An electronic control system has been developed for a Raman spectrometer by using electronics based on microcontroller technology. With these microcontrollers it is possible to emulate control circuitry capable of performing complex tasks, such as the monochromator step motor control and the photomultiplier pulse count required in the Raman spectroscopy process. This approach could be used to give new life to valuable scientific instruments and tools. The Raman spectrometer control built is now fully functional and compatible with Windows 7. Raman spectra from well-known materials are presented to compare results and in order to confirm the proper operation of the developed control system.

Se ha desarrollado un sistema electrónico de control para un espectrómetro Raman usando electrónica basada en tecnología de microcontroladores. Con microcontroladores es posible emular circuitos electrónicos capaces de desempeñarse en tareas complejas tales como el control del motor de pasos del monocromador y llevar la cuenta de fotones requerida durante el proceso de espectroscopia Raman. Esta propuesta podría ser usada para “revivir” instrumentos y herramientas científicas de alto costo. El espectrómetro que se reconstruyo gracias a la electrónica desarrollada es totalmente funcional y compatible con Windows7. Se presentan resultados de materiales cuyo espectro Raman es bien conocido para fines comparativos y para demostrar el correcto funcionamiento de sistema de control propuesto.

It is a common problem in laboratories that valuable equipment stops working due to technical issues derived from malfunction of the electronics controlling such equipment. Often the rest of the mechanisms, optics or general components of the equipment are in excellent condition. However, when the equipment is several years old it is very difficult to replace the control circuitry. Sometimes the equipment maker is out of business and getting spare parts results either, impossible or too expensive. Under these circumstances many valuable laboratory instruments become useless, and it is necessary to spend large amounts of money to replace the equipment.

In this work, we show how it is possible to bring new life to an old instrument by developing homemade control system electronics. The key point to elaborate this electronics is the use of microcontroller devices. Microcontrollers are low-priced computers on a chip that include non-volatile memory, RAM, arithmetic and logic processing units, peripherals, ADC converters, and many other features useful for building powerful electronic circuits in a simple way [1, 2].

The Raman spectroscopy [3] equipment we worked on, is from Jobin-Yvon, now part of Horiba. It uses a SPEX 1403 monochromator, which features a double diffraction grating for high resolution and for light detection, a product for Research Inc. K943-02 photo multiplier tube. Originally the monochromator was controlled using a SPEX MSD-2 driver interface. After a few years of operation, the interface started to present some problems of communication until the total loss of communication with the PC. Extensive evaluation did not reveal any apparent problems, but it remained impossible to operate the monochromator using this driver. The inability to control the monochromator rendered the spectrometer inoperable.

Another issue about operating this equipment was its complexity. The original control system required two computers - one PC interfaced the monochromator through the MSD-2 driver, and the second PC acquired the data from the photomultiplier tube using a PCI acquisition card. Both PCs ran Windows 95, and this became problematic due to the difficulty to keep such old computing equipment operational. Thus, we decided to build an electronic control system capable of performing the control and data acquisition tasks required, this board also required to be able to communicate to a new PC using Windows 7. The proposed features will ensure the operation of the developed Raman spectrometer control for many years to come.

One of the goals of this paper is to encourage other research groups to develop their own control interfaces in cases where it is neither possible nor practical to acquire the original spare parts needed to rehabilitate a nonworking instrument. In this work, we indicate the tools and techniques we successfully used for our project.

2MethodologyThe first step was to analyze the functions required to be performed in a Raman spectroscopy analysis [4, 5]. The sample to be characterized is excited with laser light. The “response” from the sample (reflected and scattered light, among other electromagnetic events) enters a monochromator, which selectively separates light using diffraction; a mechanism moves the mirrors and diffraction gratings to select the desired wave number from the light input. The aim of this analysis is to measure the inelastic Stokes and anti-Stokes scattering spectrum of the characterized sample. The data obtained provides valuable information about the sample structure. Normally when a material is excited using laser light, elastic scattering predominates and inelastic scattering is very weak hence, a very sensitive light detector is required. In the case of our equipment, light detection is performed using a photomultiplier tube, which is a very sensitive device capable of detecting single photons.

