Cleft lip and palate (CLP) is the most frequent craniofacial defect. (1:1000 newborns). CLP patients present severe maxillary retrusion that require a surgical procedure to advance their maxilla. Distraction osteogenesis is an effective treatment; however available internal maxillary distraction devices present inconveniences.

ObjectiveTo design a biocompatible, inexpensive and mechanically efficient prototype of an internal maxillary distraction device. This device should be easy to place and comfortable for the patient.

MethodComputed tomography (CT) data of an adult CLP patient was obtained. DICOM files were processed and a stereolitographic (STL) model was printed. Computer aided design (CAD) software was used to design the device and to perform a finite element analysis (FEA) to evaluate the mechanical behavior of the appliance. Finally a prototype was manufactured by a computer aided manufacturing (CAM) process and tested on the STL model.

ResultsThis prototype complied with our requirements for an efficient internal maxillary distraction device.

ConclusionsThe integration of clinical knowledge with novel technology (CT, STL, CAD, FEA, and CAM) is very useful for the development of medical or dental appliances.

La malformación cráneo-facial más frecuente es el labio y paladar hendido (LPH), 1:1000 recién nacidos vivos. Estos pacientes presentan una severa retrusión de tercio medio facial que requiere de un procedimiento quirúrgico para avanzar el maxilar. La distracción osteogénica es una opción de tratamiento. Sin embargo, los distractores actuales presentan inconvenientes.

ObjetivoDiseñar un distractor maxilar intraoral, biocompatible, económico y de fácil colocación, que sea mecánicamente eficiente y cómodo para el paciente.

MétodoSe obtuvo una tomografía axial computada (TAC) de un paciente adulto con LPH, los archivos DICOM fueron procesados y a partir de estos datos se hizo un modelo de estereolitografía, en seguida se diseñaron las piezas mediante diseño asistido por computadora (CAD) y se realizó un análisis de elemento finito (FEA) del distractor para evaluar su comportamiento. Por último se realizó un prototipo físico mediante modelado asistido por computadora (CAM), el cual fue probado sobre el modelo de estereolitografía.

ResultadosSe logró el diseño de un prototipo eficiente, que cumple con los requisitos mecánicos y de operación.

ConclusionesLa integración de conocimientos clínicos y la aplicación de nuevas tecnologías de imagen clínica, prototipos rápidos, CAD, FEA y CAM son muy útiles para materializar diseños de uso médico.

Cleft lip and palate (CLP) is a congenital malformation that develops in the first few weeks of intrauterine life and consists in the lack of union of the palatal processes. In Mexico, from all newborn, 2 to 3% have some congenital malformation and from them, 15% have cleft lip and palate, so it is the most common craniofacial anomaly.1–3

The presence of cleft lip and palate causes a series of anomalies in the patient’s craniofacial growth, due in part to the presence of scars produced as a result of the surgical closure of the lip and palate. These scars cause midfacial growth restriction that affects mainly the upper jaw.4

Distraction osteogenesis, (DO) is the process of generating new bone in a gap between two bony segments as a response to the application of gradually applied force through the bone gap.

The technique for elongating bones was described in 1905 by Codivilla, who reported the elongation of a femur through the application of distraction axial forces.

Ilizarov in 1950 applied the DO technique to endochondral bone of the upper and lower extremities successfully for more than 35 years.

DO is divided into four stages, which are: osteotomy, latency, distraction and consolidation and is accompanied by the simultaneous expansion of the functional matrix of soft tissue, including blood vessels, nerves, muscles, skin mucosa, fascia, ligaments, cartilage and periosteum, this is called histogenic distraction.5

Rachmiel mentions that between 25 and 60% of patients with CLP develop maxillary hypoplasia that does not respond to maxillary orthopedic treatment or orthodontics and therefore requires surgical treatment; cleft lip palate patients have a greater tendency towards relapse after a Le Fort I advancement surgery than non- cleft-palate patients. Relapse is a disadvantage of the traditional method of maxillary advancement and rigid fixation. It occurs especially when the maxillary advancement includes the lowering of one or both segments maxillae. An alternative is distraction osteogenesis (DO) because after the sixth week from a started DO maxillary procedure, bone neoformation can be seen in the area of the pterygoid processes which at the end of the treatment makes the result stable and makes unnecessary the use of bone grafts thus eliminating possible complications in both the donor site as well as in the recipient.

