Composite metallic materials (CMMs) are prepared by dispersing copper particulates in aluminum matrix using stir-cast technique. Their behavior is compared with the alloy having similar composition. The effect of particulate composition is studied by varying the copper concentration between 5 and 15wt%. Hardness increased with increasing particulate contents in both cast and homogenized conditions. Composites show a 13% drop in strength and 15% drop in strain compared to the alloy. With increasing reinforcement content, the strength increased and dropped. Agglomeration due to increased reinforcement contents may be the reason for the decrease in strength values. Microstructures corroborate the above results.

Metal matrix composites are designed to achieve high strength properties. Metal matrix composites (MMCs) reinforced with ceramic particles are widely used because of their high specific modulus, strength and wear resistance. Many of the investigations have shown improved mechanical properties but are limited with low and poor ductility. An optimized combination of surface and bulk mechanical properties may be achieved if Al-MMCs are processed with a controlled gradient of reinforcing particles and also by adopting a better method of manufacturing. Though there is no clear relation between the mechanical properties of the composites, type and volume fraction of reinforcement, surface nature of reinforcement and size of the reinforcement are proved to be effective in improving the strength of the composites. Composite ductility is governed by matrix processors that will be affected by the presence of the reinforcements. This is evidenced by the decrease in ductility while increasing reinforcement volume fraction. An increasing trend of hardness with increase in weight percentage of SiC has been reported by Singla, Dwivedi, Singh, and Chawla (2009). Several investigators Taya, Lulay, and Lloyd (1991), Wang and Rack (1991), Bhansali and Mehrabian (1982) reviewed the influence of the manufacturing route on the properties of MMCs and the factors which control the properties of particulate MMCs by Kelly (1973). Kok (2005) studied the mechanical properties of Al2O3 particle reinforced 2024 Al alloy composites produced through vortex method. It was reported that optimum conditions of the production process are 700°C (pouring temperature), 550°C (preheated mold temperature), 900rev/min (stirring speed), 5g/min (particle addition rate), 1min (stirring time) and 6MPa (applied pressure). Kumar, Lal, and Kumar (2013) reported that the hardness and tensile strength of A359/Al2O3 MMC has been increased. It was also observed that electromagnetic stirring action adopted during the fabrication resulted in smaller grain size and good particulate matrix interface bonding. A successful attempt has been made by Venkatesh and Harish (2015) on Al/SiC composites produced through the powder metallurgy route to achieve the desired properties and also to improve the mechanical properties. For a variety of reinforcements, improvement in strength, fatigue, modulus, wear resistance and creep has been demonstrated by Neih and Chellman (1984) and Friend (1987). Studies on trimodal aluminum metal matrix composites and the factors affecting their strength are reported by Yao et al. (2010). Of these, tensile strength is the most convenient and widely quoted measurement and is of central importance in many applications. Saravanan, Subramanian, Ananda Krishnan, and Sankara Narayanan (2015) observed that there is an increase of 30% in hardness and an increase in tensile strength that is almost twice that of base aluminum alloy for TiB2 particulate reinforced composites. The effects of matrix microstructure and particle distribution on fracture of Al metal matrix composites are also reported by Nair, Tien, and Bates (1985). The influence of stirring speed and stirring time on the distribution of particles in SiC AMC has been analyzed by Prabu, Karunamoorthy, Kathiresan, and Mohan (2006). The ductility and fracture toughness of the MMC and hence indirectly the strength is governed by the reinforcement distribution apart from the reinforcement level. It is essential to have a uniform distribution of the reinforcement for effective utilization of the load carrying capacity of the resultant composite. Nieh, Raninen, and Chellman (1985) also observed, in the early stages of processing, a non-uniform distribution of reinforcement, which persists to the final product in the forms of steaks or clusters of reinforcement with their attendant porosity all of which lowered the strength, ductility, and toughness of the material. For a given matrix alloy, the elongation to failure is reduced by increasing volume fraction (Crowe, Gray, & Hasson, 1985; Kamat, Hirth, & Mehrabian, 1989; Liu, Ricket, & Lewandoski, 1989) and the size of the reinforcement (England & Hall, 1986; Girot, Quenisset, & Naslain, 1987; Manoharan & Lewandowski, 1989; Mummery & Derby, 1991). Though there are many applications for MMCs, fabrication, secondary processing, compatibility between the matrix and reinforcement and characterization are still the major hurdles in the application of these composites. The main damaging mechanisms of MMCs have been found to be loss of ductility, particle matrix interface debonding, particle cracking, particle pull out and agglomeration of particulates. Thought has been given to have the advantages of both MMCs and metal–metal combination systems by choosing conventional alloy systems for the manufacture of composites with restricted solubility. To have good compatibility between the matrix and the reinforcement, an established alloy system with proven application needs to be chosen, where the solvent acts as the matrix and the solute as the reinforcement.

Major fraction of these composites are produced by foundry routes. The advantages include bulk production, ease of fabrication and cost effectiveness. The presence of dendritic structures restricts direct application to a major extent. And this effect is much more accentuated because of the presence of reinforcements. Ingots are secondary processed to nullify these effects. Several workability tests are available to study the deformation behavior under the combined stress and strain conditions which are usually found with bulk deformation processes. Rozovsky, Hahn, and Avitzur (1973) reported that the compression of a short cylinder between anvils is a much better test for metal working applications. The deformation behavior of solid cylinders of an aluminum alloy metal matrix composite under dry condition was estimated by Joardar, Sutradhar, and Das (2012). It was reported that a cylindrical preform can be successfully compressed to a height reduction by 28–32% without fracture. Dikshit et al. (2010) carried out cold upsetting experiments under unlubricated condition on cast and homogenized AA2014/SiC composites to study the effect of homogenization on deformation behavior. Orbulov and Ginsztler (2012) indicated that engineering factors such as the aspect ratio (height/diameter ratio) of the specimens and the temperature of the tests, have significant effect on the compressive strength and properties. The effect of reinforcing particle shape and interface strength on the deformation and fracture behavior of an Al/Al2O3 composite was investigated by Romanova, Balokhonov, and Schmauder (2009). It was also reported that interface debonding and particle cracking are the two mechanisms for a particle fracture. Minghetti et al. (2001) observed high deformation rates with crack free AA6061 – Al2O3 particulate MMC samples by the cold forming process.

Cored structures are most common in as-cast metals. For some applications, a cored structure is objectionable. There are two methods for solving the problem of coring. The method preferred by the industry is to achieve equalization of composition or homogenization of the cored structure by diffusion in the solid state. At room temperature, for most metals, the diffusion rate is very slow, but if the alloy is reheated to a temperature below solidus line, diffusion will be more rapid and homogenization will occur in a relatively short time.