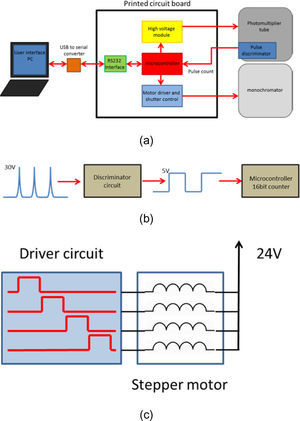

To control the Raman spectroscopy process with our equipment, the following is required: 1) a power driver to control the step motor for positioning the monochromator; 2) a high voltage DC photomultiplier source; 3) a pulse-counting acquisition module, and 4) a communication port to the PC.

To perform the required tasks, the microcontroller we chose to build our control system is the Atmega8 from Atmel. This device is an 8-bit RISC architecture microcontroller, having 8Kb flash memory for program storage, 1Kb of static RAM, peripheral features like 8 and 16 bit timer-counters, a serial communication port, and 23 programmable input/output lines [6]. To write the software for the microcontroller, we used a BASCOM-AVR Basic compiler [7]. It is easy to use and produces efficient code that can be downloaded to program Atmelmicrocontrollers. To program the microcontroller, we used the Atmel AVRISP mkII programmer [8].

Thanks to the high capacity of the microcontroller, it is possible to perform all the tasks required to control the Raman spectroscopy process with a single circuit. When building electronic circuits intended to be used for a long time, it is recommended to build a printed circuit board (PCB) instead of working on prototyping breadboards. There are many choices of software for designing PCBs, but most are too expensive. For one-off projects like this one, there are some less powerful, but free or low-cost academic versions available.

A high-voltage, direct-current regulated power supply is need for operation of the photomultiplier tube. We employed the same module used in the original equipment, a MC30 module from Gamma High Voltage. This module is capable of supplying up to 3kV DC when connected to 12volts DC.

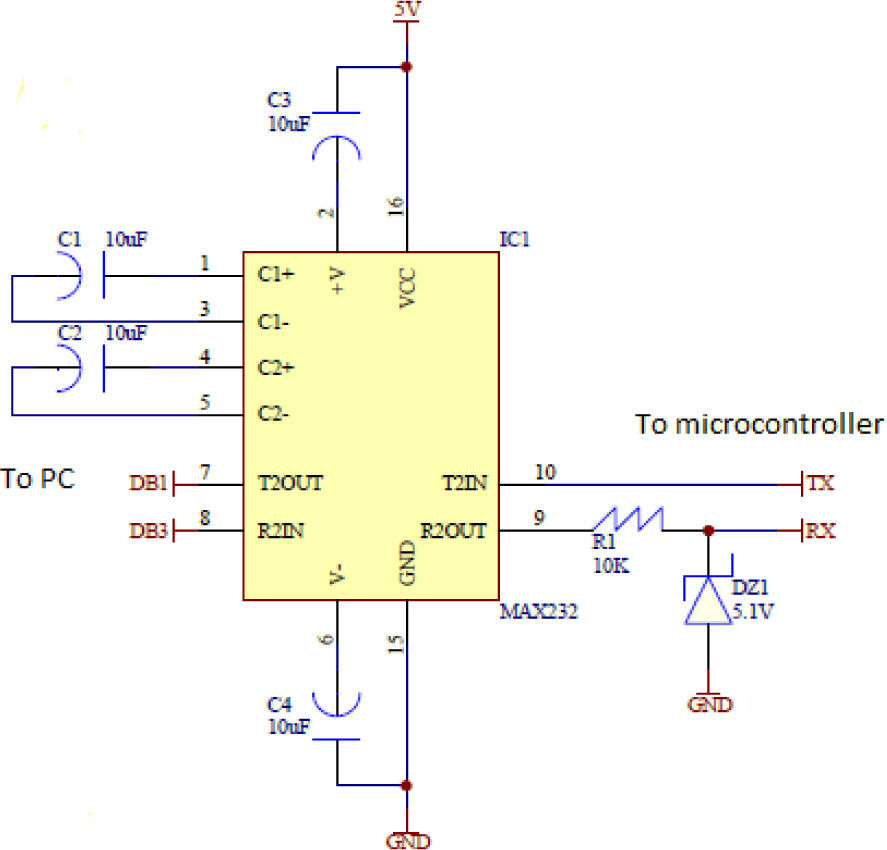

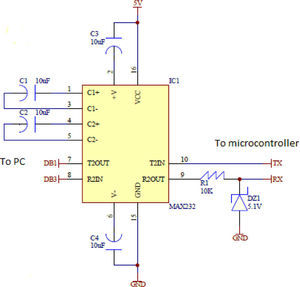

PC communicationTo establish communication between the circuit board and the PC, we used a RS-232 port [9]. RS-232 serial ports are no longer standard in brand new PCs, but they are prevalent in I/O devices, such as data acquisition cards, and there are many USB to RS232 converters that can be easily obtained. The way we implemented this RS232 port was using a MAX232 [10] integrated circuit. The diagram of the port circuit used is shown in Figure 1. This serial port was configured in software to send and receive data bytes at 19,200 bps, 8 data bits and 1 stop bit.

