The container terminal is a convergence point in the cargo flow, being a focal point for multiple supply chains. The operations performed in a container terminal involve one of the most complex environments within the transport industry. A container terminal plays a critical role in international shipping and is under pressure to cope with increasing container traffic.

This paper presents a multiagent model to solve the event management problem; this problem has a number of features which makes the agent a suitable technology to consider applying. The model presented is the basis for developing a tool for the event management process in order to contribute to the reduction of logistics cost and to enhance the competitiveness of the container terminal.

La terminal de contenedores es un punto de convergencia en la circulación de la carga, siendo un nodo neurálgico al participar en múltiples cadenas de suministro. Las operaciones realizadas en una terminal de contenedores involucran a uno de los más complejos ambientes en la industria de transporte. Además las terminales de contendores juegan un rol crítico en el comercio internacional y se encuentran bajo presión por el incremento en el tráfico de los contendores.

Este trabajo presenta una propuesta basada en un modelo multiagente para resolver el problema de la gestión de eventos en una terminal de contenedores; este problema presenta ciertas características que hacen a los agentes una tecnología a aplicar. El modelo presentado es la base para el desarrollo de una herramienta que de soporte al proceso de la gestión de eventos, contribuyendo a la reducción de los costos logísticos y a un incremento de la competitividad de la terminal de contenedores.

The port is a convergence point between the circulation load of two domains: maritime and land [1]. Port terminals handle more cargo than other types of terminals; they can be categorized in public or private, or according to the cargo: containers, bulk, hazardous materials and liquids.

However, port terminals have to improve their process in terms of its agility and ability to respond to unforeseen events. In this context, the use of management concepts from the supply chain encourages the flow of information and resources and strengthens ties between parties in the port logistics chain.

These demands are particularly important in the ports, as they are critical nodes that participate in multiple supply chains. For this reason, a system that can respond to changes and disruptions in the port is a very necessary tool to enhance resilience in the supply chain.

The problem is that resilience is based on the concepts of agility and visibility, items not readily available in highly distributed and autonomous components such as container terminals.

Furthermore, resilience is affected by other factors such=as=globalization,=decentralization,=outsourcing, reduction in the number of suppliers, etc. [2][3].

In this way, within a global supply chain, event management is understood as the component of management systems in the supply chain to reduce the gap between planning and execution, in order to minimize the impact of an exception or deviation from a current plan, allowing in turn the visibility and agility with a consequent resilience [4].

This work seeks to characterize the container terminal event management problem, where a settlement proposal seeks to provide not only monitoring activities but also control activities, acting as a decision support system or as an autonomous control system.

This container terminal event management system should work collaboratively with other supply chain event management systems [5], also given the special characteristics of a port terminal that distinguish it from the other members of the supply chain, a problem description and a particular specification of a proposal are needed.

This agent-based system will receive plans and their slack from the planning system and disruptive events from execution systems, where the results are the generation of a control action; when there is not a control action, the proposals are used as information for decision making.

The research methodology used is based on a literature review of related proposals; also, it is based on a real case study of San Antonio in Chile. We made several interviews with port activities stakeholders and subsequent analysis for the development of a conceptual model to characterize the problem. Among the expected results is the development of a conceptual model specialized in the container terminal and the agent-based model approach of event management system to act collaboratively with other supply chain event management systems providing robustness to the ports to improve overall supply chain is very relevant.

The paper is organized as follows; Section 1 focuses on the introduction to the event management problem and particularly in the container terminal.

The analysis of related work is presented in Section 2, which highlights the most event management papers focused on order monitoring, showing a slack of contributions in the area of port terminals. As several authors have noted that the port nodes have a large impact on the overall performance of the supply chain, it is quite relevant to make an effort in the risk management that threatens the overall performance [6]. Section 3 describes the container terminal with key parties and operations, identifying risks and their causes. In Section 4, we propose a conceptual model and a multiagent model for event management in the port. Finally, in Section 5, the conclusions and future work are presented.

2Related WorkIn recent years, concepts such as risks, disruptions and events have been studied by both industry and academia in the context of the supply chain [2][3][7][8][9][10]. Some of the most important are described below.

PROVE (Prototype Reasoning About Operations in Virtual Enterprise) [11] is a prototype that performs order tracking and monitoring as well as supports the negotiation between companies when one is unable to place an order, the prototype is based on mobile agents.

DIALOG [12] is an agent-based system that shares data to facilitate tracking of orders providing information on its condition. This proposal provides order visibility.

ECTL-Monitor [13] is an agent-based system that provides the possibility of tracking and tracing of orders. This system provides proactive notification elements but not information gathering. The monitoring process is initiated to user demand.

