A new plate method was developed for rapid screening of Ketogulonicigenium vulgare mutants overproducing 2-keto-l-gulonic acid (2-KLG). The screening methodology took the advantage of the acidity caused by 2-KLG, which changes the color of bromothymol blue (pH indicator) from blue to yellow. Using the proposed method, a mutant, K. vulgare 65, was selected from 20,000 colonies produced by a strain subjected to spaceflight mutagenesis. When co-cultured with Bacillus megaterium 2980 in 20-L fermenters, K. vulgare 65 showed a high conversion rate (94.45%) of l-sorbose to 2-KLG. In contrast to the traditional screening method, this one significantly improved the frequency of obtaining positive mutants. The proposed plate screening method is cost-effective and easy to run and is thus useful for the isolation and screening of K. vulgare mutants overproducing 2-KLG.

2-Keto-l-gulonic acid (2-KLG) is an important precursor for the synthesis of vitamin C (l-ascorbic acid) by a two-step fermentation process, which accounts for 90% of the global vitamin C production.1 Research has shown that 2-KLG can be bioconverted from l-sorbose by a mixed culture of Ketogulonicigenium vulgare and Bacillus spp.2,3K. vulgare contains a complete enzyme system for converting l-sorbose to 2-KLG,4 but its growth is poor in the monoculture, resulting in a very low yield of 2-KLG.5 A companion strain, Bacillus megaterium, is generally considered to generate and release, in the fermentation broth, the metabolites that stimulate K. vulgare propagation and 2-KLG accumulation.6–10 These metabolites contain active proteins,6 amino acids,8 antioxidants,10 and other active substrates.7,9 In recent years, K. vulgare has been considered to be the key microorganism for the bioconversion of l-sorbose to 2-KLG and of greater importance than the companion bacterium in 2-KLG production.11,12

Random mutagenesis and selection strategies are effective for the screening of K. vulgare mutants capable of 2-KLG overproduction.13,14 When obtaining high-efficiency mutants of K. vulgare, it is crucial to screen a large number of mutants immediately after a mutagenic treatment. Thus, easy and efficient screening methods are desired for the screening and isolation of 2-KLG-overproducing mutants of K. vulgare. Since mixed fermentation involves co-cultivation of two bacterial strains, the associated screening process is relatively laborious and complicated.7 Currently, only one method is available for the screening of K. vulgare mutants, i.e., the 2-KLG determination method.13 In this method, the primary screening is done by randomly selecting K. vulgare colonies on plates. Then, the colonies are used for fermentation with Bacillus spp. in glass tubes, followed by the determination of the amount of 2-KLG produced. After that, K. vulgare mutants with high yields of 2-KLG are selected and transferred to flasks for further fermentation. Finally, K. vulgare mutants capable of highly efficient conversion of l-sorbose to 2-KLG are selected as potential strains for industrial applications. As it involves random colony selection in the primary screening step, followed by laborious in-tube fermentation and determination of 2-KLG concentrations, this conventional screening method is considered inefficient and time-consuming.

In the present study, a new plate screening method was developed for screening of K. vulgare mutants with a high conversion rate of l-sorbose to 2-KLG. The proposed method is based on the following points: (1) the active metabolites (activators) secreted by B. megaterium enhance the growth of K. vulgare5,6,8–10; and (2) the 2-KLG secreted by K. vulgare mutants lowers the medium pH in a certain zone on agar plates, thereby changing the color of the bromothymol blue indicator from blue to yellow. The proposed method was designed for rapid screening of K. vulgare mutants to detect those capable of 2-KLG overproduction. It was further applied to the screening of 20,000 colonies of K. vulgare obtained after spaceflight mutagenesis, among which the mutant K. vulgare 65 was selected. K. vulgare 65 was co-cultured with B. megaterium under laboratory conditions, and its conversion rate of l-sorbose to 2-KLG was monitored. The results were used to evaluate the efficiency of the indicator plate method for the isolation and screening of 2-KLG-overproducing mutants of K. vulgare.

