Layered ceramics were obtained by sequential slip casting of suspensions containing different proportions of zircon (Z) and alumina (A) as follow; 60Z40A, 40Z60A, 50Z50A and 80Z20A. Three laminar samples were fabricated using five thick layers and four thin layers, being the composition 60Z40A used for the thick layers and 40Z60A, 50Z50A and 80Z20A for the thin layers. From those thick/thin layers configurations, the residual stresses were: −46.27 MPa/+173.53 MPa, −11.25 MPa/+42.19 MPa and +9.70 MPa/−36.38 MPa for 60Z40A/40Z60A, 60Z40A/50Z50A and 60Z40A/80Z20A, respectively. The CTE (thermal expansion coefficient) was determined using monolithic samples of each composition; all laminar components were characterized by SEM and by the determination of the modulus of rupture. The result showed that the modulus of rupture were higher than the properties obtained for a monolithic 60Z40A sample, being 218% and 182% higher for laminar components configuration of 60Z40A/50Z50Aand 60Z40A/80Z20A, respectively. Also, due to high strain mismatch the laminar component 60Z40A/40Z60A showed lower mechanical properties than the 60Z40A monolithic sample.

Se fabricaron materiales laminares mediante colado secuencial de suspensiones sobre molde de escayola, y las suspensiones se formularon con diferentes porcentajes de alúmina (A) y circón (Z) con el siguiente acomodo: 60Z40A, 40Z60A, 50Z50A y 80Z20A, siendo 60Z40A la composición utilizada como capa gruesa y 40Z60A, 50Z50A y 80Z20A como capas delgadas. Para las configuraciones de capa gruesa/delgada, las tensiones residuales fueron: −46,27 MPa/+173,53 MPa, −11,25 MPa/+42,19 MPa y +9,70 MPa/−36,38 MPa por 60Z40A/40Z60A, 60Z40A/50Z50A y 60Z40A/80Z20A, respectivamente. El coeficiente de expansión térmico se determinó utilizando muestras monolíticas de cada composición; todos los componentes laminares se caracterizaron por microscopia electrónica de barrido y se determinó su módulo de ruptura. Los resultados muestran que las propiedades mecánicas son mayores que las propiedades obtenidas para la muestra monolítica 60Z40A, incrementando un 218 y un 182% la configuración de componentes laminares de 60Z40A/50Z50A y 60Z40A/80Z20A, respectivamente. Por otra parte, debido a la presencia de tensiones residuales altas, el componente laminar 60Z40A/40Z60A mostró una disminución en las propiedades mecánicas respecto a la muestra monolítica 60Z40A.

In recent years, laminar ceramic materials have been studied for their use as structural materials, since they have been shown to exhibit higher mechanical resistance compared with monolithic components ([1]). From this, there are several mechanisms that can be used to improve the mechanical performance: (1) laminar materials with external layers with high compressive residual stress ([2]), (2) laminar materials composed by layers with high rupture tension separated by weak interfaces, in which the high mechanical properties are the result of the combination of the high rupture tension of the layers and high values in the R-curve as a product of delamination at the interface ([3]), or (3) laminar materials in which of external layers with high rupture tension and heterogeneous internal layers are combined ([4]). Thus, the good mechanical response of laminar materials can be as a result of crack deflection (weak interfaces), layers with high rupture tension or by inducing residual stresses by combining layers with different thermal expansion coefficient. According with Bermejo ([5]), depending of the layers composition, the resulting residual stress in the layered material can result positive for tension or negative for compression. Thus, a compressive residual stress state can increase the mechanical properties of layered materials by increasing the threshold resistance of compression layers ([2]); on the other hand, tensile residual stress state also can increase the mechanical properties of layered materials by crack deflection (in the situation of internal layers in compression). Nevertheless, the thermal expansion coefficient difference between thin and thick layers must be carefully selected to prevent delamination ([6], [7]).

