This study evaluated the surface roughness and morphology of microfilled (Durafill VS) and nanohybrid (Evolu-X) composite resins submitted to different finishing/polishing systems, with or without further additional polishing.

Methods70 specimens were fabricated and distributed to 14 sample groups (n=5 per group). The Mylar strip (MS) was the control group. Sof-Lex Pop-on (SP) and Praxis TDV (PTDV) were finishing/polishing systems used in the experimental groups. Additional polishing was performed with either a felt disc moistened with diamond paste (FP), or just a silicon carbide brush (SCB). Roughness (Ra) was measured and scanning electron microscopy (SEM) images were obtained. Data were subjected to two-way ANOVA and Tukey (p<0.05).

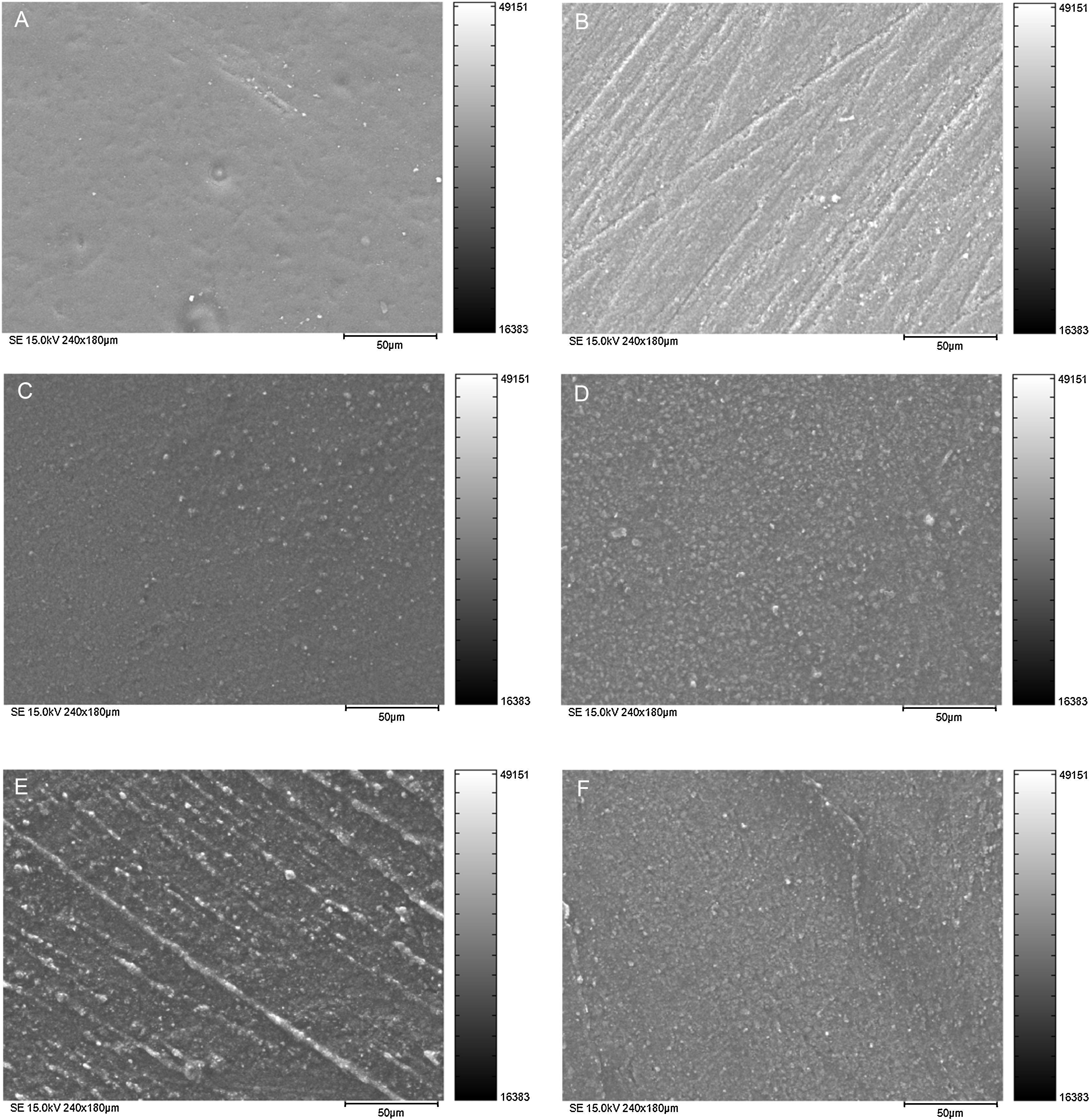

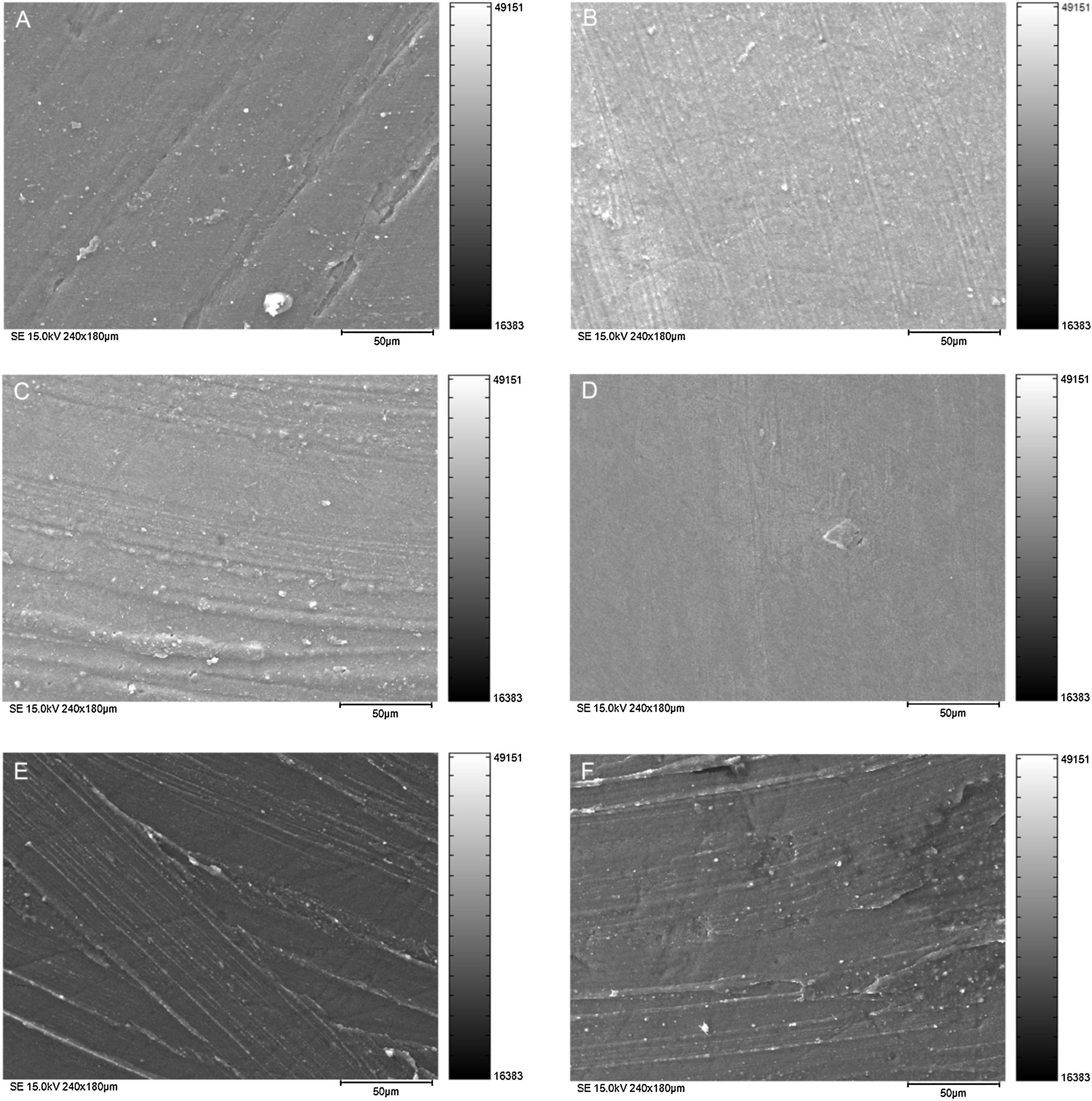

ResultsThe SP (0.186 and 0.250μm) finishing/polishing systems produced a smoother surface compared with a PTDV (0.208 and 0.296μm). The Evolu-x (EVO) resin showed lower roughness. After the additional polishing with FP, there was no difference between the resins tested and values of roughness. SEM suggests smoother Durafill VS (DUR) surface when polishing is carried out with PTDV+FP. SP provided an Evolu-x surface with fewer grooves and scratches. Evolu-x surfaces treated with PTDV and SP+SCB had a more irregular topography.