With this background, in the present investigation an attempt has been made to know the homogenization effect, compression behavior and mechanical properties of Al–Cu composite metallic materials (CMMs). The results are compared with that of the alloy.

2Experimental2.1Fabrication of alloy and compositeCut ingots of pure aluminum are melted in a stationary pot type electric heating furnace in clay graphite crucible at 700°C. Copper pieces wrapped in aluminum foil are added to the aluminum melt at 850°C and the same temperature is maintained until copper melts completely. For the fabrication of the composite, the reinforcements (powders) are produced initially by filing the copper rod, rotating on a lathe. IE grade aluminum (99.5%), supplied by M/s National Aluminum Company, India, is used as the base matrix material in the present investigation. A pre-weighed quantity of aluminum is melted in a graphite crucible using a 3-phase bottom-pour electric resistance furnace (Bhargava, Samajdar, Ranganathan, & Surappa, 1998). The bath temperature is maintained at 720°C. Pre-weighed quantities of copper particles (average particle size 250μm), thoroughly dried at 200°C in a muffle furnace, are added quickly and uniformly to the vortex in the melt, such that particles are suspended in the melt. Madhusudan, Sarcar, and Bhargava (2009) reported that the EDX analysis for the Al–Cu composite showed a gradual variation in copper concentration from the particle to the matrix with high counts to low counts.

2.2HomogenizationThe alloy and the composites are thoroughly homogenized at 100°C for 24h in a muffle furnace. Hardness values are recorded using a Vickers hardness tester. A total of 6 samples are tested in each case and average values are reported. The obtained values are converted to Mega Pascal's using the conversion factor.

2.3Compression testCompression tests are carried out on standard cylindrical specimens between the flat platens at a constant cross head speed of 0.3mm/min in dry condition using 100T, FIE-UTE-100 compression testing machine. Standard samples of 27mm×18mm Φ (height to diameter ratio, i.e., aspect ratio as 1.5) are used in the present investigation. Concentric grooves of 0.5mm depth are made on parallel faces for lubricant retention, to minimize friction hill, there by maximizing the uniformity in deformation. Samples are grid marked at mid-height for deformation studies. Upset tests were performed at room temperature between two flat platens on computer controlled servo hydraulic universal testing machine at a constant cross head speed. Specimens are subjected to plastic deformation by upsetting to 50% or the fracture initiation, whichever happens earlier. A total of 6 samples are tested in each case and average values are reported. The PC based data logging system was used to record and store the deformation behavior continuously.

2.4Tensile testSamples are tested on a 10 ton DAK tensile testing machine at a constant cross head speed of 1mm/min. Standard samples of tensile specimens ASTM-E8M are prepared for testing. A total of 6 samples are tested in each case and average values are reported.

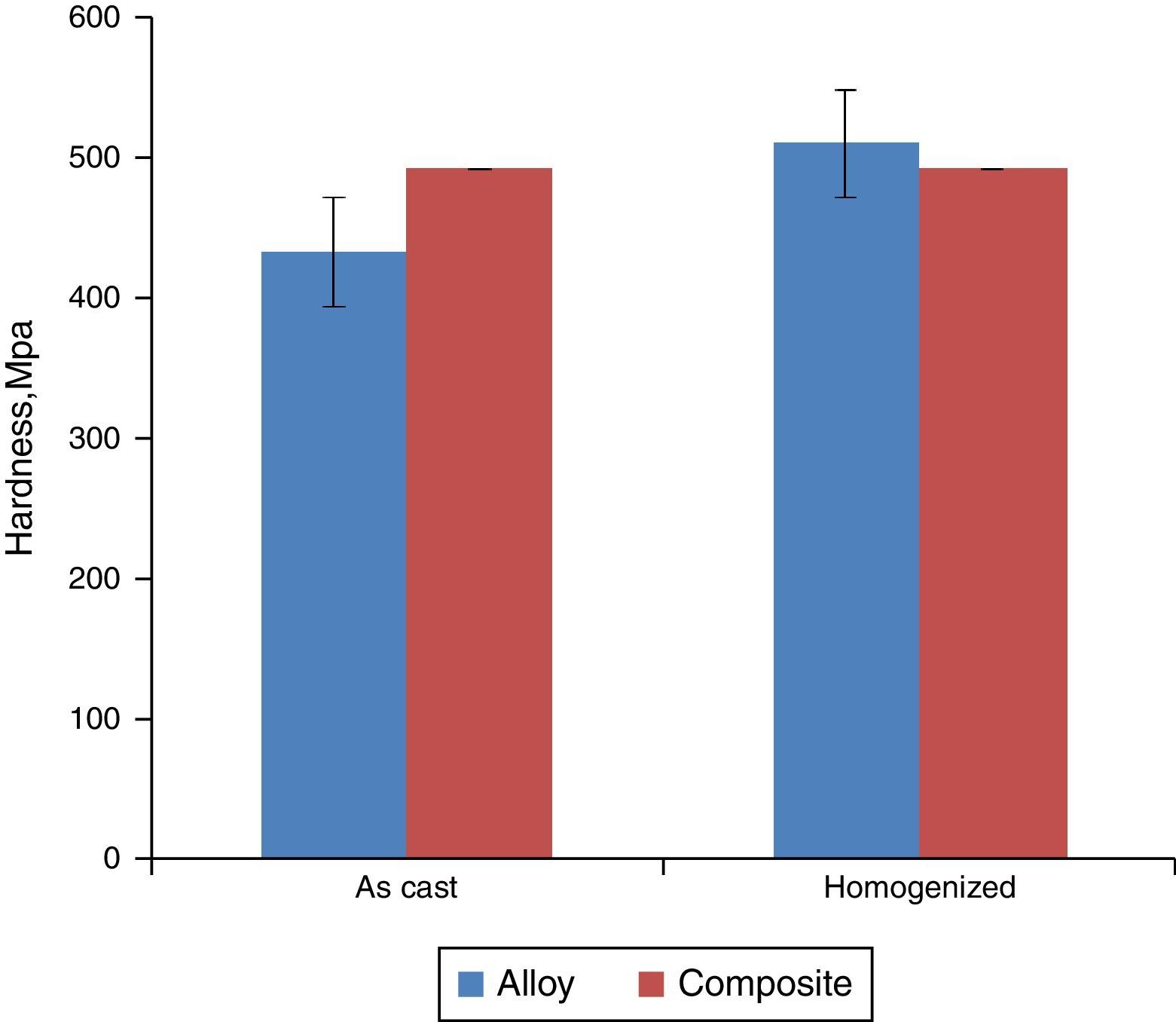

3Results and discussions3.1Homogenization effectFig. 1 shows the hardness of the alloy in cast and homogenized conditions. The alloy shows less hardness in cast condition as compared to the homogenized. Homogenization aids the solute copper diffusion from the regions of high concentration to low concentration regions, resulting in uniform composition of the alloy throughout. As a result, the hardness is improved in homogenized condition. The composite has lean diffusion of the particulate material in the matrix, due to low stir time. The presence of fine and uniform distribution of particulates enhanced the hardness of the resultant composite. Hardness increased with increasing particulate contents in both cast and homogenized conditions. Bailey (1969) reported that an increased alloy content with increased particulate concentrations is the reason for the improvement in hardness in composites, in general. The presence of reinforcement enhances this effect further.