For preparing laminates, the developments of colloidal processing techniques have proven their effectiveness in the design and preparation of laminates with high microstructural and microarchitecture control. Consequently, laminated materials with controlled architecture have been obtained by tape casting, electrophoretic deposition and sequential slip casting. In this way, the effect of residual stresses on the mechanical properties of laminar ceramics was firstly studied in multilayer systems made by stacking green sheets produced by tape casting ([8], [9]), and then Requena ([10]) showed that laminar materials with well-defined and controlled layer thickness can be obtained employing the slip casting process. Independently of the forming method used to produce de laminar composites, the system Al2O3/ZrO2 is the most studied in the field of the influence of residual stresses on the mechanical performance of laminar ceramics and theoretical modeling of fracture behavior and crack propagation ([11]). As was expected, recently, the residual stresses was employed to enhance mechanical properties in other ceramic systems, such as; Si3N4/SiC ([12]), Al2O3/Ti3SiC2 ([13]), Al2O3/Ni ([14]), etc., involving different combinations of materials from oxides, non-oxides and metals. Due to the diversity of ceramic materials, laminar composites can be composed by materials that can react during the thermal treatment, such the system ZrSiO4/Al2O3 or other chemically compatible ceramic materials. In this way, Moya ([15]) studied the ZrSiO4/Al2O3 and concluded that at 1600 °C this system reacts to produce zirconia and mullite particles and the quantity of that phases depends on the dissolution degree of zircon at given temperature and the composition of the impurities present in the zircon.

This work was focused on the design of zircon-alumina layered materials, using a thick/thin layers thickness ratio of 3:1 and different layers composition, to generate different state of residual stresses and compare the resulting mechanical properties among the fabricated layered components and one monolithic ceramic with similar composition.

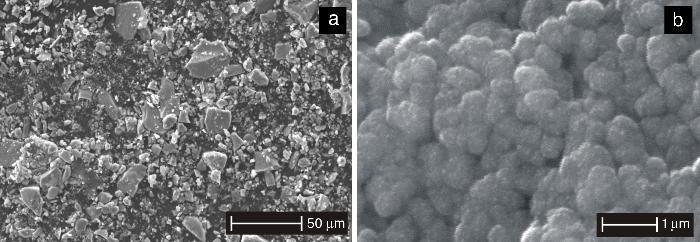

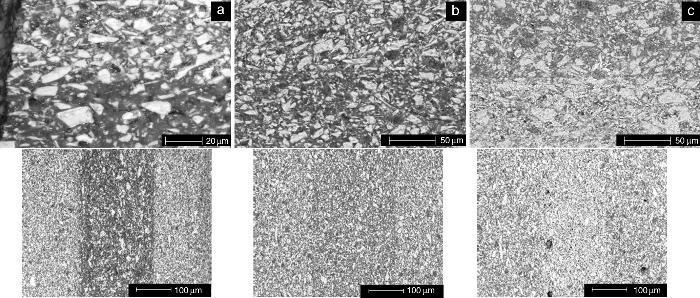

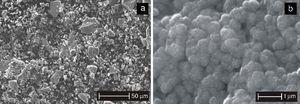

Material and methodsAs starting materials a commercial zircon powder with mean a particle size of 15 μm (zircon flour 98% purity, Z, Priceminerals, USA) that was ball milled during 5 h reaching a mean particle size of 10 μm, and a submicron-sized alumina (A, APHA-0.5, 99.99% purity, Condea Sasol, USA) was used as received, with a mean particle size of 0.5 μm and specific surface area of 7 m2/g. The particle morphology of the employed zircon and alumina powders is shown in Fig. 1.

Fig. 1. Morphology of zircon and alumina particles used in the formulated suspensions.

