The determination of optimal cutting parameters is one of the most important elements in any process planning of metal parts. In this paper, a new hybrid genetic algorithm by using sequential quadratic programming is used for the optimization of cutting conditions. It is used for the resolution of a multipass turning optimization case by minimizing the production cost under a set of machining constraints. The genetic algorithm (GA) is the main optimizer of this algorithm whereas SQP Is used to fine tune the results obtained from the GA. Furthermore, the convergence characteristics and robustness of the proposed method have been explored through comparisons with results reported in literature. The obtained results indicate that the proposed hybrid genetic algorithm by using a sequential quadratic programming is effective compared to other techniques carried out by different researchers.

($/piece) machine idle cost due to loading and unloading operations and tool idle motion time

($/piece) cutting cost by actual time in machining

($/piece) tool replacement cost

($/piece) tool cost

(mm) depth of cut for each pass for rough and finish machining

(mm) lower and upper bounds of depth of cut for rough machining

(mm) lower and upper bounds of depth of cut for finish machining

(mm) depth of material to be removed

(mm) diameter and length of the work piece

(mm/rev) feed rates for rough and finish machining

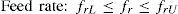

(mm/rev) lower and upper bounds of feed rate for rough machining

(mm/rev) lower and upper bounds of feed rate for finish machining

(kgf) cutting forces during rough and finish machining

(kgf) maximum allowable cutting force

(min) constants relating to cutting tool travel and approach/departure time

($/min) direct labor cost+overhead

($/edge) cutting edge cost

(constants of cutting force equation

(constants related to chip-tool interface temperature equation

(constants for roughing and finishing parameters relations

(constants related to expression of stable cutting region

(number of rough cuts (an integer)

(upper and lower bounds of n

(constants of tool-life equation

(kW) cutting power during rough and finish machining

(kW) maximum allowable cutting power

(°C) chip–tool interface rough and finish machining temperatures

(°C) maximum allowable chip-tool interface temperature

(A weight for Tp [0,1]

(mm) nose radius of cutting tool

limit of stable cutting region constraint

(mm) maximum allowable surface roughness

(min) tool life, expected tool life for rough machining and expected tool life for finish machining

(min) tool life of weighted combination of Tr and Ts

(min) upper and lower bounds for tool life

$ unit production cost except material cost

(m/min) cutting speeds in rough and finish machining

(m/min) lower and upper bounds of cutting speeds for rough machining

(m/min) lower and upper bounds of cutting speeds for finish machining

The selection of optimal cutting parameters, like the number of passes, depth of cut for each pass, feed rate and cutting speed, is a very important issue for every machining process [1].

Several cutting constraints must be considered in machining operations. Turning operation can be performed in a single pass or in multiple passes. Multipass turning is preferable over single-pass turning in the mechanical industry for economic reasons [2].

The optimization problem of machining parameters in multipass turning becomes very complicated when plenty of practical constraints have to be considered [3].

Conventional optimization techniques such as graphical methods [4], linear programming [5], dynamic programming [6, 7], and geometric programming [8, 9] have been used to solve optimization problems of machining parameters in multipass turning. However, these optimization methods may be useless for some problems. Numerous constraints and multiple passes make machining optimization problems complicated and consequently these methods are inclined to converge to local optimal results. Thus, meta-heuristic algorithms have been developed to solve machining economics problems because of their power in global searching. There have been some works regarding optimization of cutting parameters [2, 3, 10, 11, 12, 13, and 14] for different situations. In these works, authors have tried to bring out the utility and advantages of ant colony system, genetic algorithm, simulated annealing, swarm intelligence, evolutionary approach and scatter search approach. It is proposed to use the hybrid genetic algorithm by using sequential quadratic programming for the machining optimization problems.

The present paper is focused on the application of a new optimization technique, the hybrid genetic algorithm by using sequential quadratic programming, to determine the optimal machining parameters that minimize the production unit cost in multipass turning processes.