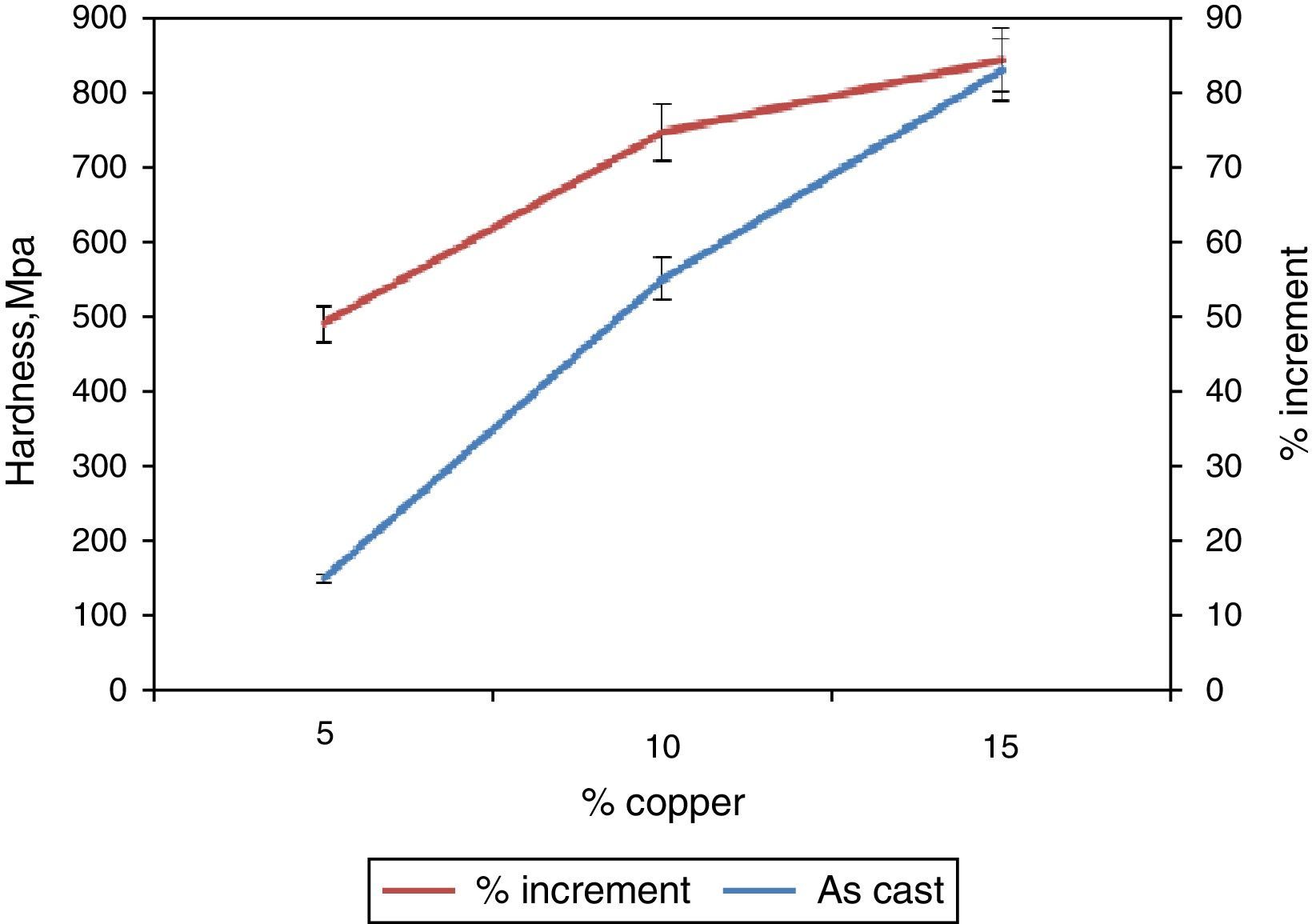

Fig. 2 shows the effect of copper addition on the resultant hardness and the effective increment in hardness. A good rise in hardness values by 10%, increment 50% and 78% in the cast condition has been observed with increased particulate contents. The low increment at lower concentration is due to lean alloy formation and low concentrations of reinforcement, only 1.5% by volume as reported by Wu (2000). Though the composite with highest concentration shows an increment in hardness, the effective increment in hardness is only 28% (78–50), showing a lesser rate compared to the 10% reinforcement addition. This drop is due to limited stir time. In total, this increment is due to the increased surface area of the particulate with increasing reinforcement content and the presence of the reinforcement as well, Bhaskar and Sharief (2012).