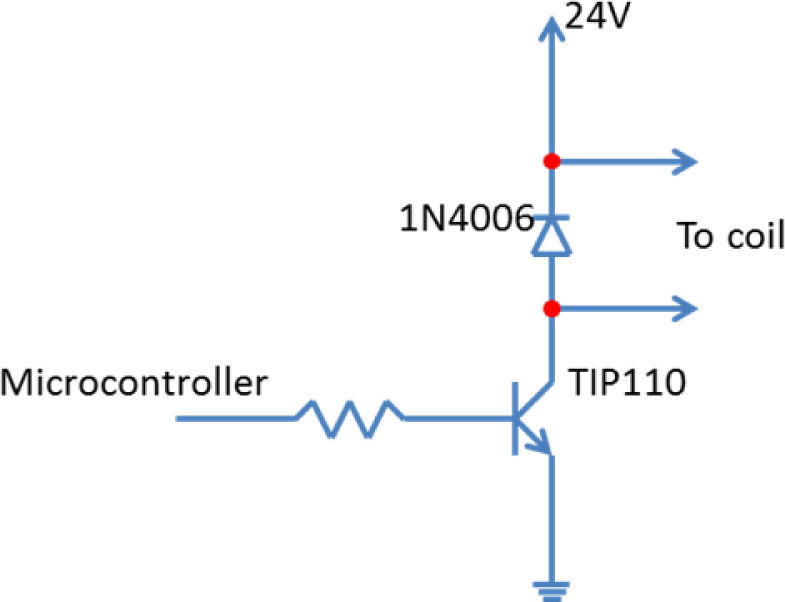

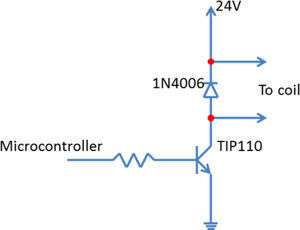

Step motor driver and shutter controlThe monochromator step motor is a 4-coil unipolar stepper motor [11]. Figure 2 depicts the driver circuit for every coil. The coil drivers are activated sequentially to move the motor forward. To move the monochromator 1cm-1, 25 steps are required. We tested different step pulse width lapses, and at 2ms the motor movement showed the best performance. TIP110 Darlington transistor [12] were used to switch the coil current. This transistor is able to switch large currents by applying a small control current from the microcontroller. A 1N4006 diode was connected in parallel to the coil, helping to absorb the kickback voltage [13] generated when the coil is switched off. If this diode is not used, the voltage peaks generated interfere with the proper operation of the microcontroller and erratic behavior is observed. As a safety feature to protect the photomultiplier tube from excess light exposure, it is possible to control a shutter servomechanism. This mechanism consists of a coil that moves a lever to displace the shutter and block or expose the light. It is controlled using the same circuit that energizes the step motor coils.

Photomultiplier high voltage source and pulse countingThe photomultiplier's MC30 high voltage module is fed by a regulated 12 volts direct current power supply. This power supply is controlled by the microcontroller using a power transistor similar to the one used to energize the motor coils and shutter. This feature allows the high voltage power supply to be safely and easily controlled via software.