Another significant advantage of maxillary DO is that the soft tissue profile substantially improves thanks to the anterior projection of the nasal tip and the nasolabial angle correction. Regarding the velopharyngeal function, in general, it is not affected in less than 15 advancements.6

The stability of the internal distractors is a very important point to be taken into consideration since, without it, the formation of a fibrous union or pseudoarthrosis in the site of the distraction can be caused. Cheung conducted a study which assessed by means of tomographic slices the thickness of the bone in 5 different maxillary regions (paranasal, infraorbital, back wall of the maxillary sinus, the alveolar and zygomatic region) to subsequently perform mechanical tests on animal bone specimens about the force required to dislodge a miniplate. The compared screws were 1.5 and 2 in diameter, 3 were used for each miniplate and were tested in 2 configurations, triangular and straight.

At the end of the study, it was concluded that the paranasal and zigomatic regions were the best to establish a maxillary anchorage and the 2 diameter screws were preferable to the 1.5mm. Miniplate configuration showed no significant difference.7

Today many authors agree that internal distractors are better than external for the patients because they are discrete, however, this type of distractors are difficult to place and their distraction vector cannot be changed as in the external devices. Internal appliances have advantages in terms of aesthetics since they are less noticeable and hinder less during sleep hours. Their main disadvantage is that they restrict oral function when eating and talking, maintaining oral hygiene also becomes more complicated.

Kebler et al. reported in 2001 the use of internal maxillary distractors in four patients with maxillary retrusion. The appliance of choice was the Zurich pediatric ramus distractor which has some extensions for activation that were placed behind the lips causing injuries and discomfort. The obtained results were advancements between 7 and 14 without relapse in post-distraction control, the need for excellent hygiene to avoid infections is highlighted, and it was mentioned that the withdrawal of the device is sometimes more complicated than its placement. The authors also refer to the need for orienting the distractors correctly at the time of their placement.8

In relation to the problems for distraction vector positioning and adjustment, Yamayi et al. in 2004, designed in Houston an internal maxillary distractor located inside the maxillary sinus, making it easy to achieve parallelism with the axis of distraction, however, a second surgery is necessary for the withdrawal of the appliance. In their study, a 15.5 advancement and an absence of relapse are reported.9

Van Sickels in 2007 reported the use of an internal distraction design and its placement in 10 patients. Although it was the same design, some distractors were made from titanium and others from stainless steel. This did not seem to have made any difference. Among complications that occurred during treatments the author noted that in one case there was a lack of union of the bony segments, in two other cases, unacceptable occlusal results. Other minor complications were loosening of the device and pain.

Among his conclusions it was also mentioned that the manufacture of stereolitographic models helps reduce operating room time, makes it easier to position the device and helps determine distraction vectors with greater precision. He also mentions that changes in the device design would help make the use of distractors more comfortable.10

ObjectiveThe aim of this study was to design a maxillary intraoral distraction device that requires a single surgery for its implantation and operation, that the withdrawal is easy and that does not require a second surgery; that it accomplishes advances of up to 20, that is flexible in terms of its distraction vector and that its volume is smaller than other distractors.

MethodsFrom a hospital population, an adult patient was selected who had a cleft lip and palate and a 12- unilateral maxillo-mandibular discrepancy. He also showed permanent dentition with appropriate arch shape for a maxillary advancement (Figure 1)