PAMAS [14] is an event management system in the supply chain based on monitoring of orders as they move into the supply chain, detecting when disruptive events occur that affect one or more orders. The system uses adaptive profiles to identify those orders to be monitored to present some characteristics that make them more vulnerable. PAMAS is an alarm system based on multiagent architecture where control actions are not part of the proposed solution.

The prototype FORWIN (Bavarian Research Network for Information Systems) [15] is a monitoring and alarm system based on the detection of deviations which discusses possible causes of these deviations and the generation of possible mitigation measures to reduce these deviations. The monitoring and controlling of the execution of orders is beyond the scope of this work.

SCEMMA [4][5] is a multiagent model for the SCEM process which is based on the identification of possible sources of disruptive events, then on these sources define control points that allow the detection of deviations and the generation of control measures aimed at minimizing the deviation detected if possible, or the notification of the deviation to the planning system to review the plan that has become obsolete. Thus, the identification of disruptive events and how they affect the plan is a dynamic process.

Rebollo et al. present a multiagent model for solving the automatic allocation problem in a container terminal. They define a different kind of agent for each one of the main tasks to be done. The first prototype of this system is currently being developed.

Poza et al. [17] developed a solution for real-time control and monitoring in a container terminal. This is a multiagent model where there is an agent for each one of the main tasks. The problem was divided in three subproblems: Container I/O System, Container Movement System and Container Service Agent.

Rida et al. [18] developed a decision support system for a container terminal. The architecture simulates container terminal operations to improve management of container terminals.

Currently, tracking and tracing systems are the status quo in most companies, but they do not fully meet the requirements for autonomous control. The new systems should be proactive and include a method of prediction and reaction to disruptive situations. In addition to detail, there is evidence that the proposals are intended to supply chains where the ports and terminals are not considered; however, they play a key role in transporting goods and people, representing 80% of international trade worldwide, making it relevant to consider how to develop the management of events in this particular node to achieve a sustainable and competitive [11]. In this way, to have a collaborative SCEM of the entire supply chain would be an important contribution to regional development.

3Container Terminal DescriptionThe port is normally understood as the set of facilities and services that provides the space required for the vessels, while performing loading, unloading and storage of goods. Moreover, today it is a major node of convergence in international transport and trade, and it is the point of contact between land and sea transport.

All these activities are planned to carry out the processes of importing and exporting goods that are supported by an integrated logistics chain between the different stakeholders involved in international trade. The aim of this study is to analyze the port logistics chain and provide a diagnosis, by determining the main stakeholders, the process and interrelations among them, and to propose a framework for the event management problem.

To maximize the value of the supply chain, firstly, the integration of the operations of all companies involved must be considered. Secondly, collaboration between all the stakeholders involved is required. And thirdly, the synchronization of the supply chain into one logical enterprise, united and fully operational with enhanced capabilities from suppliers to consumers.

Undoubtedly, in this respect, technology plays a key role, allowing communication links between the parties in an expeditious manner.

The desire to maximize the supply chain value is contrasted with the deviations that occur throughout the chain. Determining which risks affect port operations, the causes, and the impact on the chain are questions that these chain stakeholders slated to respond in order to reduce the occurrence of these events and even when mitigating the impact of the event once they already happened.

3.1Major StakeholdersAn important feature of a functioning port system is that the processes involved depend on a large number of parties of different sizes, both public and private, which must be coordinated (interenterprise coordination) in order to satisfy the expectations and requirements of the customers. By understanding this, it is possible to realize the fundamental role that each of the stakeholders have in the logistics chain, not only for the exporters or importers, but also the role played by members of the port system (intracompany coordination) as they are an important factor in the activities and decisions involved in port processes.

Exporters and importers are the users or customers of the logistics system (a port) and participate either directly or by an agent that represents them such as a freight forwarder. The return does not come from any port activities as such, unlike the other parties in the supply chain, but they use it as a means to fulfill their ultimate purpose, considering that their main objective is to transport their products in the shortest time with greater security and at the lowest possible price, and thus, to obtain significant returns from marketing their imported or exported goods.

Regulatory agencies are responsible for enforcing the regulations and guaranteeing their fulfillment by slack inspections both physical and documental.

The job of the port authority is to manage, operate, develop, and maintain the port, including all related activities inherent to the port environment and essential to its enforcement. Its infrastructure has berths and the facilities allow providing different services for national and international clients.

The business of shipping lies mainly in shipping routes in the national and international markets.