ConclusionFurthermore, the FP offered a smoother and uniform texture to the surface of both resins independent of the previous treatment. The SCB offered a smoother texture to the surface of the DUR resin than EVO.

Este estudo avaliou a rugosidade da superfície e morfologia de resinas compostas, microparticulada (Durafill VS [DUR]) e nano-híbrida (Evolu-X [EVO]), submetidas a diferentes sistemas de acabamento/polimento, com ou sem polimento mais adicional.

MétodosSetenta espécimes foram fabricados e distribuídos para 14 grupos de amostras (n=5 por grupo). A tira de poliéster (MS) foi o grupo controlo. Sof-lex Pop on (SP) e Práxis TDV (PTDV) foram os sistemas de acabamento/polimento utilizados nos grupos experimentais. Polimento adicional foi realizado com disco de feltro com pasta de diamante (FP) ou somente escova de carboneto de silício (SCB). Rugosidade (Ra) foi medida e imagens foram obtidas através de microscopia eletrónica de varredura (MEV). Os dados foram submetidos a ANOVA de 2vias e de Tukey (p<0,05).

ResultadosO sistema SP (0,186 e 0,250μm) de acabamento/polimento produziu uma superfície mais lisa em comparação com um PTDV (0,208 e 0,296μm). A resina EVO mostrou menor rugosidade (0,186 e 0,208μm). Após o polimento adicional com FP, não houve nenhuma diferença entre as resinas testadas e os valores de rugosidade (p<0,05). SEM sugeriu uma superfície mais lisa na DUR quando o polimento foi realizado com PTDV+FP. O sistema SP forneceu para EVO uma superfície mais uniforme, com menos sulcos. No entanto, as superfícies tratadas com PTDV e SP+SCB tinham uma topografia mais irregular.

ConclusãoO FP ofereceu uma textura mais lisa e uniforme sobre a superfície de ambas as resinas, independente do tratamento anterior. O SCB ofereceu uma textura mais lisa para a resina DUR do que para a EVO.

A variety of materials are developed to improve polishing and longevity of composite resin restorations. This situation is desirable for dentists and patients because most smooth surfaces prevent biofilm accumulation, gingival irritation, secondary caries and color change.1–3

In esthetic situations, microfilled and nanohybrid composite resins can be used.4 In addition to the concentration and type of filler particles, the monomers present and finishing systems/polishing used are variables that may influence the final surface polishing of composites.5–10 Several studies show that the smoother surface of a resin composite is obtained by Mylar strip,11–17 but the dental anatomy hampers its use. Therefore, some products are commercially available for finishing and polishing, such as burs, rubber, and abrasive discs (containing diamond, aluminum oxide or silicon carbide), which are capable of providing a smooth surface.18–22 Recently, silicon carbide brushes emerged in the market to be used as a final/additional polishing method in composite resins. However, it is not known if additional polishing using silicon carbide brush is able to reduce the surface roughness of microfilled and nanohybrid composites.