Materials and methodsBacterial strainsThe candidate 2-KLG-producing strains, K. vulgare 07 and B. megaterium 2980, were obtained from Northeast Pharmaceutical Group Co., Ltd. (Shenyang, China).

Laboratory mediaThree media were prepared for the maintenance, growth test, and isolation, respectively, of K. vulgare 07 and B. megaterium 2980. These included l-sorbose-limiting medium (20.0g of l-sorbose, 3.0g of corn steep liquor, 1.0g of carbamide, 1.0g of KH2PO4, 0.2g of MgSO4·7H2O, and 1.0g of CaCO3 per liter; pH 6.7–7.0), fermentation medium (80.0g of l-sorbose, 15.0g of corn steep liquor, 12.0g of carbamide, 1.0g of KH2PO4, 0.2g of MgSO4·7H2O, and 1.0g of CaCO3 per liter; pH 6.7–7.0; l-sorbose and carbamide were sterilized separately), and isolation medium (20.0g of l-sorbose, 5.0g of yeast extract, 5.0g of corn steep liquor, 10.0g of peptone, 3.0g of beef extract, 1.0g of carbamide, 1.0g of KH2PO4, 0.2g of MgSO4·7H2O, and 18g of agar per liter; pH 7.0–7.2). The media were autoclaved prior to use.

Spaceflight mutagenesisSpaceflight mutagenesis has been shown to be more efficient than other mutation methods for microbes.15–17 The unique environments in the outer space, such as microgravity, strong radiation, the presence of high-energy particles, and alternating magnetic fields, can induce gene mutations.18 In this study, the spaceflight mutagenesis technology was used to obtain more mutants.

The two candidate strains, K. vulgare 07 and B. megaterium 2980, were co-cultured on l-sorbose-limiting medium in Eppendorf tubes for 48h and then transferred to the returning module of the manned spacecraft Shenzhou VIII. The spacecraft was launched at 5:58 a.m. (Beijing time) on November 1, 2011 from the Jiuquan Satellite Launching Center (Gansu, China). After a 397-h flight in outer space, the returning module landed in the Inner Mongolia Autonomous Region, China. The Eppendorf tubes with an intact package were kept in an icebox and transported immediately to the laboratory for use.

Effects of B. megaterium-secreted activators on the growth of K. vulgareThe culture of K. vulgare 07 was prepared as 10-fold serial dilutions. A 0.1-mL aliquot of the diluted culture, containing 30–50 colony-forming units (CFU), was spread on an agar plate containing 30mL of solidified isolation medium. Two agar plates were inoculated. To one plate, 0.1mL of co-culture broth of B. megaterium 2980 and K. vulgare 07 (30-h fermentation at 29°C, OD650=0.935), pre-filtered through a sterile 0.22-μm membrane filter, was added and spread. The other agar plate was used as a control. The two plates were incubated at 29°C for 96h. The diameters of 40 colonies on each plate were determined using a Vernier caliper (0–150, Harbin Measuring & Cutting Tool Group Co., Ltd., Heilongjiang, China).

Choice of pH indicatorThree pH indicators were tested for the direct determination of 2-KLG production on plates, including methyl red [2-(4-dimethylaminophenylazo)benzoic acid; Tianjin Yongda Chemical Reagent Co., Ltd., Tianjin, China], bromocresol purple (5,5′-dibromo-O-cresolsulfonphthalein; Shenyang Xinxi Reagent Factory, Liaoning, China), and bromothymol blue (3′,3′′-dibromothymolsulfonphthalein; Tianjin Bodi Chemicals Co., Ltd., Tianjin, China). Each indicator was dissolved in distilled water containing 5% (v/v) ethanol, and the concentration was adjusted to 0.1% (w/v). One milliliter of each solution was added dropwise to each agar plate to indicate the color changes around the colonies of K. vulgare. The indicator that showed an obvious color change was chosen as a suitable pH indicator.