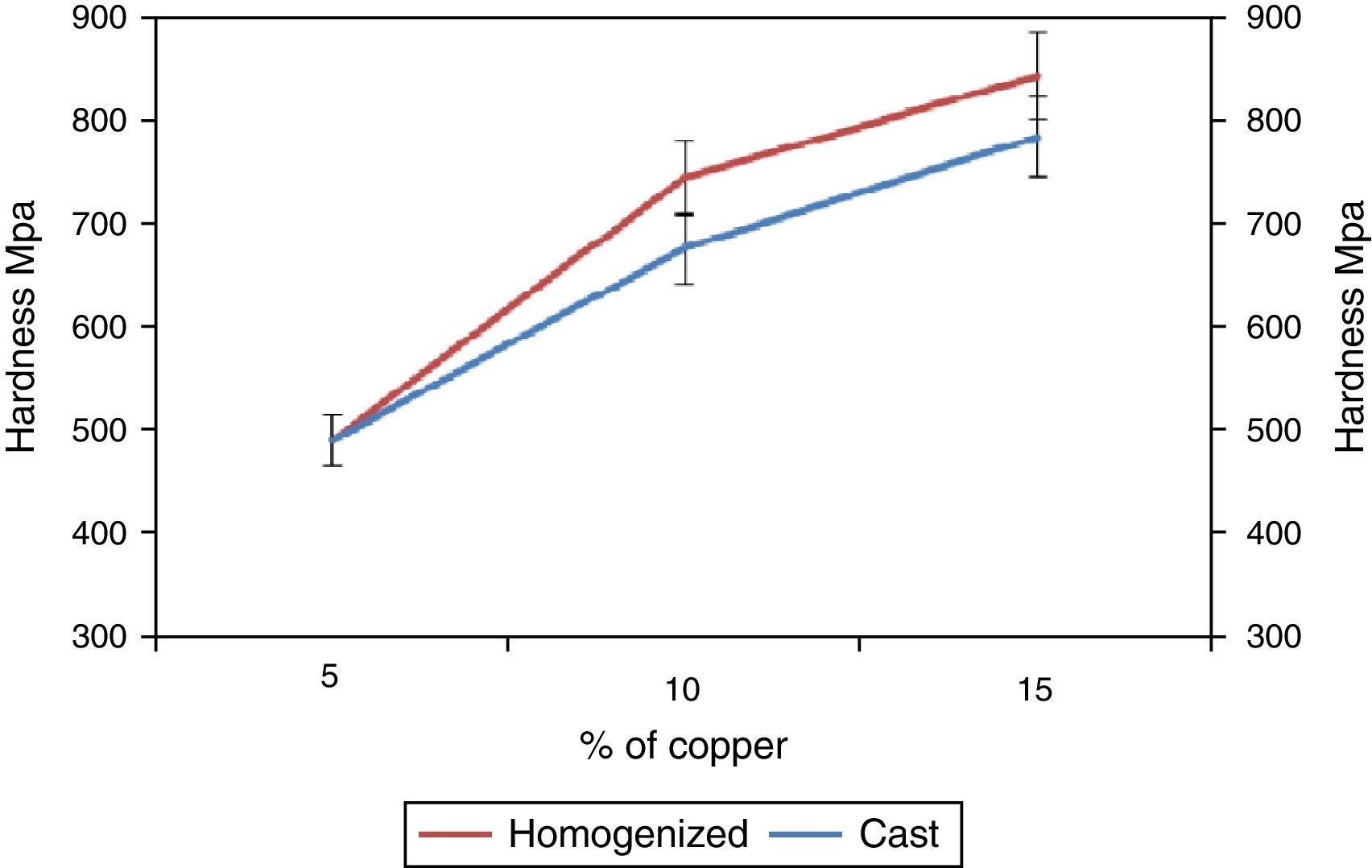

Fig. 3 shows the hardness of composites in cast and homogenized conditions. Increase in reinforcement concentrations enhances the hardness in homogenized condition. The lack of enhancement during homogenizing at lower concentrations is due to poor particulate diffusion in aluminum because of limited stir time. The reason for the increment in hardness during homogenization is discussed in the earlier paragraphs.