Suspensions were prepared to a solid loading of 47 vol% at different zircon-alumina proportions, as follows: thick layers were produced using a suspension containing 60 wt% of zircon and 40 wt% of alumina (called 60Z40A) and the composition of suspensions employed to produce thin layers were 40Z60A, 50Z50A, and 80Z20A. Each suspension was stabilized using 0.8 wt% (referred to dry solids) of a commercial polycarboxylate dispersant (Accumer 9400, aqueous dispersion with 42 wt% of the active material, Rohm and Haas, USA) and was subjected to a homogenization time of 3 h in a ball mill. The amount of particle stabilizer additive was previously determined by rheological measurements, showing that the use of 0.8 wt% produce suspensions with the lower thixotropic value ([16]). Rheological characterization was performed at 25 °C, employing a controlled stress rheometer (AR2000, TA Instruments, UK) and concentric cylinders as a sensor system. Flow curves were obtained using a controlled rate measure program composed by two segments; controlled ascending and descending shear rate from 0 to 350 s−1 and from 350 to 0 s−1, respectively, with measure time of 5 min per each segment.

Layered bodies were obtained by sequential slip casting of suspensions using a hollow rectangular acrylic mold (45 mm × 55 mm × 30 mm) attached to a plaster base to assure unidirectional casting; the layer thickness was controlled by adding a fixed volume of 3 ml and 1 ml to the mold of each suspension, to obtain a thickness of 300 μm for thick layers and 100 μm for thin layers, respectively.

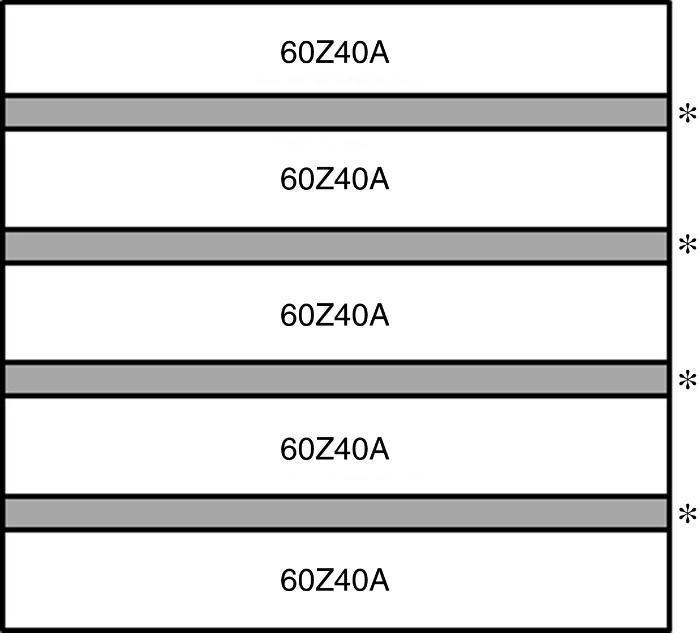

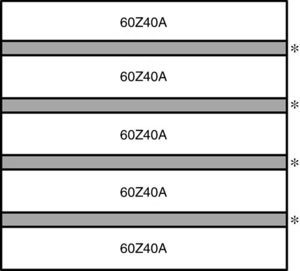

Three layered materials were tailored employing a thick: thin layer thickness ratio of 3:1, in all cases the thick layer composition was 60Z40A, so the layered components were obtained combining five thick 60Z40A layers with four thin layers produced using by one of the following zircon-alumina suspensions: 40Z60A, 50Z50A or 80Z20A, according to the schematic representation of laminated materials shown at Fig. 2.

Fig. 2. Schematic representation of layered materials obtained by sequential slip casting, (*) represent the thin layers with composition of 40Z60A, 50Z50A or 80Z20A.

