as can be seen in the “information management system” attribute from the production organization function: “[W]hat is missing is we use this tool more, as I said, in control and action. Because we already have the tools” (interviewee 14). Thus, it is noted that the respondent considered the fact of having the SI in the production organization, while respondents 13 and15 considered the effective use of SI. This fact demonstrates the need for a revision in the form of metric application with respect to systems or technologies acquired from third parties.

The pilot test results indicated a great convergence in respondent opinions regarding the evidence collected in the previous phase. From a total of 23 there were no attributes where respondents classified them in three different levels. For all the attributes, the classification of at least two respondents was the same. In general, the interviewees were in agreement with the classification of the shipyard as level 3, that is, basic innovation capability.

The technological production organization function showed the greatest dispersion. From a total of nine attributes, five were classified as level 3, while four were classified as level 2. This seems to reflect some maturation of newly made investments in shipyard expansion, which resulted in a new layout of facilities, optimized production flow, and incorporating the latest equipment.

Interviews with executives also showed that the metric helps to understand the decision to accumulate the most advanced TC: You may be looking here; to position: I am here and that is what I need to level up; what I need to develop. So I think it's a good map to look and feel inside and see what the next step is for each thing that needs to be developed… I thought it was a very good idea. (Interviewee 15)

The pilot test demonstrated that the proposed changes in the metrics developed by Figueiredo (2009) helped research operationalization in the field, as in Moreira and Pitassi (2013). The organization of attributes in bullet points as well as the clarity of their development in different levels facilitated the selection of attributes. Another factor that facilitated the exploitation of research in the field was the use of five TC levels. This fact was commented on by respondent 15: Otherwise [referring to having more than 5 levels] you will enter a refinement, and you will not even be able to judge where you are. I think if you have more than that you will make it too complex and it will not be measurable. I think 5 is a threshold number. More than that is not worthwhile.

On the other hand, the evidence collected in the pilot test suggests a relationship between the degree of innovation in the industrial sector and the number of TC levels that the metric should adopt, which is in line with the study of Figueiredo (2009). That is, sectors with high technological content could justify the use of a larger amount of TC levels.

Final considerationsThe purpose of this article was to present a TC metric adapted for the offshore support vessel construction segment. The triangulation of the information obtained from the systematic literature review and the field results demonstrated that the metric proposed in this study has a strong adherence to the studied segment, confirming its validity.

The metrics developed by Favarin et al. (2011), Souza (2009), and Coppe (2007) present a predominantly technical approach, focusing on physical structures and equipment applied to the entire marine industry, which disregards the specificities of each segment. The TC metric presented here is specific to offshore support vessels. Furthermore, the TC metric, unlike the metrics in the literature, allows the trajectory of TC to be analyzed, that is, how and with what speed shipyards can accumulate capability over time. In the metric, TC accumulation is driven through learning mechanisms. This is different from assessments based on the National Shipbuilding Research Program (NSRP), where levels are associated with the shipbuilding industry's historical development.

The assumption that the shipyards in operation reflect a chronological development of technologies used may lead to the understanding that technological catch-up can be achieved by simply buying more advanced technologies. Instead, the researched theoretical background and empirical evidence collected in the interviews revealed that just acquiring more modern machinery and equipment is not enough.

The TC metric highlights the need to develop other factors for the technological catch-up process to work satisfactorily. In addition to the acquisition of technology, it must be adapted to the shipyard industry and have people trained to operate it. It is clear that to reach the frontier of knowledge, the Brazilian shipping industry will have to break from the dependence on technology providers.

The TC metric developed in this study is systemic, making it is possible to analyze the consistency of different levels and their technological functions, while allowing the decoupling of the industry functions. Depending on its business model, a shipyard may present level 3 in projects and level 4 in production organization.

It is noted that the metric was developed with a focus on the characteristics of late-industrializing countries, which gives special importance to the challenges facing Brazil in the development of its shipbuilding industry from externalities generated by pre-salt exploitation. The TC metric—unlike traditional innovation evaluations that are in line with strategic management based on technological innovation—assesses shipyard TC levels in three technological functions and understands the challenges that need to be faced in order to accumulate more advanced TC, or even make technological leaps.

The research also identified major changes in the production organization of the shipbuilding industry, notably: (i) the adoption of innovative business models that enable the local construction of a stock of hulls and large integrated systems, connecting local shipyards to international shipyards; (ii) the construction of vessels from prefabricated and standardized modules, which facilitates the adoption of welding and robotic automation—similar to what was done in the automotive industry; (iii) the adoption of integrated management software, from the basic vessel construction project to the management of shipyard construction assets and controlling the management of business orders; and (iv) prioritizing the construction of offshore support vessels such as the multipurpose service vessel (MPSV), which has greater flexibility in its use.

For new business models and operating strategies to be adopted, in which shipyards buy integrated systems (such as sets of pumps and engines), it is essential that the Brazilian ship-part industry also develop its TC, which will require decades, as demonstrated by the success stories of Japanese and Korean shipyards. This requires a careful policy of attracting international suppliers, integrating domestic manufacturers in supply chains of those producers, and the gradual substitution of imports in accordance with national industry capacity expanding and growing sophistication. It will also be essential to the development of sophisticated TC in Brazilian firms’ projects with a view to promote best practices in naval architecture and capability expansion.

In an analytical effort to adapt Figueiredo's metric (2009), interviews were carried out that supported the decision to build a metric with fewer TC levels (five instead of seven), giving a clearer demarcation of the development trajectories of each activity. It should be noted that a larger distance between levels may cause distortions in results obtained from the application of the metric, as was the case in the study of Moreira and Pitassi (2013). However, from the evidence collected, the authors of this study believe that new empirical research focused on the application of the metric in Brazilian shipbuilding firms will contribute to the evaluation of the benefits and costs of adopting a larger or smaller number of TC levels, particularly with regard to innovation capability.

The discussions carried out in this study support the conclusion that there is no standard answer for firms, as configurations depend, among other things, on the business model adopted. This reflection leads to a question for future research: It is possible to obtain a standard response to the TC metric for each business model adopted by firms?

The research undertaken here had some limitations, notably: (i) the slight emphasis on aspects related to personnel management; (ii) a restricted view for those shipyards that prioritize a technical approach, focusing on machinery and equipment specification; (ii) difficulty in determining the levels of certain attributes, that is, low, medium, and high; and (iv) difficulty of translating analytical levels into numerical scales, reflecting the stages reached by each firm.

Regarding the latter limitation, a suggestion for future research would be to adopt weighted scores that reflect the importance of the technological functions of projects, production organization, and machinery and equipment for TC in the studied firm. For example, in the case of the pilot test conducted in this article, larger weighted scores could have been given to the role of the project management, considering that the modularized architecture of the vessel allows projects to be acquired from firms specializing in the development of projects of this nature. These weighted scores could be introduced directly into a spreadsheet to automatically generate an average value for the firm's TC.

In theory the results emphasize the need to construct an adapted sectorial metric in order to monitor technological catch-up strategies. For them to be useful these metrics should undergo systematic review in order to reflect on the advancement of technological frontiers. For R&D management practices, metric construction involves the generation of a support tool to evaluate efforts combined with TC advances in firms, serving as a basis for building management team consensus. Finally, it is concluded that the metric proposed in this article is a better instrument than metrics existing in the literature when the objective is to implement technological catch-up strategies in offshore support vessel shipbuilding firms.

Conflicts of interestThe authors declare no conflicts of interest.

Peer Review under the responsibility of Departamento de Administração, Faculdade de Economia, Administração e Contabilidade da Universidade de São Paulo – FEA/USP.