This study evaluated the surface roughness and morphology of microfilled and nanohybrid composite resins submitted to different finishing/polishing systems, with or without further additional polishing. The null hypothesis was that there would be no significant differences in surface roughness and morphology of each composite tested after additional polishing.

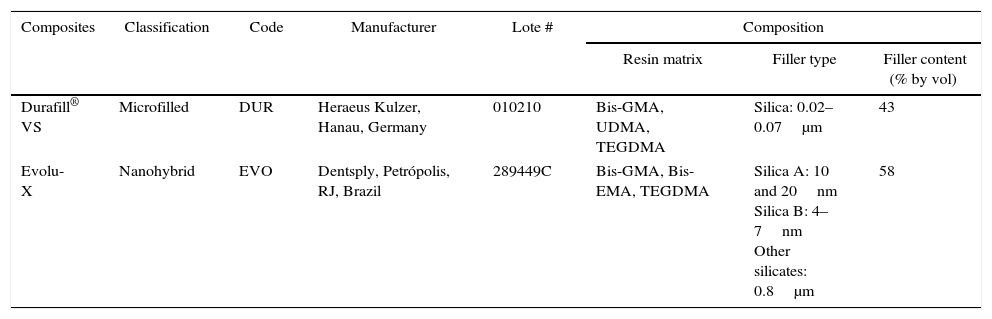

Materials and methodsTwo composite resins were used in this study. The first was microfilled (Durafill VS, Heraeus-Kulzer, Gruner Weg, Hanau, Germany) and the other was a nanohybrid resin (Evolu-X, Dentsply, Petrópolis, RJ, Brazil). The chemical components of these composites are listed in Table 1. A single operator fabricated 35 circular specimens (8mm diameter, 2mm height) per composite. A Teflon custom mold was placed on a glass plate and filled with composite. Verification of curing light intensity was performed by the radiometer Demetron (Kerr/Sybron Dental, USA). It was positioned vertically the active tip of the curing light on the central part of the photosensitive area of radiometer and ligated for 20s. After, the composite surface was then covered with a Mylar strip and photoactivated for 20s with a Coltolux light-emitting diode (1264mW/cm2 irradiance; Coltène/Whaledent, Altstätten, Switzerland). The 70 specimens were removed from the mold and stored in plastic containers containing distilled water at 37°C for 24h before finishing/polishing procedures and distributed to 14 sample groups (n=5 per group).

Characteristics of the composite resins.

| Composites | Classification | Code | Manufacturer | Lote # | Composition | ||

|---|---|---|---|---|---|---|---|

| Resin matrix | Filler type | Filler content (% by vol) | |||||

| Durafill® VS | Microfilled | DUR | Heraeus Kulzer, Hanau, Germany | 010210 | Bis-GMA, UDMA, TEGDMA | Silica: 0.02–0.07μm | 43 |

| Evolu-X | Nanohybrid | EVO | Dentsply, Petrópolis, RJ, Brazil | 289449C | Bis-GMA, Bis-EMA, TEGDMA | Silica A: 10 and 20nm Silica B: 4–7nm Other silicates: 0.8μm | 58 |

Bis-GMA, bisphenol A glycidyl dimethacrylate; UDMA, urethane dimethacrylate; TEGDMA, triethylene glycol dimethacrylate; Bis-EMA, bisphenol A ethoxylate dimethacrylate.