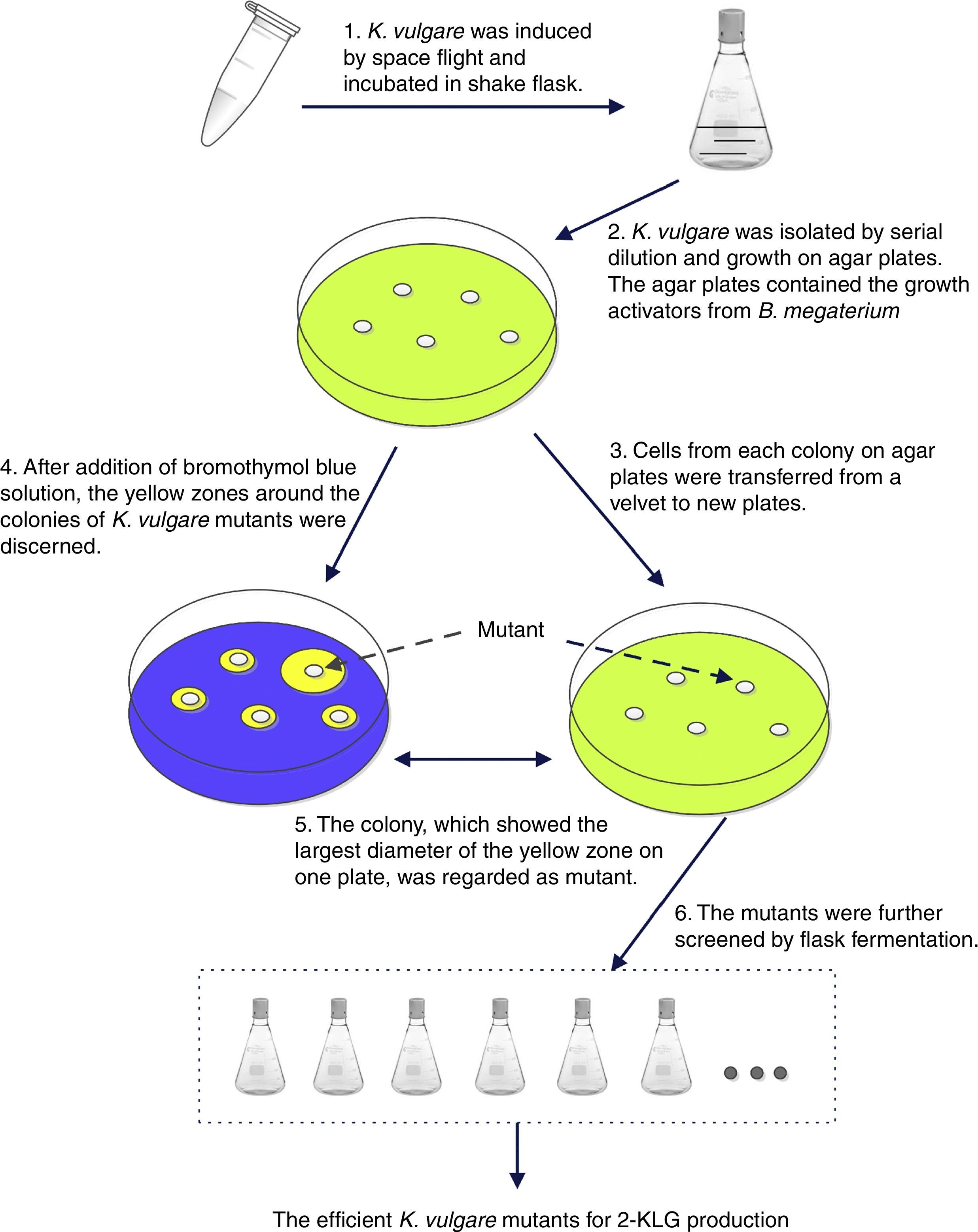

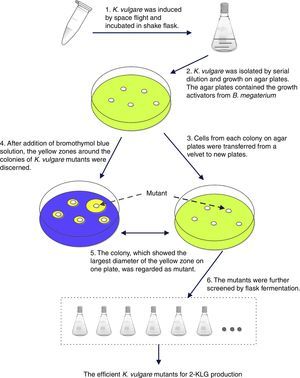

New plate screening methodThe schematic of the plate screening procedure is shown in Fig. 1. First, 10-fold serial dilutions of a culture of K. vulgare 07 subjected to spaceflight mutagenesis were prepared. A 0.1-mL aliquot of the diluted culture containing 30–50CFU/mL was then spread on an agar plate containing 30mL of solidified isolation medium. Second, 0.1mL of co-culture broth of B. megaterium 2980 and K. vulgare 07 (30-h fermentation at 29°C, OD650=0.800–1.000), pre-filtered through a sterile 0.22-μm membrane filter, was added to each agar plate inoculated with the spaceflight-induced K. vulgare mutants. After 96h of incubation at 29°C, colonies of K. vulgare mutants appeared on each plate. Third, to obtain pure mutant isolates, cells from each colony grown on agar plates were transferred to fresh agar plates using velvets and incubated at 29°C for 96h. Finally, 1mL of a bromothymol blue solution (0.1%, w/v) was added dropwise to each agar plate, and the plates were incubated at 29°C for 30–60min. Yellow zones were observed around the colonies of K. vulgare 07 mutants, and the diameters of the yellow zones were measured using a Vernier caliper. Colonies with the largest diameters of yellow zones on agar plates were selected as potential mutants of interest for further flask fermentation screening. Approximately 20,000 colonies of K. vulgare 07 were screened, and 500 potential mutants were selected for further screening.

Shake-flask fermentation screening and fermentation testsAfter the primary agar plate screening, the selected mutants were further screened by shake-flask fermentation. The K. vulgare 07 mutants were co-cultured with B. megaterium 2980 in triplicate 250-mL Erlenmeyer flasks containing 20mL of fermentation medium. After 48h of fermentation at 29°C on a rotating platform shaker (HZQ-R, Donglian Group Co., Ltd., Heilongjiang, China) at 220rpm, a K. vulgare 07 mutant with the highest production of 2-KLG (K. vulgare 65) was chosen to evaluate the fermentation stability in 20-L fermenters. The 2-KLG concentration in the fermentation broth was determined by iodometry.19 The sorbose concentration was measured by the sulfuric anthrone reaction and detected at 620nm using a UV–Vis spectrophotometer (VIS-7220, Rayleigh Analytical Instrument Co., Ltd., Beijing, China).20 The conversion rate was defined as the ratio of the 2-KLG yield in the fermentation broth to a theoretical value.