Also a reference monolithic material was produced employing only the 60Z40A suspension, to compare the resulting mechanical properties of both the monolithic and the layered composites. The densities of sintered monolithic materials were determined by the Archimedes method in water and employing the theoretical density of 3.97 g/cm3 for Al2O3 and 4.6 g/cm3 for zircon. Green components, monolithic and laminar, were dried at room temperature during 24 h, and subsequentially thermally treated at 1500 °C for 1 h. After that, the cast plates were cut into parallelepipedic bars with 4 mm × 4 mm × 45 mm for monolithic materials and 4 mm wide x 45 mm long for layered materials, using a diamond wheel and a high speed cutter (Struers Accutom-5) and tested according to the B configuration of ASTM C1161-02 standard test (Standard test method for flexural strength of advanced ceramics at ambient temperature of the American Society for Testing and Materials). The thermal expansion coefficients were determined employing a NETZSCH DIL 402 PC dilatometer with a measurement cooling range temperature of 1300–25 °C and cooling rate of 10 °C/min, using three sintered samples obtained by casting each suspension. The Young's modulus values were experimentally obtained for each sintered composition using the pulse-echo ultrasonic technique, employing Epoch-IV Panametrics equipment with a single-crystal transducer operated at 5 MHz. The Mechanical tests were performed using three-point bending configuration employing a universal testing machine Qtest-100 with a load cell of 500 N. An increasing load was applied with a constant head rate of 0.5 mm/min, until the catastrophic fracture of the specimen appears. The modulus of rupture (MOR) was determined on five samples of each laminate. Finally, samples were characterized by SEM using a Phillips XL30 SEM microscope and DRX characterization was carried out on powdered samples of each formulation using a Philips X’Pert 3040 diffractometer.

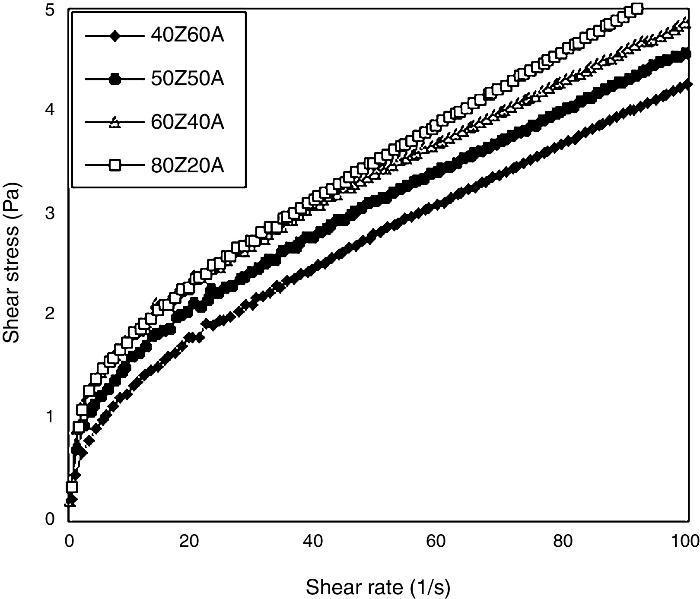

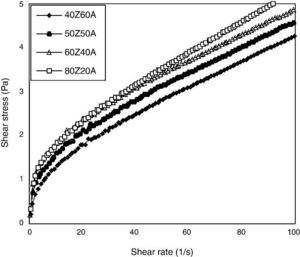

Results and discussionRheological characterizationSlip casting method requires the preparation of moderately concentrated suspensions with a shear thinning flow behavior to assure good mold filling and free of bubbles in order to avoid porosity in the cast specimens. Fig. 3 shows the experimental flow behavior of the different suspensions. A first view to the plot revels that suspensions’ flow behavior was affected by the quantity of zircon in the mixtures, producing more viscous suspensions at higher zircon content. Olhero ([17]) studied the effect of particle size distribution on suspensions’ viscosity containing coarse and fine particles; the authors concluded that viscosity decreases when fine particles are added to suspensions containing coarse particles as a consequence of the ability of fine particles to increase packing. From this, in a system containing fine and coarse particles, the fine particles would occupy the interstitial voids among the coarser particles, improving the packing fraction and offering less resistance to flow. This effect is clearly seen in the suspensions formulated in this work, as the fine alumina particles increases in the suspensions, the viscosity and yield stress decreases. Nevertheless, all suspensions showed a typical shear thinning flow behavior needed for the casting forming methods.

Fig. 3. Flow curves of zircon-alumina suspensions used to produce the different layers.