3.2Main OperationsWe considered two case studies: Puerto Valparaiso and Puerto de San Antonio. In both cases, the processes involved in the international commerce are detailed below, presenting the relations and activities that involved the different stakeholders. Both the import and export processes require a high degree of synchronization among all participants for a continuous flow of goods and information, for example.

The importation is the entry of foreign goods for use or consumption in the country. This process begins when someone in the country wants to enter merchandise. There is then a negotiation between the foreign manufacturer and importer in the country who define the contractual conditions for importing the goods. Finally, the importer should contact Customs to take the steps to approve the entry of the load.

The other general process that takes place in the port is the export which is the legal transmission of national or nationalized goods for use or consumption abroad. This process starts when an exporter needs to send cargo overseas to a third country; to do that, a negotiation between the members that regulate the contractual terms for the sale of products is required.

3.3Events in the Container TerminalConsidering that a container terminal can identify internal events (occurring within the terminal) and external events (originating in the related stakeholders). The disruptive events caused by uncontrollable events such as natural and/or social contingencies are not captured directly, but the effect on the resources that affect them.

The internal events of the container terminal are associated with resources (cranes, trucks, storage blocks). Examples of internally disruptive events are:

- •

Berth unavailable because it must be repaired.

- •

Crane problems

- •

Truck problems

- •

Blocks unavailable

- •

Container problems

The external events are associated with the related stakeholders. These events mean the storage blocks reallocation in the yard with changes in the other resources use. Some external events are:

- •

The need to discharge the vessel, replan the stowage and load the ship again.

- •

Delay of a ship.

- •

Truck problems.

- •

Damaged containers.

- •

The container does not meet the conditions (documentation or physical rquirements) to be imported/exported.

- •

Delays because of problems with the documentation submitted by the Customs Agency.

- •

Delays related to the care of the ship.

- •

The vessel does not meet legal standards for sailing.

There are two important concepts in this work: plan and solution. A plan is defined as a set of orders. In this context, the orders are transferences indicating resources required time and capacity of them. A solution is a set of control actions to mitigate the effect of a disruptive event.

In this approach we adopt the SCEMMA vision [4,5]. The following section shows how SCEMMA is instantiated in this problem.

4.1Model of main components of the approachSCEMMA vision [4, 5] defines an event management system for each relevant member of a supply chain in which agents are viewed as distributed and heterogeneous systems. This concept can be applied to the port logistics chain; for each of the stakeholders (importers, exporters, customs brokers, auditors, port authorities, shipping, land transportation companies, port terminal) the SCEMMA is instantiated but the instantiation process is not direct or else the model is adapted to specific domains. In particular, in this section the SCEMMA instantiation for a container terminal is presented. Figure 1 shows an example of instantiation.

According to the proposed SCEMMA, the effect of a disruptive event can be mitigated by distributing the variation between the members of the supply chain in a collaborative way.

Therefore, the CTEMS must interact with the Planning System. The CTEMS receives the plan to be managed and notifies when a plan has become unfeasible.

Similarly, the CTEMS is also related with the Execution Systems. The CTEMS receives events from the Execution System and notifies them of plan changes to respond to these disruptive events.

In some cases, the CTEMS establishes a coordination process with other event management systems members (Figure 1 shows the case of a trucking company) so as to look for a collaborative solution.

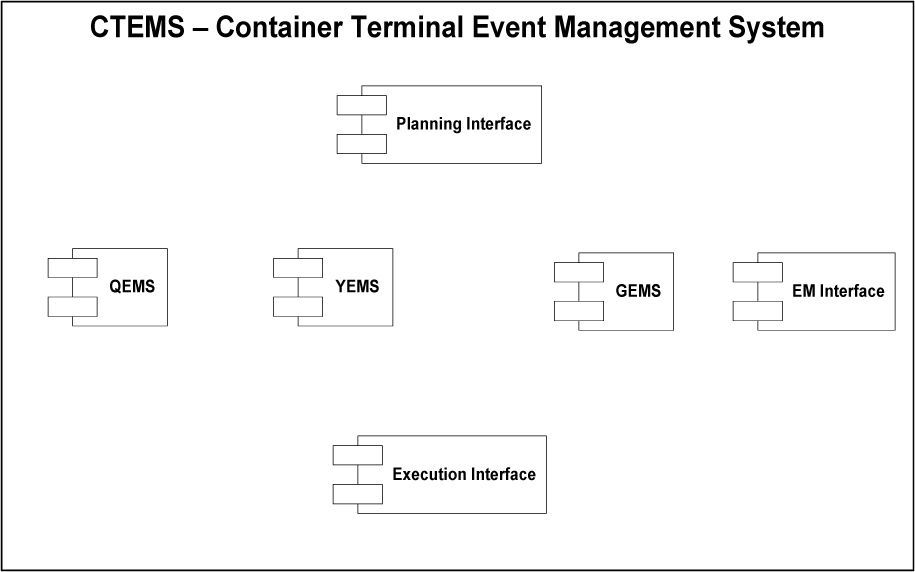

4.2Components of model CTEMSIn order to address the problem complexity and to respect the characteristics and functions of the different areas of a container terminal, the proposed solution is based on decomposing the CTEMS in different subsystems. The system architecture (Figure 2) is composed of six subsystems:

The Planning Interface is responsible for interacting with the container terminal planning system. The Planning Interface receives the quay plan, the yard plan, and the gate plan, and notifies the planning system of those disruptive events that have produced unfeasible results and a replanning is required.

The Execution Interface receives the events from the Execution System and notifies them to the adequate system. On the other hand, when a solution to disruptive event is found, the Execution Interface must notify the changes to the Execution System.

The EM Interface (Event Management Interface) is a subsystem that allows the interaction with the other members of the port logistics chain.

The QEMS (Quay Event Management System), YEMS (Yard Event Management System) and GEMS (Gate Event Management System) are event management systems specialized in a specific domain.

The QEMS Subsystem is responsible for managing the disruptive events that occur in the terminal quay. The main plan is based on the planning of the vessels, indicating for each one of the vessels changes of quays and the resources needed for loading and unloading. The major disruptive events are related to the variability of the arrival time and operation of the ships as well as problems with the resources and climate events, among others.

The GEMS subsystem is responsible for managing the disruptive events that occur in the gate terminal. The nature of this subsystem depends largely on the way the gate operates. One possible scenario is that the gate operation is based on scheduling systems for delivery and pick-up of containers. At the other extreme are the gates that operate based on the random arrival of the trucks, being able to present mixed-system scenarios that combine dates with random arrivals. The manner of operation determines, in some respects, the characteristics of the subsystem as the certainty varies. In general, regardless of how they operate, the resources involved in gate operations are sources of disruptive events.

YEMS is a subsystem that manages disruptive events at the terminal yard where containers are stored. The yard acts as a buffer between the quay and the gate hence any problem with one of these subsystems affect the operation. The main internal disruptive events are associated with the resources involved with the operations as well as with the containers and spaces used for storage. Furthermore YEMS must deal with events originating both at the quay and gate according to how they affect the plans.

Each is a multiagent system where there are specialized agents for each resource. For example, in YEMS are the crane agent, the truck agent, the container agent, and the block agent. These models were presented in different preliminary meetings with main stakeholders who validated these studies.

5Conclusions and Future WorkThe import and export services in the ports undoubtedly require great coordination and collaboration between the stakeholders involved in different processes, defining the efficiency of the service provided and, therefore, the value delivered to the client that requested it.

In this paper, we present the container terminal event management problem and a solution approach in the context of the port logistics chain. The proposal is based on the study of San Antonio Port and Valparaíso Port. The first step was to identify the main stakeholders related with the container terminal and the process. The next step was the identification of potential sources of internal disruptive events; these sources are the resources (crane, trucks, berth, etc.) in the container terminal. The external disruptive events are originated from the stakeholders involved.

The proposal developed in this work is to specify a collaborative system based on the interaction of event management systems for each of the parties in the chain, these systems are derived from the model proposed by Bearzotti et al. [4], [5]. This model is based on the perspective of multiagent technology to try to model complex control systems with heterogeneous autonomous parties and provide communication support collaboration between companies, which studied the chain delivery: visibility, strength, flexibility and agility.

In this first approach, we model a container terminal in the port logistics chain obtaining the CTEM model. This model has six subcomponents with specialized tasks, for example, YEMS which performs the event management process in the container yard. YEMS is a multiagent system consisting of the crane agent, the truck agent, the container agent, and the block agent; there is an agent for each relevant resource to manage.

The global behavior arises from the agents and component interactions following coordination protocols.

As future works are to develop and adapt the model instantiation SCEMMA [4][5] for each subsystem in CTEMS, another aspect to develop is instantiating SCEMMA for each relevant party in the port logistics chain, taking the specific characteristics of each domain. It is also important to implement systems based on these models and their integration with other proposals that seek to incorporate the concepts from supply chains-port logistics chains such as Demand Management, Vehicle Management, and Order Management [20] as these systems are natural sources of information about the plans that have been developed collaboratively as well as the execution of them. To conclude, there is a challenge in how to integrate these new systems with the proposed model with existing systems.