2Cutting process model2.1Decision variablesIn the construction of the optimization problem, six decision variables are considered: cutting speeds for rough and finish machining (VrVf), feed rates for rough and finish machining (fr,ff) and depth of cut for each pass for rough and finish machining (dr,df).

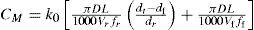

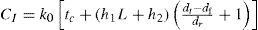

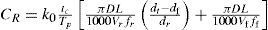

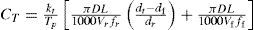

2.2Objective functionBased on the minimum unit production cost, UC, criterion, the objective function for a multipass turning operation is given as follows [10],

With:

2.3ConstraintsSome constraints that affect the selection of optimal cutting conditions will be considered. The constraints for rough and finish machining are as outlined below:

2.3.1Rough machiningParameter boundsDue to the limitations on the machine and cutting tool and due to the safety of machining, the cutting parameters are limited with the bottom and top limit.

Tool-life constraintThe constraint on the tool life is

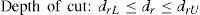

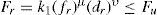

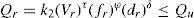

Cutting force constraintThe maximum amount of cutting forces Fu should not exceed a certain value as higher forces produce shakes and vibration. This constraint is given as

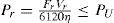

Power constraintThe nominal power of the machine PU limits the cutting process:

With efficiency η=0.85

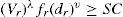

Stable cutting region constraintThis constraint is given as

The constraint on the stable cutting region has been suggested by Philipson and Ravindran [15] in order to take into account the prevention of chatter vibration, adhesion and formation of a built-up edge. Equation (12) adopted in this research for determination of the stable cutting region was proposed by Narang and Fischer (1993) for multipass turning operations.

The values of λ and SC are based on the values used by Philipson and Ravindran [15] while the value for v is assumed to be that proposed by Narang and Fischer [16].

Chip–tool interface temperature constraint2.3.2Finish machiningAll the constraints other than the surface finish constraint are similar for rough and finish machining. [17].

Surface finish constraintIn the finishing operations, the obtained surface roughness must be smaller than the specified value SRU, given by technological criteria so that the following equation is satisfied:

Constraints for roughing and finishing parameters relations

2.3.3The number of rough cutsThe possible number of rough cuts is restricted by

Where nL≤n≤nU

The optimization problem in multipass turnings is divided into m=(nU−nL+1) subproblems. In each subproblem, the number of rough cuts n is fixed; hence, the search for the solution of the optimization problem is to find the solutions of msubproblems, the minimum of these results will be the solution of the global optimization problem.

3Genetic algorithm (GA) and Sequential quadratic programming (SQP)Due to the good coverage of the genetic algorithm and sequential quadratic programming techniques in the literature [18, 19, 20], only the hybrid GASQP method will be briefly mentioned here.

4Hybrid GA-SQPSQP requires a smaller number of objective and constraint function calls than the GA. It can also find accurate optimum results as it is a deterministic algorithm. However, because SQP uses gradient information in its search algorithm, it tends to be trapped in the local optimum and suffers from noise in objective or constraint functions whereas the GA searches more globally and has more chance to find a global optimum. The GA should be used to perform the initial global search. The results are used to guide the local search.

In order to benefit the global search ability of a GA and the accurate local search of a SQP, they are used as a complement of each other. To do so, the GA stopping criteria are set so that the GA would stop prematurely, for example, with a low generation, a low population or a high tolerance. It is assumed that the GA should find its optimal results near the true global optimum. The GA results are therefore used as an initial point for the SQP algorithm. The SQP proceeds the local search and find its local optimum, which is the global optimum searched.

