The purpose of this study was to determine the quality of the size of 0.018”×0.025” slots in brackets of three trading companies (3M, GAC and ORMCO).

Methods120 first premolar stainless steel brackets of three trading houses were analyzed forming three groups of 40 brackets. Each bracket was observed under a Profile Projector Microscope. Three measurements were obtained for each slot: depth, internal and external height. The data were tabulated and statistically analyzed by the ANOVA test and the Student’s t test.

ResultsThe results showed that there were statistically significant differences in depth and internal and external height between the bracket’s slot of 3 different companies (p < 0.05). The companies 3M and GAC fulfilled the manufacturer’s specifications (p < 0.05). In terms of internal height, GAC complied with the manufacturer’s specifications (p < 0.05). In relation to external height, ORMCO complied with what is specified by the manufacturer (p < 0.05).

El propósito de este estudio fue determinar la calidad del tamaño de ranuras 0.018”×0.025” en los brackets de tres casas comerciales (3M, GAC y ORMCO).

MétodoSe analizaron 120 brackets de acero inoxidable de los primeros premolares superiores de tres casas comerciales, conformando tres grupos de 40 brackets. Cada bracket se observó en un microscopio proyector de perfiles. Se obtuvieron tres medidas por cada ranura: profundidad, altura interna y externa. Los datos fueron tabulados y analizados estadísticamente por medio de la prueba de ANOVA y t de Student.

ResultadosLos resultados demostraron que existen diferencias estadísticamente significativas en profundidad, altura interna y externa de la ranura de brackets de las tres marcas comerciales (p < 0.05). La 3M y la GAC en profundidad cumplieron con lo especificado por el fabricante (p<0.05). En términos de altura interna la GAC cumplió con lo especificado por el fabricante (p<0.05). En cuanto a la altura externa de la ORMCO cumplió con lo indicado por el fabricante (p < 0.05).

Tridimensional orthodontic tooth placement occurs as a result of the interaction between the arches and preadjusted brackets that are cemented on teeth within healthy support tissues.1–3

Little has been talked about the quality in manufacture and tolerance of the slots of different bracket systems and how this situation affects orthodontic treatments. Orthodontists should then be aware that the preadjusted brackets and wires extensively used in clinical practice may not produce the tridimensional control required for an acceptable result. This may be particularly evident in cases that require tipping correction of an incisor, and the clinician should be aware that you must add additional torqueing force to the arch to compensate for the incorrect dimensions of bracket manufacture, clearly reducing simplicity and effectiveness in the use of a straight wire in a preadjusted system.

The effects of anterior torque force loss with brackets with a bigger than necessary slot size were illustrated by Siatkowski, who noted that maxillary and mandibular incisors may suffer an unexpected loss of torque force of 5-10°, and this is compared to 1.9 millimeters of lingual retrusion during retraction to close residual spaces.4

Creekmore and his team demonstrated that the results of the tolerance measurements on the slot height of brackets from the company Unitek, varied the torque between the different sizes of archwires on the two sizes of slot: .018” and .022”.5

Likewise, Sebanc observed under a microscope the slot tolerance of .018” and .022” brackets as well as the characteristics of the wall surfaces of the slots on both brackets demonstrating that all slots were found to be larger than what is specified by the manufacturer.6

Tolerance in manufacturing can affect the angle of deflection and therefore torque; the manufacturers of orthodontic appliances usually do not provide their tolerances and do not inform orthodontists of the smoothness of slot walls, of which there are few reports.7

Torstein developed a method for effectively measuring the slot height in a bracket and showed that the variation in slot height was much larger than established.8 The same is true for Kusy and Whitley, who examined 24 brackets of eight different manufacturers and also found variations: the slots of three brackets were smaller, and for the other 20, the dimensions were larger than described by their manufacturers.

The largest slot of .018 inches measured 16% more than indicated, and the largest slot of .022 inches measured 8% more than what is established.9 Cash also concluded, as a result of a study, that all the measured bracket slots are larger than what was said by the manufacturers and he also found that there was variation in slot geometry from one brand to another.