Comparison of traditional and pH indicator screening methodsThe culture of K. vulgare 07 subjected to spaceflight mutagenesis was prepared as 10-fold serial dilutions and spread on agar plates. For the traditional screening method, colonies of K. vulgare were selected randomly, then inoculated with B. megaterium 2980 in 250-mL flasks containing 20mL of the fermentation medium, and incubated at 29°C for 38h.21 The colonies that produced higher concentrations of 2-KLG (≥62.0mg/mL) were regarded as positive mutants. For the new screening method, the agar-plate colonies with the largest diameters of zones whose color changed after the addition of 1mL of a bromothymol blue solution (0.1%, w/v) were selected for further flask fermentation screening, similar to the traditional screening method. Fifty colonies were chosen from agar plates by each screening method for flask fermentation. The number of positive mutants obtained by each method was counted.

Statistical analysisThe difference in 2-KLG production between groups was evaluated using the Student's t-test in the Statistical Program for Social Sciences (SPSS 13.0 for Windows, SPSS, Inc., Chicago, IL, USA). A p-value of <0.05 was considered statistically significant.

ResultsEffects of B. megaterium filtrate on growth of K. vulgareThe results of the bacterial growth test showed that the average colony diameter (4.209mm) of K. vulgare 07 incubated on a plate with a B. megaterium 2980 filtrate was significantly greater (p<0.05) than that (3.019mm) of K. vulgare 07 incubated without the B. megaterium 2980 filtrate. A further growth test of K. vulgare 07 with gradient volumes (0.1, 0.2, and 0.3mL) of the B. megaterium 2980 filtrate showed no statistically significant differences (p>0.05) in the colony diameters (data not shown). These observations were consistent with reports showing that B. megaterium acts as a companion bacterium and secrets one or multiple activators promoting the growth of K. vulgare.5,22 Because of the increased cell number of K. vulgare 07, the corresponding 2-KLG concentration was improved in the fermentation broth.21 Together, these findings indicate that the activators secreted by B. megaterium increase the growth rate of K. vulgare 07, enhancing the production of 2-KLG.