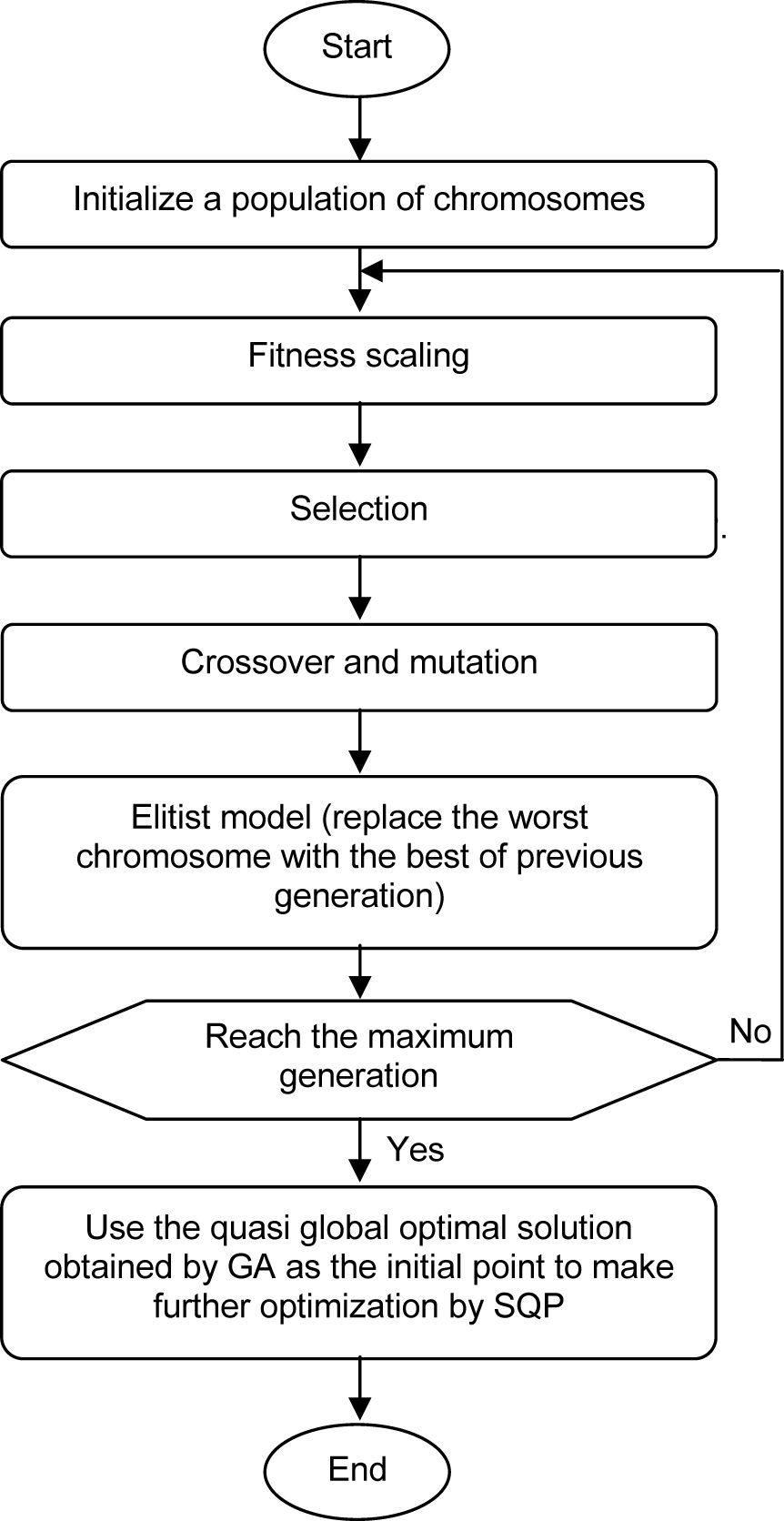

Figure 1 shows the flowchart of the hybrid GA. At the beginning, the genetic algorithm searches the global optimum in the whole solution region to obtain a quasi-optimal solution, and then, the global optimal solution can be obtained by sequential quadratic programming. The method is named GA+SQP.