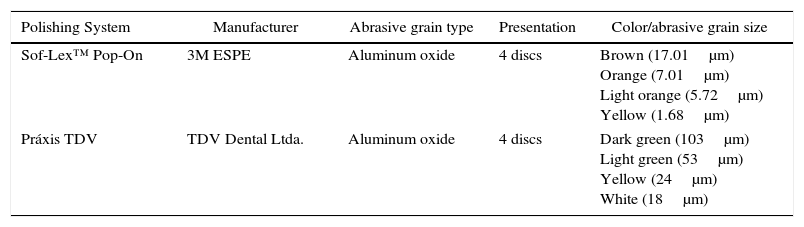

First, 5 samples of each resin were separated as control. For the remainder, the aluminum oxide discs Sof-Lex Pop-On (3M ESPE Dental Products, St. Paul, MN, USA) and Práxis TDV (TDV Dental Ltda., Pomerode, SC, Brazil) were used, then two additional polishing materials: Felt Discs (TDV Dental Ltda.), Diamond Gloss™ polishing paste (KG Sorensen, Sao Paulo, Brazil and a Silicon Carbide Brush – Astrobrush™ (Ivoclar Vivadent, Amherst, NY, USA) (Tables 1–3). The specimens were divided into groups according to resin type and finishing and polishing systems (n=5 per group).

Characteristics of finishing/polishing systems.

| Polishing System | Manufacturer | Abrasive grain type | Presentation | Color/abrasive grain size |

|---|---|---|---|---|

| Sof-Lex™ Pop-On | 3M ESPE | Aluminum oxide | 4 discs | Brown (17.01μm) Orange (7.01μm) Light orange (5.72μm) Yellow (1.68μm) |

| Práxis TDV | TDV Dental Ltda. | Aluminum oxide | 4 discs | Dark green (103μm) Light green (53μm) Yellow (24μm) White (18μm) |

Characteristics of additional polishing systems.

| Polishing system | Manufacturer | Abrasive grain type | Presentation |

|---|---|---|---|

| Dimond paste (Diamond Gloss™) | KG Sorensen | Nanoparticles of diamonds | Syringe (2g) |

| Silicon carbide brush (Astrobrush™) | Ivoclar Vivadent, New York, USA | Silicon carbide particles | Brush (7mm diameter) |

All the specimens from groups 2, 3, 4, 9, 10 and 11 received treatment with SP, from coarse grains to fine grains, in a total of four grains applied for 30s. The same procedures were applied for the groups 5, 6, 7, 12, 13 and 14, with PTDV. Each disc was used for only one specimen, washed with air/water spray to remove residues, and dried by air jet. The specimens were subjected to Ultrasonic Cleaner (Unique, Sao Paulo, Brazil; 25kHz power, 120W frequency) at the end of the finishing process for 3min between the uses of progressively smoother discs to remove particles left by the previous disc. Only groups 3, 6, 10 and 13 were subject to additional polishing with FP, and groups 4, 7, 11 and 14 with SCB.

All the specimens polished with FP received a 4mg portion of Diamond Gloss™ polishing paste, with the felt disc, then discarded after use. Those specimens and the ones polished only with SCB received the same protocol for periodic movements, at low speed, for 30s, unrefrigerated, in one direction.

To measure the surface roughness of the specimens, a surface rugosimeter (Surtronic 25 TaylorHobson®, Cerdanyola Del Vallès, Barcelona, Spain) was used, with a 0.25mm cutoff value and 2mm tracing length. Three measurements were recorded in different locations, and the average surface roughness (Ra) was determined for each specimen.

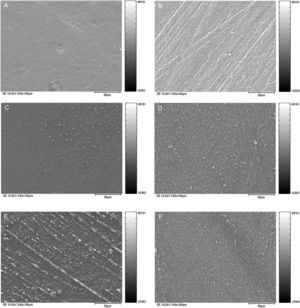

One specimen of each group was randomly assigned for scanning electron microscopy (SEM) analysis. The specimens were fixed in metallic stubs, sputter-coated with gold (MED 010, Baltec, Balzers, Leichtenstein) and observed with a scanning electron microscope (SSX-550 Shimadzu Superscan, Bangrak, Bangkok, Thailand). Representative images were obtained with 300× magnification.