In orthodontics, the placement of the maximum prescription wire in a preadjusted bracket produces tridimensional forces of tooth movement. These forces are provided as a result of the intimate union between wire and slot in the bracket and some spacing between these two components may lead to an alteration in the incomplete transmission of the bracket prescription.10

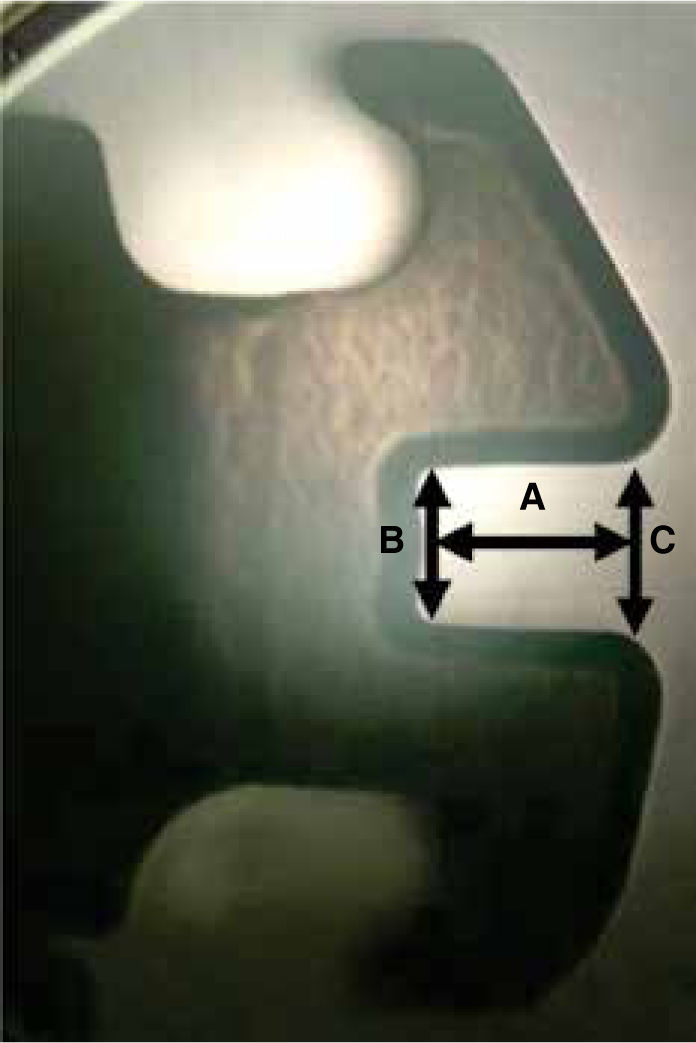

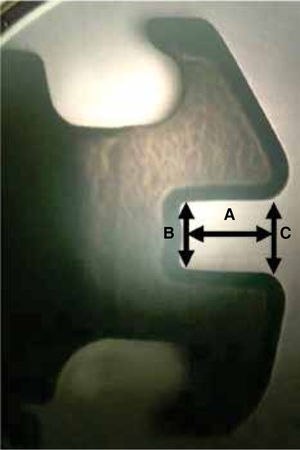

Materials and methodsOne hundred and twenty stainless steel brackets selected randomly (40 3M Unitek brackets, 40 Ormco brackets and 40 GAC brackets) were analyzed. All brackets were used for upper right premolars. Each bracket was fixed on its left side, on top of a plastic surface (clay). They were observed under the lens of the Profile Projector microscope (Nikon, Model V-16D with serial number 77507) of the Center for Applied Sciences and Technological Development of the UNAM, in such a way that when observed from above the slot could be seen clearly defined, without wall interferences from the same slot. All measurements were made with an increase of 100x. When placing the bracket over the plate, an image divided by X and Y coordinates was projected in the projector screen.