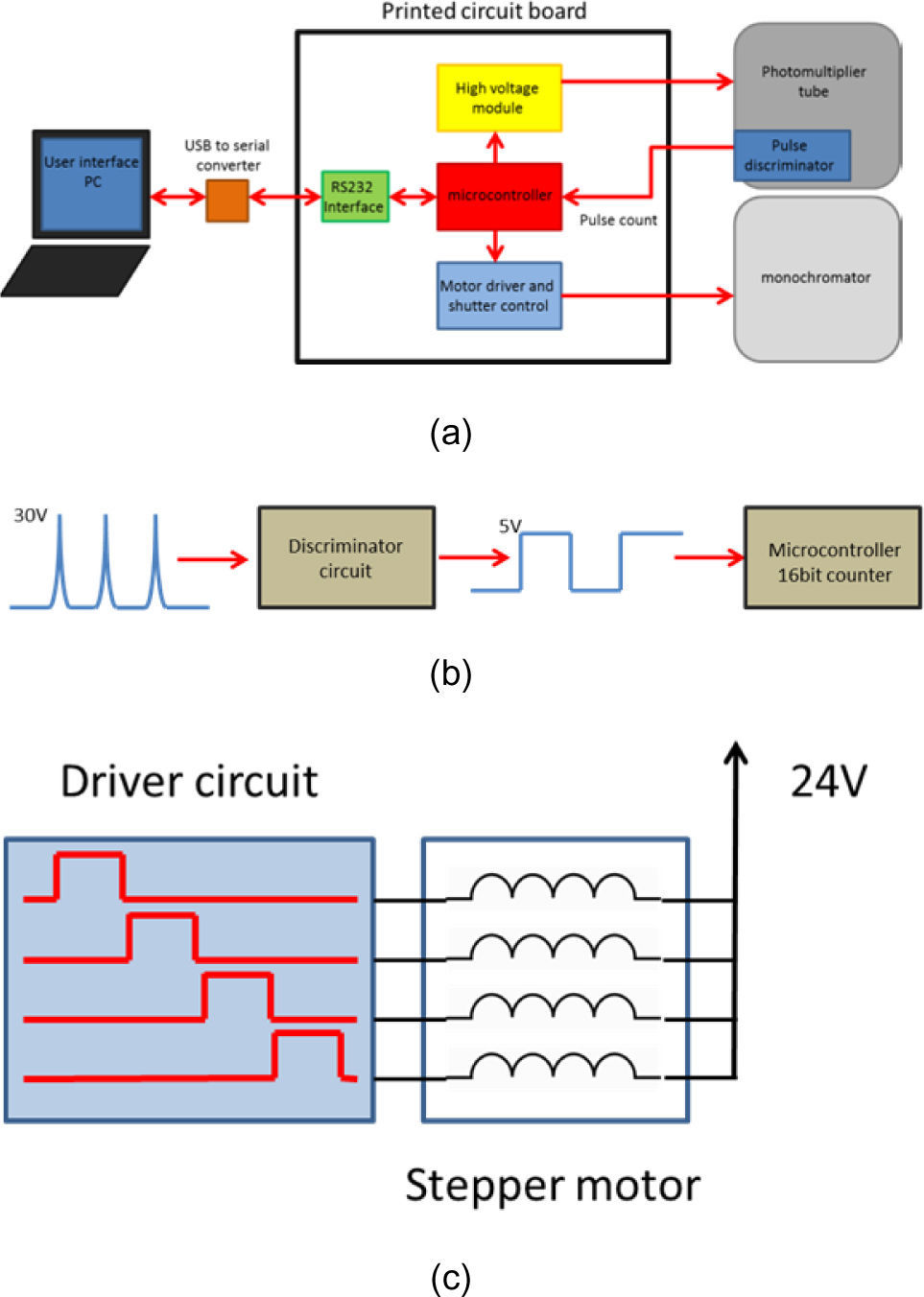

In spectroscopy it is important to accurately measure the light response at different wavelengths. When using photomultiplier tubes, light intensity is measured by counting pulses. The number of pulses in a fixed time gives the relative intensity of the measured light. A discriminator circuit that detect pulses of about 30 volts produced by the photomultiplier tube has been used, these pulses are converted to a frequency divided-by-two output signal, the output signal is TTL therefore, compatible with the microcontroller implemented. The system developed is capable to detect down to 500nS pulses; from this minimum pulse width, frequencies up to 2Mhz can be detected. Using a microcontroller, this task is easily performed, because the microcontroller used in our PCB includes one 16-bit timer/counter peripheral capable of counting pulses while measuring for a fixed period. (integration time). When performing light measurement, the integration time can be manipulated by software in order to obtain the desired resolution. A larger integration time will yield better resolution, but the characterization will take longer.

Block diagram for Raman spectrometer controlFigure 3 shows the block diagram of the Raman control system developed. Most of the control is integrated over the same printed circuit board; this integration simplifies the interconnection of the control system to the interface PC, monochromator and photomultiplier tube.

