The aeronautical sector is strategically important for the economic development of Mexico and has grown steadily over the last 10 years. Furthermore, it generates high added value for its products. In Mexico, the aircraft manufacturing sector mainly focuses on the fabrication of heat exchangers, seals, fuel ducts, and engine support rings. Currently, this sector is not involved in the manufacture of engine hot section components such as combustion chambers and turbine blades. Estimation of the associated costs enables assessment of the feasibility of fabricating such components. This study investigates the feasibility of establishing production lines for aeronautical combustion chamber fabrication in factories dedicated to the manufacture of aeronautical gas turbine engines.

The federal government of Mexico, together with several state governments, has implemented strategies to increase investment in the aerospace industry, hence Mexico has the scientific and technological capability to manufacture specialized components of gas turbine motors for aeronautical use – an industry hotspot. Thus, both domestic and foreign industries established in the country can analyze the convenience of manufacturing these sections (Pro-Aéreo, 2011).

Companies dedicated to the design, engineering, and manufacture of aeronautical motors constitute 2.9% of the total number of aerospace firms existing in Mexico, and these companies design and manufacture the following components (Plan de Vuelo Nacional, 2009; Pro-Aéreo, 2011):

- •

Motor support rings

- •

Compressor blades

- •

Seals

- •

Couplings

- •

Motor covers

- •

Fuel ducts

- •

Heat exchangers

However, these companies only manufacture cold section components and auxiliary parts of gas turbines for aeronautical use. Hot sections such as combustion chambers and turbines are not manufactured domestically towing to the restrictions imposed by the International Traffic in Arms Regulations; however, these restrictions are not applicable to foreign companies operating in Mexico (Plan de Vuelo Nacional, 2009). The materials used in the manufacture of combustion chambers must have the following characteristics (Campbell, 2008):