Choice of pH indicatorWhen selecting bacterial mutants with enhanced 2-KLG productivity, simple and reliable methods are desired for the qualitative analysis of 2-KLG production. Here, we developed a plate method for the screening and isolation of K. vulgare mutants with altered 2-KLG productivity. The rationale was based on the fact that the 2-KLG secreted by colonies of K. vulgare 07 lowers the surrounding pH on an agar plate. To this end, a proper indicator is needed to show the changes in the pH of the medium. Upon the addition of a pH indicator, the color of the zone around a mutant colony grown on an agar plate would change. Theoretically, the diameter of the zone with a changed color should increase with the increase in the production of 2-KLG. In this study, three pH indicators were tested for the direct determination of 2-KLG production on a plate. The results showed that bromothymol blue was superior to the other two indicators in terms of the obvious color change and a suitable pH range (blue to yellow at pH 6.5–7.5). Upon the addition of a bromothymol blue solution (0.1%, w/v) to an agar plate, zones surrounding colonies of K. vulgare 07 mutants changed their color from blue to yellow because K. vulgare 07 mutants released 2-KLG on agar plates, thereby acidifying surrounding areas around colonies.

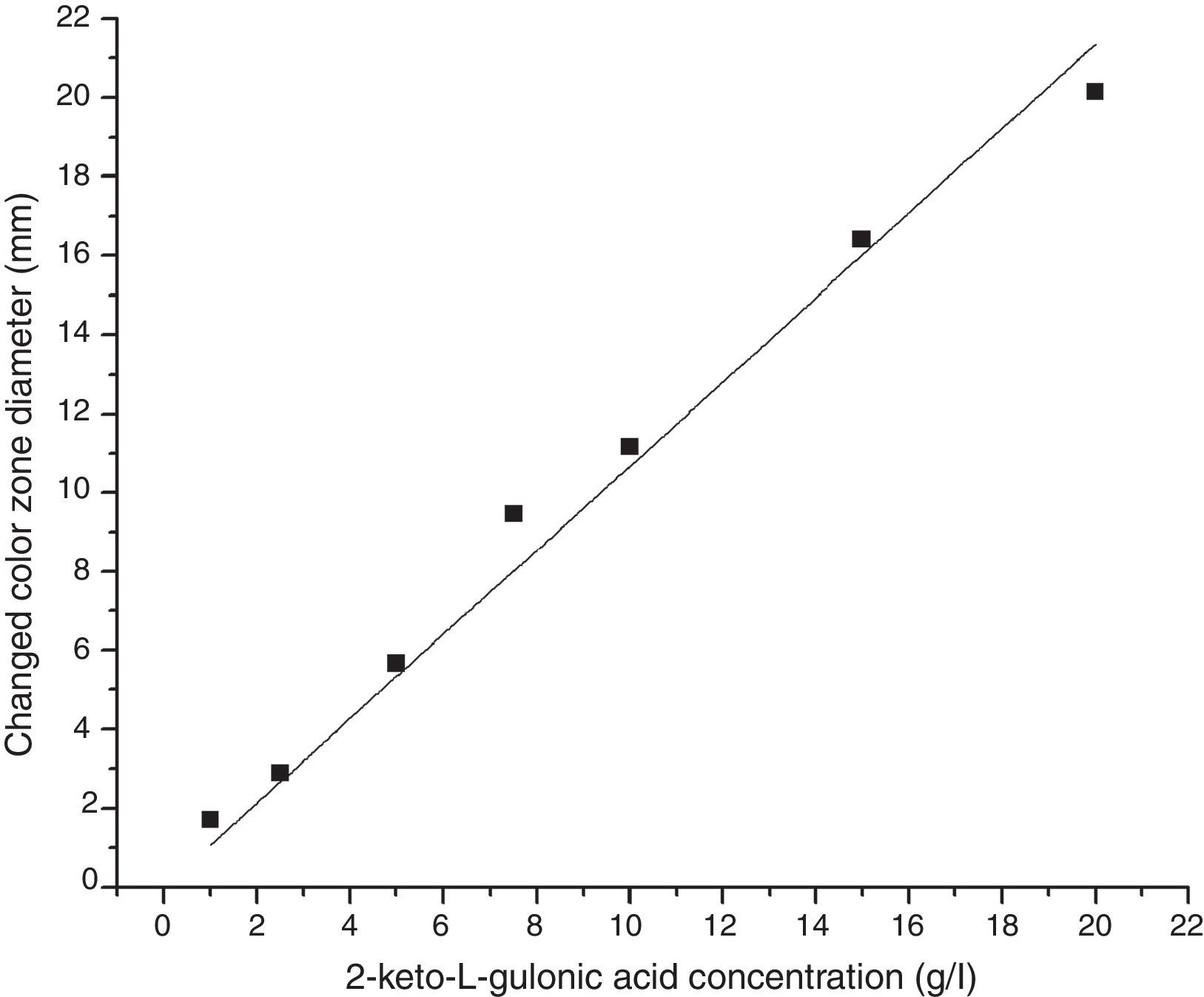

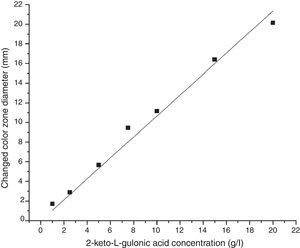

Relationship between the size of color-changing zone and 2-KLG concentrationWhen a given volume of a 2-KLG solution was pipetted onto an agar plate, yellow zones were observed. To evaluate the correlation between the size of the yellow color zone and the concentration of the bacterially produced 2-KLG, 50μL of a 2-KLG solution (0–20g/L) was added to an agar plate. With an increasing dose of 2-KLG, the yellow zones accordingly increased (Fig. 2). The correlation analysis showed that the diameter of the color-changing zone was linearly correlated (R2=0.984) with the quantity of 2-KLG released into the agar.