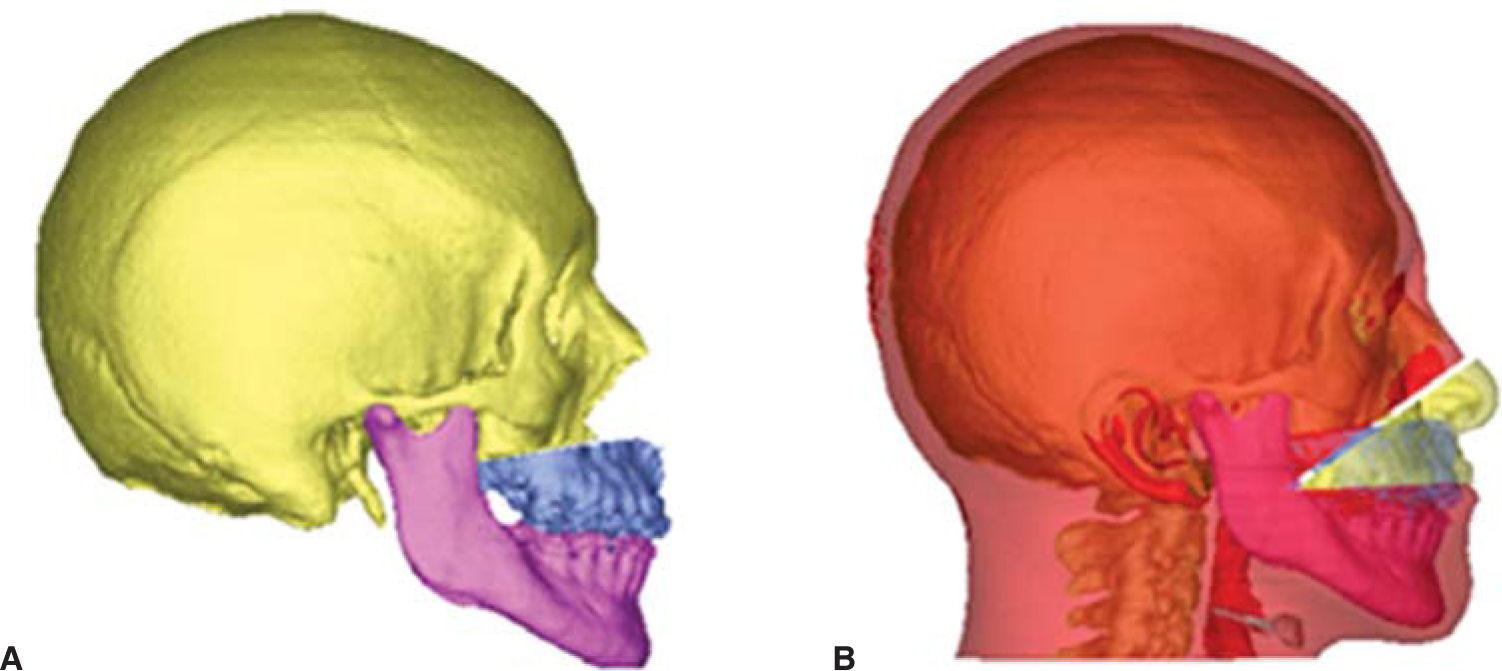

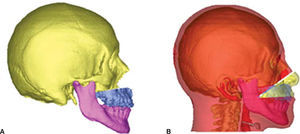

A cranial tomography of the selected patient was obtained (Helical Computed Tomography Somatom Plus 4 from Siemens, Germany) with 1 slices and a virtual three dimensional reconstruction of the skull was made by processing the tomograph DICOM files using the software (Mimics 8.11 Materialise). Belgium). In the reconstruction a Le Fort I osteotomy and maxillary advancement was simulated (Figure 2).