- •

High mechanical resistance to high temperatures

- •

High resistance to oxidation and corrosion

- •

Low density

- •

Low thermal expansion

- •

Low elastic modulus

- •

High resistance to thermal fatigue

- •

Low cost

- •

High feasibility for manufacturing

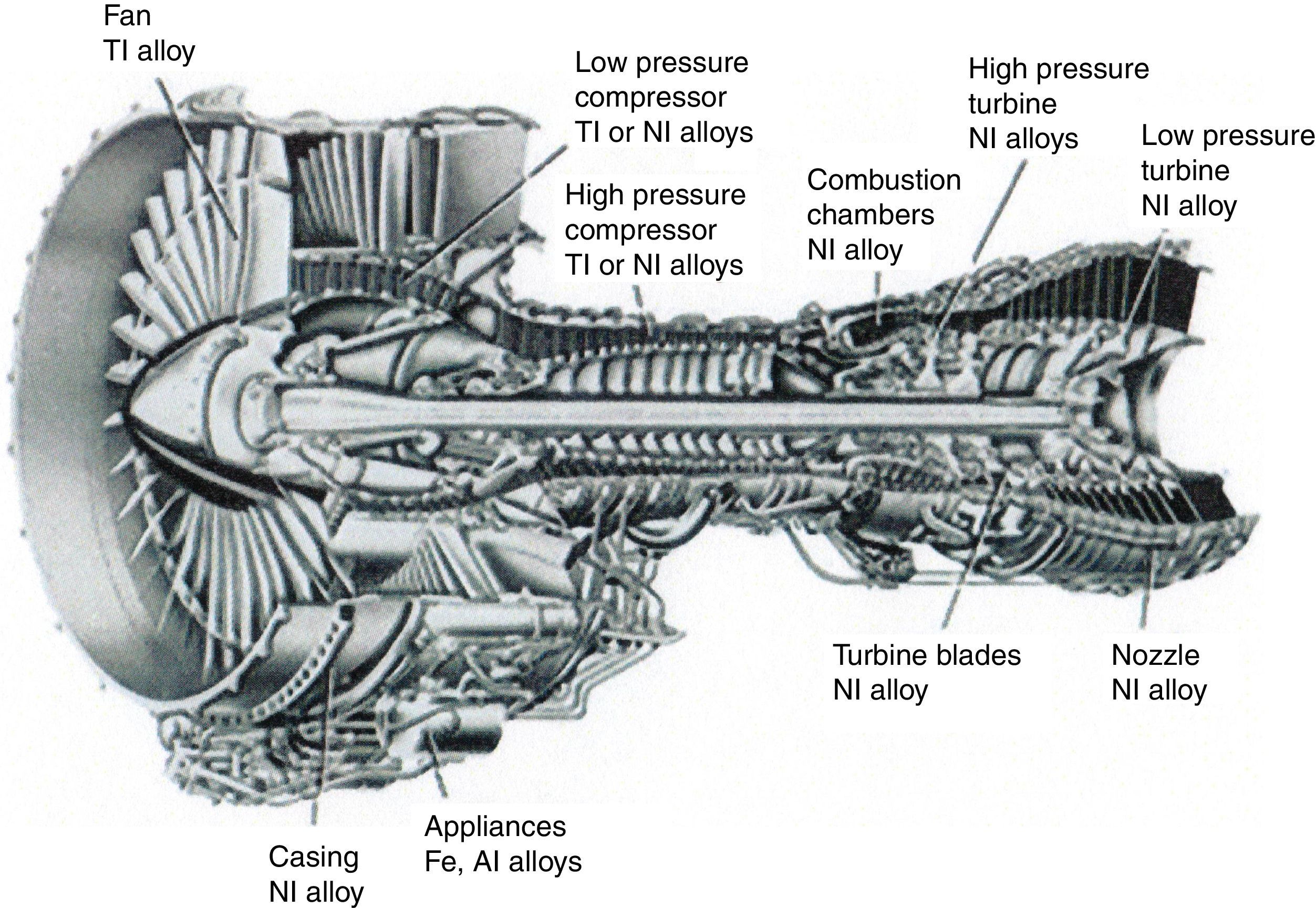

Superalloys such as nickel, iron-nickel, and cobalt alloys meet most of the abovementioned requirements; furthermore, they frequently operate at temperatures exceeding 800K and have a combination of high resistance to applied loads, resistance to fatigue and creep, and resistance to corrosion at high temperatures for long periods of time. Therefore, superalloys are the most extensively used alloys in the manufacture of hot section components of gas turbine motors, which constitute more than 50% of the motor's total weight (Fig. 1) (Pollock & Tin, 2006; Reed, 2006).

Aircraft engines are manufactured using superalloys, mainly for hot turbine sections (Reed, 2006).

Nickel-based alloys are solutions that are stabilized with aluminum, copper, chromium, iron, molybdenum, tungsten, and tantalum and maintain a face centered cubic structure. Aluminum and titanium are hardening and precipitating elements, whereas molybdenum and tungsten are beneficial for because of their ability to reduce creep (Pollock, Dibbern, Tsunekane, Zhu, & Suzuki, 2010; Reed, 2006).