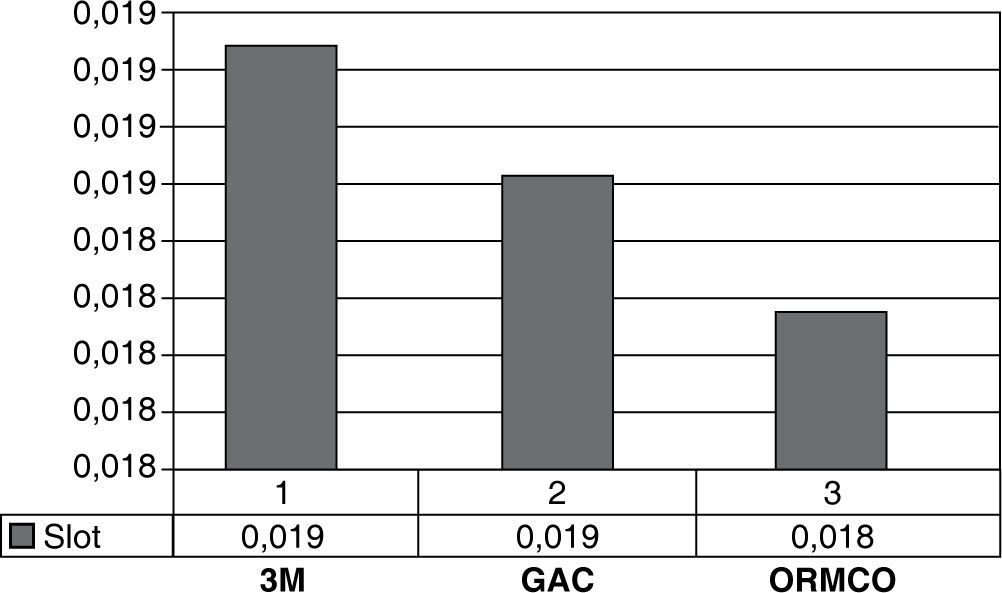

The image was carried to the coordinate intersection through the special handles of the projector designed for that matter. Three measurements were obtained for each slot: depth, internal height and external height (Figure 1). Each measurement was obtained in millimeters and subsequently converted to thousandths of an inch.

A direct measurement was performed by the researcher. The data were tabulated mechanically by means of the computer and the Excel program and were statistically analyzed with the ANOVA test and the Student’s t test.

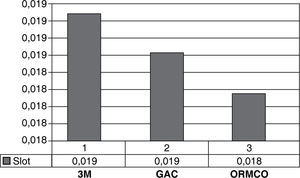

ResultsThe results were analyzed using ANOVA and it was determined that there were statistically significant differences in terms of the brackets’ slot depth in the 3 brands (p < 0.05). Statistically significant differences in the internal and external height of the bracket slot for the 3 brands (p < 0.05) were also determined, indicating that the three brands are different among themselves with regard to the measures of the assessed dimensions.

By means of the Student’s t test each obtained measurement was compared with its gold standard and the following results were obtained: In terms of depth no statistically significant difference was found so the slot in the 3M bracket did meet with the manufacturer’s specified measurements (p < 0.05).

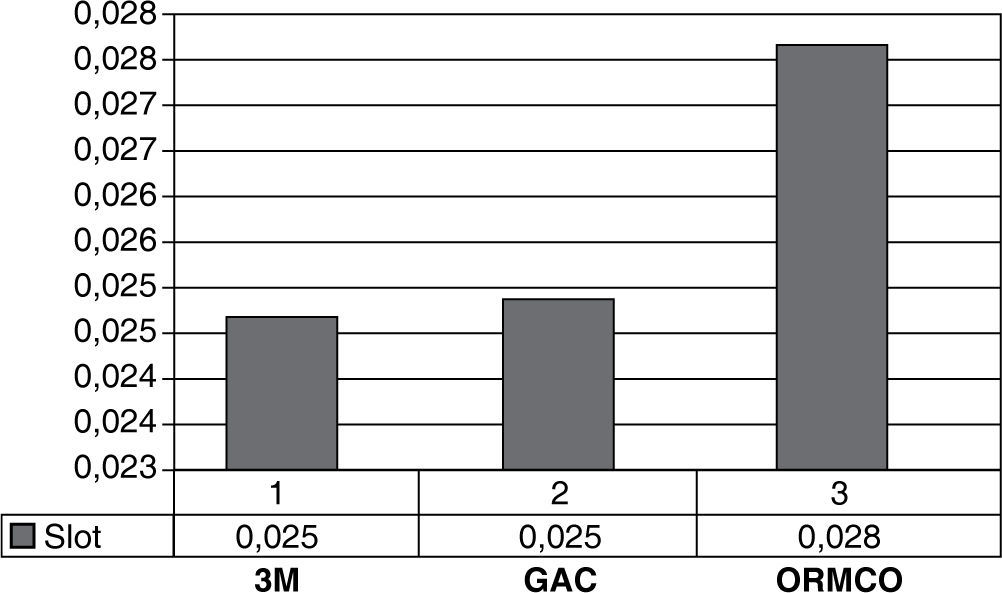

Similarly, it was noted that the GAC brand showed no statistically significant differences (p < 0.05) so it also complies with the standards of depth measurement, on the other hand, the ORMCO brand did show statistically significant differences thus it did not meet the criteria specified by the manufacturer in terms of depth (p < 0.05).