(a). Block diagram for the rehabilitated Raman spectroscopy equipment. The motor driver, high voltage module and pulse counting are integrated in the same printed circuit board, as this integration makes the system easy to interconnect. (b) Graphical description of the signal processing of the pulses produced by the photomultiplier tube to be counted by the microcontroller. (c) Unipolar step motor driver circuit sequence

The microcontroller in the PCB control circuit performs basic tasks, such as monochromator displacement, high voltage activation and pulse counting. However, to obtain spectrums using our rehabilitated equipment it is necessary to integrate all these functions. Using a PC is a good way to do this because a PC has large processing power, many peripherals, and software tools are available to manage the control processes and data. In addition, PCs are affordable and easy to replace.

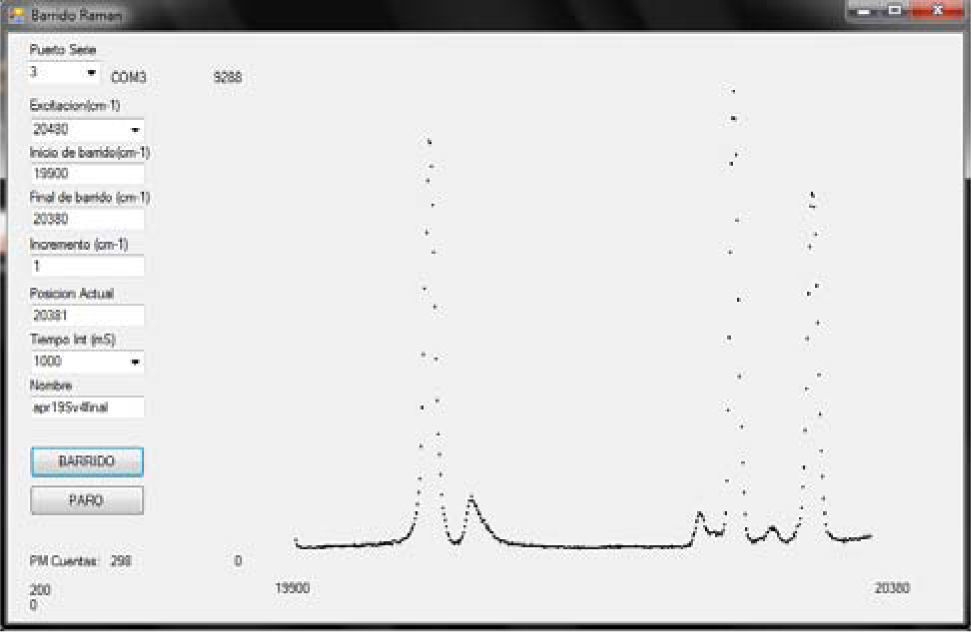

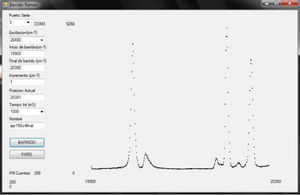

To develop our spectroscopy software, we used Visual Basic Express 2010 a powerful and easy to use integrated development environment (IDE) for developing PC software applications. Visual Basic Express is freeware; one only needs to register in order to download the package. In this programming environment it is possible to access serial ports, so we used a virtual serial port to communicate between the PC and the control PCB. The program window of the Raman spectrometer software is shown in figure 4.

In the program interface window of the spectrometer the user can set the desired parameters to perform a Raman spectroscopy characterization: serial port used (this depends on the PC used), laser excitation wave number (This value depends on the type of laser used for sample excitation, for example 20,480cm-1 for Argon laser), spectrum start wave number; spectrum final wave number; sampling step size in cm-1; actual monochromator position; file name and integration time in microseconds. The execution time for reading photomultiplier count values depends mostly on integration time set by the user, this time could be as short as 10mS and as long as 10 seconds.