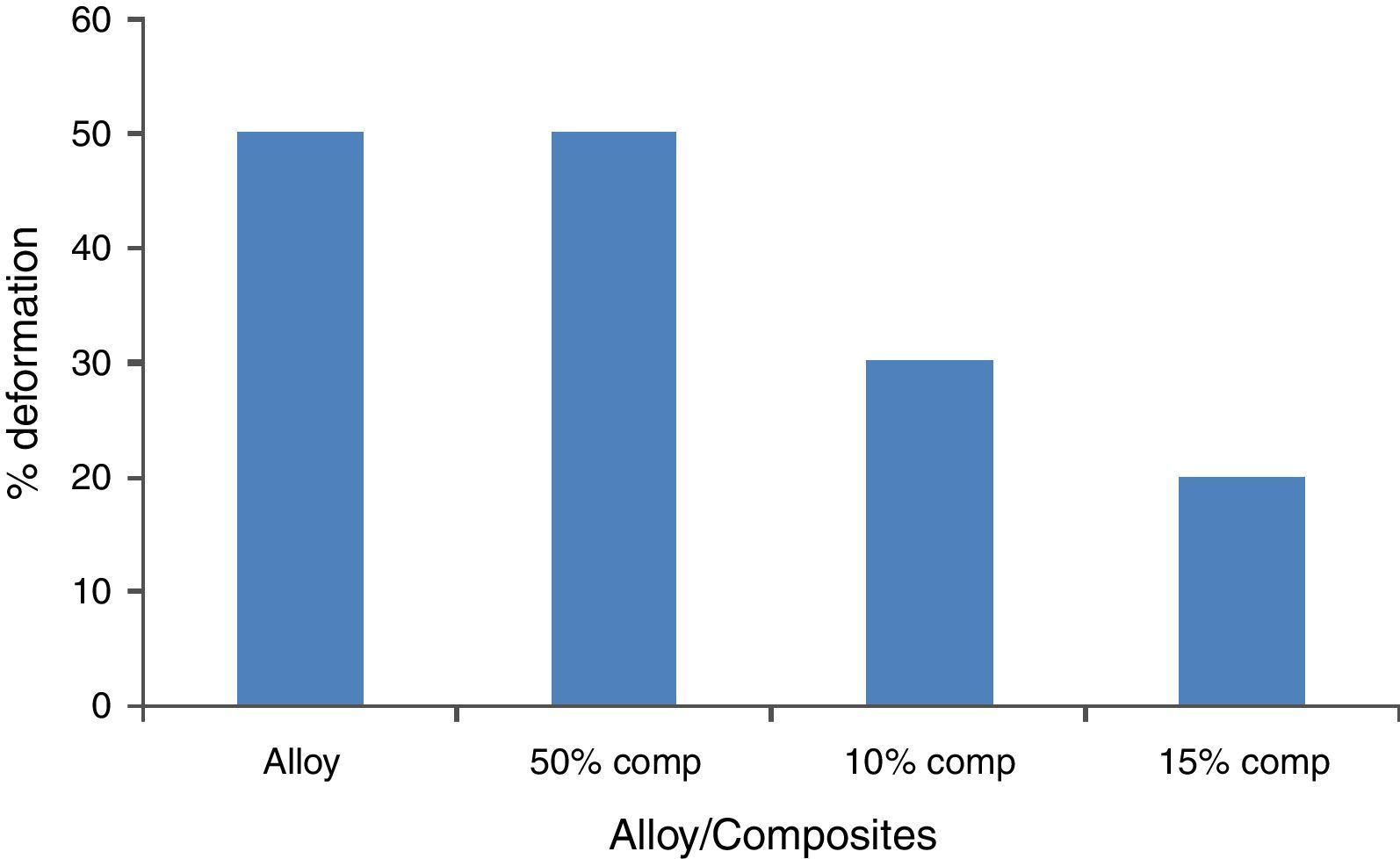

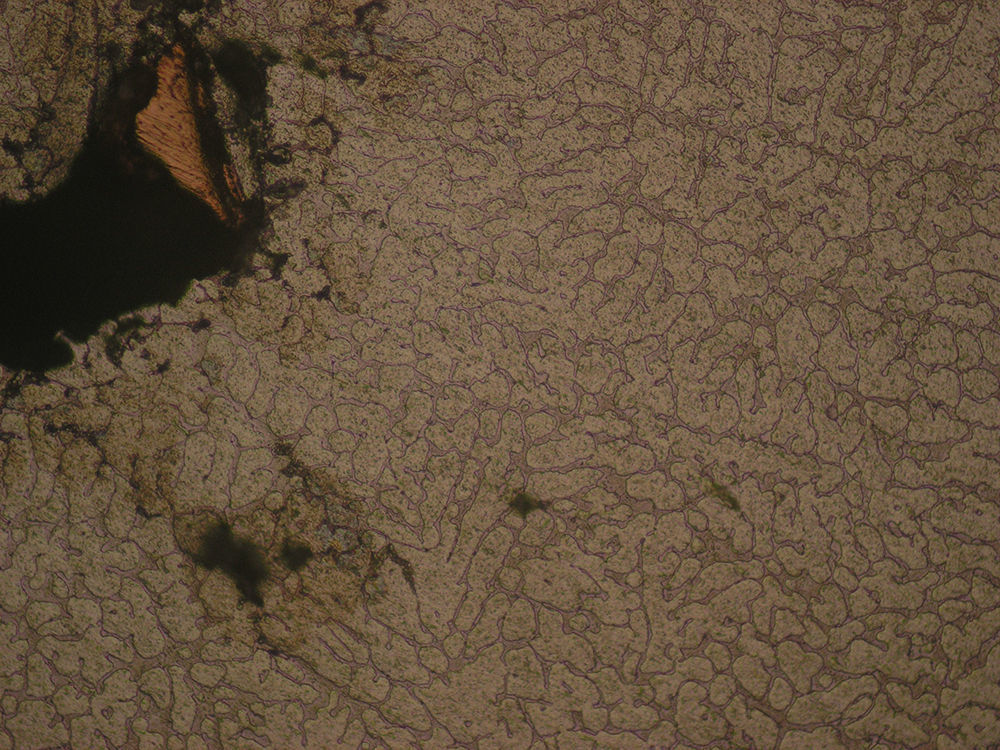

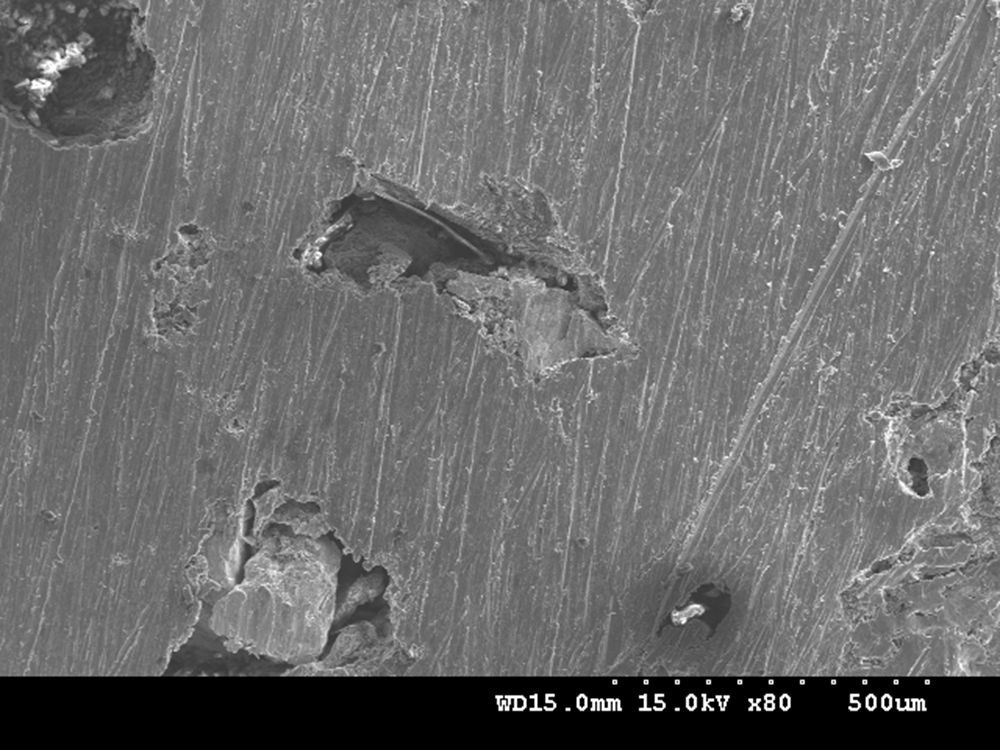

3.2Compression behaviorAl–5% Cu alloy and composites with 5, 10, and 15wt% particles of copper are subjected to deformation up to 50%. Both the alloy and the corresponding composite with 5% reinforcement could deform up to 50% (Fig. 4). The thorough deformation of the alloy is self-explanatory as it consists of a solid solution of aluminum and intermetallics CuAl2. The composite having similar composition does consist of a lean aluminum–copper alloy matrix and the copper particulates as reinforcements with an interface, comprising a series of alloys from the matrix to the reinforcement, aluminum rich alloys to copper rich alloys, respectively. Composites with higher concentrations (10% and 15%) of reinforcement have failed at 30% and 20%, respectively (Fig. 4). The reason for the early failure is due to the fast addition of the reinforcements in short times (30s), leading to agglomeration/clustering (Fig. 5). During deformation, agglomerates result in inhomogeneous deformation cause void generation between the particulates (Figs. 6 and 7).