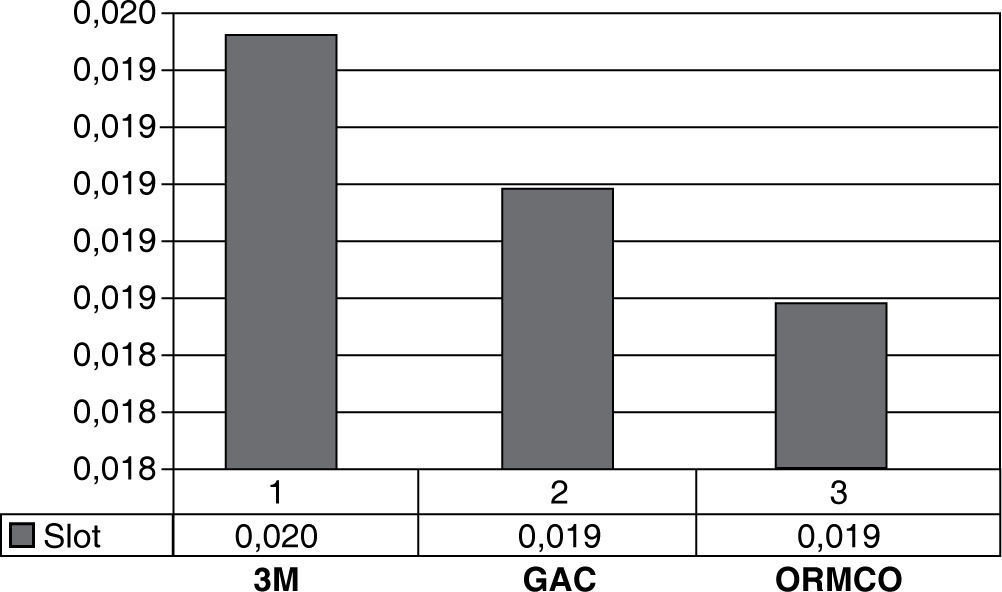

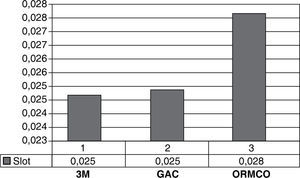

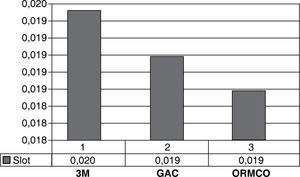

Regarding the internal height of the 3M and the ORMCO slot statistically significant differences were identified, which is why they do not comply with the measurements specified by the manufacturer in this assessment (p < 0.05). On the other hand, the GAC brand showed no statistically significant difference in relation to internal height so it did meet with the manufacturers specifications (t=1.00, p < 0.05).

As to the external slot, 3M and GAC showed statistically significant differences, thus they did not comply with the measurements specified by the manufacturer in this regard (p <0.05).ORMCO,incontrast, did not show a statistically significant difference so it can be declared that in relation to external height it did meet with the manufacturer’s indications (t=0.07, p < 0.05).

Figures 2-4 show the averages of each dimension measured in the three brands.

Tridimensional orthodontic tooth placement occurs as a result of the interaction between arches and brackets, any lack of contact between these two components may lead to an alteration of incomplete transmission of the bracket prescription.1–3,10

Torque angulation in preadjusted appliances is of great importance during orthodontic treatment in order to improve root angulations.

With the obtained results it can be suggested that in terms of slot depth and height, the three companies assessed (3M, GAC and ORMCO) showed broader dimensions than indicated by themselves, in agreement with the results reported by John Sebanc,6 Torstein and Meling,7 Kusy9 and Cash10 in their respective investigations.

In a treatment that is almost entirely dependent on the accuracy of appliances, it is disappointing to find that, in some cases, the orthodontists’ tools can be manufactured in an inaccurate way, which may result in treatments with deficiencies in finishing in relation to dental torque as was described by Siatkowski,1 Creekmore3 and Torstein7 in each one of their studies.

ConclusionsThe results of this study indicate that the slots in the brackets of the three companies are larger than what is prescribed by the manufacturers, so dimensional control of the tooth can be compromised, especially in the expression of torque. The clinician should be aware that there may be a loss of tooth control as a result of the use of brackets with larger slot size.