Experimental flow curves were fitted using the Herschel–Bulkley rheological model (Eq. (1)) for better characterization. This rheological model gives important information of parameters, such as; yield point (τ0), viscosity (η) and flow index (n). The presence of yield point indicates the minimum shear stress or shear rate needed to initiate the flow of a given suspension and the value of flow index gives the corresponding flow behavior, as follows; n = 1 for Newtonian flow, n < 1 for shear thinning and n > 1 for shear thickening. From the fitting results, Table 1, the yield point and viscosity are higher when the zircon content increases, however, all suspensions behave as a shear thinning fluid and have almost the same value of flow index. With this it is possible to assume that all suspensions will behave in the same way during casting and the production of the ceramic laminates.

Table 1. Herschel–Bulkley model fitting results.

| Suspension | Yield stress (Pa) | Flow index | Viscositya (mPa s) |

| 40Z60A | 0.8 | 0.842 | 70.1 |

| 50Z50A | 1.0 | 0.800 | 89.7 |

| 60Z40A | 1.3 | 0.796 | 91.8 |

| 80Z20A | 2.5 | 0.860 | 153.1 |

a Viscosity form the Herschel–Bulkley model.

The thermal expansion coefficient (CTE) and the Young's modulus (E) of the materials constituting the layered material, as well as the number of layers and layers thickness are considered as the principal parameters. Usually the residual stress appears during cooling of a system constituted by two different materials having different CTE, or by size changes produced by some chemical reaction or phase transformation, that produce a strain mismatch that can be quantified byΔ¿, Eq. (2).

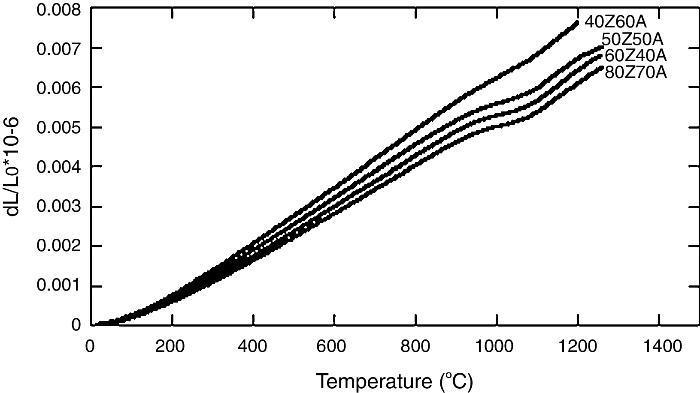

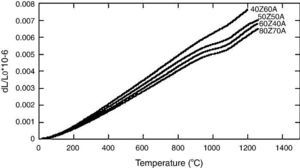

where α is thermal expansion coefficients of the materials a and b, Δ T is the temperature change from a high enough temperature ( TH), to prevent the development of stresses, to room temperature ( TRM), Δ ¿t and Δ ¿r are the deformation produced by phase transformations and chemical reaction, respectively. In the case of this work, the values of Δ ¿ were obtained from the experimental determination of thermal expansion coefficient, assuming that the experimental values includes all deformations due to chemical reactions and phase transformations. Fig. 4 shows the experimental dilatometric curves of monolithic sintered samples produced with the same formulated suspensions used to obtain the laminated components.Fig. 4. Dilatometric curves obtained during cooling for each sintered sample, containing different zircon-alumina weight proportions.

From the experimental data of Fig. 4, the thermal expansion coefficients were calculated in the linear part of the dilatometric curves, considering TH = 1000 °C and TRM = 25 °C and resulting a ΔT of 975 °C. Table 2 summarizes the calculated values of thermal expansion coefficients and Young's modulus determined by the ultrasonic technique.