The roughness data was analyzed using analysis of variance and Tukey's post hoc test (p<0.05). Statistical tests were performed using Assistat software (version 7.6 beta 2013, Campina Grande, PB, Brazil).

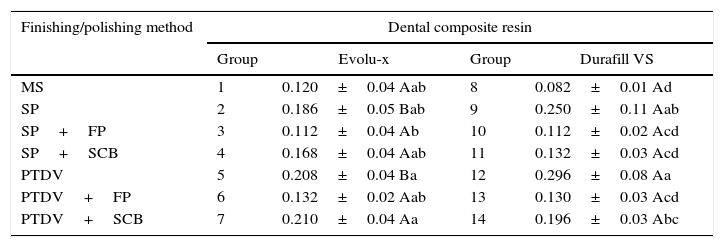

ResultsThere were statistically significant differences (Ra) in the interaction between “composite resins” and “finishing/polishing methods” (p<0.05). Comparisons among the groups are listed in Table 4.

Surface roughness means (Ra) in μm and standard deviations of composite resins according to different finishing and polishing methods and additional polishing.

| Finishing/polishing method | Dental composite resin | |||

|---|---|---|---|---|

| Group | Evolu-x | Group | Durafill VS | |

| MS | 1 | 0.120±0.04 Aab | 8 | 0.082±0.01 Ad |

| SP | 2 | 0.186±0.05 Bab | 9 | 0.250±0.11 Aab |

| SP+FP | 3 | 0.112±0.04 Ab | 10 | 0.112±0.02 Acd |

| SP+SCB | 4 | 0.168±0.04 Aab | 11 | 0.132±0.03 Acd |

| PTDV | 5 | 0.208±0.04 Ba | 12 | 0.296±0.08 Aa |

| PTDV+FP | 6 | 0.132±0.02 Aab | 13 | 0.130±0.03 Acd |

| PTDV+SCB | 7 | 0.210±0.04 Aa | 14 | 0.196±0.03 Abc |

MS, Mylar strip; SP, Sof-Lex Pop-On; PTDV, Praxis TDV; FP, felt disc associated to diamond paste; SCB, silicon carbide brush. Different letters indicate statistically significant differences among the groups (p<0.05): lowercase letters, comparison among dental composite resins in a same finishing and polishing system; uppercase letters, comparison among the finishing and polishing agents in a same composite resin.

When only traditional aluminum oxide discs were used, Durafill VS dental composite resin (0.250 and 0.296μm) showed a statistically rougher surface than Evolu-X (0.186 and 0.208μm). On the other hand, the use of additional polishing methods provided statistically similar roughness to both dental composite resins (p<0.05).

For Evolu-X, the use of additional polishing methods (0.112, 0.168, 0.132 and 0.210μm) provided statistically better roughness values than those subjected to aluminum oxide discs only, SP (0.186μm) and PTDV (0.208μm). However, FP (0.112 and 0.132μm) provided a statistically less rough surface than SCB (0.168 and 0.210μm), either for SP or PTDV. PTDV (0.208μm) and PTDV+SCB (0.210μm) groups presented the statistically highest roughness values, while the SP+FP (0.112μm) group presented the statistically lowest values.

For Durafill VS, the use of additional polishing methods provided statistically less rough values to samples subjected to SP or PTDV. The groups: SP+FP (0.112μm), SP+SCB (0.132μm) and PTDV+FP (0.130μm), provided statistically similar roughness values (p<0.05). PTDV group (0.296μm) showed the statistically highest roughness values, while MS (0.082μm) showed the statistically lowest values.

According to the analysis operator, electron microscopy suggests smoother Durafill VS surface when polishing is carried out with PTDV+FP in comparison to other methods (Figure 2). SP provided an Evolu-x surface with fewer grooves (Figure 1). Evolu-x surfaces treated with PTDV and SP+SCB had a more irregular topography (Figure 1). The photographs by SEM in this study were used to assist the results of the quantitative method (Figures 1 and 2).

