This Special Issue contains a small collection of the papers presented during the second edition of the joint conference on Cellular Materials, together with the International Conference on Dynamic Behaviour of Cellular Materials, and held at the Department of Mechanical Engineering, University of Aveiro, Portugal (September 25 to 27, 2017). Within three days, experts from different countries (Brazil, Colombia, Croatia, France, Germany, Italy, Mexico, Poland, Portugal, Russia, Slovenia and Turkey) presented about 50 lectures (both in oral and poster sessions), including five plenary lectures given by renowned international experts.

Cellular solids and porous materials have become the most promising lightweight multifunctional materials, being used in a wide range of commercial, biomedical, industrial and military applications [1–8]. This is due to an unusual combination of properties derived from their porous cellular structures together with the properties of the material they are made of [1]. These materials are defined as having a porosity superior to 70% and are made up of an interconnected porous network of solid struts or plates, which form the edges and faces of pores/cells. Two phases are observed, a discontinuous or continuous gaseous phase (cells or pores) and a continuous solid phase (base material or matrix). Their use contributes to an immediate and significant weight reduction and material savings, combined with other benefits, namely an excellent performance in vibration damping, sound attenuation, energy absorption, good filtration capability, catalytic properties and insulation. In literature, some of these materials are also designated by other technical terms, like foams (e.g., metal foams), and sponges (e.g., bone). The term “foam” refers to a special case of porous materials, in which the solid foam is created from a liquid foam where gas bubbles are dispersed in a liquid. The term “sponge”, on the other hand, refers to a porous material with complex and interconnected porosity, that cannot be subdivided into well-defined unit cells/pores.

Scientists have grouped and classified these cellular materials in different ways. They can be immediately classified into natural and man-made (or artificial) cellular materials [1]. Cork, wood, human bones, plant stems and marine sponges [1,8] are examples of natural cellular materials, some of them being widely used in engineering applications. For example, cork based products are adopted in buildings, construction, automotive, aeronautical, aerospace, footwear and outdoor furniture. Wood is also considered an important construction material, being used for building shelters, houses and boats. The human bone is the key component of the skeletal system that has several functions, such as body support, locomotion and protection of internal organs. These natural materials are light, but simultaneously display unusual engineering properties, mainly due to their cellular structures. Inspired by these natural materials, man started to develop similar alternatives made of polymers, metals and ceramics, which are called man-made cellular (or bio-inspired) materials.

Based on the base material, these materials started to be grouped into three categories: cellular metals[4], cellular ceramics[5] and cellular polymers[6]. In addition to these, there are also two other groups of important engineering materials that recently emerged: cellular composites and cellular nanocomposites. These are reinforced materials that have been developed by incorporating micro and nano-sized reinforcements into the bulk matrix to enhance the properties of the conventional ones. For example, ceramic nanoparticles and carbon nanofillers have been explored as mechanical reinforcements to fabricate high-strength metal foams [9]. Carbon nanofillers have also investigated as flame retardants for polymeric foams for enhancing their thermal stability, flammability and fire retardancy, without compromising their mechanical properties [10].

Cellular materials can be further classified by the cell type (as open or closed), cell size, variability in cell size (as stochastic and periodic) and porosity. Based on the cell types, two main groups appear [1]: open-cell and closed-cell structures, in which the cells are interconnected by cell edges, or isolated from each other by solid faces, respectively. This characteristic makes these materials suitable candidates for applications in different technological areas, as either functional (open-cells) or structural (open-cells) options. Open-cell structures are permeable and have a very high internal surface area, characteristics required for flow-through applications or when surface exchange are involved. They are widely used as filters, gas-flow controlling devices, electrodes, batteries, catalysts, heat exchangers, biomedical implants and bearings. Closed-cell structures, especially those based on metals and polymers, provide an excellent structural efficiency and excellent capacity to absorb energy under both impact and sound, together with damping noise and vibration in structures such as houses, cars, trains and equipments.