Table 2. Values of thermal expansion coefficients (α) and Young's modulus (E) calculated from experimental data and determined by the ultrasonic technique, respectively.

| Composition of sintered samples | α (K−1) | E (GPa) | Density (g cm−1) | Porosity (%) |

| 40Z60A | 6.64 × 10−6 | 249.2 (±4.3) | 4.01 | 4.3 (±0.3) |

| 50Z50A | 5.90 × 10−6 | 229.2 (±2.4) | 4.10 | 3.6 (±0.5) |

| 60Z40A | 5.65 × 10−6 | 225. 5 (±4.8) | 4.19 | 3.2 (±0.2) |

| 80Z20A | 5.34 × 10−6 | 160.3 (±1.7) | 4.33 | 3.3 (±0.6) |

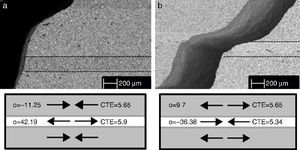

Other important factor to be considered is the adequate joining between layers to impede crack formation or delamination during cooling. From this, colloidal forming methods offers good microstructural control in each layers and high capability to produce good joining between layers. Fig. 5 shows a view of the joining area of the layered materials produced by combining thick 60Z40A layers with thin layers composed by 40Z60A, 50Z50A and 80Z20A.

Fig. 5. SEM micrographs of the joining zone between thick-thin layers; (a) 60Z40A/40Z60A, (b) 60Z40A/50Z50A, (c) 60Z40A/80Z20A.

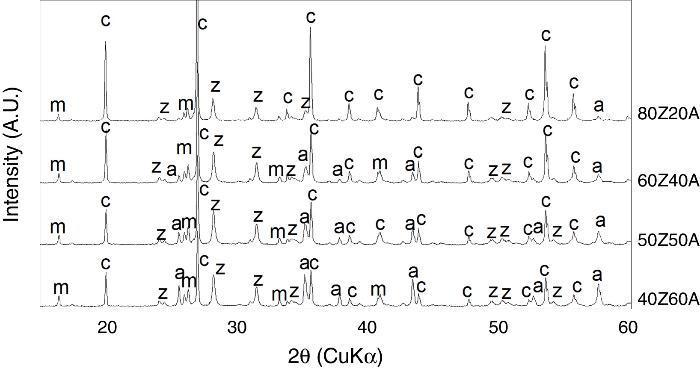

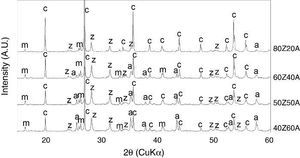

As can be seen, all interfaces are well joined and no cracking or delamination was observed, also there was no evidence of chemical reaction or formation of new phases at the contact area between layers. However, as expected from the results of X-ray diffraction, and according with Moya ([15]), at 1500 °C zircon and alumina reacts to produce zirconia and mullite (Fig. 6), nevertheless we assume that all size changes produced during cooling were measured when the thermal expansion coefficients were determined.

Fig. 6. Diffraction patterns of zircon/alumina samples used to determine the thermal expansion coefficients (c, zircon; a, alumina; z, zirconia; m, mullite).

From this, Eqs. eq0015, eq0020 were considered for the calculation of the residual stresses in the layered materials.

where σa = is the thick layer residual stress, σb = is the thin layer residual stress, E′ = E/(1 − υ) ( E = Young's modulus and υ = Poisson ratio), n = the number of layers, ta = the thickness of the thick layer and tb = the thickness of the thin layer. According with Sánchez-Herencia ( [18]), Xu ( [19]) and Chartier ( [8]) Eqs. eq0015, eq0020 correspond to a model that consider a homogeneous stress distribution across the layers, and the combination of those equations makes it possible to establish that for a resulting thermal strain the residual stresses can be produced by manipulating the thickness of the layers, Eq. (5). Also, this equation considers that the mean forces across any section is zero, being the base to design layered components containing residual stresses when materials with different thermal expansion coefficient are used in the production of layered components.Table 3 shows the calculated theoretical residual stress values of the layered components produced in this work. The Poisson ratio for each layer was assumed as 0.25, being the reported values, for zircon 0.25 and for alumina from 0.2 to 0.25 ([20]). As was mentioned, layered components were tailored employing a thick layer: thin layer thickness ratio of 3:1, in all cases the thick layer composition was 60Z40A and different layered components were obtained combining the thick 60Z40A layer with thin layers of different zircon-alumina weight proportion.