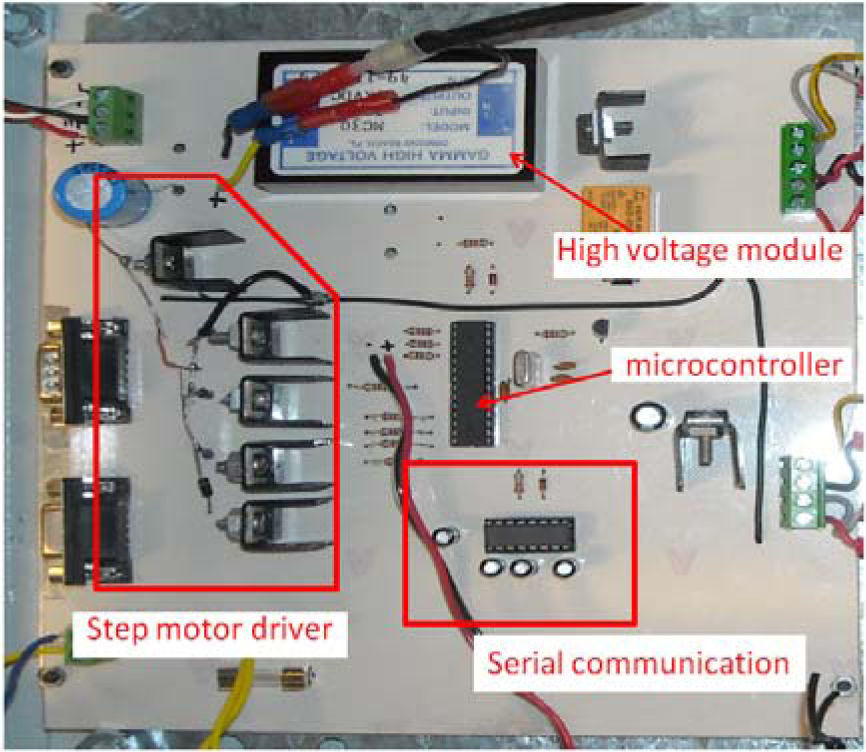

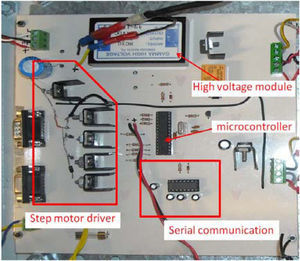

3ResultsThe constructed printed circuit board (20×20 cm) containing the modules described in the methodology section is shown in Figure 5. In spite of the complexity of the tasks performed by this device, the circuitry is simple. The motor driver is capable of moving 1000cm-1 in 50 seconds with no noticeable position error. The high voltage output, when activated, sources 2,000 volts DC with a 70 Mohm load. Data communication between PC and control PCB is flawless. Photomultiplier pulse counting on dark (due to photo thermal emission [14]) is about 60 counts per second.