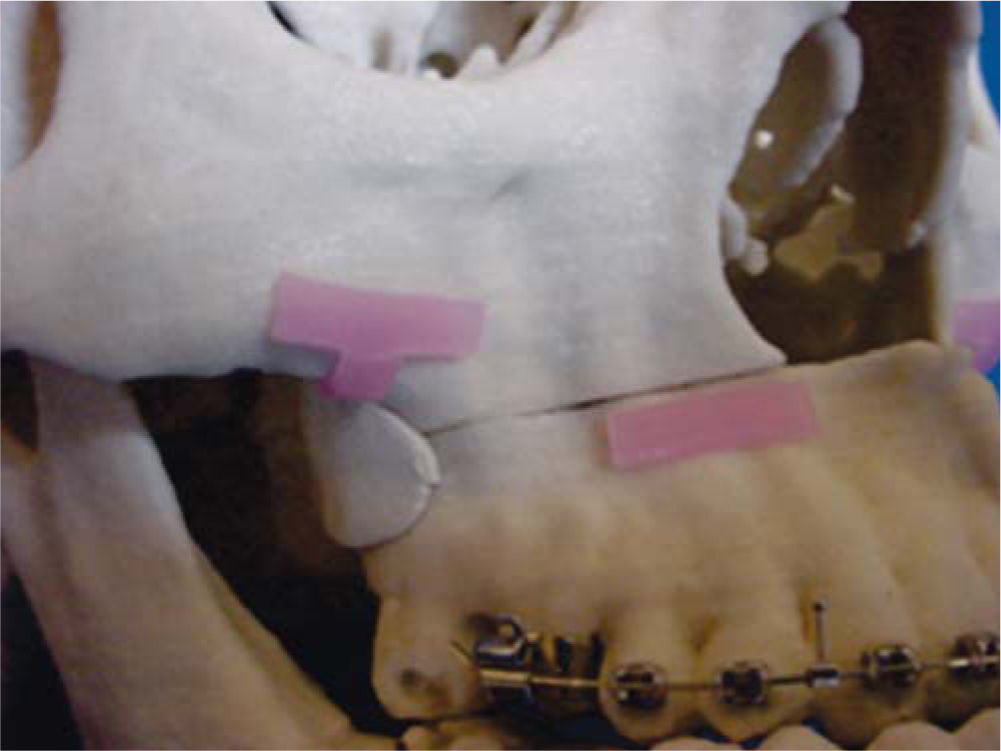

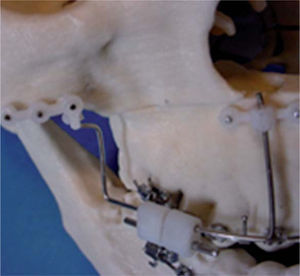

After taking this, a three dimensional model of the patient’s skull was printed using a calcium sulfate- based Stereolithography (Z310 Z Stereolithograph - corp, United States) and over the three dimensional physical model of the patient’s skull with the osteotomies made and the mandible separated, it was proceeded to build a wax prototype (Pink Wax Filenes, Mexico) to estimate the size and spaces that the anchors of the distraction device were to occupy always taking into consideration the information obtained from CT scans regarding the sites of increased bone density (Figure 3).