Table 3. Experimental and theoretical values of layered components, using 60Z40A as a thick layer and compared with a monolithic component (M) fabricated using the same thick layer composition.

| Layered component thick/thin layers arrangement (a/b/a/b/a/b/a/b/a) | Residual stress in thick layer (MPa) | Residual stress in thin layer (MPa) | MOR of the layered component (MPa) |

| (a) 60Z40A (b) 40Z60A | −46.27 | +173.53 | 90.33 (±8.4) |

| (a) 60Z40A (b) 50Z50A | −11.25 | +42.19 | 228.21 (±6.5) |

| 60Z40A (M) | – | – | 104.32 (±7.8) |

| (a) 60Z40A (b) 80Z20A | +9.70 | −36.38 | 190.48 (±9.6) |

Also from Table 3, the negative values of the residual stress represent a compression stress arrangement among layers and positive values represent a tensile stress. From this, the multilayer components fabricated with thin layers with higher alumina content, than the thick layer, generate residual compressive stress that can contribute to better mechanical response by reducing the crack propagation. Unexpectedly, the laminar component containing thin layers with the highest alumina content (laminar 60Z40A/40Z60A) showed the lower MOR value, we assume that the highest value of the tensile residual stress in the thin layer is the responsible of the low mechanical performance of this laminar component, being very high that can be too close to a certain critical value before delamination, nevertheless this behavior will be studied in future work. On the other hand, it was evaluated the effect of thin layers with less alumina content, than the thick layer, in this case was found that the generated residual stresses in the layered component changes to produce tensile residual stress on the external layers that can modify the mechanical behavior of layered material.

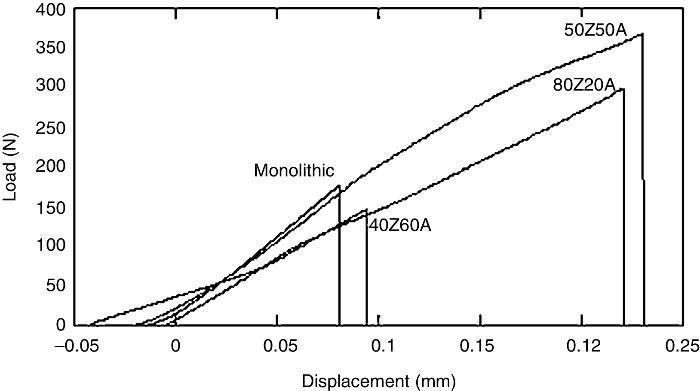

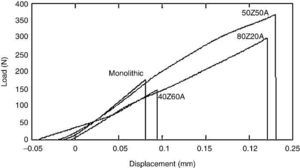

It is well known that the use of residual stresses to manipulate the mechanical behavior of ceramic components is very critical, because they can improve or harm the final mechanical performance. In this way, by changing the zircon-alumina ratio in the layers it is possible to create laminar components in which the residual stresses act in a different manner to preserve its integrity when they are subjected to mechanical tests. Fig. 7 shows the mechanical response of the layered components and the monolithic one, from the load vs. displacement curves is very clear that inducing residual stresses a much better mechanical properties were obtained. Comparing the resulting mechanical properties, when the 50Z50A thin layer was employed the rupture modulus was 218% higher than the obtained for the monolithic sample (228 MPa and 104 MPa, respectively), also with use an 80Z20A thin layer the modulus was 190 (182% higher). However, when a 40Z60A layer was employed in the laminar component the MOR value decreased 13% compared with the MOR value of the monolith.

Fig. 7. Mechanical response of layered and monolithic components.