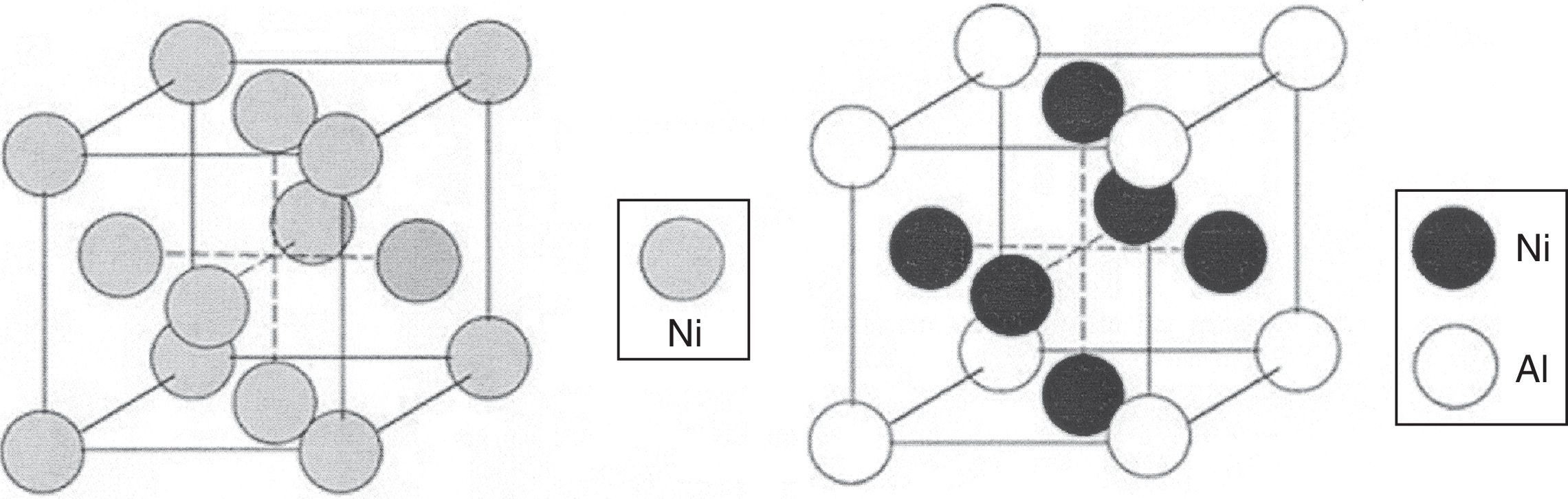

The most important precipitate in nickel and iron-nickel alloys is the γ′ phase (Fig. 2), in the form of Ni3Al or Ni3Ti. This phase is precipitated during thermal hardening and aging treatments (Reed, 2006).

Cell unit arrangements. (a) Nickel has a face centered cubic structure forming the γ phase. (b) Nickel and aluminum also form a face centered cubic structure forming the γ′ phase Ni3Al (Reed, 2006).