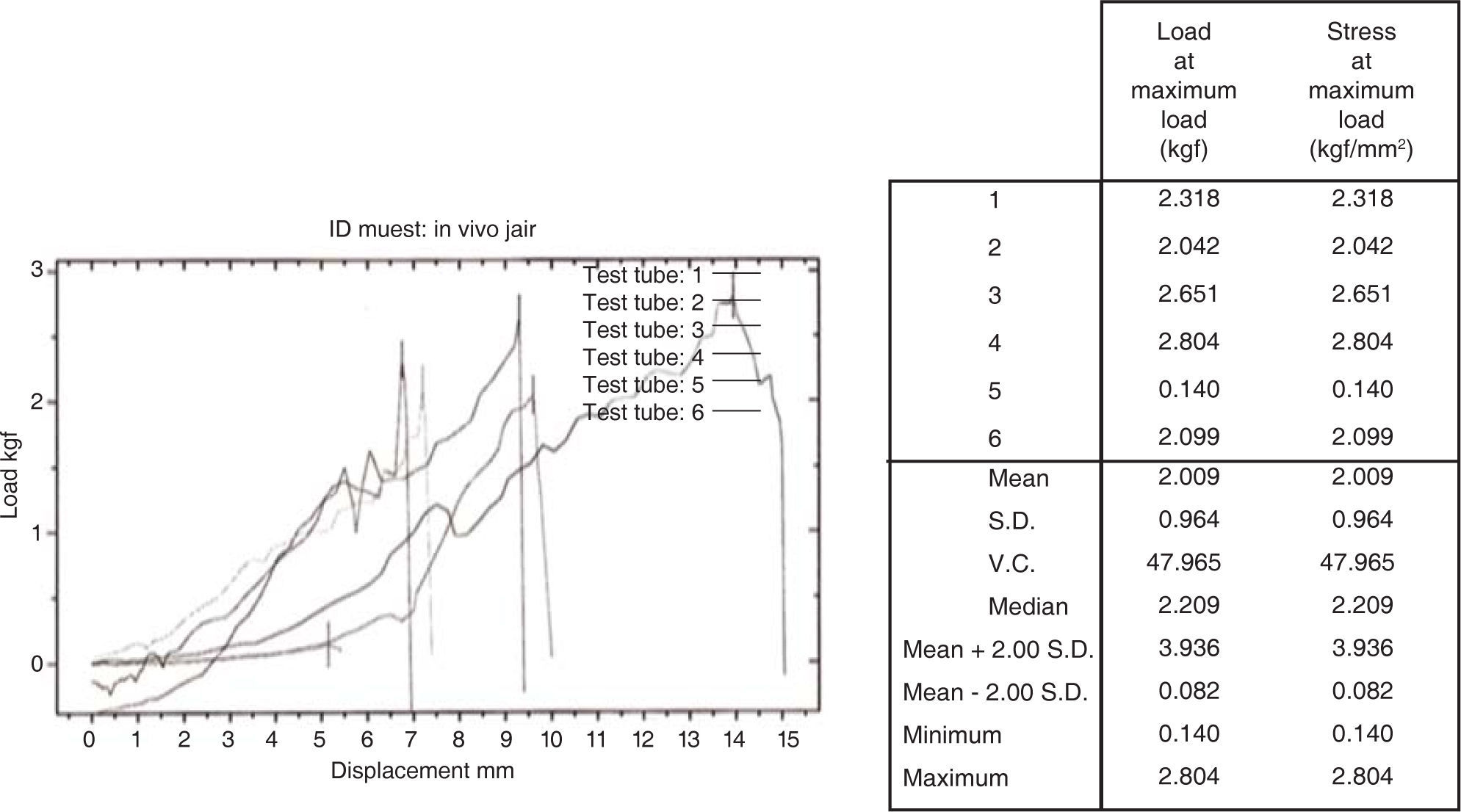

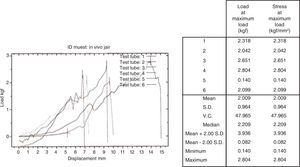

With the aim of having an approximate quantity of the stress magnitude that our design would have to endure with the help of a universal testing machine (Instron, England) and a buccal shield, a stress test was performed in order to calculate the maximum resistance that the perioral musculature might exert over the distraction device (Figure 4).

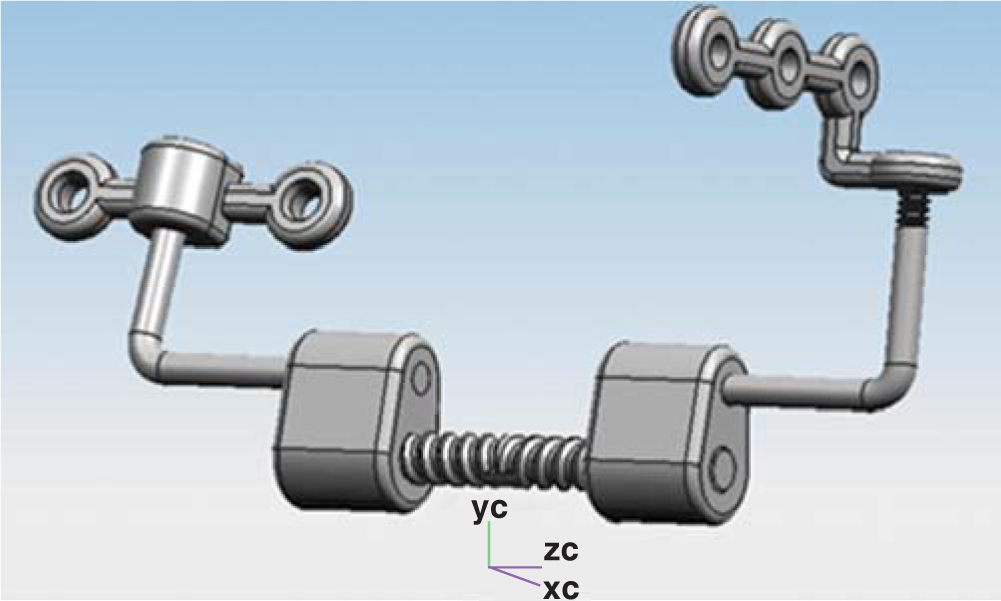

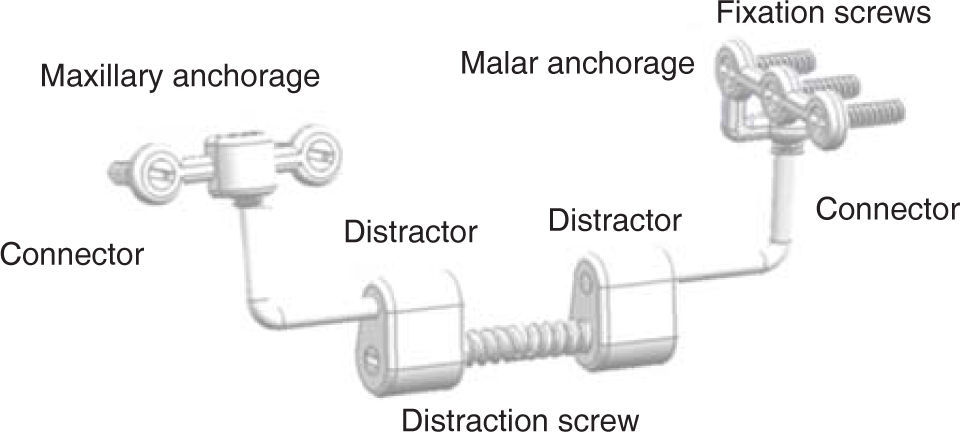

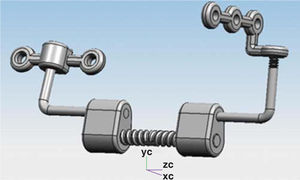

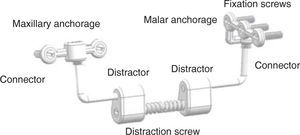

Once the distraction device size was calculated, planes and tridimensional virtual reconstruction were made with the aid of a CAD system (NX3, UGS, U.S.A.) (Figure 5).