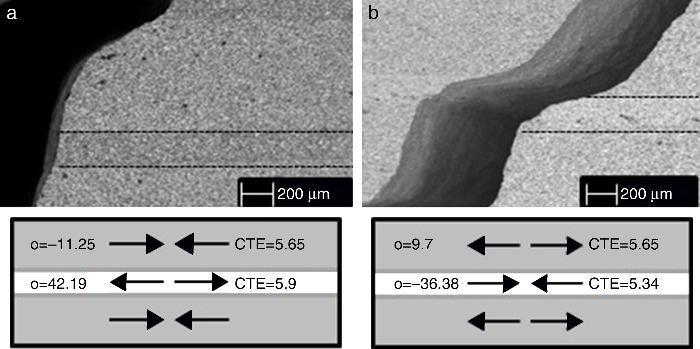

According to Sánchez-Herencia ([7]), when αa < αb the outer layers are in compression, the so called strengthening approach increases the mechanical properties and higher mechanical resistance is expected, compared with a monolithic component fabricated with the composition of the thick layer. This fact was observed from comparing the MOR value of the monolithic with the obtained for the layered component with a 60Z40A/50Z50A arrangement. Thus, when the thin layers contain less zircon than the thick layers the strain mismatch create a tensile residual stress in the thin layer and a compressive residual stress in the outer thick layers. The occurrence of compressive stress in the thick layer could impede the crack propagation on it and the crack path will be ruled by microstructural defects, contrarily, when the crack reach the thin layer, the tensile residual stress on it is responsible of the occurrence of the brittle fracture, nevertheless we assume that the global mechanical properties of this layered component were increased due to the chemical composition difference between thick and thin layers, Fig. 8(a). In this way, Gurauskis ([21]) found that for laminates prepared at two thick/thin layers thickness ratio the R-curve behavior was similar for both systems, but the laminar with higher thickness ratio shows better mechanical response. Thus, in that case, Gurauskis concluded that the high mechanical properties of laminar materials where the outer layers are in compression depend not only on the magnitude of the compressive residual stress, but also of the thickness of the outer layer. From this, we expects that a similar R-curve behavior can be obtained on the laminar components fabricated in this work, this experiments will be carried out for further characterizations of zircon-alumina laminates.

Fig. 8. Crack profile and schematic representation of residual stresses in layered components; (a) 60Z40A/50Z50A and (b) 60Z40A/80Z20A.

On the other hand, when αa > αb, the residual stress state changes, producing laminates with the internal layers in compression ([18]), as the observed in layered components fabricated with thin layers containing higher concentration of zircon than the thick layer, thus the thin layer is compressed by the thick layer generating a compressive residual stress on it. As can be seen in Fig. 8(b), this effect affects the crack path at the thick/thin layer interface changing the crack direction. From this, the crack bifurcation and the corresponding step-like fracture observed in this layered component is the responsible of the higher damage tolerance.

On the other hand, the layered component composed by 40Z60A thin layers and 60Z40A thick layers give lower mechanical properties than the monolithic sample, obtaining a 13% less modulus of rupture. Analyzing this result, we can assume that the strain mismatch, produced by the difference between the corresponding thermal expansion coefficients of the layers, was very high. As is well known, ceramic materials respond very well when they are subjected to compressive stresses, but its intrinsic characteristics makes them materials with poor mechanical properties when they are exposed to high tensile stresses. Thus, the high tensile residual stress value in the thin layer can promote the micro-cracks formation, lowering the global mechanical properties of the component.

ConclusionsIn this work, layered materials were produced from alternating zircon-alumina layers with different composition and it was found that it is possible increase the mechanical properties of components by changing the residual stress state configuration, compressive outer layer/tensile inner layer and vice versa. Depending of the character of the generated residual stress, compressive or tensile, in the outer and inner layers the crack shape was different, being step-like fracture when the residual stress inner layer is compressive. Also, the magnitude of the thermal expansion coefficients of layers is very important, because instead of better mechanical properties a lower mechanical performance can be obtained, that was the case of layered components formed by a 60Z40A/40Z60A configuration. However, layered components with good final mechanical properties were obtained, reaching 218% and 182% more resistance, compared with the monolithic sample, for laminate configurations composed by 60Z40A/50Z50A and 60Z40A/80Z20A, respectively.

Acknowledgements

M. León-Carriedo thanks to CONACyT-México for the scholarship 203707. This work was supported by CONACyT-México under the project “Design of multilaminar composites with different structural and functional properties”, No. 106110.

Received 26 October 2015

Accepted 13 April 2016

Corresponding author. monica.leon@cinvestav.edu.mx