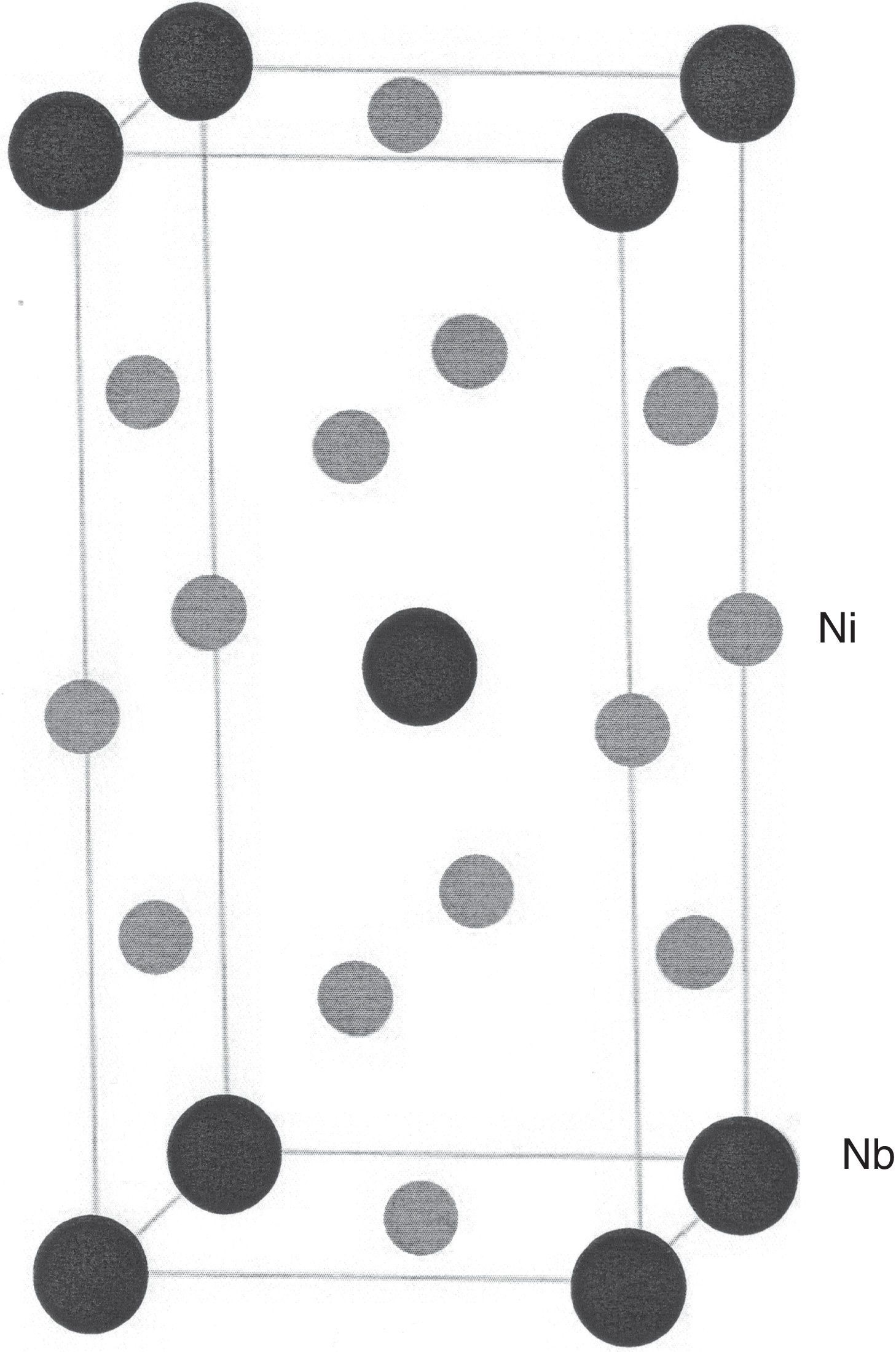

The γ′ phase is only 0.1% dispersed throughout the austenitic matrix; thus, it precipitates homogeneously on the surface (Pollock et al., 2010). The balance between γ and γ′ is maintained at high temperatures, even hold at 70% of the fusion temperature of the material (Tm). The presence of niobium in the superalloy leads to the formation of a precipitate with a body centered tetragonal crystalline structure known as γ′ (Fig. 3), which is a product of the reaction between Ni and Nb (Ni3Nb). This precipitate increases hardness in Ni–Fe-based alloys; therefore, it is an important constituent of superalloys. Note that this property contributes to the control of the superalloy microstructure during the forging process (Reed, 2006).

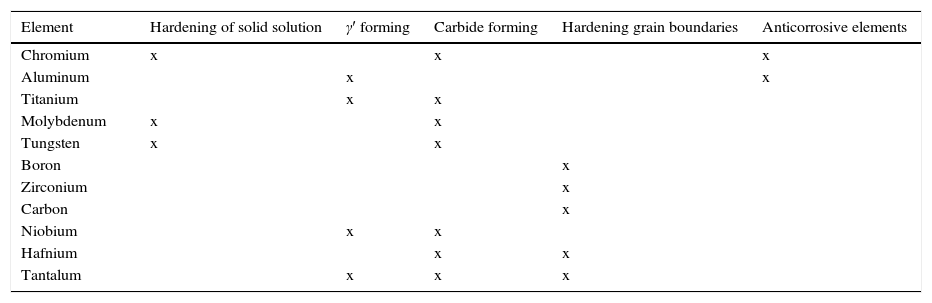

The composition of commercial superalloys is complex (some contain more than a dozen alloy components). The function of each of these alloyed elements is shown in Table 1.

Composition effects of elements in superalloys.

| Element | Hardening of solid solution | γ′ forming | Carbide forming | Hardening grain boundaries | Anticorrosive elements |

|---|---|---|---|---|---|

| Chromium | x | x | x | ||

| Aluminum | x | x | |||

| Titanium | x | x | |||

| Molybdenum | x | x | |||

| Tungsten | x | x | |||

| Boron | x | ||||

| Zirconium | x | ||||

| Carbon | x | ||||

| Niobium | x | x | |||

| Hafnium | x | x | |||

| Tantalum | x | x | x |

The addition of chromium and aluminum provide resistance to high-temperature corrosion by forming Cr2O3 and Al2O3, which are very stable at high temperatures (Jang et al., 2011), on the surface of the superalloy; in contrast, elements such as molybdenum, tantalum, tungsten, and rhenium favor hardening (Pollock et al., 2010; Reed, 2006).

By adding small quantities of boron, zirconium, or hafnium, the mechanical properties of Ni- and Ni–Fe-based alloys can be improved. The carbon content of Ni-based alloys varies from 0.02% to 0.2% for alloys that are forged and up to 0.6% for those that are casted. Metal carbides can be formed both in the metal matrix and in the grain boundaries. At high service temperatures, the precipitation of chromium carbides causes alloy embrittlement (Reed, 2006). Further, morphology of the alloys can be improved by adding small quantities of zirconium and boron, thus stabilizing the formation and precipitation of carbides in the grain boundaries (Al-Jarba & Fuchs, 2004).