Newly proposed agar plate screening methodBased on the above experimental results, a simple and rapid agar plate screening method was developed for the preliminary screening and isolation of K. vulgare mutants capable of efficient production of 2-KLG. The schematic of the plate screening procedure is shown in Fig. 1, and the detailed description of the new method is provided in Materials and Methods.

Comparison of conventional and pH indicator screening methodsThe colonies of K. vulgare 07 grown after spaceflight mutagenesis were screened by the two different screening methods to compare their screening efficiencies. The results showed that by using the traditional screening method, only three positive mutants were obtained after screening 50 colonies randomly selected from 50 agar plates each (about 2000 colonies in total). On the contrary, by using the new screening method, 19 positive mutants were obtained after screening 50 colonies from 50 agar plates each. The results indicated that the new screening method greatly improved the probability of obtaining positive mutants.

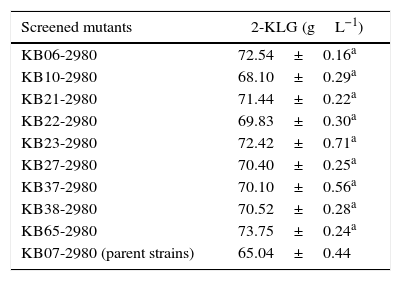

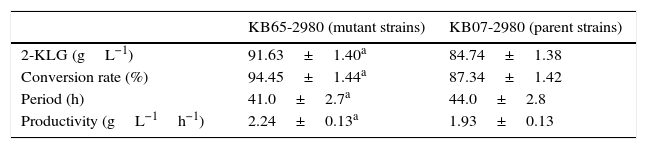

Screening of K. vulgare mutants using proposed pH indicator plate methodIn order to verify the efficiency of the newly established pH indicator plate method, we screened more than 20,000 post-spaceflight mutagenesis colonies of K. vulgare 07. After agar plate screening and flask fermentation screening, nine efficient mutants were finally obtained. Each of these mutants displayed a significantly higher (p<0.05) 2-KLG yield than that of the parent strain (Table 1). The highest 2-KLG concentration (73.75g/L) was achieved in a co-culture of K. vugare 65 and B. megaterium 2980, with the rate increase of 12.75% relative to that in a co-culture of the parent strain (K. vulgare 07) and B. megaterium 2980. Furthermore, an average l-sorbose-to-2-KLG conversion rate of 94.45% and 2-KLG productivity of 2.24gL−1h−1 were achieved by co-cultivation of K. vulgare 65 and B. megaterium 2980 (KB65-2980) in 10 batches in 20-L fermenters (Table 2).