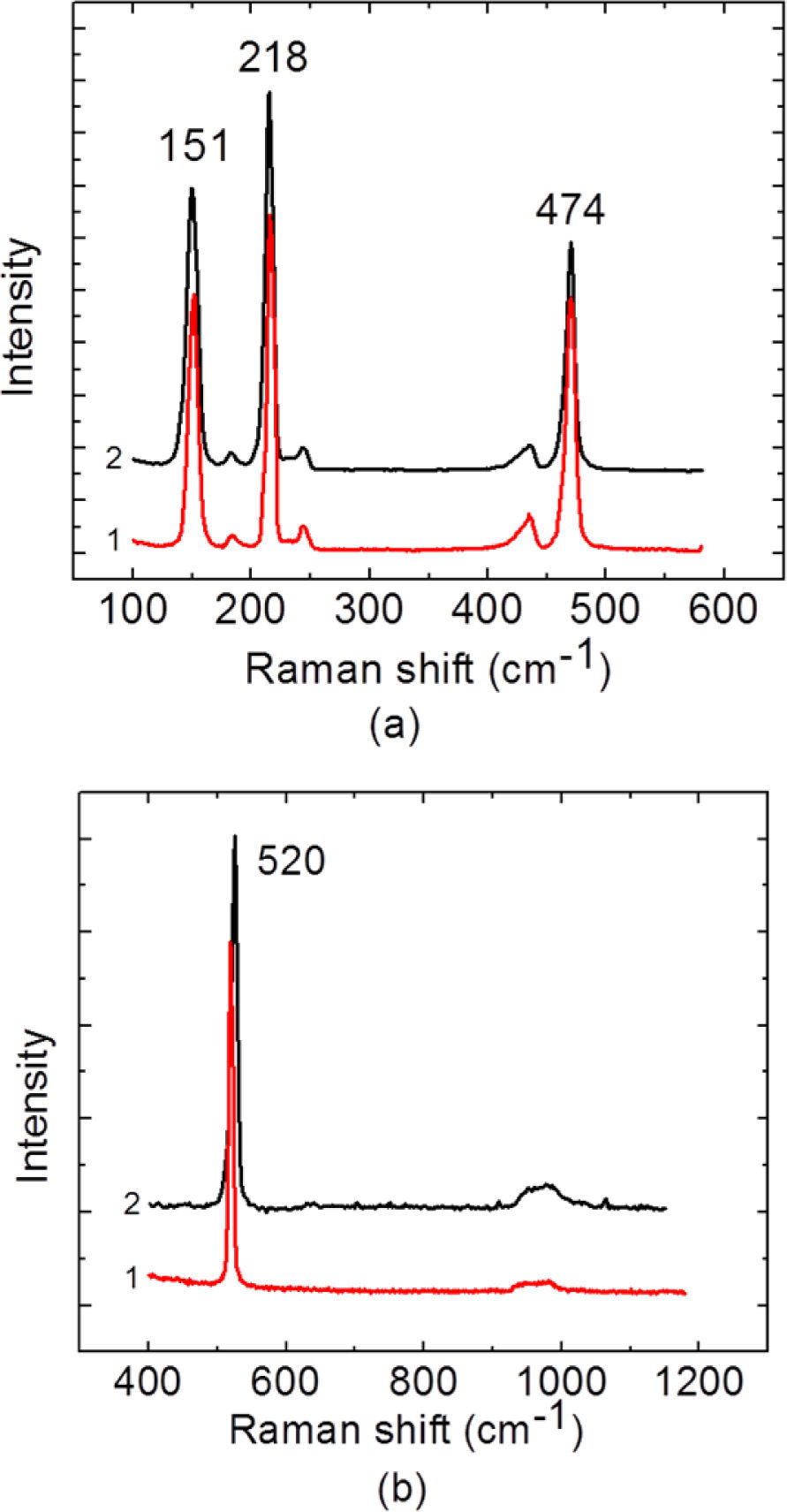

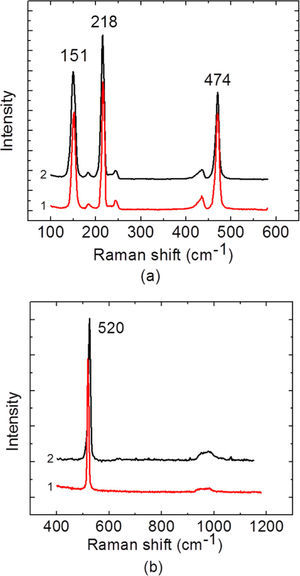

To test the performance of our instrument, we compared the spectrum results from silicon (Si) and sulfur (S) samples. The materials normally used to calibrate Raman spectrometers due to their well-known Raman response (spectra) [15, 16]. A Dilor LabRamll micro Raman spectrometer was used to collect the comparison spectra. The spectra from a pressed sulfur pellet are shown in Figure 6 (a), and the spectra from a (100)-oriented silicon wafer are shown in Figure 6 (b).

(a). Raman spectra comparison from a pressed sulfur pellet, (b) Raman spectra comparison from a silicon wafer. Red plots (labelled 1) are the spectra obtained with the rehabilitated Raman spectrometer; black plots (labelled 2) are the spectra obtained using a Dilor LabRamll micro Raman spectrometer

ln the S Raman spectra in Figure 6 (a), it can clearly be observed that the 151cm-1, 218cm-1 and 474cm-1 peaks match in position and intensity from both spectrometers. These peaks are fingerprints of S8; the 151cm-1 peak is assigned to E2 symmetry interactions, and the 218cm-1 and 474cm-1 peaks are assigned to A1 vibration modes [15]. For the Si Raman spectra (Figure 6 (b)) the position and intensity of the peak at 520cm-1 are effectively identical. This peak is associated with the Si crystalline structure [16].

4ConclusionsRaman shift spectra measured from sulfur and silicon samples showed that the results obtained using the developed control equipment match the results from a well-tested and calibrated, commercial micro Raman instrument. The possibility to replace obsolete and non-working electronic control equipment with in-house developed control systems was demonstrated. Tools like microcontrollers and visual programming environments allowed small research groups to develop technology levels that used to be only attainable by corporations or highly specialized laboratories. It was shown that the use of these tools could yield benefits to any laboratory with outdated equipment. It is important to note that there are other well developed tools that can be used in similar applications, such as Labview or Matlab. The selection of the tools used would depend on the functions required by the equipment and the expertise of the people implementing the project.

We acknowledge proofreading by Michael S. Boldrick and technical assistance from Gerardo Cota Arellano and Martín A. Hernández Landaverde. AJG also acknowledges financial support from Conacyt scholarship No. 203609.