Carbides in superalloys have the following main functions: (1) when the carbide is formed, it hardens the grain boundaries, preventing them from being crossed or slowing the process down, and allows for relaxation in the applied forces applied; (2) a thin distribution of the precipitated carbide within the grain increases the mechanical resistance of the superalloy; And (3) carbides control elements that promote the formation of unstable phases during the service stage of the material (Campbell, 2008). However, if a continuous layer of carbide is present along the length of the grain boundaries, it can embrittle the grain, favoring the appearance of cracks. Therefore, the optimal distribution would be a discontinuous chain of carbides along the length of the grain boundaries (Al-Jarba & Fuchs, 2004).

Thus, the main superalloys used in the manufacture of combustion chambers are as follows (Lefebvre & Ballal, 2010; Mattingly, 2002):

- •

Hastelloy X

- •

Haynes 188

- •

Nimonic 75

- •

Nimonic 263

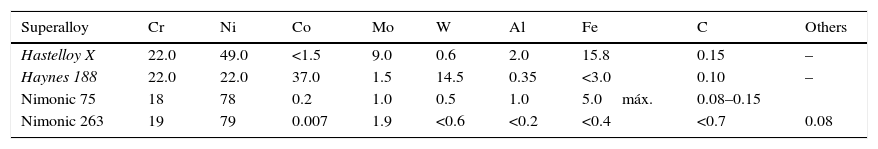

The compositions of these superalloys are shown in Table 2.

Composition of superalloys used in the manufacture of combustion chambers.

| Superalloy | Cr | Ni | Co | Mo | W | Al | Fe | C | Others |

|---|---|---|---|---|---|---|---|---|---|

| Hastelloy X | 22.0 | 49.0 | <1.5 | 9.0 | 0.6 | 2.0 | 15.8 | 0.15 | – |

| Haynes 188 | 22.0 | 22.0 | 37.0 | 1.5 | 14.5 | 0.35 | <3.0 | 0.10 | – |

| Nimonic 75 | 18 | 78 | 0.2 | 1.0 | 0.5 | 1.0 | 5.0máx. | 0.08–0.15 | |

| Nimonic 263 | 19 | 79 | 0.007 | 1.9 | <0.6 | <0.2 | <0.4 | <0.7 | 0.08 |

Most components of combustion chambers are manufactured through forging and then undergo secondary operations leading up to their assembly (Schreiber & Floege, 2007). Forging is a shaping process in which the workpiece is molded through the use of a die that applies compression forces exceeding the material's yield strength (Groover, 2007).

Nickel-based superalloys are more difficult to forge than most metals because of their good mechanical resistance at high temperatures. Thus, forgeability varies depending on the material's composition (Forbes-Jones & Jackman, 1999). Note that nickel-based alloys behave in a manner similar to austenitic stainless steels, implying that their forgeability is reduced (Shen & Furrer, 2000).

Open-die forging is often used to prepare preforms of large pieces, as in the case of turbine discs. Preforms in open dies are usually finished in closed-die forges; this is the most common forging method used in superalloy processing (Campbell, 2008; Shen & Furrer, 2000). Rotary forges can be used to produce preforms intended for use in closed-die forges. This method takes advantage of much more material than the above process and reduces the number of operations in the closed-die forge. Ring forging is a process similar to rotary forging, which also takes advantage of the greatest amount of raw material and is used to create tubes and billets with openings. Processes such as isothermal forging and hot-die forging offer advantages with respect to the required tolerances; thus, costs are reduced because machining times decrease and the requirement for rectification reduces (Campbell, 2008).

The billets of nickel-based superalloys are more susceptible to sulfide attack during heating. Therefore, cleaning the billets before heating is critical to remove potential contaminants such as lubricants and paints. Furthermore, to heat ovens, low-sulfur fuels such as natural gas, propane, or butane (Campbell, 2008; Forbes-Jones & Jackman, 1999) and lubricants that are free of sulfur or colloidal graphite-based lubricants should be used; therefore, matrices must also be cleaned and lubricated to facilitate the removal of pieces that have already been forged (Campbell, 2008).

Hot work can be defined as a plastic deformation conducted at softening temperatures such that the material recovers and recrystallizes. To conduct hot work, dies should be made of a nickel-based superalloy and heated to temperatures between 650°C and 870°C (Shen & Furrer, 2000).