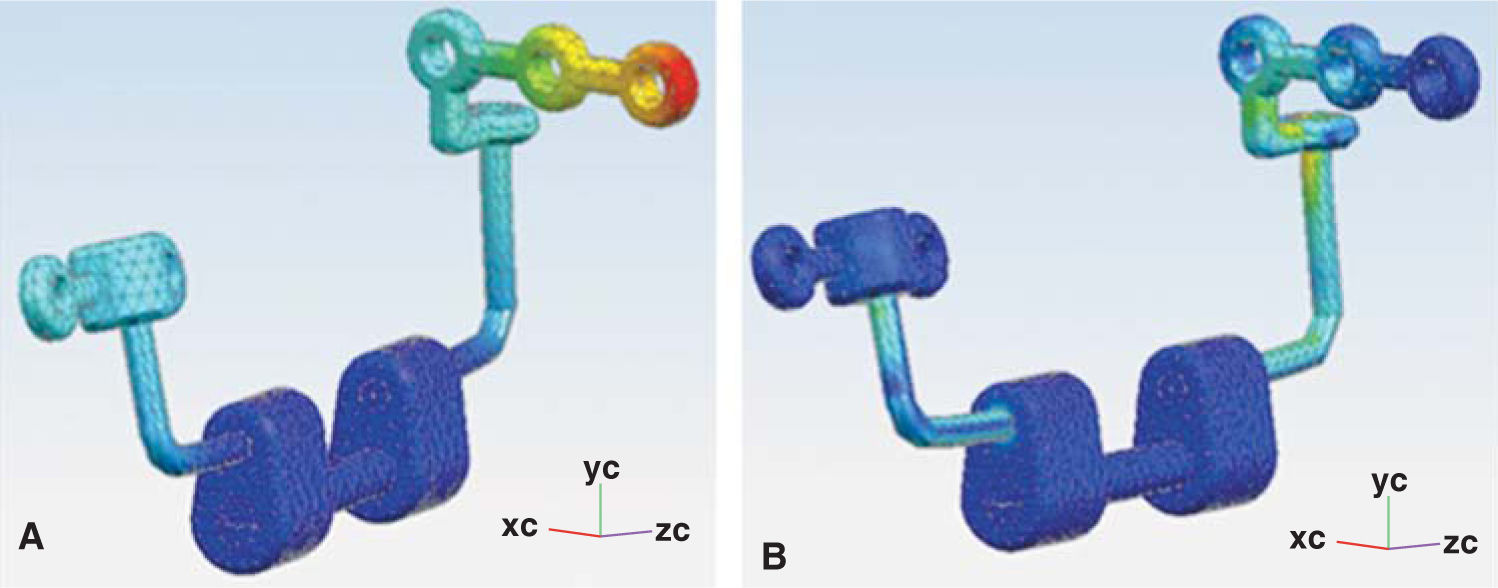

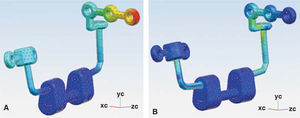

Upon finishing the three dimensional model with all its parts separate, to each of its parts it was assigned the mechanical properties of a Ti-6Al-4V alloy and subsequently by means of a specialized software (UGS NX3, United States) a finite element analysis (FEA) was carried out where the operation of the appliance under load was simulated t (Figure 6).