This study investigated the surface roughness of an anterior only (DUR) and a universal composite resin (EVO). Since statistically significant differences among Ra values of each composite tested after additional polishing, the null hypothesis was rejected.

The Mylar strip was previously used on the surface of composites as a control group. This was done because it is a standard method in most studies to produce the smoothest surface.23–28 However, this method is not commonly used in clinical practice because the correct anatomical contour of the restoration is rarely achieved using only a Mylar strip.29–31 Moreover, the high content of submerging organic matrix promotes an insufficient polymerization, which results in reduced hardness and discoloration of the surface.32

Therefore, the finishing/polishing of composites is critical to obtaining resistance, color stability, longevity and esthetics of the restorations.22,33–36 Care must be taken during and after the restorative treatment because Ra values may exceed the critical limit of surface roughness for bacterial adhesion (0.20μm), so that composite restorations need to be polished again over time.37

The two finishing/polishing systems composed of four aluminum oxide discs (SP and PTDV) have abrasive particles of different sizes between them. Therefore, we wanted to know whether this difference in superficial roughness was enough to overcome the critical value for bacterial adhesion. It was observed that for both composites tested, the SP group has enhanced surface smoothness when compared to PTDV system. But in general, all the means within the standard deviation limit were above the critical value for bacterial adhesion. This result underscores the need for additional polishing after use of studied aluminum oxide discs.

According to a previous study,24 the texture of the final surface is dependent on the technique and material used. However, there is no consensus as to the material and technique that provides the smoothest surfaces for each type of composite used.22 Therefore, two additional polishing systems were tested: the SCB, which is an inexpensive, reusable, recent material on the market, as well as the FP, which highlights the presence of diamond nanoparticles in the composition of the polishing paste.

After the Turkey test, it was found that the FP decreased the surface roughness of the two composites after the use of both aluminum oxide disc systems. This result can be attributed to the presence of nanoparticles in the composition of the material, which wore down the varying sizes of filler particles which were not uniform within the organic matrix after using the SP or PTDV. The format of the material, which is paste, may also have influenced this wear, favoring the sliding of the particles across the surface.

The statistical test also indicated that there was no difference between SP and SP+SCB at DUR (microfilled resin), which reinforces the conclusions of a previous study18 with the same resin. This result indicates that the lowest amount of charge present in this resin allows various types of abrasive particles of different sizes and provides efficient polishing. However, a higher amount of organic matrix volume causes this resin to have lower mechanical strength and less color stability, which requires short-term re-polishing with respect to EVO resin.

The morphology of the surfaces is often viewed by SEM.38–41 The photomicrographs obtained in this study offer the professional qualitative analysis as an aid to the quantitative method profilometer to characterize the surface in order to identify the best method of finishing and polishing to be used in each restorative material.

The results of this study provide information about the surface properties of composite resins and the finishing/polishing materials tested. The comparison of Ra and surface wear after treatment in a simulated brushing machine can be another valuable and desirable approach to better understand the surface characteristics of long-term composites.42

One limitation of this study is that the Ra is a sensitive parameter to the peaks and isolated valleys. Another roughness parameter which on theoretical grounds can be supposed to give valuable information on the quality of a rough surface is kurtosis.43 More long-term studies in vitro and in vivo are needed, with a greater variety of composite resins and their performance in clinical practice.

ConclusionAdditional polishing after the use of abrasive discs improved the surface roughness of both composite resins tested. Furthermore, the FP offered a smoother and uniform texture to the surface of both resins, regardless of the previous abrasive disc used. The SCB offered a smoother texture to the surface of the DUR resin than EVO.

Ethical disclosuresProtection of human and animal subjectsThe authors declare that no experiments were performed on humans or animals for this study.

Confidentiality of dataThe authors declare that no patient data appear in this article.

Right to privacy and informed consentThe authors declare that no patient data appear in this article.

Conflicts of interestThe authors have no conflicts of interest to declare.