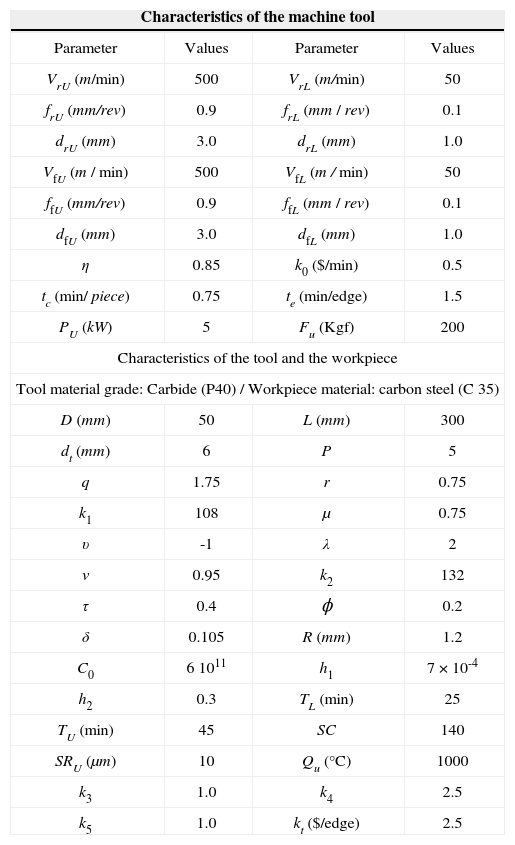

5Example of ApplicationNow, an example of application is considered to validate the used hybrid GA-SQP method for the optimization of a multipass turning operation. The parameters used for the numerical application are mentioned in Table 1.

Machining data from reference [10].

| Characteristics of the machine tool | |||

|---|---|---|---|

| Parameter | Values | Parameter | Values |

| VrU (m/min) | 500 | VrL (m/min) | 50 |

| frU (mm/rev) | 0.9 | frL (mm / rev) | 0.1 |

| drU (mm) | 3.0 | drL (mm) | 1.0 |

| VfU (m / min) | 500 | VfL (m / min) | 50 |

| ffU (mm/rev) | 0.9 | ffL (mm / rev) | 0.1 |

| dfU (mm) | 3.0 | dfL (mm) | 1.0 |

| η | 0.85 | k0 ($/min) | 0.5 |

| tc (min/ piece) | 0.75 | te (min/edge) | 1.5 |

| PU (kW) | 5 | Fu (Kgf) | 200 |

| Characteristics of the tool and the workpiece | |||

| Tool material grade: Carbide (P40) / Workpiece material: carbon steel (C 35) | |||

| D (mm) | 50 | L (mm) | 300 |

| dt (mm) | 6 | P | 5 |

| q | 1.75 | r | 0.75 |

| k1 | 108 | μ | 0.75 |

| υ | -1 | λ | 2 |

| ν | 0.95 | k2 | 132 |

| τ | 0.4 | ϕ | 0.2 |

| δ | 0.105 | R (mm) | 1.2 |

| C0 | 6 1011 | h1 | 7×10-4 |

| h2 | 0.3 | TL (min) | 25 |

| TU (min) | 45 | SC | 140 |

| SRU (μm) | 10 | Qu (°C) | 1000 |

| k3 | 1.0 | k4 | 2.5 |

| k5 | 1.0 | kt ($/edge) | 2.5 |

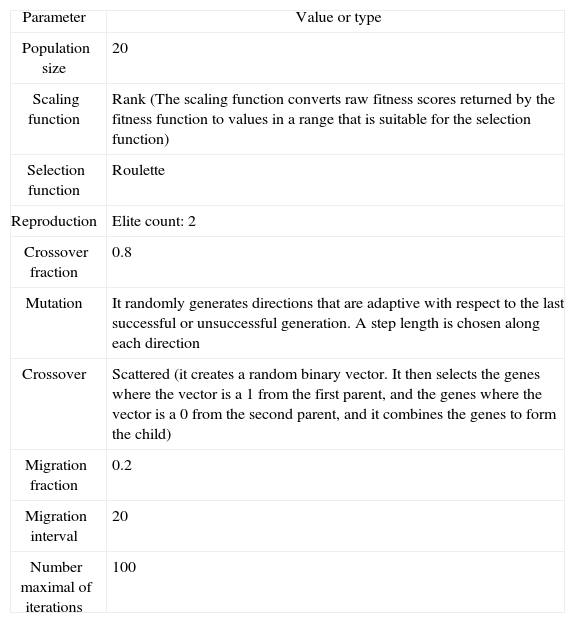

The genetic algorithm was run with the following parameters (Table 2):