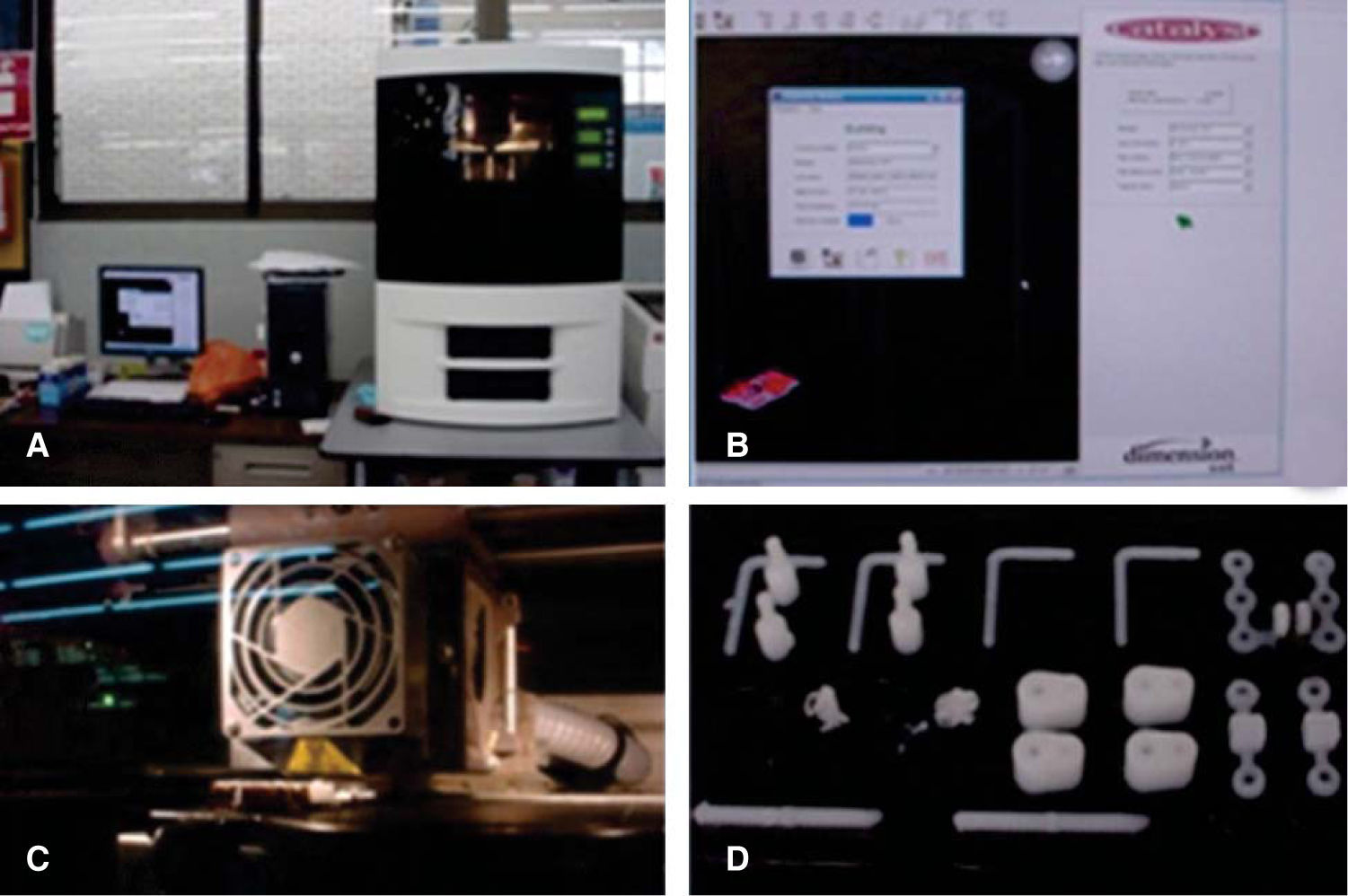

Once the FEA assessment was satisfying, the fabrication of the definitive prototype was carried out by means of a machine for fast prototypes: Fused Deposition Modelling (FDM) (Stratasys, Dimension sst. U.S.A.) (Figure 7).