The first artificial cellular materials available had irregular cellular structures, since the existing manufacturing processes did not allow to control the cellular structures during production. The fabrication of regular structures has started a hot topic in this field, made possible by developing new (or improving existing) products and processes. Scientists believe that such regular cellular structures will allow to achieve predefined performances and establish the process–structure–property relationships. Syntactic foams are an example of new recent cellular materials, developed with an easily reproducible unit cell [11,12]. Such foams are obtained by incorporating hollow spheres into a matrix. The spheres are then packed into a random dense arrangement, with interstitial spaces being occupied with a solid material matrix. This can be made by infiltrating a molten material through the interstitial spaces between hollow spheres of an ordered assembly.

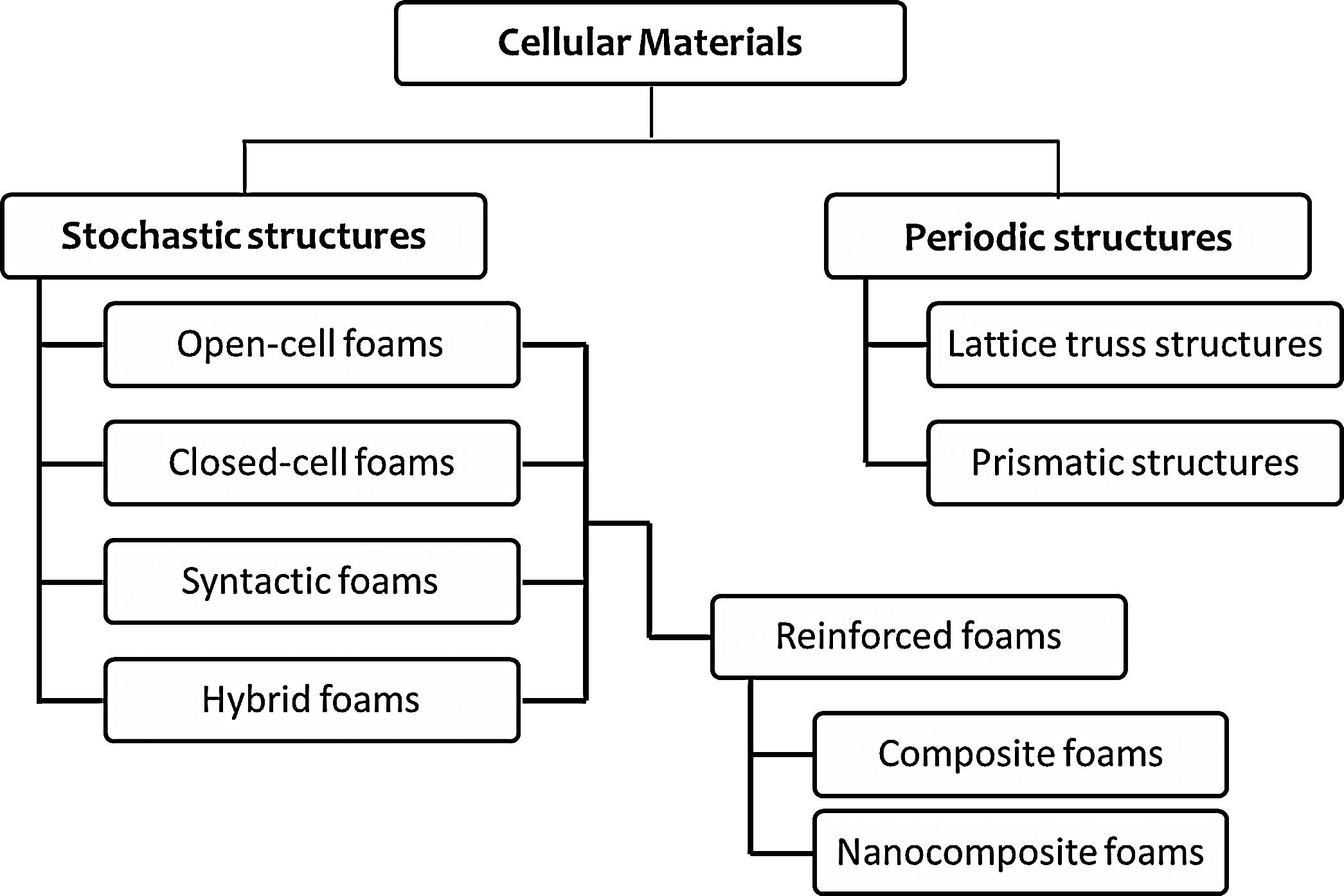

With the rapid advancements in additive manufacturing technologies (e.g., rapid prototyping and 3D printing) new regular cellular structures have appeared, called periodic cellular structures [13]. These techniques consist to build a part layer by layer, fabricating regular structures (including complex topologies and graded materials). Thus, the properties of a component can be easily tailored with a precise control of their topologies. For instance, periodic cellular structures made of titanium alloys or with auxetic properties have been tested in biomedical (scaffold design for tissue engineering) and transport (crash energy absorbers) fields, respectively. Based on these latest developments, these materials are classified in two groups [13]: stochastic and periodic cellular structures (Fig. 1).

The stochastic porous structures refer to materials that cannot be characterised by a single unit cell. On the other hand, periodic cellular materials are characterised by a unit cell that can be translated through them. If the cell is translated in two dimensions, they are designated prismatic cellular materials (e.g., honeycomb), while if the cell is translated in three-dimensional periodicity, then they are designated by periodic cellular lattice truss structures. Based on the multi-material concept, hybrid foams have been developed for crashworthiness applications [14] by combining different materials (e.g., polymer/metal) to acquire new characteristics and increase their multi-functionality.