To allow for the homogenization of the alloying elements and microstructural refinement, initial forging operations in superalloys are performed well above the solvus temperature of γ′ (1375°C). During this stage, it is important that the forging temperature does not exceed the lowest melting temperature (1415°C), since it is associated with the segregation of alloying elements (Alniak & Bedir, 2010). The subsequent deformation of the material can be accomplished below the solvus line to provide improved microstructural refinement; this is to resist creep and to support high mechanical loads (Alniak & Bedir, 2010; Campbell, 2008; Kashyap & Chaturvedi, 2000; Reed, 2006). Therefore, recrystallization must be occurs during each hot work operation to acquire the desired grain structure and flow characteristics by reducing the length of the grain boundaries that kept the mechanical properties of superalloys (Reed, 2006; Shen & Furrer, 2000). Hence, the piece must be worked while it is still hot following the last heating operation. In general, alloys that are hardened through precipitation may be cooled by air after forging; cooling in water is not recommended because of the possibility of causing a fracture via thermal shock (Campbell, 2008).

2MethodologyTo calculate the cost of manufacturing combustion chambers for aeronautical use, the flame tube and casing, which are composed of Hastelloy X and Inconel 718, respectively, must be manufactured. The cost of Hastelloy as a raw material is USD 20.75 per kilogram, whereas that of Inconel as a raw material is USD 20 per kilogram.

The software DEFORM-3D© was used to make these calculations. This software package, in addition to determining the forces required to perform the shaping process, provides the option of calculating the cost of the component using parameters similar to those mentioned in the theoretical section of this report.

To validate the results obtained theoretically, the company Frisa, which is involved in the forging of superalloys and light alloys of support rings for aviation motors, was consulted. The raw materials used are Hastelloy X and Inconel 718, which are the same as those used for manufacturing the structural components of combustion chambers.

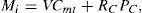

3Theoretical calculationsThe model for calculating the cost of a component is based mainly on the volume of the material and its processing conditions. The cost of the process is determined by considering the specific process and variables inherent to each manufacturing process. The cost of producing a component is expressed as follows (Swift & Booker, 2003):

where Mi=the cost of producing a component, V=the volume of raw material, Cmt=the cost of the material per unit volume, Rc=coefficients of relative costs, PC=basic processing cost.This means that the PC includes the equipment, tooling, and operation costs as well as processing time and demand. Thus, to calculate the basic operational cost, the following formula is used (Allen, Bielby, & Swift, 1991):

where α=operation cost, t=processing time, β=total cost of production, N=annual production.The basic processing cost is closely linked to the manufacturing process and annual production of the component. We observe higher production at lower costs.

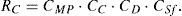

Thus, to determine the expense involved in producing a component with respect to its characteristics, the following costs must be considered:

CMP=relative cost associated with the process for the material

CC=relative cost associated with the geometry of the component

CD=relative cost associated with the dimension and thickness of the component

CSf=cost associated with finishing

With these characteristics, it is feasible to calculate the relative cost (RC):

Incorrect selection of the process can increase costs without meeting the specifications of the finished product; thus, a coefficient that associates the manufacturing process with the material is suitable for obtaining a high-quality product.

CC is the most difficult attribute to characterize, because many processes involve the rotation and translation of the tool or material (Allen et al., 1991). Therefore, CD must consider the minimum size of the piece, the dimensions of component to be produced, physical properties of the material, and the capacity of the machinery used (Ipek, Selvi, Findik, Torkul, & Cedimoglu, 2012).

Moreover, Csf delivered by each manufacturing process must be considered. This determines the quality of the surface, whereas tolerances depend on the size and thickness of the component. The cost of the material constitutes 50% of the total process cost, and from the latter, a significant part is wasted. The cost of the die constitutes 10% of the total and the remainder includes labor, operating costs, and general costs (Ashby, 2009).

Therefore, three costs must be considered during the superalloy forging process:

- 1.

Cost of the material, including losses

- 2.

Costs of operating equipment and labor and general costs

- 3.

Cost of the die

The cost of the material is calculated by the following equation:

where Mc=cost of the material, V=volume of the piece, CVM=cost by volume of material.The volume of the piece can be calculated using the total or final volume (Ashby, 2009; Swift & Booker, 2003)

4Results and discussionTo gauge the possibility of producing components for combustion chambers of motors for aeronautical use, locating and consulting companies specializing in the processing of superalloys in Mexico was necessary.