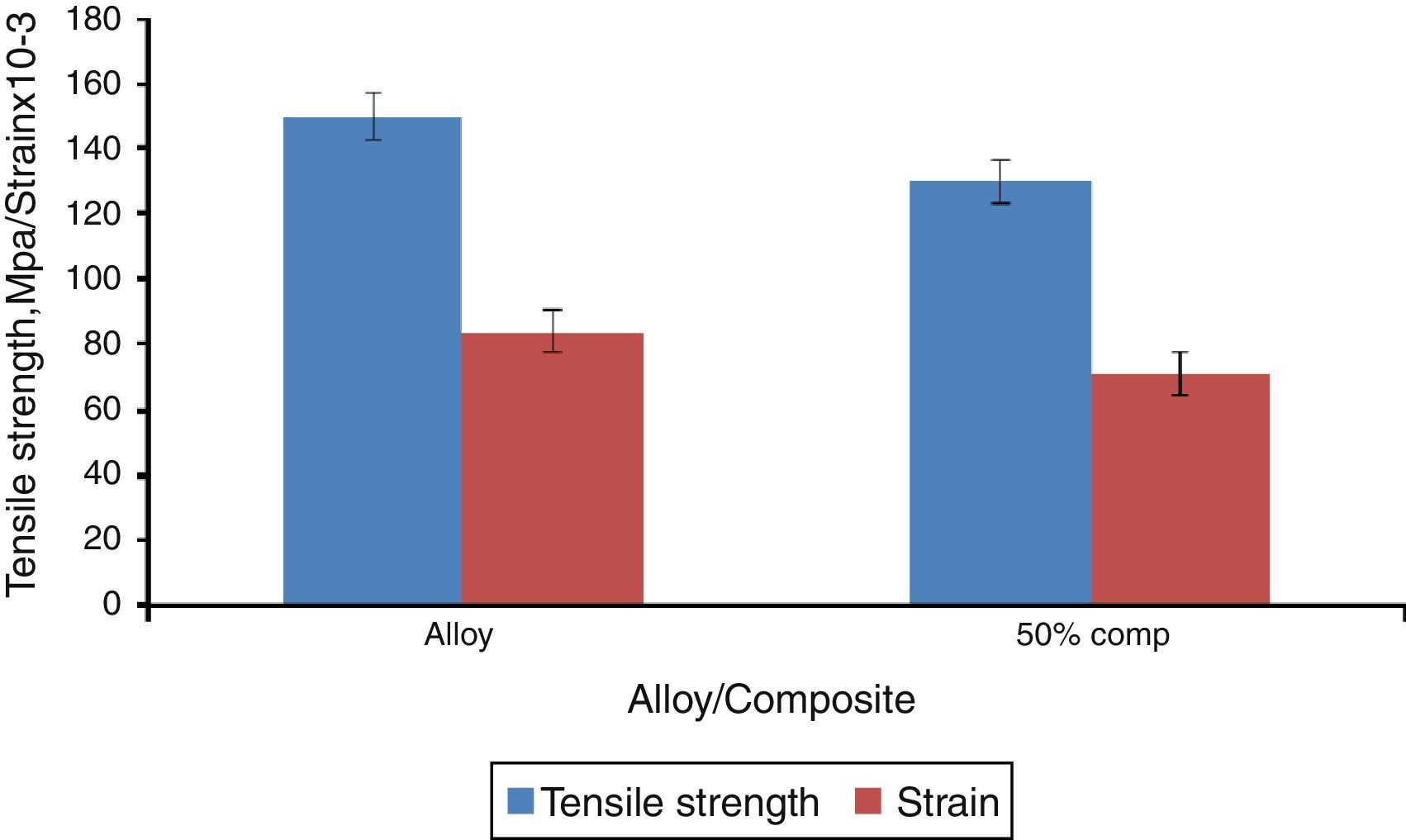

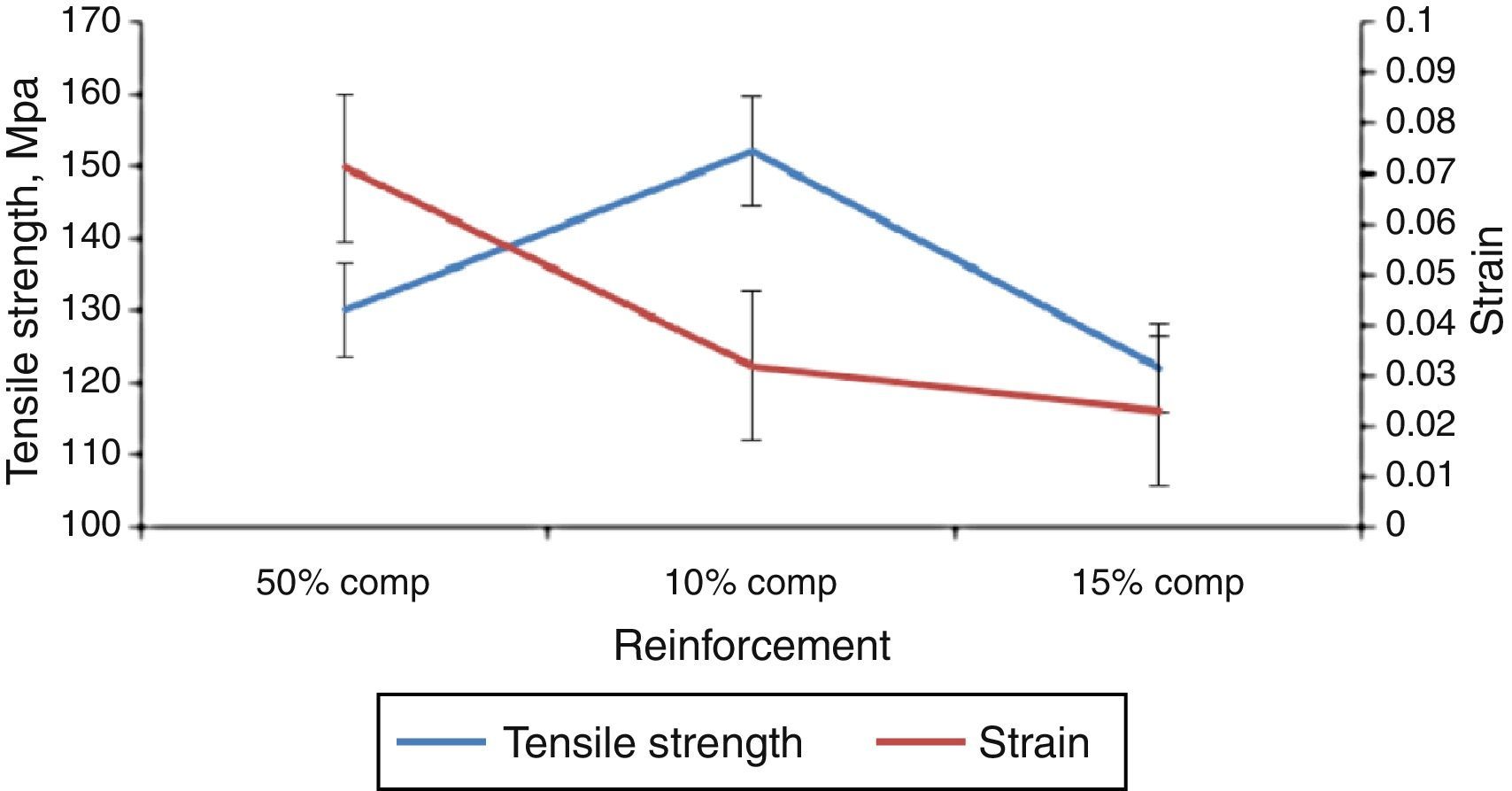

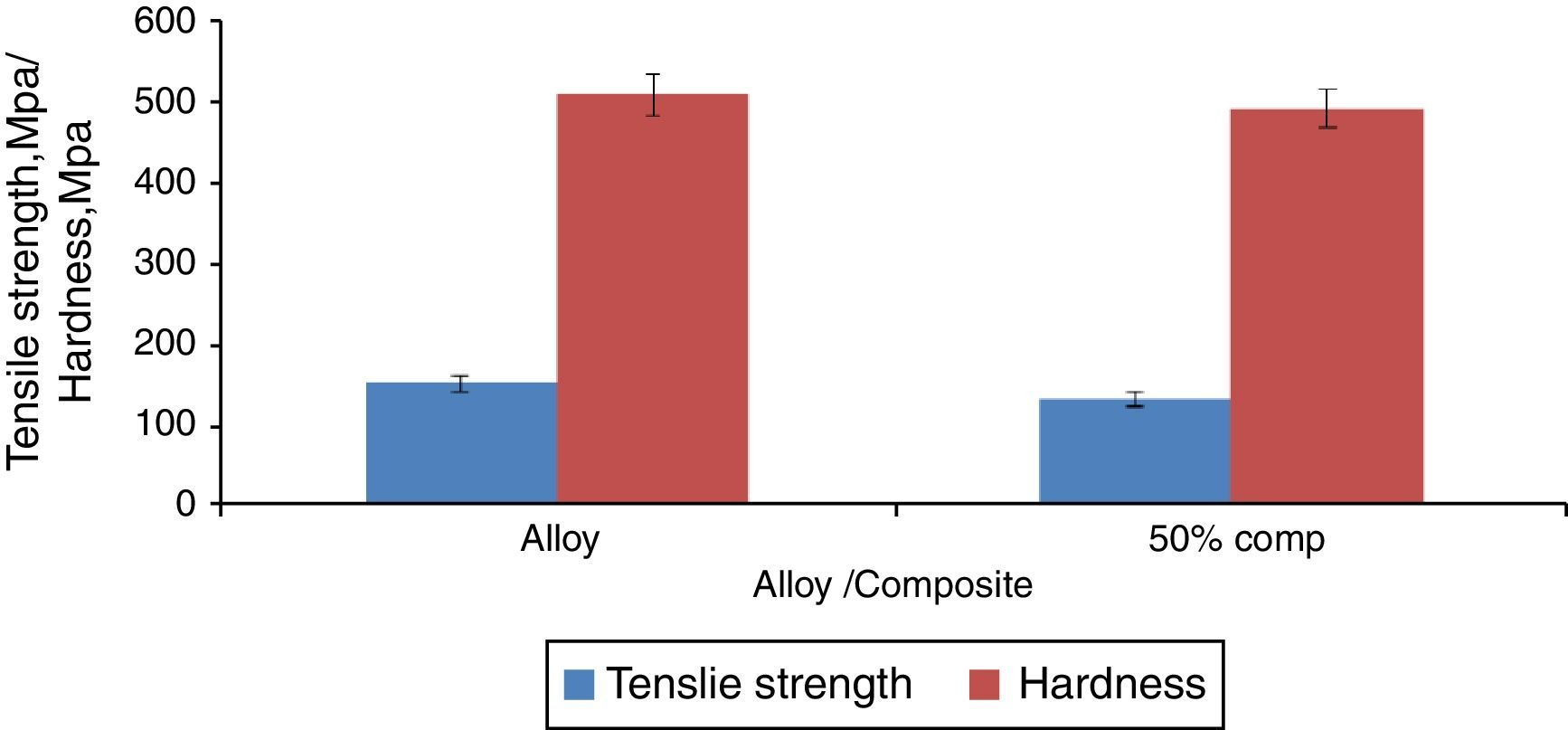

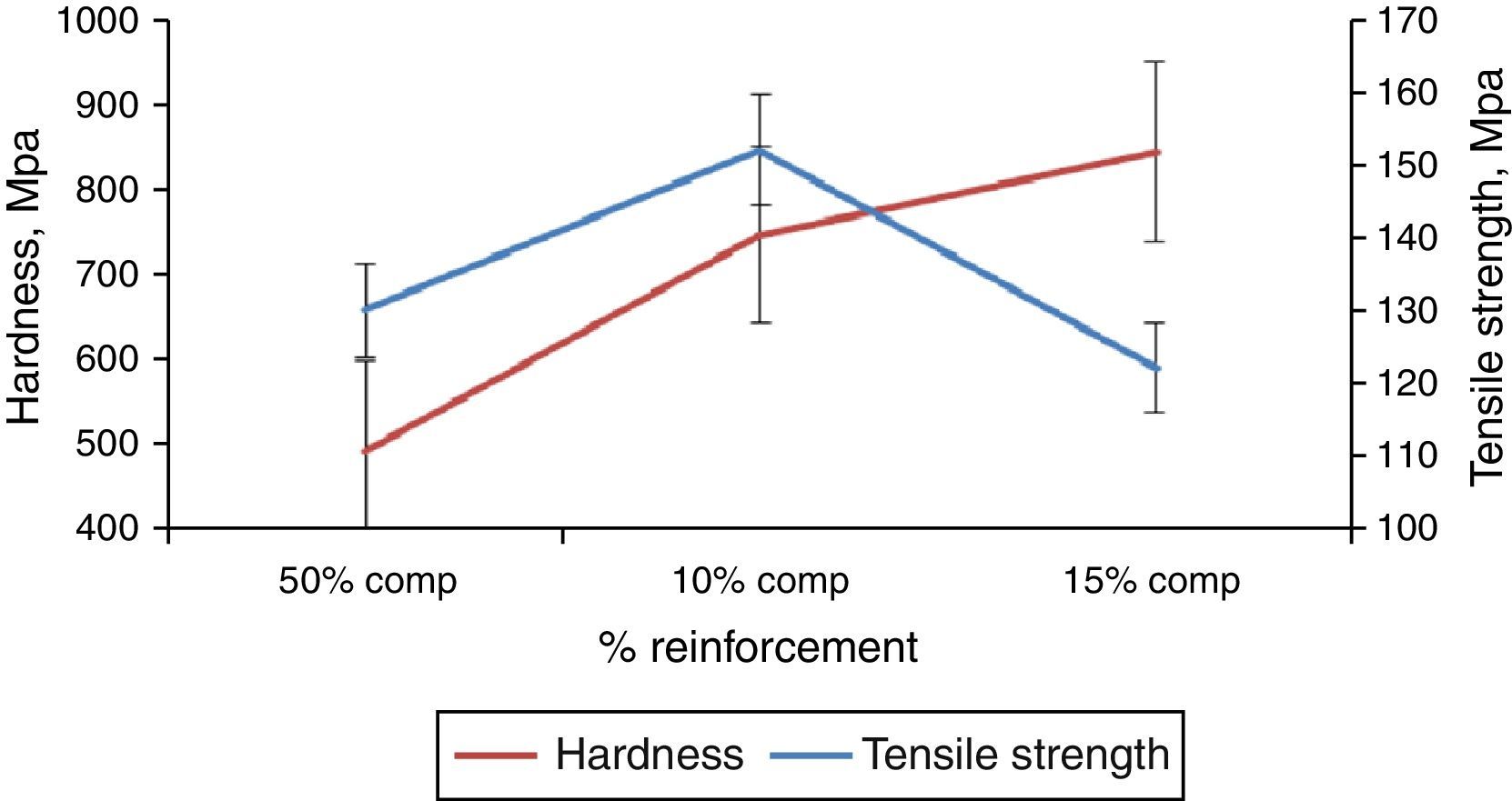

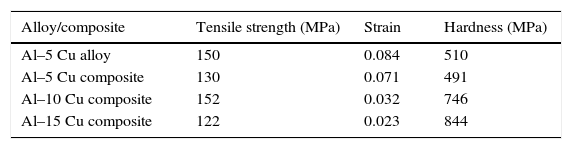

3.3Tensile propertiesTable 1 shows the summary of tensile strength, strain and hardness. Fig. 8 shows the comparison of mechanical properties between the alloy and the composite having the same composition. The composites show a 13% drop in strength and 15% drop in strain compared to the alloy. The CMMs’ behavior is not true with that of the MMCs, where compositing increases strength at the cost of strain. Wu (2000) reported that reinforcement enhances strengthening but simultaneously reduces the formability of matrix; resulting in a decreased strain. The strength of the alloy pertains to the presence of solid solution and the intermetallics and their constitution. Compared to the alloy, alloy formation around the copper particle in composite is much lean, whose contribution is to a much lesser extent. It means that the strengthening of the composite is a combined effect of the presence of the base metal (Al), the alloy and the reinforcements. Strengthening occurs mainly because of reinforcement of the base metal (Al matrix) as the time given to form the alloy (distribution of copper in Al) is much shorter, which contributes to a limited extent. The drop in strain with composite compared to the alloy corroborates the phenomena of compositing (Wu, 2000). Fig. 9 shows the effect copper (reinforcements) content on the resultant composites. With increasing reinforcement content, the strength increases and then falls. Agglomeration due to the increased reinforcement contents may be the reason for the decrease in the strength values. With increasing copper content, alloy formation also increases, which leads to the formation of a continuous layer between the metal matrix and the copper particles. The deformation becomes much more difficult, resulting