Determination of 2-KLG produced by screened mutants in flask fermentation.

| Screened mutants | 2-KLG (gL−1) |

|---|---|

| KB06-2980 | 72.54±0.16a |

| KB10-2980 | 68.10±0.29a |

| KB21-2980 | 71.44±0.22a |

| KB22-2980 | 69.83±0.30a |

| KB23-2980 | 72.42±0.71a |

| KB27-2980 | 70.40±0.25a |

| KB37-2980 | 70.10±0.56a |

| KB38-2980 | 70.52±0.28a |

| KB65-2980 | 73.75±0.24a |

| KB07-2980 (parent strains) | 65.04±0.44 |

All the data are presented as mean±S.D.

Fermentation of KB65-2980 in 20L fermenters for 10 batches.

| KB65-2980 (mutant strains) | KB07-2980 (parent strains) | |

|---|---|---|

| 2-KLG (gL−1) | 91.63±1.40a | 84.74±1.38 |

| Conversion rate (%) | 94.45±1.44a | 87.34±1.42 |

| Period (h) | 41.0±2.7a | 44.0±2.8 |

| Productivity (gL−1h−1) | 2.24±0.13a | 1.93±0.13 |

All the data are presented as mean±S.D.

Despite the rapid development of novel techniques,23 conventional methods such as mutagenesis and selection based on direct measurements still play a central role as reliable and cost-effective procedures for strain improvement.13,22,24 However, the need to use a mixed fermentation system for 2-KLG production by K. vulgare and B. megaterium makes traditional screening methods for K. vulgare mutants capable of 2-KLG overproduction laborious and complicated,7 leading to a much lower screening efficiency.

In the present study, we described a rapid screening procedure for high-efficiency 2-KLG-overproducing mutants of K. vulgare. The proposed method avoids the negative effects of the active companion bacterium on the growth and conversion activities of K. vulgare, thus significantly increasing the probability of obtaining highly efficient K. vulgare mutants. The new method is also advantageous because of the ease of operation and the possibility of screening a large number (thousands) of mutants by one operator within a short period (<30 days). Compared with the conventional screening method, our proposed pH indicator plate method shortens the screening time by 90% and needs no large instruments.

Despite that the new method allows screening of a large number of K. vulgare mutants in the preliminary screening step much faster, the selected mutants should be further confirmed by co-fermentation with B. megaterium for the following two reasons. On one hand, the indicator method used in this study cannot differentiate between secretion of 2-KLG and other acidic metabolites by K. vulgare mutants, which may influence the accuracy of the plate screening results. On the other hand, more importantly, industrial production of 2-KLG is carried out in a mixed fermentation mode; hence, the 2-KLG production efficiency of K. vulgare mutants must be tested in a co-culture with B. megaterium.

The screening method provides an approach to screening for efficient mutants for other mixed fermentation systems. With a slight adjustment of culture conditions and selection of an appropriate pH indicator, the proposed pH indicator plate method can easily be used for the screening of other bacterial strains suitable for the production of acidic products in a mixed fermentation system.

ConclusionsIn this study, we developed a novel pH indicator plate method for the isolation and screening of K. vulgare mutants capable of overproduction of 2-KLG. Compared with the existing conventional method, the proposed screening method is more rapid, sensitive, and reliable. In addition, it is cost-effective and easy to use.

Conflict of interestThe authors declare no conflicts of interest.

This study was supported by the Program of National Key New Drug Creation of China (No. 2011ZX09203-001-14). The authors would like to thank the staff, Fermentation & Biotechnology Laboratory of NEPG for their technical support.