Parameters used in the genetic algorithm.

| Parameter | Value or type |

| Population size | 20 |

| Scaling function | Rank (The scaling function converts raw fitness scores returned by the fitness function to values in a range that is suitable for the selection function) |

| Selection function | Roulette |

| Reproduction | Elite count: 2 |

| Crossover fraction | 0.8 |

| Mutation | It randomly generates directions that are adaptive with respect to the last successful or unsuccessful generation. A step length is chosen along each direction |

| Crossover | Scattered (it creates a random binary vector. It then selects the genes where the vector is a 1 from the first parent, and the genes where the vector is a 0 from the second parent, and it combines the genes to form the child) |

| Migration fraction | 0.2 |

| Migration interval | 20 |

| Number maximal of iterations | 100 |

Several GA generations are performed in order to identify the most promising areas and then the SQP optimization algorithm is applied using, as an initial guess, the best individual found by the GA. It should be noted that in this approach the GA is used to specify a good initial guess for the SQP algorithm.

The results found by the hybrid GA-SQP are mentioned in Table 3.

The optimized turning parameters.

| n | Rough machining | Finish machining | UC ($) | ||||

|---|---|---|---|---|---|---|---|

| Vr (m / min) | fr (mm / rev) | dr (mm) | Vf(m / min) | ff (mm / rev) | df (mm) | ||

| 1 | 94.4640 | 0.8660 | 3.0000 | 162.2890 | 0.2580 | 3.0000 | 1.9308 |

| 2 | 182.9710 | 0.4520 | 2.4996 | 217.3229 | 0.1794 | 1.0009 | 2.5840 |

| 3 | 145.6160 | 0.9000 | 1.6670 | 191.3630 | 0.2580 | 1.0000 | 2.6450 |

| 4 | 157.2560 | 0.9000 | 1.2430 | 171.6070 | 0.2580 | 1.0260 | 3.1230 |

| 5 | 166.5110 | 0.9000 | 1.0000 | 191.3630 | 0.2580 | 1.0000 | 3.4585 |

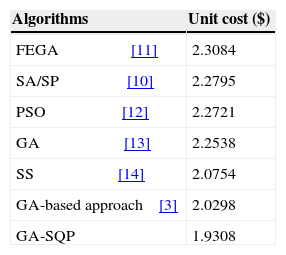

We find that the lowest value is 1.9308 $ under which the minimum number of rough cuts (1)n=is taken. The performance of the hybrid GA-SQP in comparison with other methods is shown in Table 4

The proposed hybrid approach is applied and evaluated with the same model and data provided in the references [3, 10, 11, 12, 13 and 14], but the authors of these references have used other methods.

According to Table 4 we conclude that the hybrid GA-SQP yields much better results that the other methods. Thus the hybrid GA-SQP can solve the optimization of the multipass turning operation problem efficiently to achieve better results in reducing the unit production cost.

6ConclusionThis work presents a hybrid GA-SQP optimization for solving the multipass turning operations problem. To decrease the complexity of the problem, the whole problem was divided into several subproblems according to the number of possible rough cuts.

The results obtained by comparing the hybrid GASQP with those taken from recent literature prove its efficiency.

The hybrid GA-SQP can achieve much better results than other approaches proposed previously, and the production unit cost was significantly reduced. In addition, the present method is a generalized solution method so that it can be easily employed to consider the optimization models of turning regarding various objectives and constraints.

In the machining models, no specific workpiece and tool was identified. Therefore, the solution approach can be used with any workpiece for turning optimization problems.

This study definitely indicates some directions for future work. For example: the application of the hybrid GA-SQP in complex machining systems and automated process planning systems.