in increased strength values. Hence, the resulted strength is a combination of the alloy formation, reinforcement and a good interface. On further increment in the reinforcement content, a drop in strength is obtained which may be due to two reasons. The amount of alloy content has gone beyond 5%, which has become stronger than the reinforcement causing the void formation due to the lack of compatibility between the matrix, interface and the reinforcement. Figs. 6 and 7 show the microstructures of the composite, with 15% reinforcement. The voids present cause the decrease in strength. Secondly, there is always a chance of agglomeration of particles with an increased reinforcement content. This leads to the formation of voids and this effect accumulates further during deformation. The agglomeration of particulates multiply the effect of the drop in strength further (Fig. 5). The drop in strain with increasing copper content supports the composite behavior where increase in strength was reported with decreased strain. Fig. 10 shows the material behavior during hardness testing. As discussed earlier, the alloy represents strengthening due to the solid solution and intermetallics, while the composite represents the particulate reinforcements in the aluminum matrix. The hardness testing overestimates the tensile value as it does not show the drop in strength values at 15% composite. The hardness testing is compressive in nature and also the area under the indentation is work hardened; resulting in enhanced values. According to Harindar, Nripjit, Sarabjeet, and Tayagi (2012), in tensile testing, the loading is tensile in nature, where the deformation is uniform and a rebounce effect due to work-hardening is negligible. And this effect is much more pronounced with decreasing the matrix strength as reported by Liaw, Diaz, Chiang, and Loh (1995).