The selection of the type of the cellular materials depends on the in-service conditions (environmental) and the properties required for a given application. Cellular ceramics are quite stiff and can resist even at very high temperatures, being more stable in harsh environments than cellular metals and polymers. Cellular polymers increase fire hazards, while the cellular metals are non-flammable and recyclable. Cellular polymers are flexible, but cannot support high temperatures, while cellular metals are extremely tough and can plastically deform and absorb energy, being however heavier.

2MatCel seriesThe field of cellular materials has significantly increased over the last two decades, which reflects in the growth of published literature. The industry has recognised this field as a major one, increasingly gaining importance with the appearance of new bioinspired materials that have revolutionised a large number of industries. Workshops, symposiums and conferences have emerged in this field, particularly in Europe. In this context, in 2015, the 1st edition of a conference dedicated to cellular materials (MatCel) was organised at the University of Aveiro, in Portugal. The aim of this 1st edition was to identify the number of Portuguese teams that actively develop research in this field. The conference was held at the Department of Mechanical Engineering (September 7–8, 2015), with most of the participants being from Portugal. After this successful event, a 2nd edition was organised (September 25–27, 2017), also at University of Aveiro. This 2nd edition was co-organised with the International Conference on Dynamic Behaviour of Cellular Materials. This event was organised and structured in three days with scientific sessions, as well as five plenary lectures given by renowned international experts, being most of the participants from abroad. All abstract contributions in both editions were published as books [15,16], and a special issue on Cellular Materials [17] was made available in 2016, with papers from 1st edition.

The present special issue contains a small collection of papers from the 2nd edition of MatCel and aims to reflect the latest developments on this thematic, mainly in the periodic cellular structures, and covering experimental, numerical and theoretical issues.

The event has now assumed itself as a biennial conference, aiming to be a regular and privileged forum for the exchange and discussion between scientists, academia and industry, inspiring future collaborations and bringing up new ideas within this field.

The Guest Editors of this special issue express their sincere appreciation to all Authors and Reviewers for their dedication in putting together a high quality body of joint work. A very special thanks for João Dias-de-Oliveira (Department of Mechanical Engineering, University of Aveiro) for having created the cover image of this special issue. Our acknowledgments are also to the editors of Science and Technology of Materials, together with Elsevier publishing teams and staff, for their excellent cooperation and support.