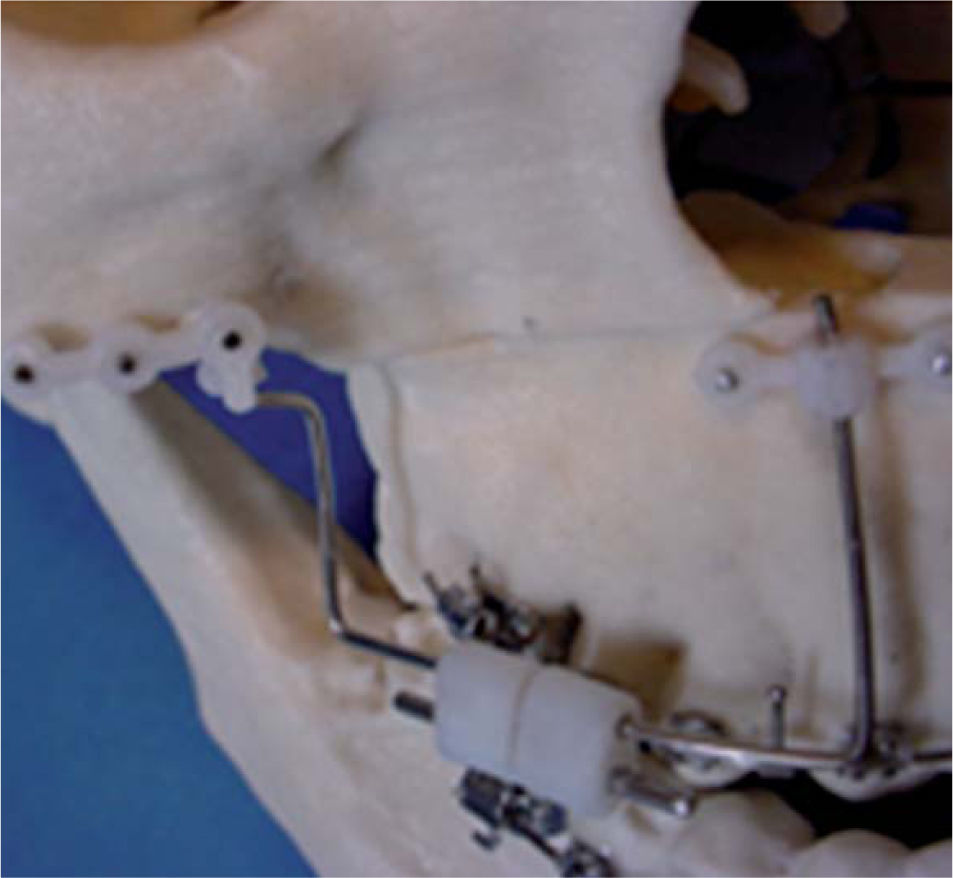

Finally, the definitive prototype was put to the test mounted on the stereolitographic model previously manufactured to assess its in vitro performance and evaluate its behavior with regard to distraction vectors (Figure 8).

ResultsIn the present study results were divided in three parts since it presents results derived from the virtual design phase of the maxillary distraction device, results of its displacement and stress both obtained by finite element analysis and another group of results derived from the assessment of the behavior of the physical prototype.

In order to provide an estimate of the magnitude of stress that our design must be capable of enduring, a stress test was carried out by means of a universal testing machine and an oral screen, to calculate the maximum resistance that the perioral musculature can oppose to the advancement provided by the distraction device (Figure 9).

According to the bibliographical review and to the information obtained from the computed tomography, anchorage was designed to be placed on the sites of increased bone density to prevent evictions or loosening of the distraction device and thereby ensure a good function. Round forms were also selected to avoid friction with oral teguments (Figure 10).

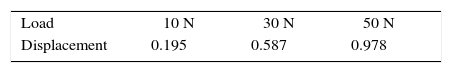

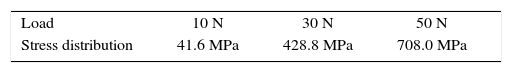

The results from the finite element analysis for displacement and stress distribution are summarized in the tables IandII. The range of 10 N is where we think the distractor will work under normal conditions, 30 N is the maximum that perioral musculature can oppose to the anterior displacement of the maxilla and 50 N is the over-designed parameter that provides for some extreme situation.

According to the results of the FEA for displacement, the part of the distraction device that could exhibit a larger displacement is the distal portion of the malar anchorage, however, at 10 N a 0.195 displacement is of no clinical relevance and at50 N wherethere isadisplacement of 0.978 it would have to be considered that precisely in that site, there is a fixation screw that would prevent displacement. However, an eviction of the appliance would not happen since the fixation screws are longer than that amount of displacement (Table I).

Once the distractor was validated virtually from the mechanical point of view, the next step was to manufacture a prototype by using the Fused Deposition Modeling (FDM) technique. Subsequently, the prototype was assembled and mounted in the model to make in vitro stereolitographic tests to assess the behavior of the distraction device (Table II).

Due to the connections between the connectors and the malar anchorage, it is possible to achieve a 180° motion of the distractor in a horizontal direction. Obviously, this movement is limited by soft tissues, however, from a clinical point of view the possibility of this movement is very useful in a case that requires transverse expansion of the maxillary segments. In the sagittal direction, the distractor proved to be capable of allowing a tilt movement of 20°, which from a clinical point of view is useful for cases where it is necessary to lower the maxillary segments or to make a slight expansion for better stability. In terms of advancement magnitude, it was possible to accomplish an advancement of 20. This amount of advancement allows the correction of the vast majority of patients with maxillary retrusions or hypoplasia.

ConclusionsThe design of the internal maxillary distractor appliance for patients with cleft lip and palate called J1, under the methodology in this study, is the result of the clinical observation of patients who require maxillary advancement, of the conviction that distraction osteogenesis is the best method so far for these treatments and of the inquiry of the virtues and shortcomings of existing devices. All this combined with a formal and sophisticated process of virtual design, a finite element analysis considering biocompatible materials, rapid prototyping techniques, computerized tomography, stereolithography and other resources has provided the design of a promising appliance that apparently overcomes the disadvantages of current distraction devices.