Fig. 11 compares the effect of copper content on tensile strength and hardness. Unlike tensile behavior, increasing the copper content composite showed increased hardness values. The trend can be a result of the alloy formation and reinforcing effect. As discussed earlier, it is the fundamental difference in the loading, in which the material undergoes uniform plastic deformation, while plastic deformation is restricted and concentrates in the localized region.

4Conclusions- 1.

The alloy and the composite with same compositions exhibit uniform deformation up to 50%.

- 2.

Increasing reinforcement concentrations decrease the upsetting characteristics of the resultant composites.

- 3.

CMMs respond similarly to MMCs in tensile properties.

- 4.

Matrix alloy with lean composition is the reason for low strength of the resultant composite compared to the alloy of same composition; however, it is compensated by the reinforcement effect of the particulates.

- 5.

With compositing, the presence of reinforcement decreases the strain to failure.

- 6.

The agglomeration of reinforcements at higher concentrations causes a drop in strength.

- 7.

At all concentrations of the reinforcement, composites exhibit higher hardness.

The authors have no conflicts of interest to declare.

It is a great pleasure to express my deep sense of gratitude and indebtedness to my research guides Prof. M.M.M. Sarcar, Vice Chancellor, JNTU Anantpur, India and Prof. N. Bhargava Rama Mohan Rao, Department of Metallurgical Engineering, Andhra University, India for their inspiration, guidance, encouragement, moral support and affection during the course of my work. I place on record my profound feeling of reverence for sparing their valuable time in spite of busy schedules. Under their guidance I had an opportunity to enjoy the freedom and liberty of work. I shall forever cherish my association with them for their perennial approachability and actions I have enjoyed during the past several years.

Peer Review under the responsibility of Universidad Nacional Autónoma de México.