Frisa manufactures support rings for compressors and turbines composed of Hastelloy X and Inconel 718; it implements the following path:

- •

Raw material yards (superalloy)

- •

Cutting of the billet for ring manufacture

- •

Heating of the billet for hot working

- •

Preforming of the ring using an open forge

- •

Rolling

- •

Heat treatment

- •

Machining

- •

Inspection

- •

Delivery of piece

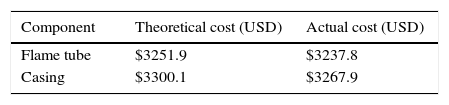

The company was asked to provide an approximate quote for the cost of manufacturing flame tubes composed of Hastelloy X and shells composed of Inconel 718; these were quoted as USD 3237.8 and USD 3267.9 per unit, respectively.

The market cost of Hastelloy X is USD 20.75 per kilogram (The Boeing Company 2010 Annual Report, 2011); thus, the cost expressed per unit volume is USD 0.00017 per cubic centimeter. The volume of the piece is established using the component model, and the flame tube has a final volume of 38,750mm3 Thus, Eq. (4) is used to determine the volume of raw material required. The waste coefficient must correspond to the piece geometry and manufacturing process. The flame tube would be manufactured using a closed-die forging process and the classification of the complex components would be performed using a thin wall, indicating that the waste coefficient is 1.3. Therefore, the cost of the material for manufacturing the flame tube is USD 8.6.

It is also essential to know the number of pieces to be manufactured, which depends upon the number of aircraft that are to be equipped with the engine. The aircraft using this motor are Airbus A320 and Boeing 737. In 2010, a total of 756 aircrafts, including 376 Boeing 737s and 380 Airbus A320s, were delivered (European Aeronautic Defence & Space Company, 2012; The Boeing Company 2010 Annual Report, 2011). Each aircraft uses two motors, so the number of flame tubes and casings to be built is 1512. PC from annual production is estimated at USD 110.

Therefore, CMP must be determined. The value of the coefficient for working nickel alloys in a closed-die forge is 2. As mentioned previously, the flame tube has a complex geometry with a thin wall thickness. Due to its characteristics, its process-associated value is 3.38.

To calculate CD of the component, the maximum dimension of the flame tube is considered to be the external diameter (165.5mm), and the wall thickness is 2.5mm. Thus, the value obtained is 1.3.

Closed-die forging is a process by which very narrow tolerances can be achieved. The highest-quality components reach tolerances of 0.1mm (Chryssolouris, 2006), which are required for all shaped components of aeronautical use. Note that closer tolerances can be reached for these types of components, but they require secondary operations that are not considered in this work. Using a tolerance of 0.1mm, the value of the tolerance coefficient (Cst) is determined to be 3.3.

Once the relative costs have been determined, their coefficient is estimated using Eq. (3), resulting in a value of 29. The total cost of the flame tubes is calculated from MC, PC, and the coefficient of the relative costs. Therefore, the final value of the forged component is USD 3198.6.

Similarly, the final value of the casing is calculated to be USD 3207.7.

Confirming these results, Frisa's quote showed that the costs of the flame tube and casing in the shaping stage are USD 3237.8 and USD 3267.9, respectively (Table 3).

This demonstrates combustion chambers for aeronautical use can be manufactured in Mexico. However, while Mexico possesses the knowledge to manufacture these components, it does not presently have the required equipment.

5ConclusionsCombustion chambers can be entirely manufactured in Mexico, since the country has both the means and knowledge required to process and manufacture components from nickel-based superalloys. Most components manufactured domestically for aviation motors are obtained through seamless rolling.

The manufacturing costs of the components obtained from the proposed methodology correspond to estimates provided by Frisa. Since the methodology used in this study is based on figures obtained from statistical studies from metalworking industries specializing in shaping processes, the estimates of the costs of any piece shaped from any metal should be similar to the real price of the component.

Therefore, we envision that within a period of 10–15 years, Mexico can have an assembly line of aeronautical motors, with the possibility of designing and building gas turbine engines for aircraft domestically by embracing new trends and technological challenges.

Conflict of interestThe authors have no conflicts of interest to declare.

The following work would not be possible without the invaluable help provided by Dr. Octavio Covarrubias Alvarado, Frisa.

Peer Review under the responsibility of Universidad Nacional Autónoma de México.